Injɛkshɔn moldin na wan versatile manufacturing process we dɛn kin yuz fɔ mek plastic komponent dɛn. Fɔ pik di rayt rɔna sistɛm na impɔtant tin fɔ efyushɔn ɛn kwaliti.

Dis atikul de gi wan dip kɔmpiashɔn fɔ hot rɔna ɛn kol rɔna injɛkshɔn mold. Yu go lan dɛn difinishɔn, advantej, prɔblɛm, ɛn aw fɔ pik di bɛst sistɛm fɔ yu nid.

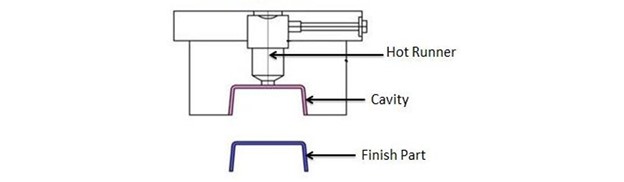

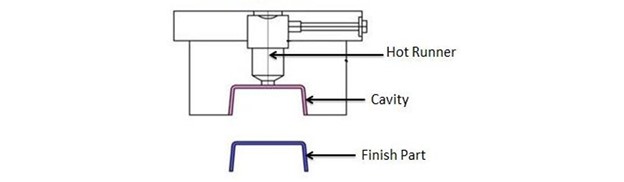

Wetin na wan hot rɔna injɛkshɔn mold?

Wan ɔt rɔna injɛkshɔn mold na wan sofistikieted moldin sistem we de kip di plastic matirial we dɛn dɔn molt ɔl di tɛm we dɛn de injekt am. I de yuz wan manifold we dɛn dɔn ɔt fɔ mek di plastic we di plastic de frɔm di injɛkshɔn noz to di mold kaviti, kɔntinyu fɔ de.

Aw Hot Runner Systems de wok .

Insay wan hot rɔna sistem, di manifold kin wam bay wan siriɔs hita. Dis kin kip di plastic insay wan molten stet as i de flɔ tru di manifold ɛn go insay di mold cavity. Dɛn kin ɔt di noz dɛn bak, ɛn mek shɔ se di plastic kɔntinyu fɔ de insay di wata rayt te i go insay di mol.

Advantej dɛn fɔ Hot Runner Molds .

Fasta Saykl tɛm dɛn .

Bikɔs di plastic stil dɔn rɔtin, dɛn kin put am insay di mol kwik kwik wan. Dis de ridyus di ɔvala saykl tɛm, we de alaw fɔ mek dɛn prodyuz fast fast.

Di west we dɛn dɔn ridyus di tin dɛn we dɛn dɔn ridyus .

Hot Runner systems nɔ nid kol rɔna, we na wan sɔlid pies plastic we de kɔnɛkt di noz to di mold cavity. Dis min se na smɔl matirial west de, as di kol rɔna de dɔn.

Impɔtant pat kwaliti ɛn kɔnsistɛns .

Di kɔnsistɛns tɛmpracha we di ɔt rɔna sistɛm de mentɛn de rilizɔt mɔ yunifom pat dɛn wit smɔl dɛfɛkt dɛn. Dis de improve ovala pat kwaliti en konsistensi.

Disadvantages of hot runner molds .

Ay initial invɛstmɛnt ɛn mentenɛns kɔst .

Hot Runner molds na mɔ kɔmpleks ɛn dɛn nid ɔda tin dɛn, lɛk hita ɛn tɛmpracha kɔntrol. Dis de mek di fɔs invɛstmɛnt ɛn di mentenɛns kɔst dɛn we de kɔntinyu fɔ wok, go ɔp to di kol rɔna mold dɛn.

Limitɛd kɔmpitibliti wit sɔm ɔt-sɛnsitiv matirial dɛn .

Sɔm tin dɛn we dɛn kin yuz fɔ mek di wam wam kin pwɛl ɔ bɔn na wan hot rɔna sistem. Dis de stɔp di arenjmɛnt fɔ di matirial dɛn we dɛn kin yuz wit hot rɔna mol.

Difikulti fɔ mek chenj dɛn pan kɔlɔ .

Bikɔs di plastic de kɔntinyu fɔ rɔtin na di ɔt rɔna sistɛm, i kin tranga fɔ pul di kɔlɔ we bin de bifo am kɔmplit wan we i de mek chenj in kɔlɔ. Dis kin mek di tɛm we dɛn kin chenj fɔ lɔng tɛm ɛn di tin dɛn we kin mek di kɔlɔ nɔ shayn.

