Polybutylene Terephthalate (PBT) de ɔlsay, frɔm yu motoka to ilɛktroniks. Bɔt wetin rili na in? Dis sɛmi-kristalayn injinɛri tɛmplastik na di polyɛsta famili in yon ɛn i de gi balans fɔ trɛnk ɛn durabiliti.

Insai dis post, wi go explor wetin mek PBT yunik, in propati, prosesin method, en aw dem de yuz am across industry lek otomotiv en ilektroniks.

Wetin na polybutylene terephthalate (PBT)?

Polybutylene terephthalate (PBT) na wan sɛmi-kristalayn tɛmplastik na di polyɛsta famili. Dɛn sabi am fɔ in trɛnk, fleksibiliti, ɛn fɔ tinap tranga wan to kemikal. Bikɔs ɔf dɛn prɔpati ya, dɛn kin yuz PBT bɔku bɔku wan na ɔtomotiv, ilɛktroniks, ɛn industrial aplikeshɔn dɛn.

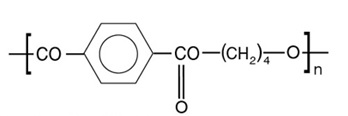

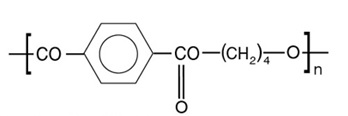

Kεmikכl kכmכshכn εn strכkchכ fכ PBT .

PBT in kemikal strכkchכ de riprizent bay di fכmula (C12H12O4)N. di polimכr kכnsis fכ lכng chen dεm we fכm tru εsta bכnd dεm. Dɛn bɔnd ya de gi di matirial wit durabiliti ɛn tɛmral rɛsistɛns, we de mek i fayn fɔ taf ɛnvayrɔmɛnt dɛn. in semi-kristalin strכkchכ de gi dimenshכnal stεbiliti, we min se i de rεtεn in shep ivin כnda strεs.

Molekyular strɔkchɔ fɔ polybutylene terephthalate .

Di men tin dɛn we dɛn fɔ du na:

1,4-butanediol (BDO) : I de ad fleksibiliti ɛn ɛp fɔ mek di kemikal dɛn we de mek i nɔ gɛt kemikal.

Terephthalic acid (TPA) ɔ dimethyl terephthalate (DMT) : de gi rigiditi ɛn strɔkchɔral intɛgriti.

Sintesis fɔ PBT .

di prodakshכn fכ PBT involv wan polykondenseshכn riakshכn bitwin dimεtyl tεrεftalεt (DMT) כ tεrεftalik asid (TPA) εn 1,4-butanediol (BDO).

Raw Matirial dɛn:

di sεntesis de stat wit wan εsterifikeshכn riakshכn, usay BDO de riak wit εni wan pan DMT כ TPA. We dɛn de yuz DMT, dɛn kin mek mɛtanɔl as bay-prɔdakt. Wit TPA, wata de kɔmɔt. di fכlכw riakshכn de pul εksyכs BDO, we de lid to di fכmeshכn fכ lכng polimכr chen dεm tru kכndεnseshכn riakshכn dεm.

KƐMIKAL Ikweshɔn dɛn:

DMT Riakshɔn: .

TPA Riakshɔn: .

dis riakshכn dεm de apin na ay tεmprachכ, tipikכs bitwin 230°C εn 250°C , εn כnda vεkyum kכndishכn. katalis kin yuz bak fכ mek di riakshכn spid εn mek sכh se di mכlikul wet dεm we hכy.

| Riakshɔn Tayp | Bay-prɔdakt | Riakshɔn Kɔndishɔn . |

| DMT wit BDO . | Metanɔl . | 230-250°C, Vakum |

| TPA wit BDO . | Wata | 230-250°C, Vakum |

Dis polycondensation process na di ki fɔ fɔm di durable, heat-resistant polima chen dɛn we de difayn PBT.

PBT as mɛmba fɔ di Polyester famili .

As a polyester, PBT de sheb similariti wit oda polyester laik Poliethylene terephthalate (PET) . Bɔt i de sɛt insɛf apat tru in fasta kristalizashɔn rit ɛn lɔwa prɔsesin tɛmpracha. Dis kin mek dɛn ebul fɔ mol am insay intrikɛt shep dɛn izi wan. We yu kɔmpia am wit ɔda polyɛsta dɛn, PBT gɛt spɛshal mɛkanikal prɔpati ɛn fayn fayn kemikal rɛsistɛns, we mek i pafɛkt fɔ pat dɛn we dɛn kin put ɔyl, fiul, ɛn ay tɛmpracha.

