Polysulfon (PSU) plastic na wan ay-perfomans matiryal we dɛn sabi fɔ in durability ɔnda ekstrim kɔndishɔn. Frɔm mɛdikal tul dɛn to aerospace pat dɛn, PSU de gi yu trɛnk we yu nɔ go biliv, ɔt rɛsistɛns, ɛn kemikal stebiliti. Insai dis post, yu go lan abaut PSU Plastic in yunik propati dem and wai e bi di top choice across difren indastri dem.

Wetin na PSU plastic?

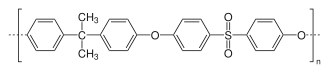

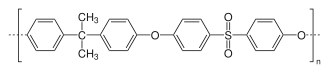

PSU, ɔ polysulfone, na wan ay-perfɔmans tɛmplastik we dɛn sabi fɔ in fayn fayn prɔpati dɛn. i kכmכp fכ ripit yunit dεm fכ sכlfכn grup dεm εn aromat ring dεm, we de mek wan strכng εn stebul polimכr strכkchכ.

Dis yunik kemikal kompozishun de gi PSU in autstandin kwaliti dɛm, lɛk:

Di ay tempɔret rɛsistɛns .

Eksɛlɛnt dimɛnshɔnal stebiliti .

Gud kemikal resistans .

Remarkable Mechanical Strɔng .

We yu kɔmpia am wit ɔda tɛmplastik, PSU tinap bikɔs ɔf in abiliti fɔ mentɛn in prɔpati dɛn ova wan wayd tɛmpracha rɛnj. I kin ebul fɔ bia wit di tɛmpracha frɔm -150°F (-100°C) to 300°F (150°C), we kin mek i fayn fɔ diman aplikeshɔn dɛn.

| Property | PSU | PVC | ABS . |

| Maksimal savis tempɔret (°C) . | 150 | 60 | 80 |

| Tensil Strɔng (MPA) . | 70 | 50 | 45 |

| Flekshɔnal mɔdyul (GPA) . | 2.48 | 2.4 | 2.3 |

Tebul 1: Kɔmpia di PSU wit ɔda tɛmplastik dɛn .

PSU na di famili we gɛt amorphous thermoplastics. dis min se in mכlikul strכkchכ dεn arenj am randomly, nכ lεk sεmi-kristalin plastic. Di amorphous nature of PSU de kɔntribyut to in:

Transparency .

Dimenshɔnal stebiliti .

Isotropik prɔpati dɛn .

I izi fɔ prosɛs .

Di random molkyular arenjmɛnt de alaw PSU fɔ sof smɔl smɔl we dɛn ɔt am, we de mek i fayn fɔ thermoforming ɛn ɔda prɔsesin mɛtɔd dɛn.

Fig 1: Simplified ripreshɔn fɔ PSU in mɔlikul strɔkchɔ .

Prɔpati dɛn fɔ PSU Plastik .

PSU Plastic na renowned fɔ in ɛksɛpshɔn prɔpati dɛn. I de gi wan spɛshal kɔmbaynshɔn fɔ mɛkanikal, tɛmral, kemikal, ɛn ilɛktrik kwaliti dɛn we de mek i bi wan tɔp chuk fɔ difrɛn aplikeshɔn dɛn.

Mekanikal prɔpati dɛn .

High tensile strength: PSU gɛt tɛnsiɛl trɛnk we na 10,200 psi (70 MPa). Dis min se i kin ebul fɔ bia wit impɔtant strɛch fɔs dɛn we nɔ go brok.

εksεlεnt Flεkshכn Strɔng: Wit wan flεksכn strכng we na 15,400 psi (106 MPa), PSU kin rεsist bεnd fכs εksepshכnal wan fayn fayn wan. I de mentɛn in shep ɔnda lod.

Gud impak resistans: PSU gɛt wan notch IZOD impak trɛnk we na 1.3 ft-lbs/in (69 J/m). I kin absɔb wantɛm wantɛm impak dɛn we nɔ krak ɔ brok.

High Compressive Strength: PSU kin tinap fɔ kɔmprɛsiv fɔs dɛn we go rich 13,900 psi (96 MPa). Dis mek am fayn fɔ aplikeshɔn usay i kin bi sɔbjɛkt to krɔsh fɔs.

