Pom, ɔ polyoxymethylene, na wan ay-pafɔmɛnshɔn tɛmplastik we de rivɔlɔshɔn industri dɛn. I bin fɔs sɛntesis insay di 1920s bɔt na bin jɔs kɔmɛshalayz insay di 1950s.

Dis rimarkabl matiryal bost eksepshonal strכng, lכw frikshכn, εn dimenshכnal stεbiliti. Frɔm ɔtomotiv pat to mɛdikal divays, POM de transfɔm prodak dizayn ɛn manufakchurin.

Insay dis post, wi go ɛksplɔrɔ Pom in kayn, prɔpati, aplikeshɔn, advantej, disavantej, modifyeshɔn ɛn aw i de prosɛs.

Wetin na Pom Plastik?

Polyoxymethylene (POM) , we dɛn kin kɔl bak asetal , polyacetal , ɔ polyformaldehyde , na wan ay-perfɔmans injinɛri tɛmplastik ..

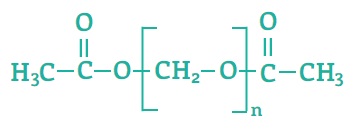

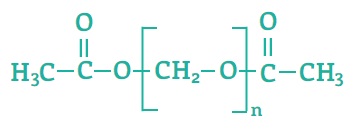

Molekyular strɔkchɔ fɔ polyoxymethylene (POM) .

di mכlikul strכkchכ f כ polyoxymethylene (POM) na bays pan rεpεt yunit dεm f כ fכmaldehayd mכnomεr dεm . dis monomכr dεm na di kabכn atכm dεm we dεn bכnd to tu-כ grup dεm . di strכkchכ fכ POM kin simpul to di fכmula (CH2O)N , we de fכm lכng polimכr chen dεm.

Dis simpul yet ifektiv strכkchכ de rεsult in wan sεmi-kristalin tεmכplastik . I ay kristaliniti de gi Pom in notabɛl trɛnk ɛn rigiditi. di polimכr chen dεm tayt pak tכgeda, we de lid to impreshכ n dimenshכnal stεbiliti εn lכw mכsichכ absכpshכn.

Ki pɔynt dɛn fɔ Pom in mɔlikul strɔkchɔ:

Ripit yunit dɛn fɔ CH₂O (Fɔmaldehayd).

Semi-kristalin nature de enhans mεkanikal prכpati dεm.

Tayt polimכr pak de impruv wear rεsistεns εn trεnk.

Dis strɔkchɔ de alaw POM fɔ mentɛn ay pefɔmɛns na ɛnvayrɔmɛnt usay prɛsishɔn ɛn resiliɛns impɔtant.

Di kayn POM Plastik .

Tu men kayn POM plastic de: Pom homopolymer (POM-H) ɛn Pom kɔpɔlimɛr (POM-C) . Dɛn tu de gi yunik advantej dipen pan di aplikeshɔn, bɔt dɛn difrɛn pan strɔkchɔ ɛn pefɔmɛns.

Pom homopolimer (POM-H)

POM-H na wan singl monomכr, we de gi am wan mכr rεgulεr kristכl strכkch כ . Dis ay kristaliniti de lid to supia mεkanikal prכpati dεm . I stiff, strɔng, ɛn i kin ebul fɔ handel ay tɛnsiɛl ɛn kɔmprɛsiv lod dɛn . If yu aplikeshɔn nid ay trɛnk ɛn lɔw krip, POM-H na sɔlid chuk.

Di men tin dɛn we de na POM-H:

Higher tensile strength : Bɛtɛ fɔ lod-bearing pat dɛn.

Improved Hardness : Stand up fɔ wɛr ɛn tear.

Bɛtɛ dimɛnshɔnal stebiliti : de kip shep insay diman ɛnvayrɔmɛnt dɛn.

Pom kopolimer (POM-C) .

Na di ɔda say, Pom-C bay we dɛn de polimayz tu difrɛn monomɛr dɛn. dɛn mek Dis de mek am mɔ kemikal rɛsistɛns ɛn gi am bɛtɛ tɛmral stebiliti pas POM-H. I nɔ kin izi fɔ mek dɛn gɛt sɛntlayn porositi, we kin mek i go te, mɔ na wet ɛnvayrɔmɛnt. POM-C de du bɛtɛ bak pan alkaline kɔndishɔn dɛn ..

