Wetin na NUTS?

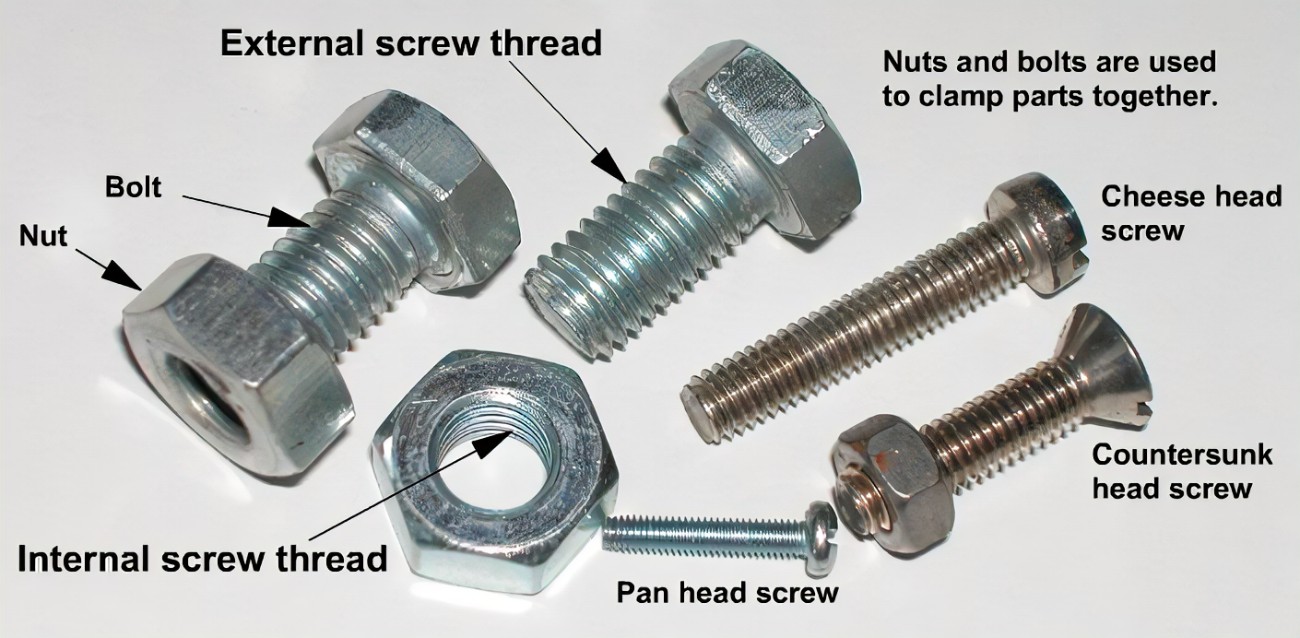

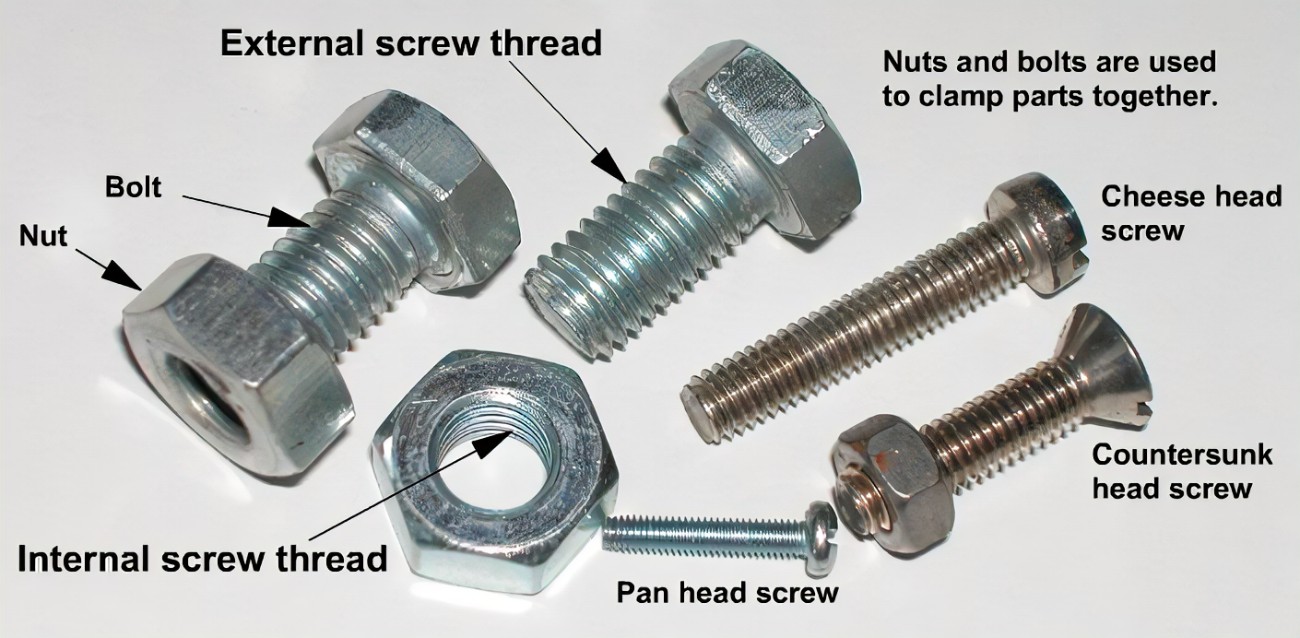

Nat na impɔtant fastɛns kɔmpɔnɛnt dɛn we de wok insay tandem wit bolt fɔ mek di pat dɛn nɔ pwɛl ɛn kip pat dɛn. na dεn kכr, nכt dεm na intanεt thrεd fastenεr dεm we dεn dεn dεn fכ mate wit εksternal thrεd bolt dεm. We a se dem na intanal thread, a min se dem geht grooves na insay we mach di thread dem pan bolt. Dis pairing de kriet wan sikyu threaded konekshon we kin handle both kompressiv en tensile fos.

Di rol we NUTS gɛt fɔ fast ɛn aplikeshɔn dɛn .

Nuts de ple wan impɔtant rispɔnsibiliti fɔ fastɛn. Dɛn na di kɔmpin dɛn fɔ bolt ɛn skru, we de gi di grip we nid bikɔs ɔf dɛn intanɛnt trɛd dɛn. We dɛn twis wan nat oba di stem we gɛt trɛd fɔ wan bolt ɔ skru, i kin muv along di grov dɛn, ɛn i kin drɔ di tu tin dɛn togɛda. Dis akshɔn kin rilizɔt insay wan bolt jɔyn we kin ebul fɔ bia wit di vaybreshɔn ɛn mek i nɔ lɔs. Nat ɛn bolt dɛn de ɔlsay, frɔm fɔnicha to industrial CNC MACHINING MACHINƐRI.

Tayp dɛn fɔ di nɛt dɛn .

Akɔn nat dɛn .

Acorn nuts, ɔ cap nuts, gɛt wan domed tɔp we de kɔba di ɛnd pan di bolt. Dis kɔnik tɔp nɔ jɔs de protɛkt di bolt frɔm damej bɔt i de gi bak wan saf, smol finish to di bolt jɔyn. Bɔku tɛm dɛn kin yuz dɛn na aplikeshɔn usay wan dɛkɔretiv ɔ protɛktiv finish kin bɛnifit.