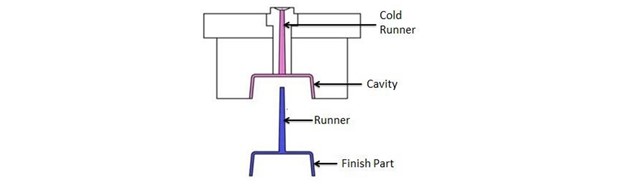

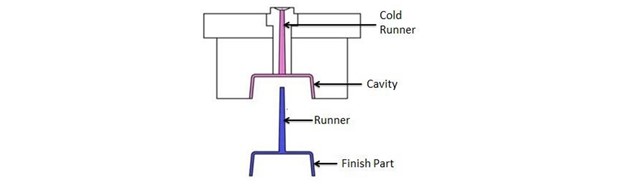

Wetin na kol rɔna injɛkshɔn mold?

Kol rana injɛkshɔn mold na tradishɔnal moldin sistem usay di rɔna (di chanɛl we de kɛr di molten plastic frɔm di noz to di mold cavity) nɔ de wam. Di rɔna na pat pan di mold insɛf ɛn dɛn kin pul am wit di pat we dɔn dɔn.

Aw kol runner sistem de wok .

Insay kol rɔn sistɛm, dɛn kin put di plastic we dɔn rɔtin insay di mol tru wan spru. Dɔn i de flɔ tru di kol rɔna ɛn go insay di mold kaviti. Afta di pat dɔn kol ɛn strɔng, di mol go opin, ɛn dɛn kin pul di pat wit di pɔsin we de rɔn.

Advantej dɛn fɔ kol rɔna mold dɛn .

Lɔw initial invɛstmɛnt ɛn mentenɛns kɔst .

Kol rɔna mol dɛn simpul ɛn dɛn nid fɔ gɛt smɔl kɔmpɔnɛnt dɛn we yu kɔmpia to hot rɔna mol dɛn. Dis kin mek dɛn nɔ dia fɔ mek ɛn fɔ mek dɛn kɔntinyu fɔ de.

Kompatibiliti wit wan big rεnj כf mεtirial dεm .

Kol rana mold kin wok wit wan brayt spɛktrum fɔ matirial, inklud ɔt-sɛnsitiv polima. Dɛn nɔ de risk fɔ degrad ɔ bɔn di plastic lɛk aw hot rɔna sistɛm dɛn kin du.

I izi fɔ mek di kɔlɔ chenj .

Bikɔs di pɔsin we de rɔn kin solidify wit ɛni saykl, i izi fɔ pul di kɔlɔ we bin de bifo am kɔmplit wan we yu de mek chenj na di kɔlɔ. Dis kin mek dɛn chenj kwik kwik wan ɛn dɛn nɔ kin gɛt bɔku prɔblɛm fɔ mek di kɔlɔ kɔntamin.

Disadvantej dɛn fɔ kol rɔna mold dɛn .

Slower cycle taims kompare to hot runner molds .

Di solidification of di rana in each saikl ad to di ovala saykl taim. Dis mek kol rana mold slo pas hot runner molds.

Matirial west frɔm rɔna ɛn sprues .

Di solidified rana de eject wit ɛni pat, we de mek matirial west. Dis west fɔ risaykul ɔ trowe, ɛn ad to di kɔst fɔ prodyus.

Lɔwa pat kwaliti ɛn kɔnsistɛns we yu kɔmpia am wit hot rɔna mold dɛn .

Di difrɛns na di tɛmpracha as di plastic de flɔ tru di kol rɔna kin mek di pat dɛn we dɔn dɔn. Dis kin rilizɔt in lɔwa ɔvala pat kwaliti ɛn kɔnsistɛns kɔmpia to hot rɔna mol.

