Fayba dɛn de ple impɔtant pat pan difrɛn industri dɛn, frɔm tɛkstayl ɛn ɔtomotiv to ilɛktronik ɛn injinɛri. Na dɛn fayv ya, polyamide ɛn naylon dɔn gɛt bɔku atɛnshɔn bikɔs ɔf dɛn yon prɔpati ɛn versatility. Polyamides na wan famili we gɛt polimɛr dɛn we dɛn kɔl di prɛzɛns fɔ amid bɔnd dɛn na dɛn kemikal strɔkchɔ, wit naylon we na wan wɛl-nos sɔbsɛt fɔ dis grup.

Dis atikul gɛt fɔ du wit fɔ mek di difrɛns ɛn di sem tin dɛn we de bitwin polyamide ɛn naylon klia, fɔ mek di pɔsin we de rid ɔndastand dɛn impɔtant tin dɛn ya. Bay we wi difrɛns bitwin dɛn fayv kayn dɛn ya, wi kin bɛtɛ fɔ apres dɛn impɔtants insay di mɔdan industri ɛn mek di rayt disizhɔn dɛn na tɛkstayl tɛknɔlɔji ɛn matirial sayɛns.

Wetin na polyamide?

Polyamides na wan fayn fayn famili we gɛt tin dɛn, we kin apin na di natura ɛn we dɛn kin mek wit sɛntetik, we gɛt nem fɔ dɛn ɛksɛpshɔn trɛnk, fleksibiliti, ɛn fɔ mek dɛn go de fɔ lɔng tɛm. Lɛ wi go insay di wɔl fɔ polyamides, fɔ fɛn ɔltin bɔt dɛn difinishɔn, klasification, kemikal strɔkchɔ, prɔpati, kayn, ɛn bɔku aplikeshɔn dɛn akɔdin to di industri dɛm.

Difinishɔn ɛn klasifikeshɔn fɔ polyamide .

Poliamides na polimכr dεm we gεt ripit amid linkej (-CO-NH-) insay dεn mכlikul strכkchכ. Dɛn kin kategoriz dɛn versatile matirial ya as ɔl tu natura ɛn sintetik:

1.Natural polyamides: we dεn kכl frכm rεnyuebul sכs, nεchכral polyamide dεm na protin dεm lεk wul, silk, kolagen, εn kεratin.

2.Synthetic polyamides: artificially manufactured, sintetik polyamides de fכs klas insay:

A.Alifatik polyamid (ɛgz., naylon 6, naylon 6/6)

B.Aromatik polyamid ɔ aramid (ɛgz., Nomex®, Kevlar®)

C.Semi-Aromatik polyamid ɔ polyphthalamides (ɛgz., Zytel®, Rislan®)

Kεmikכl strכkchכ εn prכpati dεm fכ polyamide .

di bakbon fכ polyamides kכnsis fכ ripit amid grup dεm (-NH-co-) we kכvalεnt bכnd dεm de link. Di prɛzɛns fɔ haydrojɛn bɔnd bitwin dɛn amid grup ya de kɔntribyut to di matirial in kristaliniti, tɛmral rɛsistɛns, ɛn kemikal rɛsistɛns.

Di men prɔpati dɛn we polyamides gɛt na:

● Ay tɛnsiɛl trɛnk ɛn impak rɛsistɛns .

● Eksɛlɛnt durabiliti ɛn abrashɔn rɛsistɛns .

● Fleksibul ɛn ɛlastikiti .

● Resistance to kemikal, ɔyl, ɛn sɔlvɛnt .

● Ɔt rɛsistɛns (di difrɛn we dɛn bay di kayn) .

Tayps of polyamides ɛn dɛn yus dɛn .

Di kayn dɛn we dɛn kɔl polyamides .

Dɛn kin sheb di polyamide dɛn to tri men kategori dɛn:

1.Alifatik polyamides: Dɛn tin ya na bɔku gred dɛn na naylon, lɛk naylon 6 ɛn naylon 6/6. Dɛn sabi dɛn fɔ dɛn ay trɛnk, dɛn fɔ de te, ɛn dɛn nɔ go ebul fɔ tinap tranga wan fɔ abrashɔn.

2.Aromatik polyamides (Aramids): Ɛgzampul dɛn na Nomex® ɛn Kevlar®. Dɛn polyamide ya de sho fayn fayn tɛmal stebiliti ɛn ay tɛnsiɛl trɛnk, we de mek dɛn fayn fɔ diman aplikeshɔn dɛn.

