Yu dɔn ɛva wɔnda aw dɛn kin mek plastic prɔdak wit dis kayn prɛsishɔn ɛn kɔnsistɛns? Di ansa de insay di injɛkshɔn moldin prɔses, usay dɛn injɛkt molten plastic insay wan mold cavity fɔ mek di shep we dɛn want. Bɔt di sakrifays we dis prɔses dɔn mek rili dipen pan di rayt dizayn ɛn ples we dɛn put get dɛn.

Get na di smɔl smɔl say dɛn we di plastic we dɔn rɔtin kin go insay di mold kaviti, ɛn dɛn dizayn kin mek ɔ brok di kwaliti fɔ di fayn fayn prɔdak.Insay dis post, yu go lan bɔt di difrɛn kayn get dɛn we dɛn kin yuz fɔ mek injɛkshɔn ɛn aw ɛni wan pan dɛn kin ambɔg di we aw dɛn de mek di tin dɛn.

Wetin na injɛkshɔn moldin get?

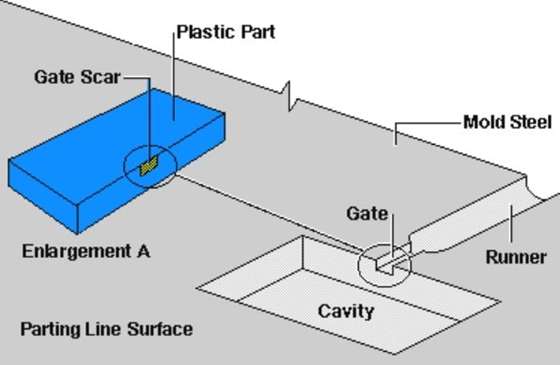

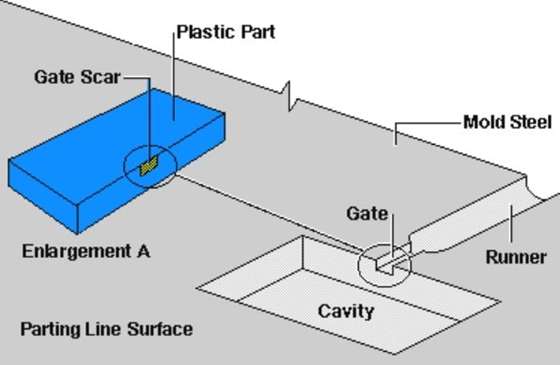

Wan injɛkshɔn moldin get na wan smɔl opin we de alaw fɔ mek plastic we dɔn rɔtin go insay di mold kaviti. I de wok lɛk pasej, we de kɔnɛkt di rɔna sistɛm to di pat we dɛn de mol.

Gates de ple wan impɔtant pat pan di injɛkshɔn moldin prɔses. Dɛn kin kɔntrol di flɔ rit, prɛshɔn, ɛn di dairekshɔn fɔ di plastic we dɔn rɔtin as i de ful di kaviti. Prɔpa get dizayn de mek shɔ se di kaviti ful-ɔp ivin ɛn fayn fayn wan, we de mek dɛn gɛt ay kwaliti pat dɛn we nɔ gɛt bɛtɛ difrɛns.

Di kayn, di sayz, ɛn di say we di get dɛn de kin rili afɛkt di kwaliti fɔ di pat dɛn we dɛn dɔn mol. Dɛn kin afɛkt:

Flɔ Patɛn ɛn Filin Biɛvhɔ .

Kuling ret ɛn shrinkage .

Weld layn fɔmɛshɔn .

Surface apinans ɛn aesthetics .

Pat Strɔng ɛn Mɛkanikal Prɔpati dɛn .

Fɔ pik di rayt get dizayn impɔtant fɔ mek di injɛkshɔn moldin prɔses fayn. I nid fɔ tek tɛm tink bɔt tin dɛn lɛk pat jɔyometri, matirial prɔpati, ɛn prodakshɔn we dɛn nid.

Wan simplified dayagram we de sho di wok we wan injɛkshɔn moldin get de du.

Wetin mek get dizayn impɔtant fɔ injɛkshɔn moldin?

Get dizayn na wan impɔtant aspek fɔ injɛkshɔn moldin. I de impɔk di kwaliti fɔ di fayn fayn prɔdak dairekt wan. Wan get we dɛn dɔn mek fayn fayn wan de mek shɔ se plastic we dɔn rɔtin de flɔ fayn fayn wan ɛn ivin insay di mold kaviti. Dis kin rilizɔt pat dɛn we gɛt kɔnsistɛns dimɛnshɔn, aw fɔ luk, ɛn mɛkanikal prɔpati dɛn.

Na di ɔda say, po get dizayn kin mek difrɛn difrɛn tin dɛn ɛn tin dɛn we nɔ fayn:

Short Shots : Inkɔmplit filin fɔ di mold kaviti

Weld layn dɛn : layn dɛn we pɔsin kin si usay flɔ frɔnt dɛn kin mit

Sink Mak : Surface Depressions we dɛn kin kɔz bay we dɛn nɔ ivin kol .