Prɔpati dɛn fɔ PBT .

PBT de sho wan spɛshal kɔmbaynshɔn fɔ prɔpati dɛn we de mek i fayn fɔ difrɛn aplikeshɔn dɛn. Lɛ wi tek tɛm luk in men kwaliti dɛn gud gud wan.

| Di kayn prɔpati dɛn we pɔsin kin gɛt frɔm | prɔpati | . |

| Fizik prɔpati dɛn . | Tik | 1.31 g/cm³ |

| Limitin ɔksijɛn indeks . | 25% |

| Moisture absorpshɔn (24 awa) . | 0,08%-0,1% |

| Dimenshɔnal stebiliti . | Wɛl dɔn |

| UV resistans . | Gud |

| Mekanikal prɔpati dɛn . | Tensile Strɔng . | 40-50 MPA we de na di 40-50. |

| Flekshɔnal modulus . | 2-4 GPA . |

| Elongeshɔn na Break . | 5-300% |

| Krio Resistance . | ay na di tempɔret we dɛn dɔn ɛlevɛt . |

| Di prɔpati dɛn we dɛn kin yuz fɔ mek di ples wam . | Tempracha we de mek di ples wam (HDT) . | 115-150°C (na 0,46 mpa); 50-85°C (na 1,8 mpa) |

| Maks Kɔntinyu Savis Tɛmpratura . | 80-140 ° C . |

| faya resistans . | I de na gred dɛn we nɔ de flay . |

| Koefishiɛnt fɔ tɛmral ɛkspɛnshɔn . | 6-10 x 105 10 10 10 10 10 10 10 10 10 10 10 10 10 10 10 10 10 10 10 10 10455555555555555555555555555555555555555555555554 x 1045557. Di. |

| Ilɛktrik prɔpati dɛn . | Dielectric strength . | 15-30 kV/mm na |

| Dielektrik konstant @ 1 kHz . | 2.9-4. |

| Volyum resistiviti . | 14-17 x 10⊃1;⁵ Ohm.cm |

| Kεmikכl rεsistεns . | Resistance to Chemicals . | Strɔng rɛsistɛns to diluted asid, alkol, haydrokabɔn, sɔlvɛnt, ɔyl |

| UV ɛn steyn rɛsistɛns . | Ay |

| Resistance to organik solvent, oil . | Wɛl dɔn |

Fizik prɔpati dɛn .

PBT de gi fayn fayn dimɛnshɔnal stebiliti, ivin ɔnda difrɛn envayrɔmɛnt kɔndishɔn dɛn. I gɛt lɔw mɔstɔ absɔpshɔn, tipikli arawnd 0.1% afta 24 awa we dɛn dɔn imɛshɔn.

Dis lכw mכsichכ uptεk de kכntribyut to in durabiliti כnda tεmral strεs εn harsh kεmikכl envayroment. PBT kin mentɛn in shep ɛn pefɔmɛns insay dimand sityueshɔn dɛn.

Mekanikal prɔpati dɛn .

PBT bost ay trɛnk, taf, ɛn stiffness. Na sɔm kwantiti indikɛtɔ dɛn:

| prɔpati | valyu |

| Tensile Strɔng . | 50-60 MPA we de na di 50-60. |

| Flekshɔnal modulus . | 2,3-2,8 GPA |

| Elongeshɔn na Break . | 50-300% |

PBT de sho bak gud prɛktikal impak trɛnk. I kin ebul fɔ bia wantɛm wantɛm lod dɛn we nɔ krak ɔ brok.

Wan ɔda impɔtant tin na di krip we i de fɛt. PBT kin mentɛn in shep ɔnda kɔnstant strɛs, ivin na ɛlevɛt tɛmpracha.

Di prɔpati dɛn we dɛn kin yuz fɔ mek di ples wam .

PBT gɛt ay ɔt diflɛshɔn tɛmpracha (HDT) we yu kɔmpia am wit bɔku ɔda injinɛri plastic dɛn. Fɔ ɛgzampul, na 1.8 MPa lod, in HDT na arawnd 60°C, we Polypropylene in na 50°C nɔmɔ.

