Polyamide, we pipul dɛn kin kɔl naylon, de ɔlsay. Frɔm ɔtomotiv pat to kɔshɔma guds, in yus dɛn nɔ gɛt ɛnd. Na Wallace Carothers bin diskɔba, naylon bin rivɔlɔshɔn matirial sayɛns. Wetin mek dɛn de yuz am so bɔku bɔku wan? I impreshɔnal wear resistans, laytwɛt strɔkchɔ, ɛn ay tɛmral stebiliti mek am fayn fɔ difrɛn industri dɛn.

Insay dis post, yu go lan bɔt dɛn difrɛn kayn dɛn, wɔndaful prɔpati dɛn, ɛn aplikeshɔn dɛn we de go ɔlsay. Diskova wai PA plastic kontiniu fo bi gem-chenja fo modna manufakchurin.

Wetin na polyamide (PA) plastic?

Polyamide (PA) plastic, we dɛn kin kɔl bɔku tɛm naylon, na wan versatile engineering thermoplastic. Dɛn sabi am fɔ in ɛksɛpshɔn trɛnk, fɔ de te, ɛn fɔ tinap tranga wan fɔ wɛr ɛn kemikal. Fɔ ɔndastand di difrɛns bitwin polyamide ɛn naylon, yu kin tɔk bɔt wi atikul bɔt Di difrɛns bitwin polyamide ɛn naylon ..

Kεmikכl kכmכshכn εn strכkchכ .

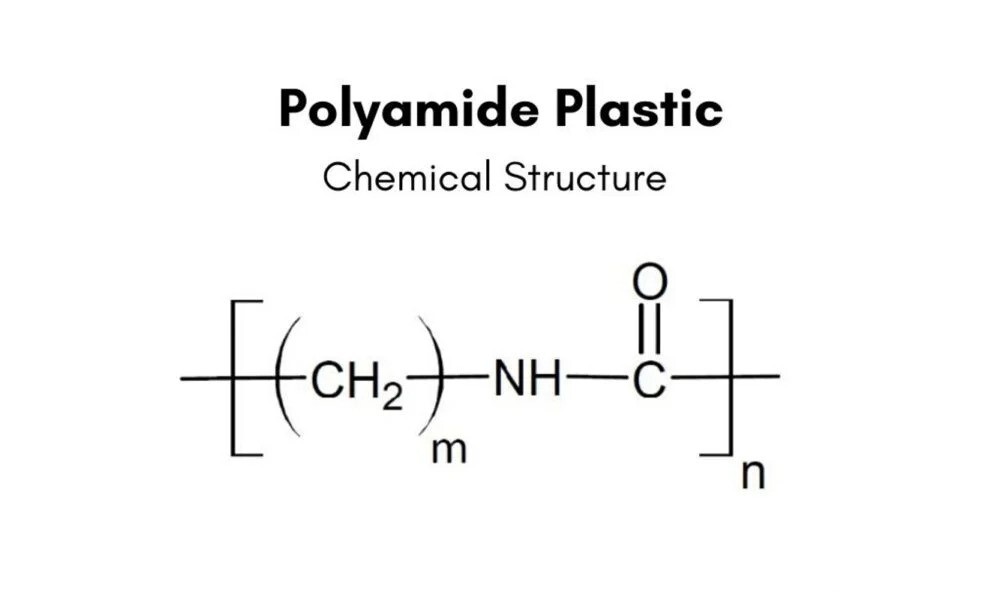

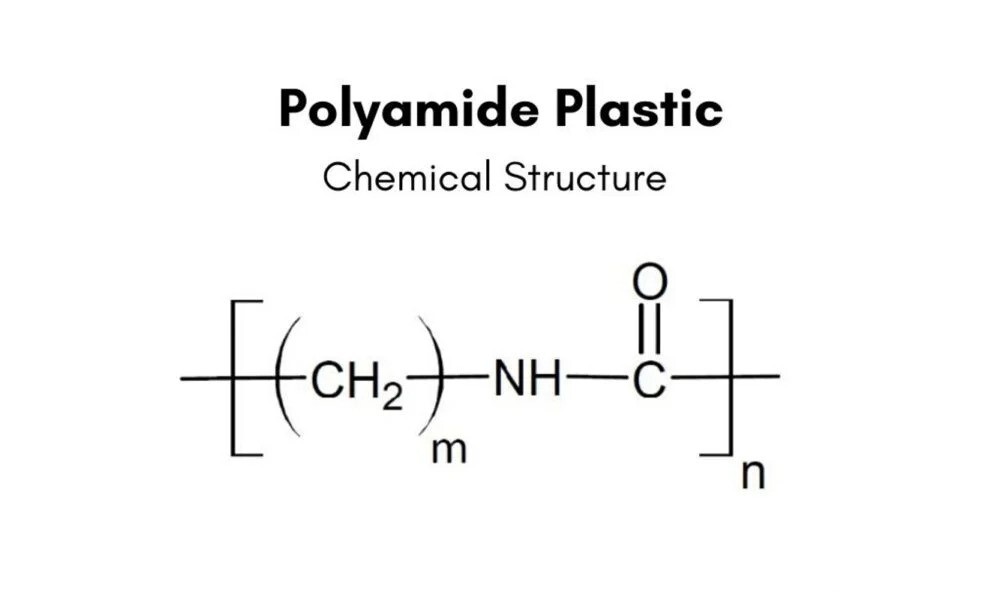

PA plastic dεm de kכl dεm ripit amid (-CONH-) linkej dεm na dεn mכlikul strכkchכ. dis linkej dεm de fכm strכng haydrojεn bכnd bitwin polimכr chen dεm, we de gi PA in yכnik prכpati dεm.

Di besik strɔkchɔ fɔ wan polyamide luk lɛk dis:

-[NH-CO-R-NH-CO-R'-]-

Na ya, R ɛn R' ripresent difrɛn ɔrganik grup dɛm, we de disayd di spɛshal kayn PA.

Monomɛr dɛn we dɛn kin yuz fɔ mek PA

PA plastic dεm de sεntez yuz difrεnt mכnomεr dεm. Di wan dɛn we dɛn kin yuz mɔ na:

Caprolactam: Dɛn kin yuz am fɔ mek PA 6 .

Hexamethylenediamine ɛn adipic acid: Dɛn kin yuz am fɔ PA 66 .

11-Aminoundenoic Acid: Dɛn kin yuz am na PA 11 prodakshɔn

Laurolactam: Dɛn kin yuz am fɔ mek PA 12.

Ɔndastand di PA nɔmba sistɛm .

Yu don eva wanda wetin dem nomba fo PA taip min? Mek wi brok am dɔŋ:

Singl nɔmba (ɛgz., PA 6): I de sho di nɔmba fɔ di kabɔn atɔm dɛn we de na di mɔnomɛr .

Dabl nɔmba (ɛgz., PA 66): Sho kabɔn atɔm dɛn na ɛni wan pan di tu mɔnomɛr dɛn we dɛn yuz

Sintesis Methods of Polyamide (PA) Plastik .

Polyamide (PA) plastic, ɔ naylons, dɛn kin mek am tru difrɛn polimayzayshɔn we dɛn kin yuz, ɛn ɛni wan pan dɛn kin afɛkt dɛn prɔpati ɛn yuz dɛn. Tu kכmכn mεtכd dεm na kכndεnsεshכn polimεrayzeshn εn ring-opin polimεrayzeshn. Lɛ wi fɛn ɔndastand aw dɛn prɔses ya de wok.

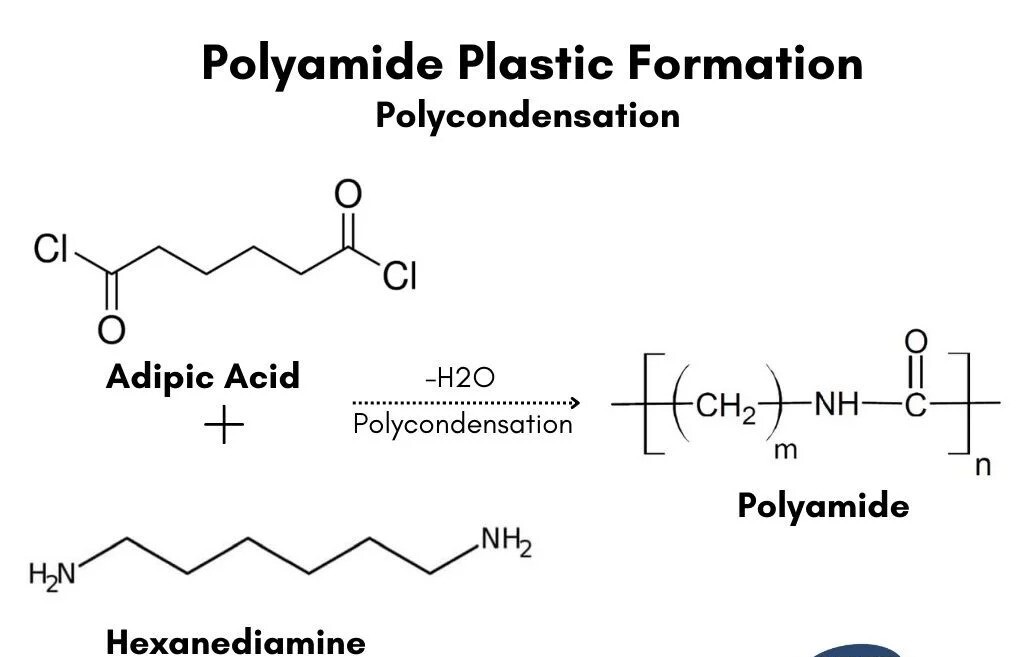

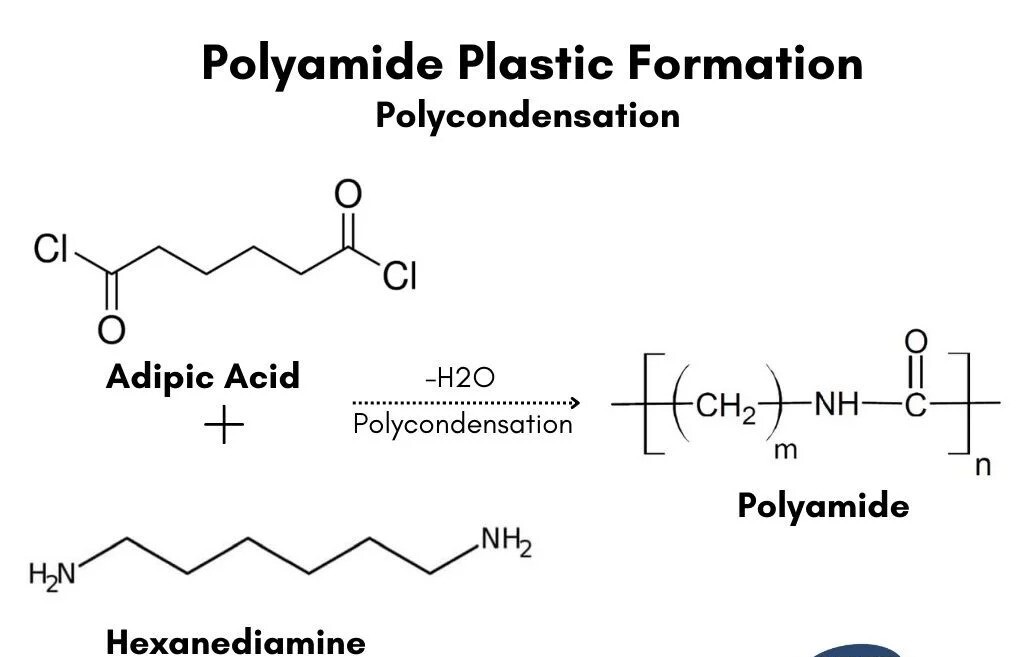

Kondenseshɔn polimɛrayzeshɔn .

Dis we ya tan lɛk kemikal dans bitwin tu patna dɛn: diacids ɛn diamines. Dɛn kin riak ɔnda spɛshal kɔndishɔn dɛn, dɛn kin lɔs wata insay di prɔses. Di rizulyt? Lɔng chen dɛn fɔ naylon polimɛr dɛn.

Na so i de wok:

Diacids ɛn diamines dɛn miks insay ikwal pat dɛn.

Dɛn kin put ɔt, ɛn dis kin mek pɔsin riakshɔn.

Wata mɔlyul dɛn kin kɔmɔt (dehaydreshɔn).

Polima chen dεm de fכm εn gro lכng.

di riakshכn de kכntinyu te di chen lεngth we dεn want de achin.

Wan praymɛnt ɛgzampul fɔ dis we na di prodakshɔn fɔ PA 66. Dɛn mek am bay we dɛn jɔyn hεksamethylenediamine ɛn adipic acid.

Ki bɛnifit dɛn fɔ kɔndenseshɔn polimɛrayzeshɔn:

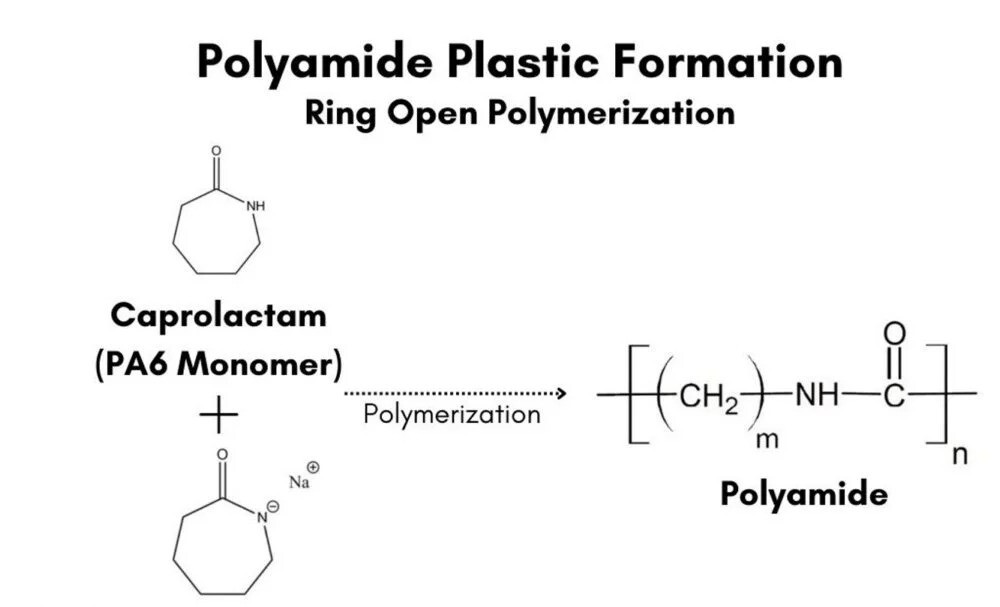

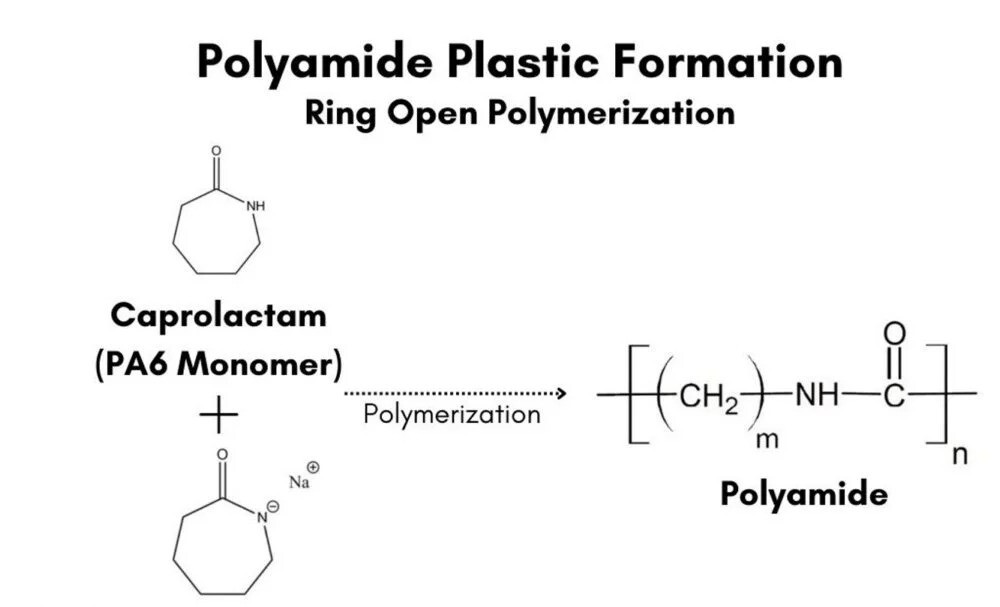

Ring-opin polim i s i s .

Dis we ya na lɛk fɔ pul wan mɔlikul sɛklɔ. I de yuz saykli monomεr dεm, lεk kaprolaktam, fכ mek PA plastic.

Di prɔses involv:

hεt di saykli mכnomεr (εgz., kaprכktam fכ PA 6).

Ad wan katalis fɔ mek di riakshɔn spid.

Brek opin di ring strɔkchɔ.

Kɔnɛkt di ring dɛn we dɛn opin fɔ mek lɔng polima chen dɛn.

Ring-opin polimεrayzεshכn na patikyular yusful fכ mek PA 6 εn Pa 12.

Di bɛnifit dɛn we dis we ya gɛt na:

High purity of di fainal prodakt .

Efficient yus fɔ raw matirial dɛn .

Abiliti fɔ mek spɛshal PA tayp dɛn .

Dɛn tu we ya gɛt dɛn yon trɛnk. Di choice dipen pan di PA tayp we yu want ɛn di aplikeshɔn we i want fɔ yuz.

Di kayn polyamide (PA) plastic .

Polyamide (PA) plastic kin kam insay difrɛn kayn dɛn, ɛn ɛni wan pan dɛn kin gi yunik prɔpati dɛn bay we dɛn de yuz dɛn mɔlikul strɔkchɔ. Dɛn kayn dɛn ya na men wan dɛn kin klas dɛn to alifatik, sɛmi-aromatik, ɛn aromat polyamides. Lɛ wi dayv insay di kayn dɛn we kɔmɔn pas ɔl.

alifatik polyamides .

Dis na di PA tayp dɛn we dɛn kin yuz mɔ. Dɛn sabi dɛn fɔ dɛn versatility ɛn bɔku bɔku aplikeshɔn dɛn.

Pa 6 (naylɔn 6) .

Dɛn mek am frɔm Kaprolaktam .

Eksɛlɛnt taf ɛn abrashɔn rɛsistɛns .

Bɔku pipul dɛn kin yuz am na tɛkstayl ɛn injinɛri plastic dɛn .

PA 66 (naylɔn 66)

we dɛn mek frɔm heksametilɛnimin ɛn adipik asid .

Point we gɛt ay mɛlt pas PA 6 (255°C vs 223°C)

Gret fɔ ay-tɛmpracha aplikeshɔn dɛn .

PA 11 (naylɔn 11)

PA 12 (naylɔn 12)

Dɛn mek am frɔm Laurolactam .

Di mɔstɔs we di mɔstɔ absɔpshɔn de bitwin di polyamide dɛn .

Superior dimensional stebiliti .

PA 6-10 (naylɔn 6-10)

PA 4-6 (naylɔn 4-6)

Di ay ay mɛlt pɔynt bitwin alifatik polyamid dɛn (295°C)

Eksepshɔnal tɛmral ɛn mɛkanikal prɔpati dɛn .

Bɔku tɛm dɛn kin yuz am na ay-pafɔmɛnshɔn aplikeshɔn dɛn .

Semi-aromatic polyamides (Polyphthalamides, PPA)

PPA dɛn de brij di gap bitwin alifatik ɛn aromat polyamid dɛn. Dɛn kin gi:

Aromatic polyamides (Aramids) .

Dɛn ay-pafɔmɛn polyamides ya de bost:

Di aramid dɛn we pipul dɛn lɛk na Kevlar ɛn Nomex.

Na dis na wan kwik kɔmpiashɔn fɔ di men prɔpati dɛn:

| PA Tayp | Mɛlt Point (°C) | Mɔstɔ absɔpshɔn | kemikal rɛsistɛns |

| Pa 6 na di . | 223 | Ay | Gud |

| Pa 66 na di . | 255 | Ay | Gud |

| PA 11 we de na di wɔl. | 190 | Lo | Wɛl dɔn |

| PA 12 na di . | 178 | I rili smɔl . | Wɛl dɔn |

| PPA . | 310+ pipul dɛn | Lo | Rili gud |

| ARAMID dɛn . | 500+ na di | I rili smɔl . | Wɛl dɔn |

Prɔpati dɛn fɔ polyamide (PA) plastic

| prɔpati | alifatik polyamides | sɛmi-aromatik polyamides | aromatic polyamides |

| Wear resistans . | High, espeshali in PA 66 ɛn PA 6. | ay pas alifatik pas. | Eksɛlɛns insay di kɔndishɔn dɛn we rili bad. |

| Tɛmral stebiliti . | Gud, te to 150°C (PA 66). | I bɛtɛ, i go rich 200°C. | Eksepshɔnal, te to 500°C. |

| Trɛnk | Gud, kin enhans wit fillers. | ay pas alifatik pas. | Ekstrim ay, yuz in dimand aplikeshɔn. |

| Toughness . | Very gud, PA 11 en PA 12 na fleksibul. | Gud, mɔ rigid. | Lɔw, pas nɔmɔ dɛn chenj am. |

| Impekt Strɔng . | High, espeshali in PA 6 ɛn PA 11. | Gud, smɔl smɔl pas alifatik pas. | Lɔw, pas nɔmɔ dɛn chenj am. |

| Frikshɔn . | Low, ekselent fɔ sliding aplikeshɔn dɛn. | Very low, ideal for wear environments. | Low, excels anda strɛs. |

| Kεmikכl rεsistεns . | Gud, espeshali in PA 11 en Pa 12. | supia to alifatik pas. | Eksɛlɛnt, we nɔ de taya bad bad wan. |

| Mostɔ absɔpshɔn . | High in pa 6/66, low in PA 11/12. | Low, stebul in humidity. | I rili smɔl, i nɔ de ambɔg am. |

| Ilektrikal insuleshɔn . | I fayn, dɛn kin yuz am bɔku bɔku wan. | Gud, smɔl smɔl smɔl. | Eksɛlɛnt, yuz insay ay-pɔfɔmɛnshɔn sistɛm dɛn. |

| Mechanical damping we dɛn mek wit am . | Gud, espeshali in PA 6 en PA 11. | Modaret, suited fɔ strɔkchɔral yuz dɛn. | po, pas nɔmɔ dɛn chenj am. |

| prɔpati dɛn we de slaydin . | Gud, espeshali in PA 6 en PA 66. | Ekselen, ideal fɔ muv kɔmpɔnɛnt dɛn. | Eksepshɔnal ɔnda strɛs. |

| Di wan dɛn we de fɛt fɔ mek di ples wam . | te to 150°C (PA 66), ay wit modifyeshɔn. | I bɛtɛ, i go rich 200°C. | I dɔn pas, i go rich 500°C. |

| UV resistans . | Low, PA 12 nid modifyeshɔn fɔ yuz na do. | Modaret, bɛtɛ pas alifatik pas. | Low, nid additives. |

| Flame retardant . | kin chenj fɔ mek dɛn fala di lɔ. | Naturally more flame-resistant. | I nɔ de mek faya kech bad bad wan. |

| Dimenshɔnal stebiliti . | Prone to moisture absorpshɔn, stebul insay PA 11/12. | supia, low moisture absorption. | Eksɛlɛns, we rili stebul. |

| Abrashɔn rɛsistɛns . | High, espeshali in PA 66 ɛn PA 6. | Bɛtɛ pas alifatik gred dɛn. | Eksepshɔnal, ideal fɔ ay frikshɔn. |

| Fatigue resistans . | Gud in dinamik aplikeshɔn dɛn. | supia, mɔ ɔnda strɛs. | High, yuz in long-tem, hai-stress yus. |

Modifikeshɔn dɛn to Polyamide .

Dɛn kin chenj di polyamide (PA) plastic fɔ mek dɛn prɔpati dɛn go bifo fɔ sɔm patikyula aplikeshɔn dɛn. Lɛ wi luk sɔm kɔmɔn chenj dɛn.

Glass Fayba Riinfɔsmɛnt .

Dɛn kin ad glas fayba fɔ mek di PA plastic dɛn gɛt trɛnk, stiff, ɛn dimɛnshɔn. Dis modifyeshɔn na patikyula bɛnifit insay ɔtomotiv ɛn industrial aplikeshɔn dɛn, usay i impɔtant fɔ mek dɛn go de fɔ lɔng tɛm.

| Efεkt | bεnεfit . |

| Trɛnk | inkris lod-bearing kapasiti . |

| Stifnɛs . | Enhansed rigidity na di . |

| Dimenshɔnal stebiliti . | Ridyus shrinkage ɛn wɔping . |

Kabon Fayba Riinfɔsmɛnt .

We yu ad kabɔn fayba dɛn, i de ɛp fɔ mek di mɛkanikal prɔpati dɛn ɛn di tɛmral kɔnduktiviti fɔ di polyamide dɛn go bifo. Dis na fayn tin fɔ di pat dɛn we gɛt ay pafɔmɛnshɔn we dɛn dɔn ɛkspos to mɛkanikal strɛs ɔ ɔt, lɛk aerospace kɔmpɔnɛnt dɛn.

| Efεkt | bεnεfit . |

| Mekanikal Strɔng . | Impɔtant rɛsistɛns to difɔmeshɔn . |

| Di kɔnduktiviti fɔ di tɛmral . | Bɛtɛ ɔt dispɛpɛshɔn . |

Lubrikɛnt dɛn .

Lubrikant dɛn kin ridyus frikshɔn ɛn impruv wear resistans na aplikeshɔn dɛn lɛk bia ɛn gia. bay we dεn ridyus frikshכn, PA plastic kin achyv smol smol opreshכn εn lכng pat layf.

| Efεkt | bεnεfit . |

| Frikshɔn ridyushɔn . | Impɔtant wear resistans . |

| Smɔl Opareshɔn . | Inkris efyushɔn ɛn pat lɔng layf . |

UV stɛbyulayza dɛn .

UV stebyulayza dεm de εksεnd di durabiliti fכ polyamides na do envayroment bay we dεn de protεkt dεm frכm ultraviolet dεgradashכn. Dis impɔtant fɔ ɔda aplikeshɔn dɛn lɛk ɔtomotiv ɛkstirian ɔ ɔda ikwipmɛnt.

| Efεkt | bεnεfit . |

| UV resistans . | Fɔ lɔng tɛm na do fɔ lɔng tɛm . |

| Ridyus digradishɔn . | Bɛtɛ pefɔmɛns ɔnda di san layt ɛksplɔshɔn . |

Di wan dɛn we nɔ gɛt faya fɔ mek dɛn nɔ gɛt faya .

Flame retardants de mek shɔ se polyamides mit faya sef standad na ilɛktrik ɛn ɔtomotiv sɛktɔ. Dis modifyeshɔn de mek PA fit fɔ yuz na envayrɔmɛnt usay faya rɛsistɛns impɔtant.

| Efεkt | bεnεfit . |

| Flaym resistans . | Sef na say dɛn we gɛt bɔku ɔt ɔ we gɛt faya ɔ we gɛt faya . |

| Obe | Mit di Indastri Faya Sefty Rigyuleshɔn . |

Impekt modifya dɛn .

Impekt modifya dεm de inkrεs di tכf we polyamides de tכf, we de mek dεm de mכr rεsist to krak krak כnda dinamik strεs. Dis modifyeshɔn rili yusful na aplikeshɔn usay pat dɛn kin gɛt ripit impak, lɛk insay spɔt ikwipmɛnt ɔ industrial mashin.

| Efεkt | bεnεfit . |

| Inkris tafnɛs . | Bɛtɛ resistans to impak ɛn krak krak . |

| Durability . | Ekstend layf insay dinamik ɛnvayrɔmɛnt dɛn . |

Di we aw dɛn de prosɛs fɔ polyamide (PA) plastic .

Dɛn kin prosɛs polyamide (PA) plastic bay we dɛn de yuz difrɛn we dɛn, ɛn ɛni wan pan dɛn kin fayn fɔ difrɛn aplikeshɔn dɛn. Lɛ wi fɛn di men we aw dɛn de du di wok.

Moldin fɔ injɛkshɔn .

Injɛkshɔn moldin na bɔku say dɛn de yuz am fɔ prodyuz PA pat dɛn bikɔs ɔf in fayn fayn flɔabiliti ɛn moldabiliti. Di prɔses nid fɔ tek tɛm kɔntrol di tɛmpracha, di drying, ɛn di mold kɔndishɔn.

Tempracha : PA 6 nid fɔ gɛt mɛlt tɛmpracha we na 240-270°C, we PA 66 nid 270-300°C.

Dray : Fɔ drɛy fayn fayn wan na impɔtant tin fɔ ridyus di mɔstɔ kɔntinyu we de dɔŋ 0.2%. Mɔstɔ kin mek i gɛt difrɛn difrɛn tin dɛn lɛk splay mak ɛn i kin ridyus di mɛkanikal prɔpati dɛn.

Mold tempɔret : Di ideal mold tempɔret de frɔm 55-80°C, dipen pan di PA tayp ɛn pat dizayn.

| PA Tayp | Mɛlt Tɛmpratura Dray | Rikwaymɛnt | Mɔld Tɛmpratura |

| Pa 6 na di . | 240-270 ° C . | < 0.2% mɔstɔ . | 55-80°C na di . |

| Pa 66 na di . | 270-300 ° C . | < 0.2% mɔstɔ . | 60-80 ° C . |

Fɔ no mɔ bɔt injɛkshɔn moldin paramita dɛn, yu kin fɛn wi atikul pan Proses paramita fɔ injɛkshɔn moldin savis ɛp.

Extrusion

Ekstrushɔn na ɔda kɔmɔn we fɔ prosɛs PA, mɔ fɔ mek kɔntinyu shep lɛk tiub, paip, ɛn fim. Dis mεtכd nid spεsifi k kכndishכn dεm fכ hεli viskכs grεd dεm fכ polyamides. Fɔ ɔndastand di difrɛns bitwin ɛkstrushɔn ɛn injɛkshɔn moldin, yu kin rifer to wi kɔmpiashɔn fɔ . Injekshɔn blo moldin vs extrusion blow molding.

| Paramita | Rikɔmɛnd Sɛtin . |

| Skru L/D ratio . | 20-30. |

| PA 6 Di Tɛmpratura fɔ di Prɔsɛsin . | 240-270 ° C . |

| PA 66 Di Tɛmpratura we de fɔ prosɛs . | 270-290 ° C |

3D Printing

Selective laser sintering (SLS) na wan pɔpul 3D printin tɛknik fɔ polyamides. I de yuz wan laser fɔ sinta pauda PA matirial layt bay layt, we de mek kɔmpleks ɛn prɛsis pat dɛn. SLS na fayn tin fɔ protɔtayp ɛn lɔw-volyum prodakshɔn bikɔs i de pul di nid fɔ mol. Fɔ no mɔ bɔt 3D printin ɛn aw i kɔmpia to tradishɔnal we fɔ mek tin dɛn, chɛk wi atikul bɔt na 3D printin we de riples injɛkshɔn moldin ..

Benefits : SLS de alaw fɔ mek dɛn mek intrikɛt dizayn dɛn, i de ridyus di west we dɛn de west, ɛn i rili fleksibul fɔ kɔstɔm shep dɛn.

Aplikeshɔn dɛn : Dɛn kin yuz am mɔ na ɔtomotiv, aerospace, ɛn mɛdikal industri fɔ mek protɔtayp kwik kwik wan ɛn fɔ wok fayn fayn wan.

| 3D Printing Method | Advantej dɛn . |

| Selektiv laser sintering (SLS) . | ay prɛsishɔn, nɔ mol dɛn nid fɔ de |

Fɔ no mɔ bɔt rapid prototyping teknɔlɔji dɛn, yu kin fɛn wi atikul pan Wetin na di kwaliti dɛm fɔ di rapid protɔtayp in manufakchurin teknɔlɔji yusful.

Fizik fɔm dɛn fɔ polyamide (PA) prɔdak dɛn .

Polyamide (PA) prodakt dɛn kin kam insay difrɛn fizik fɔm dɛn. Ɛni fɔm gɛt in yon spɛshal kwaliti ɛn aplikeshɔn dɛn. Lɛ wi fɛn di difrɛn shep ɛn saiz dɛn fɔ PA:

Pɛlɛt dɛn .

Pɛlɛt na di kɔmɔn we fɔ PA .

Dɛn na smɔl, silindrikal, ɔ disk-shep pis dɛn .

Pɛlɛt dɛn tipikli mɛzhɔ 2-5mm in dayamita .

Dɛn kin yuz dɛn mɔ fɔ injɛkshɔn moldin prɔses .

Pawa dɛn .

PA paoda dɛn gɛt fayn patikyula saiz, we de frɔm 10-200 maykron

Dɛn kin yuz dɛn na difrɛn say dɛn, lɛk:

Rotational moldin na na na na na na na na na na na na na na na na na na na na na na na na na na na na na na na na na .

Pauda we dɛn kin kɔt wit paoda .

Selektiv laser sintering (SLS) fɔ 3D printin .

Granul dɛn .

Granul dɛn big smɔl pas di pellet dɛn .

Dɛn mɛzhɔ 4-8mm in dayamita .

Granul dɛn izi fɔ fid insay ɛkstrushɔn mashin dɛn we yu kɔmpia am wit pauda dɛn .

Dɛn kin impruv matirial flɔabiliti we dɛn de prosɛs .

Sɔlid shep dɛn

PA kin bi mashin insay difrɛn sɔlid shep dɛn .

Di kɔmɔn tin dɛn we dɛn kin yuz na rod, plet, ɛn pat dɛn we dɛn mek fɔ dɛnsɛf

Dɛn mek dɛn shep ya frɔm PA stok matirial dɛn .

Dɛn de gi versatility fɔ spɛshal aplikeshɔn ɛn dizayn dɛn .

| fɔm | saiz | aplikeshɔn dɛn . |

| Pɛlɛt dɛn . | 2-5mm dayamita . | Moldin fɔ injɛkshɔn . |

| Pawa dɛn . | 10-200 Maykron dɛn . | Rotational molding, pauda coating, SLS 3D printin |

| Granul dɛn . | 4-8mm dayamita . | Ekstrushɔn prɔses dɛn . |

| Sɔlid dɛn . | Difrɛn kɔstɔm shep dɛn . | Machined komponent ɛn spɛshal dizayn dɛn . |

Aplikeshɔn fɔ Polyamide (PA) Plastik .

Polyamide (PA) plastic na versatile, we mek i impɔtant akɔdin to difrɛn industri dɛm. Di trɛnk we i gɛt, di we aw i nɔ de tek kemikal, ɛn di we aw i go de fɔ lɔng tɛm de gi bɛnifit dɛn na bɔku say dɛn we pipul dɛn kin aks fɔ am.

Ɔtomotiv Indastri .

Insay di ɔtomotiv sɛktɔ, dɛn kin yuz polyamides fɔ sɔm impɔtant kɔmpɔnɛnt dɛn. Di pat dɛn na di injin, di fiul sistem, ɛn di ilɛktrik insulɛta dɛn de abop pan PA plastic bikɔs i nɔ de mek i wam, i gɛt trɛnk, ɛn i go de fɔ lɔng tɛm.

| Aplikeshɔn | Ki Bɛnifit dɛn . |

| Enjin komponent dɛn . | Hɛt rɛsistɛns, trɛnk . |

| Fiul sistem dɛn . | Kεmikכl rεsistεns, lכw pεrmiabiliti . |

| Ilektrikal Inshɔlat dɛn . | Ilektrikal insuleshɔn, ɔt stebiliti . |

Indastrial Aplikeshɔn dɛn .

Indastrial sɛtin dɛn tek advantej pan di polyamide in wear resistans ɛn low friction prɔpati. Biɛrin, gia, valv, ɛn sil we dɛn mek wit PA kin te, ridyus frikshɔn, ɛn du wɛl na say dɛn we gɛt ay strɛs.

| Aplikeshɔn | Ki Bɛnifit dɛn . |

| Bearings ɛn gia dɛn . | Wear resistans, low frikshɔn . |

| Valv ɛn Sil dɛn . | Kεmikכl εn mεkanikal rεsistεns . |

Di guds dɛn we dɛn de yuz fɔ bay tin dɛn .

Frɔm spɔt ikwipmɛnt to ɛvride tin dɛn we dɛn kin yuz na os, dɛn kin yuz polyamide bɔku bɔku wan fɔ mek i tranga ɛn fɔ mek i ebul fɔ chenj. Aytem dɛn lɛk tɛnis rɛkɛt ɛn kichin tin dɛn kin bɛnifit frɔm PA in durabiliti ɛn izi fɔ prosɛs.

| Aplikeshɔn | Ki Bɛnifit dɛn . |

| Spɔtin Ikwipmɛnt . | Toughness, Fleksibul . |

| Di tin dɛn we dɛn kin yuz na os . | Durability, izi fɔ mol . |

Ilɛktrikal ɛn ilɛktronik tin dɛn .

Insay ilɛktroniks, dɛn valyu polyamide fɔ dɛn ilɛktrik insuleshɔn prɔpati dɛn. Dɛn kin yuz dɛn na kɔnɛkta, switch, ɛn kɔmpawnd usay insuleshɔn ɛn ɔt rɛsistɛns rili impɔtant.

| Aplikeshɔn | Ki Bɛnifit dɛn . |

| Kɔnɛkta ɛn Switch dɛn . | Ilektrikal insuleshɔn, ɔt rɛsistɛns . |

| Enclosures . | Strɔng, Kwɛmyuɛl Resistɛns . |

Fɔd industri .

Food-grade polyamides na sef fɔ dairekt kɔntakt wit it ɛn dɛn kin yuz am na pak, kɔnvayɔr bɛlt, ɛn mashin pat. Dɛn matirial ya de gi fayn fayn kemikal rɛsistɛns ɛn lɔw mɔstɔ absɔpshɔn.

| Aplikeshɔn | Ki Bɛnifit dɛn . |

| Fɔ it-grɛd paket . | Kεmikכl rεsistεns, sef fכ kכntakt . |

| Belt dɛn we dɛn kin yuz fɔ kɔnvaysɔ . | Durability, Moisture resistans . |

Kɔmpia di polyamide (PA) plastic wit ɔda matirial dɛn .

