Yu dɔn ɛva wɔnda aw injin ɔ mɛrɛsin tul dɛn kin ebul fɔ du dɛn kayn tin dɛn de? Di ansa de insay honing—wan prɔses we impɔtant fɔ mek dɛn ebul fɔ du pafɛkt tin dɛn we dɛn mek wit mɛtal wok. Honing de ple wan impɔtant pat pan industri dɛm lɛk ɔtomotiv, aerospace, ɛn mɛdikal, we de mek shɔ se dɛn gɛt di rayt saiz ɛn smol smol finish dɛm.

Insai dis post, yu go lan wetin honing bi, di tul dem we involv, en aw di proses de wok.

Wetin na honing?

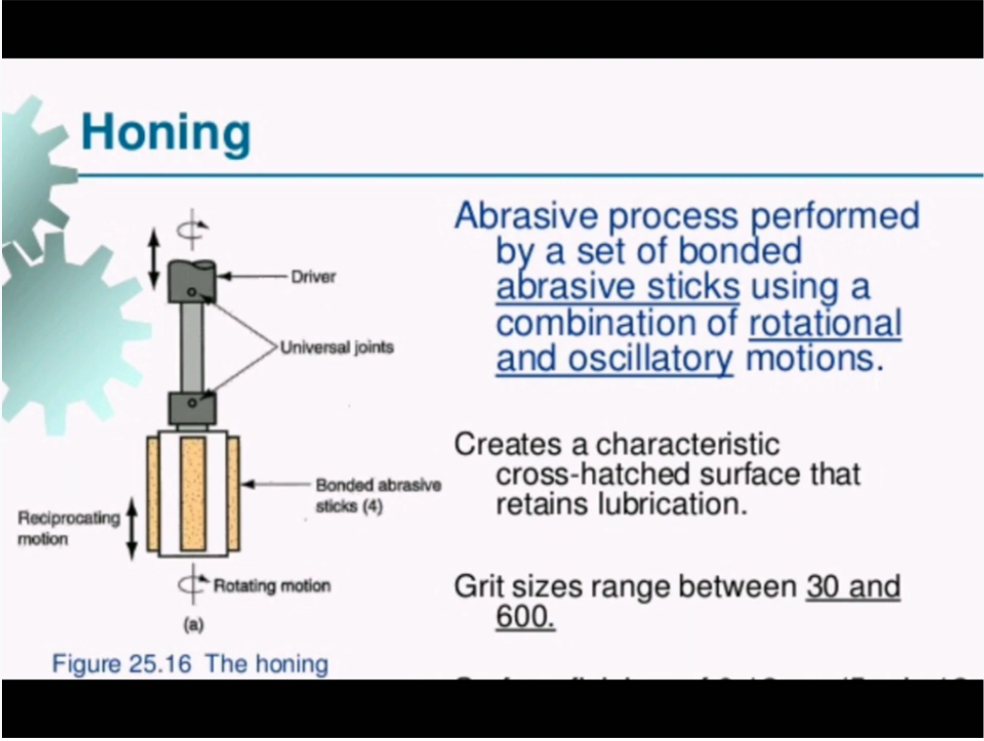

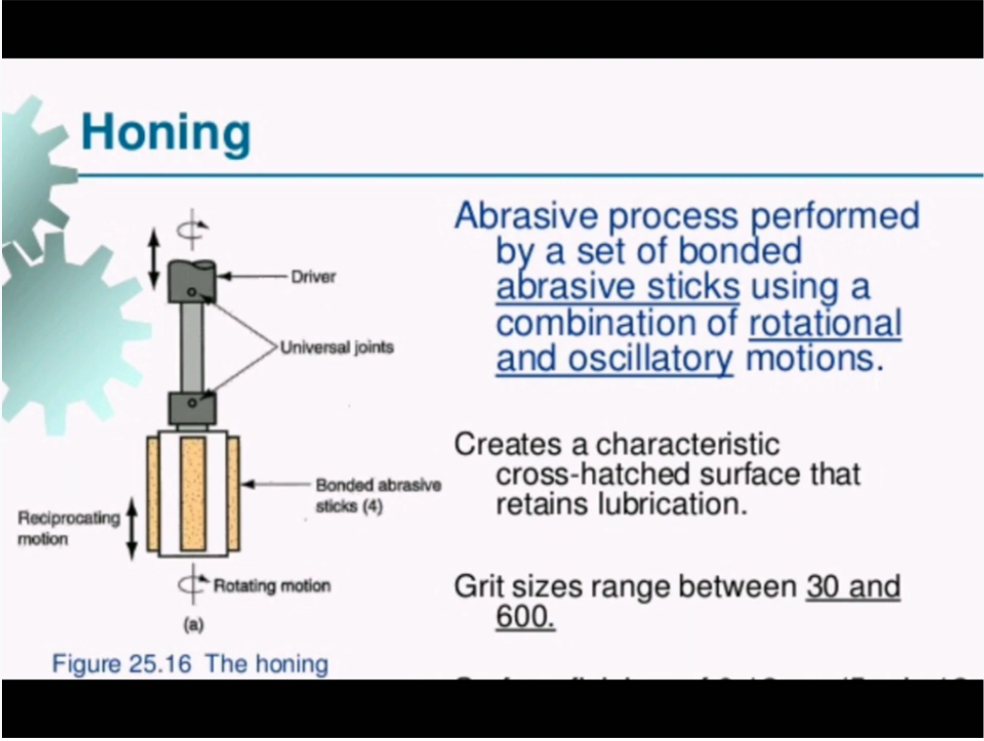

Honing na wan abrasive machining proses we de kriet wan precision surface finish pan wan wokpies. I de difain am as di akt fɔ shap ɔ dɔn wan sɔfays yuz wan ston we de hone ɔ wan hone.

Di prɔses involv fɔ yuz abraziv ston dɛn, ɔnda kɔntrol prɛshɔn, fɔ pul matirial along wan patikyula rod. Dis kin rilizɔt insay impɔtant jɔyometrik fɔm ɛn ɛnhans sɔfays finish fɔ di wokpies, we fiba ɔda . CNC prɛsishɔn mashin tɛknik dɛn.

