Di advansmɛnt fɔ mɔtalman sivilizayshɔn ɛn sosayti prɔgrɛs na intrinsically linked to di yus fɔ mɛtal matirial. Fɔ fala di ston ej, di bronz ej ɛn di ayɛn ej bin difayn bay di yutilizeshɔn fɔ mɛtal dɛn. Insay di tɛm we wi de naw, wan difrɛn difrɛn tin dɛn we dɛn kin yuz fɔ mek tin dɛn we dɛn mek wit mɛtal, kin mek wan impɔtant fawndeshɔn fɔ di divɛlɔpmɛnt fɔ mɔtalman sosayti.

Mɛtal dɛn kin kam insay difrɛn kayn dɛn, ɛn ɛni wan pan dɛn kin gɛt difrɛn kwaliti dɛn. Pan ɔl we dɛn kin notis sɔm mɛtal dɛn fɔ dɛn had, ɔda wan dɛn kin du fayn fayn wan ɔ yuz ilɛktrik kɔnduktiviti. Insai dis blog post, wi go explor di yunik propati dem fo difren metal en dem aplikeshon. Wi go delv insay kɔmɔn alɔy ɛn fɛnɔt wetin mek dɛn difrɛn. So, if yu rili want fɔ lan mɔ bɔt di fayn fayn wɔl we gɛt mɛtal, kɔntinyu fɔ wach!

Ferrous Metals: Tayp ɛn kwaliti dɛn .

Fɛro mɛtal, we de kɔba ɔltin frɔm klin ayɛn to kɔmpleks alɔy dɛn lɛk stenlɛs stiɛl, na impɔtant tin na wi wɔl. Dɛn de gi wan rich prɔpati lɛk hadnɛs, tɛnsiɛl trɛnk, ɛn kɔrɛshɔn rɛsistɛns we de mek dɛn fit fɔ difrɛn aplikeshɔn dɛn na industrial manufakchurin ɛn biyɔn. Wit dɛn difrɛn kayn dɛn, ɛni kayn fɛro mɛtal de briŋ sɔntin we spɛshal na di tebul, we de mek dɛn impɔtant na di mɔdan industri.

Ɔndastand Indastrial Pure Iron .

Pure iron na wan fondamental element in industrial manufakchurin. Na wan ki pleya fɔ mek difrɛn mɛtal alɔy dɛn. Na dis mek i spɛshal:

Malleability: Pure iron na kwik soft ɛn izi fɔ shep.

Magnɛtik prɔpati dɛm: I naturally magnetic, we de mek i impɔtant na ilɛktrik aplikeshɔn dɛm.

Kast Ayɔn: Kɔmpozishɔn ɛn Yuz dɛn .

Kast ayɛn na ayɛn alɔy we gɛt miks pan kabon, silikon, ɛn smɔl ɔda tin dɛn lɛk manganɛs, sɔlfɔ, ɛn fɔsfɔr.

Durability: Dɛn sabi am fɔ in fayn fayn durabiliti ɛn wear resistans.

Aplikeshɔn dɛn: Yu go si am na kuk, ɔtomotiv pat dɛn, ɛn mashin dɛn.

Kabon Stiɛl: Varieties ɛn Aplikeshɔn dɛn .

Kabon stiɛl na wan blend fɔ ayɛn ɛn kabon, wit difrɛn kayn dɛn lɛk lɔw, midul, ɛn ay kabɔn stɛl. Ɛni kayn gɛt in yon we fɔ yuz am.

Ay kabɔn stiɛl: Dɛn sabi am fɔ in had ɛn trɛnk, dɛn kin yuz am na tul ɛn bled.

Low Carbon Steel: More ductile ɛn yuz in strɔkchɔral aplikeshɔn bikɔs ɔf in tafne .

stenlɛs stiɛl: prɔpati ɛn industrial usay dɛn de yuz am

Stenless Steel na wan alɔy we dɛn sabi fɔ in kɔrɛshɔn rɛsistɛns. Na miks fɔ ayɛn, kabon, ɛn kromiɔm.

Non-corrosive: I nɔ de rɔst izi wan, na dat mek i pɔpul na kichin ɛn mɛrɛsin ikwipmɛnt.

Versatility: Dɛn kin yuz am na ɔltin frɔm kɔtlɛri to skayskrɛpa freym dɛn.

Di ayɛn we dɛn dɔn mek: prɔpati ɛn aplikeshɔn dɛn .

Wrought Iron na ayɛn alɔy we gɛt rili lɔw kabon kɔnsɛntreshɔn. I sabi fɔ bi strɔng yet daktayl.

Istri yus: Wans di men mɛtal fɔ blaksmit. Tide, dɛn kin si am na tin dɛn we dɛn kin yuz fɔ mek fayn fayn tin dɛn lɛk fɛns ɛn get dɛn.

Strɔng: in fibrous strɔkchɔ de gi am wan spɛshal kɔmbaynshɔn fɔ trɛnk ɛn fɔmabiliti.

Ɔda Fɛro Mɛtal dɛn: Krɔmiɔm, Manganɛs, ɛn dɛn alɔy dɛn

Fɛro mɛtal dɛn lɛk kromiɔm ɛn manganɛs de ple impɔtant pat fɔ mek difrɛn stɛl alɔy dɛn.

Nɔn-fɛro mɛtal dɛn: difrɛn difrɛn aplikeshɔn dɛn .

Nɔn-fɛro mɛtal dɛn de ple impɔtant rol dɛn na difrɛn difrɛn industri dɛn bikɔs ɔf dɛn yon prɔpati dɛn lɛk kɔrɛshɔn rɛsistɛns, ilɛktrik kɔnduktiviti, ɛn laytwɛt nature. Frɔm di erospace industri to di mɔdan teknɔlɔji aplikeshɔn, dɛn mɛtal ya de kɔntribyut bɔku bɔku wan to di advansmɛnt dɛn na di industrial manufakchurin ɛn ɛvride layf.