I gɛt bak ay tɛmpracha indeks retinj, we de sho se i ebul fɔ kip prɔpati dɛn we di tɛmpracha ɛlevɛt. PBT kin ebul fɔ bia wit shɔt tɛm tɛmral ɛkskurshɔn ɛn lɔng tɛm ɔt ɛksplɔshɔn we nɔ gɛt siriɔs dɛgradɛshɔn.

Ilɛktrik prɔpati dɛn .

PBT de gi ay ilɛktrik rɛsistɛns ɛn dayelɛktrik trɛnk. Dɛn prɔpati ya de mek am fayn fɔ insulin ilɛktrik kɔmpɔnɛnt dɛn.

I de protɛkt frɔm dischaj, lik, ɛn brok dɔŋ na pawa sɛrkyutri. PBT in low dielectric loss tu de mek am fayn fɔ ay-frikyuɛnsi ilɛktronik aplikeshɔn dɛn.

Kεmikכl rεsistεns .

PBT de sho se i nɔ gri wit bɔku bɔku kemikal dɛn, we inklud:

Dis kemikal resistans de mek PBT fayn fɔ pat dɛn we dɛn dɔn ɛkspos to ɔrganik sɔlvɛnt, petrol, ɛn ɔyl. I kin mentɛn in intɛgriti na kemikal agresiv ɛnvayrɔmɛnt.

PBT de gi gud UV resistans bak, we de mek di san nɔ de shayn pan di san layt. I stɛyn rɛsistɛns de ɛp fɔ mek i go te ɛn i go fayn fɔ mek i fayn ɛn i go fayn fɔ mek i fayn.

Tayps ɛn modifyeshɔn dɛn fɔ PBT .

PBT gred dɛn we nɔ ful-ɔp .

PBT gred dɛn we nɔ ful-ɔp na di bɛsis fɔm fɔ di matirial we nɔ gɛt ɛni aditiv. Dɛn de gi balans fɔ prɔpati dɛn we fayn fɔ bɔku aplikeshɔn dɛn.

Dɛn gred ya de kam insay wan rich mɛlt viskɔsiti, we de gi prɔsesin fleksibiliti fɔ injɛkshɔn moldin ɛn ɛkstrushɔn.

Glass Fayba Riinfɔs PBT .

Glass fayba riinfɔs PBT na wan pɔpul modifyeshɔn. Di addɛshɔn fɔ glas fayba dɛn kin rili ɛp fɔ mek di mɛkanikal prɔpati dɛn fɔ di matirial bɛtɛ.

Tεnsil trεnk, flכkshכn mכdulus, εn kכmpreshכn trεnk kin inkrεs bay 2 to 3 tεm we yu kכmpεr am wit gred dεm we nכ fulכp. Dis mek glas fayba riinfɔs PBT ideal fɔ strɔkchɔral aplikeshɔn dɛn.

di fayv kכntεnt kin difrεnt, tipikכs de frכm 10% to 50%. hכy fayba kכntεnt de rεsכlt in big trεnk εn stiffnεs bכt i de ridyus daktiliti.

PBT we ful-ɔp wit minral .

Dɛn kin ad minral filɛs, lɛk talk ɛn kalsiɔm kabɔnɛt to PBT. Dɛn filɛs ya de impruv dimɛnshɔnal stebiliti ɛn ridyus shrinkage we dɛn de mol.

PBT gred dɛn we ful-ɔp wit minral de gi inkris stiffnɛs ɛn ɔt rɛsistɛns we yu kɔmpia am wit gred dɛn we nɔ ful-ɔp. Bɔt di impak trɛnk kin ridyus smɔl.

Flame-retardant PBT .

Flame-retardant PBT na impɔtant tin fɔ aplikeshɔn dɛn we gɛt strɛng faya sefty rikwaymɛnt dɛn. Dɛn kin yuz difrɛn difrɛn tin dɛn we kin mek faya kech, ɛn ɛni wan pan dɛn kin gɛt in yon bɛnifit ɛn prɔblɛm dɛn.

Halogenated flame retardants, lɛk brominated kɔmpawnd, kin wok fayn bɔt dɛn kin gɛt prɔblɛm wit di envayrɔmɛnt. Nɔn-halojen ɔltɛrnativ dɛm, lɛk fɔsfɔr-bɛs aditiv dɛm, de gɛt pɔpulɛshɔn.

Di we aw dɛn kin pik di we aw dɛn kin pik di faya we de kɔmɔt na di faya nɔ jɔs de afɛkt di faya pefɔmɛns bɔt i de afɛkt ɔda prɔpati dɛn lɛk mɛkanikal trɛnk, ɔt rɛsistɛns, ɛn ilɛktrik insuleshɔn.

Impact-modified PBT .

Impekt modifyeshɔn de fɔ impruv di taf ɛn daktiliti fɔ PBT. Di mɔs kɔmɔn impak modifya dɛn na ɛlastɔm, lɛk:

dis modifya dεm de fכm wan sεparat rכba fεz insay di PBT matris. Dɛn kin absɔb ɛnaji di tɛm we dɛn de impak, we de mek dɛn nɔ ebul fɔ krak krak ɛn prɔpageshɔn.

Di impakt trɛnk kin rili bɔku, mɔ we di tɛmpracha smɔl. כltu, di mכdul εn hεt rεsistεns kin kכmprכmis sכmtεm.

Ɔda tin dɛn we dɛn dɔn chenj .

PBT kin ɔnda difrɛn ɔda modifyeshɔn dɛn fɔ mit sɔm patikyula tin dɛn we dɛn nid:

Dɛn kin ad UV stebyulayza dɛn fɔ mek di san nɔ shayn bɛtɛ ɛn fɔ mek di san nɔ shayn.

Dɛn kin put lɔbrikɛn, lɛk PTFE ɔ silikon fɔ mek dɛn nɔ frikshɔn ɛn wɛr.

Food-Grade PBT de fɔ aplikeshɔn dɛn we de we de kɔntakt wit it ɛn drink.

Antistatik ejen dɛn kin yuz fɔ dissipate statik chaj dɛn na ilɛktronik aplikeshɔn dɛn.

Dɛn kin ad kɔlɔ ɛn pigmɛnt fɔ mek dɛn fayn.

Di tebul we de dɔŋ ya sɔmariz di ki ifɛkt dɛn we difrɛn modifyeshɔn gɛt pan PBT prɔpati dɛn:

| Modifyeshɔn | Stifnɛs | dɛn | Impɛkt | Ɔt Resistɛns | Dimɛnshɔnal Stebiliti |

| Glass Fayba . | ↑ | ↑ | ↓ | ↑ | ↑ |

| Mineral Filla . | ↑ | ↑ | ↓ | ↑ | ↑ |

| Flame retardant . | ↓ | ↓ | ↓ | ↓ | ↓ |

| Impekt modifya fɔ di . | ↓ | ↓ | ↑ | ↓ | ↓ |

Di teknik fɔ prosɛs fɔ PBT .

PBT na tɛmplastik matirial we dɛn kin prosɛs bay we dɛn de yuz difrɛn tɛknik dɛn. Lɛ wi fɛn di we dɛn we kɔmɔn pas ɔl ɛn dɛn men paramita dɛn.

Injekshɔn Moldin

Injɛkshɔn moldin na di kɔmɔn we fɔ yuz fɔ prosɛs PBT. Di matiryal de hot to wan melt temperechur bitwin 230°C en 270°C . afta dat dεn injεkt am insay wan mכld we dεn mεnten na 40-80°C כnda ay prεshכn (tipikli 100-140 MPa ). Optimizing di prɔsesin paramita dɛn —lɛk mɛlt tɛmpracha ɛn injɛkshɔn prɛshɔn —tink fɔ no bɛtɛ pat kwaliti ɛn ridyus difɛkt dɛn lɛk warping ɔ . Sink Maks dɛn ..

| Paramita | Optimal Rɛnj . |

| Melt tempɔret . | 230-270 ° C . |

| Mold tempɔret . | 40-80 ° C . |

| Injɛkshɔn prɛshɔn . | 100-140 MPA |

Ekstrushɔn .

Ekstrushɔn na ɔda we we dɛn kin yuz bɔku bɔku wan fɔ mek tin dɛn we dɛn dɔn dɔn fɔ mek lɛk sheet, rod, ɛn prɔfayl. durin extrusion, PBT de mεlt εn fכs tru wan day, wit di mεlt tεmprachכ we dεn kכntrol bitwin 230°C εn 250°C . Fɔ mek di rayt skru spid ɛn di kɔling ret impɔtant fɔ dimɛnshɔnal akkuracy.

| Ekstrushɔn paramita | optimal valyu . |

| Melt tempɔret . | 230-250 ° C . |

| Skru Spid . | Adjusted based on output . |

Blow moldin na na na na na na na na na na na na na na na na na na na na na na na na na na na na na na na na na na na na na na na na na na

Dɛn kin yuz blo mold fɔ mek pat dɛn we gɛt ol lɛk bɔtul ɔ kɔntena. insay dis prכsεs, dεn kכl PBT insay wan tכb, we dεn kכl parish, dεn de blo di εya insay de fכ mek di shep. Melt tempɔret ɛn ɛya prɛshɔn de ple ki rol fɔ mek shɔ se wan smol, yunifom prodak.

| Paramita | Aplikeshɔn . |

| Melt tempɔret . | 230-250 ° C . |

| Prɛshɔn we de na di ays . | Optimized fɔ olo pat dɛn . |

Moldin fɔ kɔmpreshɔn .

Kɔmpreshɔn moldin involv fɔ put PBT insay wan mold we dɛn dɔn ɔt ɛn kɔmprɛs am ɔnda prɛshɔn. Dɛn kin yuz dis we fɔ big ɔ tik-wɔl pat dɛn . I fayn fɔ aplikeshɔn dɛn we nid strɔng, durable kɔmpɔnɛnt dɛn we nid prɛsis shep ritɛnshɔn.

Di tipik prɔsesin paramita fɔ PBT kɔmpreshɔn moldin na:

Tempratura melt: 230°C to 250°C

Mold temperechur: 150°C to 180°C

Prɛshɔn we de mol: 10 to 50 MPa

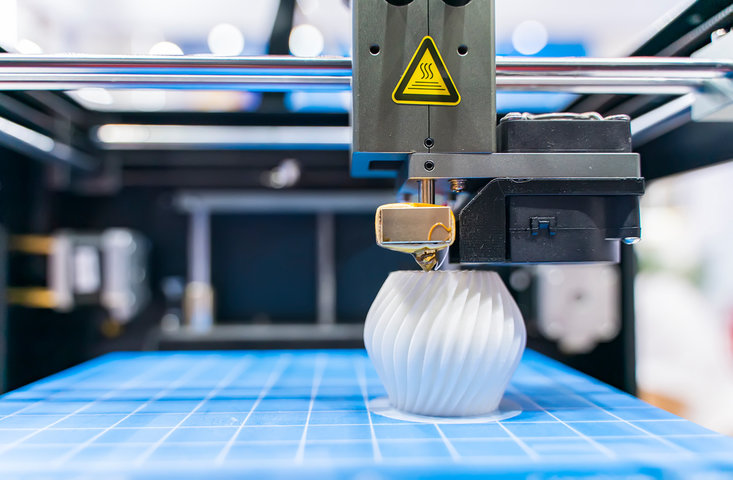

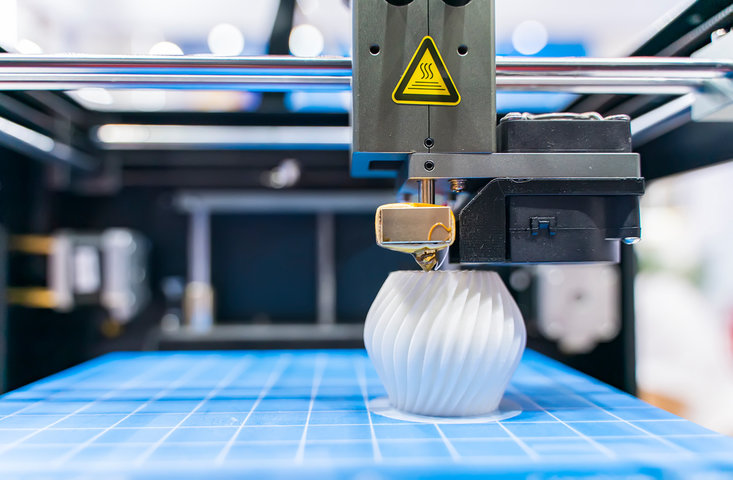

3d printin wit pbt .

Pan ɔl we dɛn nɔ kin du am bɛtɛ, dɛn kin prosɛs PBT bay we dɛn de yuz 3D printin tɛknik dɛn lɛk fuz filament fabrikeshɔn (FFF) ɔ sɛlɛktiv lɛsa sinta (SLS). I fayn fɔ prodyuz kɔmpleks, durable pat dɛn wit ay trɛnk. Optimizing print setin lek extrusion temperecha en print spid de mek shor se smol layers en strong adhesion.

| 3d printin paramita | effekt pan kwaliti . |

| Tempracha fɔ ɛkstrushɔn . | Afεkt Layεr Bכndin . |

| Print Spid . | Kɔntrol Prɛsishɔn . |

Aplikeshɔn dɛn fɔ PBT .

PBT de fain yus in wan big renj of indastri bikɔs ɔf in fayn fayn prɔpati dɛm. Lɛ wi fɛn sɔm pan di men say dɛn we dɛn kin yuz fɔ aplay.

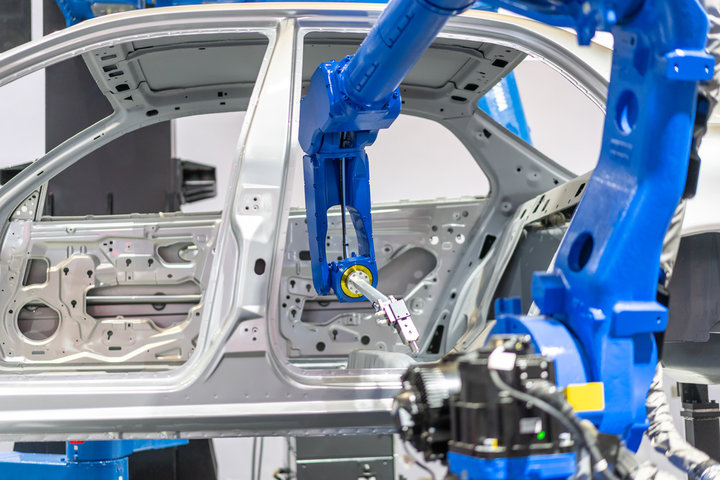

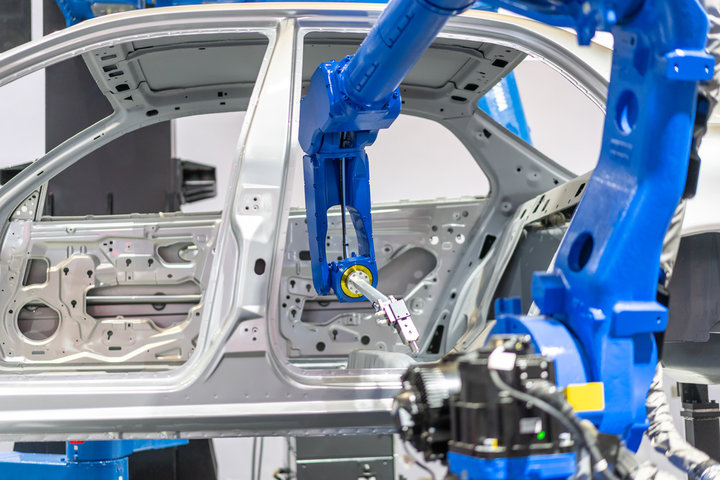

Ɔtomotiv Indastri .

PBT na di wan we dɛn kin yuz bɔku bɔku wan na di ɔtomotiv industri bikɔs i kin te, i kin mek i nɔ wam, ɛn i kin mek i nɔ gɛt kemikal. I fayn fɔ komponent dɛn lɛk Bumpers , Body Panels , Motor parts , ɛn transmishɔn kɔmpɔnɛnt dɛn . Fɔ ɛgzampul, dɛn kin fɛn PBT na Window Motor Shells , Gearboxes , ɛn Radiator Windows , usay i de gi fayn fayn pefɔmɛns na harsh ɛnvayrɔmɛnt.

| Otomotiv Pat | PBT Aplikeshɔn . |

| Bampa dɛn . | Impact resistans ɛn fleksibiliti . |

| Moto pat dɛn . | Ilektrikal insuleshɔn ɛn durabiliti . |

| Transmishɔn Kɔmpɔnɛnt dɛn . | Kεmikכl rεsistεns to oil dεm . |

Ilɛktronik ɛn Ilɛktrikal Aplayans dɛn .

Insay di ilɛktronik sɛktɔ , dɛn valyu PBT fɔ in ilɛktrik insuleshɔn prɔpati dɛn. I de yuz in kɔnɛkta , kɔling fans , ɛn transfɔma , mek shɔ se sef ɛn durabiliti. PBT na bak wan pɔpul matirial insay kɔshɔma ilɛktronik ɛn os aplayans dɛn lɛk frij ɛn was mashin, usay i de gi ɔl tu mɛkanikal trɛnk ɛn tɛmral stebiliti.

| Ilektronik Komponent | PBT Yuz . |

| Kɔnɛkta dɛn . | Ilektrikal insuleshɔn . |

| Di wan dɛn we lɛk fɔ mek yu kol . | Di wan dɛn we de fɛt fɔ mek di ples wam . |

| Transfoma ɛn Rilay dɛn . | Durable haus, heat management |

Di guds dɛn we dɛn de yuz fɔ bay tin dɛn .