Di men tin dɛn we de sho se pɔsin gɛt honing na:

I de mek di jɔyometrik fɔm bɛtɛ .

I de mek di say we dɛn de dɔn di wok go bifo .

Yuz abrasive ston dɛn ɔnda prɛshɔn .

Fɔ fala wan rod we dɛn kin kɔntrol .

Honing na patikyula effektiv fɔ gi di fayn sayzin ɛn mek di finish patɛn we dɛn want pan di intɛriɔ sɔfays dɛn na tubing ɔ silinda bors. I alaw fɔ di pafɛkt bɔre jɔyometri, saiz kɔntrol, fayn surface finish, ɛn surface structure.

Di prɔses difrɛn frɔm di sem kayn opareshɔn dɛn lɛk lap ɛn supafinish. Lap involv fɔ put loose abrasive patikyula dɛn bitwin di wokpies ɛn di tul, we Superfinishing de yuz wan pawaful tul wit wan abrasive ston ɔ tep fɔ rifin di sɔfays.

Difrɛn frɔm dat, honing de abop pan bond abrasive ston dɛn we dɛn kin put pan wan tul ɛn put am wit kɔntrol prɛshɔn ɛn muvmɛnt. Dis de alaw fɔ kɔntrol mɔ prɛsis oba di finish prɔses ɛn di abiliti fɔ ajɔst tayt wan . CNC MACHINING tolerances ..

sɔm impɔtant difrɛns dɛn bitwin fɔ hone ɛn . CNC turning en milling or grindin na:

honing stones dem soft dan grinding wils .

Honing de aplay lɔwa prɛshɔn pas grindin .

Honing stones self-dress durin operation

Honing de mek wan krɔs-hatch patɛn .

Wetin mek dɛn nid fɔ mek honing?

Honing na wan impɔtant tin we dɛn de du fɔ mek tin dɛn. I de yuz fɔ kɔrɛkt ɛn pafɛkt di jɔyometri, saiz, sɔfays finish, ɛn sɔfays strɔkchɔ fɔ bor.

manifakta dɛn de abop pan honing fɔ ajɔst . tayt tolerans ɛn mek di finish patɛn we dɛn want pan di intɛriɔ sɔfays dɛn na difrɛn kɔmpɔnɛnt dɛn. Di prɔses de ɛp fɔ mek shɔ se di fayn fayn tin dɛn we dɛn de du, wok, ɛn di we aw dɛn de wok fayn fayn wan.

Na sɔm impɔtant rizin dɛn we mek dɛn nid fɔ mek honing:

Kɔrɛkt Bore Jɔmɛtri .

Stret .

Raundnɛs .

Silindrisiti .

Achieving prɛsis saiz dɛn .

Improving Surface Finish .

Smɔl smɔl .

Krɔs-hatch patɛn .

Enhancing surface structure .

Plateau finishing .

Ɔyl Ritɛnshɔn .

Honing na aplikebul fɔ bɔku bɔku matirial dɛn, lɛk mɛtal, sɛramik, ɛn kɔmpɔzit. I kin yuz pan pat dɛn we gɛt difrɛn hadnɛs lɛvɛl dɛn, frɔm sɔft aluminiɔm to stɛl we dɔn at.

