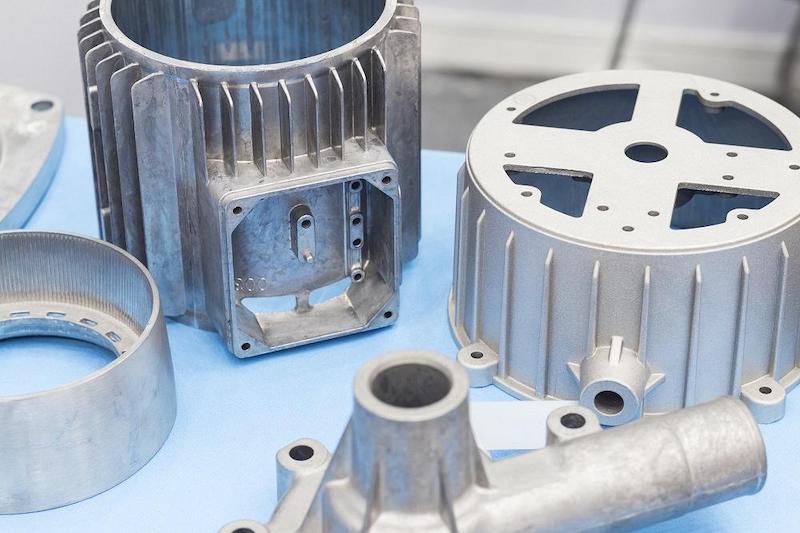

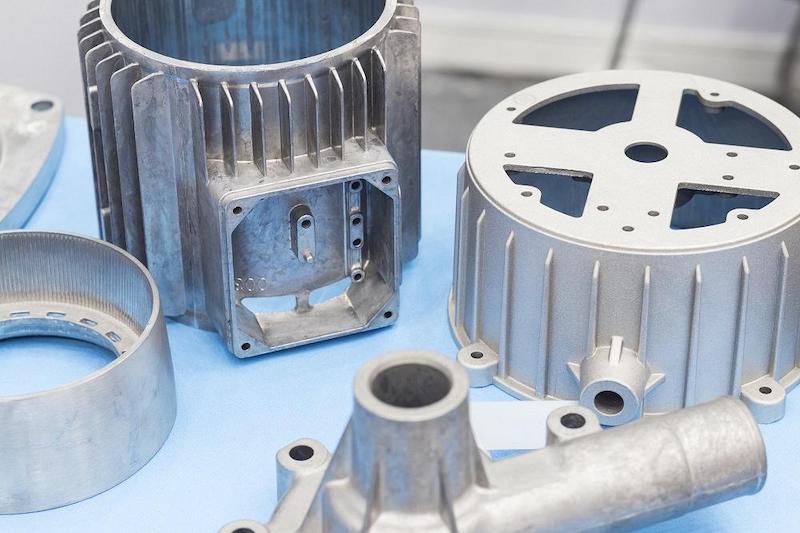

Dɛn kin tɔn mɛlt stɛl insay wan mol tru di kɔs fɔ di aluminiɔm kastin manufakchurin prɔses fɔ prodyuz kɔmpɔnɛnt ɔ mɛkshɛnidi wit prɛsis dimɛnshɔn. Aluminium ingots ɔ skrap dɛn fɔs mɛlt insay wan ɔfna we di tɛmpracha bɛtɛ pas 660 stej sɛlshiɔs. Dat na di melting point fɔ aluminiɔm. Afta dat, dɛn kin tek tɛm tɔn di aluminiɔm we dɔn rɔtin insay wan mol, we dɛn kin bil wit san, stɛl, ɔ sɛramik, i kin dipen pan di fayn fayn tin we di prɔdak gɛt ɛn di polish we dɛn lɛk.