Hot Runner vs. Kold Runner Kɔmpiashɔn

| Atribyut | Hot Rɔna | Kol Rɔna |

| Kwik dizayn ɔ chenj dɛn we gɛt kɔlɔ . | Nɔ | Yɛs |

| Ay digri fɔ tolɛreshɔn . | Yɛs | Nɔ |

| I de wok wit difrɛn difrɛn tɛmplastik dɛn . | Nɔ | Yɛs |

| Di kɔst fɔ mek dɛn gɛt ay mentenɛns . | Yɛs | Nɔ |

| I de mek big big volyum fɔ pat dɛn . | Yɛs | Nɔ |

| I de yuz rɔna we nɔ gɛt ɔt . | Nɔ | Yɛs |

| Molten thermoplastic ɔ polima de yuz . | Yɛs | Yɛs |

| Initial Sɛtup Kɔst . | Ay | Lo |

| Lid tɛm (prɔdakshɔn spid) | Shɔt | Lɔng |

| Di west we dɛn de yuz fɔ mek tin dɛn . | Lo | Ay |

| I fayn fɔ mek dɛn yuz tin dɛn we gɛt ɔt-sɛnsitiv . | Nɔ | Yɛs |

| Saykl tɛm . | Kwik | Tek tɛm |

| Pat kɔnsistɛns ɛn kwaliti . | Ay | Soba |

| I izi fɔ ɔtomɛshɔn . | Ay | Soba |

| Tipik Aplikeshɔn dɛn . | Big volyum prodakshɔn, ay prɛsishɔn pat dɛn . | Low to midul volyum prodakshɔn, ɔt-sɛnsitiv matirial dɛn . |

| Dimensional tolerance . | I de mek pat dɛn we gɛt ay prɛsishɔn . | Pat dɛn gɛt lɔwa dimɛnshɔnal akkuracy . |

| Di kɔmpitibliti fɔ di matirial . | Limitɛd to tin dɛn we nɔ gɛt ɔt-sɛnsitiv . | Kompatibl wit wan big rεnj כf tεmכplastik, inklud hεt-sεnsitiv wan dεm . |

| Runner fɔ ɔt . | Yuz dɛn we gɛt ɔt rɔna dɛn . | I de yuz rɔna dɛn we nɔ gɛt ɔt . |

| Sɛtup Kɔst . | Di ay initial sɛtup kɔst dɛn . | Lower initial setup kɔst dɛn . |

| Suitability fɔ ɔt-sɛnsitiv matirial dɛn . | Nɔ fayn fɔ di tin dɛn we dɛn kin yuz fɔ mek ɔt-sɛnsitiv . | I fayn fɔ mek dɛn yuz tin dɛn we gɛt ɔt-sɛnsitiv . |

| Automation Ease na na na na na na na na na na na na na na na . | High Ease of Automation . | Modaret izi fɔ ɔtomɛshɔn . |

Factors fɔ tink bɔt we yu de pik bitwin hot rɔna ɛn kol rɔna mold dɛn .

Fɔ pik bitwin wan hot rɔna ɛn kol rɔna mol na impɔtant tin fɔ disayd. I kin rili ambɔg yu prodakshɔn prɔses ɛn di kwaliti fɔ yu las prɔdak. Na sɔm impɔtant tin dɛn fɔ tink bɔt we yu de mek dis chuk:

Prodakshɔn volyum ɛn batch saiz .

Yu prodakshɔn volyum ɛn batch saiz de ple wan impɔtant pat fɔ no di rayt mold tayp. If yu de prodyuz bɔku bɔku pat dɛn, bɔku tɛm, wan hot rɔna mol na di bɛst we fɔ pik. I kin ebul fɔ handle ay volyum dɛn mɔ efyushɔn.

Na di ɔda say, if yu gɛt smɔl batch saiz ɔ lɔwa prodakshɔn volyum, kol rɔna mol kin fayn mɔ. I jenerali les expensive fo smol runs.

Pat kɔmplisiti ɛn dizayn rikwaymɛnt dɛn .

Di kɔmplisiti fɔ yu pat dizayn de inflɔws bak yu mold sɛlɛkshɔn. Hot Runner molds na fayn ples fɔ pat dɛn we gɛt intrɛstin dizayn ɔ tayt tolɛreshɔn. Dɛn kin gi mɔ prɛsis kɔntrol pan di injɛkshɔn prɔses.

Kol rɔna mol, pan ɔl we i simpul, i nɔ go ebul fɔ ajɔst di sem lɛvul fɔ ditil ɛn kɔrɛkt. Dem beta fit fo les komplex pat.

Matirial prɔpati ɛn ɔt sɛnsitiviti .

Di matirial we yu de yuz na ɔda impɔtant tin fɔ tink bɔt. Sɔm polimɛr dɛn kin gɛt ɔt-sɛnsitiv ɛn dɛn kin pwɛl ɔ bɔn na ɔt rɔna sistɛm. Insay dɛn kayn tin ya, kol rɔna mol na di say we sef fɔ pik.