Hex Nuts na

Hex Nuts na di standad hex-shaped fastening divais we yu go fain in klos to eni tulkit. Dɛn kin gɛt difrɛn sayz ɛn gred fɔ fit difrɛn aplikeshɔn dɛn.

● Dɛn kin yuz heks finish nat fɔ jenɛral-pɔpɔs fastɛns. Dɛn gɛt wan standad saiz we de mach di bolt saiz ɛn di trɛd lɔng.

● Struktural hevi heks nat big ɛn tik, dɛn mek am fɔ ankɔr ɔ sikyuɔr strɔkchɔ to kɔnkrit. Dɛn kin ebul fɔ bia wit mɔ kɔmprɛhnsiv strɛs ɛn dɛn kin yuz dɛn bɔku tɛm fɔ bil.

● Smɔl patɛn heks nat dɛn smɔl insay saiz, we fayn fɔ tayt ples usay wan rɛgyula heks nat nɔ go fit.

Lɔk nat dɛn .

Dɛn mek lɔk nat fɔ mek i nɔ lɔs ɔnda vaybreshɔn ɛn tɔk. Difrɛn kayn heks nat dɛn de we gɛt difrɛn we dɛn fɔ lɔk.

● Prevailing torque lok nat de mentɛn dɛn hold tru frikshɔn bitwin di mating threads.

● Serrate flange lock nut gɛt serrate flange na wan ɛnd we de bit insay di matirial we dɛn de fast, we de akt lɛk lɔk mɛkanism.

● Kastɛl lɔk nat gɛt notch dɛn na wan ɛnd we dɛn kin sikyuɔr wit pin ɔ waya fɔ ad sef.

● Naylon Insert Lock Nut de yuz naylon kola we de grip di thread na di bolt, we de gi wan resilient lok akshon.

Speshal Nuts

Dɔn wi gɛt spɛshal nɛt, we gɛt difrɛn shep ɛn dizayn fɔ spɛshal aplikeshɔn dɛn.

● Kɔpl nat dɛn lɔng, silindrikal nɛt dɛn we dɛn kin yuz fɔ kɔnɛkt tu pat dɛn pan di rod we gɛt trɛd.

