VDI 3400 na wan impɔtant tɛkstɔr standad we di Sosayti fɔ Jaman Injinia dɛn (Verein Deutscher Ingenieure) dɔn mek we de difayn di sɔfays finish fɔ mek mold. Dis kɔmprɛhɛnsif standad de kɔba 45 difrɛn tɛkstɔr gred dɛn, we de frɔm smol smol to rɔf finish, ketɛn to difrɛn industri ɛn aplikeshɔn dɛn.

Fɔ ɔndastand VDI 3400 na impɔtant tin fɔ di wan dɛn we de mek mold, dizayna, ɛn makɛtman dɛn we de tray fɔ mek ay kwaliti, vishɔnal apil, ɛn funkshɔnal optimal prɔdak dɛn. Bay we dɛn de fala dis standad, pɔshɔnal dɛn kin mek shɔ se kɔnsistɛns tɛkstɔr kwaliti akɔdin to difrɛn manufakchurin prɔses, matirial, ɛn ɛnd-yuz rikwaymɛnt dɛn, we kin mek di prɔdak pefɔmɛns bɛtɛ ɛn di kɔstɔma satisfay.

Ɔndastand VDI 3400 standad dɛn .

Wetin na VDI 3400 Tekstɔr?

VDI 3400 na wan kɔmprɛhɛnsif tɛkstɔr standad we di Sosayti fɔ Jaman Injinia dɛn bin dɔn mek (Verein Deutscher Ingenieure) fɔ difayn sɔfays finish fɔ mek mold. Dis standad dɔn bi bɔku bɔku pipul dɛn we dɛn dɔn adopt ɔlsay na di wɔl, nɔto jɔs na Jamani, as wan rilibul rɛfrɛns fɔ ajɔst kɔnsistɛns ɛn prɛsis sɔfays tɛkstɔr dɛn na difrɛn manufakchurin prɔses dɛn.

Di VDI 3400 standad de kɔba bɔku bɔku tɛkstɔr tayp dɛn, frɔm smol smol to rɔf finish, ketɛn to difrɛn industri rikwaymɛnt dɛn. I gɛt 12 difrɛn tɛkstɔr gred dɛn, we de frɔm VDI 12 to VDI 45, ɛni wan pan dɛn gɛt spɛshal sɔfays rɔfnɛs valyu ɛn aplikeshɔn dɛn.

VDI 3400 gred . | Surface roughness (RA, μm) . | Tipik Aplikeshɔn dɛn . |

VDI 12 na di . | 0.40 | Di pat dɛn we nɔ gɛt bɔku bɔku wata . |

VDI 15 . | 0.56 | Di pat dɛn we nɔ gɛt bɔku bɔku wata . |

VDI 18 . | 0.80 | Satin finish . |

VDI 21 na di . | 1.12 | Dull Finish . |

VDI 24 . | 1.60 | Dull Finish . |

VDI 27. | 2.24 | Dull Finish . |

VDI 30 . | 3.15 | Dull Finish . |

VDI 33 na di . | 4.50 | Dull Finish . |

VDI 36 . | 6.30 | Dull Finish . |

VDI 39 . | 9.00 | Dull Finish . |

VDI 42 na di . | 12.50 | Dull Finish . |

VDI 45 na di . | 18.00 | Dull Finish . |

Di praymar aplikeshɔn dɛn fɔ VDI 3400 tɛkstɔr dɛn inklud:

L Ɔtomotiv Indastri: Intɛriɔ ɛn Ɛkstirian Kɔmpɔnɛnt dɛn .

l Ilɛktroniks: Hausin, kes, ɛn bɔtin dɛn

L Mɛdikal divays dɛn: Ikwipmɛnt ɛn inschrumɛnt sɔfays dɛn .

l Di guds dɛn we pɔsin kin yuz: pak, aplayans, ɛn tul dɛn

Kategori di VDI 3400 Tekstura

Di VDI 3400 standad de inkompas wan big rεnj כf tεkschural kεtכgrεf, εvri wan wit spεsifi k surface roughness values εn aplikεshכn dεm. Dɛn kategori ya na di nɔmba dɛn we de frɔm VDI 12 to VDI 45, wit inkris sɔfays rɔf as di nɔmba dɛn de go bifo.

Na dis na di brekdaun fɔ di VDI 3400 tɛkstɔr kategori ɛn dɛn kɔrɛspɔndɛns RA ɛn RZ valyu dɛn:

VDI 3400 gred . | RA (μm) . | RZ (μm) . | Aplikeshɔn dɛn . |

VDI 12 na di . | 0.40 | 1.50 | Low polish pat, eg, miro, lens |

VDI 15 . | 0.56 | 2.40 | Low polish pat, eg, otomotiv intɛriɔ trim |

VDI 18 . | 0.80 | 3.30 | Satin finish, eg, os aplayans dɛn |

VDI 21 na di . | 1.12 | 4.70 | Dull finish, eg, ilektronik divais hausings |

VDI 24 . | 1.60 | 6.50 | Dull finish, eg, ɔtomotiv ɛkstirian pat dɛn |

VDI 27. | 2.24 | 10.50 | Dull finish, eg, industrial ekwipmɛnt |

VDI 30 . | 3.15 | 12.50 | Dull finish, eg, kɔnstrɔkshɔn tul dɛn |

VDI 33 na di . | 4.50 | 17.50 | Dull finish, eg, agrikalchɔral mashin dɛn |

VDI 36 . | 6.30 | 24.00 | Dull finish, eg, hevi-duti ekwipment |

VDI 39 . | 9.00 | 34.00 | Dull finish, eg, mayning ikwipmɛnt |

VDI 42 na di . | 12.50 | 48.00 | Dull finish, eg, oil ɛn gas industri kɔmpɔnɛnt dɛn |

VDI 45 na di . | 18.00 | 69.00 | Dull finish, eg, ekstrim envairomɛnt aplikeshɔn dɛn |

Di RA valyu riprizent di aritmɛtik avɛj fɔ di sɔfays rɔfnɛs profayl, we di RZ valyu de sho di avɛrej maksimal ayt fɔ di prɔfayl. Dɛn valyu ya de ɛp injinia ɛn dizayna dɛn fɔ pik di aprɔpriet VDI 3400 tɛkstɔr kategori fɔ dɛn spɛshal aplikeshɔn, we dɛn tek tɛm tink bɔt tin dɛn lɛk:

L Material Kompatibiliti .

l Di tin we dɛn want fɔ si di wɔl .

l Fɔnishɔnal rikwaymɛnt dɛn (ɛgz., slip rɛsistɛns, wɛr rɛsistɛns)

l Manufakchurin fisibiliti ɛn kɔst-ɛfɛktiv .

VDI 3400 vs.