Bɔt if yu matirial ebul fɔ bia wit di sɔstayn ɔt we wan ɔt rɔna gɛt, i kin bɛnifit frɔm di impɔtant flɔ ɛn kɔnsistɛns we wan ɔt rɔna de gi.

Chenj fɔ di kɔlɔ dɛn we de na di kɔlɔ

If yu chenj di kɔlɔ dɛn we yu de mek bɔku tɛm, kol rɔna mol de gi yu advantej. Di strɔng rɔna kin kɔmɔt ɔlsay, we kin mek di kɔlɔ chenj kwik kwik wan ɛn izi.

Wit hot rana, kola chenj kin tek mo taim-konsum. Di kala we bin de bifo nid fɔ ful-ɔp frɔm di manifold we dɛn dɔn ɔt ɛn di nɔz dɛn.

Badjɛt ɛn kɔst kɔnsidareshɔn dɛn .

Yu badjɔt na tin we kin apin ɔltɛm na ɛni manufakchurin disizhɔn. Hot Runner molds gɛt ay initial kɔst bikɔs ɔf dɛn kɔmplisiti ɛn di adishɔnal kɔmpɔnɛnt dɛn we dɛn nid, lɛk hita ɛn kɔntrol.

Kol rana mold dɛn kin jɔs nɔ dia bifo tɛm. Dɛn gɛt simpul kɔnstrɔkshɔn ɛn smɔl pat dɛn nɔ bɔku.

Bɔt, i impɔtant fɔ tink bɔt di lɔng tɛm kɔst dɛm bak. Di inkris efyushɔn ɛn ridyus west fɔ wan hot rɔna sistɛm kin mek dɛn sev kɔst ova tɛm, mɔ fɔ ay-volyum prodakshɔn.

Di saykl tɛm we dɛn want ɛn di prodakshɔn efyushɔn .

Fɔ dɔn, tink bɔt yu target saykl tɛm ɛn ɔvala prodakshɔn efyushɔn. Hot runner molds tipikli gɛt fasta saykl tɛm bikɔs di plastic de kɔntinyu fɔ mol, we de alaw fɔ injɛkshɔn kwik kwik wan ɛn nɔ kol tɛm.

Kol rana mold dem get slo saikl taim bikos of di nid fo kul en solidify di rana wit evri shot. Dis kin ad op ova di kɔs fɔ wan prodakshɔn rɔn.

Aplikeshɔn ɛn Indastri dɛn .

Hot Runner ɛn Cold Runner Molds de fɛn aplikeshɔn dɛn akɔdin to bɔku bɔku industri dɛn. Ɛni kayn mold fit fɔ sɔm patikyula prodakshɔn rikwaymɛnt dɛn ɛn di prɔdak kwaliti dɛn. Lɛ wi tek tɛm luk usay dɛn kin yuz dɛn mol dɛn ya.

Kɔmɔn aplikeshɔn fɔ hot rɔna mold dɛn .

Hot Runner molds excel in aplikeshɔn dɛn we nid ay-volyum prodakshɔn ɛn prɛsis, kɔnsistɛns pat dɛn. Sɔm kɔmɔn aplikeshɔn dɛn na:

Awtomotiv Kɔmpɔnɛnt dɛn .

Divays dɛn fɔ mɛn pipul dɛn .

Ilektroniks we de yuz kɔnsuma .

Packaging (ɛgz., kap ɛn klos)

Toys ɛn ɛnjɔymɛnt prɔdak dɛn .

Bɔku tɛm, dɛn aplikeshɔn ya kin gɛt fɔ du wit kɔmpleks, mɔlti-kaviti mol dɛn. Dɛn kin bɛnifit frɔm di fasta saykl tɛm ɛn ridyus di west we di ɔt rɔna sistɛm dɛn kin gi.

Kɔmɔn aplikeshɔn fɔ kol rɔna mold dɛn .

Bɔku tɛm dɛn kin yuz kol rɔna mol fɔ aplikeshɔn wit lɔwa prodakshɔn volyum ɔ usay dɛn kin chenj di matirial ɛn kɔlɔ bɔku tɛm. Tipik aplikeshɔn dɛn na:

Prototayp ɛn lɔw-volyum prodakshɔn .

Ilɛktrikal kɔmpɔnɛnt dɛn ɛn os dɛn .

