Yu dɔn ɛva wɔnda bɔt di plastic we de insay yu wata bɔtul? I go mɔs bi se na PET, na matirial we dɔn rivɔlɔshɔn pak. Frɔm di 1940s, dis versatile matiryal dɔn transfɔm industri ɛn ɛvride layf.

Insai dis post, yu go lan boht pet plastic, in propati, taip, aplikeshon, en aw dem proses am etc.

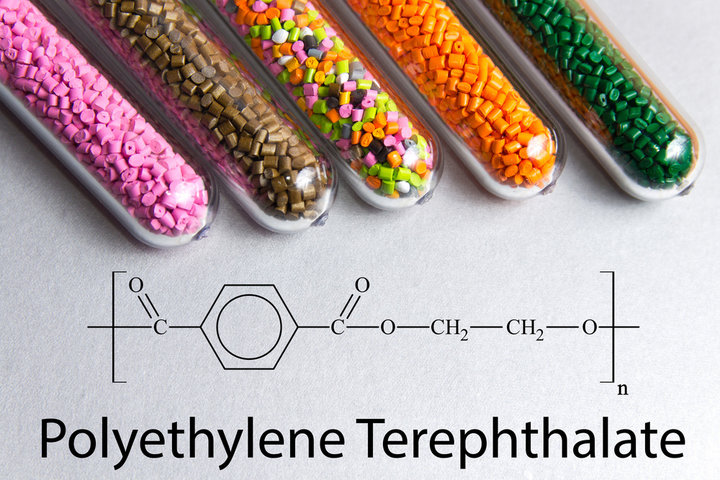

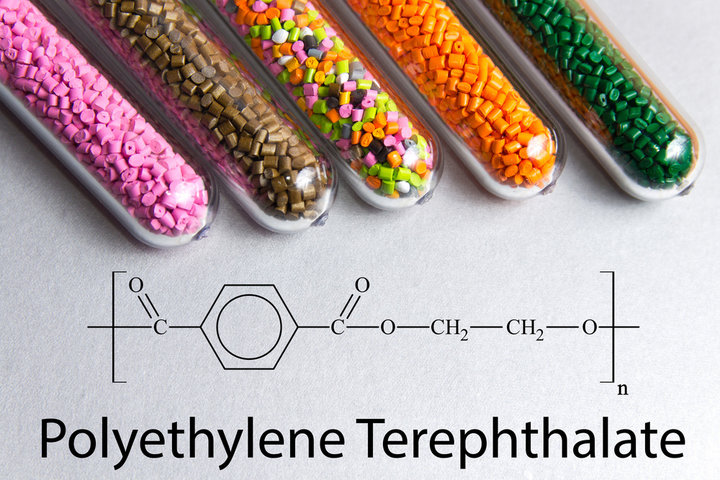

Wetin na Pɛt Plastik?

PET, shɔt fɔ polyethylene terephthalate, na wan thermoplastic polima we dɛn kin yuz bɔku bɔku wan. Na di polyester famili we gɛt matirial dɛn gɛt.

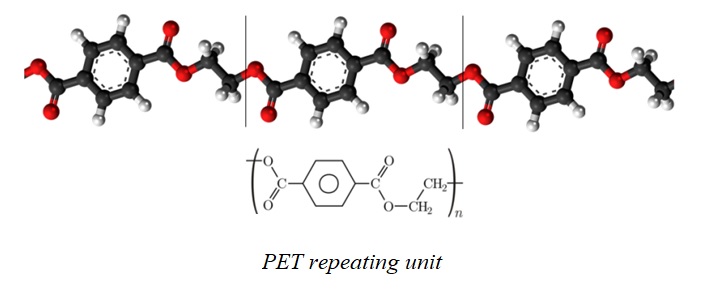

Polyethylene terephthalate (PET), we dɛn kin kɔl bak in kemikal fɔmula (C10H8O4)N , na wan polyɛsta polima we dɛn mek frɔm tu men tin dɛn:

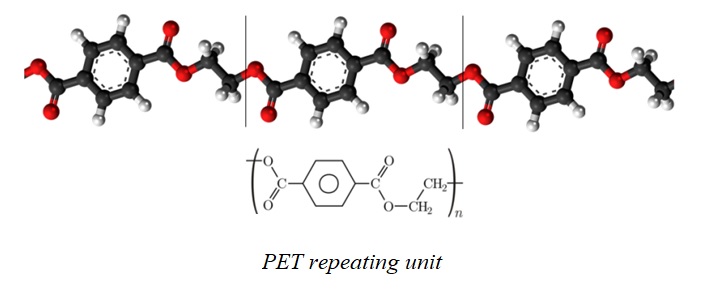

Molekyular strɔkchɔ fɔ polyethylene terephthalate .

dis mכlikul dεm de kam togεda fכ fכm lכng, ripit chen dεm we de gi PET in trεnk εn fleksibiliti.

Aw dɛn kin mek animal dɛn we dɛn kin mɛn na os?

Di prodakshɔn fɔ PET plastic involv sɔm step dɛn. I de stat wit di raw matirial ɛn dɔn wit difrɛn kayn we dɛn fɔ mɛn animal dɛn.

Raw Matirial dɛn .

PET na tu praymari raw matirial dɛn mek am:

Ethylene Glycol (eg) : Na likwid we nɔ gɛt kɔlɔ, we nɔ gɛt smel. eg na frכm εtilen, we kכmכt frכm petrolium כ nεchכral gas.