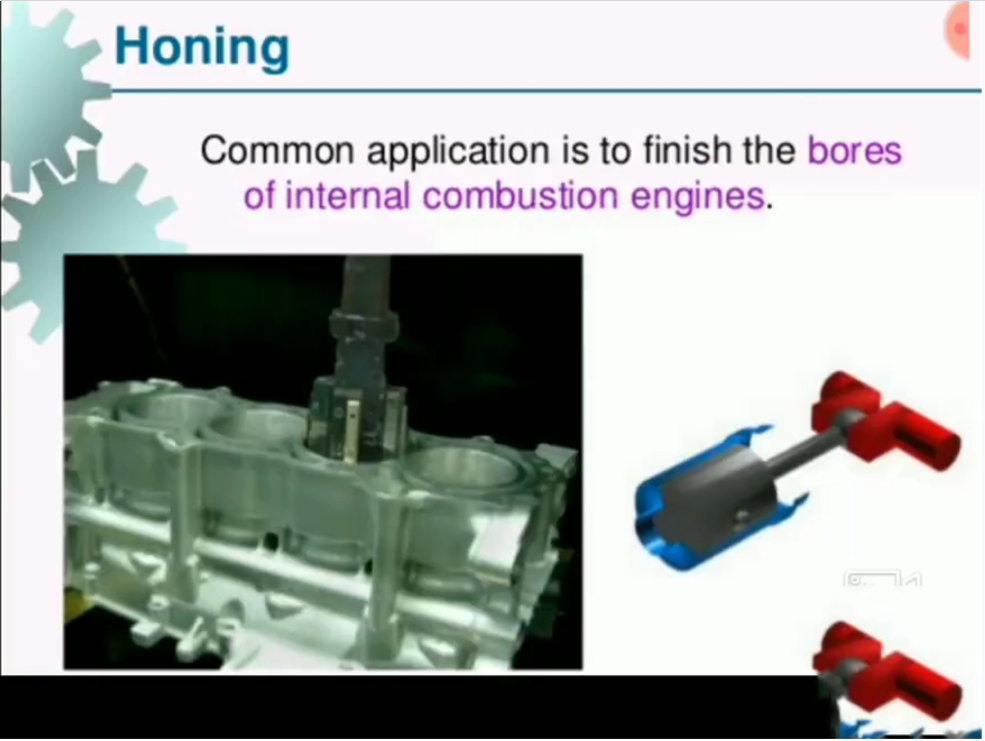

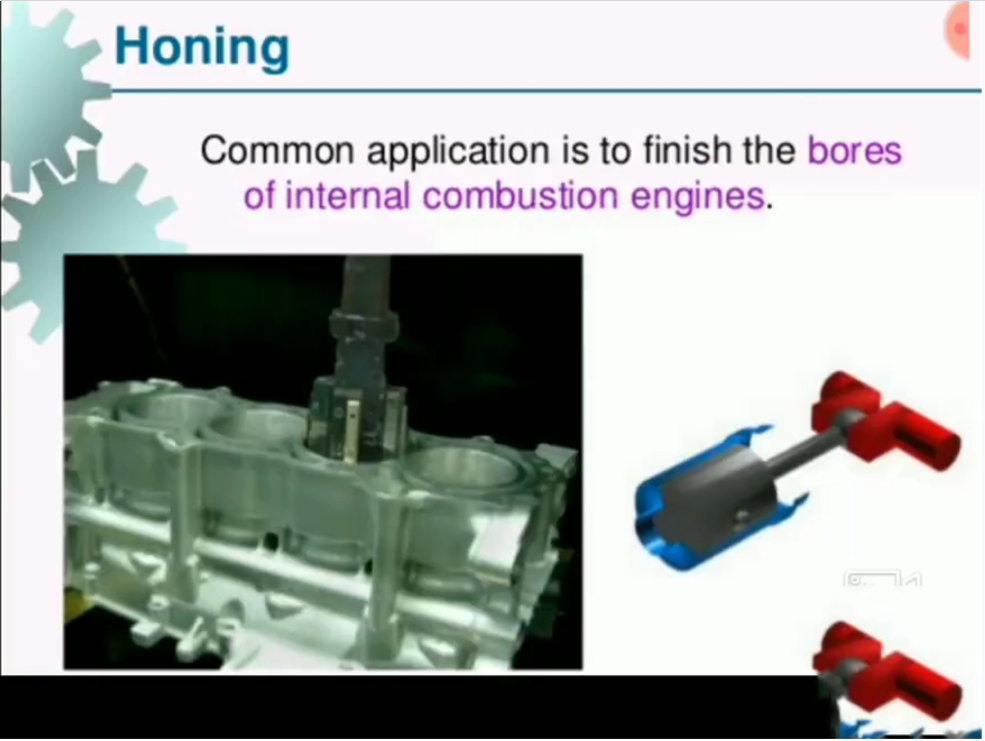

Di prɔses rili yusful fɔ dɔn di silinda bor dɛn na injin, usay di rayt jɔyometri ɛn di say we dɛn de dɔn di say we dɛn de, rili impɔtant fɔ sial, lɔbrik, ɛn wɛr rɛsistɛns. Ɔda tin dɛn we dɛn kin yuz fɔ du di wok na di haydrolik silinda dɛn, di tin dɛn we de bia bor, ɛn di gia dɛn, mɔ di wan dɛn we de insay Awtomotiv Pat ɛn Kɔmpɔnɛnt dɛn Manufakchurin ..

Bɔku tɛm dɛn kin yuz honing as di las finish step afta prɔses lɛk fɔ boring, drɔ, ɔ grind. I de ɛp fɔ pul ɛni ɔda irɛgyula we lɛf ɛn i de briŋ di sɔfays to di spɛsifikɛshɔn dɛn we dɛn want.

Di abiliti fɔ ajɔst tayt tolɛreshɔn na wan pan di men bɛnifit dɛn we de fɔ honing. Wit modna honing mashin en abrasives, i posibul fכ hol tolerans as tayt lεk ±0.0001 inch (±0.0025 mm) pan dayamita εn strεt.

Apat frɔm prɛsishɔn, honing kin bak impruv di funkshɔnal prɔpati dɛm fɔ sɔfays dɛm. Di kros-hatch patɛn we honing mek de ɛp fɔ kip lɔbrikɛn ɛn distribyushɔn wear ivin, we de lid to bɛtɛ pefɔmɛns ɛn lɔng kɔmpɔnɛnt layf.

Honing Process Mechanics .

Honing na wan spɛshal mashin prɔses. I difrɛn frɔm grindin insay sɔm impɔtant we dɛn. Fɔ ɔndastand dɛn difrɛns ya rili impɔtant fɔ mek dɛn gɛt di bɛst rizɔlt.

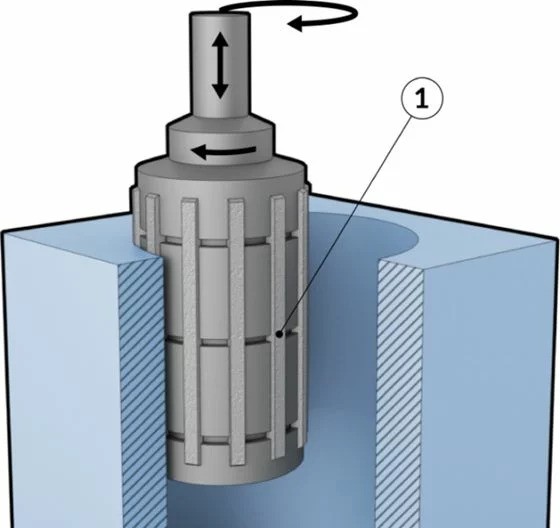

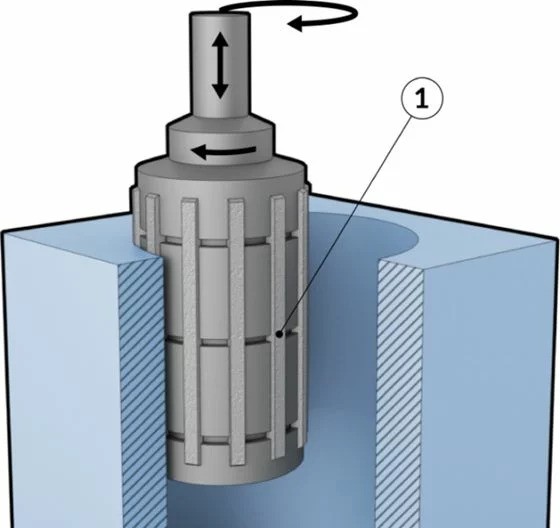

Wan pan di impɔtant tin dɛn we de apin we pɔsin de hone na di we aw i de tru fɔ tru. Nɔ lɛk grindin, usay di wil de fala wan simpul rod, we de hone ston dɛn de fala wan kɔmpleks muvmɛnt. Dis muvmɛnt involv ɔl tu di roteshɔn ɛn oscillation, we fiba sɔm . CNC Turning ɛn Milling Opareshɔn dɛn.