Aluminium: Karakta ɛn Indastrial Impɔtant

Aluminium na silva mɛtal , we pipul dɛn sabi fɔ bi pat pan di boron grup wit atɔmik nɔmba we na 13. I gɛt nem fɔ bi layt we nɔ strɔng yet strɔng.

High thermal conductivity: Ideal fɔ aplikeshɔn usay ɔt transfa na ki, lɛk insay redyuta ɛn kichin utensils.

Indastrial yus: Dɛn kin yuz aluminiɔm bɔku bɔku wan na di aerospace industri bikɔs ɔf in trɛnk-to-weyt ratio.

Nikel: Prɔpati ɛn difrɛn we dɛn fɔ yuz am .

Nikel, we na wan mɛtal we de na di wɔl, we nɔ de rɔtin, ɛn we nɔ de rɔtin, bɔku tɛm dɛn kin si am na alɔy.

Kɔpa: Aplikeshɔn dɛn insay Mɔdan Tɛknɔlɔji

Kɔpa na transishɔn mɛtal wit fayn fayn ilɛktrik kɔnduktiviti. Na malleable ɛn daktayl.

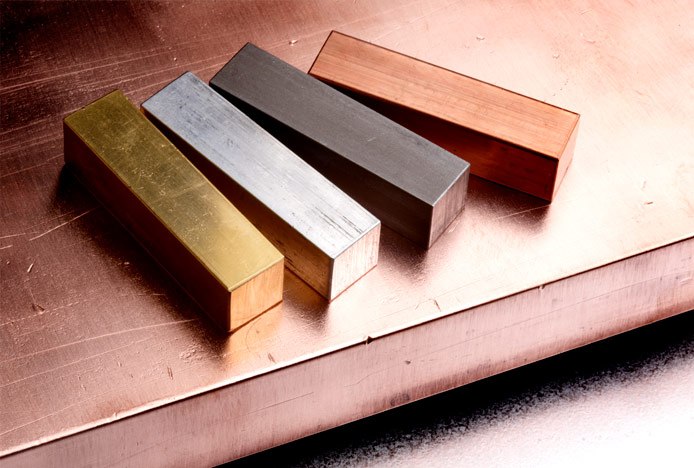

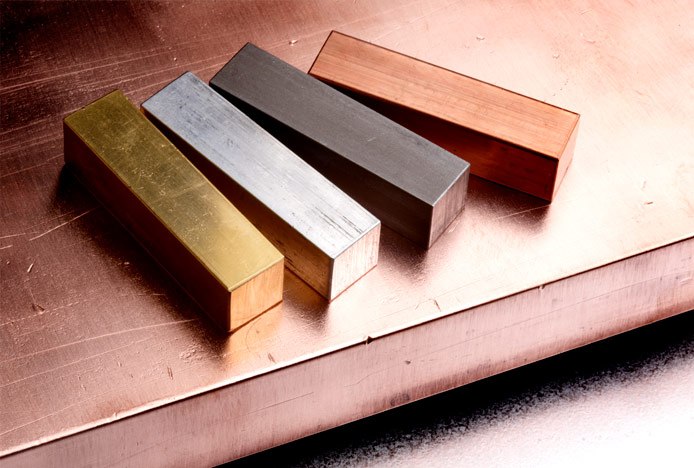

bras ɛn brɔnz: kɔmpozishɔn ɛn yuz dɛn .

Bras ɛn brɔnz na impɔtant nɔ-fɛro rɛd mɛtal dɛn, bikɔs na alɔy dɛn fɔ kɔpa ɛn zink ɔ tin, rispɛktful wan.

Mekanikal ɛn ilɛktrik kwaliti dɛn: Dɛn kin yuz bras na myuzik inschrumɛnt ɛn tin dɛn we dɛn kin yuz fɔ mek tin dɛn we dɛn kin yuz fɔ mek tin dɛn, ɛn dɛn kin lɛk fɔ yuz brɔnz fɔ mek i nɔ west pan bia ɛn fɔ mek tin dɛn we dɛn mek wit skapul.

Di impɔtant tin dɛn we bin apin trade trade: Bronz bin rili impɔtant fɔ wi fɔs fɔstɛm mɛtal dɛn, ɛn dis bin mek di Bronz Ɛj.

Zinc: Indastrial ɛn Kɔmɛshɔnal Aplikeshɔn dɛn .

Zinc na wan we dɛn sabi fɔ in kɔrɛshɔn-rɛsistant prɔpati dɛm, mɔ insay galvanizing stɛl.

Galvanizashɔn: I de protɛkt stɛl fɔ mek i nɔ rɔsti, i de mek in layf go bifo na ɔda aplikeshɔn dɛn na do.

Zinc Alloys: Yuz in die-casting fɔ prɛsishɔn kɔmpɔnɛnt dɛn na di ɔtomotiv ɛn ilɛktroniks industri dɛn.

Prɛshɔ mɛtal dɛn .

Prɛshɔ mɛtal dɛn lɛk gold, silva, ɛn platina kin ple impɔtant pat pas di we aw dɛn kin yuz dɛn fɔ mek jɔy ɛn mɔni. Dɛn spɛshal prɔpati dɛn, we inklud kɔrɛshɔn rɛsistɛns, ilɛktrik kɔnduktiviti, ɛn aesthetic apil, de mek dɛn indispɛns insay industri dɛn we de frɔm ilɛktronik ɛn mɛrɛsin to ɔtomotiv manufakchurin. Dɛn mɛtal dɛn ya nɔto jɔs sayn dɛn bɔt jɛntri; Dɛn na impɔtant tin dɛn we de mek wi ebul fɔ du tin dɛn we go mek wi ebul fɔ liv fayn fayn wan ɛn fɔ mek wi liv bɛtɛ layf.

Difayn kwaliti dɛn fɔ prɛshɔ mɛtal dɛn .

Dɛn sabi prɛshɔ mɛtal fɔ dɛn rare, biuti, ɛn ikɔmik valyu. Di men tin dɛn we di kwaliti dɛn gɛt na:

Corrosion Resistance: Dɛn nɔ de kɔrɛd ɔ ɔksidayz izi wan.