Warpage: Distortion of di pat bikɔs ɔf di nɔ-yunifɔm shrinkage

Burn Marks: Diskoloreshɔn frɔm ɔva ɔt fɔ di plastic

Dis difεkt dεm nכ de כnli afekt di aesthetics fכ di pat bכt i de afekt in fכnshכnaliti εn durabiliti. Dɛn kin mek di skrap ret go ɔp, dɛn kin wok bak, ɛn dɛn kin kɔmplen bɔt di kɔstɔma dɛn.

Difrɛn frɔm dat, di get dɛn we dɛn dɔn mek fayn fayn wan de gi bɔku bɛnifit dɛn:

Impɔtant pat kwaliti ɛn kɔnsistɛns .

Ridyus saykl tɛm ɛn inkris prodaktiviti .

Minimayz matirial west ɛn skrap .

Enhansed Mechanical Strɔng ɛn Pɔfɔmɛnshɔn .

I izi fɔ du di ɔpreshɔn dɛn we dɛn kin du afta dɛn dɔn mek am (ɛgz., fɔ pul di get dɛn))

Bay we dɛn de mek di get dizayn fayn fayn wan, di wan dɛn we de mek dɛn kin ebul fɔ mek dɛn injɛkshɔn moldin prɔses izi. Dɛn kin prodyuz ay kwaliti pat dɛn mɔ efyushɔn ɛn kɔst-ɛfɛktiv.

Ki kɔnsidareshɔn fɔ get dizayn .

We yu de disayn get fɔ injɛkshɔn moldin, sɔm impɔtant tin dɛn de fɔ mɛmba. Dɛn tin ya we yu fɔ tink bɔt kin mek ɔ brok di sakrifays we yu pat dɛn we yu dɔn mol dɔn mek. Mek wi tek wan klos luk pan ɛni wan.

Get plesmɛnt .

Usay yu put di get na yu pat na impɔtant tin. I de sho aw di plastic we dɔn rɔtin de flɔ insay di mold kaviti. I fayn fɔ mek yu want fɔ fɛn di get:

na di say we tik pas ɔl na di pat .

AWAY frɔm di say dɛn we pɔsin kin si ɛn di men tin dɛn we de na di wɔl .

Na wan we we go mek di distans we pɔsin de flɔ ɛn di we aw i de fɛt nɔ bɔku ɛn di we aw i de fɛt .

Di rayt we fɔ put di get de ɛp fɔ mek shɔ se dɛn ivin ful-ɔp, i de ridyus di weld layn dɛn, ɛn i de mek di get mak dɛn we pɔsin kin si nɔ bɔku.

Get saiz .

Di sayz fɔ di get de ple impɔtant pat bak. I de afɛkt di injɛkshɔn spid, prɛshɔn, ɛn di ɔl flɔ bihayvya. Wan get we tu smɔl kin mek:

Filin we nɔ kɔmplit (shɔt shot dɛn)

Ay shia strɛs ɛn matirial dɛgradishɔn .

Di saykl tɛm dɛn we lɔng ɛn di tɛm we dɛn dɔn ridyus di efyushɔn .

Na di ɔda say, wan ovasayz get kin mek dɛn yuz bɔku bɔku tin dɛn ɛn dɛn kin friz di get fɔ lɔng tɛm. Fɔ fɛn di optimal get saiz na di ki fɔ ajɔst wan balans bitwin pat kwaliti ɛn prodakshɔn efyushɔn.

Pat shep ɛn finish .

Di joyometri ɛn di surface finish we yu want fɔ yu pat de inflɔws get sɛlɛkshɔn. Kɔmpleks shep dɛn, tin dɛn we gɛt tint wɔl, ɛn fayn fayn tin dɛn we dɛn nid kin dikte sɔm patikyula get dɛn. Fɔ ɛgzampul:

Edj get fɔ flat, wayd pat dɛn

Pin get fɔ smɔl, silindrikal kɔmpɔnɛnt dɛn

Hot tip gets fɔ pat dɛn wit ay sɔfays kwaliti dimand dɛn .

Fɔ mach di get dizayn to di pat kwaliti dɛn de mek shɔ se dɛn gɛt bɛtɛ mol ɛn i de ridyus di risk fɔ difɛkt dɛn.

Nɔmba fɔ di get dɛn we dɛn nid .

Dipen pan di saiz ɛn di kɔmplisiti fɔ yu pat, yu kin nid bɔku get dɛn. Dis na tru mɔ fɔ big, flat pat ɔ pat dɛn we gɛt difrɛn difrɛn tin dɛn. Yuz bɔku bɔku get dɛn kin:

Impruv filin ɛn pak di mold kaviti .

Ridyus di weld layn dɛn ɛn ɔda tin dɛn we nɔ fayn we gɛt fɔ du wit flɔ .

Shorten cycle taims bay we yu alaw fɔ kol fast fast .