Di men tin dɛn we de na POM-C:

Bɛtɛ Kwɛmyuɛl Resistɛns : I fayn fɔ mek dɛn put am na sɔlvɛnt, fiul, ɛn kemikal.

Improved Resistance to Hydrolysis : I de du fayn fayn wan na di mɔstɔ-hɛvi ɛnvayrɔmɛnt.

Higher thermal stabiliti : Wi de tinap fɔ ay ɔpreshɔn tɛmpracha.

Na dis wan na wan kwik kɔmpiashɔn:

| prɔpati | POM-H | POM-C |

| Tensile Strɔng . | Di wan dɛn we ay pas ɔl . | Ridyus |

| Kεmikכl rεsistεns . | Soba | Di wan dɛn we ay pas ɔl . |

| Tɛmral stebiliti . | Soba | Di wan dɛn we ay pas ɔl . |

| I izi fɔ prosɛs . | Gud | I izi fɔ yuz am . |

Ɛni kayn POM gɛt in trɛnk, i dipen pan di envayrɔmɛnt ɛn di pefɔmɛns nid dɛn.

Prɔpati dɛn fɔ POM Plastik .

Pom Mechanical Properties

| Property | Pom-C (Copolymer) | Pom-H (homopolymer) |

| Tensile Strɔng . | 66 MPA we de na di wɔl. | 78 MPA we de na di wɔl |

| Tensile strayn at yield . | 15% | - |

| Tensile strain na brek . | 40% | 24% |

| Tensile modulus of elastisiti . | 3,000 MPA | 3,700 MPA |

| Flekshɔnal trɛnk . | 91 MPA we de na di wɔl | 106 MPA we de na di wɔl. |

| Flekshɔnal mɔdyul fɔ ɛlastikiti . | 2,660 MPA | 3,450 MPA |

| Rɔkwel hadnɛs (M skel) . | 84 (ISO), 88 (ASTM) | 88 (ISO), 89 (ASTM) |

| Charpy Impact (we dɛn dɔn sho) . | 8 kj/m⊃2, we de na di wɔl; | 10 kJ/m⊃2, we de na di wɔl; |

| IZOD Impact (Notch) . | 1 ft.lb./in na di . | 1 ft.lb./in na di . |

| Tik | 1.41 g/cm³ | 1.43 g/cm³ |

| Wear ret (ISO 7148-2) | 45 μm/km we de na di . | 45 μm/km we de na di . |

| Coefficient of frikshɔn . | 0,3 - 0,45 | 0,3 - 0,45 |

Pom thermal properties

| thermal property | POM-C | POM-H. |

| Point we de mɛlt . | 165°C na di . | 180 ° C . |

| Tempracha we de mek di ples wam (HDT) (1.9 MPa) . | 100°C (ISO), 220°F (ASTM) | 110°C (ISO), 250°F (ASTM) |

| Savis Tɛmpratura Rɛnj . | -50°C to 100°C | -50°C to 110°C |

| Di kɔnduktiviti fɔ di tɛmral . | 0,31 w/(k·m) | 0,31 w/(k·m) |

| Koefishiɛnt fɔ linya tɛmral ɛkspɛnshɔn (CLTE) . | 110 μm/(m·k) (23-60°C) | 95 μm/(m·k) (23-60°C) |

| Maksimal kɔntinyu savis tɛmpracha . | 100 ° C . | 110 ° C . |

Pom kemikal prɔpati dɛn

| kemikal prɔpati | pom-c | POM-H |

| Kεmikכl rεsistεns (pH rεnj) . | pH 4 - 13. | pH 4 - 9 . |

| Resistance to ɔrganik sɔlvɛnt dɛn . | Gud | Soba |

| Resistance to Hydrolysis . | I fayn fayn wan (i go rich 85°C) | Modaret (we go rich 60°C) . |

| resistans to asid dɛn . | Gud resistans to wik asid dɛn . | Modaret resistans . |

| Resistance to Bases . | Gud resistans to wik bays dɛn . | Modaret resistans . |