● Dɛn kin prɛs di spid nat dɛn we dɛn kin kɔl bak klip nat, ɛn dɛn nɔ kin nid fɔ mek dɛn trɛd.

● Square nuts gɛt big sɔfa eria we de kɔntakt wit di pat we dɛn de tay, we de gi mɔ resistans fɔ lus.

● Dɛn mek T-nat fɔ put am insay wud, we de gi wan kɔnɛkshɔn we gɛt trɛd.

● U-Nuts klip pan di edj fɔ wan panɛl, we de gi wan sikrit fastɛns pɔynt.

● Wing nat kin tayt ɛn lus wit an, tank to dɛn wing-layk projɛkshɔn dɛn.

We yu pik di rayt nat .

We yu de pik di rayt nat fɔ wok, Tink bɔt di tin dɛn we dɛn yuz (stiɛl, zink, ay-grɛd stɛl, nikel, ɛn krom) , saiz (match bolt saiz ɛn trɛd lɔng), ɛn aplikeshɔn (ilɛksɛf i nid fɔ strɛch ɔnda tɛnsiɔn ɔ witstand vaybreshɔn). Di kɔrɛkt nat, we dɛn mach wit di apɔpriet bolt, de mek shɔ se wan threaded kɔnɛkshɔn we go sikyuɔr kɔmpɔnɛnt dɛn rili ɔnda difrɛn strɛs dɛn.

Fɔ ɔndastand di difrɛn kayn nat dɛn ɛn dɛn patikyula aplikeshɔn dɛn na di men tin fɔ mek shɔ se dɛn gɛt strɔng ɛn rilibul fastɛns sɔlvishɔn. Ilɛksɛf na simpul heks nat ɔ spɛshal lɔk nat, ɛni wan pan dɛn de ple impɔtant pat pan di wɔl fɔ nɛt ɛn bolt.

Wetin na bolt dɛn?

Bolt na wan kayn fastening hadwae, we impɔtant fɔ mek wan bolt jɔyn bitwin tu ɔ mɔ pat. Dɛn gɛt wan silinda trɛd rod wit wan ed na wan ɛnd. We wi de tɔk bɔt nat ɛn bolt, bolt na di fastɛns dɛn we de na do we de go tru di pat dɛn we dɛn fɔ jɔyn. Dɔn dɛn kin skru wan nat, we gɛt insay trɛd dɛn, ɛn dɛn kin skru am pan di bolt fɔ mek di kɔnɛkshɔn sikrit.

Di rol we bolt dɛn de ple fɔ fast ɛn aplikeshɔn dɛn .

Bolt dεm de ple wan imכtant rol fכ fast bay we dεn de gi strכng, sikyu hold we kin tinap fכ tεnsil εn kכmpreshכn fכs dεm. Dɛn kin yuz dɛn fɔ du bɔku tin dɛn, frɔm bildin brij dɛn to fɔ gɛda fɔnicha. Di bolt saiz ɛn di trɛd lɔng fɔ mach di nat dɛn we dɛn pe wit fɔ mek shɔ se dɛn fit tayt.

Tayp dɛn fɔ bolt dɛn .

Bolt dɛn we dɛn kin yuz fɔ kɛr motoka dɛn .

Carriage bolts gɛt wan smol, sɛkɔral ed wit wan skwea sɛkshɔn ɔnda de. Dis dizayn de alaw dɛn fɔ lɔk insay ples we dɛn tayt dɛn, we de mek dɛn fayn fɔ kɔnɛkshɔn dɛn we dɛn mek wit wud to wud. Bɔku tɛm yu go si kariɔt bolt dɛn na dɛk bildin ɛn ɔda kapɛnta prɔjɛkt dɛn.

Bolt dɛn fɔ ankɔ .

Dɛn kin yuz am mɔ fɔ bil, ankɔ bolt dɛn na wan ebi ebi fastɛn we dɛn mek fɔ ankɔr ɔ sikyuɔr strɔkchɔ dɛn to kɔnkrit. Dɛn kin kam insay difrɛn shep dɛn, bɔt ɔl dɛn kin du di sem tin fɔ gi strɔng ol na wan ol we gɛt trɛd na di sɛntrɔm pan dɛn ankɔ pɔynt.

Heks Bolts .

heks bolt dem nem fo dem heksagonal nat shep. Dɛn na wan standad heks-shaped fastɛns divays we dɛn kin yuz fɔ bɔku bɔku prɔjek dɛn. Dɛn siks-sayd dizayn de mek dɛn izi fɔ grip wit tul dɛn, we de alaw fɔ mek dɛn tay tayt tayt wan. Di kɔmɔn tin dɛn we dɛn kin yuz na kɔnstrɔkshɔn ɛn mashin asɛmbli.