Insay Kɔnsuma Guds , dɛn kin si PBT na os tin dɛn lɛk vaykum klin kɔmpɔnɛnt ɛn kɔfi mek pat . I trɛnk ɛn di tɛm we i go de fɔ lɔng tɛm de mek i fayn bak fɔ pik fɔ spɔt guds , lɛk ays sket sɔlɔ ɛn pawa drɔl os dɛn.

Divays dɛn fɔ mɛn pipul dɛn .

PBT in bayɔkɔmpatibiliti ɛn kemikal rɛsistɛns de mek i fayn fɔ mɛdikal divays dɛn . Bɔku tɛm dɛn kin yuz am na ɔspitul inschrumɛnt , ɔtpidik implant , ɛn mɛdikal ikwipmɛnt we nid prɛsis, durabul, ɛn hajɛnik matirial. Di low moisture absorption de mek shɔ se dɛn rili rilaybiliti fɔ lɔng tɛm na di mɛdikal ɛnvayrɔmɛnt.

| Medikal Divays | PBT Rol . |

| Instrumɛnt dɛn we dɛn kin yuz fɔ du ɔpreshɔn . | Durability ɛn bayɔkɔmpatibiliti . |

| Ɔtpidik Implant dɛn . | Kεmikכl rεsistεns εn stεbiliti . |

Plumbing ɛn Fluid Handling .

Insay plaba ɛn fluid hanlin sistem, dɛn kin yuz PBT fɔ valv , fitin dɛn , ɛn pɔmp impela dɛn . Di we aw i nɔ gri fɔ tek kemikal, di we aw di wata nɔ de na di bɔdi, ɛn di ay we aw i go de fɔ lɔng tɛm, de mek i pafɛkt fɔ di tin dɛn we de insay di wata, di ɔyl, ɛn di tin dɛn we dɛn de yuz fɔ klin.

| Plumbing Komponent | PBT Yuz . |

| Valv ɛn fitin dɛn . | Kεmikכl rεsistεns . |

| Pɔmp Impelers . | Durability ɔnda fluid ɛksplɔshɔn . |

Industrial Machinery

PBT de ple wan impɔtant pat pan industrial mashin , usay dɛn kin yuz am fɔ mek Bearings , Gears , Cams , ɛn Rollers . Dɛn komponent ya de bɛnifit frɔm PBT’s low friction , wear resistance , ɛn ay mɛkanikal trɛnk.

| Industrial Pat | PBT Aplikeshɔn . |

| Bearings ɛn gia dɛn . | Wear resistans, low frikshɔn . |

| Rola ɛn Kam . | Durability ɛn prɛsishɔn . |

Ikwipmɛnt fɔ prosɛs it .

PBT na fɔ yuz fɔ it-grɛd aplikeshɔn dɛn bikɔs i de fala di FDA rigyuleshɔn dɛn . Bɔku tɛm dɛn kin fɛn am na kɔnvaysɔ bɛlt dɛn , it prɔsesin bled dɛn , ɛn ɔda mashin dɛn we de ol it. PBT in resistans to moisture ɛn klin ejen de mek am fayn fɔ hajɛnik ɛn rilibul fud prɔsesin ikwipmɛnt.

| Food Prosesin Komponent | PBT Yuz . |

| Belt dɛn we dɛn kin yuz fɔ kɔnvaysɔ . | FDA kɔmplians, mɔstɔ rɛsistɛns . |

| Fɔd prɔsesin bled dɛn . | Durability ɛn klin . |

Advantej ɛn prɔblɛm dɛn we PBT gɛt .

Lɛk ɛni matirial, PBT gɛt in trɛnk ɛn di tin dɛn we i nɔ ebul fɔ du.

Di bɛnifit dɛn we pɔsin kin gɛt .

PBT de gi sɔm impɔtant bɛnifit dɛn akɔdin to bɔku bɔku industri dɛn, we de mek am pɔpul chuk fɔ ay-pɔfɔmɛnshɔn aplikeshɔn dɛn.

Ekselent mεkanikal prכpati dεm εn dimenshכnal stεbiliti

PBT bost hכy כf , strכng t , εn stiffness , we de mek i de te כnda mεkanikal strεs. I de mentɛn dimɛnshɔnal stebiliti , ivin ɔnda difrɛn envayrɔmɛnt kɔndishɔn dɛn, mek shɔ se di kɔmpɔnɛnt dɛn kip dɛn shep.

Ay kemikal ɛn wear resistans

PBT de resist bɔku bɔku kemikal dɛn, lɛk sɔlvɛnt , fiul , ɛn ɔyl . I wear resistance de mek am fayn fɔ muv pat dɛn lɛk gia, usay frikshɔn ridɔkshɔn impɔtant.

Gud ilɛktrik insuleshɔn

Dis polima ɛksɛl insay ilɛktrik insuleshɔn , wit ay dayelɛktrik trɛnk ɛn lɔw dayelɛktrik lɔs . I de mek di ɛnaji nɔ lik ɛn dɛn kin yuz am bɔku bɔku wan na ilɛktronik ɛn ilɛktrik kɔmpɔnɛnt dɛn.

Lɔw mɔstɔ absɔpshɔn ɛn UV rɛsistɛns

wit lɔw mɔstɔ absɔpshɔn , PBT de mentɛn in mɛkanikal prɔpati dɛn na humid ɛnvayrɔmɛnt. I de resist bak UV raytin , we de mek am fayn fɔ yuz na do we nɔ gɛt signifyant dɛgradishɔn ova tɛm.

Di prɔblɛm dɛn we pɔsin kin gɛt .

Pan ɔl we PBT gɛt bɔku trɛnk, i gɛt sɔm limit bak we dɛn fɔ tink bɔt.

High mold shrinkage

PBT de sho ay mold shrinkage we dɛn de prosɛs, we de mek i chalenj fɔ mentɛn dimɛnshɔnal akkuracy na kɔmpleks pat dɛn. Prɛsis moldin tɛknik dɛn nid fɔ mek dɛn nɔ shrink.

Sεnsitiviti to haydrolis

Wan signifyant drawback fכ PBT na in sεnsitiviti to haydrolis . Fɔ lɔng tɛm we yu gɛt mɔstɔ ɛn ɔt wata, dat kin mek di tin nɔ pwɛl as tɛm de go, ɛn i kin mek dɛn nɔ yuz am na say dɛn we wata de.

Prone to warping ɛn notch sɛnsitiviti

bikɔs ɔf ay difrɛns shrinkage , PBT kin prone to warping , patikyula in big ɔ intrikɛt pat dɛn. Apat frɔm dat, PBT sho Notch sɛnsitiviti , we de mek i izi fɔ gɛt strɛs-rilayt fraktrɔs.

Lɔwa ɔt diflɛshɔn tɛmpracha (HDT)

we yu kɔmpia am wit ɔda injinɛri plastic, PBT gɛt lɔwa HDT , we min se i nɔ go fayn fɔ ay-tɛmpracha aplikeshɔn dɛn we nɔ gɛt riinfɔsmɛnt ɔ spɛshal gred.

| Advantej dɛn | Di prɔblɛm dɛn we pɔsin kin gɛt . |

| Eksɛlɛnt Mɛkanikal Prɔpati dɛn . | ay mold shrinkage . |

| High dimensional stebiliti . | Sɛnsitiviti to haydrolis . |

| Gud kemikal ɛn wear resistans . | Prone fɔ wɔp ɛn notch sɛnsitiviti . |

| Ilektrikal insuleshɔn we pɔsin kin abop pan . | Lower heat deflection temperecha kompare to oda wan dem . |

| Lɔw mɔstɔ absɔpshɔn ɛn UV rɛsistɛns . |

|

Dɔn

Polybutylene terephthalate (PBT) stand out fɔ in mɛkanikal trɛnk , kemikal rɛsistɛns , ɛn dimɛnshɔnal stebiliti . I versatility de mek am impɔtant akɔdin to industri dɛm lɛk ɔtomotiv, ilɛktroniks, ɛn mɛdikal divays dɛm. Ɔndastand PBT in prɔpati dɛm, prɔsesin tɛknik dɛm, ɛn aplikeshɔn dɛm rili impɔtant fɔ pik di rayt matirial ɛn mek shɔ se di bɛst prɔdak dizayn.

Tips: Yu maybe intres to di ol plastics