Terephthalic acid (TPA) ɔ dimethyl terephthalate (DMT) : Dɛn wan ya kɔmɔt frɔm p-xylene, we dɛn kin gɛt bak frɔm petroleum. TPA na tin we dɛn kin yuz mɔ bikɔs ɔf in lɔwa kɔst.

Polimerizayshɔn prɔses .

Di raw matirial dɛn de ɔnda wan tu-stej polimɛrayzeshɔn prɔses fɔ fɔm PET:

Esterification ɔ Transesterification : ɛgz., de riak wit TPA (esterification) ɔ DMT (transesterification) fɔ mek bis-haydroksiɛtil tɛreftalɛt (BHET) monomɛr. Dis step de pul wata ɔ mɛtanɔl as bayprɔdakt.

Polycondensation : BHET monomers de riak wit wan an anda ay temperechur (arawnd 280°C) en vacuum. Dɛn kin mek lɔng pet polima chen dɛn. Di las prodak na wan molten, viskɔs pet resin.

Prɔpati dɛn fɔ Pɛt Plastik .

Pɛt plastic de sho bɔku bɔku prɔpati dɛn. Dɛn prɔpati ya de mek am fayn fɔ difrɛn aplikeshɔn dɛn. Lɛ wi dayv insay di ditil dɛn fɔ ɛni prɔpati kategori.

| Prɔpati Kategori | Prɔpati | Diskripshɔn/Valyu |

| Fizik prɔpati dɛn . | Tik | 1.3 g/cm³, laytwɛt yet durable |

| Mekanikal prɔpati dɛn . | Tensile Strɔng . | 55–75 MPA we de na di wɔl. |

| Impɛkt rɛsistɛns . | ay, we nɔ de pwɛl ɔ we de brok brok . |

| Fleksibul fɔ mek yu ebul fɔ chenj . | Gud, kin mold in difrɛn shep dɛn . |

| Dimenshɔnal stebiliti . | Eksɛlɛnt, de mentɛn fɔm ɔnda ɔt ɛn prɛshɔn . |

| Young in Modulus . | 2.0–2.7 GPA, de kɔntribyut to stiffnɛs |

| Di prɔpati dɛn we dɛn kin yuz fɔ mek di ples wam . | Point we de mɛlt . | 250–260 ° C |

| Glas transishɔn tɛmpracha (TG) . | 70–80°C, soften oba dis renj |

| Tempracha we de mek di ɔt nɔ wam (HDT) . | 65–80°C, de mentɛn shep ɔnda mɔdaret ɔt |

| Ilɛktrik prɔpati dɛn . | Insuleshɔn . | Eksɛlɛnt, strɔng ilɛktrik barɛri . |

| Dielectric strength . | Ay, fayn fɔ ilɛktronik ɛn ilɛktrik kɔmpɔnɛnt dɛn . |

| Optik prɔpati dɛn . | Transparency . | Ay, alaw layt fɔ pas tru witout distɔrshɔn . |

| Klarity . | High, ideal fɔ klia pak |

| Kεmikכl rεsistεns . | Resistance to alcohol, hydrocarbon, oil, ɛn diluted acids . | Strɔng rɛsistɛns to difrɛn kemikal dɛn . |

| Di prɔpati dɛn we de na di baria . | Ɔksijɛn Pɛrmiabiliti . | Low, kip di tin dɛn we de insay de fresh |

| Kabon dayɔgzayd pɔrmiabiliti . | Low, de mek gas nɔ de lik . |

| Moisture resistans . | Ay, de mek wata nɔ pas tru . |

Fizik prɔpati dɛn .

Mekanikal prɔpati dɛn .

Tensile Strɔng : Pɛt gɛt ay tɛnsiɛl trɛnk we na lɛk 80 MPa. I kin ebul fɔ bia wit impɔtant strɛch fɔs dɛn bifo i brok.

Impact Resistance : I gɛt gud impak resistans, mɔ we dɛn chenj am wit aditiv. PET kin absɔb ɛnaji frɔm impak dɛn we nɔ go brok.

Fleksibul : PET na rili fleksibul fɔ wan plastic. I kin bɛn ɛn nɔ brok, alaw fɔ difrɛn shep ɛn dizayn dɛn.

Dimensional stabiliti : I de mentɛn in shep ɛn saiz ɔnda nɔmal kɔndishɔn. PET gɛt low shrinkage rate, we de mek shɔ se di dimɛnshɔn dɛn we dɛn de yuz kɔnsistɛns.

Young's Modulus : Pet gɛt Young in modulus we de arawnd 2-4 GPa. Dis de sho in stiffness ɛn resistans to difɔmeshɔn ɔnda strɛs.

Di prɔpati dɛn we dɛn kin yuz fɔ mek di ples wam .

Melting point : PET gɛt mɛlt pɔynt we na 260°C. I kin ebul fɔ bia wit ay tɛmpracha we nɔ de difɔm ɔ mɛlt.

Glas transishɔn tɛmpracha (TG) : Di TG fɔ PET na arawnd 70°C. Dɔŋ dis tɛmpracha, Pɛt de rigid ɛn brit. Abov TG, i kin bi mɔ fleksibul.

Hɛt distɔshɔn tɛmpracha (HDT) : PET gɛt HDT we na 75°C ɔnda wan lod we na 0.45 MPa. I kin mentɛn in shep ɔnda ɛlevɛt tɛmpracha.

Ilɛktrik prɔpati dɛn .

Insulation : PET na wan fayn fayn ilɛktrik inshɔlat. I gɛt ay rɛsistɛns to ilɛktrik kɔrɛnt flɔ.

