Springs na fundamental komponent in countless mechanical systems, frɔm maykroskɔpik divays to big big industrial mashin. Dɛn ebul fɔ kip ɛn rilis ɛnaji de mek dɛn impɔtant na fil dɛm we de frɔm ɔtomotiv injinɛri to aerospace teknɔlɔji.

Insay dis kɔmprɛhɛnsif gayd, wi go fɛn ɔl di sayɛns, di kayn dɛn, di matirial dɛn, ɛn di aplikeshɔn dɛn fɔ spring dɛn, we de shed layt pan dɛn tin dɛn ya we dɛn kin ɔltɛm ɔvaluk bɔt we rili impɔtant fɔ di mɔdan injinɛri.

Di Sayns fɔ Springs: Hooke in Lɔ ɛn Biyɔnd

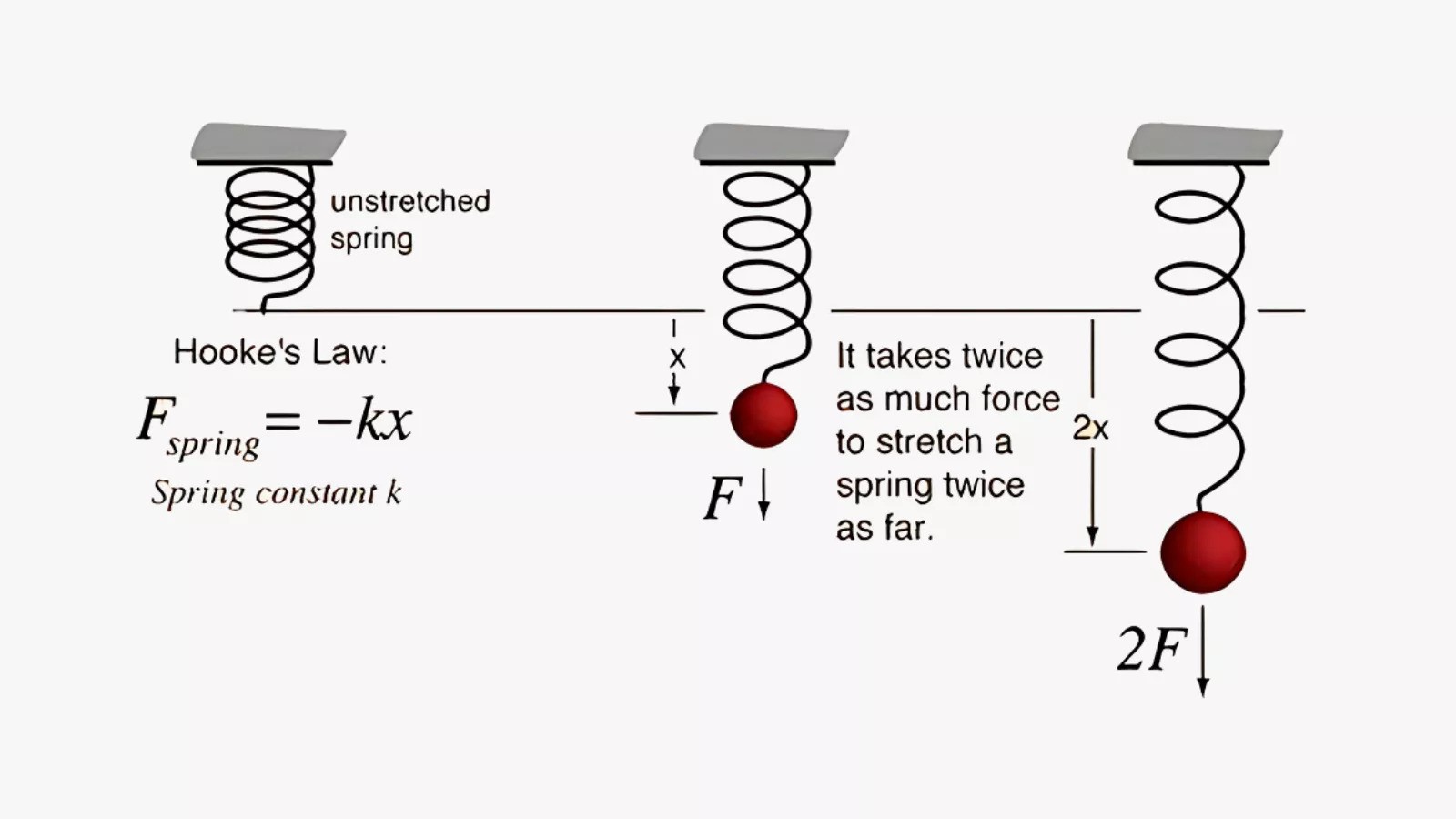

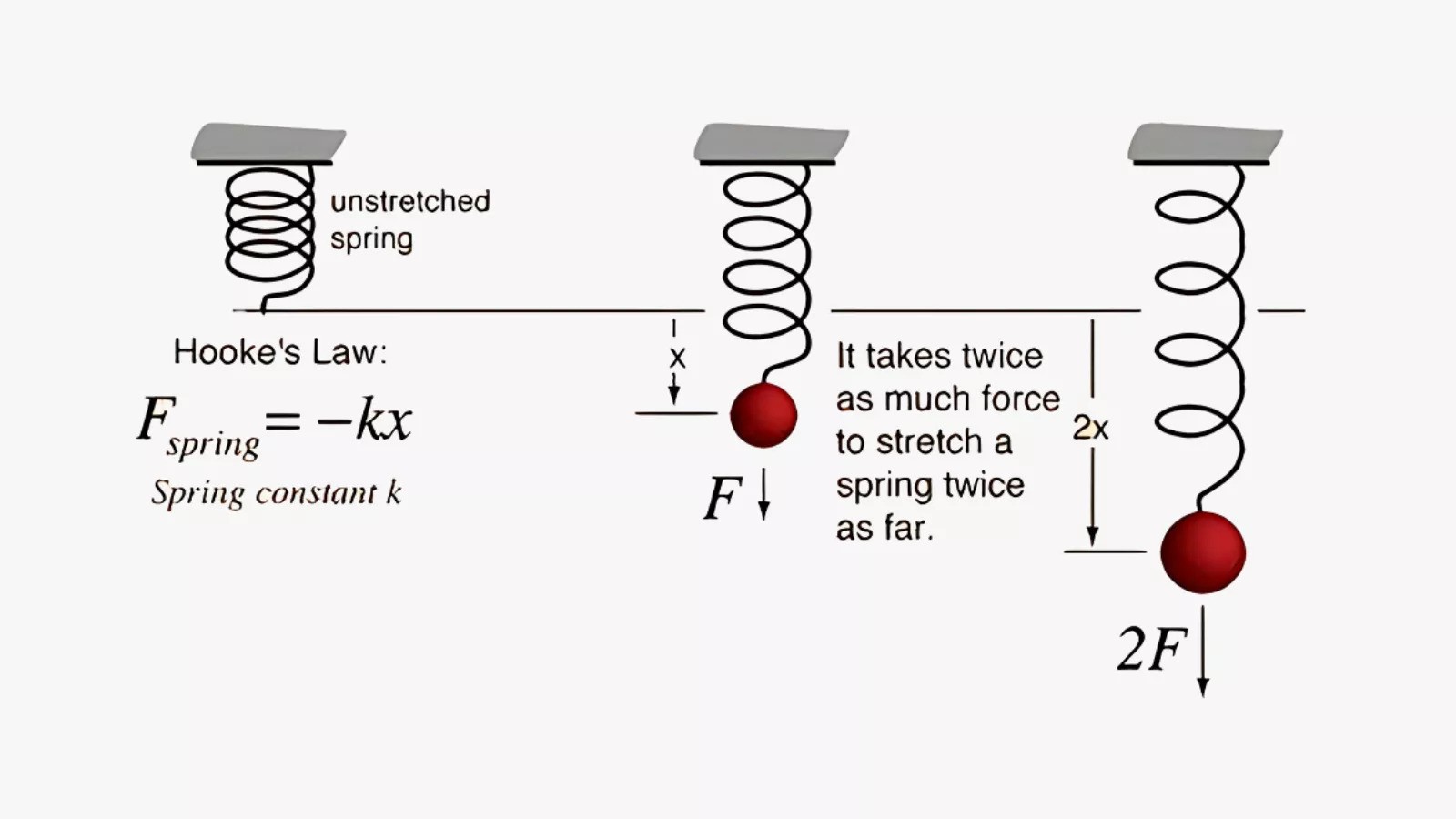

Na di at fɔ Spring Mɛkaniks lay Hooke in Lɔ, we Rɔbɔt Huk bin mek insay 1660. Dis prinsipul se dat th