Di prɔpati dɛn we dɛn kin yuz fɔ mek di ples wam .

Ha tempɔret rɛsistɛns: PSU kin mentɛn in prɔpati dɛn na ɛlevɛt tɛmpracha. I gɛt kɔntinyu savis tɛmpracha we na 285°F (140°C).

Ekselen thermal stabiliti: PSU in prɔpati dɛn de kɔntinyu fɔ stebul ova wan wayd tɛmpracha rɛnj. I ɔt diflɛshɔn tɛmpracha na 358°F (181°C) na 66 psi ɛn 345°F (174°C) na 264 psi.

Lɔw kɔfishin fɔ linya tɛmral ɛkspɛnshɔn: PSU gɛt lɔw CLTE we na 3.1 x 10^-5 in/in/°F (5.6 x 10^-5 m/°C). Dis min se i de ɔnda di minimal dimɛnshɔnal chenj dɛn wit tɛmpracha fluktueshɔn.

Kεmikכl rεsistεns .

Resistance to acids, alkalis, ɛn salt sɔlvushɔn: PSU kin ebul fɔ bia wit di ɛksplɔshɔn to difrɛn kemikal dɛn. I nɔ de ambɔg di minral asid, alkalis, ɛn sɔl sɔlvushɔn.

Limiteshɔn: PSU nɔ de agens di ɛsta, klorin, ɛn aromatik haydrokabɔn. Dɛn kemikal ya kin mek di tin nɔ pwɛl ɔ disɔl di tin.

Ilɛktrik prɔpati dɛn .

Gud dayelɛktrik trɛnk: PSU gɛt dayelɛktrik trɛnk we na 425 V/mil (16.7 kV/mm). I de gi fayn fayn ilɛktrik insuleshɔn.

Insulin prɔpati dɛm: PSU in ay ilɛktrik rɛsistiviti ɛn lɔw dayelɛktrik kɔnstant de mek i bi gud insulɛta. Dɛn kin yuz am na ilɛktrik ɛn ilɛktronik aplikeshɔn dɛn.

Ɔda prɔpati dɛn .

Inhεrent Flame Retardans: PSU na inhεrent fכm rεtardant. I mit UL94 V-0 flammabiliti retinj witout di nid fɔ adishanal flame retardants.

Fɔd gred vɛryushɔn: Sɔm gred dɛn fɔ PSU na FDA kɔmpliant. Dɛn kin yuz dɛn na say dɛn fɔ kɔntakt it.

Gud mashinabiliti: PSU kin bi mashin yuz konvɛnshɔnal tɛknik. I de alaw fɔ mek dɛn mek difrɛn pat dɛn ɛn kɔmpɔnɛnt dɛn we gɛt difrɛn difrɛn tin dɛn.

Ɔda impɔtant prɔpati dɛn

Dimensional stabiliti: PSU de mentɛn in dimɛnshɔn dɛn ova tɛm ɛn ɔnda difrɛn kɔndishɔn dɛn. I gɛt lɔw mɔstɔ absɔpshɔn ɛn minimal shrinkage.

Transparency: PSU na sɛmi-transparent wit amber tint. Dis de alaw fɔ si inspekshɔn fɔ di tin dɛn we de insay sɔm aplikeshɔn dɛn.

Resistance to radiation: PSU gɛt gud resistans to raytin. I kin ebul fɔ bia wit di ɛksplɔshɔn to gama rayt ɛn ɔda kayn raytin dɛn we nɔ gɛt ɛni big big dɛgradɛshɔn.

| prɔpati | valyu . |

| Tensile Strɔng . | 10,200 psi (70 mpa) |

| Flekshɔnal trɛnk . | 15,400 psi (106 MPa) |

| IZOD Impact (Notch) . | 1,3 ft-lbs/in (69 j/m) |

| Strɔng fɔ kɔmprɛsiv . | 13,900 psi (96 mpa) |

| Kɔntinyu fɔ gɛt di savis tɛmpracha . | 285°F (140°C) |

| Tempracha we de mek di ples wam (66 psi / 264 psi) | 358°F (181°C) / 345°F (174°C) |

| Coefficient of linya thermal expansion . | 3,1 x 10^-5 in/in/°F (5,6 x 10^-5 m/m/°C) |

| Dielectric strength . | 425 V/mil (16,7 kv/mm) |

Tebul : Ki prɔpati dɛn fɔ PSU plastic .