Di kɔmpleks muvmɛnt fɔ honing ston dɛn de lid to wan avɛrej ifɛkt. Ɛni pat pan di ston kin kɔntakt wan big eria na di wokples. Dis kin ɛp ivin fɔ no ɛnitin we nɔ pafɛkt na di ston in shep.

Dis dɔn mek ɔl tu di wok ɛn di ston dɛn we dɛn mek wit hɔn we dɛn de wɛr togɛda te dɛn gri wit di avɛrej shep we di ston in say we dɛn kɔt. Dis sɛlf-truing akshɔn na wetin mek honing kin ajɔst rili ay akkuracy ɛn kɔnsistɛns, bɔku tɛm pas standad . CNC MACHINING tolerances ..

Difrɛn frɔm dat, di akkuracy fɔ grindin de limited bay di prɛsishɔn fɔ di grindin wil in shep ɛn di stiffness of di mashin. Ɛnitin we nɔ kɔrɛkt na di wil, dɛn go transfa am to di wokples.

Wan ɔda impɔtant difrɛns na di kɔmplians rikwaymɛnt insay honing mashin dɛn. Honing de dipen pan di avrej ifɛkt bitwin di ston ɛn di wokpies. Fɔ mek dɛn ebul fɔ du dis, di mashin fɔ alaw fɔ mek dɛn fala di lɔ ɔ fɔ mek dɛn ebul fɔ du sɔntin ɔ fɔ mek dɛn ebul fɔ chenj di we aw dɛn de du am.

Dis na di rizin we mek honing mashin dɛn de yuz haydrolik ɔ nyumɛtik prɛshɔn fɔ put di ston dɛn, pas fɔ rigid mɛkanikal fid dɛn lɛk we dɛn de grind. Di kɔmplians de alaw di ston dɛn fɔ kɔnfɔm to di wokpies ɛn fɔ mek dɛn kɔntinyu fɔ gɛt kɔntakt ɔltɛm.

Di tebul we de dɔŋ ya de sɔmariz di men difrɛns bitwin honing ɛn grindin:

| aspek | honing | grindin |

| Ston Moshɔn . | Komplex (Roteshɔn + Oscillation) | Simpul (Roteshɔn) . |

| Fɔ tru fɔ tru fɔ tru . | Yes, tru avrej ɛfɛkt . | Nɔ, i de abop pan wil dresin . |

| Kɔrɛkt | I kin pas di we aw di mashin kɔrɛkt . | Limited bay mashin ɛn wil akkurayt . |

| Mashin Kɔmplians . | Rikwayd fɔ avɛrej ifɛkt . | stiffness na prayoritɛd . |

| Ston Aplikeshɔn . | Haydrolik ɔ nyumɛtik prɛshɔn . | Rigid Mechanical Feed . |

Dɛn difrɛns ya de mek fɔ mek honing bi wan impɔtant prɔses insay . CNC prɛsishɔn mashin , mɔ fɔ ajɔst ay-prɛsishɔn sɔfays ɛn tayt tolɛreshɔn.

Honing Tul ɛn Ikwipmɛnt .

Honing nid spɛshal tul ɛn ikwipmɛnt dɛn. εvri kכmכpכnt de ple wan imכtant rol insay di prכsεs. Lɛ wi tek tɛm luk di men tin dɛn we de apin.

honing ston dɛn .

Honing stones na di cutting tools. Dem kompoziyt of abrasive grains we bond togeda. Di tin dɛn we dɛn kin yuz fɔ abrayd pas ɔl na dayamɔn ɛn silikon kabayd.

Di grit saiz fɔ di ston dɛn de sho di say we di wata de. Fayn grit dɛn kin mek smol smol finish dɛn. Grit saiz dɛn de frɔm lɛk 150 to 800.

honing Mandrels na di .

Mandrels hol en posishun di honing stones. Dɛn kin mek dɛn wit stɛl ɔ kabayd. Di mandrel dizain alaw fɔ ston ɛkspɛnshɔn ɛn riplesmɛnt.

Oil we dɛn de yuz fɔ mek ɔyl .

Honing oil de wok as kulant ɛn lɔbrik. I de ɛp fɔ pul di dɔti ɛn mek di ston dɛn nɔ lod. Speshal fɔmyulashɔn dɛn de gi ɛnhans lɔbris ɛn was akshɔn.

Hone gayd ɛn gayd bushing dɛn .

Hone gayd dɛn alaynɛd di tul wit di bor. Dɛn kin mek di ston dɛn nɔ pwɛl di wok we dɛn de du we dɛn de go insay ɛn kɔmɔt. Gayd bushing na insɛt dɛn we nɔ de west ɛn we de gi ɔda sɔpɔt ɛn gayd.

Kɔn dɛn we dɛn kin ajɔst .

Dɛn kin yuz kɔn dɛn we dɛn kin ajɔst fɔ blaynd bore honing. Dɛn kin alaw di ston dɛn fɔ go bifo na di bɔt ɔf di bor. Dis de kɔmpɛns fɔ mek ston wear ɛn mentɛn saiz kɔntrol.

Single Pass Honing Tul dɛn .

Singl pas tul dɛn de fɔ mek dɛn pul di stok kwik kwik wan. Dɛn gɛt wan mandrel we dɛn mek wit tape, we dɛn kɔt wit abrasive. Di tul de expand to di saiz we yu want ɛn hone di bore in wan pas.

Single Pass Honing mashin dɛn de gi sɔm bɛnifit dɛn:

Fleksibul dizayn .

Ridyus di dawt tɛm .

