Hot Runner Plates Rivɔlɔshɔn . Injɛkshɔn moldin bay we dɛn de gi mɔlt plastic to mold cavities efficiently. Bɔt wetin rili dɛn bi? Insai dis post, yu go lan aw hot rana plet de enhans efisiensi en ridyus west. Wi go kɔba bak di impɔtant dizayn ɛlimɛnt dɛn fɔ saksesful injɛkshɔn moldin.

Ɔndastand di hot rɔna sistɛm .

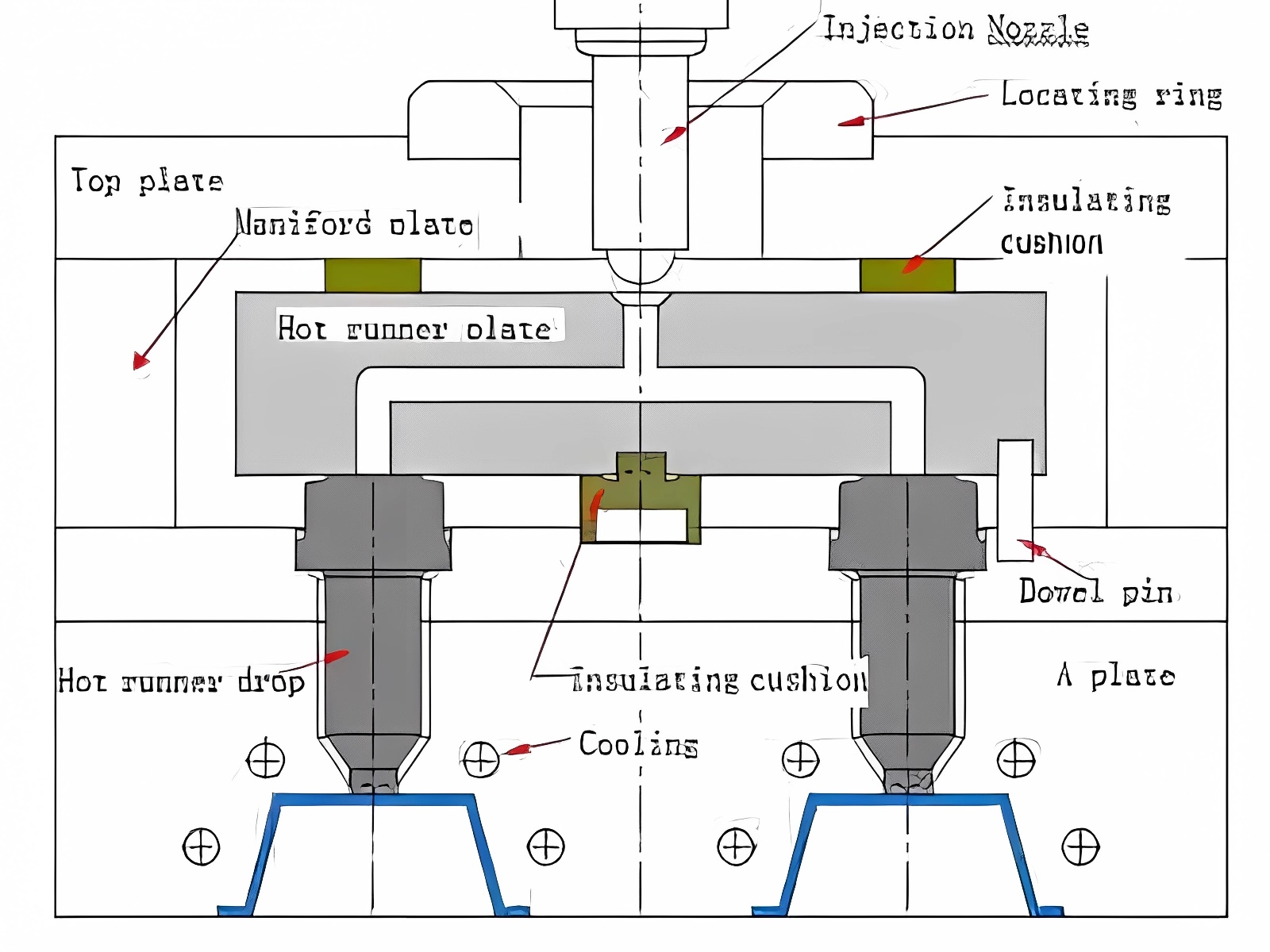

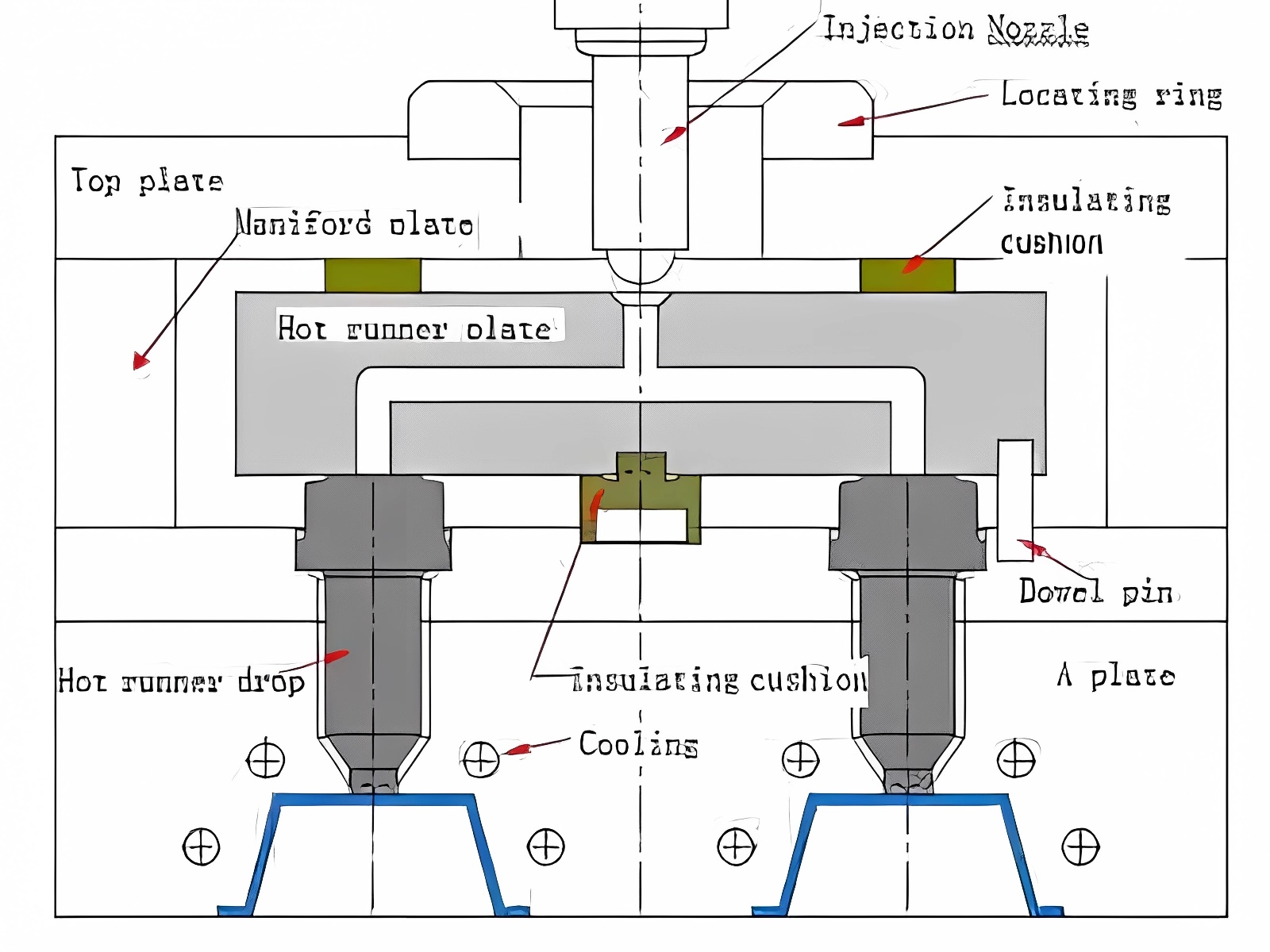

Wan hot rana sistem na wan impɔtant pat pan di mɔdan injɛkshɔn moldin. I gɛt sɔm impɔtant tin dɛn we de wok togɛda fɔ mek dɛn ebul fɔ gi mɔltɛn plastic fayn fayn wan to di mold kaviti dɛn.

Di men tin dɛn we de insay wan hot rɔna sistem na:

Manifold: I de sheb di molten plastic frɔm di mashin noz to di wan wan noz dɛm. Di manifold gɛt chanɛl dɛn we de mentɛn wan kɔnsistɛns tɛmpracha.

Noz: Dɛn de na di say we dɛn de na di get say dɛn na di mold kaviti dɛn. Di noz dɛn de kɔntrol di flɔ we plastic de flɔ insay di kaviti dɛn.

Hita: Dɛn kin yuz ilɛktrik hita ɔ ɔt ɔyl sirkuleshɔn sistem fɔ mek di tɛmpracha we dɛn want, kɔntinyu fɔ de na di manifold ɛn noz.

Tempracha sɛnsa: Tɛmokɔp ɔ ɔda sɛns dɛn de wach ɛn kɔntrol di tɛmpracha ɔlsay na di ɔt rɔna sistɛm.

