Di yus fɔ aluminiɔm alɔy dɛn de go akɔdin to difrɛn industri dɛn , we inklud kɔnstrɔkshɔn, ɛrospɛs, spɔt ikwipmɛnt, ilɛktrik, ɛn ɔtomotiv. Dɛn ɔdasayz trɛnk-to-weyt rɛtɛshɔn, ay rilitiv trɛnk, kɔrɛshɔn rɛsistɛns, ɛn mashinabiliti de mek dɛn rili want dɛn. Bɔt wit bɔku bɔku aluminiɔm alɔy dɛn we de, di disizhɔn-mɛkin prɔses kin rili at.

Insay dis atikul, a go kɔmpia 6061 ɛn 7075 aluminiɔm alɔy, we de sho dɛn spɛshal tin dɛn ɛn ɛp yu fɔ no us alɔy fit yu prɔjek nid di bɛst. Frɔm kɔnduktiviti ɛn kɔrɛshɔn rɛsistɛns to ɔvala trɛnk, dɛn tu aluminiɔm alɔy ya gɛt dɛn difrɛn advantej ɛn aplikeshɔn dɛn. So, lɛ wi dayv insay di wɔl fɔ 6061 ɛn 7075 aluminiɔm alɔy ɛn diskɔba wetin mek dɛn difrɛn.

Alloy 6061 - Wan Kɔmprɛhɛnsif Ɔvaviu

Cemical kompozishun fɔ 6061 .

Aluminium 6061 na wan strɔkchɔral mɛtal we bɔku pipul dɛn no fɔ in versatility. I kemikal mek-ap inklud miks magnesium ɛn silikon, we na di ki fɔ in prɔpati dɛm. Na dis wan na wan simpul brekdaun:

● Magnɛsiɔm(mg): 1.0%

● Silikɔn: 0.6%

● Kromium(CR): 0,2%

● Kɔpa(CU): 0.28%

● Aluminium(Al): 97.9%

Dis blend na wetin mek 6061 bi alɔy. Na nɔto jɔs pure aluminium - di ad ɛlimɛnt dɛn chenj aw i de biev.

Fizik ɛn Mɛkanikal Prɔpati dɛn .

We wi de tɔk bɔt 6061, wi de luk pan wan matirial we dɛn dɔn ɔt trit fɔ inkrisayz in tɛnsiɛl trɛnk. Na sɔm kwik tin dɛn ya:

● Tɛnsiɛl Strɔng: Arawnd 20,000 to 42,000 psi

● Yield trɛnk: Na lɛk 8,000 to 35,000 psi

● Densiti: roughly 2.7 g/cm³

6061 na wan we dɛn sabi bak fɔ in gud kɔrɛshɔn rɛsistɛns ɛn wɛldabiliti. I nɔ at lɛk sɔm ɔda aluminiɔm alɔy, bɔt i strɔng fɔ bɔku wok. Plus, i gɛt wan sɛnt trɛnk-to-weyt rɛsɛshɔn.

Kɔmɔn Aplikeshɔn ɛn Yuz dɛn .

6061 na in dɛn kin yuz pan bɔku tin dɛn. Na kɔmɔn tin na:

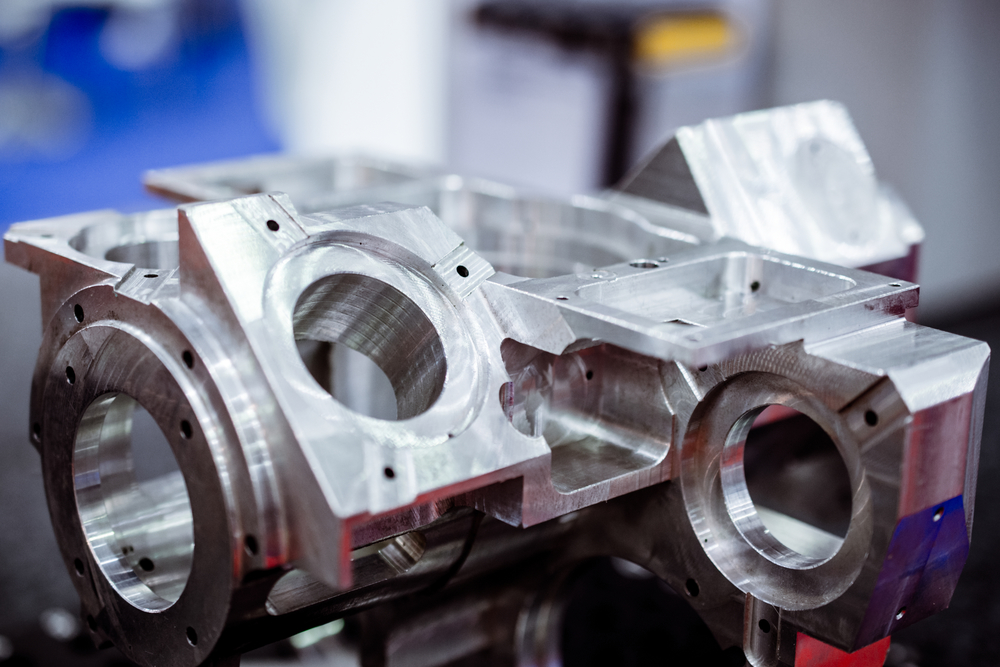

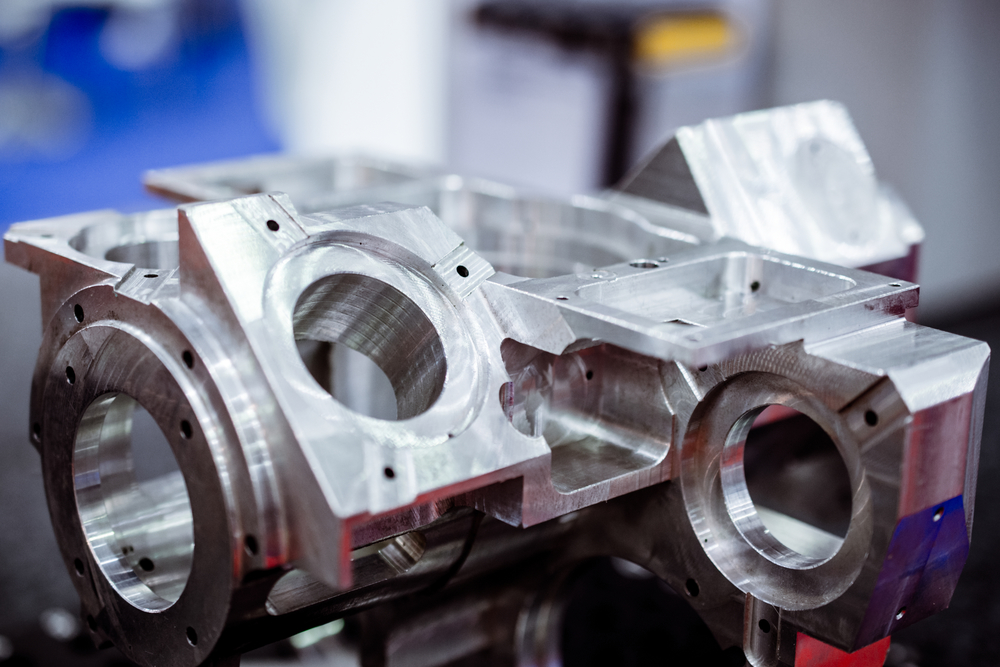

● Aluminium Machining Projekt dɛn .

● Extrusion projɛkt dɛn lɛk tyub ɛn rod dɛn

● Pat dɛn we nid 5-aks prɛsishɔn mashin .

Na go-to fɔ . CNC mashin bikɔs i izi fɔ kɔt ɛn shep. Yu go si am na motoka, bot, ɛn ivin na sɔm bildin dɛn.

Di bɛnifit dɛn ɛn di tin dɛn we yu nɔ fɔ du .

Lɛ wi tɔk bɔt di gud ɛn nɔ-so-gud pat dɛn na 6061. Fɔs, di prɔs dɛn:

● Gud mashinabiliti: I izi fɔ kɔt ɛn shep.

● Welding: I de weld gud gud wan, we fayn fɔ bil tin dɛn.

● Kɔroshɔn rɛsistɛns: I tinap fɔ di ɛlimɛnt dɛn fayn fayn wan.

Bɔt, i nɔ pafɛkt. Na sɔm bad bad tin dɛn:

● Strɔng: I nɔ strɔng lɛk 7075, mɔ na ay-stress aplikeshɔn dɛn.

● Ɔt tritmɛnt: I nid fɔ trit am wit kia fɔ gɛt di bɛst mɛkanikal prɔpati dɛn.

Alloy 7075 - Wan in-dip luk .

Kεmikכl kompozishun na 7075 .