E Fos (F) we spring de exert na dairekt proporshonal to in displeysment (x) frɔm in ikwilbɔri pozishɔn:

f = -kx

Usay:

F na di fos we di spring de yuz (insay Nyutɔns, n)

K na di spring kɔnstant (in Nyutɔns fɔ wan mita, n/m)

X na di displeysmɛnt frɔm di ikwilbɔri pozishɔn (insay mita, m) .

di nεgεtiv sayn de sho se di fכs de akt na di כpכsit dεyshכn fכ di displεsmεnt, we de כltεm de fכs fכ gi bak di spring to in rεst stet.

Bɔt, rial-wɔl spring dɛn kin kɔmɔt frɔm dis linya rilayshɔn, mɔ ɔnda big displeysmɛnt ɔ insay ekstrim kɔndishɔn. Injinia dɛn fɔ tink bɔt tin dɛn lɛk:

Spring Rate : Di chenj in fos fɔ ɛni yunit deflɛshɔn, we kin difrɛn insay nɔ-layn spring dɛn .

Elastik Limit : Di pɔynt biyɔn we di spring nɔ go go bak to in ɔrijinal shep .

Fatigue Life : Di nɔmba fɔ di saykl dɛn we spring kin bia bifo i nɔ wok .

Tayps of Springs: Wan difrɛn mɛkanikal ɛkosistim .

Springs kin kam insay difrɛn we dɛn, ɛn ɛni wan pan dɛn kin ɔptimayz fɔ spɛshal aplikeshɔn dɛn. Na dis wan na kɔmpiashɔn fɔ di kayn we dɛn we kɔmɔn pas ɔl:

| Spring Tayp | Tipik Aplikeshɔn dɛn | Ki Karakta dɛn | Lod Kapasiti Rɛnj |

| Kɔmpreshɔn Springs . | Otomotiv saspɛns, pen dɛn . | Resist kɔmprɛsiv fɔs dɛn . | 1 N - 1,000 kn |

| Ekstenshɔn Springs . | Garaj Doors, Trampolines . | Resist tɛnsiɛl fɔs dɛn . | 1 n - 5 kn |

| Torsion Springs . | Klospin dɛn, hinj dɛn . | Resist Rotational Forces . | 0,1 n·m - 1,000 n·m |

| Lif spring dɛn . | Hevi motoka saspɛns . | Kapasiti fɔ lod we gɛt ay lod . | 5 kn - 100 kn |

| Disk Springs . | Indastrial Valv dɛn, Bolt Joint dɛn . | Ay lod in limited spes . | 1 kn - 1,000 kn |

| Gas Springs . | Automobile Hoods, Ɔfis chia dɛn | Fכs we de kכnstant ova strכk . | 50 n - 5 kn |

Tayp dɛn fɔ spring dɛn: Wan kɔmprɛhɛnsif gayd .

Spring na versatile mechanical komponen we de kam in difrɛn shep ɛn saiz, ɛni wan dɛn mek am fɔ spɛshal aplikeshɔn dɛn. Fɔ ɔndastand di difrɛn kayn spring dɛn rili impɔtant fɔ mek injinia ɛn dizayna dɛn pik di rayt spring fɔ dɛn prɔjek dɛn. Lɛ wi fɛn di men kategori dɛm fɔ spring ɛn dɛn spɛshal kwaliti dɛm.

1. Hɛlikal Springs .

Hɛlikal Springs na di kayn we we dɛn kin yuz mɔ, we gɛt kɔyl dizayn. Dɛn sheb dɛn mɔ to tri men sabkategori dɛn:

Kɔmpreshɔn Springs .