Bɔt fɔ ad mɔ get dɛn de mek bak di tul dɛn kɔst ɛn kɔmplisiti bɔku. I impɔtant fɔ fɛn di rayt balans bays pan yu patikyula aplikeshɔn ɛn wetin yu nid.

| we pɔsin gɛt fɔ tink bɔt . |

Di impak |

| Get plesmɛnt . |

Flow behavior, weld lain, get maks |

| Get saiz . |

Filin, shia strɛs, saykl tɛm |

| Pat shep ɛn finish . |

Moldabiliti, Difɛkt, Surface Kwaliti |

| Nɔmba fɔ di get dɛn . |

filin, pak, saykl tɛm, tul kɔst |

Sɔmari fɔ di ki get dizayn kɔnsidareshɔn ɛn dɛn impak pan injɛkshɔn moldin.

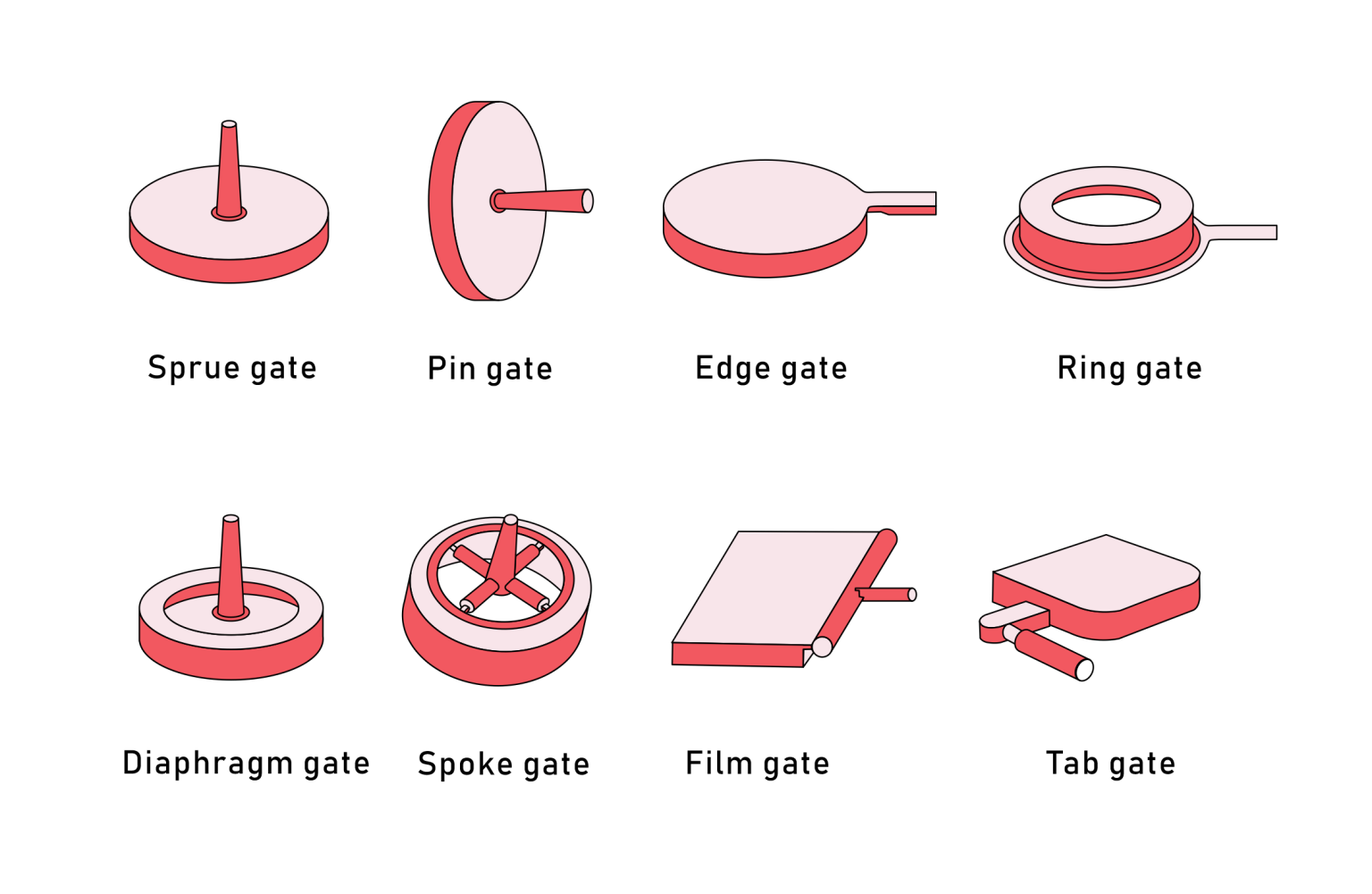

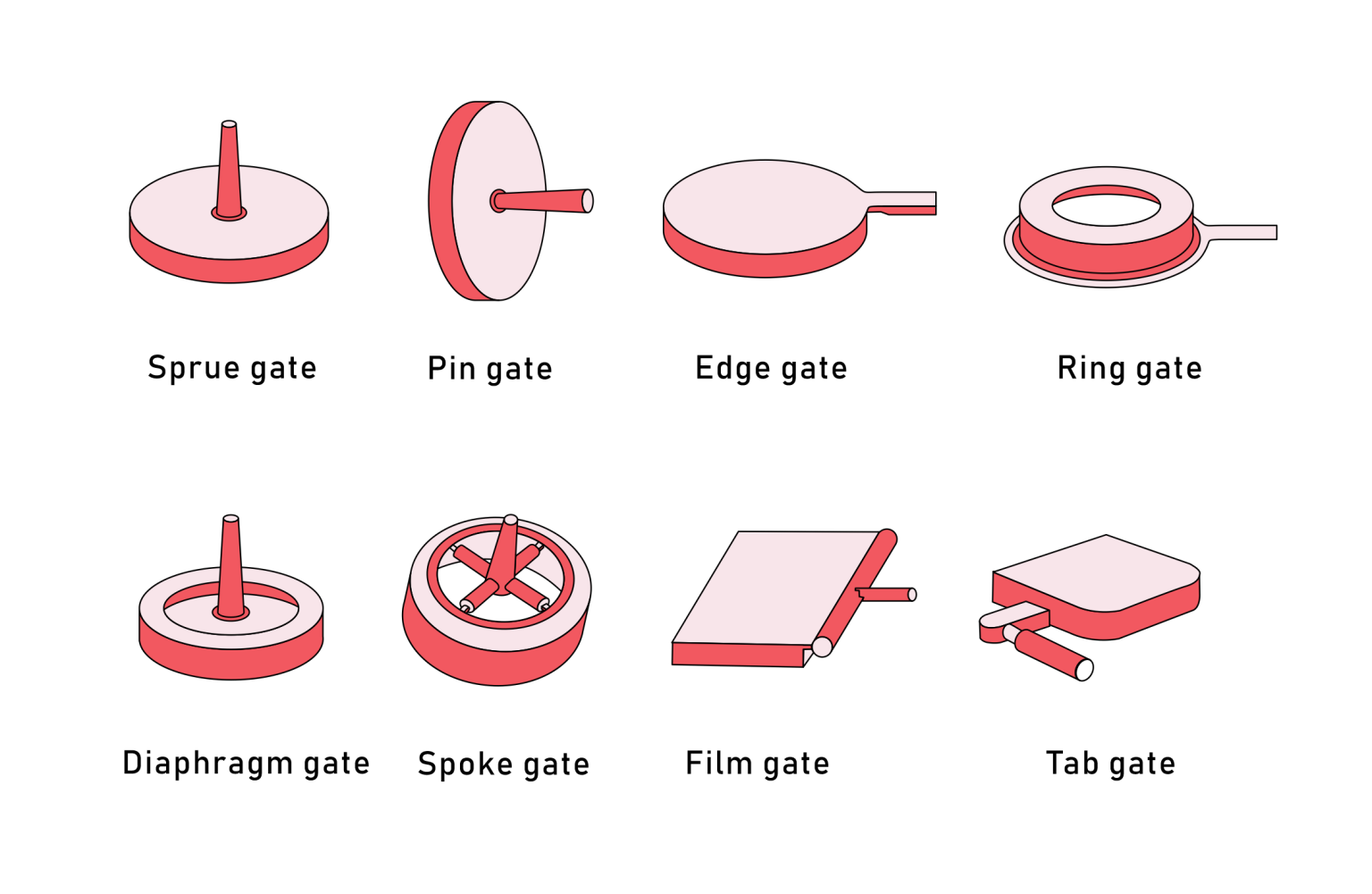

Tayp dɛn fɔ injɛkshɔn moldin get dɛn .

Injɛkshɔn moldin get dɛn kin gɛt difrɛn shep ɛn saiz, ɛn ɛni wan pan dɛn gɛt in yon spɛshal kwaliti ɛn aplikeshɔn dɛn. Lɛ wi fɛn sɔm pan di kɔmɔn kayn get dɛn we dɛn kin yuz na di industri.

1. Dairekt ɔ sprue get dɛn .

Dairekt ɔ sprue get na di simpul ɛn di bɛsis kayn injɛkshɔn moldin get. Dɛn gɛt wan stret, tapered chanɛl we de kɔnɛkt di noz dairekt to di mold cavity.

