Plastic extrusion powers everything from the water pipes in your walls to the smartphone chargers on your desk. Yet most people sourcing these parts have no idea how it actually works—or worse, they're paying way more than they should because they picked the wrong manufacturer. The truth: understanding plastic extrusion isn't just technical knowledge. It's your competitive advantage.

Whether you're launching a product, scaling production, or hunting for cost savings, this guide cuts through the noise. We've covered everything you need to make informed decisions and avoid costly mistakes.

What you'll learn:

● What is plastic extrusion — The core fundamentals and why it matters

● How the plastic extrusion process works — From raw material to finished product

● Plastic extrusion applications — Where these parts show up across industries

● Types of plastic extrusion products — Pipes, tubes, profiles, and custom solutions

● Plastic extrusion machines and dies — The equipment that makes it happen

● Finding reliable plastic extrusion manufacturers — Sourcing quality from factories worldwide

● Custom plastic extrusions — Getting exactly what your project needs

● Plastic extrusion molding variations — Different techniques and when to use them

If you're working with a plastic extrusion company, you already know speed and precision matter. Team MFG handles everything from rapid prototyping to mass production across multiple extrusion methods—so you're not juggling different vendors. With over a decade in the game and 99.9% on-time delivery, we've become the go-to partner for brands that can't afford delays.

Plastic extrusion is a manufacturing process where raw plastic material gets melted, pushed through a shaped opening called a die, and cooled into a continuous profile. Think of it like a sophisticated pasta maker—except instead of dough, you're working with molten polymers, and the shapes can be infinitely more complex.

Raw plastic pellets enter a heated barrel, melt into a uniform consistency, and get forced through a custom-shaped die under pressure. What emerges on the other side is a continuous, uniform profile that gets cooled and cut to length. It's remarkably efficient because there's no downtime between cycles—material flows continuously.

Benefit | Why It Matters |

Speed | Continuous production vs. batch cycles |

Cost-effective | Lower per-unit pricing at scale |

Minimal waste | Material flows through without excess scrap |

Design flexibility | Creates virtually any linear shape |

You'll find plastic extrusion products everywhere:

● Plastic pipes — Plumbing, drainage, irrigation systems

● Plastic tubes — Medical, automotive, industrial applications

● Weather stripping, cable conduits, window profiles, seals

The versatility is why custom plastic extrusions dominate manufacturing. Once your die is made, you unlock unlimited production runs of identical parts.

The plastic extrusion process follows a straightforward sequence, but precision matters at every stage. Slight temperature variations or pressure imbalances can ruin an entire batch, which is why experienced operators and quality control systems are non-negotiable.

Material preparation — Raw plastic pellets are fed into the hopper (sometimes pre-dried to remove moisture)

Heating — The barrel gradually heats the material to its melting point, typically 200-300°C, depending on polymer type

Melting and mixing — A rotating screw blends the molten plastic into a uniform, bubble-free consistency

Pressurization — The screw forces the melted plastic toward the die at controlled pressure

Extrusion — Material flows through the shaped die opening, forming the desired profile

Cooling — The hot profile moves through water baths or air jets to solidify quickly

Cutting — Finished parts are trimmed to specified lengths

Quality inspection — Dimensions, appearance, and material properties get verified

Temperature control is everything. Too cold and the plastic won't flow properly. Too hot and you risk degradation or warping. Plastic extrusion machines maintain precision through multiple heating zones, allowing operators to create complex profiles without defects.

Pressure and screw speed also determine wall thickness consistency and surface finish. This is why plastic extrusion manufacturers invest in advanced equipment rather than cutting corners.

The die is the unsung hero of extrusion. It's a precision-engineered tool that shapes the molten plastic as it flows through. Custom dies cost money upfront but amortize quickly across high-volume production runs. A well-designed die from a reputable plastic extrusion factory can produce millions of parts with minimal variation.

Plastic extrusion applications span nearly every industry because the process creates durable, cost-effective parts at scale. From infrastructure to consumer goods, extruded plastics are doing heavy lifting behind the scenes.

Construction & Infrastructure

● Plastic pipe extrusion for water supply, sewage, and gas distribution lines

● Weather stripping and seals for windows and doors

● Cable trays and conduits for electrical systems

Automotive

● Door seals, window channels, and trim pieces

● Fuel and coolant tubing

● Interior trim profiles

Medical & Pharmaceutical

● Plastic tube extrusion for IV lines, catheters, and diagnostic equipment

● Sterile tubing for laboratory applications

Electronics & Technology

● Cable conduits and protective sleeves

● Heat shrink tubing

● Wire insulation profiles

Consumer Goods

● Shower enclosures, bathtub trim

● Furniture components and edging

● Packaging materials

Industry | Key Benefit |

Construction | Long-run production of standardized profiles keeps costs low |

Automotive | Complex shapes improve aerodynamics and seal performance |

Medical | Tight tolerances ensure safety and reliability |

Electronics | Consistent insulation quality protects components |

The flexibility of extrusion means plastic extrusion companies can serve niche markets without massive retooling. That's why it remains the go-to process for both commodity products and specialized applications.