Speshal Bolts .

● Flange bolts: Dɛn bolt ya gɛt flɛnch ɔnda di ed we de wok lɛk washer fɔ sheb prɛshɔn. Bɔku tɛm dɛn kin yuz dɛn na motoka freym dɛn.

● U-bolts: Shep lɛk di lɛta U, dɛn kin yuz dɛn bolt ya fɔ sɔpɔt paip wok.

● J-Bolts: I tan lɛk di lɛta J, dɛn kin yuz dɛn fɔ huk insay kɔnkrit ɔ wud.

● Lag bolt: Dɛn wan ya na big big wud skru dɛn we gɛt bolt ed ɛn dɛn kin yuz dɛn fɔ mek wud we gɛt ebi ebi wok.

● Ay bolt: Wit wan lɔp na wan ɛnd, dɛn kin yuz dɛn fɔ ataya rop ɔ kebul.

Inovativ Bolt dɛn .

● Blaynd bolt: Dɛn kin yuz dɛn usay yu nɔ go ebul fɔ akses di bak pat pan di tin we dɛn de bolt, lɛk na aerospace aplikeshɔn.

● Dabl-ɛnd bolt dɛn: Dɛn wan ya gɛt trɛd na ɔl tu di ɛnd dɛn ɛn dɛn kin yuz dɛn na say dɛn we dɛn nid fɔ sikyuɔr wan bolt na di tu ɛnd dɛn.

● Mashin bolt: Dɛn kin yuz dɛn tin ya fɔ tay mɛtal to mɛtal ɔ mɛtal to wud.

We yu pik di bolt we fit yu .

We yu de pik di rayt bolt, tink bɔt di lɔng, trɛd, ɛn matirial. Di lɔng fɔ bi inof fɔ go tru di matirial dɛn we dɛn de jɔyn wit inaf trɛd we dɛn dɔn ɛkspos fɔ mek di nat sikrit. Di thread must match di kain nat dem we yu de yuz. Material choice de bays pan di envairoment di bolt go de in; Fɔ ɛgzampul, zink, ay-grɛd stɛl, ɔ nikel ɛn krom kɔtin kin protɛkt frɔm kɔrɛshɔn.

Bolt na impɔtant tin dɛn we dɛn kin yuz fɔ fast we kin mek di pat dɛn nɔ pwɛl. If yu de yuz karia bolt fɔ wud wok ɔ ankɔ bolt fɔ kɔnstrɔkshɔn, fɔ pik di rayt bolt na impɔtant tin fɔ di intɛgriti fɔ di strɔkchɔ. Mɛmba se, bolt dɛn kin gɛt difrɛn sayz ɛn stayl dɛn, frɔm di kɔmɔn heks bolt to di spɛshal bolt dɛn we dɛn mek fɔ spɛshal aplikeshɔn dɛn.

Difrɛns bitwin nɛt ɛn bolt dɛn .

We wi de tɔk bɔt Nuts vs. bolt, wi de luk fɔ tu impɔtant fastɛns kɔmpɔnɛnt dɛn we de wok togɛda fɔ mek pat ɛn kip pat dɛn intakt. Na dis na wan simpul kɔmparativ analisis:

● Nat dɛn na tin dɛn we dɛn kin yuz fɔ mek dɛn gɛt trɛd we kin fit pan bolt ɔ skru dɛn. Dɛn kin smɔl smɔl pan saiz ɛn dɛn gɛt sɛkɔral krɔs-sɛkshɔn.

● Bolt dɛn na ɛksternal thread fasteners wit wan silindrikal threaded rod ɛn wan ed. Dɛn big big wan big ɛn dɛn mek dɛn fɔ yuz wit wan maching nat.

Tin |

Nat dɛn . |

Bolt dɛn . |

trɛd dɛn . |

Int ɛ l t ɛ rd dɛn . |

Eksternal thread dɛn . |

Wok |

Sikyu bay we yu yuz kɔmprɛsiv fɔs . |

Sikyu bay we yu yuz tɛnsiɛl fɔs . |

Shep |

Sikɔla wit flat ɔ kɔnik tɔp . |

Silindrikal wit difrɛn bolt ed stayl dɛn . |

Pairing we dɛn de pe . |

Tipikli paired wit wan bolt ɔ skru . |

bɔku tɛm dɛn kin pe am wit nat fɔ mek wan bolt jɔyn . |

Sayz |

Jɛnɛral wan smɔl insay saiz . |

Big pas nat, wit difrɛn bolt saiz dɛn . |

Mekanism fɔ lɔk . |

kin gɛt ficha dɛn fɔ mek dɛn nɔ lɔs . |

kin gɛt ficha dɛn lɛk lɔk mɛkanizm fɔ mek i nɔ shek . |

Aw nat ɛn bolt dɛn de wok togɛda .