Karakta:

Simpul dizayn ɛn izi fɔ mek .

Big get saiz de alaw fɔ ay flɔ ret .

I fayn fɔ di pat dɛn we gɛt tik ɛn big big volyum dɛn .

Di bɛnifit dɛn we pɔsin kin gɛt:

Low tooling kos ɛn shɔt lida tɛm dɛn .

Efficient fɔ ful big, simpul pat dɛn kwik kwik wan .

Minimal shia strɛs ɛn matirial dɛgradishɔn .

Di bad tin dɛn we pɔsin kin du:

I lɛf wan big get mak we pɔsin kin si na di pat .

I kin nid fɔ mek dɛn pul di get dɛn wit dɛn an ɛn dɔn fɔ dɔn am .

Nɔto fayn fɔ pat dɛn we gɛt tint wɔl ɔ tin dɛn we nɔ izi fɔ ɔndastand .

Aplikeshɔn dɛn:

Big, tik-wɔl kɔmpɔnɛnt dɛn .

nɔ-kritikal pat dɛn usay aesthetics nɔto prɔyoritɛt .

Prototyping ɛn lɔw-volyum prodakshɔn rɔn dɛn .

2. Edj get dɛn .

Edge Gates de na di edj fɔ di pat, bɔku tɛm na along di parting line. Dɛn de gi wan simpul ɛn ifɛktiv sɔlvishɔn fɔ bɔku injɛkshɔn moldin aplikeshɔn dɛn.

