Injɛkshɔn moldin na wan we we dɛn kin yuz fɔ mek tin dɛn we dɛn kin yuz fɔ du bɔku tin dɛn we kin mek dɛn gɛt ay kwaliti plastic pat dɛn we gɛt fayn fayn say dɛn fɔ mek di say dɛn we dɛn de. Di surface finish of wan molded pat de ple wan impɔtant rol insay in aesthetics, functionality, ɛn konsuma percepshɔn. Fɔ ebul fɔ gɛt di say we dɛn want fɔ dɔn di wok, yu nid fɔ ɔndastand di difrɛn standad ɛn tɛknik dɛn we de fɔ du gud gud wan.

Di Sosayti fɔ di Plastik Indastri (SPI) dɔn mek wan sɛt fɔ gaydlayn fɔ standad mold finish dɛn na di plastic industri. Dɛn dɔn adopt dɛn SPI gaydlain ya bɔku bɔku wan frɔm we dɛn bigin fɔ yuz dɛn insay di 1960 dɛm, we de gi wan kɔmɔn langwej to dizayna, injinia, ɛn manifakta fɔ kɔmyuniket di surface finish rikwaymɛnt fayn fayn wan.

SPI Surface Finish Standart dɛn .

Wetin na SPI Finish?

SPI Finish, we dɛn kin kɔl bak SPI Mold finish ɔ SPI sɔfays finish, de tɔk bɔt di standad sɔfays finish gaydlayn dɛn we di Sosayti fɔ di Plastik Indastri (SPI) dɔn sɛt. Dɛn gaydlain ya de gi wan yunivasal langwej fɔ diskrayb di sɔfays we i luk ɛn di tɛkstɔr fɔ injɛkshɔn mold plastic pat dɛn.

SPI finish standad na impɔtant tin fɔ injɛkshɔn moldin fɔ sɔm rizin dɛn:

l Fɔ mek shɔ se kɔnsistɛns sɔfays kwaliti akɔdin to difrɛn mold ɛn manifakta dɛn .

l Fɔ mek dɛn ebul fɔ tɔk klia wan bitwin dizayna dɛn, injinia dɛn, ɛn pipul dɛn we de mek tul dɛn

l Enabling dizaina dɛn fɔ pik di finish we fit pas ɔl fɔ dɛn aplikeshɔn .

L optimizing di aesthetics ɛn funkshɔnaliti fɔ di fayn prodak .

Di SPI finish standad dem divayd insay fo men kategori, evri wan wit tri sabkategori:

Kayn | Sabkategori dɛn . | Tɔk bɔt |

A. Glɔs | A-1, A-2, A-3. | Finish dɛn we smɔl pas ɔl ɛn we de shayn pas ɔl . |

B. Sɛmi-glɔssy | B-1, B-2, B-3. | Intamɛdiet lɛvɛl fɔ glosnɛs . |

C. Matte . | C-1, C-2, C-3. | Non-glossy, diffuse finishes |

D. Tɛkstɔr . | D-1, D-2, D-3. | Rough, patɛn finish dɛn . |

εvri sabkategori de fכs difεn bay in spεsifi k sεf rכfnes rεnj, we dεn mכsu insay maykromita (μm), εn di kכrεspכndεnt fכnish mεtכd dεm we dεn yuz fכ achy di risal we dεn want.

Bay we dɛn de fala dɛn standad kategori ya, di wan dɛn we de mek di tin dɛn kin mek shɔ se di pat dɛn we dɛn dɔn injɛkshɔn kin mit di say we dɛn dɔn tɔk bɔt di say we dɛn de dɔn, we kin mek dɛn gɛt ay kwaliti, dɛn kin si fayn fayn wan, ɛn dɛn kin wok fayn fayn wan.

Di 12 gred dɛn fɔ SPI Finish .

Di SPI finish standad kompris 12 distinkt gred, we dɛn ɔganayz insay 4 men kategori: Glossy (A), sɛmi-glɔs (B), mat (C), ɛn tɛkstɔr (D). Ɛni kategori gɛt tri sabkategori dɛn, we dɛn sho bay Nɔmba 1, 2, ɛn 3.

Di 4 men kategori dɛm ɛn dɛn kwaliti dɛm na:

1. Glossy (A) : Di finish we smol pas ɔl ɛn we de shayn pas ɔl, we dɛn dɔn ajɔst bay we dɛn yuz dayamɔn buffing.

2. Semi-glossy (B) : Na intamɛdiet lɛvɛl fɔ glos, we dɛn kin gɛt tru grit pepa polishing.

3. Matte (C) : Nɔn-glos, difyuz finish, we dɛn mek yuz ston polishing.

4. Tekstɔr (D) : Raf, patɛn finish, we dɛn prodyuz bay dray blast wit difrɛn midia.

Na dis na di ditel brekdaun fɔ di 12 SPI finish gred dɛn, wit dɛn finish we dɛn de yuz ɛn di tipik sɔfays rɔfnɛs rɛnj dɛn:

SPI gred . | Finish (tayp) . | Finishing Method . | Surface roughness (RA) renj (μm) . |

A-1 we de na di wɔl. | Super high glossy yu gi oh . | Gret #3, 6000 grit dayamɔn buff . | 0,012 - 0,025 |

A-2 we de na di wɔl. | Di wan dɛn we gɛt ay glos . | Gret #6, 3000 grit dayamɔn buff . | 0,025 - 0,05 |

A-3 we dɛn de yuz | Nɔmal Glossy . | Gret #15, 1200 grit dayamɔn buff . | 0,05 - 0,10 |

B-1 we de na di wɔl. | Fayn sɛmi-glossy . | 600 grit pepa . | 0,05 - 0,10 |

B-2 na di . | Midul sɛmi-glossy . | 400 grit pepa . | 0,10 - 0,15 |

B-3 na di . | Nɔmal sɛmi-glɔs . | 320 grit pepa . | 0,28 - 0,32. |

C-1 na di . | Fayn Matt . | 600 grit ston . | 0,35 - 0,40. |

C-2 na di . | Midul Matt . | 400 grit ston . | 0,45 - 0,55 |

C-3 na di . | Nɔmal Matte . | 320 grit ston . | 0,63 - 0,70 |

D-1 na di . | Satin tekstured | Dray blast glas biad #11 | 0,80 - 1,00 |

D-2 na di . | Dull textured | Dray blast #240 oksayd . | 1,00 - 2,80 |

D-3 na di . | Rough textured | Dray blast #24 Oxide . | 3,20 - 18,0. |

As wi si na di chɔt, ɛni SPI gred kɔrɛkt to wan patikyula finish tayp, finish we, ɛn sɔfays rɔfnɛs rɛnj. Fɔ ɛgzampul, dɛn klas wan A-1 finish as supa ay glos, we dɛn ajɔst yuz wan gred #3, 6000 grit dayamɔn buff, we de rilizɔt wan sɔfays rɔf bitwin 0.012 ɛn 0.025 μm. Na di ɔda say, dɛn klas wan D-3 finish as rɔf tɛkstɔr, we dɛn kin gɛt bay we dɛn de blast dray wit #24 ɔksayd, we kin mek dɛn gɛt bɔku rɔf say wit RA rɛnj we de frɔm 3.20 to 18.0 μm.

We dɛn spɛsifa di rayt SPI gred, dizayna ɛn injinia dɛn kin mek shɔ se di injɛkshɔn mold pat dɛn mit di sɔfays finish we dɛn want, we go mek di aesthetics, functionality, ɛn kwaliti fɔ di fayn prodak fayn.

Kɔmpia wit ɔda sɔfays finish standad dɛn .

Pan ɔl we SPI Finish na di standad we bɔku pipul dɛn sabi fɔ injɛkshɔn moldin sɔfays finish, ɔda industri standad dɛn de, lɛk VDI 3400, MT (MoldTech), ɛn Ys (Yick Sang). Lɛ wi kɔmpia SPI Finish wit dɛn ɔda we ya:

1. VDI 3400 :

wan. VDI 3400 na wan Jaman standad we de pe atɛnshɔn pan sɔfays rɔf pas aw i de apin.

