Yala i delila k’i yɛrɛ ɲininka cogo min na motɛriw walima furakɛli baarakɛminɛnw bɛ se ka o yɔrɔ tigitigiw sɔrɔ wa? Jaabi bɛ sɔrɔ honing (jatebɔ) la—o ye fɛɛrɛ ye min nafa ka bon kosɛbɛ walasa ka dafalenya sɔrɔ nɛgɛ baara la. Honing jɔyɔrɔ ka bon kosɛbɛ iziniw kɔnɔ i n’a fɔ mobili, aerospace ani furakɛli, a bɛ bonya tigitigiw ni a labancogo ɲuman sabati.

Nin sɛbɛn in kɔnɔ, i bɛna a dɔn honing ye min ye, baarakɛminɛnw bɛ o ko la, ani taabolo bɛ baara kɛ cogo min na.

Honing ye mun ye?

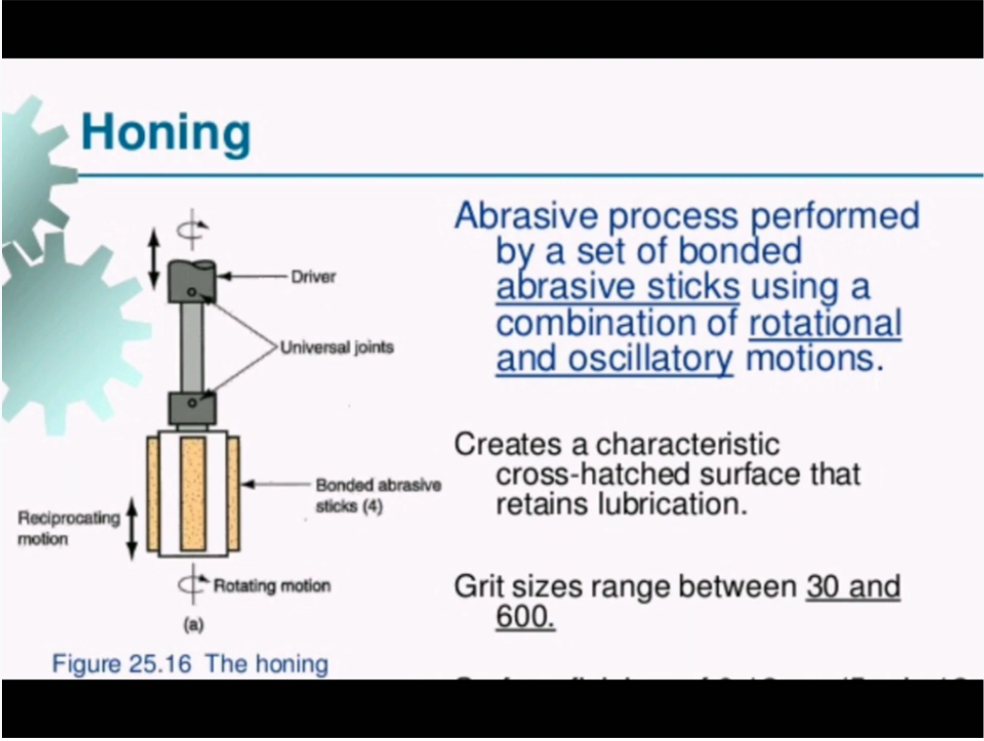

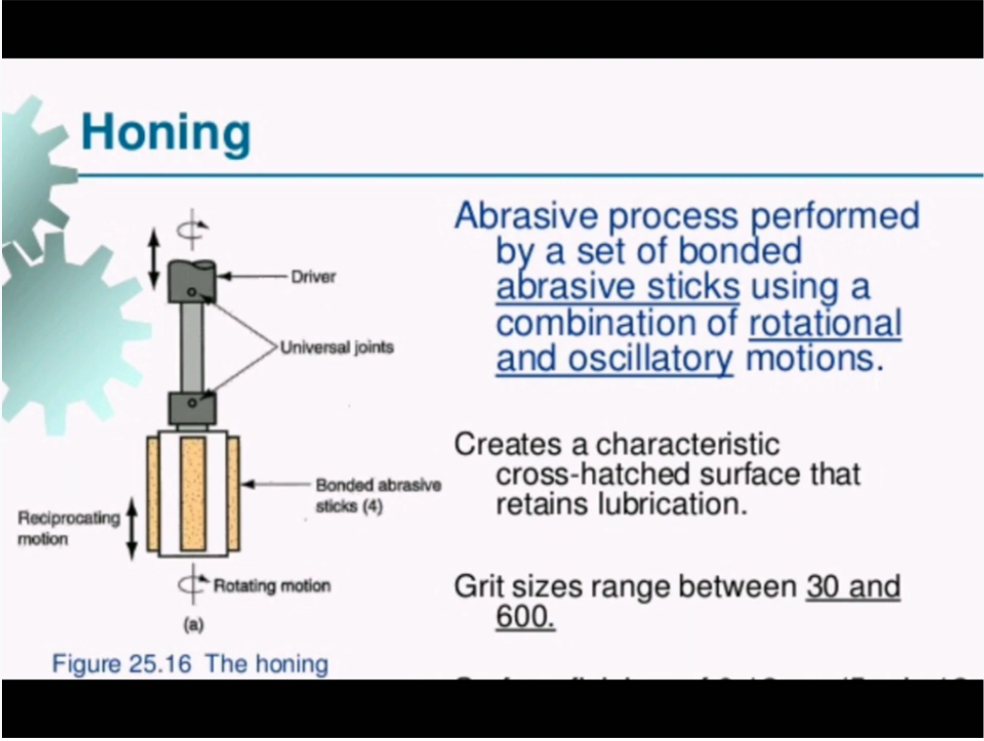

Honing ye machining (masin) ye min bɛ kɛ ni abrasive (abrasive) ye min bɛ surface (yɔrɔ) dafalen dilan baarakɛminɛn kan. A bɛ Fɔ a ma ko wale min bɛ Kɛ ka surface (yɔrɔ) dɔ Labɛn walima k'a Ban ni honing (jirisun) ye walima ni hone (hone) ye.

O kɛcogo ye ka baara kɛ ni kabakurunw ye minnu bɛ kɛ ka fɛnw sɔgɔ, degun kɔrɔsilen na, walasa ka fɛnw bɔ sira kɛrɛnkɛrɛnnen dɔ kan. O bɛ na ni jateminɛcogo ɲuman ye ani baarakɛminɛn in ka surface finishing of the workpiece, o bɛ tali kɛ . CNC Precision Machining Techniques.

Honing ka jogo jɔnjɔnw ye:

A bɛ jateminɛ kɛcogo ɲɛ .

A bɛ surface finish bonya .

A bɛ baara kɛ ni abrasive kabakurunw ye degun na .

A bɛ tugu sira dɔ kɔ min bɛ kɔrɔsi .

Honing bɛ se ka kɛ kɛrɛnkɛrɛnnenya la ka dantigɛli laban di ani ka fini laban cogoya ɲininen dilan tubabukan walima silinda sɔgɔlenw kɔnɔna na. A bɛ sira Di bore geometry (jatebɔ) dafalen ma, a bonya kɔlɔsili, a laban laban fini, ani a ka surface structuring (yɔrɔ labɛncogo).

O baara in ni baarakɛcogo kelenw tɛ kelen ye i n’a fɔ lapping ani superfinishing. Lapping (lapping) bɛ Kɛ ni fɛnɲɛnamafagalanw ye minnu bɛ Kɛ baarakɛminɛn ni baarakɛminɛn cɛ, k’a sɔrɔ superfinishing (superfinishing) bɛ baara Kɛ ni baarakɛminɛn ye min fanga ka bon ni kabakurun walima kasɛti ye walasa ka a sanfɛla Labɛn.

O ni ɲɔgɔn cɛ, honing bɛ a jigi da kabakurunw kan minnu bɛ siri ni sirilan ye minnu bɛ sigi baarakɛminɛn dɔ kan ani ka u kɛ ni degun ni lamaga ye min bɛ kɔrɔsi. O bɛ kɛ sababu ye ka se ka dantigɛli kɛ ka ɲɛ ka ɲɛsin finidoncogo ma ani se ka sɔrɔ ka gɛlɛya sɔrɔ . CNC Machining Tolerances ..

Danfara jɔnjɔn dɔw bɛ Honing ni . CNC jiginni ni a sɔgɔli walima a sɔgɔli ye:

Honing kabakurunw ka nɔgɔn ka tɛmɛ wuluwuluw kan .

Honing bɛ degun dɔgɔya ka tɛmɛ sɔgɔli kan .

Honing Stones yɛrɛ-fini bɛ baara kɛ waati .

Honing bɛ cross-hatch pattern dɔ da .

Mun na honing mago bɛ a la?

Honing ye baara nafamaba ye fɛn dilanni na. A bɛ kɛ ka jateminɛ, bonya, dugukolo sanfɛla, ani dugukolo sanfɛla sigicogo latilen ani k’a dafa.

dilanbagaw bɛ u jigi da honing kan walasa ka se . Tolerances sirilenw ani ka finiw cogoya ɲininenw dilan kɔnɔna yɔrɔw kan minnu bɛ sɔrɔ yɔrɔ suguya caman na. O kɛcogo bɛ dɛmɛ ka fɛn laban ka se ka bɛn, ka baara kɛ cogo bɛnnen na, ani ka baara kɛ ka ɲɛ.

Kun jɔnjɔn dɔw filɛ nin ye minnu b’a to honing ka kan ka kɛ:

correcting bore geometry .

tilennen .

Roundness .

Silindriki .

Achieving precises sizes .

Diamètre Contrôle .

Fasaya

Surɔfɛnw ɲɛnabɔli ɲɛtaa .

Sɔgɔsɔgɔninjɛ .

Modèle cross-hatch .

Surface structure (Sanfɛyɔrɔ) bonya .

Plateau ka finiw .

Tumu marali .

Honing bɛ se ka kɛ fɛn caman na, i n’a fɔ nɛgɛw, seramikiw ani fɛnɲɛnamafagalanw. A bɛ se ka kɛ yɔrɔw kan minnu gɛlɛya hakɛ tɛ kelen ye, k’a ta aliminiyɔmu nɔgɔlen na ka se nɛgɛ gɛlɛn ma.

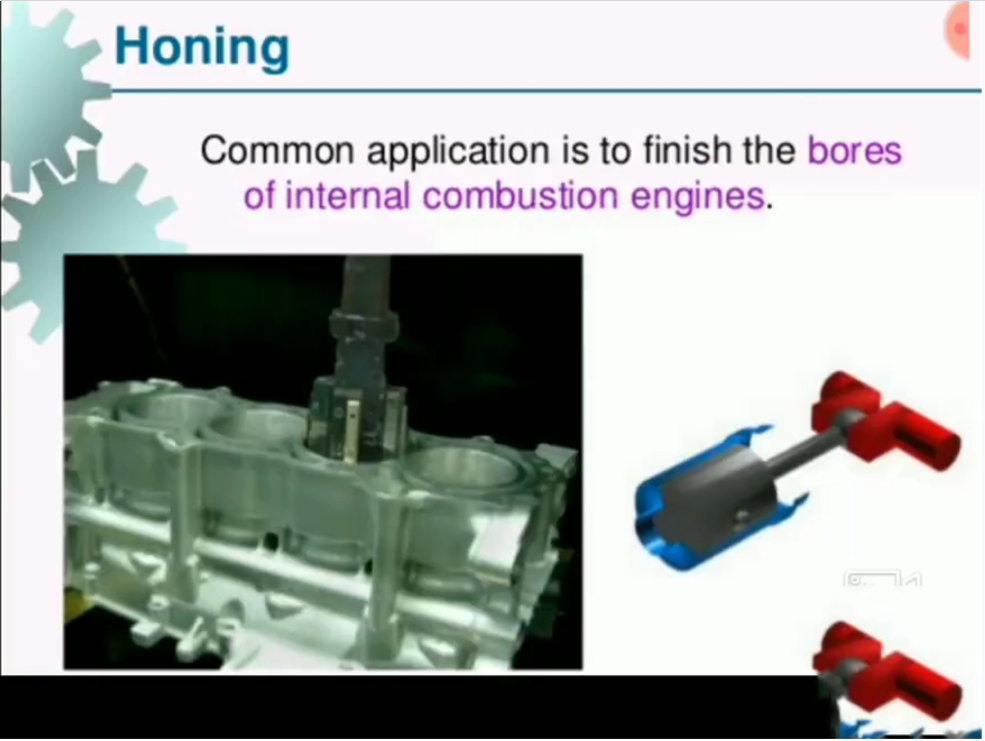

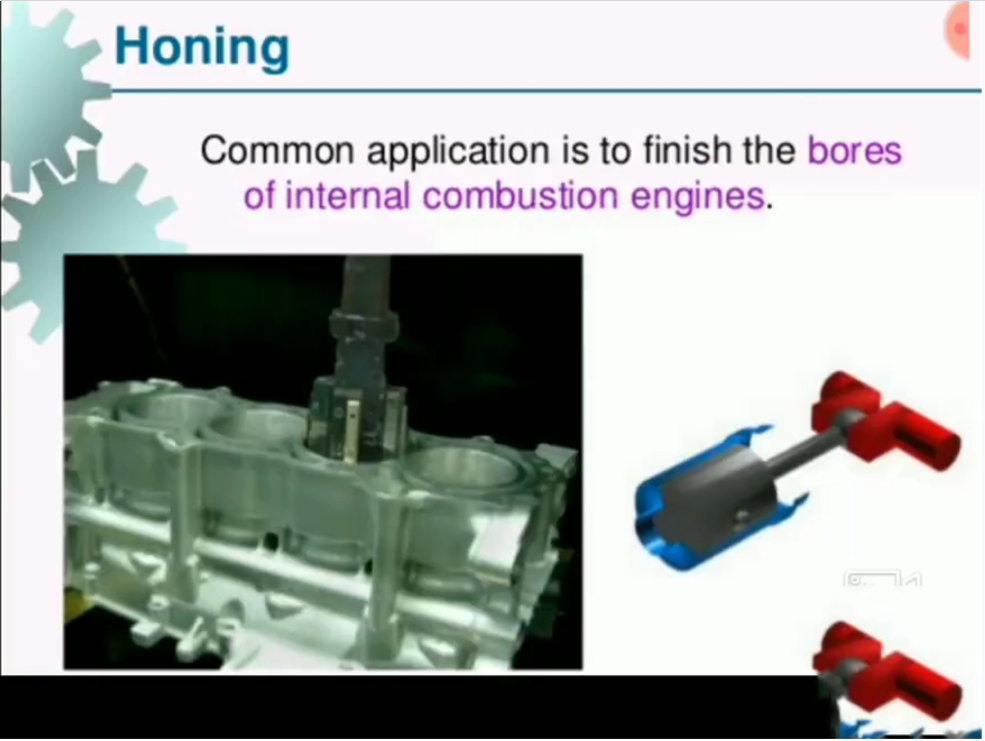

O kɛcogo nafa ka bon kɛrɛnkɛrɛnnenya la silindaw bancogo la motɛriw kɔnɔ, yɔrɔ minnu na jateminɛcogo ɲuman ni a sanfɛla dafalen nafa ka bon kosɛbɛ walasa ka da tugu, ka tulu kɛ, ani ka sɛgɛn. Baara wɛrɛ minnu bɛ kɛ tuma caman na, olu ye jilafɛnw, birikiw, ani girinw ye, kɛrɛnkɛrɛnnenya la . Mobili yɔrɔw ani a yɔrɔw dilanni ..

A ka ca a la, honing bɛ kɛ labanko laban ye walew kɔfɛ i n’a fɔ sɛgɛn, sɔgɔli, walima sɔgɔli. A bɛ dɛmɛ ka sariya tiɲɛni tolenw bɔ yen ani ka surface (yɔrɔ) lase fɛn ɲɛfɔlenw ma minnu b’a fɛ.

Se min bɛ mɔgɔ ye ka muɲuli gɛlɛnw sɔrɔ, o ye nafa jɔnjɔn dɔ ye min bɛ sɔrɔ honing na. Ni bi honing machines ani abrasives, a bɛ se ka tolerances minɛ ka gɛlɛn i n’a fɔ ±0.0001 inch (±0,0025 mm) a cɛmancɛ ni a tilennen kan.

Ka fara tigitigiya kan, honing bɛ se ka surfaces baarakɛcogo fana ɲɛ. Honing ye cross-hatch pattern min da, o bɛ dɛmɛ ka tulumafɛnw mara ani ka sɛgɛnw tila ɲɔgɔn na, o bɛ na ni baara kɛcogo ɲuman ye ani a yɔrɔw ɲɛnamaya janya.

Honing Process Mechanics .

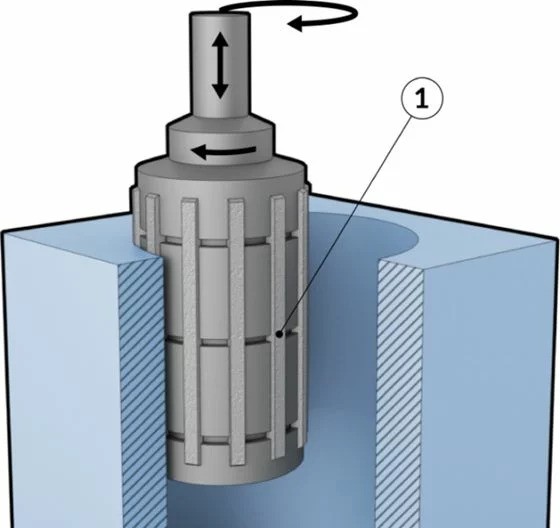

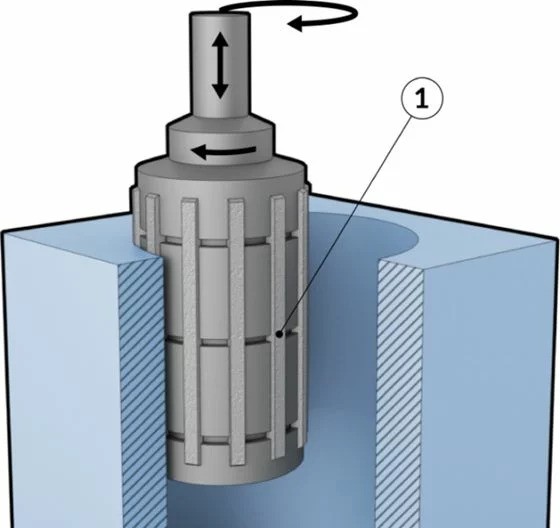

Honing ye masina kɛcogo ye min ɲɔgɔn tɛ. A bɛ danfara Bɔ ni sɔgɔli ye cogo jɔnjɔn damadɔ la. O danfara ninnu faamuyali nafa ka bon kosɛbɛ walasa ka ɲɛtaa ɲumanw sɔrɔ.

O fɛn nafamaba dɔ ye a yɛrɛ-yɛrɛ-yɛrɛ-ko ye. A tɛ i n’a fɔ sɔgɔli, yɔrɔ min na wotoro bɛ tugu sira nɔgɔman dɔ la, kabakurunw bɛ tugu lamaga gɛlɛn dɔ kɔ. O lamaga in bɛ tali Kɛ 'yɔrɔ-yɔrɔ-ko ni 'yɛrɛyɛrɛli fla bɛɛ la, minnu ni dɔw bɛ Taa ɲɔgɔn fɛ . CNC jiginni ni a sɔgɔli baarakɛcogo.

Kabakurunw lamagacogo gɛlɛn bɛ na ni nɔ ye min bɛ se ka kɛ. Kabakurun yɔrɔ kelen-kelen bɛɛ bɛ maga baarakɛminɛn yɔrɔba dɔ la. O bɛ dɛmɛ don hali dafabaliya fɛn o fɛn na kabakurun cogoya la.

O de kosɔn, baarakɛminɛn ni honing kabakurunw bɛɛ bɛ ɲɔgɔn sɔrɔ fo u ka bɛn kabakurun tigɛyɔrɔ cogoya cɛmancɛ ma. O yɛrɛ-tiɲɛni wale in de y’a to honing bɛ se ka tiɲɛni ni bɛnkanba sɔrɔ kosɛbɛ, a ka c’a la, a bɛ tɛmɛ sariya kan . CNC Machining Tolerances ..

O ni ɲɔgɔn cɛ, sɔgɔli tiɲɛni bɛ dan sɔgɔlan cogoya tiɲɛni ma ani masin ka gɛlɛya ma. Tiɲɛni o tiɲɛni bɛ kɛ wotoro kɔnɔ, o bɛna bila baarakɛminɛn na.

Danfaraba wɛrɛ ye sariya labatoli wajibiyalen ye honing machines kɔnɔ. Honing bɛ a jigi da kabakurun ni baarakɛminɛn cɛ. Walasa k’o sɔrɔ, masin ka kan ka sira di sariya labatoli ma walima ka se ka fɛn caman kɛ.

O de y’a to honing machines bɛ baara kɛ ni hydraulique walima pneumatic pressure ye ka kabakurunw kɛ, sanni ka feed chigide mécaniques kɛ i n’a fɔ grinding. O sariya labatoli bɛ sira di kabakurunw ma u ka bɛn baarakɛminɛn ma ani ka ɲɔgɔn sɔrɔ tuma bɛɛ.

Tablo min bɛ duguma, o bɛ danfara jɔnjɔnw lajɛ honing ni grinding cɛ:

| aspect | honing | grinding . |

| Kabakurun lamaga . | complexe (rotation + oscillation) . | Simple (rotation) . |

| Yɛrɛ-yɛrɛ-yɛrɛ-yɛrɛ-ko . | Ɔwɔ, ka tɛmɛ averaging effect fɛ . | Ayi, a bɛ a jigi da wotoroninw ka finidoncogo kan . |

| Fáranfasiya | A bɛ se ka tɛmɛ masin ka tiɲɛni kan . | A dan ye masin ni wotoro tiɲɛni ye . |

| Masina sariya labatoli . | A wajibiyalen don ka kɛɲɛ ni effect ye . | gɛlɛya bɛ bila jɔyɔrɔ fɔlɔ la . |

| Kabakurun baarakɛcogo . | Tansiyɔn min bɛ sɔrɔ ji la walima min bɛ kɛ ni fiɲɛ ye . | Balo mécanique rigide . |

O danfara ninnu bɛ kɛ sababu ye ka ɲɛtaa kɛ wale jɔnjɔn ye san 2019 kɔnɔ. CNC Precision Machining , kɛrɛnkɛrɛnnenya la walasa ka se ka yɔrɔw sɔrɔ minnu ka ɲi kosɛbɛ ani ka muɲuli gɛlɛnw sɔrɔ.

Honing baarakɛminɛnw ni minɛnw .

Honing bɛ baarakɛminɛnw ni minɛnw kɛrɛnkɛrɛnnenw de wajibiya. O yɔrɔ kelen-kelen bɛɛ jɔyɔrɔ ka bon kosɛbɛ o baara in na. An ka fɛn kolomaw lajɛ kosɛbɛ.

Honing Stones .

Honing kabakurunw ye tigɛminɛnw ye. U bɛ Kɛ ni sumanw ye minnu bɛ ɲɔgɔn Dòn. Fɛn minnu ka ca ni fɛn tɔw bɛɛ ye, olu ye diamant ni silicon carbide ye.

Kabakurunw ka grit hakɛ de bɛ surface finish (yɔrɔ dafalen) de latigɛ. Grit minnu ka ɲi, olu bɛ finiw dilan minnu ka nɔgɔn. Grit hakɛw bɛ Bɔ 150 fo 800 ɲɔgɔn na.

Mandrels honing .

Mandreliw bɛ honing kabakurunw minɛ ka u bila. U bɛ dilan ni nɛgɛ walima karɔbɔli ye cogoya la. Mandrel dilancogo bɛ sira di kabakurunw bonya ma ani ka u bila u nɔ na.

Honing Oil .

Tumu min bɛ kɛ ka a sɔgɔ, o bɛ kɛ nɛnɛmadalan ni tulumafɛn fila bɛɛ ye. A bɛ dɛmɛ ka nɔgɔw bɔ a la ani ka kabakurunw bali ka doni ta. Fura kɛrɛnkɛrɛnnenw bɛ tulu ni ko kɛcogo ɲuman di.

Hone Guides ani Guide bushings .

Hone Guides bɛ baarakɛminɛn in labɛn ni bore ye. U bɛ kabakurunw bali ka baarakɛminɛn tiɲɛ don ni bɔ waati la. Guide bushings ye dondaw ye minnu bɛ se ka sɛgɛn, minnu bɛ dɛmɛ ni bilasirali wɛrɛw di.

Cones adjustables .

Cones adjustables bɛ kɛ ka fiyentɔw ka bore honing kɛ. U b’a to kabakurunw ka bonya bore jukɔrɔ. O bɛ kabakurunw sɛgɛncogo musaka bɔ ani ka u bonya kunbɛn.

Tɛmɛsira kelen-kelen bɛɛ lajɛlen ka baarakɛminɛnw .

Tɛmɛsira kelen-kelenw dabɔra ka sɔrɔ ka sɔrɔ teliya la ka bɔ stock la. U bɛ ni mandrel ye min bɛ kɛ ni fɛn dɔ ye, min bɛ kɛ ni fɛn ye min bɛ kɛ ni fɛn ye min bɛ kɛ ni fɛn ye min bɛ kɛ ni fɛn ye min bɛ kɛ ni fɛn ye min bɛ kɛ ni fɛn ye min bɛ kɛ ni fɛn ye min bɛ kɛ ni fɛn ye min bɛ kɛ ni fɛn ye min bɛ kɛ ni fɛn ye min bɛ kɛ ni fɛn ye min bɛ kɛ ni fɛn ye min bɛ kɛ ni fɛn dɔ ye min bɛ kɛ ni fɛn ye min bɛ kɛ ni fɛn ye min bɛ kɛ ni fɛn ye min bɛ kɛ ni fɛn ye min bɛ kɛ ni fɛn ye min bɛ kɛ ni fɛn dɔ ye. Baarakɛminɛn bɛ bonya ka se hakɛ ɲininen ma ani ka bore (boli) kɛ tɛmɛsira kelen na.

Tɛmɛsira kelen-kelen-masinw bɛ nafa caman di:

Flexible design .

Dɔgɔyali waati la .

Honing minɛn nafama wɛrɛw ye:

Nafa minnu bɛ sɔrɔ honing na .

Honing bɛ nafa caman di ka tɛmɛ finidoncogo tɔw kan. O nafaw b’a kɛ baarakɛminɛn nafama ye bi fɛn dilanni na.

Nafa jɔnjɔn dɔ ye a ka se ka tiɲɛniba sɔrɔ. Honing bɛ se ka bore geometries (jatebɔ bore) bɔ ni a laminiko ye min tɛ ɲɔgɔn ta ye, a bɛ tilennen, ani a bonya cogoya. A bɛ se ka minɛ . Tolerances ka gɛlɛn i n’a fɔ ±0,0001 inch (±0,0025 mm).

Nafa wɛrɛ ye a seko ye ka Bore cɛmancɛ-yɔrɔ fɔlɔ mara. Honing Stones ka yɛrɛdɔn wale bɛ a to baarakɛminɛn ka tugu bore axis kɔrɔ la. O bɛ kɛ sababu ye ka bɛnkan walima ka ban.

Honing fana bɛ se ka kɛ fɛn caman ye. A bɛ se ka kɛ fɛn caman na, k’a ta nɛgɛ nɔgɔlenw na i n’a fɔ aliminiyɔmu fo ka se seramiki gɛlɛnw ni karibiw ma. O kɛcogo bɛ se ka yɔrɔw ɲɛnabɔ ni gɛlɛya hakɛ tɛ kelen ye, i n’a fɔ fɛnw minnu bɛ gɛlɛya ni funteni ye ani minnu furakɛra ni funteni ye.

Honing process (fɔli kɛcogo) bɛ kɛ sababu ye ka baarakɛminɛn in ka chucking (sɔgɔli) walima ka a sɔrɔ. Baarakɛminɛn in bɛ ɲɛminɛ bore yɛrɛ fɛ, o la, farati tɛ filiw la ka bɔ fixturing na. O bɛ sigicogo nɔgɔya ani ka dɔ bɔ fɛn tiɲɛnenw na.

Honing bɛ surface pattern crosshatched (yɔrɔ min ɲɔgɔn tɛ) Dabɔ. O cogoya in bɛ Sɔrɔ kabakuruw ka 'yɔrɔ-yɔrɔ-ko ni 'yɛrɛyɛrɛli lamaga-lamagaliw 'cɛ. O yɔrɔ min bɛ sɔrɔ o la, o bɛ ni tulu marali ɲuman ye ani tulumafɛnw.

Crosshatched pattern fana bɛ dɛmɛ ka wears tila ɲɔgɔn na ani ka cɛnimusoya yɔrɔw ɲɛnamaya janya. O nafa ka bon kɛrɛnkɛrɛnnenya la baarakɛcogo la i n’a fɔ . Motɛri silindaw , yɔrɔ min na pisini bololanɛgɛw ka kan ka sigi ka ɲɛsin bore surface ma.

Honing masinw ka nɔgɔn kosɛbɛ ani u bɛ se ka ladamu. u ka kapitali musaka ka dɔgɔ ni tɔw ye . Precision finishing processus . Baarakɛminɛnw fana sɔngɔ man gɛlɛn wa u bɛ se ka ladilan nɔgɔya la ka kɛɲɛ ni bore hakɛw ni u cogoya wɛrɛw ye.

Nin ye nafa wɛrɛw ye minnu bɛ sɔrɔ honing na:

Surface Finish (Sɔrɔdasi) ɲɛtaa .

Baarakɛminɛn doncogo dɔgɔyara .

dɔ farala sɛnɛfɛnw bɔli hakɛ kan .

Seko ni dɔnko wajibiyalenw dɔgɔyali .

Laminiko siratigɛ la (a bɛ baara kɛ ni ji-nɛnɛ-minɛnw ye minnu bɛ sɔrɔ ji la) .

Dantigɛliw kɛli ka ɲɛsin honing ma .

Hali ni honing bɛ nafa caman di, a bɛ na ni dan damadɔw ye minnu ka kan ka jateminɛ.

Processus dɔɔnin dɔɔnin .

honing ka nafa minnu ka ca kosɛbɛ , olu dɔ ye a taabolo ye min bɛ kɛ dɔɔnin dɔɔnin . Ni i y’a suma ni masin-fɛɛrɛ tɔw ye, a bɛ fɛnw Bɔ a la dɔɔnin dɔɔnin. O bɛ se ka kɛ nafa ye min bɛ sɔrɔ fɛn caman sɔrɔli la, teliya nafa ka bon yɔrɔ min na. Nka, ɲɛtaa minnu kɛra fɛɛrɛko la, i n’a fɔ kabakurunw ni masinw ɲɛnabɔli, olu ye jiginni waatiw dɔgɔya, o kɛra sababu ye ka baara kɛcogo teliya ka tɛmɛ fɔlɔ kan.

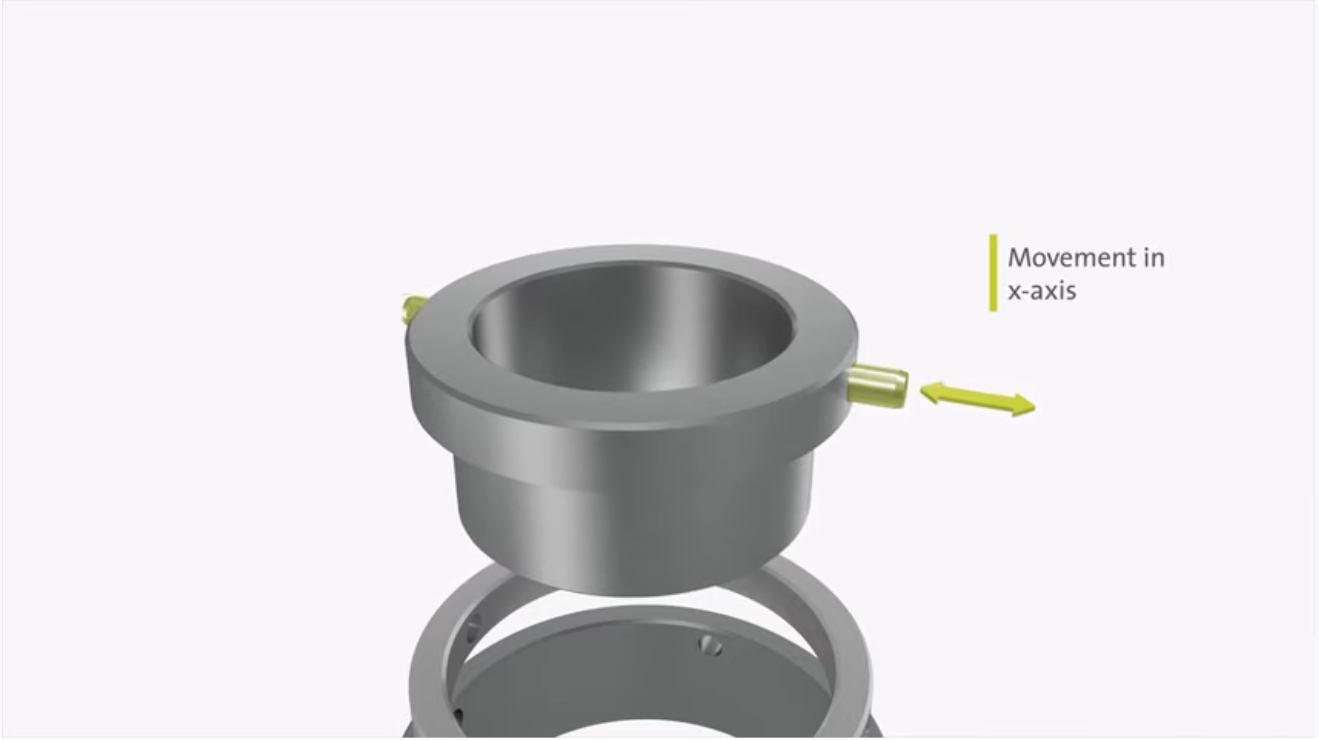

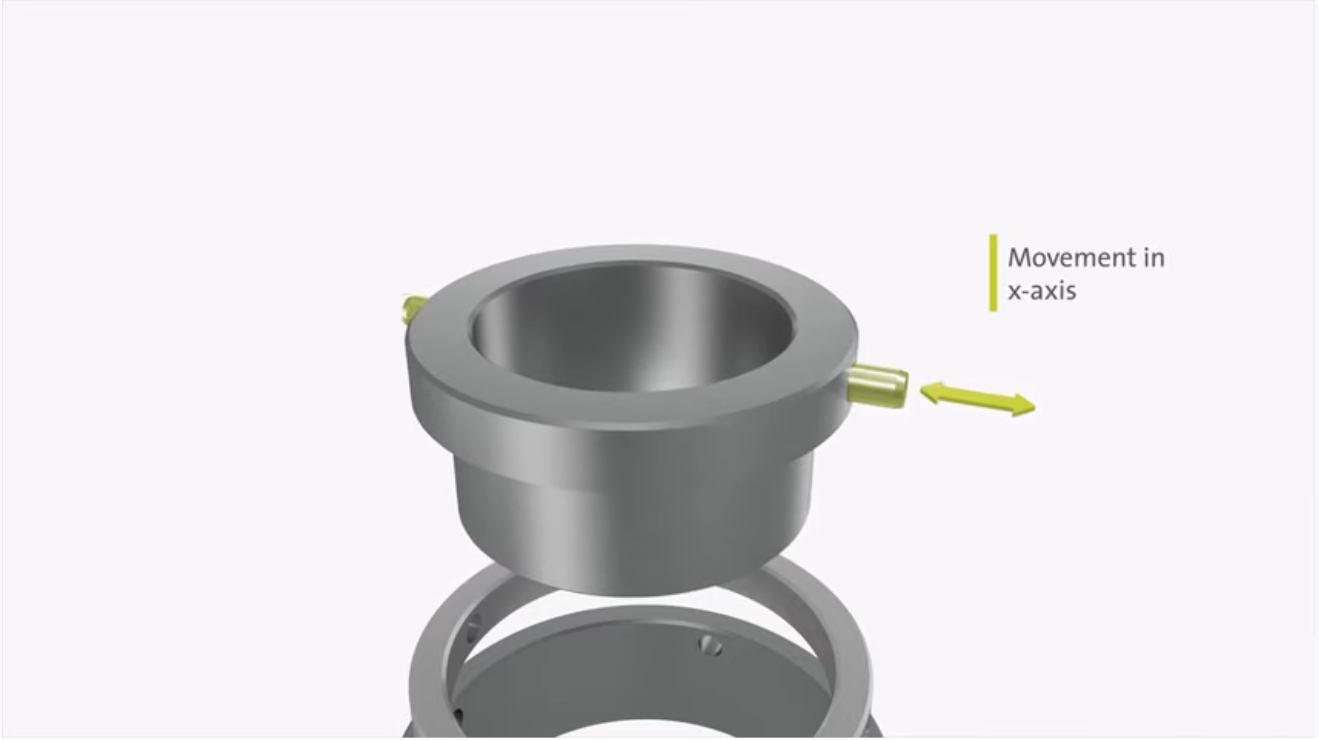

Se bɛ oval dingɛw ye horizontal honing kɔnɔ .

Dan wɛrɛ bɛ kɛ horiing horining kɔnɔ , kɛrɛnkɛrɛnnenya la ni baara bɛ kɛ ni baarakɛminɛnw ye minnu ka fin walima minnu tɛ dɛmɛ sɔrɔ. Ni a yɔrɔ ma dɛmɛ ka ɲɛ walima ni a ma wuli ka ɲɛ o baara senfɛ, farati bɛ yen ka dingɛw dilan minnu bɛ i n’a fɔ oval . O bɛ se ka nɔ bila yɔrɔ laban in tiɲɛni na. Baarakɛminɛn dɛmɛcogo ɲuman walima a jiginni bɛ se ka dɛmɛ don ka o farati dɔgɔya ani ka a lajɛ ko bore bɛ to a lamini na.

Dantigɛliba minnu bɛ kɛ honing kan:

Taabolo sumayalen, hali ni a bɛ ɲɛtaa sɔrɔ ni fɛɛrɛ kuraw ye.

farati bɛ oval dingɛw la horizontal honing kɔnɔ ni dɛmɛ bɛrɛ tɛ.

Honing ka baarakɛcogo .

Honing bɛ kɛ ka caya izini suguya caman kɔnɔ, u kelen-kelen bɛɛ bɛ nafa sɔrɔ a bɛ min di tigitigi ani a bɛ kɛ cogo min na. Nin ye baarakɛminɛn jɔnjɔn dɔw lajɛ ye.

Mobili industrie .

la Mobiliko , honing nafa ka bon kosɛbɛ motɛri yɔrɔw la minnu bɛ kɛ ni masinw ye. A bɛ kɛ ka motɛri silindaw ni mansinw ban, k’a jira ko u bɛ muɲuli sirilenw dafa minnu ka kan ka kɛ walasa ka baara kɛ ka ɲɛ. O kɛcogo bɛ bore geometry ni surface finish ɲɛ, o min nafa ka bon kosɛbɛ yɔrɔw la i n’a fɔ piston rings walasa ka sigilan ɲuman dilan silindaw kɔnɔ.

Motɛri silindaw : Honing bɛ crosshatched pattern dɔ dilan min bɛ dɛmɛ ka tulu ni tulu mara motɛri silindaw la.

Crankshafts : Taabolo bɛ tilennen ni lamini, min nafa ka bon kosɛbɛ mansinw ka baara la.

Aerospace industrie .

Aerospace industry bɛ a jigi da fɛnw dilanni n’u ladonni bɛɛ kan. Motɛri yɔrɔw, birikiw ani fɛnw sirilanw bɛ muɲuli gɛlɛnw de wajibiya, minnu bɛ se ka kɛ fɛn ye minnu bɛ se ka kɛ. O kɛcogo tɛ kɛ dɔrɔn ka o yɔrɔw ban, nka a bɛ kɛ fana ladonni kɛcogo kɔrɔ la walasa motɛri yɔrɔw ka lakana ni baarakɛcogo sariyaw dafa.

Mold Making: Moule sur les plus précités sur les surfaces .

kɔnɔ Mold Making , honing bɛ kɛ ka nɔgɔ yɔrɔw tiɲɛni n’u kɛcogo ɲɛ. Nɔgɔw bɛ yɔrɔ minnu na minnu ka nɔgɔn kosɛbɛ ani minnu bɛ kɛ ka ɲɛ walasa a yɔrɔ labanw ka kɛ fiɲɛ tɛ minnu na. Honing bɛ dɛmɛ ka surface quality wajibiyalen sɔrɔ, o bɛ na ni a yɔrɔ ɲuman ni a cogoya ɲuman ye.

Dɔgɔtɔrɔso baarakɛlaw: Opereli minɛnw ni u doncogo .

Dɔgɔtɔrɔso baarakɛlaw bɛ bɔ opereli minɛnw ni fɛnw doncogo la minnu bɛ muɲuli wajibiyalenw dafa. Tiɲɛni nafa ka bon furakɛli minɛnw na, hali ni fɛn fitinin minnu bɛ se ka kɛ, olu bɛ se ka nɔ bila baarakɛcogo ni lakana la. Honing bɛ dɛmɛ don walasa opereli minɛnw ni fɛnw doncogo ka ɲɛ, ka tiɲɛ, ani ka sariyaw labato.

Opereli minɛnw : A bɛ se ka kɛ sababu ye ka fɛnw kɛ ka ɲɛ, o bɛ a to minɛnw kana kɛ ni buruw ni fiɲɛw ye, ka baara kɛcogo ɲɛ.

Implants : honing bɛ surface finishes tigitigiw dilan, minnu nafa ka bon kosɛbɛ walasa ka fɛnw don ɲɔgɔn na ka ɲɛ ni farikolo ye.

Baara kɛcogo ni honing ye fɛn dilanni na .

Honing ye fɛɛrɛ ye min bɛ kɛ fɛn caman na, min bɛ kɛ ka fɛn dilanni kɛ walasa ka se ka fɛnw sɔrɔ minnu ka ɲi kosɛbɛ ani minnu bɛ kɛ ka ɲɛ. Fɛɛrɛw bɛ yen minnu bɛ kɛ ka ɲɛsin mɔgɔw ma, ka kɛɲɛ ni baara in bonya n’a gɛlɛya ye.

Masina Honing baarakɛcogo .

kɔnɔ Machine Honing , o baara bɛ ɲɛnabɔ CNC (ɔridinatɛri jatebɔcogo) fɛɛrɛw fɛ, o b’a to a ka ɲi kosɛbɛ baarakɛcogo ɲuman ni otomatiki la . CNC bɛ bɛnkan ni tiɲɛni sabati, ni hadamadenw ka dɛmɛ fitinin ye. Nin fɛɛrɛ in bɛ kɛ ka caya masɔrɔli la, yɔrɔ min na muɲuli sirilenw ni jateminɛ minnu bɛ se ka segin-ka-bɔ.

CNC-Controlled Process : Masina bɛ honing stone lamagacogo ɲɛnabɔ tigitigi, ka bore hakɛ tigitigiw sabati.

Kɔrɔlenkoba : A bɛnnen don iziniw ma i n’a fɔ aerospace ani mobili, yɔrɔ min na tigitigi ye ko kɔrɔba ye.

Manuel honing operation .

Walasa ka baara kɛ ni baarakɛminɛn fitininw ye walima baara kɛrɛnkɛrɛnnenw kama, bololabaara bɛ kɛ. Yan, baarakɛla bɛ honing baarakɛminɛn ɲɛnabɔ, k’a lamaga baarakɛminɛn kan ni bolo ye. O fɛɛrɛ in bɛ se ka sɛgɛsɛgɛ ka ɲɛ nka a bɛ a jigi da masinw ka seko kan. Bololabaara bɛ kɛ ka caya yɔrɔ kelen walima baara minnu na, otomatiki tɛ se ka kɛ yɔrɔ minnu na.

Operator-Controlled Process : Machiniste bɛ honing baarakɛminɛn ɲɛminɛ walasa ka surface finishing ɲininen dilan.

A bɛnnen don baara kɛrɛnkɛrɛnnenw ma : a ka ɲi kosɛbɛ fɛn dilanni na walima a yɔrɔw la ni jateminɛ gɛlɛnw ye.

Honing Tools and Equipment ɲumanw sugandili .

ɲuman sugandili Honing tools ni minɛnw nafa ka bon walasa ka ɲɛtaa ɲumanw sɔrɔ. O ye ka honing kabakurunw, abrasives ani machine suguya sugandi. Fɛn minnu bɛ kɛ i n’a fɔ fɛnw gɛlɛya , u bonya hakɛ, ani u ka kan ka kɛ cogo min na, olu ka kan ka jateminɛ ni u bɛ baarakɛminɛn ɲumanw ta.

Honing masinw sigili ani u baaracogo .

Setup ɲuman nafa ka bon walasa ka honing machine baara kɛ ka ɲɛ. O ye ka baarakɛminɛn in ni baarakɛminɛn in ɲɔgɔnna labɛn ani k’a lajɛ ko a yɔrɔw bɛɛ bɛ sigi ka ɲɛ. Kalibreli nafa ka bon walasa ka tiɲɛni kɛ opereli bɛɛ la.

Jogoɲumanya kɔlɔsili ani yɔrɔw sɛgɛsɛgɛli .

Honing kɔfɛ, jogoɲini ka kan ka kɛ walasa ka yɔrɔ labanw sɛgɛsɛgɛ. O ye ka bore diamètre, roundness , ani surface finish suman walasa u ka to ka muɲuli kɛrɛnkɛrɛnnenw sɔrɔ. Baarakɛminɛn minnu bɛ Kɛ i n’a fɔ bore gauges ani profilometers (porofilomɛtiriw) olu bɛ Kɛ ka sɛgɛsɛgɛli Kɛ.

Honing vs. lapping: danfara jɔnjɔnw .

Honing ni lapping fila bɛɛ bɛ kɛ ka surface finiw ɲɛ, nka u bɛ danfaraba don u ka baarakɛcogo n’u kɔlɔlɔw la. An ka danfara jɔnjɔnw sɛgɛsɛgɛ nin fila ninnu cɛ . Masini kɛcogo ɲuman ..

Baarakɛcogo cogoya .

Honing , abrasive kabakurunw bɛ kɛ ka fɛnw bɔ ka sɔrɔ baarakɛminɛn bɛ sira gɛlɛn dɔ fɛ. O jiginni ni ɲɔgɔn falen-falen faralen ɲɔgɔn kan , o bɛ kɛ sababu ye ka yɔrɔ basigilen sɔrɔ. Lapping , fan dɔ fɛ, a bɛ baara kɛ ni fɛnɲɛnamafagalanw ye minnu bɛ kɛ ka fɛnw sɔgɔ, minnu bɛ kɛ ka u kɛ yɔrɔ ye min bɛ kɛ ni fɛn dɔ ye walima min bɛ kɛ ni fɛnw ye. Sɔgɔsɔgɔninjɛ bɛ sɔgɔ baarakɛminɛn ni lapping baarakɛminɛn cɛ, ka surface fini finman dɔ dilan.

Honing : A bɛ baara kɛ ni abrasive kabakurunw ye, ka taa sira kɛrɛnkɛrɛnnenw na, a ka c’a la, silinda yɔrɔw la.

Lapping : A bɛ kɛ ni sɔgɔsɔgɔninjɛ ye ani a bɛ baara kɛ ka ɲɛ yɔrɔw la minnu bɛ kɛ fla ye walima minnu bɛ kɛ ni fɛnw ye.

Materiel hakɛ min bɔra .

Honing ye stock removal process ye , min bɛ se ka fɛn hakɛ fitininw bɔ nka a nafa ka bon, o b’a to a ka ɲi ka bore hakɛ ni a cogoya ladilan. Lapping bɛ fɛn dɔ bɔ min ka ɲi kosɛbɛ, tuma caman na, a bɛ kɛ ka dugukolo kan dafabaliya latilen k’a sɔrɔ a ma fɛn caman sɛmɛntiya yɔrɔ jateminɛcogo la.

Honing : A bɛ fɛn caman bɔ, a dafalen don ka ɲɛsin bore correction ma.

Lapping : A bɛ fɛn caman bɔ, a ka c’a la, a tɛ mikromɛtiri damadɔw bɔ.

Tiɲɛni ni seko ni dɔnko ka se ka kɛ sababu ye ka fili kura don .

Hali ni honing bɛ tiɲɛ kosɛbɛ, a ka baara kɛli ni jiginni ye, o bɛ se ka oval shapes don tuma dɔw la ni a ma kɔlɔsi ka ɲɛ, kɛrɛnkɛrɛnnenya la honing horizoning kɔnɔ. O ni lapping tɛ kelen ye, a ka c’a la, lapping bɛ kɛ ka ɲɛ, kɛrɛnkɛrɛnnenya la yɔrɔ fitininw na, k’a sababu kɛ a kɛcogo nɔgɔman ye ani baarakɛyɔrɔ fla. Nka, lapping tɛ se ka jateminɛ fili nafamaw latilen.

Honing : Tiɲɛ don nka a bɛ se ka siginiden misɛnw don dɔw la ko dɔw la.

Lapping : A bɛ tiɲɛ kosɛbɛ yɔrɔ misɛnninw na, ni farati tɛ fiɲɛ kuraw la.

baarakɛcogo fɛɛrɛw ni baarakɛlaw ka seko wajibiyalenw .

Honing ye caman na automatique ye , ni CNC masinw bɛ baarakɛminɛnw sira gɛlɛnw minɛ. O b’a To a kɛli ka nɔgɔn, hali n’a bɛ baarakɛlaw ka seko dɔw de Лini hali bì. Lapping bɛ baara caman kɛ wa a bɛ baarakɛlaw ka seko caman de wajibiya walasa ka surface quality ɲininen sɔrɔ, kɛrɛnkɛrɛnnenya la bololabaara la.

Honing : A ka c’a la, CNC-contrôlée, min bɛ bolo doncogo dɔgɔya, o bɛ tali kɛ tɔw la . CNC jiginni ni a sɔgɔli baarakɛcogo.

Lapping : Bololabaara, ka baarakɛlaw ɲini minnu bɛ se kosɛbɛ walasa ka ɲɛtaa tigitigi sɔrɔ.

Danfaraba minnu bɛ danfaraba la:

| Criteria | Honing | Lapping . |

| Baarakɛcogo cogoya . | Kabakurun minnu bɛ sɔgɔ ni baarakɛminɛnw ye . | Abrasive slurry ni baarakɛminɛn fla . |

| Materiel hakɛ min bɔra . | Ka bɛrɛbɛn | Minimuma . |

| Fáranfasiya | A ka bon, nka a farati ka bon ovalité . | A ka bon kosɛbɛ, kɛrɛnkɛrɛnnenya la flatiw kan . |

| Baarakɛla ka seko wajibiyalenw . | Ka bɛrɛbɛn | Jamanjan |

Kuncɛli

Honing nafa ka bon kosɛbɛ fɛn dilanni na , min bɛ tiɲɛni caman kɛ ani ka finiw don minnu bɛ kɛ ka ɲɛ izini caman kɔnɔ. I mana baara kɛ mobili, aerospace, walima furakɛli yɔrɔw la, honing bɛ se ka baara kɛcogo n’a yɔrɔw janya. Aw ye aw ka porozɛ nata jateminɛ walasa ka ɲɛtaa ɲuman sɔrɔ. Walasa ka ɲɛfɔli kɛ dɔnnikɛlaw fɛ, aw bɛ taa dɔgɔtɔrɔso la min bɛ fɛnw sɛgɛsɛgɛ walasa ka sɔrɔ ɲumanw sɔrɔ aw ka ɲininiw na.

Yala aw bɛ ka machining tigitigi ɲini ani ka ban aw ka porozew kama wa? Team MFG bɛ dingɛw dilanni ni dugukolo furakɛli baara caman di, i n’a fɔ sɔgɔli, sɛgɛn, sɔgɔli, sɛgɛsɛgɛli, sɔgɔli, ani honing. Aw bɛna surface machine yɔrɔw ni prototypes ɲininenw sɔrɔ cogo la min musaka ka dɔgɔ ani min bɛ teliya.