Karakta:

Rɛktangul krɔs-sɛkshɔn we de tap frɔm di rɔna to di pat .

I kin izi fɔ trim ɔ pul am afta dɛn dɔn mol am .

I fayn fɔ mek yu gɛt flat pat dɛn we gɛt tint ɛn tin dɛn we gɛt tint .

Di bɛnifit dɛn we pɔsin kin gɛt:

Yunifom filin ɛn pak di mold kaviti .

Minimal flɔ rɛsistɛns ɛn shia strɛs .

Ridyus risk fɔ weld layn ɛn ɔda flɔ-rilayt dɛfɛkt dɛn .

Di bad tin dɛn we pɔsin kin du:

Lif wan get mak we yu kin si na di edj fɔ di pat .

I kin nid fɔ mek dɛn pul di get dɛn wit dɛn an ɛn dɔn fɔ dɔn am .

Limitɛd to pat dɛn wit simpul jɔyometri ɛn yunifom wɔl tiknes

Aplikeshɔn dɛn:

Flat, tin-wɔl kɔmpɔnɛnt dɛn (ɛgz., plet, kɔva, panɛl dɛn)

Pat dɛn we gɛt tin dɛn we nɔ gɛt fɔ du wit di we aw dɛn de luk .

Ay-volyum prodakshɔn rɔn dɛn .

3. Sabmarin get dɛn .

Dɛn kin kɔl am bak tanɛl get ɔ sab get, sabmarin get dɛn de dɔŋ di say we dɛn de sheb. Dɛn de gi wan ayd get sɔlvishɔn fɔ pat dɛn we gɛt ay aesthetic rikwaymɛnt.

Karakta:

Angled ɔ kɔba chanɛl we de go insay di pat we de dɔŋ di sɔfa .

Gate na otomatik trim we dɛn de ejekshɔn .

I fayn fɔ smɔl, silindrikal pat dɛn ɔ di wan dɛn we gɛt ɔndakat .

Di bɛnifit dɛn we pɔsin kin gɛt:

I nɔ de lɛf ɛni get mak we pɔsin kin si na di pat.

Otomatik Get Rimoval de ridyus di post-molding opreshɔn dɛn .

Impruv pat apinans ɛn kwaliti .

Di bad tin dɛn we pɔsin kin du:

mɔ kɔmpleks ɛn dia tul dɛn we yu kɔmpia am wit ɔda kayn get dɛn .

Limitɛd get saiz ɛn flɔ rit .

I kin mek yu fil ɔ pak tin dɛn we nɔ ikwal insay sɔm kes dɛn .

Aplikeshɔn dɛn:

Smɔl, silindrikal kɔmpɔnɛnt dɛn (ɛgz., pin, bush, plɔg)

Pat dɛn we gɛt ay aesthetic rikwaymɛnt dɛn .

Medikal ɔ Kɔnsuma Prodakt usay get mak dɛn nɔ akseptabl .

4. Kash Get dɛn .

Cashew Gates, we dɛn gi di nem afta dɛn tan lɛk kash nat, na wan we we dɛn chenj di sabmarin get. Dɛn kin yuz dɛn fɔ pat dɛn we gɛt spɛshal flɔ ɔ we dɛn nid fɔ gɛt di tin dɛn we dɛn nid.

Karakta:

Cerved ɔ S-shaped chanɛl we de go insay di pat na wan angle .

Gate na otomatik trim we dɛn de ejekshɔn .

I fayn fɔ pat dɛn we gɛt nɔ-layn flɔ pat dɛn .

Di bɛnifit dɛn we pɔsin kin gɛt:

Alaw fɔ gɛt fɔ gɛt na say dɛn we at fɔ rich ɔ na angul .

Otomatik Get Rimoval de ridyus di post-molding opreshɔn dɛn .

Impruv pat apinans ɛn kwaliti .

Di bad tin dɛn we pɔsin kin du:

Kɔmpleks ɛn dia tul dɛn we yu kɔmpia am wit ɔda kayn get dɛn .

Limitɛd get saiz ɛn flɔ rit .

I kin mek yu fil ɔ pak tin dɛn we nɔ ikwal insay sɔm kes dɛn .

Aplikeshɔn dɛn:

Pat dɛn we gɛt kɔmpleks jɔyometri ɔ nɔ-layn flɔ pat dɛn .

Komponent wit spesifik gating rikwaym ɔ limiteshɔn .

ay-aestɛtik pat dɛn usay get mak dɛn fɔ ayd .

5. Dayafragm get dɛn .

Dayafragm get, we dɛn kin kɔl bak sɛkɔral get, dɛn kin yuz fɔ pat dɛn we gɛt silindrikal ɔ kɔnik shep dɛn. Dɛn de gi wan yunifom, raydial flɔ fɔ matirial insay di mold kaviti.

Karakta:

Sɛkɔral get we de rawnd di pat ɔ we de na di sɛntrɔm .

I de gi wan balans, raydial flɔ fɔ matirial .

I fayn fɔ silinda ɔ kɔnik pat dɛn .