Aluminium 7075 stand out bikɔs ɔf in yon kemikal kɔmpɔzishɔn. Na blend we inklud ay levul fɔ zink ɛn kɔpa, wit sɔm magnɛsiɔm ɛn silikon. Dis miks de giv am wan robust set of atribyut. Na dis wan na wan simpul brekdaun:

● Zinc: Na lɛk 5.6-6.1%

● Magnɛsiɔm: 2.1-2.9%

● Kɔpa: 1.2-2.0%

● Krɔmiɔm (CR): 0.23%

Dɛn ɛlimɛnt ya de wok togɛda fɔ mek wan mɛtal we tranga ɛn rɛdi fɔ chalenj wok dɛn.

Fizik ɛn Mɛkanikal Prɔpati dɛn .

We wi de tɔk bɔt 7075 alɔy, wi de luk sɔm impreshɔnal fizik ɛn mɛkanikal prɔpati dɛn. Dis mεtal na hεt trit, we de bכst in tεnsil strכng bכku bכku wan. Na dat mek 7075 T6, we na wan patikyula kayn pan dis alɔy, na in pipul dɛn de luk fɔ so. Na sɔm impɔtant tin dɛn ya:

● Densiti: 2.81 g/cm³

● Tɛnsiɛl trɛnk: te to 83,000 psi

● yield strength: te to 73,000 psi

● Point we de mɛlt: 477-635°C (890-1175°F)

Dɛn nɔmba ya de tɛl wi se 7075 aluminiɔm na wan taf kuki, mɔ fɔ ay-stres aplikeshɔn dɛn.

Indastrial Aplikeshɔn ɛn Yutilayzeshɔn .

Insay di wɔl fɔ industrial aplikeshɔn, 7075 aluminiɔm na wan sta. Na di go-to fɔ aerospace pat dɛn bikɔs ɔf in trɛnk-to-weyt ratio. Yu go fɛn am na:

● Fitin dɛn we dɛn mek fɔ plen dɛn .

● Gia ɛn shaft dɛn .

● Di pat dɛn we de na di mishɔl

I nɔ jɔs de bɔt plen ɛn rɔket, bɔt. Dis alɔy bak fayn fɔ ɛkstrushɔn prɔjek ɛn kɔmɛshɔnal pɔpɔshɔn usay durabiliti na ki.

Strɔng ɛn Chalenj dɛn .

Mek wi chat abaut di gud en di tof pat dem fo wok wit 7075 aloy. Di tin dɛn we i ebul fɔ du klia wan:

● Supa ay-stress resistans .

● Gret fɔ aerospace ɛn soja gia

● Sɔlid kɔrɛshɔn rɛsistɛns .

Bot, no bi ol smol smol seil. Sɔm prɔblɛm dɛn de bak:

● I at fɔ weld pas 6061 .

● Nɔto so gud fɔ anodiz lɛk ɔda aluminiɔm alɔy dɛn .

● I kin dia pasmak, so kip yu yay pan da badjɔt de .

Mekanikal ɛn fizik prɔpati dɛn .

We wi de tɔk bɔt aluminium 6061 ɛn aluminium 7075, wi de luk tu tɔp alɔy gred wit difrɛn mɛkanikal prɔpati dɛn. Naw, lɛ wi brok dɔŋ dɛn prɔpati ya fɔ si us mɛtal go bi di rayt chuk fɔ yu prɔjek.

Strɔng kɔmpiashɔn: 7075 vs 6061

7075 Dɛn kin kɔl Alɔy ‘Aircraft Grade’ bikɔs i rili strɔng. I gɛt ay tɛnsiɛl trɛnk pas 6061 alɔy, we min se i kin ebul fɔ handle mɔ fɔs we i nɔ brok. 7075 gɛt zink as in praymari alɔy ɛlimɛnt, we de gi am dis ɛkstra trɛnk.

Na di ɔda say, dɛn mek 6061 wit magnɛsiɔm ɛn silikon. I nɔ strɔng lɛk 7075, bɔt i stil rili tranga. Fɔ prɔjek dɛm we nɔ nid di ays trɛnk, lɛk sɔm ɛkstrushɔn prɔjek ɔ kɔmɛshɔnal pɔpɔshɔn, 6061 kin bi big fit.

Densiti ɛn wet fɔ tink bɔt .

We i kam pan density ɛn wet, 6061 aluminiɔm layt. Dis mek am go-to fɔ wok usay yu want fɔ kip tin layt bɔt stil strɔng. Tink bɔt pat dɛn we nid fɔ izi fɔ muv ɔ kɛr.

Hɛt tritmɛnt ɛn tɛmral kɔnduktiviti .

Ɔl tu di 6061 ɛn 7075 aluminiɔm dɛn kin ɔt trit. Hɛt tritmɛnt kin mek dɛn strɔng mɔ. Bɔt dɛn kin ansa difrɛn we to am. Fɔ ɛgzampul, 7075 T6 na wan pan di tranga opshɔn dɛn we de de afta ɔt tritmɛnt.