B. I gɛt 45 gred dɛn, we de frɔm VDI 0 (smoothest) to VDI 45 (we nɔ rich di wɔl).

c. VDI 3400 kin roughly kɔrɛlat wit SPI finish gred, lɛk aw dɛn sho na di tebul we de dɔŋ ya:

SPI FINISH . | VDI 3400 na di . |

A-1 to A-3. | VDI 0 to VDI 15 . |

B-1 to B-3 . | VDI 16 to VDI 24 . |

C-1 to C-3 na di . | VDI 25 to VDI 30 . |

D-1 to D-3 . | VDI 31 to VDI 45 . |

2. MT (MoldTech) :

wan. MT na wan standad we MoldTech, we na wan Spanish kɔmni we spɛshal pan mold tɛkstɔ, dɔn mek.

B. I gɛt 11 gred dɛn, frɔm Mt 0 (smoothest) to Mt 10 (we nɔ gɛt lɛk).

c. MT gred dɛn nɔ kin kɔmpia dairekt to SPI finish gred dɛn, as dɛn de pe atɛnshɔn pan spɛshal tɛkstɔr dɛn pas sɔfays rɔf.

3. YS (Yick Sang) :

wan. YS na wan standad we sɔm Eshian manifakta dɛn de yuz, mɔ na Chaina ɛn Hɔng Kɔŋ.

B. I gɛt 12 gred, frɔm Ys 1 (we smɔl pas ɔl) to Ys 12 (we nɔ gɛt lɛk).

c. YS gred dɛn na lɛk SPI finish gred, wit YS 1-4 we kɔrɛkt to SPI A-1 to A-3, YS 5-8 to SPI B-1 to B-3, ɛn YS 9-12 to SPI C-1 to D-3.

Pan ɔl we dɛn ɔda standad dɛn ya de, SPI Finish stil de bi di standad we dɛn de yuz pas ɔl ɛn we dɛn dɔn no bɔt fɔ injɛkshɔn moldin sɔfays finish dɛn ɔlsay na di wɔl. Sɔm impɔtant bɛnifit dɛn we yu go gɛt we yu yuz SPI finish na:

l Wid akseptans ɛn famili bitwin dizayna dɛn, injinia dɛn, ɛn manifakta dɛn ɔlsay na di wɔl .

l Klir ɛn kɔnsis kategorizayshɔn fɔ di sɔfays finish dɛn bays pan ɔl tu di apinɛns ɛn di rɔfnɛs .

l I izi fɔ kɔmyunikeshɔn ɛn spɛsifikɛshɔn fɔ di sɔfays finish rikwaymɛnt dɛn .

l Kompatibiliti wit wan big renj fɔ injɛkshɔn moldin matirial ɛn aplikeshɔn dɛn .

l Bɔku bɔku tin dɛn ɛn rɛfrɛns matirial dɛn de, lɛk SPI finish kad ɛn gayd dɛn .

Bay we dɛn adopt di SPI finish standad, kɔmni dɛn kin mek shɔ se kɔnsistɛns, ay-kwaliti sɔfays finish fɔ dɛn injɛkshɔn mold pat dɛn we dɛn de fasilit fayn fayn kɔmyunikeshɔn ɛn kolaboreshɔn wit di saplay dɛn ɛn patna dɛn ɔlsay na di wɔl.

We yu pik di rayt SPI FINISH .

Factors fɔ tink bɔt we yu de pik wan SPI Finish .

We yu de pik SPI Finish fɔ yu injɛkshɔn mold pat dɛn, dɛn fɔ tink bɔt sɔm impɔtant tin dɛn fɔ mek shɔ se di bɛst tin go apin. Dɛn tin ya na fayn fayn tin dɛn, di wok we dɛn de du, di tin dɛn we dɛn go ebul fɔ du, ɛn di tin dɛn we dɛn nid fɔ du fɔ mek dɛn nɔ spɛn bɔku mɔni.

1. Aesthetics : .

wan. Di we aw yu want fɔ si di fayn fayn tin we yu want fɔ du fɔ di fayn fayn prɔdak na impɔtant tin fɔ pik wan SPI finish.

B. Glossy finishes (A-1 to A-3) de gi wan smol, shayn surface we de enhans di apiyans of di pat, we mek am ideal fɔ aplikeshɔn usay aesthetics na wan top prayoritɛd.

c. Matte finish (C-1 to C-3) de gi wan nɔ-riflektiv, difyuz apinans we kin ɛp fɔ kɔnsil di sɔfayz impɛrɛfɛkshɔn ɛn ridyus di visibiliti fɔ finga prɛnt ɔ smudj.

2. Funkshɔnaliti : .

wan. Di intended yus ɛn funkshɔn fɔ di injɛkshɔn mold pat fɔ rili inflɔws di choice fɔ SPI finish.

B. Tekstɔr finish (D-1 to D-3) de gi inkris grip ɛn slip resistans, we de mek dɛn fayn fɔ aplikeshɔn usay fɔ handle ɔ yuz intarakshɔn impɔtant, lɛk hanheld divays ɔ ɔtomotiv kɔmpɔnɛnt.

c. Smɔl finish (A-1 to B-3) bɛtɛ fɔ pat dɛn we nid fɔ gɛt klin, slip luk ɔ di wan dɛn we dɛn go peint ɔ lɛbul afta dɛn dɔn mol.

3. Di tin dɛn we pɔsin kin yuz fɔ mek di tin dɛn we dɛn dɔn yuz fɔ mek di tin dɛn we dɛn nid :

wan. Di kɔmpitibliti bitwin di matirial we dɛn pik ɛn di SPI finish we dɛn want fɔ tek tɛm tink bɔt.

B. Sɔm matirial dɛn, lɛk polypropylene (PP) ɔ thermoplastic elastomers (TPE), nɔ kin fayn fɔ ajɔst di ay-glɔs finish dɛn bikɔs ɔf dɛn inhɛrɛnt matirial prɔpati dɛn.

c. Kɔnsul di matirial spɔlayt in kɔmɛnt ɔ kɔndɔkt tɛst fɔ mek shɔ se di SPI finish we dɛn dɔn pik kin fayn fayn wan wit di matirial we dɛn pik.

4. Di Implikashɔn dɛn fɔ di Kɔst :

wan. Di choice of SPI finish kin signifyantli impact di ovala kos fɔ di injɛkshɔn mold pat.

B. Di ay-grɛd finish dɛn, lɛk A-1 ɔ A-2, nid fɔ gɛt mɔ polish ɛn prɔsesin, we kin mek di tul ɛn prodakshɔn kɔst go ɔp.

c. Lɔwa-grɛd finish, lɛk C-3 ɔ D-3, kin bi mɔ kɔst-ɛfɛktiv fɔ aplikeshɔn usay sɔfayz apia nɔ rili impɔtant.

d. Tink bɔt di balans bitwin di sɔfays finish we yu want ɛn di kɔst dɛn we gɛt fɔ du wit am fɔ no di SPI finish we fit pas ɔl fɔ yu prɔjek.

We dɛn tek tɛm analayz ɛni wan pan dɛn tin ya ɛn di impak we dɛn gɛt pan di las prɔdak, dizayna ɛn injinia dɛn kin disayd fɔ du di rayt tin dɛn we dɛn de pik wan SPI finish. Dis holistic aprɔch de mek shɔ se di injɛkshɔn mold pat dɛn mit di aesthetic, functional, ɛn ikɔnomik krayteria we dɛn nid we dɛn de mentɛn kɔmpatibiliti wit di matirial we dɛn pik.

SPI Finish ɛn matirial kɔmpitibliti .