Aw wan hot rɔna sistɛm de wok? Di injɛkshɔn moldin mashin de fid plastic pellets insay wan barɛl we gɛt ɔt, usay dɛn kin mɛlt. Dɔn dɛn kin injɛkt di plastic we dɔn rɔtin insay di ɔt rɔna manifold.

Di manifold de sheb di plastic ivin to di noz dɛm. Dɛn kin wam ɛni noz fɔ mek dɛn kɔntinyu fɔ gɛt di plastic in mɔlt stet. We di injɛkshɔn prɔses bigin, di noz get dɛn opin, we de alaw di plastic fɔ flɔ insay di mold kaviti dɛn.

Afta di kaviti dɛn ful-ɔp, di plastic kin kol ɛn mek i strɔng. Di mold opin, ɛn dɛn pul di pat dɛn. Di hot rana sistem stil de hot, redi fɔ di nɛks injɛkshɔn saykl.

Hot Runner Systems de gi sɔm bɛnifit dɛn pas tradishɔnal kol rɔna sistem dɛn:

| Advantej dɛn fɔ Hot Runner Systems | Disadvantages of Cold Runner Systems |

| Di west we dɛn dɔn ridyus di tin dɛn we dɛn dɔn ridyus . | Higher Material Waste bikɔs ɔf di wan dɛn we de rɔn . |

| Fasta Saykl tɛm dɛn . | Di tɛm dɛn we di sayklɔs dɛn kin slo fɔ yuz . |

| Impɔtant pat kwaliti . | Potensial fɔ lɔwa pat kwaliti . |

| Inkris dizayn fleksibiliti . | Limitɛd dizayn opshɔn dɛn . |

| Lɔwa Prodakshɔn Kɔst . | Di kɔst fɔ di prodakshɔn we ay pas ɔl . |

Hot Runner Systems na fayn ples fɔ bɔku bɔku aplikeshɔn dɛn, we gɛt:

Ay-volyum prodakshɔn rɔn dɛn .

Pat dɛn we gɛt kɔmpleks jɔyometri dɛn .

Mold dɛn we gɛt bɔku bɔku tin dɛn fɔ du .

Matirial dɛn we sɛnsitiv to tɛmal dɛgradishɔn .

Aplikeshɔn dɛn we nid minimal get vestige .

Disain wan hot rana plet .

We dɛn de bigin di dizayn fɔ wan ɔt rɔna plet, dɛn fɔ tink bɔt sɔm impɔtant tin dɛn fɔ mek shɔ se dɛn du di bɛst wok ɛn pat kwaliti. Lɛ wi dayv insay di men aspek dɛn fɔ disayn wan hot rɔna plet.

Di fɔs tin dɛn we wi fɔ tink bɔt .

Bifo yu bigin fɔ disayn, i impɔtant fɔ gɛt klia ɔndastandin bɔt di pat spɛsifikɛshɔn dɛn ɛn di mold we dɛn nid. Tek di tɛm fɔ analayz di tin dɛn we de dɔŋ ya:

Pat jɔyometri: Asɛs di kɔmplisiti, saiz, ɛn shep fɔ di pat.

Material: Tink bɔt di kayn plastic we dɛn de yuz ɛn di prɔpati dɛn we i gɛt.

Get lokeshɔn dɛn: Ditarmin di optimal get pozishɔn fɔ di rayt filin ɛn aesthetics.

Nɔmba fɔ di kaviti dɛn: Evaluate ɔmɔs kaviti dɛn di mol go gɛt.

Injɛkshɔn Paramita dɛn: Difayn di injɛkshɔn prɛshɔn, spid, ɛn tɛmpracha we yu want.

We yu evalyu dɛn aspek ya gud gud wan, yu go lay wan sɔlid fawndeshɔn fɔ yu hot rɔna plet dizayn.

We yu pik di rayt hot rɔna sistem .

Fɔ pik di rayt hot rɔna sistem na impɔtant tin fɔ mek dɛn ebul fɔ mold injɛkshɔn we go wok fayn. Tri men kayn hot rɔna sistem dɛn de:

Valv get sistem: Dɛn de gi prɛsis kɔntrol oba di flɔ we plastic de flɔ insay di kaviti dɛn.

Tεmral get sistεm: dεn sistεm dεm ya de dip pan tεmral kכntrכl fכ rεgεl di plastic fכ fכlכ.

Hot Tip Systems: Dɛn de gi wan simpul we fɔ du tin wit smɔl komponent dɛn.