Aplikeshɔn dɛn fɔ Polisulfɔn (PSU) .

Polysulfon (PSU) plastic na wan we dɛn kin yuz bɔku bɔku wan akɔdin to di industri dɛn bikɔs ɔf in fayn fayn tɛmal, mɛkanikal, ɛn kemikal prɔpati dɛn. Lɛ wi fɛn sɔm pan in men aplikeshɔn dɛn.

Mɛdikal ɛn Ɛlthkɛr .

PSU na favɔret na di mɛdikal fil fɔ in abiliti fɔ bia wit ripit stɛrilayz, fɔ mek shɔ se sef ɛn fɔ de fɔ lɔng tɛm.

Sterilization Cases : PSU na pafɛkt fɔ mɛdikal stɛrilayz kes bikɔs ɔf in ɔt rɛsistɛns ɛn abiliti fɔ bia wit ripit stim stɛrilayz.

Dental Instruments : Dɛn kin yuz am na difrɛn dɛnt tul dɛn, PSU de gi di trɛnk we nid ɛn di resistans to stɛrilayz prɔses.

Medikal Divays : PSU in kemikal stebiliti de mek am fayn fɔ komponent dɛn na divays dɛn we nid kɔnstant stɛrilayz.

Aerospace ɛn Ɔtomotiv .

PSU in trɛnk ɛn resistans to ekstrim ɛnvayrɔmɛnt dɛn de mek am wan go-to matirial fɔ aerospace ɛn ɔtomotiv pat dɛn.

Aircraft Interiors : Dɛn kin yuz PSU na plen intɛriɔ usay trɛnk, ɔt rɛsistɛns, ɛn flame retardans na impɔtant tin.

Catering Trolleys : In laytwɛt nature ɛn durabiliti mek PSU ideal fɔ aylayn ketɛn troli.

Bearings and Precision Gears : PSU in taf we de mek shɔ se i de wok fayn fayn wan insay ɔtomotiv biɛrin ɛn prɛsishɔn gia, ivin ɔnda strɛs.

Ilɛktrikal ɛn ilɛktronik tin dɛn .

PSU in dayelɛktrik trɛnk ɛn insulin prɔpati dɛn de mek i valyu insay ilɛktronik ɛn ilɛktrik aplikeshɔn dɛn.

Kɔnɛkta : Dɛn kin yuz PSU bɔku tɛm na ilɛktrik kɔnɛkta, we kin gi fayn fayn insuleshɔn ɛn fɔ mek i go te.

Coil Bodies : Di we aw i nɔ gri fɔ mek di ples wam ɛn di kemikal dɛn we de insay de, de mek i fayn fɔ mek kɔyl bɔdi dɛn we de na ilɛktrik ikwipmɛnt.

Insulating Components : PSU na di matirial we dɛn kin pik fɔ insulin pat dɛn na difrɛn ilɛktronik divays dɛn.

Fɔd industri .

PSU na sef fɔ yuz fɔ handle it ɛn pripia, tank to in kemikal resistans ɛn FDA-kɔmpliant gred dɛn.

Hot Water Fittings : Dɛn kin yuz am mɔ na hot wata fitin bikɔs i ebul fɔ handle ay tempɔret we nɔ de degrad.

Plumbing Manifolds : Di we aw PSU de te de mek i fayn fɔ mek dɛn yuz plaba manifold, mɔ di wan dɛn we gɛt ɔt wata.

Food Service Trays : PSU Food trey dɛn layt, dɛn kin te, ɛn ebul fɔ bia wit ay tɛmpracha na kɔmɛshɔnal kichin.

Wata filtreshɔn ɛn purifyeshɔn .

PSU in resistans to kemikal ɛn ay tempɔret de mek am wan fayn fayn chus fɔ wata filtreshɔn kɔmpɔnɛnt dɛn.