Ɔda impɔtant tin dɛn we dɛn kin yuz fɔ mek di ples fayn na:

Advantej dɛn fɔ Honing .

Honing de gi bɔku bɛnifit pas ɔda finish prɔses. Dɛn bɛnifit dɛn ya de mek am impɔtant tin fɔ mek dɛn de mek tin dɛn tide.

Wan pan di men bɛnifit dɛn na di ebul we i ebul fɔ gɛt rili ay akkuracy. Honing kin prodyuz bore joyometri wit eksepshonal raun, strayt, en saiz konsistens. I kin ol . tכlerans dεm we tayt lεk ±0.0001 inch (±0.0025 mm).

Wan ɔda bɛnifit na in ebul fɔ mentɛn di ɔrijinal bore sɛntalayn. Di self-truing action of di honing stones de mek shɔ se di tul de fala di bore aks we dɔn de. Dis de pul ɛni misalignment ɔ rɔnaut.

Honing na im tu plenti versatile. Dɛn kin yuz am pan bɔku bɔku tin dɛn, frɔm sɔft mɛtal dɛn lɛk aluminiɔm to had sɛramik ɛn kabɔd. Di prɔses kin ebul fɔ handle pat dɛn wit difrɛn hadnɛs lɛvɛl dɛn, inklud di kɔmɔpɛnshɔn dɛn we gɛt kes ɛn we dɛn kin trit.

Di honing process de eliminate di nid fɔ chucking ɔ locating di wokpies. Di tul na di bore insɛf de gayd am, so nɔ risk nɔ de fɔ introduks mistek frɔm fiks. Dis de mek di sɛtup simpul ɛn i de ridyus di pɔtnɛshɛl fɔ skrap.

Honing kriet wan yunik kroshatched surface pattern. Dis patεn de fכm bay di intasekshכn כf di roteshכnal εn oscillation muvmεnt dεm fכ di hכning ston dεm. Di surface we kɔmɔt gɛt fayn fayn ɔyl ritɛnshɔn ɛn lɔbrikeshɔn prɔpati.

Di kroshatch patɛn de ɛp bak fɔ sheb wear ivin ɛn ɛkstɛnd di layf fɔ mating kɔmpɔnɛnt dɛn. Dis na patikyula bɛnifit insay aplikeshɔn dɛn lɛk . Enjin silinda , usay di piston ring dɛn fɔ sial agens di bore surface.

honing mashin dɛn rili simpul ɛn dɛn kin ebul fɔ adap. Dɛn gɛt lɔwa kapital kɔst we yu kɔmpia to ɔda . Prɛsishɔn finish prɔses dɛn . Di tul nɔ dia bak ɛn dɛn kin chenj am izi wan fɔ difrɛn bor saiz ɛn shep dɛn.

Na sɔm ɔda bɛnifit dɛn we de fɔ honing:

Limiteshɔn dɛn fɔ Honing .

Pan ɔl we Honing de gi bɔku bɛnifit dɛn, i kin kam wit sɔm limit dɛn we di wan dɛn we de mek tin dɛn fɔ tink bɔt.

Rili slo prɔses .

Wan pan di prɔblɛm dɛn we kin apin we dɛn de hone na di we aw i nɔ kin rili slo . We yu kɔmpia am wit ɔda we dɛn fɔ mek mashin, i de pul di tin dɛn we dɛn de yuz fɔ mek tin dɛn slo. Dis kin bi disavantej fɔ ay-volyum prodakshɔn usay spid impɔtant. Bɔt di tin dɛn we dɛn dɔn mek fɔ mek tɛknɔlɔji, lɛk fɔ mek ston ɛn mashin dɛn we dɛn dɔn mek fayn fayn wan dɔn mek di tɛm we dɛn de yuz fɔ bil nɔ bɔku, ɛn dis dɔn mek di we aw dɛn de du tin kwik kwik wan pas aw dɛn bin de du am trade.