As fɔ tɛmral kɔnduktiviti, 6061 na di wan we win. I de spre ɔt bɛtɛ, we kin impɔtant fɔ kip tin dɛn kol, lɛk insay aluminiɔm mashin.

Ilektrikal resistiviti ɛn mɛlt pɔynt dɛn .

7075 ɛn 6061 gɛt di sem kayn mɛlt pɔynt, arawnd 1080°C to 1200°C. Bɔt dɛn ilɛktrik rɛsistiviti difrɛn. 6061 kin gɛt bɛtɛ kɔnduktiviti, we kin impɔtant fɔ ilɛktrik aplikeshɔn dɛn.

Mechanical Properties: Elastisiti ɛn Hadnɛs .

If wi tok elastisiti, di modulus of elasticity fo di tu aluminium matiryal dem semwe. Dis min se dɛn ɔl tu go bɛn smɔl ɔnda strɛs bɔt bounce bak. Fɔ had, 7075 kin gɛt di ed, mɔ na di 7075 T6 kɔndishɔn. I at, we min se i kin resist skrat ɛn wear bɛtɛ.

We yu de pik bitwin 6061 ɛn 7075 aluminiɔm, tink bɔt di trɛnk, di wet, di ɔt tritmɛnt, di kɔnduktiviti, ɛn di mɛkanikal prɔpati dɛn lɛk ɛlastik ɛn di had we. Di tin we yu go pik go dipen pan yu badjɛt, di aplikeshɔn dɛn, ɛn di patikyula tin dɛn we yu fɔ tink bɔt fɔ mek yu du yu prɔjek.

Evaluate di machinabiliti fɔ 7075 ɛn 6061 .

We wi de tɔk bɔt aw fɔ mek mashin, wi min aw i izi fɔ shep mɛtal we yu de yuz mashin dɛn. Ɔl tu di aluminium 6061 ɛn aluminium 7075 gɛt gud mashinabiliti, bɔt dɛn difrɛn. 6061 Dɛn kin pik alɔy bɔku tɛm bikɔs i izi fɔ kɔt ɛn shep. Dis na bikɔs i gɛt magnɛsiɔm ɛn silikon insay de. Dɛn tin ya kin mek i izi fɔ wok wit we yu de yuz tul dɛn lɛk CNC mashin.

7075 Alɔy, na di ɔda say, na smɔl tin we at fɔ wok wit. Na bikɔs i gɛt mɔ zink ɛn . kɔpa . Dis kin mek i at, we kin fayn fɔ trɛnk bɔt i kin bi prɔblɛm fɔ kɔt ɛn shep.

Fɔm ɛn wɛldin kapabiliti dɛn .

Naw, lɛ wi tɔk bɔt fɔm ɛn wɛldin. Fɔm min fɔ bɛn ɔ shep di mɛtal. Welding na lɛk fɔ glu mɛtal dɛn togɛda wit ɔt. Aluminium 6061 na di sta ya. I fayn fɔ prɔjek dɛn we nid fɔ bɛn ɛn wɛl bikɔs i nɔ krak izi wan. Plus, e kin handle bi heat op en kol daun bak witout get wik.

7075 aluminium no bi so izi fo weld. Dat na bikɔs na wan mɛtal we dɛn kin trit wit ɔt. We yu wam am, i kin lɔs sɔm pan in trɛnk. So, if yu nid fɔ weld, 6061 kin bi yu bɛst bet.

Kes Study: Praktikal Aplikeshɔn dɛn na Machining .

Lɛ wi luk pan rial layf ɛgzampul dɛn. Imajin se wi de mek pat fɔ bayk. Bayk nid fɔ strɔng bɔt i nid fɔ layt bak. 6061 aluminium na in dɛn kin yuz bɔku tɛm fɔ di freym bikɔs i strɔng bɔt i izi bak fɔ shep insay tyub. Plus, e no kost plenti.

Fɔ tin dɛn we nid fɔ bi supa strɔng, lɛk pat pan plen, 7075 aluminiɔm dɛn kin yuz bɔku tɛm. Dɛn kin kɔl am ayrakt gred bikɔs i gɛt ay trɛnk-to-weyt rɛsɛshɔn. Dis min se i rili strɔng fɔ aw layt i de. Bɔt, i at fɔ shep ɛn kɔst mɔ.