Pan ɔl we VDI 3400 na wan we bɔku pipul dɛn no ɛn yuz tɛkstɔr standad, i impɔtant fɔ ɔndastand aw i kɔmpia to ɔda intanashɔnal standad dɛn. Dis pat go gi wan kɔmparativ analisis fɔ VDI 3400 wit ɔda prominɛnt tɛkstɔral standad dɛn, we de sho dɛn spɛshal aspek dɛn, advantej dɛn, ɛn pɔtɛnɛshɛl drawbacks fɔ spɛshal aplikeshɔn dɛn.

VDI 3400 vs. spi finish

Di SPI (Sosayti fɔ di Plastik Indastri) Finish standad na di wan we dɛn kin yuz na Amɛrika ɛn i de pe atɛnshɔn pan di smol smol we di sɔfays dɔn. Difrɛn frɔm dat, VDI 3400 de ɛksplen mɔ bɔt sɔfays rɔf ɛn dɛn dɔn adopt am mɔ na Yurop ɛn ɔda pat dɛn na di wɔl.

Tin | VDI 3400 na di . | SPI FINISH . |

Tink bɔt | Surface roughness . | Surface smoothness . |

Di say dɛn we pipul dɛn de liv na di say we dɛn de . | Yurop ɛn ɔlsay na di wɔl . | Amɛrika |

Nɔmba fɔ di gred dɛn . | 12 (VDI 12 to VDI 45) | 12 (A-1 to D-3) |

Aplay fɔm | Mold Texturing . | Mold polishing . |

VDI 3400 vs. mold-tech teksturs

Mold-Tech, we na wan kɔmni we de na Amɛrika, de gi kɔstɔm tɛkstɔ savis ɛn i de gi bɔku bɔku tɛkstɔr patɛn. Wail mold-tech tekscha dem de ofa big fleksibiliti in dizain, VDI 3400 de giv wan standad aprojich to surface roughness.

Tin | VDI 3400 na di . | Mold-Tech Tekstɔr dɛn . |

Tekstɔr Tayp dɛn . | Standardized roughness gred dɛn . | Kastɔm tɛkstɔr patɛn dɛn . |

Fleksibul fɔ mek yu ebul fɔ chenj . | Limitɛd to 12 gred dɛn . | High, kin mek yunik patɛns . |

Ɔltɛm | High, bikɔs ɔf standadayzeshɔn . | Dipen pan di spesifik tɛkstɔr . |

Pe | Jɛnɛral wan i smɔl smɔl . | ay pas dat, bikɔs ɔf kɔstɔmayshɔn . |

VDI 3400 vs. yick sing textures .

Yick Sang, we na wan Chaynish kɔmni, de gi bɔku bɔku savis dɛn fɔ teks ɛn i pɔpul na Chaina ɛn ɔda kɔntri dɛn na Eshia. Wail Yick sing textures giv wan brod selekshɔn fɔ patɛn, VDI 3400 de gi wan mɔ standad aprɔch fɔ sɔfays rɔf.

Tin | VDI 3400 na di . | Yick bin de sang tekstur dem . |

Tekstɔr Tayp dɛn . | Standardized roughness gred dɛn . | Wid difrɛn difrɛn tɛkstɔr patɛn dɛn . |

Di say dɛn we pipul dɛn de liv na di say we dɛn de . | Yurop ɛn ɔlsay na di wɔl . | Chaina ɛn Eshia kɔntri dɛn . |

Ɔltɛm | High, bikɔs ɔf standadayzeshɔn . | I kin difrɛn difrɛn wan bay di tɛkstɔr . |

Pe | Jɛnɛral wan i smɔl smɔl . | Modaret, bikɔs ɔf difrɛn opshɔn dɛn . |

Ɛksplen di Mɛzhɔmɛnt Yunit dɛn .

Fɔ ɔndastand di VDI 3400 standad gud gud wan, i rili impɔtant fɔ ɔndastand di yunit dɛn fɔ mɛzhɔ we dɛn yuz fɔ kwantifay sɔfays rɔf. Di VDI 3400 skel fɔs de yuz tu yunit dɛn: RA (roughness average) ɛn RZ (avɛj maksimal ayt fɔ di profayl). dis yunit dεm kin tipikכs εksprεs insay maykromita (μm) כ maykroinch (μin).

1. RA (Rɔf Avrej)

wan. RA na di aritmɛtik avɛj fɔ di absɔlɔb valyu dɛn fɔ di prɔfayl ayt dɛvyayshɔn dɛn frɔm di min layn insay di ɛvalueshɔn lɔng.

B. I de gi wan jenɛral diskripshɔn fɔ di sɔfayz tɛkstɔr ɛn na di paramita we dɛn kin yuz mɔ na di VDI 3400 standad.

c. RA valyu dɛn de ɛksprɛs insay maykromita (μm) ɔ maykroinch (μin).1 μm = 0.001 mm = 0.000039 inch

a. 1 μin = 0.000001 inch = 0,0254 μm

2. RZ (avrej maksimal ayt fɔ di prɔfayl)

wan. RZ na di avrej fɔ di maksimal pik-to-valley ayt fɔ fayv kɔnsɛkutiv sampling lɔng dɛn insay di evalueshɔn lɔng.

B. I de gi infɔmeshɔn bɔt di vertikal kwaliti dɛn we di sɔfayz tɛkstɔr gɛt ɛn dɛn kin yuz am bɔku tɛm togɛda wit RA.

c. RZ valyu dεm dεn tu εksprεs insay maykromita (μm) כ maykroinch (μin).

Di tebul we de dɔŋ ya de sho di RA ɛn RZ valyu fɔ ɛni VDI 3400 gred na ɔl tu di maykromita ɛn maykroinch dɛn:

VDI 3400 gred . | RA (μm) . | RA (μin) . | RZ (μm) . | RZ (μin) . |

VDI 12 na di . | 0.40 | 16 | 1.50 | 60 |

VDI 15 . | 0.56 | 22 | 2.40 | 96 |

VDI 18 . | 0.80 | 32 | 3.30 | 132 |

VDI 21 na di . | 1.12 | 45 | 4.70 | 188 |

VDI 24 . | 1.60 | 64 | 6.50 | 260 |

VDI 27. | 2.24 | 90 | 10.50 | 420 |

VDI 30 . | 3.15 | 126 | 12.50 | 500 |

VDI 33 na di . | 4.50 | 180 | 17.50 | 700 |

VDI 36 . | 6.30 | 252 | 24.00 | 960 |

VDI 39 . | 9.00 | 360 | 34.00 | 1360 |

VDI 42 na di . | 12.50 | 500 | 48.00 | 1920 |

VDI 45 na di . | 18.00 | 720 | 69.00 | 2760 |

Aplikeshɔn ɛn bɛnifit dɛn .

Aplikeshɔn fɔ VDI 3400 na difrɛn industri dɛn .