High Luster: Dɛn mɛtal ya gɛt wan spɛshal, natura shayn shayn.

Malleability ɛn Ductility: Dɛn kin shep ɛn strɛch dɛn izi wan.

gold, silva, platina: Wan klos luk

Gold: Na rich, briliant yɔlɔ mɛtal, we dɛn sabi fɔ in kɔrɛshɔn rɛsistɛns ɛn aesthetic apil. Bɔku tɛm dɛn kin yuz am na jɔy ɛn as standad fɔ mɔni.

Purity: Dɛn mɛzhɔ am insay Karats, wit 24 karat dɛn we na klin gold.

Silva: Dɛn no am fɔ in shayn wayt luster ɛn ay ilɛktrik kɔnduktiviti. I nɔ jɔs de fɔ jɔy; I impɔtant na ilɛktrik sɛrkyut dɛn bak.

Industrial use: Dɛn kin yuz silva na solar panɛl, batri, ɛn ilɛktroniks.

Platinum: Na wan nɔ-riaktiv mɛtal wit ɛkstra ɔdinari kɔrɛshɔn rɛsistɛns. I dense ɛn i gɛt ay mɛlt pɔynt.

Aplikeshɔn dɛn: Dɛn kin yuz am na katalaytik kɔnvɔta, ilɛktroniks, ɛn jɔyri.

Yuz dɛn fɔ prɛshɔ mɛtal dɛn na difrɛn industri dɛn .

Prɛshɔ mɛtal dɛn nɔto jɔs fɔ sho; Dɛn gɛt prɛktikal yus akɔdin to difrɛn industri dɛm.

Ilɛktronik: Gold ɛn silva na di men tin fɔ mek ilɛktronik kɔmpɔnɛnt dɛn we pɔsin kin abop pan ɛn we go wok fayn.

Medisin: Silva gɛt antibacterial prɔpati, we mek i valyu na mɛdikal ikwipmɛnt.

Ɔtomotiv: Platinum impɔtant fɔ mek dɛn mek katalaytik kɔnvɔta fɔ ridyus di efyushɔn.

Specialized metals ɛn dɛn rol dɛn .

Speshal mɛtal dɛn lɛk lid, kobalt, tin, taytaniɔm, tungsten, paladyɔm, yuraniɔm, ɛn bismut gɛt spɛshal, bɔku tɛm dɛn kin rili impɔtant fɔ du difrɛn difrɛn industrial aplikeshɔn dɛn. Dɛn yunik prɔpati dɛm, we kɔmɔt frɔm kɔrɛshɔn rɛsistɛns to ay mɛlt pɔynt dɛm, de mek dɛn indispɛns na fil dɛm lɛk aerospace, ɛnaji, ɛn teknɔlɔji. Dɛn mɛtal ya nɔ jɔs de pat pan di big big spɛktrum fɔ mɛtal ɛlimɛnt dɛn; Dɛn rili impɔtant fɔ mek di mɔdan industri go bifo ɛn fɔ wok.

Lid: Yutiliti ɛn wɛlbɔdi kɔnsidareshɔn dɛn .

Lid na wan ebi ebi mɛtal we dɛn sabi fɔ in ay density ɛn softnɛs. I gɛt say we nɔ gɛt bɔku mɛlt, we de mek am izi fɔ wok wit.

Yuz: Dɛn kin yuz am mɔ na batri, kebul sheathing, ɛn redyushɔn shild.

Ɛlth kɔnsyans: Lid na pɔyzin. Di we aw dɛn de yuz am nɔ bɔku naw, mɔ na di tin dɛn we dɛn kin yuz na os, fɔ mek dɛn nɔ gɛt wɛlbɔdi prɔblɛm.

Cobalt: Versatile aplikeshɔn dɛn na di mɔdan industri

Cobalt na transishɔn mɛtal we de ple impɔtant pat pan di mɔdan industri dɛm. Dɛn sabi am fɔ in trɛnk na ay tempɔret.

Aplikeshɔn dɛn: Dɛn kin yuz am na jet injin, gas tɔbayn, ɛn fɔ mek strɔng, pɔrmanent magnɛt.

Alɔy: Fɔm alɔy wit ay-tɛmpracha rɛsistɛns, we mek i pafɛkt fɔ kɔt tul ɛn ayrakt pat.

Tin, Titanium, ɛn Tungsten: Speshal Yuz dɛn

● Tin: Na mɛtal we nɔ de rɔtin we dɛn kin yuz bɔku tɛm fɔ kɔt ɔda mɛtal dɛn lɛk stɛl fɔ mek i nɔ rɔst.

● Titanium: Dɛn sabi am fɔ bi layt, ay-strɛng, ɛn lɔw-kɔroshɔn. I de yuz am na erospace komponent, medikal divays, ɛn spɔt ikwipmɛnt.

● Tungsten: Wit di ays mɛlt pɔynt fɔ ɔl di mɛtal dɛn, i impɔtant fɔ mek dɛn wok wit mɛtal, mayning, ɛn as tungsten kabayd insay drɔl bit dɛn.

Di mɛtal dɛn we de kɔmɔt: Palladium, yuraniɔm, ɛn bismut

● Palladium: Dɛn kin yuz dis dia dia mɛtal fɔs fɔ yuz na pɔyushɔn-kɔntrol divays dɛn lɛk katalaytik kɔnvɔta ɛn na difrɛn ilɛktroniks.

● Yuraniɔm: na ebi ebi mɛtal we dɛn kin yuz as nyuklia fiul na nyuklia pawa plant dɛn. Na di ki fɔ mek nyuklia ɛnaji.

● Bismuth: Dɛn sabi am fɔ bi had, brit, ɛn lustrous. Dɛn kin yuz am fɔ mek faya alam, ilɛktrik fiuz, ɛn alɔy dɛn we nɔ gɛt bɔku mɛlt.

Layt vs hevi mɛtal dɛn .