If yu de mek sɔntin we nid fɔ shep bɔku ɛn de pan badjɛt, go fɔ 6061. If yu nid sɔntin we supa strɔng fɔ ay-stres aplikeshɔn dɛn lɛk na aerospace, 7075 kin bi di we fɔ go, pan ɔl we i triki fɔ wok wit.

Dɛn tu aluminiɔm alɔy ya na fayn opshɔn dɛn. I jɔs dipen pan wetin yu nid fɔ yu prɔjek.

Koroshɔn rɛsistɛns ɛn anodizing .

Koroshɔn rɛsistɛns: Wan kɔmparativ stɔdi .

We wi de tɔk bɔt aluminium 6061 ɛn aluminium 7075, wi de luk tu alɔy gred wit difrɛn kemikal kɔmpɔzishɔn. Kɔroshɔn rɛsistɛns na wan impɔtant tin we wi kin tink bɔt. Aluminium 6061 gɛt magnɛsiɔm ɛn silikon as in men alɔy ɛlimɛnt dɛn. Dis miks de giv am gud difens agenst koroshon. Na di ɔda say, aluminiɔm 7075 gɛt mɔ zink ɛn kɔpa. Pan ɔl we i strɔng, i nɔ de agens kɔrɛshɔn lɛk 6061 alɔy.

Anodizing potential of 7075 ɛn 6061 .

Anodising na wan smat we fɔ protɛkt ɛn mek aluminiɔm fayn. Ɔl tu 6061 ɛn 7075 kin go tru dis ilɛktrɔkɛmik prɔses. Bɔt, 6061 kin du bɛtɛ. I de fɔm wan yunifom ɔksayd layt we kin tek pan kɔlɔ dɛn fayn fayn wan. Dis mek am wan top pik fɔ projɛkt usay luks impɔtant.

Anodising proses fɔ aluminiɔm alɔy dɛn .

Na so i de wok. Wi de dip di mɛtal insay wan asid bat ɛn rɔn wan kɔrɛnt tru am. Dis kin bil wan ɔksayd layt na di say we i de. Dis layt na wetin de fɛt ɔf rɔst ɛn mek wi ad kɔlɔ dɛn. Ɔl tu 6061 ɛn 7075 kin anodized, bɔt di rizɔlt kin luk difrɛn.

Kɔlɔ ɛn aesthetic kɔnsidareshɔn dɛn .

If yu want kala, 6061 Alloy na di we fɔ go. I tek pan daya ivin, so i luk fayn. 7075 Alloy kin gɛt kɔlɔ bak, bɔt i nɔ kin bi lɛk vibrant. Dis na sɔntin fɔ tink bɔt if di luk impɔtant lɛk di fɛnshɔn.

Fɔ lɔng tɛm fɔ lɔng tɛm ɛn fɔ mek dɛn mentenɛns .

Fɔ sɔntin we de las, ɔl tu di alɔy dɛn na strɔng chus. Bɔt 6061 kin nid fɔ gɛt smɔl kia as tɛm de go bikɔs ɔf in bɛtɛ kɔrɛshɔn rɛsistɛns. Bɔt na balans, bɔt. If yu nid mɔ trɛnk-to-weyt rɛtɛshɔn, lɛk na aerospace ɔ ay-stress aplikeshɔn, 7075 kin bi yu alɔy.

Fɔ pik di rayt aluminiɔm matirial dɛn dipen pan yu badjɛt, aplikeshɔn, ɛn di prɔpati dɛn fɔ di mɛtal dɛn we yu nid. Alloy kompareshon no bi jos abaut wan tin. Na bɔt fɔ luk ɔl di atribyut dɛn, frɔm kɔrɛshɔn rɛsistɛns to mashinabiliti to anodizing pɔtɛnɛshɔn.

Aplikeshɔn dɛn na Indastri .

Aerospace ɛn avieshɔn yuz dɛn .

Aluminium 6061 ɛn aluminium 7075 ɔl tu impɔtant na di aerospace industri. Dɛn layt wet ɛn trɛnk de mek dɛn pafɛkt fɔ plen. Di 7075 alɔy, we dɛn kin kɔl bɔku tɛm plen gred, gɛt ay tɛnsiɛl trɛnk ɛn dɛn kin yuz am bɔku tɛm fɔ mek ay-stress aplikeshɔn dɛn. I de insay wing ɛn fizulej usay di tɛm we pɔsin kin de fɔ lɔng tɛm na di men tin. Na di ɔda say, dɛn kin yuz 6061 fɔ in wɛldin prɔpati dɛn ɛn bɔku tɛm dɛn kin fɛn am na ayrakt fitin ɛn wing-tips.

Ɔtomotiv ɛn Transpɔt Aplikeshɔn dɛn .