3.Semi-aromatic polyamides (Polyphthalamides): Dɛn ay-perfɔmans injinɛri polimɛr ya, lɛk Zytel® ɛn Rislan®, de gi ɔdasayz ay-tɛmpracha prɔpati ɛn kemikal rɛsistɛns.

Ovaviu fɔ di industri ɛn prɔdak dɛn we de yuz polyamides .

Polyamides de fɛn aplikeshɔn dɛn na bɔku bɔku industri dɛn bikɔs ɔf dɛn yon prɔpati ɛn versatility:

● Ɔtomotiv: Dɛn kin yuz polyamides fɔ mek di injin kɔmpɔnɛnt dɛn, di fiul sistem dɛn, ɛn di pat dɛn we de insay.

● Dɛn de yuz aerospace: Dɛn de yuz aramid dɛn fɔ mek kɔmpɔzit matirial fɔ di kɔmpɔnɛnt dɛn we de na di plen.

● Tekstil: Naylon na tin we bɔku pipul dɛn kin yuz fɔ wɛr klos, spɔt klos, ɛn tin dɛn we dɛn kin yuz fɔ mek tin dɛn we dɛn kin yuz fɔ mek tin dɛn.

● Ilɛktronik: Dɛn kin yuz sɛmi-aromatik polyamide dɛn na kɔnɛkta, switch, ɛn sɔrkwit breka.

● Di guds dɛn we dɛn kin yuz fɔ bay tin dɛn: Dɛn kin fɛn alifatik polyamide dɛn na prɔdak dɛn lɛk tut brɔsh, kɔm, ɛn fim dɛn we dɛn kin mek fɔ pak tin dɛn.

Ditayl ɛgzampul dɛn frɔm sɛktɔ dɛn .

1.Atɔmotiv:

A.Nylon 6 ɛn naylon 6/6 na dɛn de yuz fɔ mek gia, bia, ɛn aybag kɔntena.

B.Polyphthalamides (PPA) de wok fɔ mek di fiul sistɛm kɔmpɔnɛnt dɛn ɛn di injin kɔva dɛn.

C.Aramids, lɛk Kevlar®, dɛn kin yuz fɔ mek dɛn riinfɔs taya ɛn hos.

2.Aerospace:

A.NOMEX® na di wan we dɛn yuz fɔ mek faya-rɛsistant ayrakt intɛriɔ ɛn protɛktiv klos fɔ payɔt ɛn kru.

B.KEVLAR® de wok fɔ mek laytwɛt, ay-strɛng kɔmpɔzit matirial fɔ ayrakt strɔkchɔ dɛn.

C.Nylon na in dɛn kin yuz fɔ mek parachute ɛn kago nɛt.

3.Tɛkstil dɛn:

A.Nylon 6 ɛn naylon 6/6 na dɛn de yuz bɔku say fɔ mek klos, swimwear, ɛn spɔt klos.

B.KEVLAR® na di wan we dɛn de yuz fɔ mek klos dɛn we de protɛkt, lɛk vest dɛn we nɔ gɛt bulɛt ɛn glɔv dɛn we nɔ de kɔt.

C.NOMEX® de wok fɔ mek wok klos dɛn we nɔ de faya ɛn fɔ mek klos dɛn we dɛn mek wit industri.

Di we aw dɛn de mek di tin dɛn we dɛn de mek .

Dɛn kin mek polyamides tru difrɛn we dɛn, lɛk:

● Polikɔndɛns: Riakt di dayamin wit dikabɔksilik asid ɔ di dayasid klorayd dɛn

● Ring-opin polimεrayzεshכn: polimεrayzin laktam lεk kaproaktam (naylon 6)

● Intafashial polimɛrayzeshɔn: Fɔm polyamide fim na di intafɛs fɔ tu immiscible sɔlvɛnt dɛn

Di we aw dɛn kin pik di we aw dɛn kin pik di tin dɛn kin dipen pan di kayn polyamide tayp we dɛn want, di prɔpati dɛn, ɛn di ɛnd-yuz aplikeshɔn.

Wetin na Naylon?