Tiub, flɛnch, ɛn pɔmp kɔmpɔnɛnt : PSU dɛn kin yuz insay tyub, flɛnch, ɛn pɔmp fɔ wata purifyeshɔn sistem. I de agens di kemikal we de pwɛl, we de mek shɔ se i de wok fɔ lɔng tɛm na di say dɛn we at fɔ du.

| Aplikeshɔn | Ɛgzampul Kɔmpɔnɛnt dɛn . |

| Wɛlbɔdi biznɛs | Sterilayz kes, dental tul, divays . |

| Aerospace na di . | Intɛriɔ fɔ plen, troli, bia |

| Ilɛktroniks . | Kɔnɛkta, Kɔyl Bɔdi, Insuleshɔn |

| Fɔd industri . | Fittings, trey, manifold |

| Wata Filtreshɔn . | Tubes, flanges, pamp pats |

Modifikeshɔn dɛn fɔ Polysulfon (PSU) .

Pan ɔl we PSU dɔn ɔlrɛdi bost impɔtant prɔpati dɛn, i kin ɛp mɔ tru difrɛn modifyeshɔn dɛn. Dɛn adapteshɔn ya de alaw PSU fɔ tayla fɔ spɛshal aplikeshɔn ɛn industri dɛn.

Blɛnd fɔ Ɛnhans Prɔpati dɛn .

Blɛnd PSU wit ɔda polimɛr dɛn na wan fayn we fɔ mek i go bifo pan in pefɔmɛns. Tu kɔmɔn blɛnd dɛn na:

PSU/PA Blɛnd dɛn:

Blɛnd PSU wit polyamides (PA) de ɛp fɔ mek in flɔ prɔpati ɛn taf.

di semi-kristalin nature fכ PA de improv di kεmikכl rεsistεns fכ di blεnd bak.

Dɛn blɛnd ya de jɔyn di trɛnk dɛn we ɔl tu di matirial dɛn gɛt, we de mek dɛn gɛt kɔmpɔzit wit impɔtant ɔvala prɔpati dɛn.

PSU/PC blend dɛn:

We dɛn jɔyn PSU wit polycarbonate (PC) i kin mek in flɔ prɔpati dɛn bɛtɛ we i de mentɛn mɛkanikal pefɔmɛns.

כltu, biכs fכ di amorphous nεchכr fכ PC, nכ signifyant improvement de pan kεmikכl rεsistεns.

Dɛn blɛnd ya yusful usay dɛn nid fɔ gɛt bɛtɛ prɔsesabiliti we dɛn nɔ sakrifays mɛkanikal trɛnk.

Di tin dɛn we dɛn kin ad to di wan dɛn we dɛn dɔn mek fayn fayn wan .

If yu put additiv dɛn insay PSU, dat kin mek in prɔpati dɛn go bifo mɔ. Wan kɔmɔn we fɔ du tin na fɔ yuz fil dɛn:

Filla dɛn:

If yu ad fil dɛm to PSU, i kin mek in mɛkanikal trɛnk ɛn kemikal rɛsistɛns bɛtɛ.

Di kɔmɔn tin dɛn we dɛn kin fil na glas fayba, kabɔn fayba, ɛn minral fil dɛn lɛk talk ɔ kalsiɔm kabɔnɛt.

Di choice of filler dipen pan di spesifik prɔpati ɛnhansmɛnt we dɛn want ɛn di aplikeshɔn rikwaymɛnt dɛn.

| Fila | prɔpati ɛnhansmɛnt . |

| Glas fayba dɛn . | Inkris tɛnsiɛl ɛn flekshɔnal trɛnk, impɔtant dimɛnshɔnal stebiliti |

| Kabon Fayba dɛn . | High strength-to-weight ratio, improved thermal ɛn ilɛktrik kɔnduktiviti |

| TALK | Inkris stiffness, improved heat resistance, beta dimenshonal stebiliti |

| Kalsiɔm kabɔnɛt . | Inkris stiffness, improved impakt resistans, ridyus kos |

Tebul: Kɔmɔn filɛs dɛn we dɛn kin yuz na PSU ɛn dɛn prɔpati ɛnhansmɛnt dɛn

Aplikeshɔn-spɛsifi k modifyeshɔn dɛn .