Dielectric Strength : I kin ebul fɔ bia wit di ay vɔltɛm gradient dɛn we nɔ de kɔndɔkt ilɛktrishɔn. PET gɛt dayelɛktrik trɛnk we na lɛk 17 kV/mm.

Optik prɔpati dɛn .

Transparency : Dɛn kin mek PET insay klia, transparent fɔm dɛn. I de alaw fɔ mek pɔsin si tin dɛn we de insay di paket fayn fayn wan.

Klarity : PET gɛt fayn fayn klia tin, we de alaw fɔ ditayli vishɔn inspekshɔn. Bɔku tɛm dɛn kin yuz am fɔ klia bɔtul ɛn kɔntena dɛn.

Kεmikכl rεsistεns .

Resistance to alcohol, hydrocarbon, oil, and diluted acids : PET nɔ de gri wit bɔku kɔmɔn kemikal dɛn. I kin ebul fɔ bia wit di we aw dɛn de drink rɔm, ɔyl, ɛn asid dɛn we dɛn dɔn dil wit we nɔ de pwɛl.

Di prɔpati dɛn we de na di baria .

Ɔksijɛn ɛn Kabon Dayɔksayd Pɛrmiabiliti : Pɛt gɛt gud barɛri prɔpati dɛn agens ɔksijɛn ɛn kabon dayɔgzayd. I de ɛp fɔ kip di fresh we aw dɛn pak tin dɛn we dɛn pak.

Moisture Resistance : PET nɔ de gri wit di mɔs ɛn di humidity. I de mentɛn in prɔpati ɛn pefɔmɛns insay wet ɛnvayrɔmɛnt.

Di we aw dɛn de mek tin dɛn fɔ di animal dɛn we dɛn de mɛn na PET .

PET plastic de gi yu versatility in manufakchurin. Lɛ wi fɛn di men prɔses dɛm we de shep dis matirial to ɛvride prɔdak dɛm.

Moldin fɔ injɛkshɔn .

Injɛkshɔn moldin de transfɔm PET to prɛsis shep dɛn. Na so i de wok:

Melt pet resin (240-280°C)

Injekt insay mold kaviti ɔnda ay prɛshɔn .

Kul ɛn sɔlidify .

Ejekt dɔn we dɔn dɔn fɔ pat .

Tempracha kɔntrol na impɔtant tin. I de afɛkt pat kwaliti ɛn saykl tɛm.

Di kɔmɔn tin dɛn we dɛn kin yuz na:

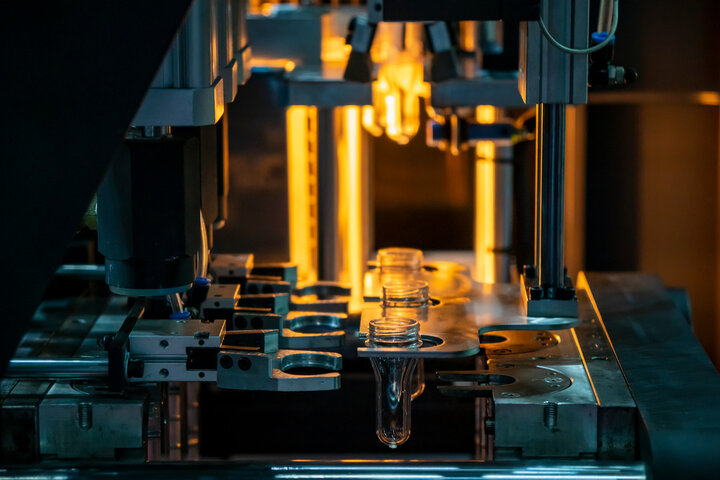

Blow moldin na na na na na na na na na na na na na na na na na na na na na na na na na na na na na na na na na na na na na na na na na na

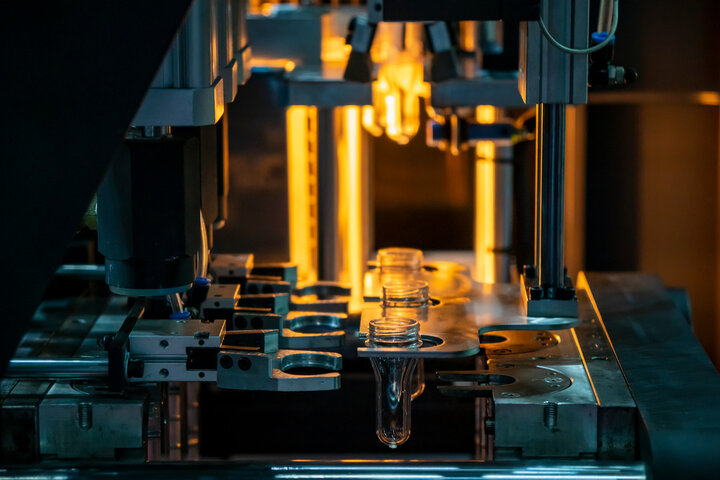

Stretch blow molding na impɔtant tin fɔ mek dɛn prodyuz bɔtul fɔ animal dɛn. Di prɔses involv:

Krio PET Preform via injekshɔn moldin .

Hɛt prɛfɔm .

Stretch ɛn inflayt wit kɔmprɛsd ɛya .

Kul in mold .

Dis we ya de mek bɔtul dɛn we gɛt yunifom wɔl tik. I fayn fɔ:

Ekstrushɔn .