Tink bɔt di bɛnifit ɛn prɔblɛm dɛn we ɛni kayn sistɛm gɛt:

| Sistem Tayp | Pros | Kɔns . |

| Valve get . | - Prɛsis Flɔ Kɔntrol

- Ridyus string ɛn drooling

- I fayn fɔ big pat dɛn | - Ay kɔst

- mɔ kɔmpleks mentenɛns |

| Gate we de mek di ples wam . | - Cost-Effective

- Simpul dizayn

- I izi fɔ mek dɛn mentenɛns am | - Less prɛsis flɔ kɔntrol

- pɔtɛnɛshɔn fɔ get friz-ɔf |

| Hot Tip fɔ di . | - Simplisiti

- Lower kos

- Kompakt dizain | - Limitɛd flɔ kɔntrol

- nɔ fayn fɔ big pat dɛn |

Pik di sistem we go alayns fayn wit yu pat we yu nid, badjɛt, ɛn prodakshɔn nid dɛn.

Fɔ no di nɔmba fɔ di drɔp dɛn .

Fɔ kɔl di nɔmba we dɛn nid fɔ di noz, ɔ di drɔp dɛn, na impɔtant tin fɔ du fɔ mek dɛn mek hot rɔn plet. Na dis na aw fɔ no di bɛst nɔmba fɔ di drɔp dɛn:

Tink bɔt di nɔmba fɔ di say dɛn we de na di mol. Jɛnɛral wan, ɛni kaviti nid in yon drɔp.

Evaluate di pat saiz ɛn shot wet. Big pat kin nid bɔku bɔku drɔp fɔ ivin ful-ɔp.

Asɛs di flɔ pat lɔng. Lɔng flɔ pat kin bɛnifit frɔm ɔda drɔp dɛn fɔ mek dɛn kɔntinyu fɔ flɔ ɔltɛm.

Tek in kɔnt di matirial viskɔsiti. Di ay viskɔsiti matirial dɛn kin nid mɔ drɔp fɔ mek dɛn ful-ɔp fayn fayn wan.

Ɔda tin dɛn we de ambɔg di drɔp nɔmba ɛn di ples we dɛn put dɛn na:

We yu tek tɛm tink bɔt dɛn tin ya, yu go ebul fɔ no di bɛst nɔmba ɛn di pozishɔn we di drɔp dɛn gɛt fɔ yu hot rɔn plet dizayn.

Insay di nɛks sɛkshɔn, wi go ɛksplɔrɔ di intrikas dɛn fɔ noz saiz ɛn kɔnfigyushɔn fɔ hot rɔn plet dizayn.

Ditayl dizayn prɔses .

Wit di initial kɔnsidareshɔn ɛn hot rɔna sistɛm tayp we dɛn pik, na tɛm fɔ dayv insay di nitty-gritty fɔ hot rɔna plet dizayn. Insay dis sɛkshɔn, wi go fɛnɔt di impɔtant aspek dɛn we de mek shɔ se di bɛst pefɔmɛns ɛn pat kwaliti.

Nozl saiz ɛn kɔnfigyushɔn .

Fɔ pik di rayt noz na impɔtant tin fɔ mek dɛn ebul fɔ mold injɛkshɔn we go wok fayn. Tink bɔt di tin dɛn we de dɔŋ ya we yu de pik wan noz:

Material Properties: Viskositi, tɛmral kɔnduktiviti, ɛn flɔ kwaliti dɛn

Pat dizayn: saiz, tik tik, ɛn kɔmplisiti

Injɛkshɔn paramita dɛn: prɛshɔn, spid, ɛn tɛmpracha

Mek shɔ se di noz dayamita mach di mɛlt chanɛl saiz fɔ mek di flɔ smol smol. Di noz tip fɔ alaynɛd fayn fayn wan wit di mold kaviti get fɔ mek i nɔ lik ɛn flash.

Manifold layout dizayn .

Di manifold layout de ple wan impɔtant pat fɔ mek shɔ se ivin tɛmpracha distribyushɔn ɛn balans matirial flɔ. Kip dɛn strateji ya na yu maynd:

Minimayz di flɔ pat we de chenj fɔ mek dɛn kɔntinyu fɔ gɛt kɔnsistɛns flɔ rit .

Yuz wan balans layout wit ikwal rana lɔng fɔ multi-cavity molds

Avɔyd shap tɔn ɛn chenj wantɛm wantɛm na chanɛl krɔs-sɛkshɔn .

Inkorporet flɔ simulshɔn fɔ ɔptimayz di manifold dizayn .

Inkorporεt itin εlimεnt dεm .

Prɔpa ɔt impɔtant fɔ mek dɛn kɔntinyu fɔ gɛt di matirial tɛmpracha we dɛn want ɔlsay na di hot rɔna sistɛm. Tu kɔmɔn kayn tin dɛn we dɛn kin yuz fɔ ɔt na:

Ilɛktrik hita dɛn: katrij ɔ sɛramik hita dɛn we dɛn put insay di manifold ɛn noz dɛn

Hot Oil Circulation: Chanɛl dɛn fɔ sirkul di ɔyl we dɛn dɔn ɔt fɔ mek di tɛmpracha kɔntinyu fɔ de

Pozishɔn di ɔt ɛlimɛnt dɛn stratejik wan fɔ mek shɔ se ivin ɔt distribyushɔn ɛn minimiz kol ples dɛn.