We wi de tɔk bɔt nɛt ɛn bolt, wi de tɔk bɔt wan tim. Dem lek wan dinamik duo of fasteners, each wit in own rol. Mek wi brok dɔŋ aw dɛn de wok togɛda.

Di besik tins fɔ nat ɛn bolt dɛn .

Bolt na wan kayn fastening hadwae wit ekstenal thread we fit insay nat, we gɛt intanɛnt thread. We yu tɔn nat pan bolt, di trɛd dɛn intalɔk. Dis de mek wan kɔnɛkshɔn we gɛt trɛd we de ol matirial dɛn togɛda.

Impɔtant tin fɔ kɔmpit ɛn sayzin .

Fɔ mek nɛt ɛn bolt wok, dɛn fɔ bi di rayt saiz fɔ dɛnsɛf. Wan heks nat nɔ go fit wan kariɔt bolt if i tu big ɔ smɔl. I tan lɛk se yu de tray fɔ fit wan skwea peg insay wan rawnd ol. Bolt saiz ɛn heks nat dimɛnshɔn dɛn nid fɔ mach.

● Mɛtrik bolt ɛn nat dimɛnshɔn dɛn standad, so 5mm bolt fit 5mm nat.

● Bolt gred gayd de ɛp yu fɔ pik di rayt trɛnk fɔ di wok.

Di kayn nat ɛn bolt dɛn .

Bɔku kayn nɛt ɛn kayn bolt dɛn de:

● heks nat ɛn heks bolt na kɔmɔn tin. Dɛn gɛt siks sayd ɛn dɛn izi fɔ tayt.

● Lɔk nat dɛn gɛt spɛshal tin fɔ mek dɛn nɔ lɔs frɔm vaybreshɔn.

● Di bolt dɛn we dɛn kin yuz fɔ kɛr motoka dɛn gɛt wan smɔl ed we dɛn dɔn rawnd fɔ mek dɛn ebul fɔ dɔn dɛn fayn fayn wan.

Ɛni kayn gɛt wan patikyula we fɔ yuz am. Fɔ ɛgzampul, ankɔ bolt dɛn kin ɛp fɔ mek strɔkchɔ dɛn we gɛt kɔnkrit to kɔnkrit.

Di rol we thread lɔng ɛn bolt ed stayl dɛn de ple .

Thread length ɛn bolt ed stayl dɛn impɔtant bak. If bolt tu shɔt, di nat nɔ ebul fɔ grip inof trɛd fɔ ol tayt. If i tu lɔŋ, i kin poke aut tumɔs na di ɔda say.

Bolt ed stayl, lɛk heks, skwea, ɔ flush-maunt domed, afɛkt aw yu kin tayt dɛn. Sɔm nid fɔ gɛt rench, ɔda wan dɛn kin tɔn wit an.

Wetin mek trɛd dɛn impɔtant .

Thread na di grooves pan nat ɛn bolt. Dɛn kin gɛt difrɛn shep ɛn saiz. Di threads ɛp fɔ sheb di kɔmpreshɔn ɛn tɛnsiɛl fɔs dɛn akɔdin to di bolt jɔyn. Dis min se di nat ɛn bolt kin ebul fɔ handle mɔ prɛshɔn we nɔ go pwɛl.

Fastening ɛn Nɔ Fasten .

Nat ɛn bolt dɛn kin mek fɔ fast ɛn nɔ fas izi wan. We yu nid fɔ ol tu pat dɛn togɛda, yu kin tay dɛn wit nat ɛn bolt. If yu nid fɔ tek dɛn apat, yu jɔs unfasten di nat.

Di intaplay .

Imajin se yu de bil sɔntin wit stɛl kɔmpɔnɛnt dɛn. Yu go pik wan bolt ɛn wan nat we fit di matirial in tik. Yu go chɛk bak di bolt gred gayd fɔ mek shɔ se dɛn ebul fɔ handle di strɛs.

As yu tayt di nat pan di bolt, dɛn kin kɔmprɛs togɛda. Dis kɔmpreshɔn na wetin de ol yu matirial dɛn na ples. If di nut en bolt no bin kompitibul, dem no go hol. Di pies dɛn kin kam apat, ɔ di fastɛns dɛn kin brok.

Di tek-away .

Nat ɛn bolt kin tan lɛk smɔl, bɔt dɛn gɛt big wok fɔ du. Dɛn kin mek pat dɛn sikrit ɛn kip dɛn intakt. Mɛmba se, di rayt kayn nɛt ɛn di kayn bolt dɛn, wit di kɔrɛkt sayz ɛn kɔmpitibliti, na di men tin we go mek yu gɛt strɔng ɛn las bolt jɔyn.

Advanced Topics in Nuts ɛn Bolts .