Difayn layt mɛtal dɛn: Taytaniɔm, aluminiɔm, magnɛsiɔm

Layt mɛtal dɛn lɛk taytaniɔm, aluminiɔm, ɛn magnɛsiɔm dɛn sabi dɛn fɔ dɛn lɔw density ɛn ay trɛnk-to-weyt rɛsɛshɔn.

Titanium: de gi ay trɛnk ɛn resistans to kɔrɛshɔn. I strɔng lɛk stɛl bɔt i layt pasmak.

Aluminium: Famous fɔ in laytwɛt ɛn tɛmral kɔnduktiviti. I izi fɔ wok wit ɛn risaykul.

Magnɛsiɔm: Di layt strɔkchɔ mɛtal, we dɛn kin yuz na alɔy fɔ mek tin layt nɔ lɔs trɛnk.

Hevi Metals ɛn dɛn yon prɔpati dɛn .

Hevi mɛtal dɛn lɛk lid, yuraniɔm, ɛn tungsten gɛt ay dens ɛn yunik prɔpati dɛn.

Lid: Dɛn sabi am fɔ in density ɛn softness. Dɛn kin yuz am na batri ɛn redyushɔn shild, bɔt i gɛt wɛlbɔdi prɔblɛm.

Yuraniɔm: Na wan dense, ebi mɛtal we dɛn kin yuz mɔ as nyuklia fiul.

Tungsten: I gɛt di ays mɛlt pɔynt fɔ ɔl di mɛtal dɛn, we impɔtant na aplikeshɔn dɛn we nid fɔ gɛt ay ɔt rɛsistɛns.

Praktikal aplikeshɔn dɛn fɔ layt ɛn ebi ebi mɛtal dɛn .

Layt ɛn ebi ebi mɛtal dɛn ɔl tu gɛt dɛn yon we fɔ yuz dɛn na difrɛn industri dɛn.

Layt Mɛtal dɛn:

Aerospace: Dɛn kin yuz taytaniɔm ɛn aluminiɔm bɔku bɔku wan bikɔs dɛn gɛt trɛnk ɛn layt.

Ilɛktronik: Dɛn kin yuz aluminiɔm na ilɛktronik divays fɔ mek i kɔnduktiv ɛn laytwɛt nature.

Hevi Mɛtal dɛn:

Enaji: Yuraniɔm na di men tin fɔ mek nyuklia pawa plant dɛn.

Medikal: Dɛn kin yuz lid fɔ protɛkt redyushɔn na ɛkstrem rum ɛn we dɛn de du redyushɔn tɛrapi.

Di difrɛns bitwin layt ɛn ebi ebi mɛtal dɛn de sho di difrɛn difrɛn tin dɛn we de na di wɔl we dɛn mek wit mɛtal. Layt mɛtal dɛn lɛk taytaniɔm, aluminiɔm, ɛn magnɛsiɔm dɛn kin valyu fɔ dɛn lɔw wet ɛn ay trɛnk, we kin mek dɛn fayn fɔ aerospace ɛn ilɛktroniks. Na di ɔda say, ebi ebi mɛtal dɛn lɛk lid, yuraniɔm, ɛn tungsten gɛt spɛshal yus fɔ ɛnaji prodakshɔn ɛn mɛdikal aplikeshɔn bikɔs ɔf dɛn density ɛn yunik prɔpati. Fɔ ɔndastand dɛn difrɛns ya rili impɔtant fɔ mek dɛn mek di industri ɛn fɔ mek nyu teknɔlɔji dɛn.

Metalloids ɛn dɛn wok .

Metalloids de ple wan impɔtant rol fɔ brij di gap bitwin mɛtal ɛn nɔ-mɛtal. Dɛn difrɛn prɔpati dɛn, lɛk difrɛn difrɛn ilɛktrik kɔnduktiviti ɛn fizik kwaliti dɛn, de mek dɛn impɔtant na difrɛn difrɛn say dɛn, mɔ na industrial manufakchurin ɛn tɛknɔlɔji. Frɔm di silikon we de na wi smart fon dɛn to di Jamaniiɔm insay Fayba Ɔptik, mɛtalɔyd dɛn de na di at fɔ bɔku kɔt-ɛj tɛknɔlɔji dɛn. Dɛn nɔto jɔs ɔda kategori fɔ ɛlimɛnt dɛn; Dɛn rili impɔtant fɔ advays wi teknɔlɔjik kapabiliti ɛn ɛp fɔ mek bɔku kɔmɔn prɔdak dɛn wok fayn.

Introdyushɔn to Mɛtaloyd Ɛlimɛnt dɛn .

Metalloids na elements wit prɔpati dɛn we de bitwin mɛtal ɛn nɔ-mɛtal. Dɛn spɛshal bikɔs dɛn kin akt lɛk ɛni wan pan dɛn, i dipen pan di kɔndishɔn dɛn. Metalloids inklud:

Spesifi k m ɛ tal l ɔd dɛn: J ɛ ry ɔ m, Antim ɔ n, Polɔniɔm

● Germanium: Dɛn kin yuz am na sɛmikɔndɔkta. Germanium kin du ilɛktrishɔn, bɔt nɔto lɛk mɛtal.

● Antimony: Dɛn sabi am fɔ in had ɛn trɛnk we alɔy. Dɛn kin yuz am na batri, mɛtal dɛn we nɔ de na frikshɔn, ɛn kebul sheathing.

● Polonium: I gɛt bɔku redioaktiv ɛn dɛn kin yuz am smɔl smɔl na divays dɛn lɛk brɔsh dɛn we de agens di statik.

Aplikeshɔn dɛn fɔ Mɛtaloyd dɛn na Mɔdan Tɛknɔlɔji .

Metalloids don fain dia we insay plenti modna teknɔlɔji bikɔs ɔf dɛn yon prɔpati dɛm.

Sɛmikɔndɔkta dɛn: Ɔl tu di Jamaniiɔm ɛn Silikon (ɔda mɛtalɔyd) na di men tin fɔ mek kɔmpyuta chips ɛn solar sɛl dɛn.