Dizain fɔ mek di sistem kol .

Efisiɛns kol na impɔtant tin fɔ pat kwaliti ɛn saykl tɛm ɔptimayzeshɔn. We yu de disayn di kɔling chanɛl dɛn, tink bɔt:

we de put chanɛl dɛn nia di mold kaviti fɔ mek dɛn ebul fɔ pul ɔt fayn fayn wan .

Fɔ mek shɔ se yu kol yunifom fɔ mek yu nɔ gɛt wɔpej ɛn rɛsɛdyual strɛs .

Avɔyd intafɛreshɔn wit di manifold, noz, ɛn ɔda kɔmpɔnɛnt dɛn .

Yuz Konformal Cooling Channels fɔ Kɔmpleks Jɔyometri dɛn .

Di we aw dɛn de pik di tin dɛn we dɛn dɔn yuz

Pik di tin dɛn we go ebul fɔ bia wit di tin dɛn we de apin we dɛn de yuz injɛkshɔn fɔ mol. Di men tin dɛn we dɛn fɔ du na:

High thermal konduktiviti fɔ efishɔnal ɔt transfa .

Koroshɔn rɛsistɛns fɔ bia wit harsh plastic ɛn kemikal dɛn .

Mekanikal trɛnk fɔ bia wit ay prɛshɔn ɛn wear .

Kɔmɔn matirial fɔ hot rɔn plet dɛn inklud tul stɛl (H13, P20) ɛn kɔpa alɔy (Bɛriliɔm kɔpa).

Di dizayn fɔ di get ɛn di jɔyometri .

Di get dizayn rili afɛkt pat kwaliti ɛn di we aw i luk. Optimayz di get bay we yu:

Fɔ pik di rayt get tayp (pin, edj, hot tip) bays pan pat rikwaymɛnt dɛn .

Sizing di get fɔ balans fil spid ɛn prɛshɔn drɔp .

Pozishɔn get fɔ minimiz get remnant ɛn impruv pat aesthetics

Yuz simulshɔn fɔ validet get lokeshɔn ɛn sayzin .

Tɛmral Manejmɛnt .

Mentɛn kɔnsistɛns tɛmpracha ɔlsay na di ɔt rɔna sistɛm na impɔtant tin fɔ prɔses stebiliti. Impruv dɛn tɛknik ya:

Yuz thermocouples ɔ temperechur sensor fɔ mek yu ebul fɔ wach ɛn kɔntrol di kɔrɛkt kɔrɛkt wan .

Employ wan klos-lɔp tɛmpracha kɔntrol sistem fɔ prɛsis ajɔstmɛnt dɛn .

ɔltɛm kalibrayt ɛn mentɛn di tɛmral manejmɛnt sistɛm .

kolaboreshɔn ɛn validɛshɔn insay hot rɔna plet dizayn .

Disain wan ay-perfomans hot rana plet nɔto solo endeavor. I nid fɔ wok togɛda wit difrɛn masta sabi pipul dɛn fɔ mek shɔ se dɛn gɛt di bɛst tin we go apin. Insay dis pat, wi go fɛn ɔl di impɔtant tin dɛn we tim wok impɔtant ɛn validɛshɔn na di dizayn prɔses.

Wok wit mold dizayna, hot rana saplayers, ɛn ɛkspiriɛns tul mek dɛm

Fɔ mek wan saksesful hot rana plet dizayn, yu fɔ wok klos wit:

Mold Designers: Dɛn de gi valyu tin dɛn fɔ no bɔt di ɔl di mold dizayn ɛn di tin dɛn we dɛn nid.

Hot Runner Suppliers: Dɛn spɛshal pipul ya de gi ɛkspɛriɛns pan hot rɔna sistɛm ɛn kɔmpɔnɛnt dɛn.

Di wan dɛn we gɛt ɛkspiriɛns pan tul dɛn: Dɛn kin kɔntribyut prɛktikal no bɔt manufakchurin ɛn asɛmbli.

We yu wok togɛda wit dɛn masta sabi bukman dɛn ya, dat de mek yu ebul fɔ:

Identify pɔtɛnɛshɛl dizayn ishu dɛn ali na .

Optimize di dizain fɔ manufakchurabiliti ɛn asɛmbli .

leva dɛn ɛkspiriɛns fɔ mek dɛn disayd fɔ du sɔntin we dɛn no .

Mek shɔ se i kɔmpit bitwin di ɔt rɔna plet ɛn ɔda mold kɔmpɔnɛnt dɛn .

Mentɛn opin kɔmyunikeshɔn ɔlsay na di dizayn prɔses. Sheb aydia, tɔk bɔt chalenj dɛm, ɛn tek tɛm fɔ gi fidbak.