Fɔ pik di rayt matirial na impɔtant tin fɔ ajɔst di SPI finish we yu want insay injɛkshɔn mold pat dɛn. Di kɔmpatibiliti bitwin di matirial ɛn di finish we dɛn pik kin rili ambɔg di fayn fayn we aw i luk, di we aw i de wok, ɛn di kwaliti we di prɔdak gɛt. Na sɔm impɔtant tin dɛn wi fɔ tink bɔt:

1. Di prɔpati dɛn we dɛn gɛt:

wan. Ɛni plastic matirial gɛt spɛshal prɔpati dɛn we de afɛkt in ebul fɔ ajɔst sɔm SPI finish dɛn.

B. Fɔ ɛgzampul, matirial dɛn we gɛt ay shrinkage ret ɔ lɔw flɔ kwaliti dɛn kin bi mɔ chalenj fɔ polish to ay glos finish.

2. Aditiv ifɛkt dɛn:

wan. Di prɛzɛns fɔ aditiv dɛm, lɛk kɔlɔrant, fil, ɔ riinfɔsmɛnt, kin inflɔws di matirial in kɔmpatibiliti wit spɛshal SPI finish dɛm.

B. Sɔm tin dɛn we dɛn kin ad kin mek di say we dɛn de mek di wɔl go ɔp ɔ i kin mek di tin nɔ ebul fɔ polish.

3. Mold dizayn ɛn prɔsesin:

wan. Di mold dizayn ɛn prɔsesin paramita dɛn, lɛk di say we di get de, di tik we di wɔl tik, ɛn di we aw i de kol, kin ambɔg di we aw di matirial de flɔ ɛn di we aw i de luk.

B. Prɔpa mold dizayn ɛn prɔses ɔptimayzeshɔn kin ɛp fɔ ajɔst di SPI finish we dɛn want kɔnsistɛntli.

Fɔ ɛp fɔ gayd di matirial sɛlɛkshɔn, luk dis kɔmpitibliti chɔt fɔ kɔmɔn plastic ɛn dɛn fit fɔ ɛni SPI gred:

Tin dɛn | A-1 we de na di wɔl. | A-2 we de na di wɔl. | A-3 we dɛn de yuz | B-1 we de na di wɔl. | B-2 na di . | B-3 na di . | C-1 na di . | C-2 na di . | C-3 na di . | D-1 na di . | D-2 na di . | D-3 na di . |

ABS na ABS | ○ | ○ | ● | ● | ● | ◎ Yu go si se di tin dɛn we de apin. | ◎ Yu go si se di tin dɛn we de apin. | ◎ Yu go si se di tin dɛn we de apin. | ◎ Yu go si se di tin dɛn we de apin. | ◎ Yu go si se di tin dɛn we de apin. | ◎ Yu go si se di tin dɛn we de apin. | ● |

PP we de na di . | ✕ | △ | △ | ● | ● | ◎ Yu go si se di tin dɛn we de apin. | ◎ Yu go si se di tin dɛn we de apin. | ◎ Yu go si se di tin dɛn we de apin. | ◎ Yu go si se di tin dɛn we de apin. | ◎ Yu go si se di tin dɛn we de apin. | ◎ Yu go si se di tin dɛn we de apin. | ◎ Yu go si se di tin dɛn we de apin. |

PS . | △ | △ | ● | ◎ Yu go si se di tin dɛn we de apin. | ◎ Yu go si se di tin dɛn we de apin. | ◎ Yu go si se di tin dɛn we de apin. | ◎ Yu go si se di tin dɛn we de apin. | ◎ Yu go si se di tin dɛn we de apin. | ◎ Yu go si se di tin dɛn we de apin. | ◎ Yu go si se di tin dɛn we de apin. | ◎ Yu go si se di tin dɛn we de apin. | ● |

HDPE we de na di . | ✕ | △ | △ | ● | ● | ◎ Yu go si se di tin dɛn we de apin. | ◎ Yu go si se di tin dɛn we de apin. | ◎ Yu go si se di tin dɛn we de apin. | ◎ Yu go si se di tin dɛn we de apin. | ◎ Yu go si se di tin dɛn we de apin. | ◎ Yu go si se di tin dɛn we de apin. | ◎ Yu go si se di tin dɛn we de apin. |

Naylon . | △ | △ | ● | ● | ◎ Yu go si se di tin dɛn we de apin. | ◎ Yu go si se di tin dɛn we de apin. | ◎ Yu go si se di tin dɛn we de apin. | ◎ Yu go si se di tin dɛn we de apin. | ◎ Yu go si se di tin dɛn we de apin. | ◎ Yu go si se di tin dɛn we de apin. | ◎ Yu go si se di tin dɛn we de apin. | ● |

PC . | △ | ● | ◎ Yu go si se di tin dɛn we de apin. | ● | ● | △ | △ | ✕ | ✕ | ◎ Yu go si se di tin dɛn we de apin. | ✕ | ✕ |

TPU . | ✕ | ✕ | ✕ | ✕ | △ | △ | ● | ● | ● | ◎ Yu go si se di tin dɛn we de apin. | ◎ Yu go si se di tin dɛn we de apin. | ● |

Akrilik . | ◎ Yu go si se di tin dɛn we de apin. | ◎ Yu go si se di tin dɛn we de apin. | ◎ Yu go si se di tin dɛn we de apin. | ● | ● | ● | ● | ● | ● | △ | △ | △ |

Soso stori:

L ◎: Ɛksɛlɛnt kɔmpitibliti

L ●: Gud kɔmpitibliti

L △: Avrej kɔmpatibiliti

L ○: Di wan dɛn we de dɔŋ ya we nɔ de dɔŋ ya

L ✕: Nɔ Rikɔmɛnd

Di bɛst we fɔ pik di bɛst matirial-finish kɔmbaynshɔn:

1. Kɔnsul wit matirial saplayers ɛn injɛkshɔn moldin ɛkspɛkt fɔ gɛt rɛkɛmɔndeshɔn bays pan yu spɛshal aplikeshɔn ɛn rikwaymɛnt dɛn.

2. Kɔndɔkt protɔtayp tɛst yuz di matirial we yu dɔn pik ɛn SPI dɔn fɔ validet di apinɛns we yu want ɛn di pefɔmɛns.

3. Tink bɔt di ɛnd-yuz ɛnvayrɔmɛnt ɛn ɛnitin we dɛn nid fɔ du afta dɛn dɔn prosɛs am, lɛk fɔ peint ɔ fɔ kɔt, we yu de pik di tin ɛn dɔn.

4. Balans di SPI finish we dɛn want wit di matirial in kɔst, avaylabl, ɛn prɔsesabiliti fɔ mek shɔ se dɛn gɛt kɔst-ɛfɛktiv ɛn rili prodakshɔn prɔses.

Bay we dɛn ɔndastand di kɔmpatibiliti bitwin di matirial ɛn SPI finish, dizayna ɛn injinia dɛn kin mek infɔm disizhɔn dɛn we go ɔptimayz di apinɛns, funkshɔnaliti, ɛn kwaliti fɔ dɛn injɛkshɔn mold pat dɛn.

Di tin dɛn we dɛn fɔ du fɔ mek dɛn yuz di aplikeshɔn .

Fɔ pik di rayt SPI Finish fɔ yu injɛkshɔn mold pat dɛn dipen mɔ pan di aplikeshɔn we dɛn want fɔ yuz ɛn di patikyula tin dɛn we dɛn nid fɔ mek dɛn luk, aw dɛn de wok, ɛn aw di pɔsin we de yuz am de tɔk to dɛnsɛf. Na sɔm rɛkɛmɔndeshɔn fɔ kɔmɔn aplikeshɔn dɛn:

1. Glossy finish (A-1 to A-3) :

wan. I fayn fɔ yuz fɔ aplikeshɔn dɛn we nid fɔ gɛt ay kwaliti, polish apinans .

B. Ideal fɔ pat dɛn we gɛt optik rikwaymɛn, lɛk lens, layt kɔva, ɛn miro

c. Eksɛlɛnt chus fɔ transparent ɔ klia kɔmpɔnɛnt dɛn, lɛk displei kes ɔ protɛktiv kɔva .

d. Ɛgzampul dɛn: Ɔtomotiv Layt, Kɔsmɛtik Pakɛj, ɛn Kɔnsuma Ilɛktronik Displei

2. Semi-glossy finish (B-1 to B-3) :

wan. I fayn fɔ aplikeshɔn dɛn we nid balans bitwin aesthetics ɛn functionaliti .