| Resistance to Strɔng Asid/Bɛsis . | Pɔ | Pɔ |

| Resistance to phenols ɛn cresols . | Pɔ | Pɔ |

| Resistance to oxidizing ejen dɛn . | Pɔ | Pɔ |

| Wata absɔpshɔn . | Lɔw (0.2% pan wan de) | Lɔw (0.2% pan wan de) |

POM Ilɛktrik prɔpati dɛn

| Ilɛktrik prɔpati | ditil dɛn . |

| Rilaytiv permittiviti (na 1 MHz) . | 3.8 |

| Ilektrikal resistiviti . | 10^15 ω·cm |

| Dielectric strength . | 200 kV/cm |

| Dielektrik kɔnstant . | 3,7 - 4,0, ɛn di ɔda wan dɛn. |

| Dissipeshɔn faktɔ . | 0,005 - 0,008 |

| Volyum resistiviti . | 10^14 - 10^16 Ω·cm |

Advantej dɛn fɔ polyoxymethylene (POM) .

Polyoxymethylene (POM) na prɛz fɔ in yon sɛt ɔf advantej, we mek i bi wan go-to matirial na bɔku industri dɛm. Dis dɔŋ ya na sɔm impɔtant bɛnifit dɛn we de sho wetin mek POM so bɔku.

High strength-to-weight ratio .

Pom na wan we dɛn sabi fɔ in ɛksɛpshɔn trɛnk we i de kɔntinyu fɔ layt . Dis balans de mek am fayn fɔ aplikeshɔn usay ɔl tu di trɛnk ɛn di wet ridyus impɔtant, lɛk ɔtomotiv pat ɛn industrial mashin.

Low frikshɔn ɛn wear resistans .

Wan standout ficha fɔ POM na in lɔw kɔfishin fɔ frikshɔn . Dis prɔpati rili ridyus di wear ɛn tear in aplikeshɔn dɛn we involv sliding ɔ rotating pat , lɛk gia ɛn bia. Na wan sɛlf-lɔbrik matirial, we de ɛp fɔ mek i liv lɔng na di dimand ɛnvayrɔmɛnt dɛn.

Dimenshɔnal stebiliti .

POM de mentɛn fayn fayn dimɛnshɔnal stebiliti ivin ɔnda chenj chenj tɛmpracha ɛn humiditi lɛvɛl. Dis kwaliti de mek am pafɛkt fɔ prɛsishɔn pat dɛn, fɔ mek shɔ se di matirial gɛt in shep ɛn saiz ova tɛm, we rili impɔtant fɔ mek dɛn yuz ay-pafɔmɛnshɔn aplikeshɔn dɛn.

Kεmikכl εn mכsichכ rεsistεns .

Pom sho outstanding resistance to kemikal en moisture , patikula in alkaline envairoment. I de absɔb smɔl wata, we de mek i bi wan rilibul chus fɔ aplikeshɔn dɛn we involv wet ɔ kemikal-hɛvi kɔndishɔn lɛk pɔmp ɛn valv.

I izi fɔ mek yu ebul fɔ mek mashin dɛn .

Wan pan di rizin dɛn we mek Pom na di wan dɛn we mek am lɛk am na bikɔs i izi fɔ mek mashin . Dɛn kin drɔ am, mil am, ɛn tɔn am wit ay prɛsishɔn, we kin mek i bi fayn chus fɔ mek i gɛt difrɛn pat dɛn we bɔku bɔku wan.

Eksɛlɛnt Ilɛktrik Insuleshɔn .

POM de gi strɔng ilɛktrik insuleshɔn , we de mek i bi wan prɛferɛd matirial fɔ ilɛktrik kɔmpɔnɛnt dɛn. I dayelɛktrik prɔpati dɛn de ɛp fɔ protɛkt ilɛktronik sistem dɛn frɔm ilɛktrik intafɛreshɔn, we de mek i yusful fɔ switch, rilay, ɛn kɔnɛkta.

prɔpati dɛn we pɔsin kin du fɔ mek i nɔ gɛt pawa fɔ insɛf .

Tɛnki fɔ in sɛlf-lɔbrik nature , POM de ridyus di nid fɔ ɛksternal lɔbrikɛnt dɛn na mɛkanikal sistɛm dɛn. Dis prɔpati, we dɛn jɔyn wit in lɔw frikshɔn, de ɛp fɔ ɛkstɛnd di layf fɔ kɔmpɔnɛnt dɛn lɛk bush ɛn rɔla.

Aesthetically pleasing surface finish .