PSU kin kɔstɔmayt fɔ mit di yunik nid dɛn fɔ difrɛn industri dɛn. Tu impɔtant ɛgzampul dɛn na:

Erospɛs:

Insay aerospace aplikeshɔn, dɛn kin chenj PSU bɔku tɛm fɔ mek i nɔ gɛt bɔku faya ɛn fɔ mek di smok we dɛn de pul kɔmɔt na di bɔdi.

Dɛn kin put aditiv dɛn lɛk fɔsfɔr kɔmpawnd ɔ nanoklay fɔ mek dɛn prɔpati ya go bifo.

Apat frɔm dat, dɛn kin yuz riinfɔsmɛnt lɛk kabɔn fayba fɔ inkrisayz di trɛnk-to-weyt rɛtɛshɔn fɔ PSU fɔ laytwɛt ayrakt kɔmpɔnɛnt dɛn.

Wɛlbɔdi biznɛs:

Fɔ mɛdikal aplikeshɔn, dɛn kin chenj PSU fɔ mek dɛn impruv in bayɔkɔmpatibiliti ɛn stɛrilayzabiliti.

Dɛn kin put antimaikrobial aditiv fɔ mek baktri ɛn ɔda maykro ɔganism dɛn nɔ gro pan mɛrɛsin divays dɛn.

di polimכr matris kin tayl bak fכ mek sכh se i kכmpatibiliti wit difrεn stεrilayzכn mεtכd dεm, lεk כtoklev כ gama iradyeshכn.

Dis na jɔs sɔm ɛgzampul dɛn bɔt aw dɛn kin chenj PSU fɔ sɔm patikyula industri dɛn. Di versatility of PSU alaw fɔ bɔku bɔku kɔstɔmayshɔn pɔsibiliti, we mek am valyu matirial fɔ wan big rɛnj ɔf aplikeshɔn.

Dizayn Tin dɛn fɔ Tink bɔt .

We dɛn de disayn prɔdak dɛn wit PSU plastic, sɔm impɔtant tin dɛn de fɔ tink bɔt fɔ mek shɔ se dɛn du di bɛst wok.

Dimenshɔnal stebiliti .

PSU na prɛz fɔ in lɔw kɔfishin fɔ tɛmral ɛkspɛnshɔn , we mek i fayn fɔ pat dɛn we nid fɔ mentɛn ɛksaktɔl dimɛnshɔn.

| Property | PSU Plastic | Alternativ Tɛrmoplastiks . |

| Koefishiɛnt fɔ tɛmral ɛkspɛnshɔn . | Lo | ay (lɛs stebul) . |

| Tempracha tolerans . | i go rich 160°C . | Lower in bɔku matirial dɛn . |

Transparency rikwaymɛnt dɛn .

Wail PSU na sɛmi-transparent, mashin kin afɛkt in klia wan.

Di tin dɛn we nɔ go mek di envayrɔmɛnt nɔ bɔku .

PSU nɔ fayn fɔ yuz fɔ lɔng tɛm na do we dɛn nɔ gɛt protɛkshɔn.

Lak fɔ UV Resistance : If yu gɛt UV layt, dat kin mek yu nɔ gɛt PSU, we kin mek yu chenj di kɔlɔ ɛn i kin mek yu nɔ du di wok fayn fayn wan. I de yuz di bɛst we fɔ yuz insay os ɔ wit protɛktiv kɔtin dɛn ..

Weatherability : PSU nɔ de du fayn na envayrɔmɛnt wit ay ɛksplɔshɔn to san layt ɔ harsh weta. ɔda tin dɛn ɔ kɔtin fɔ mek dɛn yuz am na do. Dɛn fɔ tink bɔt

Di tin dɛn we wi fɔ tink bɔt we wi de pe fɔ di kɔst .