Aluminium na di . Die casting molds na tul dɛn we dɛn mek fayn fayn wan we de kapchɔ ɛvri nuans fɔ di fɔm we dɛn bin want. Fɔ mek dɛn go ebul fɔ liv di kayn we we rili wam na di aluminiɔm we dɔn rɔtin, dɛn kin trit dɛn bak. Afta dɛn dɔn tɔn am, di mɛtal kin kol ɛn i kin at insay di mol, ɛn i kin mek di ol we i gɛt prɛsis. Dɛn kin pul di aluminum aytem we dɛn mek wit aluminum kɔmɔt na di mol wans i dɔn kol. I kin go tru sɔm tin dɛn we dɛn kin du fɔ dɔn di wok, lɛk fɔ peint, grind, ɔ sand, fɔ mek i luk ɔ fɔ mek i wok fayn.

Wan smɔl ɛgzampul bɔt di bɛnifit dɛn we di aluminiɔm kastin gɛt

Di motoka sɛktɔ na wan eria usay dɛn de yuz aluminiɔm kastin na prɔsis. enjin elemɛnt dɛn lɛk silinda ed ɛn piston dɛn de .

Dɛn mek am wit laytwɛt yet durable aluminium matirial dɛn. Dis de mek di motoka in ɔl wet de mek di motoka fayn, i de mek di fiul wok fayn, ɛn i de mek di injin wok fayn bikɔs aluminiɔm gɛt wan spɛshal ɔt dilɛj.

Kwɛshɔn ɛn ansa dɛn bɔt aluminiɔm kastin:

K: Us kayn aluminiɔm kastin dɛn de?

Difrɛn kayn difrɛn kayn aluminiɔm kastin we dɛn kin yuz kin roughly klas insay difrɛn kategori dɛn.

Day kastin: Dis prɔses involv fɔ fos molten aluminiɔm ɔnda ay prɛshɔn insay wan mɛtal mold we dɛn kɔl day. I rili efishɔnal fɔ mas prodakshɔn, we de prodyuz pat dɛn we rili kɔrɛkt ɛn we tan lɛk smɔl smɔl pat dɛn. Die casting na gud tin fɔ kast we tik ɛn gɛt tint sɔfays.

Sand Casting : Wan pan di ol we fɔ mek pɔt, sand kastin de yuz miks san fɔ mek pɔt. I fayn fɔ mek big big prodakshɔn ɛn i de mek am izi fɔ mek dɛn chenj dizayn. Bɔt di finish ɛn shep akkuracy nɔ ay lɛk day kastin.

Regular mold casting: Dis we ya de yuz mold dɛn we dɛn kin yuz bak, we dɛn kin mek wit mɛtal, we kin gi bɛtɛ finish ɛn shep pas sand kastin bɔt i nɔ kin gɛt bɛtɛ fleksibiliti pan tin dɛn we gɛt fɔ du wit dizayn kɔmplisiti ɛn i kin fayn fɔ mek dɛn prodyuz midul to ay-volyum.

Coin casting: Dɛn sabi dis we fɔ mek i kɔba ɛn rili fayn sɛkshɔn dɛn, we dɛn mek wan waks patɛn, we dɛn kin kɔt wit wan flame retardant coating fɔ mek wan mold. As di waks de mɛlt di aluminiɔm we dɔn rɔtin de tɔn insay di mol.

K: Aluminium Frames: Wetin na dɛn?

A: Dɛn kin yuz sɔm jenɛral kategori dɛn fɔ kategoriz aluminiɔm kastin dɛn, ɛn ɛni wan pan dɛn gɛt difrɛn kwaliti dɛn:

Dɛn kin fos aluminiɔm we dɛn dɔn kɔt insay wan mɛtal mol, we dɛn kɔl day, ɔnda di prɛshɔn we pasmak we dɛn de du di day-kast. I rili effektiv fɔ bɔku aplikeshɔn dɛn ɛn i de gi rili prɛsis ɛn smol dizayn dɛn. Prɛshɔn day kastin na fayn tin fɔ ɔl tu di tik ɛn tin sɔfays.

Sand kastin: Wan pan di ol we fɔ mek pɔt, sand kastin na fɔ yuz miks san fɔ mek pɔt. I fayn fɔ mek big big prodakshɔn ɛn i de mek am izi fɔ mek dɛn chenj dizayn. Bɔt di finish ɛn di akkuracy nɔ ay lɛk day kastin.