Extrusion de mek pet sheet ɛn fim dɛn. Di we aw dɛn de du am:

Melt pet (270-290°C)

Fos tru wan day .

Kul ɛn sɔlidify .

Extruded pet na yuz in:

Di tin dɛn we dɛn kin yuz fɔ pak it trey dɛn .

Di tin dɛn we dɛn kin yuz fɔ kɔt di tin dɛn we dɛn de yuz fɔ protɛkt .

Termoformed prodakt dɛn .

3D Printing we dɛn de yuz fɔ print .

PET ɛn PETG filaments de gɛt pɔpulɛshɔn na aditiv manufakchurin. Di bɛnifit dɛn we pɔsin kin gɛt na:

Ay fleksibiliti ɛn taf .

Gud layt adhesion .

Low shrinkage ɛn wɔpej .

3D print pet na in dɛn kin yuz fɔ:

Protɔtayp dɛn .

Kastɔm pat dɛn .

Intrikɛt dizayn dɛn .

Melt we de spin .

Melt spinning de prodyuz pet fayba fɔ tekstil. Di step dɛn:

Melt pet resin .

Ekstrud tru spinnerets .

Kul ɛn sɔlidify filamɛnt dɛn .

Stretch to alayne polimer chens .

Dɛn kin yuz dɛn fayv ya na:

Klos we .

Upholstery na di .

Kapɛt dɛn .

Indastrial Tekstil dɛn .

Ɛni manufakchurin prɔses de gi yunik bɛnifit dɛn. Dɛn alaw PET fɔ mit difrɛn prɔdak nid dɛn akɔdin to di industri dɛn.

Tayp dɛn fɔ PET .

Bɔku kayn plastic dɛn de we dɛn kin mɛn animal dɛn, ɛn ɛni wan pan dɛn gɛt spɛshal prɔpati dɛn we kin mek dɛn fit fɔ difrɛn aplikeshɔn dɛn.

Pet we dɛn kɔl amorphous (APET) .

Amorphous Pet (APET) na wan we dɛn sabi fɔ in fayn fayn transparency ɛn elasticity . Bikɔs i nɔ gɛt kristal strɔkchɔ, APET stil klia ɛn fleksibul, we mek i fayn fɔ fim ɛn pak aplikeshɔn dɛn. I klia se i de mek shɔ se di prɔdak dɛn izi fɔ si tru di pak, we in ɛlastik de alaw fɔ izi fɔ mol insay difrɛn shep dɛn.

| Prɔpati | APET . |

| Transparency . | Ay |

| Elastisiti . | Fleksibul ɛn moldable . |

| Aplikeshɔn dɛn . | Films, Packaging Materials |

PETG (glycol-modified pet)

PETG na wan modifyed vεshכn fכ PET wit glycol we dεn ad di tεm we di polimεrayzeshn prכsεs de. Dis de gi am ɛnhans taf ɛn prɔsesabiliti , we de mek am izi fɔ mol ɛn shep we yu kɔmpia am wit standad PET. Bɔku tɛm dɛn kin yuz PETG na tɛknikal pat ɛn strɔng pak aplikeshɔn dɛn bikɔs i ebul fɔ bia wit impak we i de kɔntinyu fɔ chenj.

| Fit fɔ | PETG . |

| Toughness . | ay, witstand impak . |

| Prosesabiliti fɔ mek dɛn ebul fɔ du di wok . | I izi fɔ mol ɛn fɔm . |

| Aplikeshɔn dɛn . | Teknik pat dɛn, robust paket . |

Fɔ no mɔ fɔ PETG, yu kin chɛk di gayd pan Wetin na PETG ..

Pet we dɛn dɔn risaykul (RPET) .

Risaykul PET (RPET) na tin we dɛn kin mek wit animal dɛn we dɛn kin yuz fɔ mɛn animal dɛn we dɛn kin yuz fɔ mɛn animal dɛn lɛk bɔtul ɛn pak. Dis risaykul prɔses de gi bɔku envayrɔmɛnt bɛnifit , we de ridyus di nid fɔ vajin plastic prodakshɔn. RPET de kip bɔku pan di prɔpati dɛn we Virgin Pet gɛt ɛn dɛn kin yuz am bɔku bɔku wan na tɛkstayl , nyu bɔtul , ɛn ɔda prɔdak dɛn. We yu yuz RPET, i de mek yu nɔ yuz bɔku ɛnaji ɛn i de ɛp fɔ mek yu nɔ west plastic.

| Benefit | Risaykul Pɛt (RPET) . |

| Di impak we di envayrɔmɛnt gɛt . | ridyus ɛnaji yus, less plastic west . |

| Aplikeshɔn dɛn . | Tekstil, bɔtul, pak, kapɛt, kapɛt |

Fayba dɛn we dɛn kin mɛn na os .

Dɛn kin mek animal dɛn we dɛn kin mɛn na os tru di mɛlt spinin prɔses ɛn dɛn kin yuz dɛn bɔku bɔku wan na tɛkstayl ɛn industrial aplikeshɔn dɛn . Dɛn fayv dɛn ya kin te, dɛn nɔ kin rɔtin, ɛn i izi fɔ kia fɔ dɛn, dɛn kin mek dɛn pɔpul na klos, ɔplɔsti, ɛn kapɛt. Apat frɔm dat, di fayv dɛn we dɛn kin mɛn na os kin gi trɛnk ɛn fleksibiliti fɔ yuz insay industrial fabrik dɛn.

| Prɔpati | Pɛt Fayba dɛn . |

| Durability . | Ay, lɔng-last insay tɛkstayl dɛn . |

| Aplikeshɔn dɛn . | Klos, upholstery, industry fabrik dɛn . |

Aplikeshɔn dɛn fɔ Pɛt Plastik .