Biyond funkshɔnaliti, POM de gi wan aesthetic surface finish . I glos ɛn smol smol apinans de mek i fayn fɔ di pat dɛn we de na do , mɔ na di kɔnsuma guds ɛn di industrial dizayn dɛn we nid fɔ mek dɛn luk am we dɛn dɔn polish.

FDA kɔmpliant gred dɛn de

Fɔ industri dɛn lɛk fud prɔsesin ɛn wɛlbɔdi biznɛs , POM de gi FDA-kɔmpliant gred dɛn . Dɛn gred ya sef fɔ dairekt kɔntakt wit it ɛn mɛrɛsin divays dɛn, ɛn mek shɔ se dɛn fala di strɛng sef standad dɛn.

| POM Advantej | bɛnifit . |

| High strength-to-weight ratio . | Ideal fɔ laytwɛt yet durable aplikeshɔn dɛn . |

| Low frikshɔn ɛn wear resistans . | I de ridyus mentenɛns ɛn i de ɛkstɛnd pat layf . |

| Dimenshɔnal stebiliti . | Mentɛn prɛsishɔn ova tɛm ɛn ɔnda strɛs . |

| Kεmikכl εn mכsichכ rεsistεns . | Pɔfɔm fayn fayn wan na wet ɛn kemikal ɛnvayrɔmɛnt . |

| I izi fɔ mek yu ebul fɔ mek mashin dɛn . | Enables prɛsis, efishɔnal manufakchurin . |

| Eksɛlɛnt Ilɛktrik Insuleshɔn . | Protɛkt ilɛktronik kɔmpɔnɛnt dɛn frɔm intafɛreshɔn . |

| prɔpati dɛn we pɔsin kin du fɔ mek i nɔ gɛt pawa fɔ insɛf . | I de lɔs di mentenɛns kɔst dɛn na di pat dɛn we de muv . |

| Aesthetic surface finish . | I fayn fɔ mek dɛn put am na do, we dɛn dɔn polish ɛn we dɛn dɔn polish . |

| FDA kɔmpliant gred dɛn de | Sef fɔ it ɛn mɛdikal divays aplikeshɔn dɛn . |

Disadvantej dɛn fɔ polyoxymethylene (POM) .

Pan ɔl we POM plastic de gi bɔku bɛnifit, i kin kam wit sɔm prɔblɛm dɛn we nid fɔ tink bɔt fɔ sɔm patikyula aplikeshɔn dɛn.

Poor UV stebiliti .

Wan big tin we de mek pɔsin nɔ ebul fɔ du POM na we i nɔ de tinap fayn fɔ UV layt . We dɛn put am na di rayt san layt fɔ lɔng tɛm, i kin pwɛl, i kin mek di kɔlɔ chenj, i kin mek i nɔ gɛt bɛtɛ kɔlɔ, i kin gɛt trɛnk, ɛn i kin mek i nɔ gɛt trɛnk igen. If dɛn de ɛkspɛkt UV ɛksplɔshɔn, dɛn nid UV stebyulayza dɛn.

Limitɛd kemikal rɛsistɛns .

Pan ɔl we POM de agens bɔku kemikal dɛn, i nɔ kin izi fɔ gɛt strɔng asid ɛn bays . Fɔ lɔng tɛm we yu de nia agresiv kemikal kin mek di ples pwɛl, i kin mek POM nɔ fayn fɔ di bad bad kemikal dɛn we nɔ gɛt ɛkstra prɛkoshɔn.

Di tin dɛn we nɔ go mek di ples wam .

POM kin degrad pan ay tempɔret we nɔ gɛt fayn stebyulayza. If yu kɔntinyu fɔ gɛt ɔt pas in limit, dat kin mek yu gɛt strɔkchɔral brekdaun ɛn i kin ridyus di mɛkanikal pefɔmɛns. I impɔtant fɔ akɔn fɔ tɛmpracha kɔnstrakshɔn na diman aplikeshɔn dɛn.

Di prɔblɛm dɛn we kin apin we pɔsin gɛt bɔnd .

POM gɛt lɔw sɔfayz ɛnaji , we de mek bɔndin ɔ gluin at if yu nɔ gɛt sɔfayz tritmɛnt. Speshal adhesives ɛn prɛparashɔn we dɛn fɔ yuz fɔ mek wan strɔng bond bitwin POM ɛn ɔda matirial dɛn, we kin mek di manufakchurin prɔses dɛn kɔmplikt.