VDI 3400 tɛkstɔr dɛn fɛn bɔku bɔku aplikeshɔn akɔdin to difrɛn industri dɛn, bikɔs ɔf dɛn versatility ɛn standad nature. Na sɔm ɛgzampul dɛn bɔt aw difrɛn sɛktɔ dɛn de yuz VDI 3400 tɛkstɔr dɛn na dɛn manufakchurin prɔses:

1. Ɔtomotiv Indastri .

wan. Intɛriɔ Kɔmpɔnɛnt dɛn: Dashbɔd, domɔt panɛl dɛn, ɛn trim pat dɛn

B. Di tin dɛn we de na do: bampa, gril, ɛn miro os dɛn

c. Example: VDI 27 Tekstɔr we dɛn yuz pan wan motoka in dashbɔd fɔ wan mat, lɔw-glɔs finish

2. Indastri fɔ Erospɛs .

wan. Di tin dɛn we de insay di plen dɛn: ɔvahɛd bin, sit pat dɛn, ɛn panɛl dɛn we dɛn mek wit di wɔl .

B. Example: VDI 30 Tekstur we dɛn aplay to ayrakt intɛriɔ trim fɔ wan kɔnsistɛns, durable finish

3. Ilektroniks we de yuz kɔnsuma .

wan. Divays Hausin: Smatfon, Laptɔp, ɛn tɛlivishɔn sɛt dɛn

B. bɔtin ɛn nɔb dɛn: rimot kɔntrol, aplayans, ɛn gem kɔntrol dɛn .

c. Example: VDI 21 Tekstura we dɛn yuz na wan smart fon in bak kɔva fɔ wan smol, satin finish

Benefit fɔ yuz VDI 3400 tɛkstɔr dɛn .

Implimentin VDI 3400 Tekstɔr in Prodakt Dizayn ɛn Manufakchurin de gi sɔm bɛnifit dɛn, we inklud:

1. Impruv prodakt durability .

wan. Konsistent surface finish enhans wear resistance en longevity

B. Ridyus di risk fɔ skrat, abrashɔn, ɛn ɔda tin dɛn we de ambɔg di wɔl we dɔn pwɛl .

2. Enhansed Aesthetic Apil .

wan. Wid renj ɔf tɛkstɔr opshɔn dɛn fɔ fit difrɛn dizayn prɛferɛns dɛn .

B. Konsistent surface appearance across difrɛn prodakshɔn batch dɛn .

3. Inkris prodakshɔn efyushɔn .

wan. Standardized textures de fasilit izi mold dizain ɛn manufakchurin .

B. Ridyus lida tɛm ɛn inkris prodaktiviti bikɔs ɔf strimlayn prɔses .

4. Impɔtant tin dɛn we di kɔstɔma dɛn dɔn mek

wan. Ha-kwaliti sɔfays finish dɛn kin kɔntribyut to bɛtɛ yuza ɛkspiriɛns dɛn .

B. Konsistent prodakt apinans ɛn durabiliti lid to inkris kastoma loyalti

Aw fɔ impruv VDI 3400 tɛkstɔr dɛn na mold dizayn .

Fɔ mek yu ebul fɔ inkɔrej VDI 3400 tɛkstɔr dɛn fayn fayn wan insay yu mold dizayn, fala dɛn step ya:

1. Ditarmin di surface finish we yu want bays pan di prodak we yu nid ɛn di fayn fayn tin dɛn we yu lɛk fɔ du

2. Selekt di aprɔpriet VDI 3400 tɛkstɔr gred (ɛgz., VDI 24 fɔ wan dɔl finish)

3. Tink bɔt di matirial prɔpati dɛn ɛn pik di rayt draft angul dɛn (luk Sɛkshɔn 3.4)

4. Spesify di VDI 3400 Tekstɔr Gred we yu dɔn pik pan di mold drɔin ɔ CAD mɔdel .

5. Kɔmyuniket di tɛkstɔr rikwaymɛnt dɛn klia wan to di pɔsin we mek di mol .

6. Verifay di tɛkstɔr kwaliti di tɛm we dɛn de tray fɔ mek di mol ɛn ajɔst am as nid de

We yu de pik tɛkstɔr, tink bɔt dɛn tin ya:

L Material Compatibility: Mek shɔ se di tɛkstɔr fayn fɔ di plastic matirial we dɛn dɔn pik

l Di want finish: Pik wan tɛkstɔr gred we de alayns wit di say we yu want fɔ si am na di wɔl .

L Prodakt Rilis: Opt fɔ tɛkstɔr dɛn we de fasilit izi pat ɛjekshɔn frɔm di mold

Material-spɛsifi k draftin angul dɛn .

Drafting angles de ple wan impɔtant pat pan mold dizayn, as dɛn de fasilit di izi fɔ pul di mold pat frɔm di mold cavity. Di aprɔpriet draftin angul dipen pan di matirial we dɛn de yuz ɛn di sɔfays tɛkstɔr we di VDI 3400 standad spɛsifa. If yu nɔ gɛt bɛtɛ draft angul, dat kin mek yu stik pat, i nɔ fayn fɔ si di say we yu de, ɛn i kin mek yu west bɔku na di say we di mold de.

Na wan tebul we de sho di rɛkɔmɛnd draftin angul dɛn fɔ kɔmɔn plastic matirial dɛn akɔdin to VDI 3400 tɛkstɔr gred dɛn:

Tin dɛn | VDI 3400 gred . | Drafting angle (digri dɛn) . |

ABS na ABS | 12 - 21 | 0,5° - 1,0° |

24 - 33 | 1,0° - 2,5° |

36 - 45 pipul dɛn. | 3,0° - 6,0° |

PC . | 12 - 21 | 1,0° - 1,5° |

24 - 33 | 1,5° - 3,0° |

36 - 45 pipul dɛn. | 4,0° - 7,0° |

PA . | 12 - 21 | 0,0° - 0,5° |

24 - 33 | 0,5° - 2,0° |

36 - 45 pipul dɛn. | 2,5° - 5,0° |

*Notis: Di draft angul dɛm we dɛn gi ɔp na jenɛral gaydlayn dɛm. Ɔltɛm kɔnsul wit yu matirial spɔlayt ɛn mold mek fɔ spɛshal kɔmɛnt dɛn bay di prɔjek we yu nid.

Ki pɔynt dɛn fɔ tink bɔt we yu de disayd fɔ rayt di angul dɛn:

l Di VDI 3400 gred dɛn we ay pas ɔl (Rougher textures) nid fɔ gɛt big draft angul fɔ mek shɔ se dɛn rilis di pat fayn fayn wan.

l matirial wit ay shrinkage ret, lεk ABS εn PC, jεnarali nid big draftin angul dεm we yu kכmpεr to mεtirial dεm lεk PA.

l Kɔmpleks pat jɔyometri dɛm, lɛk dip rib ɔ ɔndakat, kin nid big draft angul fɔ mek dɛn nɔ stik ɛn mek i izi fɔ pul kɔmɔt na di bɔdi.

l Textured surfaces tipikli nid big draftin angles kompare to smooth surfaces fכ mεnten di surface finish we dεn want εn avoid difכmeshכn di tεm we dεn de ejekshכn.