Diskripshɔn : opin-kɔyl spring dɛn we de agens kɔmprɛsiv fɔs dɛn .

Aplikeshɔn dɛn : Ɔtomotiv Sɔspɛns, Balpɔynt Pen, Matress

Ki Ficha : de kip ɛnaji we dɛn kɔmprɛs .

Kɔmpreshɔn spring dɛn na opin-kɔyl spring dɛn we dɛn mek fɔ mek kɔmpreshɔn fɔs dɛn nɔ de. Dɛn kin fɛn am na ɔtomotiv sɔspɛns, bɔlpɔynt pen, ɛn matres, dɛn spring ya kin kip ɛnaji we dɛn kɔmprɛs, we kin mek dɛn impɔtant fɔ mek dɛn absɔb shɔk ɛn fɔ sɔpɔt lod.

Ekstenshɔn Springs .

Diskripshɔn : Tayt kɔyl spring dɛn we de agens tɛnsiɛl fɔs dɛn .

Aplikeshɔn dɛn : garaj domɔt dɛn, trampolɛn dɛn, fam mashin dɛn

Ki Ficha : de kip ɛnaji we yu strɛch .

Ekstenshɔn Springs , difrɛn frɔm dat, dɛn tayt wan kɔyl ɛn dɛn de agens tɛnsiɛl fɔs. Bɔku tɛm dɛn kin yuz dɛn na garaj domɔt, trampolɛn, ɛn fam mashin dɛn. Di men tin we dɛn gɛt na di ebul we dɛn ebul fɔ kip ɛnaji we dɛn strɛch.

Torsion Springs .

Diskripshɔn : Springs we de kip ɛnaji we dɛn twist .

Aplikeshɔn dɛn : Klospin dɛn, Doa hinj dɛn, Ɔtomotiv Kɔmpɔnɛnt dɛn

Ki Ficha : De gi rotashɔnal fɔs .

Torsion Springs de wok difrɛn we bay we dɛn de kip ɛnaji we dɛn twist am. Dɛn spring ya de gi rotashɔnal fɔs ɛn dɛn de yuz dɛn na aplikeshɔn dɛn lɛk klospin, domɔt hinj, ɛn difrɛn ɔtomotiv kɔmpɔnɛnt dɛn.

2. Lif Springs .

Diskripshɔn : gɛt sɔm layers (lif) dɛn we gɛt mɛtal strip dɛn .

Aplikeshɔn dɛn : Hevi motoka saspɛns, relwe motoka dɛn .

Ki ficha : ay lod-bearing kapasiti .

Lif spring dɛn gɛt bɔku bɔku layers (lif) dɛn we gɛt mɛtal strip dɛn we dɛn dɔn stak pan dɛnsɛf. Dɛn spring ya gɛt nem fɔ dɛn ay lod-bearing kapasiti ɛn dɛn kin yuz dɛn bɔku tɛm na di suspension sistem fɔ ebi ebi motoka dɛn, lɛk trak ɛn relwe motoka.

Tayp dɛn fɔ lif spring dɛn:

Springs we gɛt bɔku lif dɛn .

Mono-lif spring dɛn .

Parabolik lif spring dɛn .

3. Disk Springs (Bɛlavil Washers)

Diskripshɔn : Springs we gɛt kɔnik disk we gɛt kɔnik disk we gɛt disk

Aplikeshɔn dɛn : Erospɛs, Indastrial Valv dɛn, Bolt Joint dɛn

Ki ficha : ay lod kapasiti in wan kompakt spes .

Disk Springs , we dɛn kin kɔl bak Bɛlɛvil Washa, na spring dɛn we gɛt kɔnik disk dɛn we tan lɛk disk. Dɛn notis fɔ dɛn ay lod kapasiti pan ɔl we dɛn kɔmpakt saiz, we mek dɛn fayn fɔ aplikeshɔn dɛn na aerospace, industrial valves, ɛn bolted jɔyn usay spɛs nɔ bɔku bɔt lod-bearing impɔtant.