Medisin: Dɛn kin yuse sɔm mɛtaloyd fɔ mɛn mɛrɛsin ɛn fɔ no if pɔsin gɛt sik.

Alɔy: If yu ad mɛtalɔyd lɛk antimɔni to mɛtal kin mek dɛn trɛnk ɛn kɔrɛshɔn rɛsistɛns bɛtɛ.

Redioaktiv Mɛtal dɛn .

Ovaviu fɔ Redioaktiv Mɛtal dɛn .

Redioaktiv mɛtal na ɛlimɛnt dɛn we de gi raytin as dɛn de brok dɔŋ. Dɛn kin kɔl dis prɔses redioaktiv dɛkayshɔn. Dɛn mɛtal dɛn ya na:

Yuraniɔm: Dɛn kin yuz am bɔku bɔku wan na nyuklia pawa plant dɛn.

Plutonium: Na bayprodukt fɔ nyuklia riaktɔ, we dɛn kin yuz na sɔm kayn nyuklia wɛpɔn dɛn.

Radium: Wan tɛm dɛn kin yuz am fɔ mek pent dɛn we gɛt glɔ-in-di-dak.

Ɛlth ɛn sefty aspek dɛn fɔ handle redioaktiv mɛtal dɛn .

Fɔ handle redioaktiv mɛtal dɛn nid strikt sefty mɛsej bikɔs ɔf dɛn wɛlbɔdi risk.

Radiation Exposure: I kin mek yu gɛt siriɔs wɛl bɔdi prɔblɛm, lɛk kansa.

Di tin dɛn we dɛn fɔ du fɔ mek dɛn nɔ gɛt prɔblɛm: Glɔv ɛn kɔntena dɛn we gɛt lid layn, ɛn di tɛm we dɛn fɔ put di tin dɛn we dɛn de yuz fɔ mek dɛn nɔ gɛt prɔblɛm, na sɔntin we rili impɔtant.

Dispɔzishɔn: Dɛn fɔ tek tɛm trowe redioaktiv mɛtal dɛn fɔ mek dɛn nɔ tek tɛm fɔ mek dɛn nɔ kɔntamin di envayrɔmɛnt.

Redioaktiv mɛtal dɛn na ɛnaji ɛn mɛdikal fild dɛn .

Pan ɔl we dɛn kin gɛt prɔblɛm, redioaktiv mɛtal dɛn gɛt impɔtant tin dɛn fɔ yuz na difrɛn say dɛn.

Enaji prodakshɔn: Yuraniɔm na di men tin fɔ mek nyuklia pawa, we de gi wan impɔtant sɔs fɔ ɛnaji.

Medikal Aplikeshɔn: Dɛn kin yuse am na sɔm kayn tritmɛnt fɔ kansa ɛn mɛdikal imej tɛknik.

Redioaktiv mɛtal dɛn lɛk yuraniɔm, plutoniɔm, ɛn rediɔm, pan ɔl we i de mek bad bad tin apin, dɛn de ple impɔtant pat pan wi wɔl, mɔ na di ɛnaji we dɛn de mek ɛn di mɛdikal fild. Dɛn ebul fɔ rilis ɛnaji tru redioaktiv dɛkayshɔn de harnas insay nyuklia pawa plant dɛn, we de gi wan pawaful ɛnaji sɔs. Insay mɛrɛsin, dɛn tek tɛm kɔntrol aw fɔ yuz raytin frɔm dɛn mɛtal ya de gi bɛnifit fɔ trit ɛn no bɔt sik dɛn. Bɔt fɔ handle dɛn mɛtal ya, nid fɔ gɛt strikt sefty protɔkol fɔ protɛkt wɛlbɔdi ɛn di envayrɔmɛnt.

Kɔmɔn kayn mɛtal dɛn ɛn dɛn prɔpati dɛn .

Mɛtal dɛn lɛk aluminiɔm, kɔpa, ayɛn, ɛn stɛl na impɔtant tin dɛn na wi layf ɛvride, ɛn ɛni wan pan dɛn gɛt spɛshal prɔpati dɛn we de mek dɛn fayn fɔ difrɛn aplikeshɔn dɛn. Frɔm di laytwɛt aluminiɔm we de insay plen to di stenlɛs stiɛl we nɔ de rɔtin na kichin, dɛn mɛtal ya rili impɔtant fɔ mek dɛn mek tin dɛn ɛn ɔda tin dɛn. Nich mɛtal dɛn lɛk kobalt, taytaniɔm, ɛn tungsten, pan ɔl we dɛn nɔ bin de yuz am smɔl, dɛn kin ple impɔtant pat dɛn na spɛshal aplikeshɔn dɛn bikɔs ɔf dɛn spɛshal kwaliti dɛn. Fɔ ɔndastand di prɔpati ɛn di we aw dɛn de yuz dɛn mɛtal ya na di men tin fɔ gladi fɔ dɛn impɔtant tin dɛn na wi mɔdan wɔl.

Aluminium: Layt ɛn kɔnduktiv

Aluminium na silva mɛtal, we dɛn no fɔ in laytwɛt nature ɛn fayn fayn tɛmral kɔnduktiviti.

Aplikeshɔn dɛn: Dɛn kin yuz am bɔku bɔku wan we dɛn de mek plen, pak, ɛn bil.

Fit: I nɔ gɛt magnɛtik, i nɔ de spak, ɛn dɛn kin risaykul am we nɔ go lɔs prɔpati.

Kɔpa ɛn in alɔy dɛn: bras ɛn brɔnz

Kɔpa na wan versatile mɛtal we dɛn sabi fɔ in daktiliti ɛn ilɛktrik kɔnduktiviti.

Brass: Wan alɔy we gɛt kɔpa ɛn zink, we dɛn sabi fɔ in kɔrɛshɔn rɛsistɛns ɛn akostik prɔpati dɛn.

Bronz: Na alɔy we dɛn kin yuz mɔ fɔ kɔpa ɛn tin, dɛn kin yuz am fɔ mek i gɛt trɛnk ɛn fɔ mek i nɔ pwɛl.