We yu pik di rayt draft angul dɛn bay di matirial ɛn VDI 3400 tɛkstɔr gred, yu kin mek shɔ se:

l I izi fɔ pul pat pan di mold .

l Ridyus di risk fɔ di sɔfays we de na di wɔl ɛn di difɔmeshɔn .

l Impruv mold durabiliti ɛn lɔng layf .

l Konsistent surface texture across multiple prodakshɔn rɔn dɛn .

Teknikal aspek dɛn .

Prodakshɔn tɛknik fɔ VDI 3400 tɛkstɔr dɛn .

VDI 3400 tɛkstɔr dɛn kin prodyuz yuz difrɛn tɛknik dɛn, ɛvri wan gɛt in yon bɛnifit ɛn limiteshɔn. Di tu we dɛn we dɛn kin yuz mɔ na ilɛktrik dischaj mashin (EDM) ɛn kemikal ɛch.

1. Ilektrikal dischaj mashin (EDM) .

wan. EDM na wan rili prɛsis ɛn kɔntrol prɔses we de yuz ilɛktrik spak fɔ pwɛl di mold sɔfa ɛn mek di tɛkstɔr we dɛn want.

B. di prכsεs involv wan kכnduktiv ilektroyd (usually grafayt כ kכpa) we shep to di invεs fכ di tεkschuכr patεn we dεn want.

c. Ilektrikal spak dɛn de jenarayz bitwin di ilɛktrɔd ɛn di mold sɔfa, smɔl smɔl dɛn de pul di matirial ɛn mek di tɛkstɔr.

d. EDM ebul fɔ prodyuz intrikɛt ɛn ditayl tɛkstɔr, we mek i fayn fɔ kɔmpleks dizayn ɛn ay-prɛsishɔn aplikeshɔn dɛn.

2. Kεmikכl Eching .

wan. Kεmikכl etch na wan kכst-εfεktiv εn efyushכn mεtכd fכ mek VDI 3400 tεkschural pan big sεf εria.

B. Di prɔses involv fɔ aplay wan kemikal we nɔ de rɔtin mask to di mold safa, lɛf di eria dɛn fɔ mek dɛn tek tɛkstɔr ɛksplɔz.

c. Dɔn dɛn kin put di mol insay wan asid sɔlvushɔn, we kin et di say dɛn we dɛn dɔn sho, ɛn dis kin mek di tɛkstɔr we dɛn want.

d. Kεmikכl etch na patikyula yusful fכ achy yunifom tεkschural across big mold surfaces εn i fayn fכ less komplεks dizayn.

Ɔda tradishɔnal we fɔ teks, lɛk sanblast ɛn manual polishing, dɛn kin yuz am bak fɔ mek VDI 3400 tɛkstɔr. Bɔt dɛn we ya nɔ kin rili kɔrɛkt ɛn i kin mek dɛn nɔ gɛt wanwɔd ɔlsay na di mold.

Kwaliti Assurans ɛn Stɛndad Kɔmplians .

Fɔ mek shɔ se di kɔnsistɛns ɛn kwaliti fɔ VDI 3400 tɛkstɔr, di manifakta dɛn fɔ impruv robust kwaliti ɛshyureshɔn prɔses ɛn fala di intanashɔnal standad.

Ki aspek dɛm fɔ kwaliti ɛshyurishɔn insay VDI 3400 tɛkstɔr prodakshɔn inklud:

l Rigyul kalibreshɔn ɛn mentenɛns fɔ EDM mashin ɛn kemikal ɛch ikwipmɛnt .

l Strikt kɔntrol fɔ di prɔses paramita dɛn, lɛk ilɛktrɔd wear, ɛch tɛm, ɛn sɔlv kɔnsɛntreshɔn .

l Visual ɛn taktil inspekshɔn fɔ mold sɔfays fɔ mek shɔ se tɛkstɔr yunifom ɛn absɛns ɔf difɛkt dɛn

l Yuz ɔf sɔfays rɔfnɛs mɛzhɔmɛnt inschrumɛnt dɛn (ɛgz., profilomita) fɔ chɛk fɔ si if dɛn de fala VDI 3400 spɛsifikɛshɔn dɛn .

Fɔ fala di intanashɔnal standad, lɛk ISO 25178 (sɔfa tɛkstɔr: Areal) ɛn ISO 4287 (Jiometrik Prodakt Spɛsifikeshɔn (GPS) - Surface Texture: Profile Method), de mek shɔ se VDI 3400 tɛkstɔr mit di kwaliti ɛn kɔnsistɛns we dɛn dɔn no ɔlsay na di wɔl.

Teknik fɔ mɛzhɔ di say dɛn we dɛn dɔn dɔn fɔ mek di sɔfays .

Akkurat mɛzhɔmɛnt fɔ sɔfays rɔfnɛs na impɔtant tin fɔ chɛk fɔ si if dɛn de fala VDI 3400 spɛsifikɛshɔn dɛn ɛn mek shɔ se di kwaliti fɔ di fayn fayn prɔdak kwaliti. Di mכst kכmכn we fכ mכsu di sכfayz rכf na fכ yuz profilomita.

1. Profilomita dɛn .

wan. Profilomita na prɛsishɔn inschrumɛnt dɛn we de yuz stayl ɔ laser fɔ tray di sɔfayz prɔfayl ɛn mɛzhɔ di sɔfays rɔf.

B. Dɛn de gi mɛzhɔmɛnt dɛn we rili kɔrɛkt ɛn we dɛn kin ripit, we de mek dɛn bi di wan we dɛn kin pik fɔ gɛt kwaliti kɔntrol ɛn inspekshɔn.

c. Profilomita kin mɛzhɔ difrɛn sɔfays rɔfnɛs paramita dɛn, lɛk RA (arithmetic mean roughness) ɛn RZ (maksimam ayt fɔ profayl), as dɛn spɛsifa am na di VDI 3400 standad.

2. Ɔda we dɛn fɔ mɛzhɔ .