Prodakt dɛn we dɛn kin yuz wan tɛm nɔmɔ (ɛgz., kɔntena dɛn fɔ it, kɔtlɛri)

Promoshɔnal tin dɛn ɛn giv-away dɛn .

Pat dɛn we gɛt simpul jɔyometri dɛn .

Kol rɔna mold dɛn de gi wan kɔst-ɛfɛktiv sɔlvishɔn fɔ dɛn aplikeshɔn dɛn ya. Dɛn de gi di fleksibiliti fɔ chenj di matirial ɛn di kɔlɔ dɛn kwik ɛn izi wan.

Indastri dɛn we kin yuz ɔt rɔna mol dɛn .

Bɔku industri dɛn kin abop pan hot rɔna mol fɔ dɛn ay-volyum, prɛsishɔn moldin nid dɛn. Sɔm pan di men industri dɛn na:

Ɔtomotiv .

Mɛdikal ɛn Ɛlthkɛr .

Di guds dɛn we dɛn de yuz fɔ bay tin dɛn .

Packaging .

Ilɛktroniks .

Bɔku tɛm dɛn industri ya kin nid bɔku bɔku pat dɛn fɔ di sem pat dɛn wit tayt tolɛreshɔn. Hot Runner Molds kin deliv di spid, kɔnsistɛns, ɛn kwaliti we dɛn de aks fɔ.

Indastri dɛn we kin yuz kol rɔna mold dɛn .

Kol rana mold dɛn kin kɔmɔn fɔ fɛn na industri usay di prodakshɔn volyum dɛn smɔl ɔ usay di prɔdak dizayn kin chenj bɔku tɛm. Sɔm ɛgzampul dɛn na:

Prototyping ɛn Prodakt Divɛlɔpmɛnt .

Ilɛktrik ɛn tɛlikomyunikeshɔn .

Fɔ it ɛn drink .

Promoshɔnal Prodakt dɛn .

Toys ɛn ɔbi dɛn .

Dɛn industri ya gladi fɔ di versatility ɛn kɔst-ɛfɛktiv we kol rɔna mol dɛn gɛt. Dɛn kin prodyuz bɔku difrɛn pat dɛn we nɔ gɛt di ay invɛstmɛnt fɔ wan hot rɔna sistɛm.

Na tru se, dɛn tin ya na jɔnaral tin dɛn we de apin. Di patikyula choice bitwin wan hot rana ɛn kol rɔna mold go dipen pan di yunik nid dɛm fɔ ɛni prɔdak ɛn manifakta. Bɔku industri dɛn kin yuz ɔl tu di kayn mol dɛn fɔ difrɛn aplikeshɔn dɛn.

Di men tin na fɔ tek tɛm luk wetin yu nid fɔ mek di prodakshɔn, di prɔpati dɛn we yu gɛt, ɛn di badjɔt. Dis go ɛp yu fɔ pik di mold tayp we go alayns fayn wit yu gol ɛn kɔnstrakshɔn.

Dɔn

Hot Runner ɛn Cold Runner mold dɛn ɔl gɛt spɛshal bɛnifit ɛn prɔblɛm dɛn. Di wan dɛn we de rɔn hot kin gi fasta saykl ɛn dɛn nɔ kin west bɔku. Di wan dɛn we de rɔn kol kin tek mɔ kɔst ɛn dɛn kin yuz bɔku tin dɛn wit tin dɛn. I rili impɔtant fɔ tink bɔt yu prɔjek in patikyula nid dɛn we yu de pik wan sistɛm. Fakta dɛm lɛk kɔst, matirial kɔmpitibliti, ɛn prodakshɔn volyum impɔtant. Assɛst yu rikwaymɛnt dɛn fayn fayn wan. If yu luk wit di wan dɛn we sabi bɔt injɛkshɔn fɔ mold, dat kin mek shɔ se yu disayd fɔ du di bɛst tin fɔ yu prɔjek.

Kɔntakt Tim MFG fɔ ɛkspɛkt gayd fɔ pik di ɔptimal rɔna sistɛm fɔ yu injɛkshɔn moldin projɛkt. Wi ɛkspiriɛns injinia dɛn go gi wan ditayl kɔst-bɛnifit analisis ɛn ɛp yu fɔ mek di bɛst disizhɔn bay yu patikyula rikwaymɛnt dɛn. Rich out tide fɔ wan fri kɔnsultɛshɔn.