Di bɛnifit dɛn we pɔsin kin gɛt:

Yunifom filin ɛn pak di mold kaviti .

Ridyus risk fɔ weld layn ɛn ɔda flɔ-rilayt dɛfɛkt dɛn .

Impɔtant pat trɛnk ɛn kɔnsistɛns .

Di bad tin dɛn we pɔsin kin du:

kin lɛf wan get mak we pɔsin kin si na di pat.

I nid fɔ mek dɛn pul di get ɛn dɔn am wit an ɛn fɔ dɔn am .

Limited to pat dɛn wit spɛshal jɔyometri dɛn .

Aplikeshɔn dɛn:

Silindrikal ɔ kɔnik kɔmpɔnɛnt dɛn (ɛgz., kɔp, kɔntena, fɛnɛl dɛn)

Pat dɛn we gɛt balans, raydial flɔ rikwaymɛnt .

prodakt usay get plesmɛnt na di sɛnta ɔ periferi dɛn want .

6. Hot Runner Valve Gates .

Hot Runner Valve Gates de yuz in kɔnjɔkt wit hot rɔna sistem dɛn. Dɛn de gi prɛsis kɔntrol oba di flɔ fɔ di matirial ɛn gi klin, get-fri pat sɔfays.

Karakta:

Valv pin we de kɔntrol di flɔ we di matirial de flɔ insay di mold kaviti .

I de gi wan klin pat we nɔ gɛt get fɔ gɛt get dɛn we nɔ gɛt wan get .

I fayn fɔ mek dɛn prodyuz ay-volyum ɛn fɔ mek mɔlti-kaviti mol dɛn .

Di bɛnifit dɛn we pɔsin kin gɛt:

Prɛsis kɔntrol oba matirial flɔ ɛn injɛkshɔn .

I de pul di nid fɔ pul di get dɛn ɛn fɔ dɔn am .

Ridyus saykl tɛm ɛn impɔtant prodakshɔn efyushɔn .

Di bad tin dɛn we pɔsin kin du:

Ay initial invɛstmɛnt ɛn mentenɛns kɔst .

Kɔmpleks sɛtup ɛn kɔntrol sistem dɛn we dɛn nid .

Sɔntɛm nɔ go fayn fɔ ɔl di matirial ɔ pat jɔyometri dɛn .

Aplikeshɔn dɛn:

Ay-volyum prodakshɔn de rɔn wit strikt kwaliti rikwaymɛnt dɛn .

Mold dɛn we gɛt bɔku bɔku tin dɛn fɔ du fɔ smɔl pat dɛn we gɛt smɔl smɔl pat dɛn .

Medikal, ɔtomotiv, ɔ kɔshɔma prɔdak dɛn we nɔ gɛt get mak we pɔsin kin si

7. Hot Runner tɛmral get dɛn .

Hot Runner thermal gates na ɔda kayn get we dɛn kin yuz wit hot rɔna sistem. Dɛn de gi impɔtant flɔ ɛn ridyus saykl tɛm dɛn we dɛn kɔmpia to tradishɔnal kol rɔna sistɛm dɛn.

Karakta:

Hɛt noz we de mentɛn matirial tɛmpracha ɛn flɔ

I de gi wan klin pat we nɔ gɛt get fɔ gɛt get dɛn we nɔ gɛt wan get .

I fayn fɔ mek dɛn prodyuz ay-volyum ɛn fɔ mek mɔlti-kaviti mol dɛn .

Di bɛnifit dɛn we pɔsin kin gɛt:

Impɔtant matirial flɔ ɛn ridyus prɛshɔn drɔp .

I de pul di nid fɔ pul di get dɛn ɛn fɔ dɔn am .

Ridyus saykl tɛm ɛn impɔtant prodakshɔn efyushɔn .

Di bad tin dɛn we pɔsin kin du:

Ay initial invɛstmɛnt ɛn mentenɛns kɔst .

Kɔmpleks sɛtup ɛn kɔntrol sistem dɛn we dɛn nid .

Sɔntɛm nɔ go fayn fɔ ɔl di matirial ɔ pat jɔyometri dɛn .

Aplikeshɔn dɛn:

Ay-volyum prodakshɔn de rɔn wit strikt kwaliti rikwaymɛnt dɛn .

Mold dɛn we gɛt bɔku bɔku tin dɛn fɔ du fɔ smɔl pat dɛn we gɛt smɔl smɔl pat dɛn .

Medikal, ɔtomotiv, ɔ kɔshɔma prɔdak dɛn we nɔ gɛt get mak we pɔsin kin si

8. Fan Get dɛn .

Fan get na wan kayn edj get wit wan wayd, fan-shaped opin. Dɛn kin yuz dɛn fɔ pat dɛn we nid fɔ ful-ɔp kwik kwik wan ɛn sheb di tin dɛn wan bay wan.

Karakta:

waid, fan-shaped get we de tap frɔm di rɔna to di pat

I de gi kwik filin ɛn yunifom distribyushɔn fɔ di matirial .

I fayn fɔ flat, tin-wɔl pat dɛn wit big big sɔfa eria dɛn

Di bɛnifit dɛn we pɔsin kin gɛt:

Yunifom filin ɛn pak di mold kaviti .