B. Ideal fɔ kɔshɔma prodak, haus, ɛn ɛnklɔzhɔ dɛn we de bɛnifit frɔm wan mɔdaret lɛvɛl fɔ shayn

c. Gud choice fɔ pat dɛn we dɛn go peint ɔ kɔt post-molding

d. Ɛgzampul dɛn: Di tin dɛn we dɛn kin yuz na os, di ilɛktronik divays os dɛn, ɛn di say dɛn we dɛn kin put tin dɛn fɔ yuz fɔ mɛn pipul dɛn

3. Matte finish (C-1 to C-3) :

wan. I fayn fɔ aplikeshɔn dɛn usay dɛn want fɔ mek dɛn luk wan nɔ-riflektiv, lɔw-glɔs apinans .

B. I fayn fɔ di divays ɛn prɔdak dɛn we dɛn kin ol na dɛn an we dɛn kin tɔch bɔku tɛm, bikɔs dɛn kin mek di finga prɛnt ɛn di smɔl smɔl tin dɛn we dɛn kin yuz fɔ mek tin dɛn nɔ apin .

c. Gud choice fɔ industrial komponent ɔ pat dɛn we nid wan subtil, ɔndastated luk

d. Ɛgzampul dɛn: Pawa tul dɛn, rimot kɔntrol dɛn, ɛn ɔtomotiv intɛriɔ kɔmpɔnɛnt dɛn

4. Tekstɔr finish (D-1 to D-3) :

wan. I fayn fɔ aplikeshɔn dɛn we nid fɔ mek grip ɔ slip rɛsistɛns ɛnhans .

B. I fayn fɔ pat dɛn we dɛn kin ol ɔ manipul bɔku tɛm, lɛk handel, nɔb, ɛn switch dɛn .

c. Gud choice fɔ ɔtomotiv kɔmpɔnɛnt dɛn we nid wan nɔ-slip sɔfa, lɛk stiarin wil ɔ gia shifta .

d. Ɛgzampul dɛn: tin dɛn fɔ yuz na kichin, tin dɛn fɔ yuz an, ɛn tin dɛn fɔ ple spɔt

We yu de pik wan SPI finish fɔ yu aplikeshɔn, tink bɔt dɛn tin ya:

l Di vijual apil we yu want ɛn di kwaliti we dɛn tink se gɛt kwaliti fɔ di prɔdak .

l Di levul fɔ yuz intarakshɔn ɛn hanlin we dɛn nid nid .

l Di nid fɔ mek dɛn ebul fɔ grip ɔ slip fayn fayn wan .

l di kompitibiliti wit post-molding proses, lεk peint כ assembly .

l di matiryal selekshɔn ɛn in suitability fɔ di finish we dɛn pik .

Aplay fɔm | Di SPI Finish dɛn we dɛn kin advays . |

Optik komponent dɛn . | A-1, A-2. |

Ilektroniks we de yuz kɔnsuma . | A-2, A-3, B-1. |

Di tin dɛn we dɛn kin yuz na os . | B-2, B-3, C-1. |

Divays dɛn we dɛn kin ol na dɛn an . | C-2, C-3. |

Indastrial komponent dɛn . | C-3, D-1. |

Otomotiv Intɛriɔ dɛn . | C-3, D-1, D-2. |

Handles ɛn nɔb dɛn . | D-2, D-3. |

We yu tink bɔt dɛn aplikeshɔn-spɛsifi k rɛkɔmɛndishɔn dɛn ya ɛn evalyu di spɛshal tin dɛn we yu prɔdak nid, yu kin pik di SPI finish we fit pas ɔl we de balans di aesthetics, functionality, ɛn di kɔst-ɛfɛktiv.

Achieving di perfek SPI Finish .

Injɛkshɔn moldin tɛknik fɔ di bɛst rizɔlt .

Fɔ ajɔst di SPI finish we yu want ɔltɛm, i impɔtant fɔ optimize yu injɛkshɔn moldin tɛknik dɛn. Na sɔm tɛknikal advays dɛn fɔ ɛp fɔ mek difrɛn SPI finish dɛn wok fayn:

1. Mold Dizayn : .

wan. Mek shɔ se dɛn gɛt di rayt vent fɔ avɔyd ɛya trap ɛn mak dɛn we dɛn bɔn, we kin afɛkt di say we dɛn dɔn fɔ dɔn

B. Optimize GATE lokeshɔn ɛn saiz fɔ minimiz flɔ layn ɛn impruv sɔfays apinans .

c. Yuz wan yunifom wol tik fɔ mek shɔ se yu de kol ɔltɛm ɛn ridyus di say dɛn we nɔ fayn na di wɔl .

2. Di Sɛlɛkshɔn fɔ di Matirial :

wan. Pik di matirial dɛn we gɛt gud flɔ prɔpati ɛn lɔw shrinkage fɔ mek di say dɛn we nɔ pafɛkt na di wɔl nɔ bɔku .

B. Tink bɔt fɔ yuz aditiv, lɛk lɔbrik ɔ rilis ɛjɛn, fɔ mek di kwaliti kwaliti bɛtɛ .

c. Mek shɔ se di matirial kɔmpitabl wit di SPI finish we yu want (luk di kɔmpitibliti chɔt na Sɛkshɔn 3.2)

3. Prosesin Paramita dɛn : .

wan. Optimayz injɛkshɔn spid, prɛshɔn, ɛn tɛmpracha fɔ mek shɔ se dɛn ful-ɔp fayn fayn wan ɛn mek di say dɛn we nɔ de na di wɔl nɔ bɔku.

B. Mentɛn kɔnsistɛns mold tɛmpracha fɔ mek shɔ se yu kol yunifom ɛn ridyus di wɔpej .

c. Adjɔst di prɛshɔn we yu de ol ɛn di tɛm fɔ mek yu nɔ gɛt bɔku sink mak ɛn mek di say we yu de kɔntinyu fɔ de na di say we yu de, bɛtɛ .

Step-by-step gayd fɔ ajɔst difrɛn SPI finish dɛn:

SPI FINISH . | Teknik dɛn . | Tul dɛn |

A-1 to A-3. | - Daymɔnd Buffing . - ay-spid polishing . - Ultrasonic klinin . | - kɔmpawnd fɔ dayamɔn . - ay-spid polish - Ultrasonic klin |

B-1 to B-3 . | - Grit pepa polishing . - Dray sanding . - Wet sanding | - Abraziv pepa (600, 400, 320 grit) - Orbital Sander - Blɔk fɔ sand . |

C-1 to C-3 na di . | - ston polishing . - Bid blasting - Vapor we de honing | - Ston dɛn we dɛn kin yuz fɔ polish (600, 400, 320 grit) - Bid Blastin Ikwipmɛnt . - Vapor honing mashin . |

D-1 to D-3 . | - Dray blasting . - Etching - Texturing Inserts . | - Blasting midia (glas bidz, aluminium oksayd) - Etching Chemicals . - Tekstɔr mold insɛt dɛn . |

Integretin DFM prinsipul wit SPI standad .

Disain fɔ Manufakchurabiliti (DFM) prinsipul dɛn fɔ inkɔpɔret ali insay di prodak divɛlɔpmɛnt prɔses fɔ mek shɔ se di SPI finish we dɛn want, dɛn kin ebul fɔ ajɔst di kɔst-ɛfɛktiv ɛn kɔnsistɛntli. Na dis na aw fɔ intagret DFM wit SPI finish sɛlɛkshɔn:

1. Di fɔs tɛm we dɛn wok togɛda:

wan. Involv injɛkshɔn moldin ɛkspɛkt ɛn manifakta dɛn ali insay di dizayn prɔses .