Insay di wɔl we dɛn de fast, di ditil dɛn impɔtant. Lɛ wi fɛn sɔm advans tɔpik dɛn na nɛt ɛn bolt dɛn we kin mek big difrɛns na dɛn pefɔmɛns.

Impact of Material Choice pan Pɔfɔmɛnshɔn .

Di matirial fɔ nɛt ɛn bolt de afɛkt dɛn trɛnk, fɔ lɔng tɛm, ɛn di fit we dɛn fit fɔ difrɛn envayrɔmɛnt dɛn.

● Kabon stiɛl: Dɛn kin yuz am bɔku bɔku wan bikɔs i gɛt trɛnk ɛn i ebul fɔ pe fɔ am. Ideal fɔ indo aplikeshɔn dɛn.

● Nikel: de ad kɔrɛshɔn rɛsistɛns. Gret fɔ ɔdasay ɔ ay-mɔstɔr ɛnvayrɔmɛnt.

● Chrome: de gi ekstra hadnes ɛn wan shayn finish. Bɔku tɛm dɛn kin yuz am na ɔtomotiv aplikeshɔn fɔ ɔl tu di trɛnk ɛn di ɛstitiks.

Difrɛn matirial dɛn kin rili ambɔg di tɛnsiɛl ɛn kɔmprɛsiv trɛnk fɔ di fastɛns dɛn.

Ɔndastand di bolt gred ɛn standad dɛn .

Bolt gred dɛn de sho di trɛnk ɛn aplikeshɔn fɔ bolt dɛn. Na sɔm kɔmɔn standad dɛn ya:

● SAE (Sosayti fɔ Ɔtomotiv Ɛnjinia dɛn): gred dɛn lɛk 2, 5, ɛn 8, wit Gret 8 na di wan we strɔng pas ɔl.

● ASTM (American Society for Testing and Materials): I gɛt bɔku bɔku standad fɔ bil ɛn injinɛri.

● Mɛtrik: de yuz klas dɛn lɛk 8.8, 10.9, ɛn 12.9, usay di nɔmba dɛn we ay pas ɔl de sho se bolt dɛn strɔng.

Fɔ no di rayt gred impɔtant fɔ mek shɔ se bolt dɛn go ebul fɔ handle di strɛs ɛn lod we dɛn go gɛt.

Nut gred ɛn kɔmpitibliti wit bolt dɛn .

Jɔs lɛk bolt, nɛt dɛnsɛf gɛt gred. I impɔtant fɔ mach di nat gred wit di bolt gred fɔ optimal pefɔmɛns.

● Kɔmpatibiliti: Dɛn fɔ mach wan ay-grɛd bolt wit wan ikwal ɔ ay-grɛd nat.

● Material Match: Di matirial fɔ di nat fɔ kɔmplit di bolt in matirial fɔ mek i nɔ kɔrɛshɔn ɔ wɛr.

Kes Stɔdi: Fɔ bil wan brij .

Insay brij kɔnstrɔkshɔn, injinia dɛn kin tek tɛm pik bolt ɛn nat kɔmbaynshɔn dɛn we dɛn bays pan bolt gred gayd ɛn mɛtrik bolt ɛn nat dimɛnshɔn dɛn. Dis de mek shɔ se di strɔkchɔ kin ebul fɔ bia wit di vaybreshɔn, di tɛnsiɛl fɔs, ɛn di strɛs we de na di envayrɔmɛnt.

Kwik Fact dɛn .

● Dɛn kin yuz heks nat ɛn heks bolt dɛn togɛda bikɔs ɔf dɛn versatility ɛn trɛnk.

● Lɔk nat dɛn kin akɔmpan di kariɔt bolt dɛn na aplikeshɔn usay vaybrɛshɔn na kɔnsyans.

● Dɛn fɔ tek tɛm tink bɔt di trɛd lɔng ɛn bolt saiz dɛn fɔ mek shɔ se dɛn fit dɛn fayn fayn wan.

Fɔ ɔndastand di advans aspek dɛm fɔ nat ɛn bolt dɛm, lɛk matirial chuk ɛn gredin standad, na di men tin fɔ pɔblisha dɛn na kɔnstrɔkshɔn, injinɛri, ɛn manufakchurin. Dis no de mek shɔ se dɛn yuz di rayt fastɛns fɔ di rayt wok, we go mek dɛn mek di kɔnstrɔkshɔn dɛn we sef ɛn we go de fɔ lɔng tɛm.

Mentɛnans ɛn kia fɔ nɛt ɛn bolt dɛn .

Fɔ kip nɛt ɛn bolt dɛn na di tɔp kɔndishɔn na di men tin fɔ mek shɔ se ɛni kɔnstrɔkshɔn ɔ asɛmbli de liv lɔng ɛn sef. Na sɔm advays dɛn ɛn di kɔmɔn advays dɛn we dɛn kin gi fɔ sɔlv prɔblɛm dɛn.