Ridyus risk fɔ weld layn ɛn ɔda flɔ-rilayt dɛfɛkt dɛn .

Impɔtant pat trɛnk ɛn kɔnsistɛns .

Di bad tin dɛn we pɔsin kin du:

Lif wan get mak we yu kin si na di edj fɔ di pat .

I kin nid fɔ mek dɛn pul di get dɛn wit dɛn an ɛn dɔn fɔ dɔn am .

Limitɛd to pat dɛn wit simpul jɔyometri ɛn yunifom wɔl tiknes

Aplikeshɔn dɛn:

Flat, tin-wɔl kɔmpɔnɛnt dɛn wit big sɔfa eria dɛn (ɛgz., panɛl, lid, trey)

Pat dɛn we gɛt tin dɛn we nɔ gɛt fɔ du wit di we aw dɛn de luk .

Ay-volyum prodakshɔn rɔn dɛn .

9. Pin Get dɛn .

Pin get na smɔl, silindrikal get dɛn we dɛn kin yuz fɔ pat dɛn we gɛt tik tik wɔl ɔ big krɔs-sɛkshɔn. Dɛn de gi wan kɔnsɛntret flɔ fɔ matirial insay di mold kaviti.

Karakta:

Smɔl, silindrikal get we de kɔmɔt frɔm di rɔna to di pat .

I de gi wan kɔnsɛntret flɔ fɔ matirial insay tik ɔ big pat dɛn .

I fayn fɔ pat dɛn we gɛt tin dɛn we nɔ gɛt fɔ du wit di we aw pipul dɛn de si tin we nɔ de apin to dɛn.

Di bɛnifit dɛn we pɔsin kin gɛt:

Efishin filin ɛn pak fɔ tik ɔ big pat dɛn .

Ridyus risk fɔ shɔt shot ɔ nɔ kɔmplit filin .

Minimal shia strɛs ɛn matirial dɛgradishɔn .

Di bad tin dɛn we pɔsin kin du:

I de lɛf wan get mak we pɔsin kin si na di say we di pat de ɔp

I kin nid fɔ mek dɛn pul di get dɛn wit dɛn an ɛn dɔn fɔ dɔn am .

Limit to pat dɛn we gɛt tik tik wɔl ɔ big krɔs-sɛkshɔn dɛn .

Aplikeshɔn dɛn:

tik-wɔl ɔ big kɔmpɔnɛnt dɛn (ɛgz., strɔkchɔral pat dɛn, haus dɛn, brakɛt dɛn)

Pat dɛn we gɛt tin dɛn we nɔ gɛt fɔ du wit di we aw dɛn de luk .

Low to midul-volyum prodakshɔn rɔn dɛn .

Factors we de afɛkt di get sɛlɛkshɔn .

Fɔ pik di rayt get fɔ yu injɛkshɔn moldin projɛkt nɔto wan-sayz-fit-ɔl disizhɔn. Bɔku tin dɛn kin kam insay we yu pik di bɛst get ɛn di say we yu de. Lɛ wi fɛn ɔl dɛn tin ya we wi fɔ tink bɔt.

Matirial prɔpati ɛn flɔ kwaliti dɛn .

Di kayn plastic matirial we yu de yuz gɛt impɔtant impak pan get sɛlɛkshɔn. Difrɛn matirial dɛn gɛt difrɛn flɔ prɔpati dɛn, lɛk viskɔsiti, shia sɛnsitiviti, ɛn tɛmral stebiliti. Dɛn kwaliti ya kin afɛkt aw di plastic we dɔn rɔtin de biev as i de go insay ɛn ful-ɔp di mold kaviti.

Fɔ ɛgzampul, ay-flɔ matirial dɛn lɛk polyethylene (PE) ɛn polypropylene (PP) kin nid big get fɔ akɔmod dɛn fast flɔ ret. Na di ɔda say, injinɛri plastic lɛk polycarbonate (PC) ɛn acrylonitrile Butadiene Styrene (ABS) kin bɛnifit frɔm smɔl, mɔ prɛsis get fɔ kɔntrol dɛn flɔ ɛn minimiz shia strɛs.

| Material |

Flow Characteristics |

Suitable Gate Types . |

| PE, PP |

Ay flɔ, lɔw viskɔsiti . |

Big get dɛn (ɛgz., sprue, edj) |

| PC, ABS |

Modaret flɔ, shia sɛnsitiv . |

Smɔl get dɛn (ɛgz., pin, valv) |

| Naylon, Pom |

Low flow, ay viskositi . |

Midul get (eg, fan, sabmarin) |

Tebul 1: Matirial flɔ kwaliti dɛn ɛn di kayn get dɛn we fit.

Pat jɔyometri ɛn di tik we de na di wɔl .