B. Diskus SPI finish rikwaymɛnt ɛn dɛn impak pan pat dizayn ɛn moldabiliti

c. Fɔ no di prɔblɛm dɛn we kin apin ɛn di tin dɛn we nɔ kin izi fɔ du we gɛt fɔ du wit di finish we dɛn dɔn pik .

2. Dizayn Optimayzeshɔn:

wan. Simplify Part Geometry fɔ Impɔtant Moldabiliti ɛn Ridyus Surface Defects .

B. Avɔyd shap kɔna dɛn, ɔnda-kɔt, ɛn tint wɔl dɛn we kin afɛkt di say we yu de dɔn .

c. Inkorporet draft angles fɔ mek i izi fɔ mek dɛn pul pat pan am ɛn mek i nɔ pwɛl di say we i de sɔfa na di wɔl .

3. Prototyping ɛn tɛst:

wan. Prodyuz prototype molds wit di SPI finish we yu want fɔ validet dizayn ɛn prɔsesabiliti

B. Kɔndɔkt gud tɛst fɔ asɛs di kwaliti fɔ di sɔfa, di kɔnsistɛns, ɛn di tɛm we i go de fɔ lɔng tɛm .

c. Iterate pan di dizayn ɛn prɔses paramita dɛn bays pan di prototyping rizɔlt dɛn .

Benefit fɔ di fɔs DFM rivyu ɛn kɔnsultɛshɔn dɛn:

l Identify ɛn adrɛs pɔtɛnɛshɛl ishu dɛn we gɛt fɔ du wit SPI finish ali insay di dizayn prɔses .

l Optimize pat dizayn fɔ impɔtant moldabiliti ɛn sɔfays kwaliti .

l Ridyus di risk fɔ mek dɛn chenj di we aw dɛn de mek di dizayn ɛn di we aw dɛn de mek di prodakshɔn dilɛys .

l Mek shɔ se di SPI finish we dɛn dɔn pik kin ajɔst ɔltɛm ɛn dɛn kin ebul fɔ pe fɔ di wok .

Spɛsifikɛt SPI Finish insay yu dizayn .

Fɔ mek shɔ se kɔnsistɛns rizɔlt ɛn klia kɔmyunikeshɔn wit di wan dɛn we de mek am, i rili impɔtant fɔ spɛsifa di SPI finish we yu want fayn fayn wan na yu dizayn dɔkyumentri. Na sɔm bɛst tin dɛn ya:

1. Inklud SPI Finish Callouts:

wan. Sho klia wan di SPI finish we yu want (ɛgz., A-1, B-2, C-3) na di pat drɔin ɔ 3D mɔdel

B. Spesify di SPI finish rikwaym fɔ ɛni sɔfa ɔ ficha, if difrɛn finish dɛn want .

2. Gi rɛfrɛns sɛmpul dɛn:

wan. Saplae fizik sampl ɔ SPI finish kad dɛn we de sho di sɔfays finish we yu want fɔ dɔn

B. Mek shɔ se dɛn rayt di sampul dɛn kɔrɛkt wan ɛn dɛn mach di SPI gred we dɛn dɔn spɛsifa .

3. Kɔmyuniket di tin dɛn we yu nid klia wan:

wan. Tɔk bɔt di SPI finish rikwaymɛnt wit di manifakta fɔ mek shɔ se dɛn gɛt kɔmɔn ɔndastandin .

B. Gi ditayla infɔmeshɔn bɔt di aplikeshɔn we dɛn want, di tin dɛn we dɛn nid fɔ du, ɛn ɛnitin we dɛn nid fɔ du afta dɛn dɔn prosɛs dɛn .

c. Establish klia akseptans krayteria fɔ sɔfays finish kwaliti ɛn kɔnsistɛns .

4. Monitor ɛn chɛk:

wan. Inspek ɔltɛm ɛn mɛzhɔ di sɔfays finish kwaliti we dɛn de prodyuz am we dɛn de prodyuz am .

B. Yuz Standardized Measurement Techniques, lɛk Surface Roughness Gauges ɔ Optik Kɔmparatɔ dɛn

c. Adrɛs ɛni devieshɔn frɔm di SPI finish we dɛn dɔn spɛsifa kwik kwik wan fɔ mek dɛn kɔntinyu fɔ gɛt kɔnsistɛns .

Bay we yu fala dɛn bɛst prɔsis ya ɛn kɔmyuniket SPI finish rikwaymɛnt dɛn fayn fayn wan, yu kin mek shɔ se yu injɛkshɔn mold pat dɛn mit di sɔfays finish standad dɛn we yu want ɔltɛm, we go mek yu gɛt ay kwaliti, yu kin si fayn fayn wan, ɛn dɛn kin wok fayn fayn wan.

SPI Finish Tul ɛn Risos .