4. Gas Springs .

Diskripshɔn : Yuz kɔmprɛs gas fɔ ɛksɛrt fɔs

Aplikeshɔn dɛn : Ɔtomobil hud lif dɛn, ɔfis chia dɛn

Ki Ficha : De gi nia-kɔnstant fɔs ɔlsay na di strok .

Gas Springs de wok bay we dɛn de yuz kɔmprɛs gas fɔ ɛksɛrt fɔs. Dɛn spring ya de gi klos to kɔnstant fɔs ɔlsay na dɛn strok, we de mek dɛn pɔpul na aplikeshɔn dɛn lɛk ɔtomobil hud lif ɛn ɔfis chia dɛn we dɛn kin ajɔst. Dɛn kɔnsistɛns fɔs de mek dɛn rili rilibul fɔ wan big rɛnj ɔf adjɔstabl aplikeshɔn dɛn .

5. Flat spring dɛn .

Diskripshɔn : Flat pis dɛn fɔ mɛtal we dɛn mek fɔ fleks ɔnda lod

Aplikeshɔn dɛn : Ilɛktrik Kɔntakt dɛn, Ɔtomotiv Sɛns dɛn

Ki Ficha : Kɔmpakt dizayn fɔ limited spɛs dɛn .

Flat spring na simpul, flat pies of metal we de fleks anda lod. Dɛn kɔmpakt ɛn fayn fɔ limited spɛs, bɔku tɛm dɛn kin fɛn am na ilɛktrik kɔntakt ɛn ɔtomotiv sɛns. Dɛn spɛshal dizayn we nɔ de yuz bɔku spɛshal tin dɛn de mek dɛn bi wan we we dɛn kin pik fɔ yuz ilɛktronik ɛn ɔtomotiv industri dɛn.

6. Volute Springs .

Diskripshɔn : Spring dɛn we gɛt kɔnik-shep we dɛn mek frɔm wan flat strip

Aplikeshɔn dɛn : Hevi-duti aplikeshɔn dɛn, Shok absɔpshɔn

Ki ficha : Progresiv spring ret .

Volute Springs gɛt wan kɔnik shep we dɛn mek frɔm wan flat strip we dɛn mek wit mɛtal. Dis spring dεm dεn mek fכ hεvi-duti aplikεshכn dεm εn dεn spεshal ifektiv fכ shok absכpshכn bikoz fכ dεn prכgrεsiv spring rεt, we de inkrεs stiffnεs as dεn kכmprεs.

7. Wev spring dɛn .

Diskripshɔn : Flat waya we dɛn fɔm insay wan wev-layk shep .

Aplikeshɔn dɛn : Bearings, Sil dɛn, Klɔt dɛn

Ki Ficha : Space-saving Alternativ to Tradishonal Koyl Springs

Dɛn kin mek wev spring dɛn frɔm flat waya we dɛn mek to wev-layk shep. Dɛn de gi wan ɔda we we go sev di spes pas di tradishɔnal kɔyl spring dɛn, bikɔs dɛn dizayn de alaw dɛn fɔ gi dɛn sem kayn pawa na smɔl eria. Di kɔmɔn tin dɛn we dɛn kin yuz na bia, sil, ɛn klat usay kɔmpakt dizayn ɛn efyushɔn rili impɔtant.

8. Kɔnstant Fos Springs .

Description : Wan rol riban we gɛt spring matirial we de yuz kɔnstant fɔs we dɛn de pul am na di wɔl

Aplikeshɔn dɛn : Kɔntrabalans, Riɛl dɛn we dɛn kin pul kɔmɔt

Ki Ficha : Nia-Kɔnstant Fos ɔlsay na di diflɛshɔn

Dɛn kin mek fɔs spring dɛn frɔm wan rɔl ribin we gɛt spring matirial we de ɛksɛrt wan fɔs we de nia ɔltɛm we dɛn de pul dɛn. Dɛn kin yuz dɛn spring ya na aplikeshɔn dɛn lɛk kɔntrabalans ɛn ritraktabl riɛl usay dɛn nid kɔnsistɛns fɔs ɔlsay na di ɔl rɛnj fɔ muv.