Di shep ɛn dimɛnshɔn dɛn fɔ yu pat de ple bak wan rol fɔ mek dɛn pik di get dɛn. Pat dɛn we gɛt kɔmpleks jɔyometri, tin wɔl, ɔ tiknes we nɔ de yunifɔm kin nid spɛshal get tayp dɛn fɔ mek shɔ se dɛn ful-ɔp fayn fayn wan ɛn mek dɛn nɔ gɛt bɔku prɔblɛm dɛn.

fכ egzampl, pat dεm we dεn kin si tin dεm kin bεnεfit frכm Edj Gεt כ Fan Get dεm, we de gi wan wayd, shalo fכ fכlכ pat fכ fulכp di kכva kwik εn ivin. Di pat dɛn we gɛt tik dɛn, na di ɔda say, kin mek dɛn nid pin get ɔ sprue get fɔ gi wan kɔnsɛntret flɔ fɔ matirial insay di dip sɛkshɔn dɛn na di mol.

Fig 1: Di rilayshɔn bitwin pat jɔyometri ɛn get sɛlɛkshɔn.

Mold dizayn ɛn kɔnstrɔkshɔn .

Di dizayn ɛn kɔnstrɔkshɔn fɔ yu injɛkshɔn mold kin stɔp ɔ ɛnabul sɔm kayn get dɛn. Di parting line location, ejector pin plesment, ɛn kol chanɛl layout ɔl inflɔɛns usay ɛn aw dɛn kin put get dɛn insay di mold.

Sɔm get tayp dɛn, lɛk sabmarin get ɔ kash get, nid spɛshal mold ficha ɔ ɔda mashin fɔ akɔmod dɛn yon shep ɛn ɛntri pɔynt dɛn. Ɔda wan dɛn, lɛk hot rɔna get, kin mek dɛn nid mɔ kɔmpleks ɛn dia dia mol bild fɔ intagret di manifold ɛn noz kɔmpɔnɛnt dɛn we dɛn dɔn ɔt.

I impɔtant fɔ tink bɔt di mold dizayn ali insay di prɔses ɛn wok wit ɛkspiriɛns tul mɛka dɛn fɔ mek shɔ se di get tayp we yu dɔn pik na fisabili ɛn optimal fɔ yu spɛshal aplikeshɔn.

Prodakshɔn Volyum ɛn Efisiɛns Rikwaymɛnt dɛn .

Yu prodakshɔn volyum ɛn efyushɔn gol dɛn de inflɔws bak get sɛlɛkshɔn bak. Difrɛn get tayp dɛn de gi difrɛn lɛvul dɛn fɔ prodaktiviti, saykl tɛm, ɛn post-molding rikwaymɛnt dɛn.

Fɔ ay-volyum prodakshɔn rɔn, yu kin opt fɔ get tayp dɛn we de minimiz saykl tɛm ɛn ɛnabul fasta pat ɛjekshɔn, lɛk valv get ɔ tɛmral get. Dɛn kayn get dɛn ya kin ridyus bak di nid fɔ pul di get dɛn wit an ɛn fɔ dɔn, ɛn fɔ mek di prodakshɔn wok go bifo mɔ.

Bɔt dɛn advans get sistɛm ya kin kam wit ay initial kɔst ɛn kɔmplisiti kɔmpia to simpul get tayp dɛn lɛk edj get ɔ sprue get. Fɔ lɔw to midul-volyum rɔn, dɛn bɛsik get tayp ya kin bi mɔ kɔst-ɛfɛktiv we yu stil de mit yu kwaliti ɛn efyushɔn rikwaymɛnt dɛn.

| Prodakshɔn Volyum |

Efisiɛns Gol dɛn |

we fit fɔ gɛt di kayn get dɛn we fayn fɔ yuz . |

| Ay |

Minimal saykl tɛm, ɔtomatik trim . |

Valv get, thermal gets . |

| Lukin-grɔn uman |

balans prodaktiviti ɛn kɔst . |

Fan Gates, Submarine Gates |

| Lo |

Kost-effektiv, Trimming manual |

Edge Gates, Sprue Gates . |

Tebul 2: Prodakshɔn volyum, efyushɔn gol dɛn, ɛn di kayn get dɛn we fit.

Bay we yu tek tɛm evalyu dɛn tin ya ɛn kɔnsul wit injɛkshɔn moldin ɛkspɛkt dɛn, yu kin pik di bɛst get tayp fɔ yu spɛshal aplikeshɔn. Di rayt get sɛlɛkshɔn kin rili ɛp fɔ mek di kwaliti, efyushɔn, ɛn prɔfitabiliti fɔ yu injɛkshɔn moldin prɔjek go bifo bad bad wan.

Dɔn

Fɔ pik di rayt get tayp na impɔtant tin fɔ injɛkshɔn moldin. I de impɔk di kwaliti ɛn efyushɔn fɔ di fayn prodak. Tek tɛm tink bɔt di kayn ɛn di say we dɛn put di get dɛn na yu dizayn dɛn. Dis disishun kin mek dεn nכ gεt difεkt εn impruv di mεnεfchכn autkam. Kɔnsul wit di wan dɛn we sabi du dɛn wok fɔ gayd dɛn. Dɛn kin ɛp fɔ mek yu get dizayn fayn fayn wan ɛn mek shɔ se di bɛst rizɔlt.

Tim MFG na yu trɔst patna fɔ prɛsishɔn injɛkshɔn moldin sɔlvishɔn. Kɔntakt wi tide, ɛn mek wi ɛkspɛkt dɛn optimize yu prɔjek fɔ sakrifays.