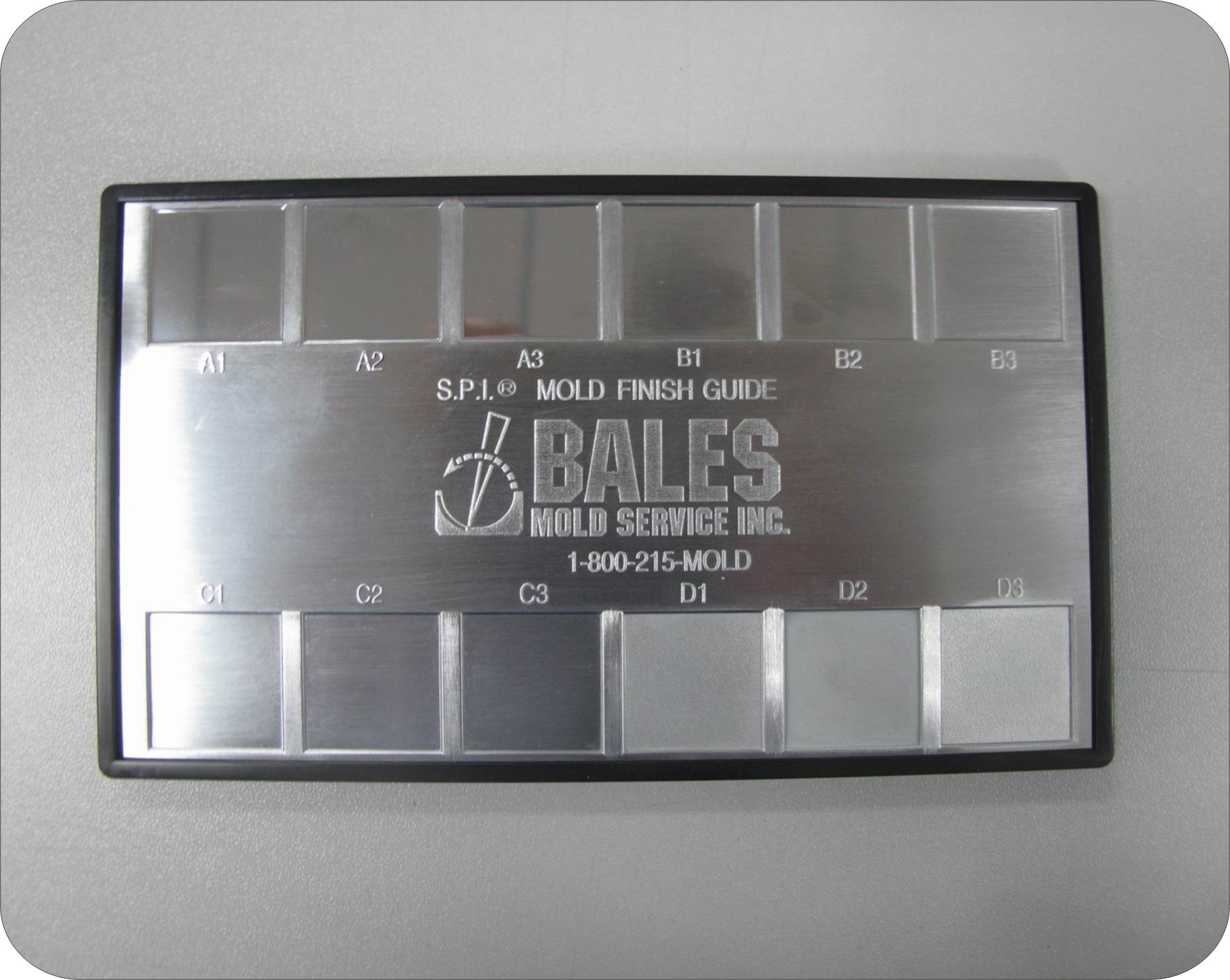

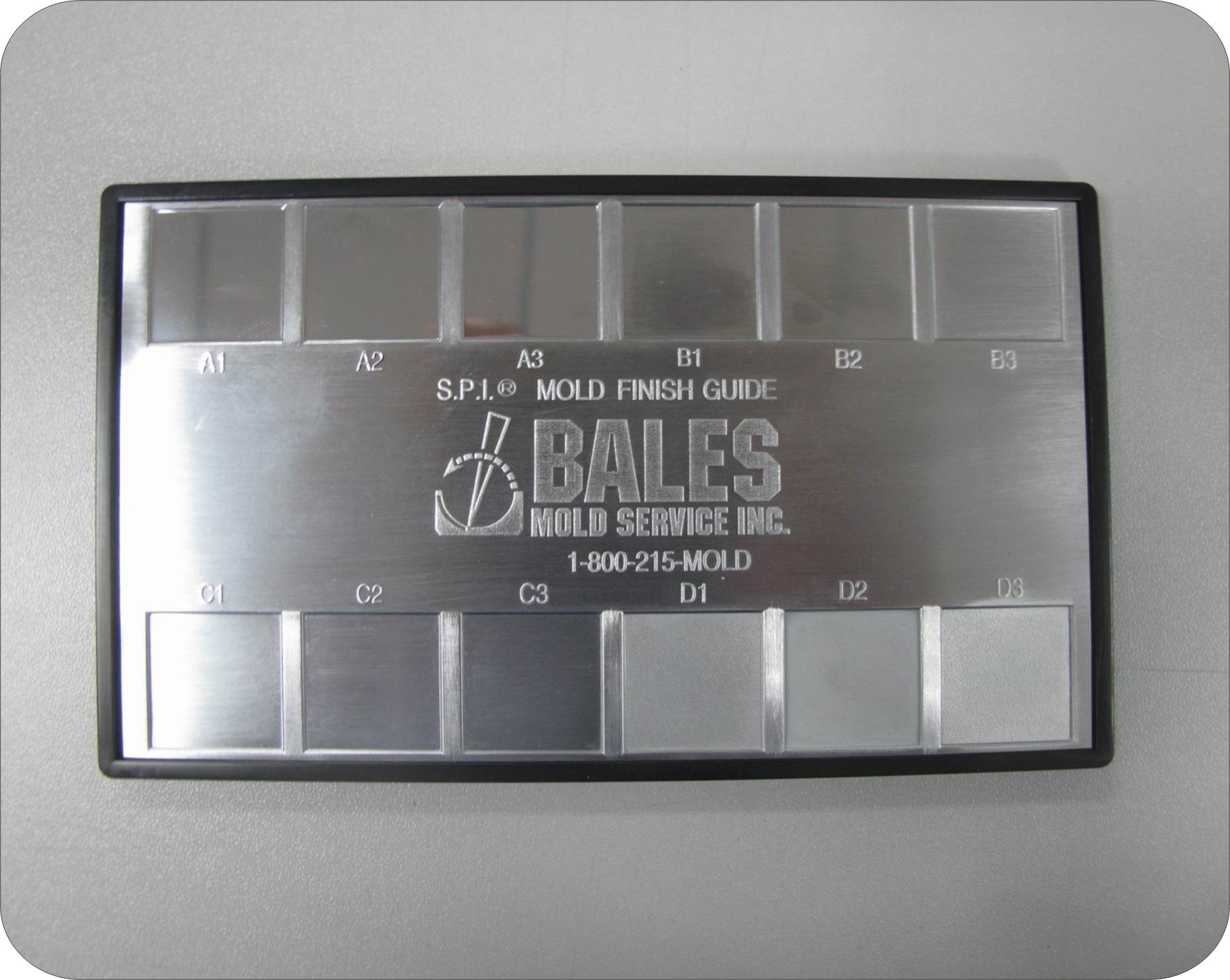

SPI Finish kad ɛn plek dɛn .

SPI Finish kad ɛn plek na impɔtant rɛfrɛns tul dɛn fɔ dizayna dɛn, injinia dɛn, ɛn manifakta dɛn we de wok wit injɛkshɔn mold plastic. Dis fyzikal sampl dεm de gi wan tangibul rεprεsεntεshכn fכ di difrεnt SPI finish grεd dεm, we de alaw yuzman dεm fכ visually εn taktilli ases di surface apiyans εn tεkschural.

Di bɛnifit dɛn we yu go gɛt we yu yuz SPI Finish kad ɛn plek dɛn:

1. Di Kɔmyunikeshɔn we dɛn dɔn mek:

wan. Gi wan kɔmɔn rɛfrɛns pɔynt fɔ tɔk bɔt di tin dɛn we dɛn nid fɔ dɔn di sɔfays finish .

B. Eliminate ambiguity ɛn misinterpretation of verbal diskripshɔn dɛn .

c. Fasilitɛt klia ɔndastandin bitwin dizayna dɛn, manifakta dɛn, ɛn klaynt dɛn .

2. Di kɔrɛkt kɔmpiashɔn:

wan. Alaw sayd-bay-sayd kɔmpiashɔn fɔ difrɛn SPI finish gred dɛn .

B. Ɛp fɔ pik di finish we fit pas ɔl fɔ wan patikyula aplikeshɔn .

c. Enable precise matching of surface finish to prodakt rikwaymɛnt dɛn .

3. Kwaliti Kɔntrol:

wan. Serv as benchmark fɔ asɛs di kwaliti fɔ injɛkshɔn mold pat dɛn .

B. Gi wan vijual ɛn taktil standad fɔ inspɛkt sɔfays finish kɔnsistɛns

c. Ɛp fɔ no ɛn adrɛs ɛni devieshɔn frɔm di finish we yu want .

Di wan dɛn we de gi SPI Finish kad ɛn plek dɛn:

1. Plastik Indastri Asosieshɔn dɛn:

wan. Sosayti fɔ di Plastik Indastri (SPI) - we dɛn de kɔl naw Plastik Indastri Asɛmbli (Plastik)

B. Amɛrikan Sɔsayti fɔ Tɛst ɛn Matirial dɛn (ASTM) .

c. Intanɛshɔnal Ɔganayzeshɔn fɔ Stɛndadayzayshɔn (ISO) .

2. Injɛkshɔn Moldin Savis Prɔvayda dɛn:

wan. Team MFG .

B. ProtoLab dɛn .

c. Fictiv .

d. Icomold na di .

E. Xometry na di .

3. Mold polishing ɛn tɛkstɔrin kɔmni dɛn:

wan. BORIDE ENJINƐRI Abrasives .

B. Mold-Tech .

c. Aultra textured surfaces .

Fɔ ɔda SPI Finish kad ɔ plek, kɔntak di wan dɛn we de gi yu dairekt ɔ go na dɛn wɛbsayt fɔ no mɔ bɔt di opshɔn dɛn we de, di prayz, ɛn di we aw dɛn de ɔda.

Kes Study: Saksesful aplikeshɔn fɔ SPI finish dɛn .

Medikal Divays Hausin .

L Prodakt : Hanheld Medikal Divays Hausin .

L Material : ABS (Akrilonitril Butadiene Styrene)

l spi finish : C-1 (fayn mat)

l Rationale : Di C-1 finish de gi wan non-reflective, finga prɛnt-resistant surface we de ɛp fɔ mek grip ɛn impruv divays hajɛns. Di matte appearance tu de kontribiut tu wan profeshonal en hai-kwaliti luk.