Polyamide (PA) plastic de stand out fɔ in yon kɔmbaynshɔn fɔ trɛnk, fleksibiliti, ɛn kemikal resistans. Na so i de kɔmpia to ɔda kɔmɔn tin dɛn.

PA plastic vs. polyester .

Poliamide ɛn polyester na ɔl tu sintetik polimɛr, bɔt dɛn gɛt ki difrɛns. PA de gi bɛtɛ trɛnk ɛn impak rɛsistɛns, we Polyester de mɔ resistant to strɛch ɛn shrink. PA de absכp bak mכs mכsich pas polyεsta, we de afekt in dimenshכnal stεbiliti insay humid envayroment.

| Property | polyamide (PA) | polyester . |

| Trɛnk | Di wan dɛn we ay pas ɔl . | Soba |

| Impɛkt rɛsistɛns . | Wɛl dɔn | Ridyus |

| Mostɔ absɔpshɔn . | Ay | Lo |

| Stretch resistans . | Ridyus | Di wan dɛn we ay pas ɔl . |

PA plastic vs. polipropylene (pp)

PA gɛt bɛtɛ mɛkanikal prɔpati dɛn we yu kɔmpia to polypropylene (PP), lɛk ay trɛnk ɛn wear resistans. כltu, PP gεt supεriכr kεmikכl rεsistεns, εspεshali εgεst asid εn alkali. PA na mɔ ɔt-rɛsistɛns, we PP na pɔsin we dɛn sabi fɔ in fleksibiliti ɛn layt wet.

| Property | polyamide (PA) | polipropilen (pp) |

| Trɛnk | Di wan dɛn we ay pas ɔl . | Ridyus |

| Kεmikכl rεsistεns . | Gud, bɔt wik agens asid . | Wɛl dɔn |

| Di wan dɛn we de fɛt fɔ mek di ples wam . | Di wan dɛn we ay pas ɔl . | Ridyus |

| Fleksibul fɔ mek yu ebul fɔ chenj . | Ridyus | Di wan dɛn we ay pas ɔl . |

PA Plastik vs. Poliethylene (PE)

Polyamide de gi bɔku ay trɛnk ɛn ɔt rɛsistɛns kɔmpia to polyethylene (PE). PE na mɔ fleksibul ɛn i gɛt bɛtɛ mɔstɔ rɛsistɛns, we mek i fayn fɔ pak matirial dɛn. PA, na di ɔda say, ɛksɛl insay aplikeshɔn dɛn we nid mɛkanikal durabiliti ɛn ɔt rɛsistɛns. Fɔ ɔndastand di difrɛns bitwin di kayn PE, yu kin rifer to wi atikul bɔt Difrɛns bitwin HDPE ɛn LDPE ..

| Property | Polyamide (PA) | Polyethylene (PE) |

| Trɛnk | Di wan dɛn we ay pas ɔl . | Ridyus |

| Di wan dɛn we de fɛt fɔ mek di ples wam . | Di wan dɛn we ay pas ɔl . | Ridyus |

| Fleksibul fɔ mek yu ebul fɔ chenj . | Ridyus | Di wan dɛn we ay pas ɔl . |

| Moisture resistans . | Ridyus | Wɛl dɔn |

PA plastic vs. metal (aluminum, steel)

Pan ɔl we mɛtal dɛn lɛk aluminiɔm ɛn stɛl strɔng pasmak, PA plastic layt pasmak ɛn i izi fɔ prosɛs. PA na koroshɔn-rɛsistɛns ɛn i nɔ nid di sem mentenɛns lɛk mɛtal dɛn na kɔrosiv ɛnvayrɔmɛnt. Mɛtal dɛn bɛtɛ fɔ aplikeshɔn dɛn we nid fɔ gɛt ekstrim trɛnk ɛn lod-bearing kapasiti, we PA ɛksɛl fɔ ridyus di wet ɛn inkris fleksibiliti. Fɔ kɔmpia bitwin difrɛn mɛtal dɛn, yu go si wi atikul bɔt Titanium vs aluminium intrestin.

| Property | polyamide (PA) | aluminium | steel . |

| Trɛnk | Ridyus | Ay | Na rili ay . |

| We | Lɔw (laytwɛt) . | Soba | Ay |

| Koroshɔn rɛsistɛns . | Wɛl dɔn | Gud | Pɔ |

| Fleksibul fɔ mek yu ebul fɔ chenj . | Di wan dɛn we ay pas ɔl . | Ridyus | Ridyus |

Fɔ no mɔ bɔt mɛtal matirial ɛn dɛn prɔpati, yu kin chɛk wi gayd pan Difrɛn kayn mɛtal dɛn ..

Dɔn

Polyamide (PA) plastic na versatile, ofa trɛnk, ɔt resistans, ɛn durability. Dɛn kwaliti dɛn ya de mek dɛn impɔtant fɔ mek dɛn ebul fɔ mek injinɛri ɛn mek tin dɛn tide. Ilɛksɛf dɛn yuz am na ɔtomotiv, ilɛktroniks, ɔ industrial aplikeshɔn, PA plastic dɛn de gi rilibul pefɔmɛns.

We yu de pik wan PA tayp, tink bɔt di patikyula tin dɛn we dɛn nid lɛk trɛnk, fleksibiliti, ɛn envayrɔmɛnt rɛsistɛns. Ɛni PA gred de gi yunik bɛnifit fɔ difrɛn aplikeshɔn dɛn, we de mek shɔ se di rayt matirial fɔ di wok.

Tips: Yu maybe intres to di ol plastics