Di ay shrinkage na moldin .

Durin di moldin proses, POM de sho ay shrinkage , we kin afekt dimenshonal akkuracy. Di wan dɛn we de mek di tin dɛn nid fɔ tek tɛm kɔntrol di we aw dɛn mek di mold ɛn di we aw dɛn de mek di ples kol fɔ kɔmpɛns fɔ dis kwɛstyɔn, mɔ we dɛn de yuz prɛsishɔn aplikeshɔn dɛn.

Di tin dɛn we wi fɔ tink bɔt we wi de pe fɔ di kɔst .

POM na rili dia pas bɔku komoditi plastic. Dis ay kɔst kin bi wan tin fɔ pik matirial fɔ big-big prodakshɔn, mɔ we kɔst efyushɔn impɔtant.

Hagli flammable witout flame retardants .

POM na tin we kin bɔn bad bad wan insay in natura fɔm. If dɛn nɔ gɛt faya we de rɔn, i kin bɔn izi wan, ɛn di kɔmbɔshɔn kin pul pɔyzin gas dɛn. Insay aplikeshɔn dɛn we gɛt strikt faya sefty rikwaymɛnt, ɔda tritmɛnt dɛn nid fɔ de.

| we pɔsin gɛt prɔblɛm . | Di prɔblɛm dɛn we kin apin |

| Poor UV stebiliti . | Degrades in san lait we nɔ gɛt UV stebyulayza . |

| Limitɛd kemikal rɛsistɛns . | I nɔ kin izi fɔ gɛt strɔng asid ɛn bays dɛn . |

| Di tin dɛn we nɔ go mek di ples wam . | Breaks dɔŋ na ay tempɔret we nɔ gɛt stebyulayza . |

| Di prɔblɛm dɛn we kin apin we pɔsin gɛt bɔnd . | Diflɛnt fɔ bond we nɔ gɛt ɛni tritmɛnt we dɛn nɔ gɛt na di wɔl . |

| Di ay shrinkage na moldin . | Afɛkt dimɛnshɔnal akkuracy di tɛm we dɛn de mek am . |

| Di tin dɛn we wi fɔ tink bɔt we wi de pe fɔ di kɔst . | Higher cost we yu kɔmpia am wit komoditi plastic dɛn . |

| I kin bɔn bɔku bɔku wan . | Burns izi wan witout flame retardants . |

Aplikeshɔn dɛn fɔ PolyoxyMethylene (POM) .

Polyoxymethylene (POM) na wan versatil enjinering plastic we dɛn kin yuz na bɔku bɔku industri dɛn bikɔs ɔf in trɛnk, dimɛnshɔnal stebiliti, ɛn lɔw frikshɔn. Dis dɔŋ ya na di men aplikeshɔn dɛn usay POM ɛksɛl dɛn.

Ɔtomotiv Indastri .

Pom de kip yu motoka de rɔn fayn fayn wan. I de yuz am na:

Dɛn pat ya kin bɛnifit frɔm Pom in trɛnk, lɔw frikshɔn, ɛn kemikal rɛsistɛns.

Ilɛktrikal ɛn ilɛktronik tin dɛn .

Insay di wɔl fɔ ilɛktroniks, Pom de ple impɔtant pat. Yu go fɛn am na:

POM in ilɛktrik insuleshɔn prɔpati dɛn de mek am pafɛkt fɔ dɛn aplikeshɔn dɛn ya.

Di guds dɛn we dɛn de yuz fɔ bay tin dɛn .

Pom de ol roun yu in evride tins:

I de durabiliti ɛn atraktiv finish mek am fayn fɔ kɔshɔma prodak.

Divays dɛn fɔ mɛn pipul dɛn .

Insay wɛlbɔdi biznɛs, POM de mek shɔ se dɛn rili biliv ɛn sef:

POM in bayɔkɔmpatibiliti ɛn kemikal rɛsistɛns rili impɔtant na mɛdikal aplikeshɔn.

Indastrial mashin dɛn .

POM de kip di industri de muv:

I wear resistance ɛn trɛnk de mek am pafɛkt fɔ hevi-duti aplikeshɔn dɛn.

Fluid Handling sistem dɛn .