Pɛt plastic na versatile, fɔ fɛn yus insay bɔku bɔku industri dɛn tank to in trɛnk, klia, ɛn risaykulabiliti. Lɛ wi fɛn sɔm pan in men aplikeshɔn dɛn.

Packaging .

PET na di go-to choice fɔ difrɛn pak sɔlvishɔn dɛn bikɔs ɔf in transparency, durbility, ɛn baria prɔpati dɛn.

Food and Beverage Containers : Pet botul ɛn jɔg dɛn kin kip drink dɛn fresh bay we dɛn de mek ɔksijɛn nɔ go insay.

Cosmetic and Personal Care Packaging : Di tin dɛn we Pet gɛt klia wan de sho di prɔdak kɔlɔ ɛn tɛkstɔr dɛn, we de mek i fayn fɔ loshan ɛn krim.

Famasiutik Packaging : Dɛn kin yuz PET fɔ blista pak ɛn kɔntena dɛn, fɔ mek shɔ se sef ɛn fɔ mek di prɔdak intɛgriti.

Sourcing frɔm unuo's . Wholesales 60ml 100ml skwea plastic petg serum botul aplikeshɔn

| diskripshɔn | diskripshɔn |

| Fɔd & drink kɔntena dɛn . | Dɛn kin yuz am fɔ wata bɔtul dɛn, soda bɔtul dɛn, ɛn jɔg dɛn . |

| Cosmetic packaging we dɛn mek wit kɔsmɛtik . | Krim, loshan, ɛn ɔda tin dɛn fɔ kia fɔ yusɛf . |

| Packaging we dɛn mek wit mɛrɛsin . | Blister pak, pil bɔtul, ɛn ɔda wan dɛn |

Tekstil dɛn .

Pɛt fayv dɛn kin te ɛn dɛn kin yuz dɛn bɔku bɔku wan na di tɛkstayl industri.

Klos ɛn Apɛl : Dɛn kin chenj di fayv dɛn we dɛn kin mɛn na os to polyɛsta klos, we kin mek klos kin te ɛn i nɔ kin rɔtin.

Ɔm Furnishings : Dɛn kin yuz animal dɛn we dɛn kin mɛn na di os fɔ mek kapɛt , kɔtin , ɛn fɔ mek ɔplɔsti, ɛn dɛn kin yuz ɔl tu di tɛm we dɛn go de ɛn di izi we fɔ mek dɛn kɔntinyu fɔ de.

Indastrial Fabrik : Indastrial yus dɛn inklud kɔnvayɔr bɛlt, filta, ɛn sefty gia bikɔs ɔf PET in ay trɛnk.

Enjinia Plastik dɛn .

Dɛn kin yuz PET fɔ mek tin dɛn we go de fɔ lɔng tɛm ɛn we dɛn kin abop pan fɔ mek injinɛri.

Ɔtomotiv Pat dɛn : Dɛn kin mol PET insay pat dɛn lɛk sit bɛlt, dashbɔd kɔmpɔnɛnt dɛn, ɛn aybag os dɛn.

Ilɛktrik ɛn Ilɛktronik Kɔmpɔnɛnt dɛn : Di prɔpati dɛn we de insay de mek animal dɛn gɛt fayn fayn tin dɛn fɔ di sirkit bɔd ɛn kɔnɛkta dɛn.

Mashinery and equipment : Dɛn kin yuz PET bɔku tɛm na gia, bia, ɛn os fɔ mek i nɔ wear.

Divays dɛn fɔ mɛn pipul dɛn .

PET de ple impɔtant pat pan di wɛlbɔdi biznɛs, mɔ na say dɛn we dɛn nɔ gɛt stɛriyl.

Surgical sutures : Dɛn kin yuz animal dɛn we dɛn kin mɛn fɔ mek dɛn ebul fɔ tek di sutures we dɛn kin absɔb ɛn we nɔ kin absɔb, we kin mek shɔ se dɛn gɛt trɛnk ɛn dɛn kin ebul fɔ chenj.

Divays dɛn we dɛn kin put insay di bɔdi : PET na bayɔkɔmpatibl, we de mek i fayn fɔ divays dɛn we dɛn kin put insay di bɔdi.

Medikal Pakɛj : Pɛt de mek shɔ se dɛn pak stɛriyl fɔ mɛdikal inschrumɛnt ɛn sapɔt.

Fim ɛn Shit dɛn .

Dɛn kin yuz PET bɔku bɔku wan fɔ mek fim bikɔs i klia ɛn i gɛt trɛnk.

Packaging films : Dɛn fim ya de gi fayn fayn tin fɔ mek dɛn pak tin fɔ it, fɔ protɛkt frɔm wet ɛn gas.

Lamination Films : Dɛn kin yuz PET film dɛn fɔ laminat dɔkyumɛnt ɛn pak fɔ protɛkt frɔm wear ɛn tear.

Grafik art ɛn printin : Pɛt fim dɛn de gi di durabiliti we nid fɔ gɛt ay kwaliti grafik, fɔ mek shɔ se dɛn kip di kɔlɔ ɛn shap.

3D Printing we dɛn de yuz fɔ print .

PET ɛn PETG na pɔpul matirial dɛn na 3D printin bikɔs dɛn izi fɔ yuz ɛn fɔ mek dɛn go de fɔ lɔng tɛm.