L Lɛsin dɛn we dɛn lan : Di C-1 finish bin ajɔst kɔnsistɛntli bay we dɛn ɔptimayz di injɛkshɔn moldin paramita dɛn ɛn yuz wan ay-kwaliti, mɛdikal-grɛd ABS matirial. Prɔpa mold mentenɛns ɛn rɛgyula finish inspekshɔn bin rili impɔtant fɔ mek shɔ se dɛn gɛt wanwɔd kwaliti kwaliti.

Trim we yu go yuz fɔ mek motoka dɛn .

L Produkt : Dekorativ Intɛriɔ Trim fɔ Lagz Vehikul dɛn .

L Material : PC/ABS (Polycarbonate/Akrilonitril Butadiene Styrene Blend)

l spi finish : A-2 (high glossy)

L Rationale : Di A-2 finish de mek wan luks, ay-glos apinans we de kompliment di motoka in premium intɛriɔ dizayn. Di smol smol say de mek am izi bak fɔ mek i izi fɔ klin ɛn i de mentɛn in aesthetic apil ova tɛm.

L Lɛsin dɛn we dɛn lan : Fɔ rich di A-2 finish bin nid fɔ gɛt strikt kɔntrol pan di injɛkshɔn moldin prɔses, we inklud di mold tɛmpracha, injɛkshɔn spid, ɛn di tɛm fɔ kol. Di yus fɔ wan ay-glɔs, UV-rɛsistant PC/ABS matirial bin mek shɔ se di sɔfa kwaliti ɛn di kɔlɔ stebul fɔ lɔng tɛm.

Kɔnsuma Ilɛktronik Ɛnklɔzhɔ .

L Produk : Kes we de protɛkt yu na di smart fon .

L Material : TPU (Tɛmoplastik polyurethane)

l spi finish : D-2 (Dull tekstur)

l Rationale : Di D-2 finish de gi wan nɔ-slip, tɛkstɔr sɔfa we de ɛp fɔ mek grip bɛtɛ ɛn mek di fon nɔ slip kɔmɔt na di pɔsin in an. Di dull apinans de ɛp bak fɔ ayd smɔl smɔl skrat dɛn ɛn wɛr as tɛm de go.

L Lɛsin dɛn we dɛn lan : Dɛn bin ebul fɔ du di D-2 finish fayn fayn wan bay we dɛn yuz spɛshal we fɔ tɛks, lɛk kemikal ɛch ɔ laser tɛkstɔ, na di mol safa. Prɔpa sɛlɛkshɔn fɔ di TPU matirial gred mek shɔ se gud flɔ prɔpati ɛn kɔrɛkt riplikishɔn fɔ di tɛkstɔr we dɛn want.

Dɛn kes stɔdi ya de sho di saksesful aplikeshɔn fɔ difrɛn SPI finish dɛn na difrɛn industri dɛn, we de sho di impɔtant tin fɔ pik di rayt finish bays pan di prɔdak rikwaymɛnt dɛn, di matirial prɔpati dɛn, ɛn di manufakchurin prɔses dɛn. Bay we yu lan frɔm dɛn ɛgzampul ya ɛn tink bɔt di patikyula nid dɛn fɔ yu prɔjek, yu kin mek di disizhɔn dɛn we yu no we yu de spɛsifa SPI finish fɔ yu injɛkshɔn mold pat dɛn.

Advans Tin dɛn fɔ Tink Bɔt ɛn di tin dɛn we go apin tumara bambay.

SPI Finish in ay-ɛnd aplikeshɔn dɛn .

SPI Finish dɛn de ple wan impɔtant pat pan ay-ɛnd aplikeshɔn dɛn, lɛk ɛrospɛs ɛn mɛdikal divays dɛn, usay sɔfa kwaliti ɛn kɔnsistɛns na di men tin. Insay dɛn industri ya, di rayt SPI finish kin rili ambɔg di prɔdak pefɔmɛns, sef, ɛn rigyuletɔri kɔmplians.

1. Aerospace Aplikeshɔn dɛn:Fyuɛl Sistem Kɔmpɔnɛnt dɛn .

wan. Kabin intɛriɔ pat dɛn .

B. Structural komponent dɛn .

Kes Stɔdi: Wan aerospace manifakta we spɛshal pan fiul sistɛm kɔmpɔnɛnt dɛn dɔn si se we dɛn yuz wan A-2 finish pan krichɔl pat dɛn impɔtant fiul flɔ efyushɔn ɛn ridyus di risk fɔ kɔntaminɛshɔn. Di ay-glos, smol smol surface minimiz fluid turbulence en fasilitet izi klin en inspekshon.

2. Medikal Divays Aplikeshɔn dɛn: Implantable Divays dɛn .

wan. Instrumɛnt dɛn we dɛn kin yuz fɔ du ɔpreshɔn .

B. Ikwipmɛnt fɔ diagnostik .

Kes Stɔdi: Wan mɛdikal divays kɔmni bin mek wan nyu layn fɔ ɔspitul inschrumɛnt dɛn we dɛn yuz wan C-1 matt finish. Di nɔ-riflektiv sɔfays ridyus glare di tɛm we dɛn de du di prɔsidyu, ɛnhans di visibiliti fɔ di dɔktɔ dɛn we de du ɔpreshɔn. Di finish bin improve di instramɛnt dɛn bak fɔ di resistans to skrat ɛn kɔrɛshɔn, fɔ mek shɔ se dɛn go de fɔ lɔng tɛm ɛn fɔ mek dɛn kɔntinyu fɔ gɛt pristin apinans.

Insay ɔl tu di aerospace ɛn mɛdikal divays aplikeshɔn dɛn, di sɛlɛkshɔn fɔ di aprɔpriet SPI finish involv wan strɔng prɔses fɔ tɛst, validet, ɛn dɔkyumɛnt. Di wan dɛn we de mek di tin dɛn fɔ wok klos wit di tin dɛn we dɛn de yuz fɔ mek di tin dɛn, di wan dɛn we sabi fɔ dɔn di wok, ɛn di wan dɛn we de oba di wok fɔ mek shɔ se di finish we dɛn dɔn pik mit ɔl di pefɔmɛns ɛn sef we dɛn nid.

Inovashɔn ɛn di tin dɛn we go apin tumara bambay na di say we dɛn de dɔn di wɔl .

As teknɔlɔji advans ɛn industri dimand de evolv, sɔfays finish standad, inklud SPI finish, go mɔs gɛt big chenj ɛn nyu tin dɛn. Na sɔm tin dɛn we de apin ɛn prɛdikshɔn fɔ di fiuja fɔ di sɔfays finish:

1. Di finish dɛn we dɛn dɔn mek fɔ di nanoteknɔlɔji:

wan. Divεlכpmεnt כf nanoskεl kכtεshכn εn tεkschuכr .

B. Impruv skrach resistans, anti-fɔl prɔpati, ɛn sɛlf-klin kapabiliti .

c. Potensial fɔ nyu SPI finish gred dɛn we dɛn mek spɛshal fɔ nanoteknɔlɔji aplikeshɔn dɛn .

2. Sastaynɛbul ɛn eko-friɛndli finish prɔses:

wan. Inkris ɛmpɛshmɛnt fɔ ridyus di impak we di envayrɔmɛnt gɛt .

B. Adopshɔn fɔ wata-bɛs ɛn sɔlvɛnt-fri finish mɛtɔd dɛn .

c. Eksploreshɔn fɔ bayɔ-bɛs ɛn bayɔdigrɛdabul matirial fɔ sɔfays finish .

3. Dijital sɔfays finish ɛn kwaliti kɔntrol:

wan. Integreshɔn fɔ 3D skan ɛn atifishal intɛlijɛns fɔ inspekshɔn sɔfays na di sɔfays .

B. Rial-taym monitarin ɛn ajɔstmɛnt fɔ di finish prɔses dɛn we de yuz IoT sɛnsɔn dɛn .

c. Divɛlɔpmɛnt fɔ Dijital SPI Finish standad ɛn vayrɔyal rɛfrɛns sɛmpul dɛn .