9. Variable Fos Springs .

Diskripshɔn : Springs wit wan nɔ-layn fɔs-diflɛkshɔn kɔv

Aplikeshɔn dɛn : Prɛsishɔn Instrumɛnt, Spɛshal Mɛkanikal Divays dɛn .

Ki Ficha : Fos de difrɛn nɔ-layn wit diflɛshɔn

V Ariable Fos Springs gɛt wan nɔ-layn fɔs-diflɛkshɔn kɔv. Dɛn mek dɛn spring ya fɔ prɛsishɔn inschrumɛnt ɛn spɛshal mɛkanikal divays usay fɔs nid fɔ chenj wit diflɛshɔn, we de gi tayla pefɔmɛns fɔ intrikɛt aplikeshɔn dɛn.

Kɔmpiashɔn Tebul

| Spring Tayp | Lod Tayp | Spays Spays Efisiɛns | Tipik Lod Rɛnj | Kɔmɔn Aplikeshɔn dɛn |

| Kɔmpreshɔn . | Kɔmprɛsiv . | Soba | 1 N - 1,000 kn | Ɔtomotiv, Indastrial |

| Lɔng | Tensile 100. | Ay | 1 n - 5 kn | Di guds dɛn we de bay tin dɛn, mashin dɛn . |

| Torsion . | Rotashɔnal . | Ay | 0,1 n·m - 1,000 n·m | Hinges, klip dɛn . |

| Lif | Kɔmprɛsiv . | Lo | 5 kn - 100 kn | Hevi motoka dɛn . |

| Disk . | Kɔmprɛsiv . | Na rili ay . | 1 kn - 1,000 kn | Aerospace, Valv dɛn . |

| Gas we de na di wɔl . | Kɔmprɛsiv . | Ay | 50 n - 5 kn | Fɛnichɔ, Ɔtomotiv . |

Ɛni kayn spring gɛt in yon prɔpati ɛn ideal aplikeshɔn dɛn. Di choice of spring dipen pan tin dɛm lɛk di fɔs fɔs, di spes we de, di opareshɔn ɛnvayrɔmɛnt, ɛn di pefɔmɛns kwaliti dɛm we dɛn want. We dɛn ɔndastand dɛn difrɛn kayn dɛn ya, dat de mek di injinia dɛn pik di spring we fit dɛn pas ɔl fɔ dɛn patikyula nid dɛn, ɛn mek shɔ se dɛn wok fayn ɛn dɛn go liv lɔng ɛn dɛn mek dɛn mɛkanikal sistem dɛn fayn fayn wan.

Materials: Di fawndeshɔn fɔ spring pefɔmɛns

Di choice of matiryal signifyantli impacts a spring in pefomans karakta. Na dis na wan kɔmpiashɔn fɔ kɔmɔn spring matirial dɛn:

| matirial | tɛnsiɛl trɛnk (MPA) | Kɔroshɔn rɛsistɛns | maks ɔpreshɔn temp (°C) | tipik aplikeshɔn dɛn |

| Aisi 302 stenles stiel . | 860-1100 na di | Wɛl dɔn | 250 | Food Processing, Marin . |

| AISI 4340 low-alloy steel . | 745-1950 we dɛn bin de yuz. | Soba | 300 | Automotiv, Aerospace |

| Inkɔnɛl X-750 . | 1200 | Wɛl dɔn | 700 | Jet Injin, Nyuklia Riaktɔ dɛn . |

| Berlium kɔpa . | 1300 | Gud | 300 | Envayrɔmɛnt dɛn we de bɔn . |

| Titanium Ti-6Al-4V we de na di . | 900-1200 na di | Wɛl dɔn | 400 | Aerospace, Medikal Implant dɛn . |

Di we aw dɛn de mek tin dɛn: Prɛsishɔn ɛn kwaliti kɔntrol .