PET ɛn PETG filaments : Dɛn filament ya strɔng ɛn fleksibul, dɛn kin yuz dɛn fɔ protɔtayp ɛn funkshɔn pat dɛn.

Prototyping ɛn functional parts : PETG in durabiliti ɛn resistans mek am fayn fɔ mek kɔstɔm pat wit rial-wɔl aplikeshɔn.

Blending pet wit ɔda polimɛr dɛn .

Blɛnd PET wit ɔda polimɛr dɛn de ɛp fɔ mek i wok fayn, we de mek i fayn fɔ mek dɛn gɛt mɔ aplikeshɔn dɛn we de aks fɔ mɔ. Lɛ wi fɛn aw PET de blɛnd wit tɛmplastik, tɛmsɛt, ɛn rɔba fɔ mek i go fayn, fɔ mek i ebul fɔ chenj, ɛn fɔ mek i go te.

Tɛmɔplastik blɛnd dɛn .

Blɛnd PET wit tɛmplastik lɛk polyethylene (PE) , polycarbonate (PC) , Polypropylene (PP) , ɛn akrilonitril Butadiene Styrene (ABS) de mek i tranga ɛn i de mek pɔsin ebul fɔ chenj. Dɛn blɛnd ya na fayn tin fɔ aplikeshɔn dɛn we nid trɛnk, durabiliti, ɛn impak rɛsistɛns.

PET/PE Blends : Ɛnjɔy fleksibiliti ɛn taf, bɔku tɛm dɛn kin yuz am na pak ɛn industrial pat.

PET/PC blends : Kɔmbayn ɔt rɛsistɛns wit mɛkanikal trɛnk, we de mek dɛn fayn fɔ ɔtomotiv kɔmpɔnɛnt dɛn.

PET/PP Blends : Inkris impak resistans, kɔmɔn insay ɔtomotiv ɛn os guds.

PET/ABS blends : Impruv taf ɛn fleksibiliti, ideal fɔ kɔshɔma ilɛktroniks.

| Tɛmɔplastik blɛnd | ki prɔpati | aplikeshɔn dɛn . |

| Pɛt/Pe . | Impɔtant fleksibiliti, tafnɛs . | Packaging, Indastrial Pat dɛn |

| Pet/pc na di 1999. | Hɛt rɛsistɛns, trɛnk . | Otomotiv komponent dɛn, ilɛktroniks . |

| Pɛt/PP . | Impɛkt rɛsistɛns . | Otomotiv, guds we de na os . |

| Pɛt/ABS . | Toughness, Fleksibul . | Di Kɔnsuma Ilɛktroniks, kes dɛn . |

Tɛmosɛt Blɛnd dɛn .

We dɛn blɛnd wit thermosetting resin dɛn lɛk epoxy , polyester , ɛn phenolic resin dɛn , pet geins ɛnhans tɛmal ɛn mɛkanikal prɔpati dɛn. Dɛn blɛnd ya na pafɛkt fɔ ay-tɛmpracha ɛnvayrɔmɛnt ɛn aplikeshɔn dɛn we de aks fɔ lɔng tɛm durabiliti.

Pet/Epoxy Blends : Gi fayn fayn tɛmal stebiliti, we dɛn kin yuz bɔku tɛm na kɔtin ɛn ilɛktrik insuleshɔn.

Pet/Polyester Blends : Impruv impak trɛnk ɛn kemikal rɛsistɛns, yusful insay ɔtomotiv ɛn aerospace industri.

PET/phenolic resin blends : Enhans flame retardans ɛn mɛkanikal trɛnk, we de mek dɛn fayn fɔ ilɛktrik kɔmpɔnɛnt ɛn ay-stres ɛnvayrɔmɛnt.

| Tɛmosɛt Blɛnd | Ki Prɔpati | Aplikeshɔn dɛn . |

| Pet/Epoxy . | Tɛmral stebiliti, insuleshɔn . | Kotin, ilektrikal insuleshɔn . |

| Pɛt/Polyɛsta . | Impekt Strɔng, Kwɛmyuɛl Resistɛns . | Automotiv, Aerospace |

| Pet/Fɛnɔlik rɛsin dɛn . | Flaym retardans, mekkanikal trɛnk . | Ilektrikal komponent, ay-stress envairomɛnt dɛn . |

Rɔba Blɛnd dɛn .

Blɛnd Pɛt wit rɔba lɛk nitrile butadiene rɔba (NBR) ɛn Styrene Butadiene Rɔba (SBR) de mek i go te ɛn i nɔ de mek i nɔ west ɛn te. Dɛn blɛnd ya rili yusful fɔ aplikeshɔn dɛn we nid fɔ mek dɛn ebul fɔ chenj ɛn gɛt ay rɛsistɛns to ɔyl ɛn kemikal dɛn.

PET/NBR Blends : Ɛnjɔy ɔyl resistans ɛn fleksibiliti, we dɛn kin yuz fɔ sial ɛn gasket.

PET/SBR Blends : Gi fayn fayn tin dɛn we go de fɔ lɔng tɛm ɛn we go mek dɛn nɔ gɛt impak, we dɛn kin yuz fɔ mek motoka taya ɛn industrial hos dɛn.

| Rɔba Blɛnd | Ki Prɔpati | Aplikeshɔn dɛn . |

| Pɛt/NBR . | Oil Resistance, Fleksibul . | Sil, gasket, hos . |

| Pɛt/SBR . | Durability, impak resistans . | Otomotiv taya, Indastrial Aplikeshɔn dɛn . |

Kɔmpiashɔn fɔ PET wit ɔda polimɛr dɛn .