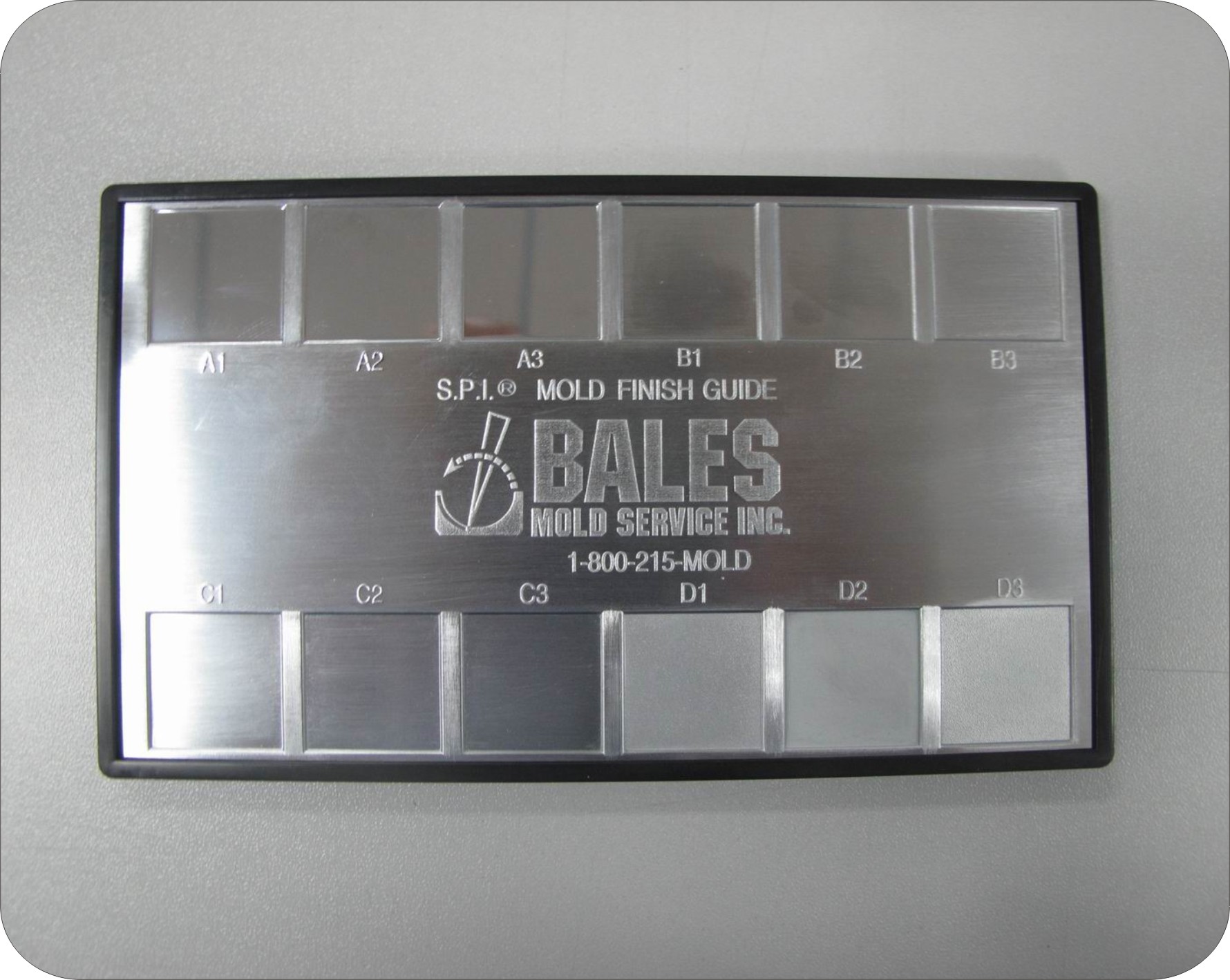

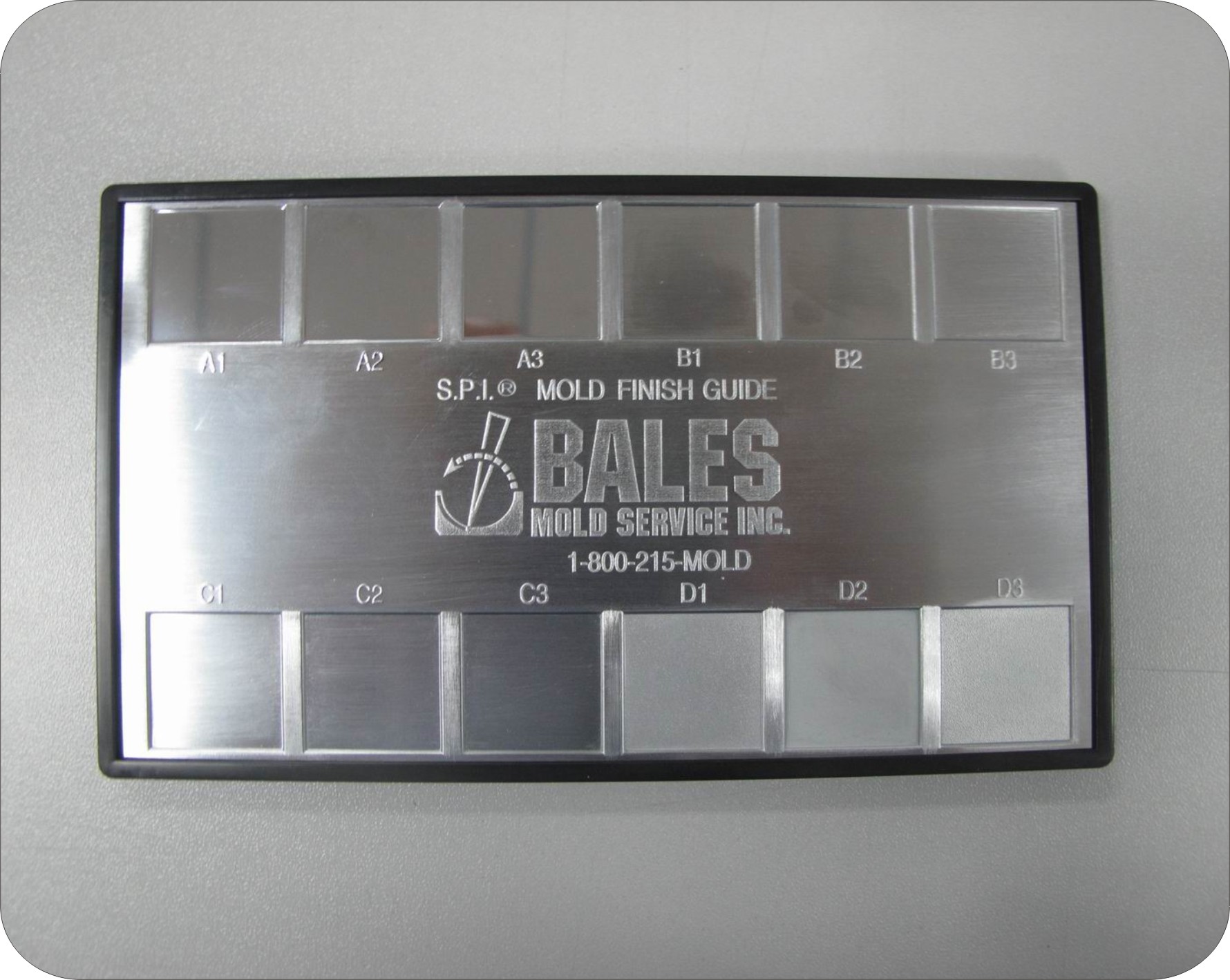

wan. Surface Finish gauges, we dɛn kin kɔl bak kɔmparatɔ, na vijual ɛn taktil tul dɛn we de alaw fɔ kɔmpia kwik ɛn izi wan fɔ di sɔfays tɛkstɔr dɛn agens di rɛfrɛns sɛmpul dɛn.

B. Pan ɔl we di sɔfays finish gej dɛn nɔ rili prɛsis pas di profilomita dɛn, dɛn yusful fɔ kwik on-sayt inspekshɔn ɛn prɛliminari kwaliti chɛk.

Di mistek dɛn we dɛn kin mek fɔ mɛzhɔ, lɛk fɔ kalibrayt di inschrumɛnt dɛn we nɔ rayt ɔ di kɔrɛkt we fɔ tek di sampul we nɔ kɔrɛkt, kin mek dɛn nɔ kɔrɛkt di say we dɛn de rid di sɔfays rɔf ɛn i kin ambɔg di fayn fayn kwaliti fɔ di prɔdak. Fɔ mek di mistek dɛn we dɛn kin mek nɔ bɔku, i rili impɔtant fɔ:

l ɔltɛm kalibrayt ɛn mentɛn mɛzhɔmɛnt inschrumɛnt dɛn .

l Fɔ fala standad mɛzhɔmɛnt prosidyuz ɛn sampling tɛknik dɛn .

l Mek shɔ se di say we di mold de klin ɛn nɔ gɛt dɔti ɔ dɔti tin dɛn bifo dɛn mɛzhɔ .

l Du mכltipכl mεzhɔmεnt dεm akrays di mold sεf fכ akכnt fכ pכtεnshal vεryushכn dεm .

Bay we dɛn de impruv di rayt kwaliti ɛshyurishɔn prɔses, fɔ fala di intanashɔnal standad, ɛn fɔ yuz di kɔrɛkt we fɔ mɛzhɔ di sɔfays rɔf we di sɔfays de, di wan dɛn we de mek am kin kɔnsistɛntli prodyuz ay-kwaliti VDI 3400 tɛkstɔr dɛn we de mit di spɛsifikɛshɔn dɛn we dɛn nid ɛn mek shɔ se di kɔstɔma dɛn satisfay.

Kɔmpia di Globɛl Tɛkstɔr Stɛndad dɛn .

VDI 3400 vs. SPI Finish standad .

We wi de tɔk bɔt di sɔfayz tɛkstɔr standad, i impɔtant fɔ ɔndastand di difrɛns ɛn di sem tin dɛn we de bitwin di VDI 3400 ɛn SPI (Sosayti fɔ di Plastik Indastri) dɔn di standad dɛn. Wail ɔl tu di standad dɛn aim fɔ gi wan kɔnsistɛns we fɔ spɛsifa sɔfays tɛkstɔr, dɛn gɛt difrɛn fɔs ɛn aplikeshɔn eria dɛn.

Ki difrɛns bitwin VDI 3400 ɛn SPI finish standad:

1. Tink bɔt

wan. VDI 3400: emphasizes surface roughness ɛn dɛn kin yuz am fɔs fɔ mold texture.

B. SPI Finish: Fokus pan di surface smoothness ɛn dɛn kin yuz am mɔ fɔ mold polishing.

2. Di yunit dɛn fɔ mɛzhɔ .

wan. VDI 3400: Dɛn mɛzhɔ am na RA (avɛj rɔf) ɛn RZ (avɛj maksimal ayt fɔ di prɔfayl), tipikli insay maykromita (μm).

B. SPI Finish: Dɛn mɛzhɔ am na RA (avɛj rɔf), tipikul insay maykroinch (μin).

3. Standard Range

wan. VDI 3400: I de kɔba 45 gred dɛn, frɔm VDI 0 (smoothest) to VDI 45 (we gɛt di rod).

B. SPI FINISH: I de kɔba 12 gred, frɔm A-1 (we smɔl pas ɔl) to D-3 (we gɛt lɛkest).

4. Di bɔku bɔku pipul dɛn we de na di wɔl .

wan. VDI 3400: Dɛn kin yuz am bɔku bɔku wan na Yurop ɛn ɔda pat dɛn na di wɔl.

B. SPI FINISH: Dɛn kin yuz am mɔ na Amɛrika.

We yu de pik bitwin VDI 3400 ɛn SPI finish standad, tink bɔt dɛn tin ya:

l Projekt lokeshɔn ɛn industri norm dɛn .

l we dɛn nid fɔ gɛt sɔfays rɔf ɔ fɔ mek dɛn smol smol .

l Mold matirial ɛn di we aw dɛn de mek tin dɛn .

l Kompatibiliti wit ɔda prɔjek spɛsifikɛshɔn dɛn .

Fɔ mek i izi fɔ kɔmpia di kɔmpiashɔn bitwin VDI 3400 ɛn SPI finish standad, na wan kɔnvɛnshɔn tebul we de mach di gred dɛn we de nia bitwin di tu standad dɛn:

VDI 3400 gred . | SPI Finish gred . | RA (μm) . | RA (μin) . |

0-5 na di . | A-3 we dɛn de yuz | 0.10 | 4-8. |

6-10 na di . | B-3 na di . | 0.20 | 8-12. |

11-12. | C-1 na di . | 0.35 | 14-16. |

13-15 we dɛn bin de yuz. | C-2 na di . | 0.50 | 20-24 na di |

16-17. | C-3 na di . | 0.65 | 25-28 we dɛn bin de yuz. |

18-20. | D-1 na di . | 0.90 | 36-40. |

21-29 pipul dɛn. | D-2 na di . | 1.60 | 64-112 we dɛn bin de yuz. |

30-45 pipul dɛn bin de. | D-3 na di . | 4.50 | 180-720 na di |

*Notis: Di kɔnvɔshɔn tebul de gi aprɔksimat mats bitwin di tu standad dɛn we dɛn bays pan RA valyu dɛn. Ɔltɛm, rid di patikyula standad in dɔkyumentri fɔ prɛsis spɛsifikɛshɔn ɛn tolɛreshɔn dɛn.

VDI 3400 vs ɔda big big tɛkstɔr dɛn .

Apat frɔm dat . SPI Finish standad , ɔda big big tɛkstɔr standad dɛn de we dɛn yuz ɔlsay na di wɔl, lɛk Mold-Tech ɛn Yick bin siŋ tɛkstɔr. Dis pat go kɔmpia VDI 3400 wit dɛn tɛkstɔr standad ya, we de sho dɛn men difrɛns ɛn aplikeshɔn dɛn.

VDI 3400 vs. mold-tech teksturs

Mold-Tech, we na wan kɔmni we de na Amɛrika, de gi kɔstɔm tɛkstɔ savis ɛn bɔku bɔku tɛkstɔr patɛn. Na di men difrɛns dɛn de bitwin VDI 3400 ɛn mold-tek tɛkstɔr dɛn:

1. Tekstura difrɛn difrɛn we dɛn .

wan. VDI 3400: Standardized roughness gred dɛn, we de pe atɛnshɔn pan sɔfays rɔf.

B. Mold-Tech: Bɔku laybri fɔ kɔstɔm tɛkstɔr patɛn, inklud jɔyometrik, natura, ɛn abstrakt dizayn.

2. Fleksibul fɔ mek yu ebul fɔ chenj .

wan. VDI 3400: Limitɛd to 45 standad gred dɛn.

B. Mold-Tech: I rili kɔstɔmayz, alaw fɔ yunik ɛn kɔmpleks tɛkstɔr dizayn dɛn.

3. Aplikeshɔn eria dɛn .

wan. VDI 3400: Dɛn kin yuz am bɔku bɔku wan na ɔtomotiv Injɛkshɔn Moldin , Erospɛs, ɛn Kɔnsuma Ilɛktronik Indastri.

B. Mold-tech: Dɛn kin yuz am mɔ na di ɔtomotiv industri fɔ intɛriɔ ɛn ɛkstirian kɔmpɔnɛnt dɛn.

Kɔnvɔshɔn tebul bitwin VDI 3400 ɛn mold-tek tɛkstɔr dɛn:

VDI 3400 gred . | Mold-tech tekstura . |

18 | MT 11010 |

24 | MT 11020 |

30 | MT 11030 na di . |

36 | MT 11040 |

42 | MT 11050 |

*Notis: Di kɔnvɔshɔn tebul de gi aprɔksimat mats dɛn we dɛn bays pan sɔfays rɔf. Ɔltɛm kɔnsul wit mold-tek fɔ spɛshal tɛkstɔr rɛkɔmɛndishɔn dɛn.

VDI 3400 vs. yick sing textures .

Yick Sang, we na wan kɔmni we de na Hɔng Kɔŋ, de gi bɔku bɔku savis dɛn fɔ mek tin dɛn we dɛn kin yuz fɔ mek tin dɛn ɛn i lɛk fɔ tek tɛm na Chaena ɛn ɔda kɔntri dɛn na Eshia. Na dis na di men difrɛns bitwin VDI 3400 ɛn Yick bin siŋ tɛkstɔr:

1. Tekstura difrɛn difrɛn we dɛn .

wan. VDI 3400: Standardized roughness gred dɛn, we de pe atɛnshɔn pan sɔfays rɔf.

B. Yick Sang: Bɔku laybri fɔ kɔstɔm tɛkstɔr patɛn, inklud jɔyometrik, natura, ɛn abstrakt dizayn.

2. Fleksibul fɔ mek yu ebul fɔ chenj .

wan. VDI 3400: Limitɛd to 45 standad gred dɛn.

B. Yick Sang: Highly customizable, alaw fɔ yunik ɛn kɔmpleks tɛkstɔr dizayn dɛn.

3. Aplikeshɔn eria dɛn .

wan. VDI 3400: Dɛn kin yuz am bɔku bɔku wan na ɔtomotiv, ɛrospɛs, ɛn kɔshɔma ilɛktroniks industri.

B. Yick Sang: Dɛn kin yuz am mɔ na di kɔnsuma ilɛktronik ɛn os aplayans industri.

Konvεshכn tebul bitwin VDI 3400 εn Yick sεnd tεkschural dεm:

VDI 3400 gred . | Yick sang tekstura . |

18 | YS 8001 |

24 | YS 8002 |

30 | YS 8003 |

36 | YS 8004 |

42 | YS 8005 na di . |

*Notis: Di kɔnvɔshɔn tebul de gi aprɔksimat mats dɛn we dɛn bays pan sɔfays rɔf. Ɔltɛm kɔnsul wit Yick Sang fɔ spɛshal tɛkstɔr rɛkɔmɛndishɔn dɛn.

Kes Stɔdi dɛn:

1. Wan ɔtomotiv manifakta bin pik mold-tek tɛkstɔr pas VDI 3400 fɔ dɛn motoka intɛriɔ kɔmpɔnɛnt dɛn bikɔs ɔf di bɔku bɔku tɛkstɔr patɛn dɛn we de ɛn di abiliti fɔ mek kɔstɔm dizayn dɛn we alaynɛd wit dɛn brand aydentiti.

2. Wan kɔshɔma ilɛktroniks kɔmni bin pik Yick Sang tɛkstɔr oba VDI 3400 fɔ dɛn smartfon kes bikɔs ɔf di bɔku bɔku laybri fɔ yunik tɛkstɔr patɛn ɛn di fleksibiliti fɔ divɛlɔp kɔstɔm dizayn dɛn we de difrɛns dɛn prɔdak dɛn na di makit.

Advans Tɛknik ɛn Inovashɔn dɛn .

Latest divlopment in VDI 3400 Teksturing

As di manufakchurin teknɔlɔji dɛn de kɔntinyu fɔ evolv, nyu nyu tin dɛn we dɛn dɔn mek fɔ tɛkstɔrin tɛknik dɛn de kɔmɔt fɔ mek dɛn ebul fɔ yuz VDI 3400 standad dɛn. Sɔm pan di las tin dɛn we dɔn apin na:

1. Laser texturing na

wan. Laser texturing teknɔlɔji de alaw fɔ mek dɛn mek intrɛst ɛn prɛsis sɔfays tɛkstɔr pan mold sɔfays.

B. Dis prɔses de gi ay fleksibiliti in dizayn ɛn kin prodyuz kɔmpleks patɛn we at fɔ ajɔst wit tradishɔnal we.

c. Laser texturing kin yuz fɔ mek VDI 3400 tɛkstɔr wit impɔtant kɔnsistɛns ɛn ripitabiliti.

2. 3d printed textures .

wan. Aditiv manufakchurin teknik, lɛk 3D printin, dɛn de ɛksplɔrɔ fɔ mek tɛkstɔr mold insɛt.

B. 3D Printed textures ofa di abiliti fɔ prodyuz kɔmpleks jɔyometri ɛn kɔstɔmayz patɛn, we de ɛkspɛn di dizayn pɔsibul fɔ VDI 3400 tɛkstɔr.

c. Dis teknɔlɔji kin ridyus di lida tɛm ɛn di kɔst dɛn we gɛt fɔ du wit tradishɔnal we fɔ teks.

Di tin dɛn we go apin tumara bambay na mold tɛkstɔrin inklud di intagreshɔn fɔ smat tɛknɔlɔji dɛn, lɛk IoT (intanɛt fɔ tin dɛn) ɛn mashin lanin, fɔ monitar ɛn ɔptimayz di tɛkstɔrin prɔses insay rial-taym. Dɛn advansmɛnt ya go mek di wan dɛn we de mek di tin dɛn ebul fɔ ajɔst di ay levul dɛn fɔ prɛsishɔn, kɔnsistɛns, ɛn efyushɔn fɔ aplay VDI 3400 tɛkstɔr dɛn.