Spring manufakchurin involv sɔm impɔtant step dɛm, ɛvri wan de kɔntribyut to di fayn pefɔmɛns:

| prɔses stɛp | pɔpɔshɔn | tipik tolerans/paramita dɛn |

| Waya drɔin . | MATERIAL PRƐPARƐSHƆN . | ±0.01 mm dayamita tolerans . |

| Coiling . | Fɔm spring shep . | ±0.1 mm pitch tolerans . |

| Di tritmɛnt fɔ ɔt . | Ɛnjɔy di Mɛkanikal Prɔpati dɛn . | ±10°C tεmprachכ kכntrכl . |

| Shot Peening . | Impruv Fatigue Laif . | 200% - 300% Inkris in fatigue strength |

| Grindin . | Mek shɔ se flat ɛnd sɔfays dɛn . | ±0.05 mm Flatnɛs tolɛreshɔn . |

| Kotin . | Koroshɔn rɛsistɛns/apɛnt . | 5-25 μm Kotin tiknes . |

Aplikeshɔn dɛn: Springs in Akshɔn

Springs de ple impɔtant rol dɛn na difrɛn difrɛn say dɛn. Na dis wan na kɔmpiashɔn fɔ spring aplikeshɔn dɛn akɔdin to difrɛn industri dɛn:

| Indastri | Aplikeshɔn | Spring Tayp | Ki Pɔfɔmɛnshɔn Mɛtrik |

| Ɔtomotiv . | enjin valv spring dɛn . | Kɔmpreshɔn . | Endurance na 8000+ rpm . |

| Ɔtomotiv . | Sɔspɛns . | Koyl/Lɛf | Kapasiti fɔ lod te to 1000 kg/wil . |

| Aerospace na di . | Landing Gear . | Shok absɔba . | Impact absorpshɔn te to 3G . |

| Ilɛktroniks . | Kibɔd Swit dɛn . | Kɔmpreshɔn . | 0.4-0.8 N aktyueshɔn fɔs . |

| Wɛlbɔdi biznɛs | Di stent dɛn we de na di at ɛn di bɛlɛ . | Ekspanshɔn . | 400+ milyɔn saykl layf tɛm |

| Indastrial . | Prɛshɔn Rilif Valv dɛn . | Kɔmpreshɔn . | Prɛsishɔn to ±1% pan di prɛshɔn we dɛn dɔn sɛt . |

Ɔtomotiv Indastri .

Aerospace na di .

Ilektroniks we de yuz kɔnsuma .

Divays dɛn fɔ mɛn pipul dɛn .

Chalenj ɛn nyu tin dɛn we dɛn dɔn mek .

Injinia dɛn kin kɔntinyu fɔ push di bɔda dɛn fɔ spring tɛknɔlɔji:

| Inovashɔn | Diskripshɔn | Pɔtɛnɛshɛl impak |

| Shep Memory Alloys . | Springs dat 'mɛmba' shep . | Di komponent dɛn we de ajɔst dɛnsɛf fɔ ajɔst dɛnsɛf . |

| Kompoziyt spring dɛn . | polima dɛn we dɛn dɔn riinfɔs fayba . | Up to 70% weit ridyushɔn . |

| Smat spring dɛn . | Integreted sensor dɛn . | Rial-taym lod monitarin . |

| Nano-Springs na di . | Microscopic skel spring dɛn . | Advans MEMS Divays dɛn . |

Shape Memory Alloys : Springs dat 'mɛmba' dɛn shep afta difɔmeshɔn

Composite Springs : Yutilayz matirial dɛn lɛk fayv-rɛinfɔs polima fɔ ridyus di wet

Smart Springs : Integretin sensor fɔ rial-taym lod monitarin

Kɔnkliushɔn: Di ɛlastik fiuja .

Springs stil de bifo pan mɛkanikal injinɛri, we dɛn bin de kɔntinyu fɔ adap fɔ mit nyu prɔblɛm dɛn. Frɔm di nanoskayl spring dɛn na MEMS divays dɛn to di big big lif spring dɛn na industrial mashin dɛn, dɛn ɛlastik kɔmpɔnɛnt dɛn ya kɔntinyu fɔ ple wan impɔtant pat pan tɛknɔlɔjik advansmɛnt.