Di kayn tin dɛn we dɛn kin yuz fɔ mek ayɛn: dɛn kin mek dɛn, dɛn kin mek dɛn, dɛn kin put dɛn, ɛn dɛn kin yuz pig ayɛn

Dɛn kin yuz ayɛn na difrɛn we dɛn, ɛn ɛni wan pan dɛn gɛt difrɛn prɔpati dɛn.

Wrought Iron: Wit wan low carbon concentration, e malleable en tof, perfekt for decorative ironwork.

Cast Iron: Dɛn sabi am fɔ mek i go de fɔ lɔng tɛm, dɛn kin yuz am fɔ kuk ɛn mashin.

Pig Ayɔn: Di bɛsis we fɔ yuz ayɛn we dɛn kin yuz na industrial aplikeshɔn ɛn as raw matirial fɔ mek dɛn rifin mɔ.

Stiɛl tayp dɛn: frɔm tul stɛl to ay kabɔn stɛl .

Stilin, we na wan alɔy we gɛt ayɛn ɛn kabon, de insay difrɛn kayn dɛn.

Tul Stilin: I gɛt tin dɛn we dɛn kin ad lɛk Tungsten ɛn Cobalt, we pipul dɛn sabi fɔ in had ɛn we nɔ de mek pɔsin nɔ gɛt abrashɔn.

Ay kabɔn stɛl: dɛn kin kɔl am in trɛnk ɛn yuz am fɔ kɔt tul ɛn bled dɛn.

Stenlɛs Stiɛl: Dɛn notis am fɔ in kɔrɛshɔn rɛsistɛns, we mek i fayn fɔ kichin ɛn mɛrɛsin inschrumɛnt dɛn.

Nich mɛtal dɛn: Kɔbalt, Taytaniɔm, ɛn Tungsten

Dɛn yuz dɛn mɛtal ya fɔ spɛshal aplikeshɔn dɛn bikɔs ɔf dɛn yon prɔpati dɛn.

Kobalt: Dɛn kin yuz am fɔ mek ay-strɛng alɔy, pɔrmanent magnɛt, ɛn na di mɛdikal fild.

Titanium: Dɛn sabi am fɔ in trɛnk, di lɔw density, ɛn di resistans to kɔrɛshɔn, we dɛn kin yuz na aerospace ɛn medikal implant.

Tungsten: I gɛt di ays mɛlt pɔynt fɔ ɔl di mɛtal dɛn, we dɛn kin yuz na layt bɔl filamɛnt ɛn tin dɛn fɔ kɔt.

Ɔndastand di kwaliti dɛn we difrɛn mɛtal dɛn gɛt .

Difrɛn mɛtal dɛn de bost difrɛn difrɛn prɔpati dɛn - frɔm di trɛnk ɛn hadnɛs fɔ tul stɛl to di daktiliti fɔ kɔpa. Dɛn kwaliti ya de sho aw dɛn fit fɔ difrɛn aplikeshɔn dɛn na industrial manufakchurin ɛn biyɔn. Fɔ ɔndastand dɛn prɔpati ya rili impɔtant we yu de pik di rayt mɛtal fɔ wan patikyula aplikeshɔn, ilɛksɛf na fɔ bil bildin, waya os, ɔ fɔ mek plen. Ɛni mɛtal, wit in yon blɛnd we gɛt mɛkanikal, kemikal, fizik, ɛn tɛknɔlɔji prɔpati, de ple impɔtant pat pan di big big wɔl we gɛt mɛtal masta sabi buk.

Mekanikal prɔpati dɛn: trɛnk, daktiliti, ɛn hadnɛs

Bɔku tɛm, dɛn kin pik mɛtal fɔ dɛn mɛkanikal prɔpati dɛn.

Strɔng: Dis na aw bɔku fɔs wan mɛtal kin ebul fɔ handle. Fɔ ɛgzampul, pipul dɛn sabi ay kabon stiɛl fɔ di wɔndaful trɛnk we i gɛt.

Ductility: Di abiliti fɔ strɛch we yu nɔ brok. Mɛtal dɛn lɛk kɔpa na ayli daktayl, we pafɛkt fɔ waya.

Hardness: Di resistans fɔ skrach ɔ bɛn. Tul stɛl, wit ɛlimɛnt dɛn lɛk Tungsten, na tin we rili at.

Kεmikכl prכpati dεm: kכroshכn rεsistεns εn riaktiviti .

Di kemikal prɔpati dɛm fɔ mɛtal dɛn de sho aw dɛn de liv lɔng ɛn sef.

Koroshɔn rɛsistɛns: Mɛtal dɛn lɛk stenlɛs stiɛl nɔ gri fɔ rɔst ɛn kɔrɛshɔn, we de mek dɛn fayn fɔ kichin tin dɛn.

Riaktiviti: Sɔm mɛtal dɛn, lɛk aluminiɔm, kin riak wit ɛya fɔ mek wan layt we de protɛkt, we de mek dɛn nɔ gɛt mɔ kɔrɛshɔn.

Fizik prɔpati dɛn: Dɛnsiti, tɛmral ɛn ilɛktrik kɔnduktiviti

Fizik prɔpati dɛn kin inflɔws aw dɛn kin yuz mɛtal dɛn na prɛktikal aplikeshɔn dɛn.

Density: Heavier metals lek lid na dense en yuz fo radiation shielding, while titanium na layt en strong, suitable fo aerospace.

Tɛm ɛn Ilɛktrik Kɔnduktiviti: Mɛtal dɛn lɛk kɔpa ɛn silva kin kɔndɔkt ɔt ɛn ilɛktrishɔn fayn fayn wan, impɔtant insay ilɛktrik kɔmpɔnɛnt dɛn.

Teknɔlɔji prɔpati dɛn: mashinabiliti ɛn wɛldability .

Teknɔlɔji prɔpati dɛn afɛkt aw dɛn de manipul ɛn yuz mɛtal dɛn na manufakchurin.

Machinabiliti: Dis de tɔk bɔt aw i izi fɔ kɔt ɛn shep di mɛtal. Dɛn sabi aluminiɔm alɔy fɔ dɛn gud mashinabiliti.