Insay di wɔl fɔ motoka ɛn transpɔt, dɛn ɔl tu aluminiɔm alɔy dɛn de ple big pat. Di 6061 alɔy na wan we dɛn sabi fɔ in versatility ɛn dɛn yuz am insay . Ɔto pat dɛn lɛk wil ɛn chɛsis . Di we aw i de fɛt di kɔrɛshɔn de mek i bi gud chus fɔ motoka bɔdi dɛn. Di 7075 alɔy, wit in ay trɛnk, dɛn yuz am na rɛs aplikeshɔn ɛn fɔ pat dɛn we tek mɔ strɛs, lɛk gia bɔks ɛn sɔspɛns kɔmpɔnɛnt dɛn.

Marin ɛn strɔkchɔral injinɛri .

Fɔ marin yus, kɔrɛshɔn rɛsistɛns na supa impɔtant. Na dat mek dɛn kin yuz aluminium 6061, wit in gud resistans to si wata, bɔku tɛm dɛn kin yuz am. I de insay bot hul ɛn marin fitin. Fɔ strɔkchɔral injinɛri, dɛn kin yuz ɔl tu di alɔy dɛn. 7075 in ay trɛnk na pafɛkt fɔ strɔkchɔ dɛn we nid fɔ layt yet strɔng.

Konstrɔkshɔn ɛn Strukchɔral Aplikeshɔn dɛn .

Insay kɔnstrɔkshɔn, 6061 aluminiɔm na wan go-to strɔkchɔral mɛtal. I gud fɔmabiliti ɛn wɛldin prɔpati dɛn mek am fayn fɔ bil freym ɛn brij. 7075 nɔ bɔku na kɔnstrɔkshɔn bikɔs ɔf in less favɔrabl fabrikeshɔn kɔnsidareshɔn dɛn.

Konsuma guds ɛn difrɛn we dɛn fɔ yuz am .

Konsuma guds de bɛnifit frɔm ɔl tu di aluminiɔm matirial dɛn. 6061 kin si bɔku tɛm na prɔdak dɛn lɛk baysikul ɛn fishin riɛl fɔ in mashinabiliti ɛn anodising abiliti. 7075 na tin we dɛn kin yuz na gadget ɛn tul dɛn we nid mɔ had ɛn trɛnk, lɛk ikwipmɛnt fɔ klaym rɔk.

Ɛni alɔy gred gɛt in yon kemikal kɔmpɔzishɔn ɛn mɛkanikal prɔpati dɛn we de mek i fayn fɔ difrɛn industrial aplikeshɔn dɛn. If na di silikon ɛn magnɛsiɔm insay 6061 ɔ di zink, kɔpa, ɛn magnɛsiɔm insay 7075, dɛn alɔy tayp ya gɛt yunik atribyut dɛn we impɔtant akɔdin to difrɛn aplikeshɔn dɛn. We yu de pik alɔy fɔ wan prɔjek, tink bɔt tin dɛn lɛk badjɛt, trɛnk-to-weyt rɛtɛshɔn, ɛn spɛshal prɔpati dɛn fɔ mɛtal dɛn we dɛn nid.

Aluminium 6061 na wan we dɛn sabi fɔ in wokabiliti ɛn kɔrɛshɔn rɛsistɛns, we aluminiɔm 7075 na rɛkɔgnayz fɔ in supia trɛnk ɛn yus insay aerospace ɛn ɔda ay-stress aplikeshɔn dɛn. Ɛni wan pan dɛn gɛt in ples na industrial aplikeshɔn, ɛn di alɔy chuk de dipen pan di prɔjek rikwaymɛnt ɛn di atribyut dɛn we dɛn want.

We yu pik di rayt alɔy fɔ yu prɔjek .

We yu de pik di rayt alɔy fɔ yu prɔjek , tink bɔt dɛn big big aidia ya: trɛnk, kɔst, ɛn fɔ gɛt. Dis na lɛk yu kɔmpas fɔ mek smat chuk.

Disishɔn Fakta dɛn: Strɔng, Kɔst, Avaylabl

● Strɔng: Aw strɔng yu nid yu mɛtal fɔ bi? Aluminium 6061 na priti tof, bot aluminium 7075 ivin strong. I tan lɛk di difrɛns bitwin gud bayk ɛlmɛt ɛn pro rɛs ɛlmɛt.

● Kɔst: mɔni impɔtant, nɔto so? Jɛnɛral wan, 6061 nɔ kin dia pasmak. If yu badjet tayt, dis kin bi di we fɔ go.