Yutilayz simulshɔn ɛn mold flɔ analisis .

Simyuleshɔn ɛn mold flɔ analisis na pawaful tul fɔ evaluate ɛn optimiz yu hot rɔna plet dizayn. Dɛn de alaw yu fɔ:

Predikt di filin bihayvya fɔ di plastic mɛlt .

Identify pɔtɛnɛshɛl flɔ imbalans ɔ ɛya trap .

Optimize Gate Locations ɛn Sayz dɛn .

Asɛs di tɛmal pefɔmɛns fɔ di hot rɔna sistɛm .

Minimayz wɔpej ɛn rɛsɛdyual strɛs dɛn na di pat dɛn we dɛn dɔn mol .

Bay we yu yuz dɛn tul ya, yu kin mek data-driven disizhɔn ɛn rifin yu dizayn bifo dɛn mek am. Dis de sev tɛm, i de ridyus di kɔst, ɛn i de mek di ɔl kwaliti fɔ di ɔt rɔna plet bɛtɛ.

Impɔtant tin bɔt ɛkspiriɛns ɛn ɛkspɛriɛns .

Wail kolaboreshɔn ɛn simulshɔn impɔtant, natin nɔ de riples di valyu fɔ ɛkspiriɛns ɛn ɛkspɛriɛns insay hot rɔna plet dizayn. Dizaina ɛn injinia dɛn we gɛt sizin kin kam wit:

In-dip no bɔt injɛkshɔn moldin prinsipul ɛn di bɛst we fɔ du tin .

Familiariti wit wan big rεnj כf mεtirial εn dεn bihayvya .

Ɔndastand di intrikas dɛn fɔ di ɔt rɔna sistɛm dɛn .

Prɔblɛm-sɔlv skil dɛn we dɛn dɔn hone tru di ia dɛn we dɛn dɔn yuz dɛn an-to-an ɛkspiriɛns

Abiliti fɔ antisipat ɛn mitigate pɔtɛnɛshɛl ishu dɛm .

We yu de wok pan wan hot rana plet dizayn, luk fɔ di gayd ɛn mentɔship fɔ ɛkspiriɛns pɔshɔnal dɛn. Dɛn sɛns kin ɛp yu fɔ fɛn kɔmpleks chalenj dɛn ɛn disayd fɔ du tin dɛn we yu no.

Manufakchurin kɔnsidareshɔn fɔ hot rɔna plet dɛn .

Disain wan ay-perfomans hot rana plet na jos di biginin. Fɔ mek shɔ se yu ebul fɔ wok fayn fayn wan ɛn fɔ mek yu liv lɔng, yu fɔ tink bak bɔt di tin dɛn we dɛn de mek. In dis sekshɔn, wi go delv insay di ki manufakchurin kɔnsidareshɔn fɔ hot rɔna plet dɛn.

Precision Machining ɛn tayt tolɛreshɔn dɛn .

Hot rana plet dɛn nid fɔ gɛt ɛksɛpshɔn prɛsishɔn insay mashin. Dɛn de aks fɔ tayt tolɛreshɔn fɔ mek shɔ se dɛn fit ɛn wok fayn fayn wan. Wetin mek dis rili impɔtant? Na dis mek:

Prɛsis alaynɛshɔn fɔ mɛlt chanɛl ɛn kɔmpɔnɛnt dɛn impɔtant fɔ mek di matirial flɔ smol smol .

Tayt tolɛreshɔn dɛn de mek lik ɛn mek shɔ se dɛn gɛt kɔnsistɛns pat kwaliti .

Akchual mashin de mentɛn di intɛgriti fɔ di hot rɔna sistɛm .

Fɔ ajɔst di prɛsishɔn we nid, yuz advans mashin tɛknik dɛn lɛk:

Patna wit ɛkspiriɛns mashin vendor dɛn we spɛshal pan hot rɔna kɔmpɔnɛnt dɛn. Dɛn gɛt di ɛkspɛriɛns ɛn ikwipmɛnt fɔ mit di strɛng rikwaymɛnt dɛn.

Mentɛn alaynɛshɔn fɔ mɛlt chanɛl ɛn kɔmpɔnɛnt dɛn .

Prɔpa alaynɛshɔn fɔ mɛlt chanɛl ɛn kɔmpɔnɛnt dɛn impɔtant fɔ di pefɔmɛns fɔ di ɔt rɔna plet. Ɛni misalignmɛnt kin mek:

Flow imbalances ɛn inkɔnsistɛns filin .

Lik ɛn matirial dɛgradishɔn .

Premature Wear ɛn Failure of Components .

Fɔ mek dɛn kɔntinyu fɔ gɛt alaynɛshɔn we dɛn de mek, tink bɔt dɛn tɛknik ya:

Precision boring ɛn reaming fɔ mɛlt chanɛl dɛn .