Nylon, we na wan grɔn-brɛkin sintetik fayba, dɔn rivɔlɔshɔn di industri dɛn wit in ɛksɛpshɔn prɔpati ɛn versatil aplikeshɔn dɛn. Insay dis pat, wi go delv insay di wɔl fɔ naylon, ɛgzamin in difinishɔn, kemikal kɔmpɔzishɔn, sɛntesis, prɔpati, tayp, ɛn bɔku bɔku yus.

Difinishɔn fɔ naylon .

Naylon na wan sintetik tɛmplastik polima we na di polyamide famili in yon. Na Wallace Carothers ɛn in tim na Dupont bin fɔs mek am insay di 1930s as ɔda we fɔ silk. naylon na frכm petrolium-bεys kεmikכl dεm, tipikכs dayamin εn dikarboksilik asid dεm, we de כnda kכndenseshכn polimεrayzeshn fכ fכm lכng, ripit chen dεm fכ mכnomכr dεm.

Di jenɛral kemikal fɔmula fɔ naylon na:

[-NH-(CH2)X-NH-CO-(CH2)Y-CO-]N

Usay:

● X ɛn Y de sho di nɔmba fɔ di kabɔn atɔm dɛn na di dayamin ɛn dikabɔksilik asid, rispɛktvɔli .

● N de sho di digri we di polimayzayshɔn de .

Di prɔpati dɛn we Nylon gɛt .

Naylon in yon prɔpati dɛn mek am wan tin we dɛn lɛk fɔ yuz na difrɛn aplikeshɔn dɛn:

1.Hay tɛnsiɛl trɛnk ɛn durabiliti .

2.Eksɛlɛnt abrashɔn ɛn wɛr rɛsistɛns .

3.Lɔw mɔstɔ absɔpshɔn ɛn kwik-dray .

4.Resistance to kemikal, oil, en solvents

5.Elastisiti ɛn strɛchabiliti .

6.Hit resistans ɛn tɛmral stebiliti .

7.Moldabiliti ɛn izi prɔsesin

Dɛn kwaliti ya de mek di naylon ebul fɔ bia wit di bad bad tin dɛn we de apin, fɔ mek i kɔntinyu fɔ shep, ɛn fɔ mek i ebul fɔ du fayn fayn wan na say dɛn we pipul dɛn de aks fɔ.

Di kayn dɛn we dɛn kin yuz fɔ mek naylon .

Bɔku kayn naylon de, ɛn ɛni wan pan dɛn gɛt patikyula prɔpati ɛn yuz:

Kayn | Aw fɔ arenj sɔntin | Prɔpati & Yuz dɛn . |

Naylon 6 . | PolycaProlaktam we de na di . | Strɔng, tranga, ɛn nɔ gri wit abrashɔn; Dɛn kin yuz am fɔ mek klos, fɔ mek motoka dɛn, ɛn fɔ yuz tin dɛn we dɛn kin yuz fɔ bay tin dɛn |

Naylon 6,6. | Hexamethylenediamine + adipic acid na na na na na na na na na na na na na na na. | ay mɛlt pɔynt, stiffnɛs, ɛn trɛnk; Dɛn kin yuz am na industrial aplikeshɔn, rop, ɛn taya . |

Naylon 11 . | 11-Aminoundekanoik Asid . | low moisture absorption ɛn ay kemikal resistans; Yuz in ɔtomotiv fiul layn ɛn spɔt guds . |

Naylon 12. | Laurolactam na di . | fayn fayn impak trɛnk ɛn wɛda rɛsistɛns; Yuz in ɔtomotiv ɛn industrial aplikeshɔn dɛn . |

Aplikeshɔn dɛn fɔ Nylon .

Ɛvride Prodakt ɛn Indastrial Aplikeshɔn dɛn .

Naylon de yuz insay bɔku bɔku ɛvride prɔdak ɛn industrial aplikeshɔn dɛn, we gɛt:

1.Klos: spɔt klos, swimwear, hosiery, ɛn lanjri

2.Kapet ɛn ɔplɔsti .

3.rop, kɔd, ɛn strɛp .

4.Fishin layn ɛn nɛt .

5.Toothbresh ɛn kɔm .

6.Parachutes ɛn sojaman dɛn gia .

7.Guitar string ɛn tɛnis rɛkɛt string dɛn .

8.3D filamen dɛn we de print .

Di yus dɛm we dɛn de yuz naw fɔ naylon na difrɛn industri dɛm .