● Avaylabl: Yu kin ebul fɔ gɛt wetin yu nid izi wan? Aluminium 6061 na lɛk di bred ɛn bɔta fɔ aluminiɔm matirial dɛn – i de ɔlsay. Bɔt 7075 kin tek smɔl mɔ fɔ fɛn.

Projekt-spɛsifi k alɔy sɛlɛkshɔn .

Mek wi se yu de wok pan wan projɛkt. Yu nid fɔ tink bɔt wetin yu de mek. Na pat fɔ bayk? Maybe som fansi gadget? Na dis wan na wan kwik gayd:

● If yu de du sɔntin we nid fɔ bɛn smɔl ɔ shep, lɛk aluminiɔm tiub ɔ plet, go fɔ 6061. I gɛt gud fɔmabiliti ɛn wɛldin na briz.

● Bɔt if yu de mek sɔntin we go gɛt supa strɛs, lɛk pat fɔ plen, yu go want 7075. I gɛt da ay-stres aplikeshɔn vib de, tank to in zink ɛn kɔpa miks.

Ɛkspɛkt opinion ɛn kes stɔdi dɛn .

Di wan dɛn we sabi bɔt aluminiɔm mashin lɛk fɔ tɔk bɔt dɛn tu alɔy gred ya. Dem go tel yu se 6061 na yu go-to fo most tins. I tan lek di frenli neighborhood metal. I gɛt magnɛsiɔm ɛn silikon, we na sɔlid tim fɔ strɔkchɔral matirial dɛn.

Bot den yu don get 7075 – di aircraft-grade hero. Na di wan we yu de kol in wen tins get tof. 7075 T6, fכ egzampl, na hεt tritmεnt fכ bi supa strכng. I de yuz in aerospace bikɔs i gɛt wan amazing strɛngth-to-weight ratio.

Na dis wan machinist se: 'For 5-aks prɛsishɔn mashin , 7075 kin bi drim. I tranga, bɔt i kin ebul fɔ handle di chalenj.' ɛn bɔt ɛkstrushɔn prɔjek dɛm, 6061 bin mɔ kɔst-ɛfɛktiv ɛn jɔs rayt fɔ di wok.

FAQ dɛn na 7075 ɛn 6061 aluminiɔm alɔys .

Wetin na di men tin dɛn we difrɛn pan di tin dɛn we dɛn mek wit kemikal?

Aluminium 6061 na magnesium ɛn silikon as in men aloying elements. Na di ɔda say, aluminiɔm 7075 gɛt ay levul dɛn fɔ zink ɛn kɔpa. Dis difrεns in kεmikכl kכmכshכn de lid to difrεnt mεkanikal prכpati dεm.

Aw di choice fɔ aloy de afɛkt di ɛnd prodak?

Di alloy choice kin mek big difrens. Fɔ ɛgzampul, dɛn sabi 6061 alɔy fɔ in versatility ɛn gud kɔrɛshɔn rɛsistɛns, we mek i fayn fɔ kɔmɛshɔnal pɔpɔshɔn dɛn lɛk fɔ mek aluminiɔm plet ɔ ɛkstrushɔn prɔjek. 7075 Alɔy, wit in ay tɛnsiɛl trɛnk ɛn hadnɛs, dɛn kin yuz am bɔku tɛm na ay-strɛs aplikeshɔn dɛn lɛk insay aerospace ɔ soja ikwipmɛnt.

Yu tink se dɛn kin yuz ɔl tu di alɔy dɛn fɔ chenj dɛnsɛf na sɔm aplikeshɔn dɛn?

Sɔntɛnde, yes. Bɔt, i dipen pan di aplikeshɔn. If di prɔjek nid ay trɛnk-to-weyt ratio ɛn ebul fɔ handle di kɔst, dɛn kin yuz 7075. Yet, fɔ prɔjek dɛm we nid gud wɛldin ɛn fɔmabiliti, 6061 na bɔku tɛm di bɛt bɛt pik.

Wetin mek 6061 fit fɔ wɛldin we yu kɔmpia am wit 7075?

Aluminium 6061 gɛt bɛtɛ wɛldin atribyut bikɔs ɔf in kemikal kɔmpɔzishɔn. I nɔ kin izi fɔ krak di tɛm we dɛn de wɛl, i nɔ tan lɛk 7075 we kin mek i nɔ wok fayn bikɔs ɔf in ay zink kɔntinyu.

Wetin mek dɛn kin lɛk 7075 na ay-strɛs aplikeshɔn dɛn?