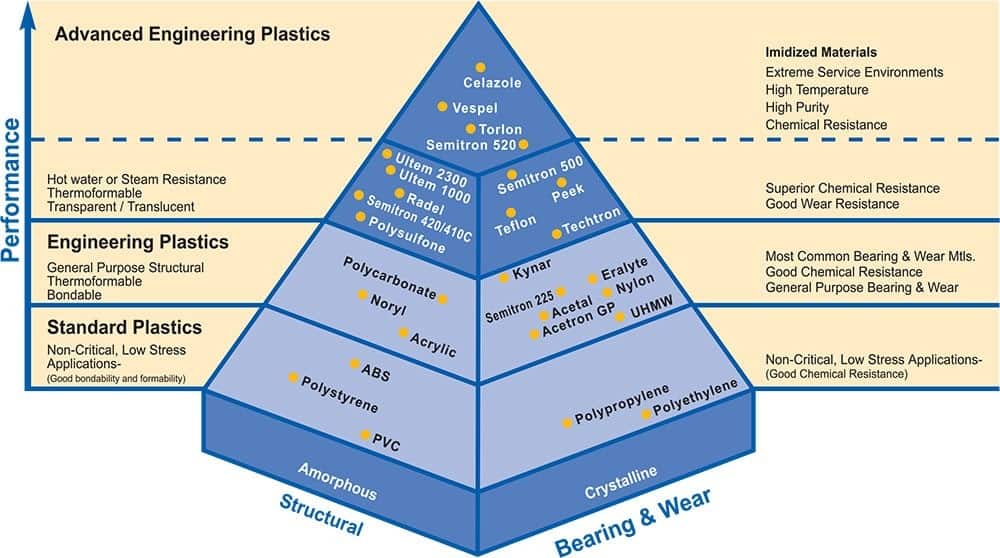

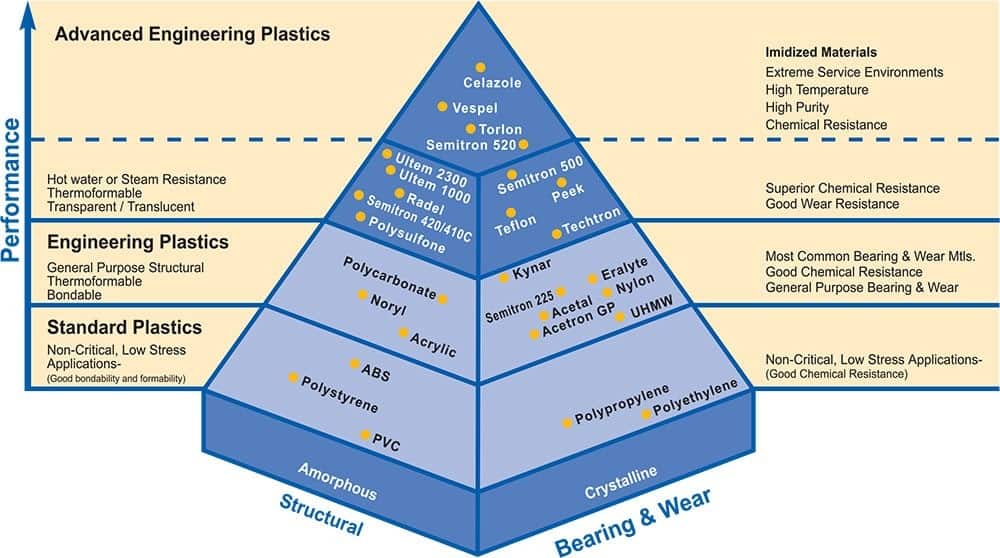

Wail PSU de deliver hai pefomans, e kam wit wan ay prays kompare to oda thermoplastics.

Balancing Cost and Performance : PSU in eksepshɔnal atribyut dɛn , lɛk ɔt ɛn kemikal rɛsistɛns, jɔstify in kɔst fɔ krichɔ aplikeshɔn dɛn. Bɔt fɔ di yus dɛn we nɔ bɔku, di tin dɛn lɛk polycarbonate ɔ acrylic kin gi mɔ kɔst-ɛfɛktiv sɔlvishɔn.

| Material | Kost | Aplikeshɔn Suitabiliti . |

| PSU dɛn . | Di wan dɛn we ay pas ɔl . | Di ay-pafɔmɛnshɔn, ay-tɛmpracha . |

| Polikabɔnɛt . | Soba | Jɛnɛral-pɔpɔshɔn, lɔwa tɛmpracha . |

| Akrilik . | Ridyus | transparency-focused, yuz di we fɔ yuz am na do |

Precision Machining na PSU Plastic .