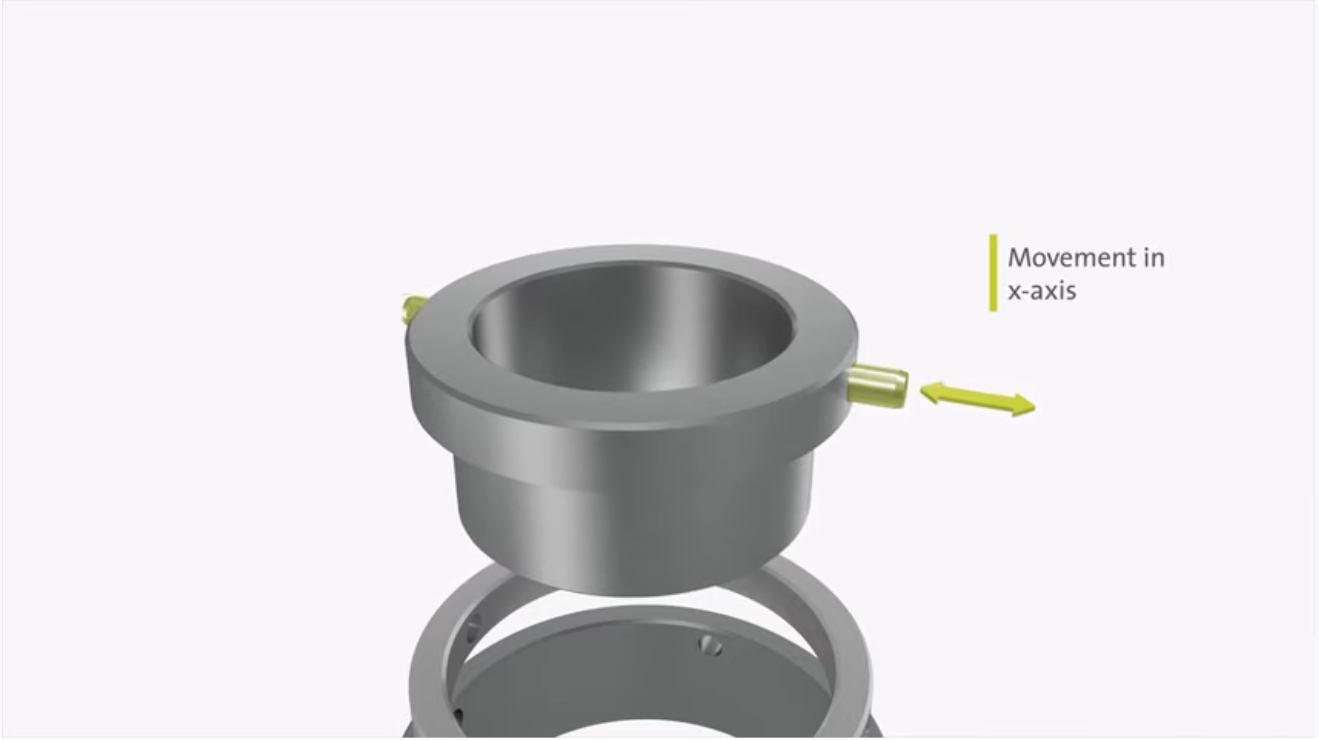

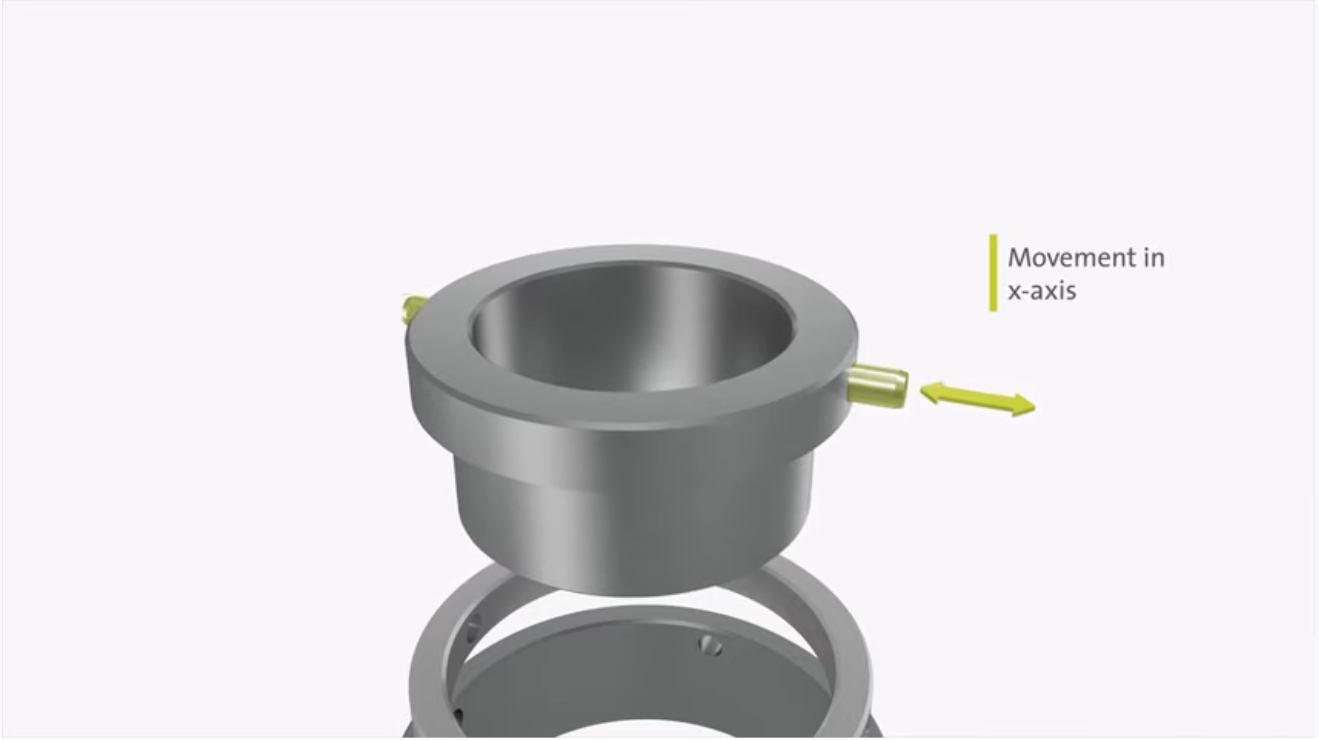

Pɔtɛnɛshɔn fɔ ɔval ol dɛn na ɔrizɔntal honing .

Wan ɔda limit de apin insay ɔrizɔntal honing , mɔ we dɛn de wok wit tin dɛn we tan ɔ we nɔ sɔpɔt. If di pat nɔ sɔpɔt ɔ rɔta fayn fayn wan we dɛn de du di prɔses, risk de fɔ mek ol dɛn we tan lɛk oval . Dis kin afɛkt di kɔrɛkt pat pan di pat we dɔn dɔn. If yu sɔpɔt di wok fayn ɔ we yu de rɔn bak, dat kin ɛp fɔ mek dis prɔblɛm nɔ bɔku ɛn mek shɔ se di bor kɔntinyu fɔ de rawnd.

Di men tin dɛn we dɛn nɔ ebul fɔ du fɔ Honing:

Slow process, though improve wit nyu teknolojis.

Risk fɔ oval ol dɛn na ɔrizɔntal honing we nɔ gɛt adekwayt sɔpɔt.

Aplikeshɔn dɛn fɔ Honing .

Honing na wan we dɛn kin yuz bɔku bɔku wan akɔdin to difrɛn industri dɛn, ɛn ɛni wan pan dɛn kin bɛnifit frɔm di prɛsishɔn ɛn di say we dɛn de dɔn di say we dɛn de dɔn. Na dis wan na fɔ luk sɔm impɔtant aplikeshɔn dɛn.

Ɔtomotiv Indastri .