Dɛn kin kɔl aluminiɔm 7075 bɔku tɛm di ayrakt gred bikɔs i gɛt rili ay tɛnsiɛl trɛnk ɛn yield trɛnk. Dis min se i kin ebul fɔ handle bɔku strɛs bifo i defɔm. Na dat mek i fayn fɔ pat dɛn we go de ɔnda bɔku prɛshɔn ɔ wet.

● Dɛn kin yuz aluminiɔm alɔy dɛn lɛk 6061 ɛn 7075 pan bɔku tin dɛn bikɔs dɛn strɔng bɔt dɛn layt.

● Dɛn kin yuz 6061 bɔku tɛm fɔ mek tin dɛn lɛk aluminiɔm tyub ɔ freym bikɔs i izi fɔ shep ɛn jɔyn togɛda.

● 7075 na we yu nid sɔntin we rili strɔng, lɛk pat fɔ plen ɔ bayk we go rili fast.

● Pan ɔl we dɛn ɔl tu na aluminiɔm, dɛn gɛt difrɛn tin dɛn we de mek dɛn fayn fɔ difrɛn wok dɛn.

Dɔn

We wi luk pan aluminium 6061 versus aluminium 7075, na wan tu impɔtant pɔynt dɛn de fɔ mɛmba. Di 6061 alɔy na wan we dɛn sabi fɔ in versatility. I gɛt magnɛsiɔm ɛn silikon ɛn i de gi gud kɔrɛshɔn rɛsistɛns ɛn wɛldabiliti. Dis mek am wan go-to fɔ bɔku kɔmɛshɔn biznɛs.

Na di ɔda say, aluminiɔm 7075 strɔng pasmak. Dɛn kin trit am ɛn i gɛt mɔ zink. Dis de gi am wan ay tɛnsiɛl trɛnk, na dat mek dɛn kin yuz am bɔku tɛm na aerospace ɛn ɔda ay-stres aplikeshɔn dɛn. Aweva, e hard bit harder fo wok wit. I mashinabiliti de dɔŋ, ɛn i nɔ fayn fɔ wɛldin.

Di bɛst we fɔ du tin fɔ pik di rayt aluminiɔm alɔy .

We yu de disayd bitwin 6061 ɛn 7075, tink bɔt dɛn pɔynt dɛn ya:

1. Aplikeshɔn: Wetin yu go yuz di mɛtal fɔ? If na fɔ strɔkchɔral matirial dɛn we nid fɔ strɔng, 7075 kin bi di bɛst. If na fɔ ɛkstrushɔn prɔjek ɔ tin dɛn we nid fɔ shep, 6061 kin bɛtɛ.

2. Badget: Bɔku tɛm, 6061 nɔ kin dia bɛtɛ. If yu badjet tayt, dis kin influens yu aloy choice.

3. Fabrication Considerations: If yu projɛkt involv bɔku aluminiɔm mashin, lɛk CNC mashin ɔ 5-aks prɛsishɔn mashin, yu go nid fɔ tink bɔt di mɛtal gred dɛn mashinabiliti. 6061 jɔs de gi bɛtɛ wokabiliti.

4. Mɛkanikal prɔpati dɛm: Yu fɔ luk di trɛnk-to-weyt ratio, yield trɛnk, ɛn hadnɛs. 7075 jεnarali de win in trεnk, bכt 6061 na mכr daktayl.

5. Kεmikכl kכmכshכn: Di aloi kכmכshכn de afekt di prכpati dεm fכ mεtal dεm. 7075 gɛt mɔ kɔpa ɛn zink, we 6061 gɛt mɔ silikon ɛn magnɛsiɔm.

6. Kɔroshɔn rɛsistɛns: If di mɛtal go ɛksplɔz to di ɛlimɛnt dɛn, kɔrɛshɔn rɛsistɛns na di ki. 6061 gɛt natura ɔksayd layt we de protɛkt am, we mek i bi gud chus fɔ ɔda aplikeshɔn dɛn na do.

7. Hɛt tritmɛnt: Yu kin fɛn 7075 na di 7075 T6 fɔm, we dɛn kin trit ful wan ɛn no fɔ yuz am na ayrakt gred aplikeshɔn dɛn. 6061 kin hεt trit bak, bכt i de bak insay wan anεl kכndishכn, we de gi mכr fכmabiliti.

Ɔltɛm tink bɔt di patikyula nid dɛn fɔ yu prɔjek. Ɛni alɔy gɛt in yon spɛshal sɛt fɔ atribyut dɛn. We yu ɔndastand di alɔy gred dɛn, di prɔpati dɛn we yu gɛt, ɛn di tin dɛn we yu gɛt fɔ mek yu bɔdi go ɛp yu fɔ disayd fɔ du sɔntin we yu no.