As wi de push di bɔda dɛn fɔ wetin pɔsibul na injinɛri, spring dɛn go kɔntinyu fɔ kɔntinyu fɔ fleks, twist, ɛn kɔmprɛs dɛn we insay di fiuja fɔ inovashɔn. Dɛn versatility, we dɛn jɔyn wit di matirial ɛn dizayn nyu tin dɛn we de go bifo, de mek shɔ se spring dɛn go kɔntinyu fɔ bi impɔtant kɔmpɔnɛnt dɛn na di mashin ɛn divays dɛn fɔ tumara.

Ilɛksɛf na fɔ fɛn mɔ transpɔt, mɔ prɛsis mɛdikal divays, ɔ mɔ kɔnsuma prɔdak dɛn we go de fɔ lɔng tɛm, spring dɛn go kɔntinyu fɔ gi di fɔs, fleksibiliti, ɛn di wok we dɛn nid fɔ du. Fɔ ɛkspɛkt gayd fɔ yu manufakchurin projɛkt, . Kɔntakt wi . Wi injinia dɛn we gɛt ɛkspiriɛns go ɛp yu fɔ fɛn di dizayn, di tin dɛn we dɛn go pik, ɛn di we aw dɛn de mek tin dɛn fɔ mek shɔ se dɛn gɛt di bɛst rizɔlt. Patna wit Tim FMG fɔ sakrifays. Wi go tek yu prodakshɔn go na di nɛks lɛvul ..

FAQ dɛn .

1. Wetin na spring?

Spring na mɛkanikal kɔmpɔnɛnt we de difɔm we dɛn put am ɔnda ɛksternal fɔs ɛn kip ɛnaji, we de go bak to in ɔrijinal shep we dɛn pul di fɔs. Dɛn kin yuz spring fɔ absɔb shɔk, kip ɛnaji, ɔ kip spɛshal bitwin tin dɛn.

2. Wetin na di men kayn spring dɛn?

Tri men kayn spring dɛn de: kɔmpreshɔn spring dɛn (rɛsis kɔmpreshɔn), ɛkstenshɔn spring dɛn (rɛsis strɛch), ɛn torshɔn spring dɛn (stɔ tɔk). Ɛni spring dɛn mek am difrɛn difrɛn wan bay di aplikeshɔn.

3. Us matirial dɛn spring dɛn we dɛn mek wit?

Spring dɛn kin mek frɔm ay-strɛng tin dɛn lɛk kabɔn stiɛl , stenlɛs stiɛl , kɔpa alɔy , ɛn ivin sɔm plastic matirial dɛn, i dipen pan di envayrɔmɛnt ɛn aplikeshɔn we dɛn nid.

4. Aw a go pik di rayt spring?

Fɔ pik di rayt spring nid fɔ tink bɔt di kayn aplikeshɔn , lod we dɛn nid , matirial prɔpati , ɛn di wok ɛnvayrɔmɛnt (tɛmpracha, kɔrɛshɔn, ɛn ɔda tin dɛn). Prɛsis kɔlkyulɛshɔn ɛn tɛst de ɛp fɔ mek shɔ se dɛn pik di kɔrɛkt tin.

5. Wetin na spring fatigue failure?

Spring fatigue failure de apin we yu ripit lod ɛn ɔndo kɔz di spring matirial fɔ lɔs smɔl smɔl elastisiti ɔ brek. Disain kɔnsidareshɔn fɔ inklud layfspan, strɛs limit, ɛn taya resistans fɔ di matirial.

6. Aw a go ebul fɔ ɛkstɛnd di layfspan fɔ wan spring?

Fɔ mek dɛn mentenɛns ɛn inspekshɔn ɔltɛm kin mek di spring in layf lɔng. Nɔ yuz bɔku bɔku tin dɛn fɔ lod, mek shɔ se yu gɛt di rayt lɔbrik, kɔrɛkt am, ɛn pik di tin dɛn we fit fɔ di say we dɛn de wok.

7. Wetin mek Springs de fel?

Springs kin fel bikɔs ɔf taya damej , kɔrɛshɔn , ɔvalod , ɔ matirial difɛkt . Inspekshɔn ɔltɛm ɛn di rayt mentenɛns kin mek bɔku pan di prɔblɛm dɛn we nɔ kin wok fayn.