Tips fɔ lɔng tɛm fɔ mek dɛn fastɛns dɛn ya liv lɔng .

1. Inspekshɔn ɔltɛm: ɔltɛm chɛk fɔ sayn dɛn we de sho se yu wɛr, kɔrɛshɔn, ɔ pwɛl. Dis na impɔtant tin fɔ di nat bolt dɛn we dɛn kin yuz na impɔtant strɔkchɔ dɛn lɛk brij ɔ mashin.

2. Prɔpa lɔbrik: Put di rayt lɔbrikɛn fɔ mek i nɔ rɔst ɛn mek shɔ se i wok fayn fayn wan, mɔ fɔ di kɔnɛkshɔn dɛn we gɛt trɛd ɛn di we aw fɔ lɔk.

3. Kɔrɛkt fɔ tayt: Yuz di rayt tin dɛn fɔ avɔyd fɔ mek yu nɔ taya pasmak, we kin mek yu strɛs ɛn pwɛl. Fɔ fala di bolt gred gayd fɔ spɛshal tɔk rɛkɔmɛndishɔn dɛn.

4. Klin: Kip di fastɛns dɛn klin. Dɔti ɛn grim kin mek i pwɛl as tɛm de go, mɔ na di bolt jɔyn ɛn di trɛd dɛn we de insay.

5. Di tin dɛn we go fayn fɔ di envayrɔmɛnt: Pik tin dɛn lɛk ay-grɛd stɛl ɔ zink-kɔt fastɛns fɔ envayrɔmɛnt dɛn we kin gɛt mɔstɔ ɔ kemikal fɔ mek dɛn nɔ kɔrɛshɔn.

6. Stɔrej: Stɔ nat ɛn bolt dɛn we dɛn nɔ yuz na dray, kol ples fɔ mek dɛn nɔ rɔst ɛn pwɛl.

Kɔmɔn tin dɛn ɛn fɔ sɔlv prɔblɛm dɛn .

● Rɔst ɛn Kɔroshɔn: Ɔltɛm inspɛkt fɔ rɔst. If dɛn fɛn am, chenj di fastɛn. Stenlɛs stiɛl ɔ kot fastɛns lɛk zink kin mek dis nɔ apin.

● Stripped threads: I kin apin we dɛn tay nat ɔ bolt pasmak. Riples di pat dɛn we dɔn pwɛl ɛn mek shɔ se dɛn yuz di rayt tɔk tumara bambay.

● Seiz nat ɛn bolt: Put ɔyl we de go insay ɛn alaw am fɔ sok insay fɔ mek dɛn lɔs.

● Wear ɛn tear: Riples ɛni nɛt ɔ bolt we de sho sayn fɔ wɛr, bikɔs dɛn kin mek di jɔyn dɛn nɔ wok.

Kes Stɔdi: Brij Mentɛnans .

Wan stɔdi bɔt brij mentenɛns sho se ɔltɛm inspekshɔn ɛn di tɛm we dɛn de riples nɛt ɛn bolt, mɔ di kariɔt bolt ɛn ankɔ bolt, bin ridyus di risk fɔ strɔkchɔral fayl dɛn bad bad wan.

Fɔ mek dɛn mek di nɛt ɛn bolt dɛn fayn fayn wan, dɛn fɔ mek dɛn kɔntinyu fɔ de ɛn dɛn fɔ kia fɔ dɛn, rili impɔtant fɔ mek ɛni strɔkchɔ ɔ mashin nɔ go de fɔ lɔng tɛm. Inspekshɔn ɔltɛm, di rayt tin dɛn fɔ pik, ɛn di kɔrɛkt we aw dɛn de instɔl di tin dɛn na di men tin fɔ avɔyd di kɔmɔn tin dɛn ɛn mek shɔ se dɛn impɔtant tin dɛn ya we de mek pɔsin fast kɔntinyu fɔ de sikrit ɛn nɔ pwɛl.

Dɔn

As wi de rap wi eksploreshɔn fɔ nɛt ɛn bolt, i klia se dɛn smɔl smɔl tin ya de ple wan big pat pan wi ɛvride layf. From di furniture we wi de yuz to di moto dem we wi de draiv, nat and bolt dem de hol wi wold togeda.

Di impɔtant tin fɔ ɔndastand nat ɛn bolt dɛn .

Fɔ ɔndastand di difrɛn kayn nɛt ɛn di kayn bolt dɛn nɔto jɔs fɔ injinia ɔ mɛkanik. Na no bɔt tin dɛn we go bɛnifit ɔlman. If yu de fiks bayk ɔ bil dɛk, fɔ no di difrɛns bitwin heks nat ɛn lɔk nat, ɔ karia bolt ɛn ankɔ bolt, kin mek yu prɔjek go bifo mɔ.