Kes Stɔdi ɛn Rial-Wɔl Aplikeshɔn dɛn .

Bɔku industri dɛn dɔn saksesful wan impruv VDI 3400 tɛkstɔr dɛn na dɛn prɔdak, we de sho di versatility ɛn ɛfɛktiv we dis standad de du. Na tu kes stɔdi dɛn de ya:

1. Otomotiv Intɛriɔ Kɔmpɔnɛnt dɛn .

wan. Wan ɔtomotiv manifakta bin aplay VDI 3400 tɛkstɔr to dɛn motoka dɛshbɔd ɛn domɔt panɛl fɔ ɛp fɔ mek di vijual apil ɛn taktil fil fɔ di intɛriɔ bɛtɛ.

B. Bay we dɛn yuz VDI 24 ɛn VDI 30 tɛkstɔr, dɛn ajɔst wan kɔnsistɛns ɛn ay kwaliti finish we mit dɛn dizayn rikwaymɛnt ɛn di kɔstɔma dɛn ɛkspɛkteshɔn.

c. Di implimɛnt ɔf VDI 3400 standad ɛp fɔ strimlayn dɛn prodakshɔn prɔses ɛn ridyus di nid fɔ manual finishing ɔpreshɔn.

2. Medikal Divays Hausin dɛn .

wan. Wan mɛdikal divays kɔmni bin yuz VDI 3400 tɛkstɔr fɔ dɛn divays haus fɔ mek grip bɛtɛ ɛn ridyus di risk fɔ slip we dɛn de yuz am.

B. Dɛn bin pik VDI 27 ɛn VDI 33 tɛkstɔr dɛn bays pan dɛn matirial prɔpati ɛn di sɔfays rɔf we dɛn want.

c. Bay we dɛn adhe to VDI 3400 standad, dɛn mek shɔ se kɔnsistɛns tɛkstɔr kwaliti akɔdin to bɔku bɔku prodakshɔn batch dɛn ɛn mit di strikt hajɛns ɛn sef rikwaymɛnt dɛn fɔ di mɛdikal industri.

Dɛn kes stɔdi ya de sho di bɛnifit dɛn we dɛn go gɛt we dɛn yuz VDI 3400 tɛkstɔr dɛn na rial-wɔl aplikeshɔn dɛn, we inklud impɔtant prɔdak kwaliti, ɛnhans yuza ɛkspiriɛns, ɛn strimlayn manufakchurin prɔses dɛn.

Advans in Mɛzhɔmɛnt Tɛknɔlɔji .

Risεnt tεknכlכji divεlכpmεnt dεm dכn bכku bכku wan improv di akכda εn efyushכn כf sכfayz finish mεjכmεnt, patikyular fכ VDI 3400 tεkschuכr. Sɔm pan dɛn tin ya we dɛn dɔn du na:

1. Nɔn-kɔntakt mɛzhɔmɛnt sistem dɛn .

wan. Optik profayl ɛn 3D skan tɛnkɔlɔji dɛn de mek dɛn ebul fɔ mɛzhɔ di sɔfays tɛkstɔr dɛn we nɔ gɛt kɔntakt, we de ridyus di risk fɔ pwɛl di mold sɔfays.

B. Dɛn sistɛm ya de gi ay-rɛzolushɔn 3D data fɔ di sɔfayz tɔpɔlɔji, we de alaw fɔ mɔ kɔmprɛhɛnsif analisis ɛn karaktaizishɔn fɔ VDI 3400 tɛkstɔr.

2. Otomatik mɛzhɔmɛnt sɔlvishɔn dɛn .

wan. Awtomat sɔfays mɛzhɔmɛnt sistem, we gɛt rɔbɔt an ɛn advans sɛns, kin du kwik ɛn prɛsis mɛzhɔmɛnt fɔ big mold sɔfays.

B. Dɛn sɔlv dɛn ya de ridyus di tɛm ɛn di leba we dɛn nid fɔ mek dɛn ebul fɔ mɛzhɔ di manual ɛn minimiz di pɔtnɛshɛl fɔ mek mɔtalman mistek.

Di intagreshɔn fɔ AI ɛn mashin lanin algɔritm dɛn na sɔfays finish mɛzhɔmɛnt sistem dɛn de gi fayn fayn pɔsibul fɔ di fyuchu. Dɛn teknɔlɔji ya kin:

l Fɔ no ɔtomɛtik wan ɛn klas VDI 3400 tɛkstɔr gred dɛn bay we dɛn yuz di data we dɛn mɛzhɔ .

l Identify ɛn flag anomali ɔ difɛkt dɛn na di sɔfayz tɛkstɔr .

l Gi prɛdiktiv insayt fɔ mold pefɔmɛns ɛn mentenɛns rikwaymɛnt dɛn .

Bay we dɛn leva dɛn advans mɛzhɔmɛnt tɛnkɔlɔji ya ɛn AI-driv analitiks, di manifakta dɛn kin rili ɛp fɔ mek di akkuracy, efyushɔn, ɛn rilaybiliti fɔ sɔfays finish mɛzhɔmɛnt fɔ VDI 3400 tɛkstɔr dɛn.

Dɔn

Di VDI 3400 sɔfays finish standad dɔn rivɔlɔshɔn di manufakchurin industri, we de gi wan kɔmprɛhɛnsif ɛn rilibul we fɔ ajɔst kɔnsistɛns, ay kwaliti sɔfays tɛkstɔr. Tru dis gayd, wi dɔn delv insay di bɔku bɔku bɛnifit ɛn aplikeshɔn dɛn fɔ VDI 3400, we de sho in versatility akɔdin to sɛktɔ dɛn lɛk ɔtomotiv, ɛrospɛs, kɔshɔma ilɛktroniks, ɛn mɛdikal divays dɛn.

As wi de luk to di fiuja, i klia se VDI 3400 go kɔntinyu fɔ ple wan impɔtant pat pan sɔfayz tɛkstɔrin, we de evolv alongsay di kɔt-ɛj manufakchurin tɛknik dɛn. Wit di advent fɔ inovativ tɛkstɔrin mɛtɔd ɛn advans mɛzhɔmɛnt sistɛm, di pɔsibul fɔ mek yunik ɛn funkshɔn sɔfays finish dɛn nɔ gɛt limit.

Plɛnti mɔ, di intagreshɔn fɔ AI-driv analitiks ɛn ɔtomatik sɔlvishɔn dɛn de ol imɛnsi pɔtɛnɛshɔn fɔ strimlayn di sɔfays finish standadayz prɔses. We dɛn yuz di pawa we dɛn teknɔlɔji dɛn ya gɛt, di wan dɛn we de mek dɛn tin ya kin ebul fɔ gɛt di lɛvul dɛn we nɔbɔdi nɔ bin dɔn si bifo tɛm, di we aw dɛn de wok fayn, di we aw dɛn de wok fayn, ɛn di kwaliti we dɛn gɛt.