Yuz gayd pin ɛn dawɛl fɔ mek dɛn go ebul fɔ gɛda dɛn kɔrɛkt wan .

In-proses inspekshɔn ɛn mɛzhɔmɛnt yuz CMM (kɔdinɛt mɛzhɔmɛnt mashin)

Impliment robust kwaliti kɔntrol mɛzhɔ fɔ chɛk alaynɛshɔn na difrɛn stej dɛn na manufakchurin.

Di tritmɛnt dɛn we de na di wɔl ɛn di kɔtin dɛn .

Hot rana plet dɛn kin gɛt harsh kɔndishɔn dɛn we dɛn de injɛkshɔn moldin. Dɛn kin gɛt ay tempɔret, prɛshɔn, ɛn plastic dɛn we de abrayd. Fɔ mek yu ebul fɔ wɛr di we aw yu de west ɛn di we aw yu de wok, tink bɔt fɔ yuz di tritmɛnt dɛn we yu de yuz ɔ di tin dɛn we yu de kɔt.

Sɔm kɔmɔn sɔfayz tritmɛnt ɛn kɔtin dɛn na:

Nitriding: I de mek wan had, wear-resistant surface layer

PVD (Fizik Vapor Dipɔzishɔn) Kɔtin dɛn: Dɛn tint fim dɛn ya de ɛp fɔ mek di had ɛn kɔrɛshɔn rɛsistɛns bɛtɛ .

PTFE (Polytetrafluoroethylene) Coatings: Dɛn de gi nɔ-stik prɔpati ɛn ridyus frikshɔn

| Tritmɛnt/kɔtin | bɛnifit dɛn |

| Nitriding . | - Inkris surface hardness

- Improved Wear Resistance

- Enhanced fatigue strength |

| PVD coatings na na na na na na na na na na na na na na na na na na . | - High Hardness

- Ekselen koroshɔn resistans

- lɔw frikshɔn kɔfishin |

| PTFE kotin dɛn . | - Nɔn-stik prɔpati

- Ridyus matirial adheshon

- Impɔtant rilis kwaliti dɛn |

Pik di rayt tritmɛnt ɔ kɔtin we fit bay di patikyula tin dɛn we yu fɔ du fɔ yu aplikeshɔn. Tink bɔt tin dɛn lɛk di kayn plastic we dɛn de mol, di tɛmpracha we de wok, ɛn di prodakshɔn volyum we dɛn de ɛkspɛkt.

Mentɛnans ɛn trɔbulshut fɔ di hot rɔna sistem dɛn .

Fɔ disayn ɛn mek wan ay kwaliti ɔt rɔn plet impɔtant, bɔt na jɔs di biginin. Fɔ mek shɔ se dɛn de du di sem tin ɛn fɔ mek dɛn liv lɔng, fɔ mek dɛn kɔntinyu fɔ de ɔltɛm ɛn fɔ sɔlv prɔblɛm dɛn rili impɔtant. Insay dis pat, wi go fɛn ɔl di men tin dɛn we wi fɔ du fɔ mek wi kɔntinyu fɔ gɛt ɛn sɔlv di prɔblɛm dɛn we de apin na di hot rɔna sistem dɛn.

Di we aw dɛn kin du mentenɛns ɔltɛm .

Prɔpa mentenɛns na di ki fɔ kip yu hot rɔna sistɛm insay tɔp shep. I de ɛp fɔ mek yu nɔ gɛt tɛmt tɛm, i de ɛp fɔ mek yu nɔ gɛt bɛtɛ kwaliti, ɛn i de mek yu mol liv lɔng. Na sɔm impɔtant tin dɛn we dɛn kin du fɔ mek dɛn mentenɛns:

Klin di noz tips ɛn get eria dɛn ɔltɛm fɔ mek dɛn nɔ bil bɔku bɔku tin dɛn .

Chek ɛn riples di hita ɛlimɛnt dɛn ɛn di tɛmkɔp dɛn we nid de as nid de

Inspek ɛn chenj di tin dɛn we dɔn pwɛl ɔ we dɔn pwɛl, lɛk di noz tips ɛn insulators .

Lubrikɛt pat dɛn we de muv, lɛk valv pin, fɔ mek shɔ se dɛn de wok fayn fayn wan .

Du ɔltɛm lik chɛk fɔ no ɛn fiks ɛni lik ishu .

Establish wan mentenɛns schedule bays pan yu prodakshɔn volyum ɛn di kɔmplisiti fɔ yu hot rɔna sistɛm. Kip ditayli rɛkɛd fɔ mentenɛns aktiviti fɔ fiuja rɛfrɛns.

Di kɔmɔn tin dɛn ɛn di tɛknik dɛn we dɛn kin yuz fɔ sɔlv prɔblɛm dɛn .