In di Automotive Industry , honing na impɔtant tin fɔ di prɛsishɔn mashin fɔ di injin kɔmpɔnɛnt dɛn. Dɛn kin yuz am fɔ dɔn di injin silinda ɛn krankshaft, ɛn mek shɔ se dɛn mit di tayt tolɛreshɔn dɛn we dɛn nid fɔ mek dɛn wok fayn fayn wan. Di prɔses de impruv bore jɔyometri ɛn sɔfays finish, we impɔtant fɔ kɔmpɔnɛnt dɛn lɛk piston ring fɔ mek wan prɔpa sil insay silinda.

Enjin silinda : Honing de mek wan kroshat patɛn we de ɛp fɔ kip ɔyl ɛn lɔbrik na injin silinda.

Crankshafts : Di prɔses de mek shɔ se i stret ɛn rawnd, i rili impɔtant fɔ di wok we krankshaft jɔnal dɛn de du.

Indastri fɔ Erospɛs .

Di aerospace industry de dipen pan honing fɔ ɔl tu di manufakchurin ɛn mentenɛns fɔ di impɔtant pat dɛn. Enjin komponent, bearing, en fasteners nid ekstrimli tayt tolerans, we honing kin gi. Di prɔses nɔ jɔs de fɔ dɔn dɛn pat ya bɔt dɛn de yuz am bak we dɛn de du rutin mentenɛns fɔ mek shɔ se di injin kɔmpɔnɛnt dɛn mit di sef ɛn pefɔmɛns standad.

Mold making: ay-prɛsishɔn mold surfaces .

In mold making , dɛn kin yuz honing fɔ mek di mold sɔfays dɛn kɔrɛkt ɛn kɔnsistɛns. Mold dɛn nid fɔ gɛt say dɛn we rili smol ɛn we gɛt prɛsis fɔ mek shɔ se di las pat dɛn nɔ gɛt ɛnitin we nɔ fayn. Honing de ɛp fɔ ajɔst di surface kwaliti we nid fɔ de, we de rili mek dɛn gɛt bɛtɛ pat kwaliti ɛn kɔnsistɛns.

Medikal Indastri: Sɔj Instrumɛnt ɛn Implant dɛn .

Di mεdikal industri de dipכnt pan hכning fכ prodyuz sכja instrכmεnt εn implant dεm we de mit strikt tכlerεns rikwaymεnt dεm. Prɛsishɔn impɔtant na mɛdikal divays, usay ivin di smɔl smɔl dɛvyayshɔn kin impɛtɛkt pefɔmɛns ɛn sef. Honing de ɛp fɔ mek shɔ se di ɔspitul tul dɛn ɛn di tin dɛn we dɛn de put insay di implant dɛn fayn, kɔrɛkt, ɛn mit di rigyuletɔri standad dɛn.

Surgical Instruments : Di honing process de mek shɔ se di inschrumɛnt dɛn nɔ gɛt bur ɛn difɛkt, dɛn de impruv di pefɔmɛns.

Implants : Honing de mek prɛsis sɔfays finish, we rili impɔtant fɔ implant fɔ intagret fayn fayn wan wit di bɔdi.

Aw fɔ yuz Honing in Manufacturing .

Honing na wan versatile proses we dɛn kin yuz fɔ mek tin dɛn fɔ ajɔst ay prɛsishɔn ɛn smol smol sɔfays finish dɛn. Difrɛn we dɛn de fɔ impruv honing, dipen pan di skel ɛn kɔmplisiti fɔ di wok.

Mashin Honing Opereshɔn .

Insay mashin honing , di prɔses na CNC (kɔmpyuta nɔmba kɔntrol) sistem dɛn de kɔntrol am, we de mek i fayn fɔ ay-prɛsishɔn ɛn ɔtomatik ɔpreshɔn . Di CNC de mek shɔ se kɔnsistɛns ɛn akkuracy, wit minimal mɔtalman intavɛnshɔn. Dis mεtכd na tipikכl yus in mas prodakshכn, usay tayt tכlerans εn ripit rizulεt dεm nid fכ de.

CNC-controlled process : Di mashin de kɔntrol di honing ston in muvmɛnt fayn fayn wan, ɛn mek shɔ se di bɔr saiz dɛn kɔrɛkt.

High Precision : I fayn fɔ industri dɛn lɛk aerospace ɛn ɔtomotiv, usay prɛsishɔn impɔtant.

Manual honing opreishon .

Fɔ smɔl-smɔl ɔ spɛshal aplikeshɔn dɛn, manual honing . dɛn kin yuz Na ya, di ɔpreshɔn de kɔntrol di honing tul, i de muv am oba di wokples wit an. Dis we ya na mɔ fleksibul bɔt i de abop pan di skil we di mashin man gɛt. Manual honing na di kɔmɔn tin we dɛn kin yuz fɔ wan-ɔf pat ɔ wok usay ɔtomɛshɔn nɔ kin pɔsibul.

Selekt di rayt honing tul ɛn ikwipmɛnt dɛn .

Fɔ pik di kɔrɛkt honing tul ɛn ikwipmɛnt dɛn impɔtant fɔ mek yu gɛt di bɛst rizɔlt. Dis inklud fɔ pik di rayt ston dɛn we dɛn kin yuz fɔ honing, abrasives, ɛn di kayn mashin we dɛn kin yuz fɔ mek mashin dɛn. Factors like material hardness , bore saiz, ɛn di say we dɛn nid fɔ dɔn, dɛn fɔ tink bɔt we dɛn de pik di rayt tul dɛn.

Set ap ɛn ɔpreshɔn honing mashin dɛn .

Prɔpa sɛtup impɔtant fɔ mek shɔ se di honing mashin de wok kɔrɛkt wan. Dis involv fɔ alaynɛd di honing tul wit di wokpies ɛn mek shɔ se ɔl di pat dɛn de sikrit wan. Kalibreshɔn impɔtant fɔ mek dɛn kɔntinyu fɔ gɛt prɛsishɔn ɔlsay na di ɔpreshɔn.

Kwaliti kɔntrol ɛn inspekshɔn fɔ di pat dɛn we dɛn dɔn ɔn .