Understanding what can and can't be extruded helps you determine if this process fits your project. Not everything benefits from extrusion—but when it does, the results are typically superior and cheaper than alternatives.

● Solid Profiles: These are single-piece shapes with no cavities. Window frames, trim strips, and solid rods fall here. They're the simplest to produce and require minimal die complexity.

● Hollow Profiles: Think of tubing or pipes with internal cavities. These require more sophisticated dies but enable lighter-weight parts and better material efficiency. Plastic pipe extrusion and plastic tube extrusion dominate this category.

● Multi-Material Profiles: Advanced extruders can extrude two or more materials simultaneously, bonding them together. A rubber gasket fused to a rigid plastic frame, for example. This reduces assembly steps and cuts production costs.

The main plastic extrusion types include:

PVC plastic extrusion is the industry standard for plumbing and electrical applications. PVC is rigid, affordable, and handles high pressures well.

● Water and sewage pipes

● Conduit tubing

● Cable trays

Polyethylene and polypropylene extrusions offer flexibility and chemical resistance:

● Flexible tubing and hoses

● Protective sleeves and conduits

● Agricultural films

Materials like nylon, PEEK, and polycarbonate get extruded for demanding applications:

● High-temperature tubing

● Transparent protective covers

● Medical-grade components

Custom plastic extrusions differ from off-the-shelf products because they're designed around your specifications—exact dimensions, material blend, color, and durability requirements. A plastic extrusion factory with strong engineering support can optimize your design for manufacturability, often identifying cost savings you'd never spot alone.

This is where plastic extrusion molding expertise matters. A manufacturer who understands material science and equipment capabilities can suggest profile modifications that reduce scrap, improve structural integrity, or enable faster cooling—all without compromising performance.

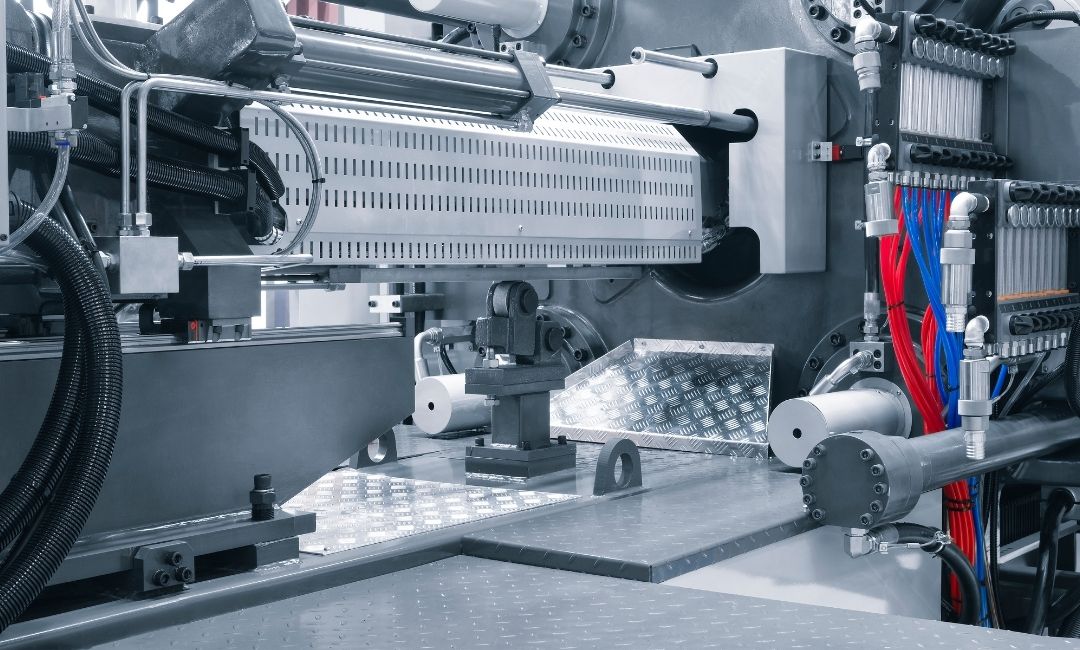

The equipment driving this process determines quality, speed, and cost. Understanding what separates entry-level machines from industrial-grade systems helps you evaluate manufacturers intelligently.