Rigyul moldin: Dis prɔses na di bɛst fɔ midul to ay prodakshɔn nɔmba bikɔs i de yuz mol we dɛn kin yuz bak, bɔku tɛm dɛn kin mek am wit stɛl, we kin gi bɛtɛ fɔm ɛn kwaliti pas san kastin bɔt less dizayn fridɔm insay tik.

Coin molding: Dis prɔses de difrɛn bay in rawnd, rili smɔl smɔl pat dɛn we de mek wan waks mol. As di waks de mɛlt, dɛn kin kɔba di mol wit wan mold refraktɔri kɔtin, ɛn afta dat dɛn kin tɔn kɔst aluminiɔm insay de.

Low prɛshɔn ɛn graviti kastin: Dɛn tɛknik ya kin kɔst aluminiɔm insay mol dɛn we dɛn de yuz ɛni wan pan di lɔw prɛshɔn ɔ di lɔw prɛshɔn. I de yuz bɔku bɔku wan na di aerospace sɛktɔ fɔ jenarayz ay-kwaliti dipɔsit wit gud mɛkanikal kwaliti dɛn.

K: I pɔsibul fɔ employ aluminiɔm kastin fɔ mas prodakshɔn?

A: Bɔku tin dɛn de mek aluminiɔm kastin nɔ jɔs fayn bɔt dɛn kin lɛk am bɔku tɛm fɔ big-big prodakshɔn:

Scalability: Dɛn kin mek ay kwaliti kɔmpɔnɛnt dɛn ɔltɛm insay ɔndrɛd to milyɔn pis dɛn we dɛn de yuz day kastin ɛn ɔda we dɛn we rili efyushɔn.

Kost: Di kost per shea na substantially low in mass prodakshon, we mek am wan fainans feasible opshon.

Bɔku aplikeshɔn dɛn: Di laytwɛt ɛn strɔng kwaliti dɛn fɔ mold aluminiɔm kɔmpɔnɛnt dɛn na advantej to di ɔtomotiv, ɛrospɛs, kɔnstrɔkshɔn, ɛn ɔda sɛktɔ dɛn.

Teknɔlɔji Integreshɔn: Advans Tɛknɔlɔji dɛn insay Ɔtomɛshɔn ɛn Kwaliti Kɔntrol de mek am izi fɔ mek big-big prodakshɔn wit aluminiɔm kastin.

K: Yu tink se wan limit de fɔ aluminiɔm kastin?

A: Pan ɔl we aluminiɔm kastin gɛt bɔku bɛnifit, dɛn gɛt limit:

Inkris Besik Ikwipmɛnt Kɔst: Di kɔst fɔ mɛtalɔji, mɔ we dɛn de kast, kin ay, we kin mek i nɔ kɔst-ɛfɛktiv fɔ smɔl manifakta dɛn .

Porositi ishu dɛm: Di prɛzɛns fɔ gas ɔ shrinkage porositi kin afɛkt di mɛkanikal trɛnk ɛn intɛgriti fɔ di kɔst pat dɛm.

Material Assembly: Sɔm we dɛn fɔ yuz fɔ kɔst kin nid fɔ gɛt patikyula tin dɛn we dɛn kin yuz fɔ mol ɛn we go ebul fɔ bia wit ay tɛmpracha ɛn di riaktiviti we dɛn kin yuz fɔ mek dɛn gɛt mɔlten aluminiɔm .

Sayz Limiteshɔn: Sɔm we dɛn fɔ trowe dɛn nɔ kin fayn fɔ smɔl ɔ rili smɔl pat dɛn.

K: Aw dɛn kin chɛk di kwaliti fɔ wan kast aluminiɔm pat?

A: Kwaliti kɔntrol fɔ aluminiɔm kastin na multifaceted ɛn i de yuz sɔm we dɛn, we inklud:

Visual Inspekshɔn: Luk fɔ eria imperfekshɔn dɛn wit krak krak, porositi, ɛn kɔrɛkt kɔndishɔn.