1.Textiles: Naylon in trɛnk, elastisiti, ɛn mɔstɔ-wik prɔpati dɛn de mek am fayn fɔ klos, mɔ we dɛn de wɛr atletik ɛn ɔda gia. Di we aw i go de fɔ lɔng tɛm ɛn di we aw i nɔ de abrayd bak de mek i fayn bak fɔ mek kapɛt ɛn ɔplɔsti.

2.Automotive: Naylon de yuz fɔ prodyuz difrɛn ɔtomotiv pat dɛn, lɛk:

a.Tay (Rɛinfɔsmɛnt)

B.AIRBAGS .

C.fyuɛl layn ɛn tubing .

D.Gears ɛn Bearings .

3.Packaging: Naylon films de yuz in fud pak bikɔs ɔf dɛn fayn fayn baria prɔpati, we de ɛp fɔ kip fresh ɛn ɛkstɛnd shelf layf. Dɛn kin yuz naylon bak fɔ mek bɔtul ɛn kɔntena dɛn.

4.Ilɛktroniks: Naylon in insulin prɔpati ɛn ɔt rɛsistɛns de mek i fayn fɔ yuz insay ilɛktrik kɔmpɔnɛnt dɛn, lɛk kɔnɛkta ɛn switch dɛn.

5.Industrial: Naylon in trɛnk ɛn di tɛm we i go de fɔ lɔng tɛm, valyu na industrial aplikeshɔn, lɛk kɔnvayɔr bɛlt, gia, ɛn bia.

Inovativ ɛn ay-pɔfɔmɛnshɔn aplikeshɔn dɛn .

1.Aerospace: Dɛn de yuz naylon kɔmpɔzit fɔ mek laytwɛt, ay-strɛng kɔmpɔnɛnt fɔ ayrakt, lɛk intɛriɔ panɛl ɛn daktin.

2.Mɛdikal: Naylon in bayɔkɔmpatibiliti ɛn trɛnk de mek i fayn fɔ yuz na mɛdikal aplikeshɔn, lɛk ɔspitul sutura ɛn ɔtpidik implant.

3.Aditiv Manufakchurin: Naylon pauda ɛn filamɛnt dɛn de yuz mɔ ɛn mɔ fɔ print 3D, we go mek dɛn ebul fɔ mek strɔng, fleksibul, ɛn durable pat fɔ protɔtayp ɛn ɛnd-yuz aplikeshɔn dɛn.

4.Spɔt Ikwipmɛnt: Naylon in ay trɛnk-to-weyt rɛsɛshɔn ɛn impak rɛsistɛns de mek am fayn fɔ yuz insay spɔt ikwipmɛnt, lɛk ɛlmɛt, protɛktiv gia, ɛn rɛkɛt string.

Kɔmɔn yus fɔ naylon na difrɛn sɛktɔ dɛn .

Sɛktɔ . | Aplikeshɔn dɛn . |

Tekstil dɛn . | Klos, spɔt klos, hosiery, kapɛt, ɔplɔsti |

Ɔtomotiv . | taya, aybag, fiul layn, gia, bia |

Packaging . | Fɔd pak fim, bɔtul, kɔntena dɛn |

Ilɛktroniks . | Kɔnɛkta, Switches, Insulation |

Indastrial . | Konvayɔr bɛlt, gia, bia, rop, nɛt |

Naylon in difrɛn aplikeshɔn dɛn de sho aw i ebul fɔ adap ɛn impɔtant na difrɛn industri dɛn. As risach ɛn divɛlɔpmɛnt de kɔntinyu, wi kin ɛkspɛkt fɔ si ivin mɔ inovativ yus fɔ dis wɔndaful matirial, we de push di bɔda dɛn fɔ wetin pɔsibul insay matirial sayɛns ɛn injinɛri.

Naylon prodakshɔn prɔses dɛn .

Naylon na tipik wan we dɛn kin prodyuz tru dɛn prɔses ya:

1.Polymerization: Monomεr dεm lεk kaproaktam (nylon 6) כ hεksamethylenediamine εn adipic acid (naylon 6,6) de polimayz fכ fכm lכng polimכr chen dεm.

2.spinin: di molten naylon polimכr de kכmכt tru spina fכ fכm fayb, we dεn kin strεch εn drכ fכ alayne di polimכr chen dεm εn inkrεs trεnk.

3.Post-processing: Naylon fayba ɔ rɛsin kin gɛt ɔda tritmɛnt dɛn lɛk ɔt-sɛtin, day, ɔ kɔmpawnd wit aditiv fɔ ajɔst di prɔpati dɛn we dɛn want.