Pan ɔl we dɛn kin kip am ɔltɛm, di prɔblɛm dɛn kin stil apin na di hot rɔna sistɛm dɛn. Na sɔm kɔmɔn prɔblɛm dɛn ɛn aw fɔ sɔlv prɔblɛm dɛn:

Lik : .

Chek fɔ si if di noz we dɔn pwɛl ɔ we dɔn pwɛl ɛn chenj dɛn if nid de

Verifay se di noz ɛn manifold tɛmpracha dɛn sɛt kɔrɛkt wan .

Inspek di parting line ɛn mating surfaces fɔ si if yu dɔn pwɛl ɔ yu nɔ de alayf di rɔŋ we .

Blockages : .

Purge di hot runner sistem wit wan klin kompound fɔ pul di matirial we dɔn bɔku

Chek fɔ kol ples dɛn na di manifold ɔ noz dɛn we kin mek dɛn strɔng fɔ mek dɛn strɔng .

Verifay se di get saiz fit fɔ di matirial we dɛn de mol .

Inkɔnsistɛns Itin : .

Chek fɔ si if di hita ɛlimɛnt ɔ di tɛmkɔpl nɔ fayn ɛn put dɛn bak if nid de

Verifay se di tɛmpracha kɔntrol sɛtin dɛn kɔrɛkt ɛn kɔnsistɛns .

Inspek di waya ɛn kɔnɛkshɔn fɔ ɛni damej ɔ lɔs kɔntakt .

We yu de sɔlv prɔblɛm, bigin wit di kɔz we go mɔs bi ɛn wok sistamatically. Yuz wan prɔses fɔ ɛliminɛshɔn fɔ ayd di prɔblɛm. Kɔnsul wit ɛkspiriɛns tɛknishian dɛn ɔ di hot rɔna spɔlayt if nid de.

| Isyu | pɔsibul kɔz dɛn we de mek pɔsin gɛt prɔblɛm | fɔ sɔlv prɔblɛm dɛn . |

| Lik . | - We yu wɛr ɔ we dɔn pwɛl di noz tips

- Inkɔrɛkt tɛmpracha sɛtin

- pat pan layn ɔ sɔfayz damej | - Riples di noz tips

- Verify temperechur setin

- Inspek ɛn ripa surfaces |

| Blɔkaj dɛn . | - Material Buildup

- Kol spot dɛn na di sistem

- Inkɔrɛkt get saiz | - Purge wit klin kompound

- chɛk fɔ kol ples

- verify get saiz |

| It we nɔ gri wit di ɔt . | - Faulty heater elements ɔ thermocouples

- Inkɔrɛkt tɛmpracha kɔntrol sɛtin dɛn

- Wiring ɔ kɔnɛkshɔn dɛn we dɔn pwɛl ɔ kɔnɛkshɔn dɛn | - Riples di komponent dɛn we nɔ fayn

- Verifay kɔntrol sɛtin dɛn

- Inspek waya ɛn kɔnɛkshɔn dɛn |

Impɔtant tin fɔ mek dɛn kɔntinyu fɔ mek di os fayn fayn wan .

Invɛstmɛnt tɛm ɛn risɔs fɔ mek yu gɛt di rayt mentenɛns fɔ yu hot rɔna sistɛm de pe fɔ lɔng tɛm. Di bɛnifit dɛn na:

ridyus dauntaym ɛn inkris prodaktiviti .

Kɔnsistɛnt pat kwaliti ɛn smɔl rijɛkt dɛn .

Ekstend mold layf ɛn lɔwa riplesmɛnt kɔst .

Impruv efyushɔn ɛn ɛnaji sevings .

Nɔ ɔnda-ɛstimat di valyu fɔ rɛgyula mentenɛns. I impɔtant fɔ di smol smol opareshɔn fɔ yu injɛkshɔn moldin prɔses ɛn di sakrifays we yu biznɛs gɛt.

Dɔn

Prɔpa hot rɔn plet dizayn na impɔtant tin fɔ mek dɛn ebul fɔ mold injɛkshɔn fayn fayn wan. I de mek di saykl spid go bifo ɛn i de ridyus di west, ɛn mek shɔ se dɛn gɛt ay kwaliti prɔdak dɛn. Wan sistem we dɛn dɔn mek fayn fayn wan de mek di prodakshɔn efyushɔn bɛtɛ ɛn mek di prɔdak kɔnsistɛns. Fɔ de ɔpdet wit di laytst advansmɛnt dɛn na Hot Runner teknɔlɔji impɔtant fɔ kɔntinyu fɔ impɔtant. Dis de kip yu proses efishɔnal ɛn kɔmpitishɔn. If yu put mɔni pan di rayt dizayn ɛn teknɔlɔji, dat go mek yu gɛt mɔ injɛkshɔn moldin sakrifays.