Dimensional Size: Mek shɔ se di tin dɛn we de fala di tolɛreshɔn spɛshal dɛn de adara bay we dɛn de yuz divays dɛn lɛk kalipa, maykromita, ɛn kɔdinɛt mɛzhɔmɛnt mashin dɛn (CMM).

Non-destructive Testing Out (NDT): Witout endangering di komponent, teknik wit ultrasonic or X-ray de aplay fo locate internal flaws.

Mechanical Tests: Test fɔ elemɛnt dɛn lɛk tɛnsiɛl trɛnk, ɛlongeshɔn, ɛn hadnɛs fɔ mek shɔ se di pat kin ebul fɔ bia wit di we aw dɛn se i de yuz am.

Kεmikכl Evalueshכn: fכ mek sכh se di aluminium aloi kכmכshכn mit di mεtirial standad dεm we dεn want.

Di tin dɛn we rili fayn:

Aluminiɔm na di maksimal ampul mɛtal we de na di wɔl in krɔst, bɔt i nɔ de apin izi wan na di nature; Bɔku tɛm, i kin gɛt sɔntin fɔ du wit difrɛn tin dɛn.

Di risaykul fɔ aluminiɔm nid lɛk fayv pasɛnt pan di trɛnk we dɛn yuz fɔ mek nyu aluminiɔm frɔm ɔyl.

Dɛn bin mek aluminiɔm kastin fɔs insay di 1800s, ɛn frɔm da tɛm de, i dɔn chenj bɔku industri dɛn.

Di pasmak tɛmal kɔnduktiviti fɔ aluminiɔm de mek am fayn fɔ prɔdak dɛn we nid fɔ mek di ples nɔ wam, lɛk redyuta ɛn ɔt sink.

Dɛn kin yuz aluminiɔm kast ɔltɛm na di aerospace program dɛn bikɔs dɛn gɛt ay trɛnk-to-weit ratio.

Fɔj aluminiɔm kin ɔnda difrɛn mɛrɛsin dɛn, inklud anodizing, fɔ fɔtify kɔrɛshɔn rɛsistɛns ɛn sɔfays hadnɛs.

Di tolɛreshɔn lɛvɛl insay aluminiɔm kastin kin bi as yunik lɛk 0.2 milimita, dipen pan di kastin apɔch.

Aluminium in nɔ-pɔyzin prɔpati dɛn de mek am fayn fɔ program dɛn na di it ɛn famasitik industri.

Sɔm landmak dɛn we bɔku pipul dɛn sabi, lɛk di pik pat na di Washintɔn monumɛnt, dɛn mek am wit di yus fɔ aluminiɔm kastin.

Di fluiditi fɔ molten aluminium alaw am fɔ ful difrɛn difrɛn mildew dizayn dɛn, we mek i fayn fɔ artwok ɛn dɛkɔretiv tin dɛn.

Dɔn:

Wan impɔtant tɛknik insay kɔntempɔral . Rapid manufacturing , aluminium casting de kam togɛda wit teknɔlɔji ɛn kriaytiv fɔ prodyuz kɔmpɔnɛnt dɛn we bɔku difrɛn sɛktɔ dɛn nid. Aluminiɔm kastin dɛn gɛt bɔku bɛnifit, frɔm impɔtant ɔtomotiv pefɔmɛns to fɔ mek akitɔkchral masta wok dɛn. Dɛn de op se aluminiɔm kastin go bi wan big patisipan na di kɔnstrɔkshɔn industri fɔ bɔku ia we de kam bikɔs ɔf kɔntinyu divɛlɔpmɛnt, tɛknɔlɔjik advansmɛnt ɛn wan kɔmitmɛnt fɔ sastaynabiliti tru matirial bikɔs ɔf di push fɔ risaykul.

Apat frɔm frɔm aluminiɔm kastin, Tim MFG de ɔfrɛd bak Rapid Prototyping Savis dɛn ., CNC mashin savis , ɛn . Injɛkshɔn moldin savis fɔ mit yu nid dɛn. Kontakt wi tide!