Weldability: Metals lek low carbon steel na easy to weld, we mek dem popular in konstrakshon en industrial aplikeshon.

Ditayl analisis fɔ mɛtal matirial prɔpati dɛn .

We dɛn de fɛn ɔl di tin dɛn we at fɔ du: Brinell, Rockwell, ɛn Vickers tɛst dɛn

Hardness in metals na wan impɔtant atribyut, we de sho se i nɔ gri wit difɔmeshɔn ɛn wear.

Brinell Hardness Test: Yuz wan stɛl bɔl indenta. Kɔmɔn fɔ tɛst sɔft mɛtal dɛn lɛk aluminiɔm.

Rockwell Hardness Test: de mɛzhɔ di dip we di penɛtrɛshɔn de ɔnda lod. Dɛn kin yuz am fɔ difrɛn difrɛn mɛtal dɛn.

Vickers Test: employ wan dayamɔn pyramid indenter, we fayn fɔ tin matirial ɛn smɔl eria dɛn.

Yield strength ɛn tɛnsiɛl trɛnk: Sigifikans insay mɛtal yuz

Strɔng impɔtant fɔ no aw wan mɛtal go du ɔnda strɛs.

Yield Strength: Di strɛs we wan mɛtal bigin fɔ difɔm plastic wan. Impɔtant fɔ pik di tin dɛn we dɛn go yuz fɔ bil.

Tensile Strɔng: Di maksimal strɛs we mɛtal kin bia we dɛn de strɛch ɔ pul am. Ay tɛnsiɛl trɛnk mɛtal dɛn lɛk sɔm alɔy stɛl dɛn de yuz insay ay-strɛs aplikeshɔn dɛn.

Elongeshɔn ɛn impak tafnɛs: Ɔndastand Plastisiti

Dɛn prɔpati ya rili impɔtant na aplikeshɔn usay fleksibiliti ɛn durabiliti na ki.

elongation: Na wan we fɔ mɛzhɔ daktiliti, we de sho aw bɔku mɛtal kin strɛch bifo i brok.

Impact Toughness: Di abiliti fɔ wan mɛtal fɔ absɔb ɛnaji ɛn plastic wan difɔm witout frakt. Dɛn kin yuz mɛtal dɛn lɛk ayɛn we dɛn dɔn mek, we dɛn sabi fɔ dɛn taf, fɔ aplikeshɔn dɛn we nid fɔ mek dɛn nɔ gɛt impak.

Speshal prɔpati dɛn: Ɔt rɛsistɛns ɛn redyushɔn rɛsistɛns .

Sɔm aplikeshɔn dɛn nid mɛtal dɛn we gɛt spɛshal prɔpati dɛn.

Hɛt rɛsistɛns: mɛtal dɛn lɛk tungsten ɛn nikel alɔy dɛn kin kip trɛnk na ay tɛmpracha, we impɔtant fɔ aerospace ɛn industrial ɔfna dɛn.

Radiation Resistance: Dɛn kin yuz sɔm mɛtal dɛn lɛk lid fɔ redyushɔn shild bikɔs dɛn gɛt ay density ɛn ebul fɔ absɔb raytin.

Ɔndastand di prɔpati dɛm fɔ mɛtal dɛm lɛk hadnɛs, trɛnk, plasticiti, ɛn spɛshal atribyut dɛm lɛk ɔt ɛn redyushɔn rɛsistɛns na impɔtant tin na dɛn aplikeshɔn akɔdin to difrɛn industri dɛm. Frɔm di brinɛl tɛst fɔ no di had we aluminiɔm at fɔ yuz tungsten na ay-tɛmpracha ɛnvayrɔmɛnt, dɛn prɔpati ya de difayn di yutiliti ɛn funkshɔnaliti fɔ mɛtal dɛn na industrial manufakchurin ɛn biyɔn. Ɛni mɛtal, wit in yon sɛt fɔ kwaliti dɛn, de ple wan impɔtant pat fɔ advays tɛknɔlɔji ɛn industrial aplikeshɔn dɛn.

Di nyu tin dɛn we dɛn dɔn mek fɔ mek tin dɛn we dɛn mek wit mɛtal .

Teknik fɔ kɔt-ɛj insay mɛtal wok .

Di fild fɔ mɛtal wok de kɔntinyu fɔ evolv, inkɔrpɔret advans tɛnkɔlɔji fɔ ɛp fɔ mek prɛsishɔn ɛn efyushɔn bɛtɛ.

Laser cutting and welding: Dɛn we ya de gi akkuracy we nɔ gɛt wan kɔmpitishɔn, we fayn fɔ kɔmpleks ɛn intrɛstin dizayn dɛn.

Otomatik ɛn rɔbɔt sistɛm dɛn: Dɛn sistɛm ya de mek di prɔdaktiviti go ɔp ɛn ridyus di mistek we mɔtalman de mek we dɛn de du di wok dɛn we dɛn de du ɔltɛm.

Di tin dɛn we go apin tumara bambay: 3D printin ɛn smat matirial dɛn

We wi de luk bifo, di fiuja fɔ mɛtal wok na fayn fayn tin wit di kam we nyu teknɔlɔji dɛn kam.

3D Printing: Rivɔlɔshɔnizing manufakchurin bay we dɛn alaw kɔmpleks mɛtal pat dɛn fɔ bil layt bay layt.

Smart Materials: Metals we kin chenj prɔpati bays pan ekstenal stimuli, opin do fɔ inovativ aplikeshɔn dɛn na difrɛn industri dɛn.

Sastaynabiliti insay mɛtal prodakshɔn ɛn risaykul .

Sastaynabiliti de bi wan impɔtant tin we dɛn de pe atɛnshɔn pan na di mɛtal industri.

Eco-friendly processes: Ridyus di envayrɔmɛnt impak we mɛtal prodakshɔn gɛt tru klin prɔses ɛn rinuɔbal ɛnaji sɔs.