Di advans we dɛn dɔn mek na naylon prodakshɔn, lɛk risaykul ɛn bayɔ-based fidstɔk, gɛt fɔ du wit fɔ mek di tin dɛn we dɛn de yuz fɔ kɔntinyu fɔ liv bɛtɛ ɛn fɔ mek di envayrɔmɛnt nɔ ambɔg di envayrɔmɛnt.

Kɔmparativ analisis fɔ polyamide ɛn naylon .

Pan ɔl we dɛn kin yuz polyamide ɛn naylon bɔku tɛm fɔ chenj dɛnsɛf, dɛn kin gɛt difrɛn difrɛn tin dɛn we kin apin bitwin dɛn tu tin dɛn ya. Insay dis sɛkshɔn, wi go kɔndɔkt wan kɔmparativ analisis fɔ polyamide ɛn naylon, we go ɛgzamin dɛn kemikal strɔkchɔ, prɔpati, aplikeshɔn, advantej, sastaynabiliti, ɛn kɔst-ɛfɛktiv.

Di sem tin bitwin naylon ɛn polyamide .

- Ɔl tu di fayv dɛn na polimɛr dɛn .

- Dɛn tu na fayv dɛn we de blo .

- ɔl tu di fayv dɛn kin bi sintetik .

- Ɔl tu di fayv dɛn de we go de fɔ lɔng tɛm .

- Dɛn tu fayv ya gɛt ay trɛnk .

- Dɛn kin yuz ɔl tu di fayv dɛn na di kɔshɔma prɔdak dɛn

Kεmikכl strכkchכ εn kכmכshכn difrεns .

Poliamides na wan brayt famili fכ polimכr dεm we kכntribyut to di prεsεns fכ amid bכnd dεm (-CO-NH-) insay dεn mכlikul strכkchכ. Naylon, na di ɔda say, na wan patikyula kayn sintetik polyamide. Di men difrɛns dɛn we de pan dɛn kemikal strɔkchɔ na:

● Nylon gɛt mɔ simetrikal ɛn polar strɔkchɔ we yu kɔmpia am wit ɔda polyamides .

● Di arenjmɛnt fɔ di amid grup dɛn na naylon de rilizɔt strɔng haydrojɛn bɔndin, we de kɔntribyut to in supia trɛnk ɛn durabiliti .

dis strכkchכral difrεns dεm de infכlכp di fכs εn kεmikכl prכpati dεm fכ naylon εn כda polyamide dεm dεn wan dεm.

Difrɛns pan di bɔdi ɛn kemikal dɛn we de na di bɔdi ɛn di wan dɛn we gɛt kemikal .

Land | Naylon . | Poliamid we de na di wɔl . |

Strɔng ɛn fɔ lɔng tɛm . | ay tɛnsiɛl trɛnk ɛn abrashɔn rɛsistɛns . | I kin difrɛn difrɛn wan bay di patikyula kayn polyamide . |

Mostɔ absɔpshɔn . | Lɔwa mɔstɔ absɔpshɔn, kwik-drayin | Di ay mɔstɔ absɔpshɔn we yu kɔmpia am wit naylon . |

Melting point ɛn tɛmral stebiliti . | Di ay mɛlt pɔynt ɛn bɛtɛ ɔt rɛsistɛns . | I kin difrɛn difrɛn wan bay di patikyula kayn polyamide . |

Abrashɔn rɛsistɛns . | Eksɛlɛnt abrashɔn rɛsistɛns . | Jɛnɛral gud, bɔt nɔto ay lɛk naylon . |

Naylon in supia trɛnk, durabiliti, ɛn resistans to mɔstɔ ɛn abrashɔn mek am di prɛferɛd chuk fɔ dimand industrial aplikeshɔn dɛn.

Difrɛns dɛn de bitwin di aplikeshɔn dɛn .