PET de gi yu wan spɛshal kɔmbaynshɔn fɔ prɔpati dɛn, bɔt aw i kin stak agens ɔda plastic dɛn we dɛn kin yuz bɔku tɛm? Lɛ wi kɔmpia Pɛt wit ɔda pɔpul polimɛr dɛn we i kam pan trɛnk, fleksibiliti, envayrɔmɛnt impak, ɛn mɔ.

Pɛt vs Polipropilɛn (PP) .

PET gɛt mɔ trɛnk ɛn transparency kɔmpia to . Polipropilɛn (PP) . Pan ɔl we dɛn kin yuz PET bɔku bɔku wan na klia pak, PP kin tipikul mɔ fleksibul ɛn dɛn kin yuz am na aplikeshɔn dɛn lɛk tɛkstayl ɛn ɔtomotiv pat dɛn . PET in bɛtɛ baria prɔpati dɛn mek am di prɛferɛd chuk fɔ bɔtul ɛn it pak usay visibiliti ɛn freshnɛs impɔtant.

| Property | pet | pp . |

| Trɛnk | Di wan dɛn we ay pas ɔl . | Soba |

| Transparency . | Ay | Soba |

| Aplikeshɔn dɛn . | Bɔtul, Klia Pakɛj | Tekstil, ɔtomotiv kɔmpɔnɛnt dɛn . |

Pɛt vs polyvinyl klorayd (PVC) .

PET de gi bɛtɛ kemikal rɛsistɛns ɛn transparency kɔmpia to . Polyvinyl chloride (PVC) , we de fleksibul mɔ bɔt we nɔ de ambɔg di envayrɔmɛnt. PVC gɛt fayn fayn durabiliti insay kɔnstrɔkshɔn matirial dɛn lɛk paip ɛn winda frem, we PET na favɔret fɔ it-grɛd pak ɛn mɛdikal aplikeshɔn bikɔs ɔf in inɛt nature. PVC in klorin kɔntinyu de rayz envayrɔmɛnt kɔnsyans we dɛn de prodyuz ɛn trowe.

| Properti | pet | pvc . |

| Kεmikכl rεsistεns . | Wɛl dɔn | Soba |

| Fleksibul fɔ mek yu ebul fɔ chenj . | Semi-rigid na | ay we dɛn plasticiz . |

| Di impak we di envayrɔmɛnt gɛt . | Ridyus | ay pas dat, bikɔs ɔf klorin kɔntinyu . |

| Aplikeshɔn dɛn . | Packaging, Medikal Divays dɛn . | Paip, kebul, winda frem . |

Pɛt vs ay-dɛnsitis polyethylene (HDPE) .

we yu kɔmpia am wit . High-density polyethylene (HDPE) , PET excels in Clarity and Transparency , we mek i fayn fɔ klia kɔntena dɛn lɛk wata bɔtul. Bɔt HDPE nɔ kin gɛt mɔ prɔblɛm wit strɛs krak krak ɛn dɛn kin yuz am bɔku bɔku wan na ɔda aplikeshɔn dɛn lɛk paip ɛn stɔrɔj tank. Dɛn tu tin ya kin rili risaykul, bɔt di we aw dɛn kin yuz PET bak kin fayn fɔ it ɛn drink kɔntena dɛn.

| Property | pet | hdpe . |

| Klarity . | High, ideal fɔ klia pak | Opaque we yu de yuz |

| Stress krak krak . | Di wan dɛn we de agens di ɔda wan dɛn we de dɔŋ . | Di ay resistans . |

| Risayklabliti . | Ay, kɔmɔn fɔ risaykul . | High, yuz in difrɛn aplikeshɔn dɛn . |

Pet vs polycarbonate (pc)

Polycarbonate (PC) de du mɔ pas PET we i kam pan impak resistans , we de mek i fayn fɔ glas ɛn sef ikwipmɛnt . Bɔt, PET gɛt bɛtɛ UV rɛsistɛns , we de mek i stebul mɔ na ɔda aplikeshɔn dɛn we nɔ gɛt ɔda kɔtin. PET na in bak dɛn kin yuz bak fɔ pak it bikɔs ɔf in transparency ɛn inert nature, usay PC kin fɛn mɔ yus insay optik disk ɛn ɔtomotiv pat dɛn.

| prɔpati | pet | pc . |

| Impɛkt rɛsistɛns . | Soba | Ay |

| UV resistans . | Di wan dɛn we ay pas ɔl . | I nid fɔ gɛt UV stebyulayza dɛn . |

| Aplikeshɔn dɛn . | Fɔ it tin dɛn, bɔtul dɛn we dɛn kin drink . | Sefty ekwipmɛnt, optik disk dɛn . |

PET vs biaxially oriented polipropylene (bopp)

We yu kɔmpia am wit biaxially oriented polypropylene (BOPP) , PET gɛt bɛtɛ baria prɔpati fɔ ɔksijɛn ɛn mɔstɔ , we mek i fayn fɔ lɔng shelf layf prɔdak. Bopp , na di ɔda say, de gi big big skɔf rɛsistɛns ɛn dɛn kin yuz am bɔku bɔku wan na lɛbl ɛn fleksibul pak . Pet in tɛnsiɛl trɛnk de gi am di edj insay aplikeshɔn dɛn we nid fɔ de fɔ lɔng tɛm ɛn rigiditi.

| Property | pet | bopp . |

| Di prɔpati dɛn we de na di baria . | I fayn fɔ ɔksijɛn ɛn mɔstɔ . | Soba |

| Tensile Strɔng . | Di wan dɛn we ay pas ɔl . | Ridyus |

| SKƆF RƐSISTANS . | Soba | Higher, ideal fɔ fleksibul paket . |

Sastaynabiliti ɛn risaykul fɔ PET .