Risayklin: Mɛtal dɛn kin rili risaykul, ɛn fɔ mek di risaykul ret bɔku na big gol fɔ ridyus di west ɛn kɔnsiv risɔs.

Metalworking na fil we de ɛva chenj, wit nyu teknɔlɔji dɛn lɛk laser kɔt ɛn 3D printin we de push di bɔda dɛn fɔ wetin pɔsibul. As wi de luk to di fiuja, tren dɛm lɛk smat matirial dɛm prɔmis fɔ rivɔlɔshɔn di industri ivin mɔ. Na di sem tɛm, fɔ pe atɛnshɔn pan sastaynabiliti fɔ prodyus ɛn risaykul impɔtant fɔ mek shɔ se di mɛtal industri kɔntinyu fɔ go bifo we nɔ go ambɔg di planɛt. Dɛn nyu tin ya nɔ jɔs de chenj di we aw wi de wok wit mɛtal; Dɛn de shep di fiuja fɔ manufakchurin ɛn teknɔlɔji.

FAQ dɛn .

Difrɛns bitwin difrɛn aluminiɔm alɔy dɛn .

Aluminium alloys na pipul dɛn we pipul dɛn lɛk bikɔs dɛn nɔ gɛt bɛtɛ trɛnk ɛn dɛn gɛt trɛnk. Di men difrɛns dɛn na:

Alloy Series: Bays pan elemɛnt dɛn we dɛn ad, lɛk kɔpa, magnɛsiɔm, ɔ silikon, we de afɛkt prɔpati dɛn lɛk trɛnk ɛn kɔrɛshɔn rɛsistɛns.

Aplikeshɔn dɛn: Difrɛn frɔm di ayrakt strɔkchɔ dɛn (ay-strɛngth alɔy) to drink kan (malleable aloys).

Brass vs. Bronz: Kompozishun ɛn yuz dɛn

Bras ɛn brɔnz na ɔl tu kɔpa alɔy bɔt dɛn gɛt difrɛn difrɛns.

Brass: Na miks fɔ kɔpa ɛn zink. Dɛn kin yuz am na myuzik inschrumɛnt ɛn dɛkɔretiv tin dɛn fɔ in akostik prɔpati dɛn.

Bronz: Kɔpa ɛn tin, we dɛn sabi fɔ in trɛnk ɛn kɔrɛshɔn rɛsistɛns. kɔmɔn na skapul ɛn industrial bia.

Stainless Steel vs. Aluminium: Wan Kɔmparativ Stɔdi

Dɛn kin yuz dɛn mɛtal ya bɔku bɔku wan bɔt dɛn gɛt difrɛn kwaliti dɛn.

Stenlɛs Stiɛl: na ayɛn alɔy, we dɛn sabi fɔ in kɔrɛshɔn rɛsistɛns. I ebi pas aluminiɔm bɔt i rili strɔng.

Aluminium: Layt ɛn wit gud kɔnduktiviti. less strong dan stenles stiel bot no rust.

Ferrous vs. Non-ferrous Metals: Fɔ no di men tin dɛn we de insay

Fɔ ɔndastand di difrɛns bitwin dɛn kayn mɛtal ya na di men tin we dɛn kin pik fɔ du di matirial.

Ferrous Metals: gɛt ayɛn. Magnɛtik ɛn prone to rɔst, bɔt rili strɔng (ɛgz., stɛl).

Nɔn-fɛro mɛtal dɛn: Nɔ gɛt ayɛn. nɔto magnɛtik ɛn mɔ resistant to kɔrɛshɔn (ɛgz., aluminiɔm, kɔpa).

CNC Machining: fayn mɛtal dɛn ɛn dɛn prɔpati dɛn .

CNC mashin nid mɛtal dɛn we kin ebul fɔ bia wit di prɔses.

Di fayn mɛtal dɛn we fayn fɔ yuz: Inklud aluminiɔm, bras, ɛn stenlɛs stiɛl, we dɛn sabi fɔ dɛn mashinabiliti ɛn trɛnk.

Tin dɛn fɔ tink bɔt: Di we aw dɛn de pik di mɛtal dipen pan di prɔpati dɛn we dɛn want fɔ di fayn fayn prɔdak, lɛk hadnɛs ɔ kɔrɛshɔn rɛsistɛns.

Dɔn

Wi dɔn fɛn bɔku bɔku mɛtal dɛn, ɛn ɛni wan pan dɛn gɛt spɛshal prɔpati ɛn aplikeshɔn dɛn. Frɔm fɛro mɛtal dɛn lɛk stɛl ɛn ayɛn, we dɛn sabi fɔ dɛn trɛnk ɛn we go de fɔ lɔng tɛm, to mɛtal dɛn we nɔ gɛt fɛro lɛk aluminiɔm ɛn kɔpa, we dɛn kin valyu fɔ dɛn kɔrɛshɔn rɛsistɛns ɛn ilɛktrik kɔnduktiviti. Wi dɔn si aw alɔy dɛn lɛk bras ɛn brɔnz de kam togɛda di bɛst pan difrɛn mɛtal dɛn, ɛn aw nich mɛtal dɛn lɛk taytaniɔm ɛn tungsten de ple impɔtant pat dɛn na spɛshal industri dɛn.

Mɛtal, insay ɔl dɛn difrɛn difrɛn we dɛn, nɔto jɔs tin dɛn; Na dɛn na di fawndeshɔn fɔ di mɔdan sivilizayshɔn ɛn teknɔlɔji. Frɔm di stɛl we de na wi bildin dɛn to di aluminiɔm insay wi plen, mɛtal dɛn de shep wi wɔl insay bɔku bɔku we dɛn. As wi de luk to di fiuja, di wok we mɛtal dɛn de du na di industri ɛn teknɔlɔji go jɔs gro, drɛb bay inovashɔn ɛn wan kɔmitmɛnt fɔ sastaynabiliti. Di joyn tru di wɔl fɔ mɛtal na wan kɔntinyu advantej, wan we prɔmis nyu diskvayri ɛn advansmɛnt wit ɛvri de we de pas.