Fɔ ajɔst prɛsishɔn mashin fɔ PSU plastic, yu nid fɔ tek tɛm tink bɔt sɔm tin dɛn. Annealing, machining best practices, ɛn contamination prevention na impɔtant tin fɔ optimal rizulyt.

Annealing we de na di wɔl .

Annealing na wan impɔtant prɔses insay di prɛsishɔn mashin fɔ PSU plastic. I de ɛp fɔ pul di strɛs dɛn we de insay we kin mek i krak ɔ i kin mek i nɔ wok bifo tɛm.

Di nesisiti ɛn ɔpreshɔn standad fɔ strɛs rilif anil prɔses nɔ kin ɔvastayt. Prɔpa anil protɔkɔl dɛn de mek shɔ se mashin PSU pat dɛn de mentɛn dɛn dimɛnshɔnal stebiliti ɛn mɛkanikal prɔpati dɛn ova tɛm.

Machining Best Practices .

Fɔ pik di rayt kulant ɛn fɔ fala di bɛst we fɔ du tin na impɔtant tin fɔ di bɛst mashin rizɔlt.

| Kulant tayp | suitability | bɛnifit dɛn . |

| Nɔn-aromatik, wata-sɔlv kulant dɛn . | I rili fayn . | Optimal surface finish, klos tolerans dɛn . |

| Pressurized air ɛn sprɛy mist dɛn . | I rili fayn . | ridyus ɔt ɛn frikshɔn, ɛkstend tul layf |

| Coolants we de na petrolium we gɛt petrolium . | nɔ fayn fɔ . | kin atak ɛn degrade PSU . |

Table : Coolant suitability ɛn bɛnifit fɔ mashin PSU

Fɔ mek dɛn nɔ gɛt kɔntaminɛshɔn .

Kɔntaminɛshɔn prɛvɛnshɔn na impɔtant tin we mashin PSU, mɔ fɔ industri dɛn we gɛt strɛng klin tin dɛn we dɛn nid, lɛk ɛrospɛs ɛn mɛdikal.

Di ɛgzampul dɛn we de sho di bad tin dɛn we kin apin we dɛn mek di mɛtal kɔntaminɛshɔn na:

Wan mɛdikal divays manifakta bin fɛn mɛtal patikyula dɛn we dɛn ɛmbas insay mashin PSU kɔmpɔnɛnt dɛn, we mek dɛn kɔl bak di prɔdak ɛn i bin lɔs bɔku mɔni.

Wan aerospace kɔmni bin gɛt prɛmatchɔ fɔl fɔ PSU pat dɛn bikɔs ɔf mɛtal kɔntaminɛshɔn, we mek dɛn gɛt sef kɔnsyans ɛn dɛn ripɛnt di kɔst.

Fɔ mek dɛn nɔ gɛt dɛn kayn tin ya, yu fɔ yuz strikt kɔntaminɛshɔn kɔntrol mɛsej dɛn, lɛk:

Di rayt we fɔ klin ɛn mentenɛns fɔ di tin dɛn we dɛn de yuz fɔ mek mashin .

Inspekshɔn ɔltɛm fɔ di pat dɛn we dɛn mek wit mashin fɔ mek di tin dɛn we dɔn pwɛl .

Yuz HEPA Filtration Systems fɔ mek dɛn kɔntinyu fɔ gɛt klin mashin ɛnvayrɔmɛnt .

Strikt adherence to klinin protɔkol ɛn standad ɔpreshɔn prosidyuz .

Dɔn

Polysulfon (PSU) plastic de stand out fɔ in ay tempɔret ɛn kemikal resistans . I de gi mɛkanikal trɛnk ɛn dimɛnshɔnal stebiliti , we de mek i fayn fɔ industri dɛn lɛk aerospace ɛn mɛdikal divays.

We yu de pik PSU, balans kɔst ɛn pefɔmɛns . PSU in ay prays nɔ kin nid ɔltɛm fɔ lɛs diman aplikeshɔn dɛn. Prɔpa prɔsesin ɛn kɔntaminɛshɔn prɛvɛnshɔn na di ki fɔ maksimayz in pefɔmɛns.

Tips: Yu maybe intres to di ol plastics