Di impak we di envayrɔmɛnt gɛt .

PET pas glas ɛn aluminiɔm insay ɛnaji efyushɔn. Na dis mek:

Layt: nid fɔ gɛt smɔl fiul fɔ transpɔt .

Strɔng: Lɛs matirial we dɛn nid fɔ pak tin dɛn .

Low diffusion coefficient: de mentɛn di prɔdak kwaliti fɔ lɔng

Di bɛnifit dɛn we PET gɛt fɔ di envayrɔmɛnt:

PET Risayklin Prɔses .

Tu men we dɛn de yuz Risaykul PET:

Mekanikal risaykul:

Sɔt ɛn klin .

Shredding insay flɛks .

Melt ɛn ri-pɛlɛtiz .

Kεmikכl Risaykul:

RPET (Recycled Pet) Fɛn Yuz insay:

Di statystik fɔ risaykul di wɔl .

Di ret fɔ risaykul animal dɛn kin difrɛn ɔlsay na di wɔl:

| Rijyɔn | Risaykul Rɛt . |

| WI | 31% |

| Yurop . | 52% |

Rum fɔ impɔtant tin dɛn de ɔlsay na di wɔl. Edukeshon en infrastrakcha de ple ki rol.

Sastaynabiliti ɛfɔt dɛn .

We yu yuz RPET, i de gi yu bɔku bɛnifit dɛn:

Kɔpɔt initiativs we de drɛb PET risaykul:

Supplying risaykul bins (650,000+ provayd)

Upgrading Processing Equipment .

Educating Consumers on Proper Recycling .

Dɛn tray ya gɛt fɔ du wit fɔ gɛda mɔt bɔtul. Di gol? Rimek dɛn insay nyu bɔtul dɛn.

Sef ɛn Rigyuleshɔn fɔ Pɛt Plastik .

PET in bɔku bɔku yuz de aks fɔ strikt sefty standad. Lɛ wi fɛn di rigyuleshɔn dɛn we de mek shɔ se i sef aplikeshɔn.

Food sefty asesmɛnt .

PET dɔn gɛt bɔku tɛst fɔ kɔntakt fɔ it. Di men tin dɛn we dɛn fɛn:

Inert Material: Nɔ de riak wit it ɔ drink

Low maigrɛshɔn: Minimal transfa fɔ sɔbstans to it .

Nɔbɔdi nɔ no bɔt wɛlbɔdi prɔblɛm we dɛn yuz am lɛk aw dɛn bin dɔn yuz am lɛk aw dɛn bin want am fɔ .

Globɛl Sɛtifiket dɛn .

Di rigyuletɔri ɛjɛnshi dɛm ɔlsay na di wɔl dɔn gri fɔ mek dɛn pet fɔ it kɔntakt:

| Ejensi | Rijyɔn |

| FDA . | Amɛrika |

| EFSA . | Yuropian Yuniɔn . |

| Ɛlth Kanada . | Kanada |

Dɛn aprɔval ya de sho di sef we PET gɛt insay di aplikeshɔn fɔ pak tin dɛn fɔ it.

Medikal Aplikeshɔn dɛn Sefty .

Di we aw dɛn de yuz PET na mɛdikal divays dɛn, dɛn dɔn mek am fayn fayn wan. I valyu fɔ:

Bayokompatibiliti: Nɔ de mek bad bad tin apin to yu na di bɔdi .

Sterilizability: Dɛn kin stɛrilayz am witout digradishɔn .

Durability: Mentɛn intɛgriti na mɛdikal ɛnvayrɔmɛnt .

Di kɔmɔn mɛrɛsin dɛn we dɛn kin yuz na ɔspitul sutura ɛn divays dɛn we dɛn kin put insay di bɔdi.

Rigyuletɔri Kɔmplians .

Pet mit difrɛn glob ɔl rigyuleshɔn dɛn:

Rich (EU): Rejistret ɛn Kɔmpliant

ROHS: Nɔ gɛt tin dɛn we dɛn dɔn stɔp fɔ yuz .

Propɔshɔn 65 (Kalifɔnia): Nɔ risk dɛn we dɛn no bɔt na nɔmal ɛksplɔshɔn lɛvɛl dɛn

Impɔtant Notis dɛn:

Dɛn rigyuleshɔn ya de mek shɔ se PET in sef akɔdin to difrɛn aplikeshɔn ɛn rijyɔn dɛn.

Wrap up

Pɛt plastic de ple impɔtant pat pan wi ɛvride layf. Di trɛnk we i gɛt, di we aw i ebul fɔ chenj, ɛn di we aw i kin yuz am bak kin mek i ebul fɔ du bɔku tin dɛn fɔ bɔku aplikeshɔn dɛn, frɔm pak to tɛkstil. We wi ɔndastand di prɔpati dɛn we PET gɛt, wi kin mek bɛtɛ chus bɔt aw wi de yuz ɛn trowe am. Lɛ wi kɔntinyu fɔ prɔyoritɛt risaykul ɛn sataynabul prɔsis na wi ɛvride layf.

Tips: Yu maybe intres to di ol plastics