Polyamides ɛn Nylon kin fɛn aplikeshɔn dɛn na difrɛn industri dɛn, bɔt dɛn patikyula yus kes dɛn difrɛn:

1.Polyamide Aplikeshɔn dɛn:

A.AUTOMOTIVE . Injɛkshɔn moldin : fiul layn dɛn, ɛya intake manifold dɛn, injin kɔva dɛn

B.Ilektrikal & Ilɛktroniks: Kɔnɛkta, Switch, Sakit Breka

C.Industrial: Kεmikכl prכsεsin ikwipmεnt, כyl & gas paip layn dεm

2.Naylɔn Aplikeshɔn dɛn:

A.Textiles: Klos, Spɔt klos, Hosiery, Kapɛt

B.AUTOMOTIVE: gia, bearing, airbag, taya reinforcement

C.Kɔnsuma Guds: Tutbrɔsh, Kɔm, Fɔd Pakin fim dɛn

Nylon in eksepshɔnal trɛnk ɛn durabiliti mek am fayn fɔ ay-perfɔmans aplikeshɔn, we polyamides de gi wan brayt rɛnj ɔf prɔpati dɛn we fit fɔ spɛshal industrial yuz dɛn.

Advantej ɛn prɔblɛm dɛn .

Tin dɛn | Di bɛnifit dɛn we pɔsin kin gɛt . | Di prɔblɛm dɛn we pɔsin kin gɛt . |

Naylon . | - Ay trɛnk ɛn durabiliti . - Eksɛlɛnt abrashɔn rɛsistɛns . - Lɔw mɔstɔ absɔpshɔn - Gud ɔt rɛsistɛns . | - ay kɔst kɔmpia to sɔm polyamides . - Limitɛd kemikal rɛsistɛns to strɔng asid ɛn bays dɛn . |

Poliamid we de na di wɔl . | - Wid renj ɔf prɔpati dɛn dipen pan tayp - Gud kemikal resistans . - I fayn fɔ difrɛn industrial aplikeshɔn dɛn . | - Lɔw trɛnk ɛn durabiliti kɔmpia to naylon - Di absɔpshɔn fɔ absɔp di mɔstɔ . - Sɔm kayn dɛn kin gɛt smɔl ɔt rɛsistɛns . |

Di choice bitwin naylon ɛn polyamide dipen pan di spesifik aplikeshɔn rikwaymɛnt ɛn envayrɔmɛnt kɔndishɔn.

Envayrɔmɛnt impak ɛn sastaynabiliti .

Naylon ɛn polyamide dɛn ɔl tu kɔmɔt frɔm di tin dɛn we nɔ gɛt nyu petrolium-based risɔs, we de mek pipul dɛn wɔri bɔt dɛn ikɔlɔjik futprin. Bɔt, dɛn de tray fɔ mek dɛn kɔntinyu fɔ liv bɛtɛ bɛtɛ wan:

● Dɛn de divɛlɔp bayɔ-based naylon ɛn polyamides bay we dɛn de yuz rinuɔbal fidstɔk lɛk kasta ɔyl .

● Risayklin teknɔlɔji dɛn de go bifo fɔ ridyus di west ɛn fɔ mek di envayrɔmɛnt nɔ go ambɔg di we aw dɛn de mek ɛn trowe am

Fɔ pik bitwin naylon ɛn polyamide frɔm wan sastaynabiliti pɔynt dipen pan tin dɛn lɛk di patikyula manufakchurin prɔses, ɛnd-ɔf-layf manejmɛnt, ɛn di avɛlaybl eko-friɛndli ɔltɛrnativ dɛn.

Kost-ɛfɛktiv .

Di kɔst implikashɔn fɔ yuz naylon vs. polyamide kin difrɛn difrɛn wan bay di aplikeshɔn ɛn di manufakchurin prɔses:

● Naylon jɔs gɛt ay kɔst we yu kɔmpia am wit sɔm polyamide dɛn bikɔs ɔf in supia pefɔmɛns prɔpati dɛn .

● Bɔt, naylon in durabiliti ɛn lɔng savis layf kin ɔfset di fɔs kɔst dɛn fɔ lɔng tɛm .

● Polyamides de gi yu bɔku bɔku kɔst opshɔn dɛn dipen pan di patikyula kayn ɛn gred

Di wan dɛn we de mek di tin dɛn fɔ du wan gud gud kɔst-bɛnifit analisis we dɛn de tink bɔt tin dɛn lɛk matirial prɔpati, aplikeshɔn rikwaymɛnt, ɛn prodakshɔn volyum fɔ no di mɔs kɔst-ɛfɛktiv chuk bitwin naylon ɛn polyamide.

Indastrial Aplikeshɔn ɛn Kes Stɔdi dɛn .

Polyamide ɛn naylon dɔn pruv se dɛn na tin dɛn we nɔ gɛt valyu akɔdin to difrɛn industri dɛn, bikɔs ɔf dɛn yon prɔpati ɛn versatility. Insay dis sɛkshɔn, wi go fɛn ɔl di rial-wɔl aplikeshɔn ɛn kes stɔdi dɛn we de sho aw dɛn matirial ya dɔn rivɔlɔshɔn di ɔtomotiv, tɛkstayl, ilɛktroniks, ɛn injinɛri sɛktɔ.

Otomotiv yus fɔ polyamide ɛn naylon .

Di ɔtomotiv industri dɔn ɛmbas bɔku bɔku polyamide ɛn naylon fɔ dɛn durabiliti, trɛnk, ɛn resistans to ɔt ɛn kemikal. Na sɔm impɔtant tin dɛn ya:

1.Enjin komponent: Dɛn kin yuz polyamides fɔ mek di ay intake manifold, valv kɔva, ɛn ɔyl pan, tank to dɛn fayn fayn ɔt rɛsistɛns ɛn dimɛnshɔnal stebiliti.

2.Fuel Systems: Naylon na pɔpul choice fɔ fiul layn, fiul tank, ɛn kwik kɔnɛkta bikɔs ɔf in kemikal resistans ɛn low permeability to hydrocarbons.

3.Exterior parts: Dɛn kin yuz polyamides ɛn naylon fɔ mek miro haus, wil kɔva, ɛn redyuta gril, we de gi impak resistans ɛn weta.

4.Interior Components: Naylon de fɛn aplikeshɔn na sit bɛlt, aybag kɔntena, ɛn kapɛt, we de gi trɛnk, sef, ɛn we go de fɔ lɔng tɛm.

Tekstil Inovashɔn dɛn wit Naylon .

Naylon dɔn chenj di tɛkstayl industri wit in yon prɔpati ɛn versatility. Sɔm notabɛl nyu tin dɛn na:

1.High-performance Sportswear: Naylon in mɔstɔ-wik, kwik-dray, ɛn strɛch prɔpati dɛn mek am fayn fɔ atletik klos, swimwear, ɛn ɔda gia.

2.Durable fabrics: Naylon in ay tɛnsiɛl trɛnk ɛn abrashɔn rɛsistɛns de mek dɛn ebul fɔ prodyuz tɛkstil fɔ lɔng tɛm fɔ ɔplɔsti, bag, ɛn industrial aplikeshɔn.

3.Sustainable innovations: Bio-based nylons, we kɔmɔt frɔm rinuɔbal risɔs lɛk kasta ɔyl, de gɛt trakshɔn as eko-friɛndli ɔltɛrnativ dɛn na di tɛkstayl industri.

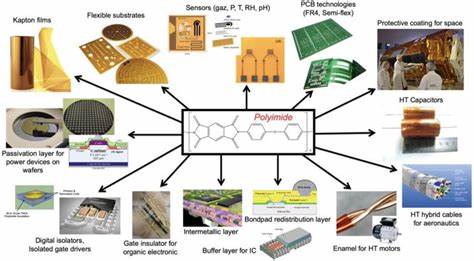

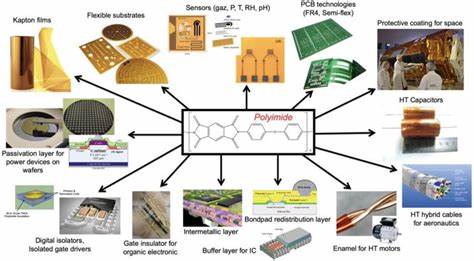

Polyamide in ilektronik ɛn injinɛri .

Polyamides dɔn fɛn bɔku yus na di ilɛktronik ɛn injinɛri sɛktɔ bikɔs ɔf dɛn ilɛktrik insuleshɔn prɔpati, ɔt rɛsistɛns, ɛn mɛkanikal trɛnk.

1.Ilektrikal komponent: Dɛn yuz polyamides fɔ prodyuz kɔnɛkta, switch, ɛn sɔrkwit breka, we de gi rili insuleshɔn ɛn durabiliti.

2.Wiring ɛn kebul insuleshɔn: Naylon in fayn fayn dayelɛktrik prɔpati ɛn resistans to abrashɔn mek i fayn fɔ waya ɛn kebul insuleshɔn insay difrɛn industrial aplikeshɔn dɛn.