A plastic extrusion machine consists of several core components working in concert. The extruder barrel heats and pressurizes material. The screw rotates to blend and move the molten plastic forward. The die shapes it. Cooling systems solidify the profile, and cutters trim it to length.

Modern machines use digital controls for temperature zones, screw speed, and line pressure. This precision is why brands specify particular manufacturers—they know the tolerances will stay tight across production runs.

● Single-screw extruders dominate standard applications. They're simpler, cheaper, and handle most materials effectively.

● Twin-screw extruders excel when you need intense mixing (for color or additive dispersion) or when processing heat-sensitive materials. They cost more but deliver superior consistency for demanding applications.

The die is essentially a custom-engineered mold that shapes flowing plastic. Designing and manufacturing a die requires deep expertise—poorly designed dies create uneven wall thickness, surface defects, or even complete blockages.

Quality plastic extrusion dies account for:

● Flow distribution — Ensuring even pressure across the die opening

● Heat management — Preventing localized overheating that degrades material

● Wear resistance — Dies run continuously and endure high friction

● Cleanability — Residual material buildup ruins subsequent batches

This is why a plastic extrusion factory with in-house die design capability delivers better results. They iterate based on real production data, not just initial specifications.

Different materials flow differently. PVC plastic extrusion requires a different die geometry than polyethylene. A manufacturer experienced across multiple polymers can optimize your die for your specific resin, maximizing output and part quality.

Choosing a plastic extrusion manufacturer ranks among the most consequential decisions in your product launch or scaling phase. The wrong partner means delays, quality issues, and wasted budget. The right one becomes a strategic advantage.

● Experience across industries — A plastic extrusion company that's served automotive, medical, and consumer goods brings deeper problem-solving capability. They've encountered edge cases. They know what fails and why.

● Advanced equipment — Modern plastic extrusion machines with precision controls and multiple heating zones produce tighter tolerances and faster cycle times. Older equipment might be cheaper, but it introduces variation.

● Engineering support — This is the multiplier. Manufacturers who review your design, identify manufacturability issues, and suggest optimizations save you money before production even starts. Many plastic extrusion manufacturers offer this as standard, while others treat it as an afterthought.

● Quality systems — ISO 9001 certification matters because it means documented processes, traceability, and continuous improvement. It's not just a badge—it's evidence of discipline.

Plastic extrusion in China has become the global hub for volume manufacturing. Lower labor costs and established supply chains mean competitive pricing. However, not all plastic extrusion factories operate at the same standard.

A reputable plastic extrusion company in China with proper certifications, modern equipment, and English-speaking engineers can deliver world-class results. But you need due diligence—site visits, reference checks, and sample validation before committing to volume.

● Unwillingness to provide references or case studies

● Vague responses about quality control processes

● No engineering support or design consultation offered

● Extremely low quotes that seem disconnected from material costs

● Limited equipment or single-machine operations

Team MFG operates across injection molding, CNC machining, and die casting—but our plastic extrusion capabilities run deep. With over a decade of experience, ISO 9001 certification, and a track record serving 73 countries, we handle everything from rapid prototyping to million-unit production runs.

Our engineering team reviews designs upfront, identifies cost optimizations, and ensures your tooling is built right the first time. For manufacturers juggling multiple vendors, consolidating with a one-stop partner eliminates coordination headaches and accelerates timelines.

Material choice shapes everything—part performance, cost, manufacturing complexity, and lifespan. Understanding the characteristics of common extrusion materials helps you make informed decisions.

Here's the list of popular materials:

PVC plastic extrusion dominates the plumbing and electrical sectors. It's rigid, cost-effective, and handles pressure well. The downside is that it is not suitable for high-temperature applications and has environmental concerns in some regions.

● Best for: Pipes, conduits, weatherstripping, vinyl trim

● Temperature range: -20°C to 60°C

● Strength: Moderate rigidity with good impact resistance

PE extrusions offer flexibility and chemical resistance. Low-density PE is soft and pliable. High-density PE is stiffer but still flexible compared to rigid plastics.

● Best for: Tubing, hoses, protective sleeves, flexible conduits

● Temperature range: -40°C to 80°C

● Strength: Lower rigidity but excellent flexibility

● Polycarbonate — Transparent, impact-resistant, withstands higher temperatures (up to 120°C). Used in protective covers, light diffusers, and optical components.

● Nylon — High strength-to-weight ratio, excellent wear resistance. Ideal for mechanical components and high-friction applications.

● PEEK — Advanced engineering plastic for extreme environments. Medical implants, aerospace components. Premium cost but unmatched durability.

Cheaper doesn't always mean better value. A plastic extrusion factory with material expertise can recommend alternatives that cut costs without compromising performance. Sometimes a blend of materials—like plastic extrusion molding with multiple polymers—delivers the ideal balance of properties at a lower cost than a premium single material.

Off-the-shelf extrusions work fine for commodity applications. But when your product demands something specific—exact wall thickness, proprietary color matching, integrated features—custom plastic extrusions become your competitive edge. This is where engineering meets manufacturing.

Standard profiles hit shelves at lower prices because they amortize across thousands of buyers. Custom plastic extrusions, by contrast, are designed around your needs. Your dimensions. Your material blend. Your performance requirements. The upfront die cost stings, but it vanishes when spread across production volume.

A manufacturer with strong design input can spot inefficiencies in your concept before tooling begins. They'll suggest profile modifications that reduce material waste, improve structural integrity, or enable faster cooling—changes that save thousands without compromising function.

Working with a plastic extrusion company on custom projects typically follows this path:

Design review — Your specs meet their manufacturing reality check

Material consultation — The right resin selected for performance and cost

Prototype production — Small test runs validate the design

Die optimization — Adjustments based on prototype feedback

Full production — Scaled manufacturing with quality gates at every stage

● Wall thickness variation — Different sections of a profile need different strengths. Custom dies accommodate this naturally.

● Multi-material bonding — Rigid plastic fused to flexible rubber. Conductive coating embedded during extrusion. These aren't possible with standard profiles.

● Integrated features — Snap-fit connectors, cable channels, or alignment guides molded directly into the profile eliminate assembly steps.

● Color and additives — Custom pigment blends or UV stabilizers for specific environments (outdoor durability, food-grade requirements, etc.).

Die costs run $2,000–$10,000+, depending on complexity. But at 10,000 units, that's 20 cents per part. At 100,000 units, it's 2 cents. The volume math works fast for products with genuine demand.

A plastic extrusion factory with transparent pricing breaks down die costs, material costs, and per-unit production fees upfront. This visibility prevents surprise invoices and lets you calculate ROI accurately.

Plastic extrusion molding isn't a monolithic process. Several distinct variations exist, each optimized for different applications and production volumes. Understanding which variation fits your project prevents costly detours.

Co-extrusion pushes two or more materials through the die simultaneously, bonding them at the molecular level. The result: layered profiles with distinct properties in one continuous piece.

Solid extrusions are simple: melted plastic flows through a single die opening. Window trim, solid rods, flat bars—straightforward profiles with no internal cavities.

Hollow extrusions require more precision. The die has multiple flow paths that converge to create internal voids. Plastic pipe extrusion and plastic tube extrusion fall here. Hollow profiles cut material weight while maintaining structural integrity, making them ideal for cost-sensitive, high-volume applications.

These variations diverge from traditional profile extrusion but share the core melting-and-pushing-through-a-die principle.

● Blown-film extrusion creates thin plastic films and bags. Molten plastic exits a ring-shaped die and gets inflated with air, forming a bubble that cools as it rises. This produces films for packaging, agricultural use, and industrial applications.

● Sheet extrusion produces flat, rigid sheets (think acrylic or polycarbonate sheets for windows or signs). The die is wide and flat, material flows across a large opening, and cooling is handled by rollers rather than water baths.

Profile extrusion handles linear shapes. Sheet and film extrusion serve packaging and protective applications. If your project needs a complex 3D part with multiple undercuts or tight internal geometries, extrusion isn't the answer—injection molding is. But if you need consistent linear profiles in high volume, extrusion beats every alternative on speed and cost.

Plastic extrusion is powerful, but only when executed right. The process, materials, equipment, and manufacturer choice all ripple through your final product's quality, cost, and time-to-market.

You now understand the mechanics—what flows through a die, how machines control precision, and why material selection matters. The next step is picking a partner who can translate that knowledge into real results.

Here's what sticks:

● Extrusion is the fastest and most cost-effective for continuous, linear profiles at volume

● Die design and machine precision directly impact part consistency and defect rates

● Material choice balances performance, cost, and manufacturing feasibility

● Quality manufacturers offer engineering support that optimizes designs before production

● Sourcing from experienced, certified plastic extrusion companies eliminates costly rework

Team MFG brings everything you need under one roof—engineering consultation, advanced plastic extrusion machines, custom die development, and quality systems that catch issues before they reach you.

Whether you're prototyping or scaling to a million units, their expertise across materials, processes, and equipment means your extrusion project ships on time and on budget. No delays. No surprises.

TEAM MFG is a rapid manufacturing company who specializes in ODM and OEM starts in 2017.