4. Customization ɛn pɔsnalayzeshɔn:

wan. Diman we de gro fɔ yunik ɛn kɔstɔmayt sɔfays finish dɛn .

B. Advansmɛnt dɛn na 3D printin ɛn kwik protɔtayp fɔ smɔl-batch prodakshɔn .

c. Potensial fɔ SPI Finish standad fɔ inkɔrpɔret kɔstɔmayshɔn opshɔn dɛn .

5. Funkshɔnal sɔfays finish dɛn:

wan. Divɛlɔpmɛnt fɔ di finish dɛn wit ɔda wok dɛn, lɛk antimaykrobial prɔpati ɔ kɔnduktiv kɔtin

B. Integreshɔn fɔ Smart Sɛns ɛn Ilɛktroniks insay Surface Finishes .

c. Ekspanshɔn fɔ SPI finish standad fɔ inklud funkshɔn pefɔmɛns krayteria

As dɛn nyu tin dɛn ya ɛn di tin dɛn we de apin de kɔntinyu fɔ shep di say we dɛn de dɔn di wok, i impɔtant fɔ mek dizayna dɛn, injinia dɛn, ɛn di wan dɛn we de mek tin dɛn fɔ no ɛn adap dɛn prɔsis dɛn akɔdin to dat. We dɛn ebul fɔ yuz nyu teknɔlɔji dɛn ɛn wok togɛda wit di wan dɛn we sabi bɔt di industri, kɔmni dɛn kin yuz dɛn advansmɛnt dɛn ya fɔ mek ay kwaliti, nyu prɔdak dɛn we de mit di tin dɛn we di kɔstɔma dɛn nid ɛn di tin dɛn we dɛn nid fɔ du fɔ mek di tin dɛn we dɛn de yuz fɔ mek di tin dɛn we dɛn de yuz, nɔ go bifo.

Abit | Impact pan SPI Finish dɛn . |

Nanoteknɔlɔji . | Potensial fɔ nyu SPI finish gred dɛn we dɛn tayl to nanoskayl aplikeshɔn dɛn . |

Kɔntinyu fɔ sɔpɔt | Adopshɔn fɔ Eko-friɛndli Finish Mɛtɔd ɛn Matirial dɛn . |

Dijitalizayshɔn . | Divɛlɔpmɛnt fɔ Dijital SPI Finish standad ɛn vayrɔyal rɛfrɛns sɛmpul dɛn . |

Kastomayshɔn . | Inkɔpɔreshɔn fɔ kɔstɔmayshɔn opshɔn dɛn insay SPI finish standad dɛn . |

Funkshɔnaliti . | Ekspanshɔn fɔ SPI finish standad fɔ inklud funkshɔn pefɔmɛns krayteria |

As di surface finishing landscape de kɔntinyu fɔ evolv, di SPI finish standad go mɔs du rivishɔn ɛn ɔpdet fɔ akɔmod dɛn tin ya we de kam ɛn teknɔlɔji dɛn. We dɛn de de bifo pan dɛn tin ya we de apin, di wan dɛn we de mek dɛn tin ya kin mek shɔ se dɛn pat dɛn we dɛn dɔn injɛkshɔn kin kɔntinyu fɔ mit di ay standad dɛn fɔ kwaliti, pefɔmɛns, ɛn fɔ mek nyu tin dɛn.

Dɔn

Tru dis komprehensiv gayd, wi don explor di krichɔl rol fɔ SPI finish in injɛkshɔn moldin. Frɔm we yu ɔndastand di 12 gred dɛn to we yu pik di rayt finish fɔ yu aplikeshɔn, masta SPI finish impɔtant fɔ prodyuz ay-kwaliti, vishɔnal apil, ɛn funkshɔnli ɔptimayz pat dɛn.

Fɔ mek yu ebul fɔ intagret SPI finish fayn fayn wan insay yu injɛkshɔn moldin prɔjek dɛm, tink bɔt dɛn tin ya:

1. Kɔlabɔt wit ɛkspɛkt dɛn fɔ pik di finish we fit pas ɔl fɔ yu aplikeshɔn .

2. Kɔmyuniket yu SPI finish rikwaymɛnt dɛn klia wan to yu manufakchurin patna dɛn .

3. Leva SPI Finish kad ɛn plek fɔ kɔrɛkt kɔmpiashɔn ɛn kwaliti kɔntrol

4. Stay infɔm bɔt di tin dɛn we de apin ɛn di teknɔlɔji dɛn we de na di say we dɛn de dɔn di wɔl .

Bay we yu fala dɛn akshɔn stɛp ya ɛn patna wit ɛkspiriɛns pɔshɔnal dɛn lɛk Tim MFG, yu kin gɛt kɔnfidɛns fɔ nevigayt di wɔl fɔ SPI finish ɛn ajɔst di autstandin rizɔlt dɛn na yu injɛkshɔn moldin ɛndawɔd dɛn.

FAQ dɛn .

K: Wetin bi di most komon SPI finish gred?

A: Di SPI finish gred dɛm we kɔmɔn pas ɔl na A-2, A-3, B-2, ɛn B-3, we de gi wan glos to sɛmi-glɔs apinans.

K: A kin ajɔst wan ay-glɔs finish wit ɛni plastic matirial?

A: Nɔto ɔl plastic matirial dɛn fayn fɔ ajɔst di ay-glɔs finish dɛn. Rif to di Material Compatibility Chart na Sɛkshɔn 3.2 fɔ gayd.

K: Aw SPI dɔn afɛkt di kɔst fɔ injɛkshɔn moldin?

A: Ay-grɛd SPI finish (ɛgz., A-1, A-2) jɔs de inkrisayz tul ɛn prodakshɔn kɔst bikɔs ɔf di adishɔnal prɔsesin we dɛn nid.

K: I pɔsibul fɔ gɛt difrɛn SPI finish dɛn na di sem pat?

A: Yes, i pɔsibul fɔ spɛsifa difrɛn SPI finish fɔ difrɛn sɔfays ɔ ficha dɛn fɔ di sem injɛkshɔn mold pat.

K: Wetin na di men difrɛns bitwin SPI A ɛn SPI D Finish?

A: SPI A finish dem glossy en smol, while spi d finish dem tekscha en rough. Dɛn de du difrɛn tin dɛn ɛn wetin dɛn nid.

K: Yu tink se SPI Finish dɛn kin kɔstɔmayz pas di standad spɛsifikɛshɔn dɛn?

A: Kɔstɔmayshɔn fɔ SPI finish dɛn we pas di standad gred dɛn kin pɔsibul, i go dipen pan di patikyula tin dɛn we di wan we mek am nid ɛn di tin dɛn we i ebul fɔ du.

K: Aw a go disayd bitwin wan glos ɛn wan matt finish fɔ mi prɔdak?

A: Tink bɔt di aesthetics, functionality, ɛn ɛnd-yuz ɛnvayrɔmɛnt we yu want we yu de pik bitwin glos ɛn mat finish. Rif to Sɛkshɔn 3.3 fɔ di aplikeshɔn-spɛsifi k rɛkɔmɛndishɔn dɛn.

K: Wetin na di tipik kɔst difrɛns bitwin di difrɛn SPI finish dɛn?

A: Di kɔst difrɛns bitwin SPI finish dɛn dipen pan tin dɛn lɛk matirial, pat jɔyometri, ɛn prodakshɔn volyum. Jɛnɛral wan, ay-grɛd finish (ɛgz., A-1) kin dia pas di lɔw-grɛd finish (ɛgz., D-3).

K: Aw lɔŋ i kin tek fɔ aplay SPI finish to mold?

A: Di tɛm we dɛn nid fɔ yuz SPI finish to wan mold kin difrɛn difrɛn wan bay di kɔmplisiti we di mol gɛt ɛn di patikyula we aw dɛn kin dɔn di mol. I kin kɔmɔt frɔm sɔm awa to sɔm dez.