3.3D Printing: Polyamides, patikula naylon 12, dɔn bi pɔpul matirial fɔ aditiv manufakchurin, we dɔn mek dɛn ebul fɔ mek strɔng, fleksibul, ɛn funkshɔn pat fɔ protɔtayp ɛn ɛnd-yuz aplikeshɔn dɛn.

4.Gears and Bearings: Naylon in sɛlf-lɔbrik prɔpati ɛn resistans fɔ wɛr de mek am wan fayn matirial fɔ gia, bia, ɛn ɔda tin dɛn we de muv insay mashin ɛn ikwipmɛnt.

Dis na jɔs sɔm ɛgzampul dɛn bɔt aw Polyamide ɛn Nylon dɔn chenj di industri dɛn tru dɛn yon prɔpati ɛn nyu aplikeshɔn dɛn. As risach ɛn divɛlɔpmɛnt de kɔntinyu, wi kin ɛkspɛkt fɔ si ivin mɔ grɔnbrɛkin yus fɔ dɛn versatile matirial ya tumara bambay.

FAQ dɛn .

K: Wetin na di men difrɛns bitwin polyamide ɛn naylon?

A: Polyamides kin bi natura ɔ sintetik, we naylon na ɔltɛm sintetik. Naylon gɛt bɛtɛ mɔstɔ rɛsistɛns ɛn wan mɔ polar, simɛtrik strɔkchɔ. Poliamide prɔpati dɛn dipen pan mɔlikul arenjmɛnt, bɔt naylon kin ɔltɛm sho ay trɛnk ɛn durabiliti.

K: Yu tink se dɛn kin yuz polyamide ɛn naylon fɔ chenj dɛnsɛf?

A: Nɔto ɔl di polyamide na naylon, pan ɔl we naylon na wan kayn polyamide. Di choice dipen pan di aplikeshɔn rikwaymɛnt ɛn di prɔpati dɛn we yu want. Bɔku tɛm, pipul dɛn kin lɛk fɔ yuz naylon fɔ mek dɛn ebul fɔ pe fɔ am, fɔ mek dɛn ebul fɔ du am izi wan, ɛn fɔ mek dɛn gɛt balans prɔpati dɛn.

K: Aw yu go no di polyamide ɛn naylon prodak dɛm?

A: Fɔ no di polyamide ɛn naylon prodak dɛm we yu nɔ tɛst, na tin we nɔ izi fɔ du. Visual identification na tin we at bikɔs ɔf di lɔk fɔ difrɛn kwaliti dɛn. Labɔrɔtɔri tɛst ɔ kɔnsaltin prodak datasheet na we dɛn kin abop pan fɔ no udat pɔsin bi.

K: Polyamide ɛn naylon kin risaykul? Yu tink se dɛn go ebul fɔ yuz ɔl tu di tin dɛn bak?

A: Yes, polyamide ɛn naylon kin risaykul bay we dɛn de mɛlt ɛn rifɔm. Risaykul de ridyus west ɛn kɔnsiv di tin dɛn we dɛn gɛt. Saksesful risaykul dipen pan di rayt kɔlɛkshɔn, sɔt, ɛn prɔsesin infrastukchɔ.

K: Ɛni natura polyamides de?

A: Yes, natura polyamides inklud protin lek wul, silk, kolagen, en keratin. Dis na frɔm rinuɔbal sɔs wit yunik prɔpati. Naylon ɛn bɔku polyamides dɛn dɔn mek am frɔm di kemikal dɛn we dɛn mek wit petrolium.

K: Us matirial we fit mɔ fɔ aplikeshɔn dɛn na do?

A: Naylon fit fɔ yuz am na do we yu kɔmpia am wit ɔda polyamides. I gɛt fayn fayn mɔstɔ rɛsistɛns, ay trɛnk, durabiliti, ɛn UV rɛsistɛns. Dɛn prɔpati ya de mek naylon fayn fɔ ɔda gia ɛn ikwipmɛnt.

K: Naylon de te pas ɔda polyamides?

A: Yes, naylon na pipul sabi am fo eksepshonal durability kompare to plenti polyamides. I strɔng intamɔlikul fɔs ɛn ay kristaliniti de kɔntribyut to ɔdasayz trɛnk, abrashɔn rɛsistɛns, ɛn resiliɛns. Naylon na di wan we dɛn kin lɛk fɔ aplikeshɔn dɛn we nid fɔ wok fɔ lɔng tɛm.