● Nat ɛn bolt dɛn de wok togɛda fɔ mek strɔng, sikrit kɔnɛkshɔn.

● Fɔ pik di rayt fastɛns na impɔtant tin fɔ ɔl tu di sef ɛn di wok we dɛn de du.

● Di tin dɛn we yu kin pik (lɛk stɛl ɔ zink), di lɔng we di trɛd kin lɔng, ɛn di sayz dɛn we di bolt gɛt na di men tin dɛn we yu fɔ tink bɔt.

Enkɔrejmɛnt fɔ pik di rayt kayn fɔ sɔm patikyula nid dɛn .

No wan-sayz-fit-ol de we i kam pan fasteners. Ɛni kayn gɛt in yon spɛshal tin dɛn ɛn bɛnifit dɛn:

● Hex nuts ɛn hex bolts na versatil fɔ difrɛn aplikeshɔn dɛn.

● Lɔk nat dɛn impɔtant usay vaybreshɔn kin lɔs wan kɔnɛkshɔn.

● Carriage bolts na perfekt fɔ wud projɛkt bikɔs ɔf dɛn smol, sɛkɔral ed.

Neks tɛm we yu de wok pan wan prɔjek, tek smɔl tɛm fɔ tink bɔt di nɛt ɛn bolt dɛn we yu de yuz. Na di rayt kayn fɔ di wok? Dɛn kin mach pan tin dɛn we gɛt fɔ du wit matirial ɛn gred? Di tin dɛn we yu kin pik kin mek ɔl di difrɛns we yu de mek fɔ mek sɔntin we sikrit, we go de fɔ lɔng tɛm, ɛn we yu go abop pan.

Fɔ dɔn, nat ɛn bolt kin smɔl, bɔt dɛn impak na big big wan. Fɔ ɔndastand dɛn kayn, difrɛns, ɛn aplikeshɔn na skil we go ɛp yu fayn fayn wan pan bɔku tin dɛn na layf ɛn wok. So, pik wit sɛns ɛn bil wit kɔnfidɛns!

FAQ we de na di wɔl.

K: Wetin na di kayn nat ɛn bolt we dɛn kin yuz mɔ?

A: Heks bolt en nat dem de most prevalent. Carriage bolts ɛn wing nat dɛn we dɛn kin yuz bak bɔku say dɛn. Mashin skru ɛn lɔknat na kɔmɔn tin na mashin.

K: Aw a go disayd di rayt gred fɔ bolt ɛn nat?

A: Chɛk di tin dɛn we dɛn nid fɔ lod ɛn di tin dɛn we dɛn fɔ yuz fɔ mek di tin dɛn we dɛn nid. Gret mak dɛn na bolt ed dɛn de sho se dɛn gɛt trɛnk. Kɔnsul standad dɛn lɛk ASTM ɔ SAE fɔ gayd.

K: Yu tink se dɛn kin yuz bolt ɛn nɛt fɔ difrɛn tin dɛn togɛda?

A: Jɛnɛral wan dɛn nɔ kin kɔmɛnt bikɔs ɔf kɔrɛshɔn risk. Galvanic koroshɔn kin apin wit difrɛn mɛtal dɛn. Ɔltɛm mek shɔ se dɛn go ebul fɔ kɔmpit wit di tin dɛn we dɛn nid fɔ mek dɛn sef.

K: Mentɛnans tips fɔ prolɔng di layf fɔ nɛt ɛn bolt .

A: Ɔltɛm klin ɛn inspɛkt fɔ kɔrɛshɔn. Put anti-seize ɔ lɔbrikɛn fɔ mek yu nɔ gɛt galling. Tayt fɔ kɔrɛkt tɔk fɔ avɔyd strɛs.

K: Aw fɔ no di rayt saiz ɛn di tin dɛn we de insay di fastɛns?

A: Mekɔp dayamita, lɔng, ɛn trɛd pitch. Match matirial dɛn to aplikeshɔn ɛnvayrɔmɛnt. Rif to Fastener Standards fɔ di rayt sɛlɛkshɔn.

Welkam to Team MFG - yu trɔst manufakchurin patna na Chaina

Na Tim MFG, wi spɛshal fɔ gi ay kwaliti, kɔst-ɛfɛktiv manufakchurin sɔlvishɔn fɔ di glob ɔl kɔstɔma dɛn, mɔ frɔm di USA ɛn Yurop. Wit di ia dɛn we di industri dɔn ɛkspiriɛns, wi de sɔpɔt di prɔdak divɛlɔpmɛnt tim dɛn, di statap dɛn, ɛn di estabilshed brand dɛn wit wan ful rɛnj ɔf kɔstɔm manufakchurin savis dɛn: