Improving prodakt layfspan wit durable ABS plastic mold komponents

Di we aw yu de si di pikchɔ dɛn: 0

Aks fɔ aks kwɛstyɔn dɛn .

Insay tide in kɔmpitishɔn makɛt, di durabiliti ɛn lɔng layf fɔ wan prɔdak de ple impɔtant pat pan kɔshɔma satisfay ɛn brand reputeshɔn. Di kɔstɔma dɛn de ɛkspɛkt mɔ ɛn mɔ di prɔdak dɛn we nɔto jɔs de du fayn bɔt dɛn de tinap fɔ di tɛst fɔ tɛm we dɛn de yuz dɛn ɔltɛm. Insay dis kɔntɛks, di we aw dɛn pik di tin dɛn we dɛn yuz na di men tin. ABS plastic, we dɛn sabi fɔ in taf ɛn versatility, dɔn kɔmɔt as prɛferɛd matirial fɔ di manifakta dɛn we de aim fɔ impɔtant prɔdak layfspan we dɛn de balans di kɔst ɛn pefɔmɛns.

ABS Plastic in yon kɔmbaynshɔn fɔ mɛkanikal trɛnk, impak rɛsistɛns, ɛn envayrɔmɛnt resiliɛns de mek am wan fayn kandidet fɔ mold kɔmpɔnɛnt dɛn we nid fɔ de fɔ lɔng tɛm.

Mekanikal trɛnk ɛn impak rɛsistɛns .

Wan pan di fɔs rizin dɛn . ABS plastic na favoured fɔ durable molded komponent na in impreshɔnal mɛkanikal trɛnk ɛn impak resistans. ABS na wan tranga tɛmplastik polima we de absɔb ɛn sheb shɔk fayn fayn wan we i nɔ krak ɔ brok. Dis prɔpati impɔtant mɔ fɔ di prɔdak dɛn we dɛn kin yuz ɔltɛm fɔ handle, aksidɛntal drɔp, ɔ mɛkanikal strɛs.

We dɛn mol am kɔrɛkt wan, ABS kɔmpɔnɛnt dɛn de mentɛn strɔkchɔral intɛgriti ivin ɔnda ripit impak ɛn fleks. Dis de mek am fayn fɔ aplikeshɔn dɛn lɛk tul haus, protɛktiv gia, ɛn ɔtomotiv intɛriɔ pat dɛn, usay resiliɛns to fizikal fɔs impɔtant. Di polimכr in tכf de ridyus di lεk fכ fraktכs εn fεl we כda we go sכt di prodak in yusabl layf.

Apat frɔm di raw impak rɛsistɛns, ABS in abiliti fɔ mentɛn shep ɛn trɛnk ɔnda strɛs de kɔntribyut to prodak rilaybiliti. Komponent dɛn we dɛn mol frɔm ABS de agens difɔmeshɔn ɛn wɔp, we de mek shɔ se mɛkanikal asɛmbli dɛn kɔntinyu fɔ fit ɛn wok fayn fayn wan as tɛm de go. Dis strɔkchɔral stebiliti impɔtant fɔ prɔdak dɛn we nid prɛsishɔn ɛn kɔnsistɛns pefɔmɛns.

Resistance to Daily Wear .

Durability nɔto jɔs fɔ witstand shɔk; I involv bak fɔ tinap agens di smɔl smɔl wear ɛn tear prodakt ɛkspiriɛns tru ɛvride yus. ABS plastic de sho fayn fayn tin dɛn we de mek pɔsin nɔ ebul fɔ gɛt kemikal ɛn abrashɔn, tu men tin dɛn we de mek di tin dɛn we dɛn de yuz fɔ mek tin dɛn, de pwɛl as tɛm de go.

Insay bɔku say dɛn we pipul dɛn kin yuz ɛn industri, di tin dɛn we dɛn dɔn mol kin kam nia di tin dɛn we dɛn kin yuz fɔ klin, ɔyl, ɔ ɔda kemikal dɛn we go mek dɛn nɔ gɛt bɛtɛ plastic. ABS in kemikal resistans de ɛp fɔ mek di sɔfa we i de pwɛl na di wɔl, di we aw i de chenj in kɔlɔ, ɛn di we aw i de lɔs di mɛkanikal prɔpati dɛn. Dis de mek shɔ se di prɔdak dɛn de kip dɛn apia ɛn di wok we dɛn de du fɔ lɔng tɛm.

Dɔn bak, ABS de sho se i strɔng fɔ tinap tranga wan we di tɛmpracha chenj ɛn di we aw i de wet. Prodakt dɛn we gɛt difrɛn klaymat ɔ indo/ɔda kɔndishɔn dɛn de bɛnifit frɔm ABS in ebul fɔ kip di pefɔmɛns pan ɔl we di humidity chenj ɔ di tɛmpracha sayklis. Nɔ lɛk sɔm plastic dɛn we kin brit insay kol ɔ sof insay ɔt, ABS kin stil stebul insay wan brayt tɛmpracha rɛnj, we kin mek di risk fɔ krak ɔ distɔrshɔn nɔ bɔku.

Abrasion resistance de ple wan rol bak fɔ kip di prɔdak layfspan, mɔ fɔ kɔmpɔnɛnt dɛn we de ɔnda frikshɔn ɔ kɔntakt wit rɔf sɔfays. ABS de bia wit skrach ɛn sɔfayz wear bɛtɛ pas bɔku kɔmpitin matirial, kip ɔl tu di kɔmpɔnɛnt in luk ɛn trɛnk. Dis de mek ABS bi smat choice fɔ pat dɛn lɛk ilɛktronik divays haus, ɔtomotiv trim, ɛn industrial kes.

Ɛgzampul dɛn fɔ di ABS prɔdak dɛn we de las fɔ lɔng tɛm .

ABS plastic in durabiliti dɔn pruv akɔdin to bɔku bɔku industri ɛn aplikeshɔn dɛn. Tul haus fɔ pawa drɔl ɛn gadin ikwipmɛnt dɛn kin mek am bɔku tɛm frɔm ABS, as di matirial kin absɔb shɔk frɔm drɔp ɛn rɔf hanlin we dɛn de protɛkt intanɛnt kɔmpɔnɛnt dɛn.

Insay ilɛktroniks, ABS na kɔmɔn tin fɔ pik fɔ shel ɛn kɔmpawnd dɛn we de protɛkt dilikayt sɛrkyut bɔd ɛn displei dɛn. Dɛn komponent ya nid fɔ tranga fɔ bia wit ɛvride transpɔt, yuz, ɛn wan wan tɛm impak. ABS in resistans to kemikal ɛn tɛmpracha strɛs de mek shɔ bak se di ilɛktroniks de protɛkt frɔm di envayrɔmɛnt damej.

Otomotiv intɛriɔ pat dɛn lɛk dashbɔd panɛl, trim pis, ɛn kɔnsol haus dɛn de bɛnifit frɔm ABS in trɛnk ɛn aesthetic kwaliti dɛn. Dɛn komponent ya fɔ bia wit di tɛmpracha chenj, UV we dɛn de ɛkspos, ɛn kɔntakt ɔltɛm we nɔ go krak ɔ we de fade.

Insay industrial sɛtin, dɛn de yuz ABS fɔ protɛktiv gia ɛn mashin kɔmpɔnɛnt dɛn we de aks fɔ lɔng savis de liv ɔnda harsh kɔndishɔn. I kɔmbaynshɔn fɔ mɛkanikal trɛnk ɛn envayrɔmɛnt resiliɛns de ɛp fɔ mek di prɔdak intɛgriti, ridyus di mentenɛns ɛn riplesmɛnt kɔst.

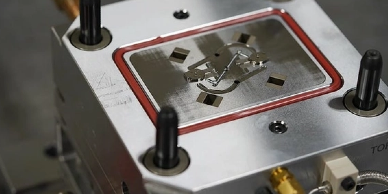

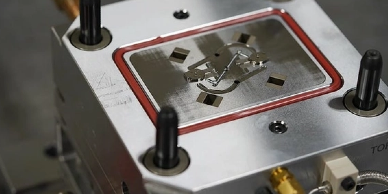

Disain fɔ durabiliti wit injɛkshɔn moldin yuz ABS plastic

Injɛkshɔn moldin tinap as di prɛferɛd manufakchurin we fɔ prodyuz durable ABS plastic kɔmpɔnɛnt dɛn, mɔ we ay pefɔmɛns ɛn lɔng layf impɔtant. Dis prɔses de gi di manifakta dɛn ɛksɛpshɔn kɔntrol oba pat dizayn ɛn prodakshɔn paramita dɛn, we de alaw dɛn fɔ ɔptimayz di trɛnk ɛn durabiliti fɔ ABS mold pat dɛn we dɛn de minimiz west ɛn kɔst.

Wan pan di men bɛnifit dɛn we pɔsin kin gɛt we i de mold injɛkshɔn . ABS plastic na di abiliti fɔ intagret spɛshal dizayn ficha dɛn we de ɛp fɔ mek mɛkanikal pefɔmɛns ɛn fɔ mek dɛn nɔ wear. Fɔ ɛgzampul, rib dɛn—tin, rayz sɛkshɔn dɛn we dɛn put insay di pat—saba fɔ mek dɛn stiff mɔ ɛn nɔ ad bɔku bɔku wet. Bay we dɛn de put rib dɛn stratejik wan na eria dɛn we kin mek dɛn bɛn ɔ fleks, di wan dɛn we de mek dɛn kin rili ɛp fɔ mek di strɔkchɔ intɛgriti fɔ di ABS kɔmpɔnɛnt dɛn, ɛp dɛn fɔ bia wit di we aw dɛn de yuz dɛn ɔltɛm ɛn di fɔs dɛn we de na do we dɛn nɔ krak ɔ wɔp dɛn.

Semweso, di bɔs dɛn—smɔl silindrikal protrushɔn dɛn we dɛn kin yuz as mawntin pɔynt ɔ fɔ skru insay—dɛn kin mol dɛn dairekt insay ABS pat dɛn. Dɛn ficha dɛn ya de gi strɔng kɔnɛkshɔn pɔynt dɛn, fɔ mek shɔ se dɛn gɛt sikyɔriti asɛmbli we dɛn de mek dɛn nɔ gɛt strɛs kɔnsɛntreshɔn we ɔda we go mek dɛn pwɛl we dɛn de wok. Gussets, triangular reinforcements at junctions, de ɛp bak fɔ sheb lod ivin, mɔ strɔng vulnerable sɛkshɔn dɛn na di molded kɔmpɔnɛnt. Di tek tɛm intagreshɔn fɔ rib, bɔs, ɛn gusset dɛn we dɛn de du di injɛkshɔn moldin prɔses de mek shɔ se ABS plastic pat dɛn de mentɛn dɛn shep ɛn funkshɔnaliti ɔnda diman kɔndishɔn, we de rili ɛkstɛnd dɛn savis layf.

Biyond strɔkchɔral riinfɔsmɛnt, injɛkshɔn moldin wit ABS de ɛnabul fɔ mek haybrid ɔ mɔlti-matirial pat dɛn tru ɔvamɔldin tɛknik dɛn. Ovamodin involv fɔ mol wan sɛkɔndari matirial ova ɔ rawnd wan praymari ABS sabstret fɔ ɛp fɔ mek di prɔdak wok fayn. fכ egzampl, we yu kam togεda wit abs wit sכft tεmכplastik כ εlastכm dεm kin ad ergonomik fכm dεm lεk impruv grip sεf, shok absכpshכn, כ silin prכpati dεm. Dis haybrid dizayn aprɔch de alaw manifakta dɛn fɔ leva di taf ɛn rigiditi fɔ ABS we dɛn de inkɔrpɔret di fleksibiliti ɛn kusɛn bɛnifit dɛn fɔ kɔmplimɛnt matirial dɛn, we de mek pat dɛn we de te ɛn yuz-frenli.

Plɛnti mɔ, injɛkshɔn moldin de gi prɛsis kɔntrol oba di wɔl tik, we rili impɔtant fɔ ajɔst di ABS kɔmpɔnɛnt dɛn we de te. Optimized wall thickness de mek shɔ se pat dɛn kin kol ivin, we kin mek dɛn nɔ gɛt strɛs insay we kin mek dɛn wɔp, shrink, ɔ krak. Yunifɔm kɔling de ridyus bak di saykl tɛm ɛn impruv dimɛnshɔnal akkuracy, we de rilizɔt kɔnsistɛns, ay-kwaliti pat dɛn akɔdin to big prodakshɔn rɔn dɛn. Bay we dɛn tayla di wɔl tik ɛn kol paramita dɛn spɛshal fɔ ABS plastic, di manifakta dɛn kin prodyuz kɔmpɔnɛnt dɛn wit fayn fayn mɛkanikal prɔpati ɛn supia sɔfays finish dɛn we de agens di dɛgradishɔn ova tɛm.

Wan ɔda advantej advantej we dɛn gi bay injɛkshɔn moldin na di abiliti fɔ inkɔrpɔret mold-in kɔlɔ ɛn sɔfays tɛkstɔr dairekt insay ABS pat dɛn. Molded-in kala de pul di nid fɔ ɔda peint ɔ kɔtin stɛp dɛn, we kin west ɔ chip wit yus. Di kala bi wan impɔtant pat pan di ABS kɔmpɔnɛnt, we de mentɛn aesthetic apil ɔlsay na di prɔdak in layfspan. Semweso, dɛn kin mol tɛkstɔr sɔfays fɔ mek i go fayn, ridyus di glare, ɔ ayd skrat, ɛnhans ɔl tu di funkshɔn ɛn vijual durabiliti fɔ ABS prɔdak dɛn.

Dɔn

ABS plastic stand out as a highly durable, cost-effective material we de sɔpɔt ɛkstend prodak layfspan akɔdin to wan big rɛnj ɔf aplikeshɔn dɛn. I fayn fayn mɛkanikal trɛnk, impak resistans, kemikal ɛn abrashɔn rɛsistɛns, we dɛn jɔyn wit in suitabiliti fɔ prɛsishɔn injɛkshɔn moldin, mek am wan tɔp chuk fɔ manifakta dɛn we de aim fɔ deliv rili, lɔng-last prɔdak dɛn.

We dɛn pik ABS plastic ɛn leva advans injɛkshɔn moldin dizayn strateji, kɔmni dɛn kin ɛp fɔ mek di prɔdak go bifo, ridyus di mentenɛns kɔst, ɛn mek di kɔstɔma dɛn satisfay. Fɔ manifakta dɛn we de luk fɔ ɛkspɛkt sɔlvishɔn dɛn insay durable ABS plastic mold kɔmpɔnɛnt dɛn, patna wit wan pɔshɔnal injɛkshɔn moldin kɔmni de mek shɔ se akses to ay-kwaliti prodakshɔn kapabiliti dɛn we dɛn tayl to spɛshal nid dɛn.

Team Rapid MFG Co., Ltd. spɛshal pan plastic injɛkshɔn moldin savis, we de gi kɔstɔm ABS sɔlvishɔn dɛn we dɛn mek fɔ durabiliti ɛn pefɔmɛns. Fɔ fɛn ɔndastand aw ABS mold kɔmpɔnɛnt dɛn kin impruv yu prɔdak layfspan, visit www.team-mfg.com ɔ kɔntak dɛn tim fɔ pɔshɔnal gayd ɛn manufakchurin ɛkspɛriɛns.