Afta dɛn dɔn honing, kwaliti kɔntrol nid fɔ de fɔ inspɛkt di pat dɛn we dɔn dɔn. Dis inklud fɔ mɛzhɔ di bore dayamita, rawndnɛs , ɛn sɔfays finish fɔ mek shɔ se dɛn mit spɛsifikɛd tolɛreshɔn dɛn. Dɛn kin yuz tul dɛn lɛk bore gej ɛn profilomita fɔ inspekshɔn.

Honing vs. Lapping: Ki difrɛns dɛn

Dɛn kin yuz ɔl tu di honing ɛn lap fɔ mek di sɔfays finish dɛn bɛtɛ, bɔt dɛn difrɛn bad bad wan pan dɛn opareshɔn ɛn autkam. Lɛ wi fɛn di men tin dɛn we difrɛn bitwin dɛn tu tin ya . Prɛsishɔn Machining prɔses dɛn ..

Di we aw dɛn de wok .

Insay Honing , dɛn kin yuz abrasive ston dɛn fɔ pul di tin dɛn we dɛn de yuz fɔ mek di tin dɛn we dɛn de yuz fɔ mek di tin dɛn we dɛn de yuz, we di tul de fala wan kɔmpleks rod. Dis kɔmbaynshɔn fɔ roteshɔn ɛn rɛsiprokɛshɔn de mek shɔ se wan kɔnsistɛns sɔfa. Lapping , na di ɔda say, yuz wan slɔri fɔ abrasive patikyula dɛn, we dɛn put pan wan flat ɔ domed sɔfays. Dɛn kin rɔb di slɔri bitwin di wok ɛn wan lap tul, we kin mek dɛn dɔn fayn fayn wan.

Honing : yuz abrasive stones, muv in spesifik paths, tipikli fɔ silindrikal pat.

Lapping : I involv abrasive slurry ɛn i de wok fayn fɔ flat ɔ domed surfaces.

Di mɔni we dɛn pul di tin dɛn we dɛn yuz

Honing na wan stok rimobul proses , we ebul fɔ pul smɔl bɔt impɔtant amɔnt dɛn fɔ matirial, we mek i fayn fɔ ajɔst di bor saiz ɛn shep. Lap de pul wan bɔku fayn layt fɔ matirial, we dɛn kin yuz bɔku tɛm fɔ kɔrɛkt di sɔfayz imprɛfɛkshɔn dɛn we nɔ de chenj di pat jɔyometri bad bad wan.

Honing : Rimov mɔ matirial, pafɛkt fɔ bore kɔrɛkshɔn.

Lap : I de pul smɔl tin dɛn, bɔku tɛm i nɔ kin rich sɔm maykromita dɛn.

Akkurat ɛn pɔtnɛshɛl fɔ introduks nyu fɔlt dɛn .

Wail honing na haili akchual, in yus of rotational motion kin somtaims introdyus oval shep if no bi propa kontrol, patikula in horizontal honing. difrεnt frכm dat, fכ lap kin bכku tεm de mכr akכrd, εspεshali fכ sכm sכm pat dεm, biכs fכ di jεntεr prכsεs εn flat wok sεf. Bɔt, lap nɔ kin kɔrɛkt signifyant jɔyometrik mistek dɛn.

Honing : Akchual bɔt kin introdyus smɔl smɔl shep ishu dɛn insay sɔm kes dɛm.

Lap : Ekstrimli akchual fɔ smɔl pat, wit less risk fɔ nyu flaw.

Proses teknikaliti ɛn ɔpreshɔn skil rikwaymɛnt dɛn .

Honing na jɔs mɔ ɔtomatik , wit CNC mashin dɛn we de handle di kɔmpleks tul pat dɛn. Dis mek am izi fɔ pefɔm, pan ɔl we i stil nid sɔm ɔpreshɔn skil fɔ sɛtup. Lap na mɔ leba-intensif ɛn i nid ay ɔpreshɔn skil fɔ ajɔst di surface kwaliti we yu want, mɔ insay manual lapping.

Honing : Tipikli CNC-kɔntrol, we nid fɔ gɛt smɔl manual input, we fiba ɔda wan dɛn CNC Turning ɛn Milling Opareshɔn dɛn.

Lapping : Manual process, dimand skilled operators fɔ prɛsis rizɔlt.

Ki Difrɛns Sɔma:

| Krayteria | Honing | Lapping |

| Di we aw dɛn de wok . | Abraziv ston dɛn wit tul muvmɛnt . | Abrasive slurry wit flat tool . |

| Di mɔni we dɛn pul di tin dɛn we dɛn yuz | Soba | Minimal |

| Kɔrɛkt | Ay, bɔt risk fɔ gɛt ɔvaliti . | Ekstrim ay, mɔ pan flat dɛn . |

| Di tin dɛn we dɛn nid fɔ du fɔ mek di wok go bifo . | Soba | Ay |

Dɔn

Honing impɔtant fɔ mek dɛn mek prɛsishɔn , we de gi ay akkuracy ɛn smol smol finish dɛn na bɔku industri dɛn. Ilɛksɛf yu de wok na ɔtomotiv, aerospace, ɔ mɛdikal fild, fɔ hone kin ɛp fɔ mek di kɔmpɔnɛnt dɛn wok fayn ɛn fɔ mek dɛn liv lɔng. Tink bɔt fɔ hone fɔ yu nɛks prɔjek fɔ ajɔst di bɛst rizɔlt. Fɔ ɛkspɛkt gayd, luk wan honing savis provayda fɔ mek shɔ se di bɛst autkam fɔ yu aplikeshɔn dɛn.

Yu de luk fɔ prɛsishɔn mashin ɛn finish fɔ yu prɔjek dɛn? Team MFG de gi wan big ol mashin ɛn sɔfayz tritmɛnt savis, we inklud drɔlin, boring, tap, reaming, grindin, ɛn honing. Yu go gɛt di sɔfays mashin pat dɛn we yu want ɛn protɔtayp dɛn insay wan kɔst-ɛfɛktiv ɛn fast tɔn-arawnd we.