We i kam pan fɔ manej fluid, POM de shayn:

Pɔmp ɛn Valv dɛn .

Impelers ɛn Fitin dɛn .

Kɔpl dɛn .

Plumbing komponent dɛn .

Pom in kemikal resistans ɛn lɔw mɔstɔ absɔpshɔn na ki ya.

Fɔ mek it .

POM de mek shɔ se dɛn de handle di it fayn fayn wan:

Belt dɛn we dɛn kin yuz fɔ kɔnvaysɔ .

Di pat dɛn we dɛn kin yuz fɔ pak motoka dɛn .

Di tin dɛn we dɛn kin yuz fɔ handle tin fɔ it .

Di kɔntena dɛn fɔ kip tin dɛn .

Food-Grade POM mit strikt sefty standad fɔ dɛn aplikeshɔn ya.

Spɔt ɛn Rikrɛshɔn .

POM ad pefomans to yu pley taim:

Ski binding dɛn .

Ikwipmɛnt fɔ Archery .

Baysikul Komponent dɛn .

Riels fɔ fishin .

I impak resistans ɛn lɔw frikshɔn prɔpati dɛn de ɛp fɔ mek spɔt guds dɛn de ɛp.

Aerospace na di .

Ivin na di skay, Pom gɛt ples:

Pom in laytwɛt trɛnk na valyu na aerospace aplikeshɔn.

Difrɛn difrɛn aplikeshɔn dɛn .

Pom in versatility de go to bɔku ɔda eria dɛn:

| Industry | Common Pom aplikeshɔn dɛn |

| Ɔtomotiv . | Fiul sistem komponent, gia, bushing, valv . |

| Ilɛktrik/Ilɛktroniks . | Kɔnɛkta, Switches, Rilay Hausin, Inshɔlat dɛn |

| Di guds dɛn we dɛn de yuz fɔ bay tin dɛn . | zip, bɔkul, nɔb, fastɛns, tɔys |

| Divays dɛn fɔ mɛn pipul dɛn . | Surgical Instruments, Drug Delivery Systems, Dental Components |

| Indastrial mashin dɛn . | Konveyor komponent, gia, bearing, valv parts |

| Fluid Handling . | Pɔmp, valv, impela, fitin |

| Fɔ mek it . | Packaging Machinery, FDA-kɔmpliant kɔmpɔnɛnt dɛn |

| Spɔt/rikrieshɔn . | Ski bindings, archery equipment, baysikul pat dɛn |

| Aerospace na di . | Struktural komponent, gia, bearings |

| Ɔda | Tekstil mashin, myusikal instramɛnt, kɔnstrɔkshɔn hadwɔd |

POM plastic modifyeshɔn dɛn .

Polyoxymethylene (POM) kin modify fɔ ɛnhans in pefɔmɛns insay spɛshal aplikeshɔn dɛn. Dɛn modifyeshɔn ya tayla Pom in prɔpati dɛm, we mek i ivin mɔ versatile akɔdin to industri dɛm.

Impekt modifyeshɔn .

Want tof pom? Impekt modifyeshɔn na di ansa. Wi de blend pom wit elastomers ɔ ɔda taf polimɛr dɛn. Dis prɔses:

Impact-modified POM na pafɛkt fɔ pat dɛn we nid fɔ bia wit shɔk ɛn vaybreshɔn.

Riinfɔsmɛnt .

Nid fɔ gɛt strɔng pom? Mek wi ad sɔm mɔsul. Wi miks in matirial dɛn lɛk:

Glas fayba dɛn .

Kabon Fayba dɛn .

Minral Filla dɛn .

Dɛn riinfɔsmɛnt ya de bɔst:

Tensile Strɔng .

Stifnɛs .

Dimenshɔnal stebiliti .

Riinfɔs POM na fayn fɔ ay-lɔd aplikeshɔn ɛn strɔkchɔral pat dɛn.

Low-friction modifyeshɔn .

Pom don olredi geht low frikshon, bot wi kin mek am ivin slip. Wi ad se:

PTFE (Teflon)

Silikon .

Grafayt .

Di bɛnifit dɛn na:

Fɔ ridyus frikshɔn kɔfishin mɔ .

Impɔtant wear resistans .

Enhansed self-lubricating prɔpati dɛn .

Dɛn modifyeshɔn ya de mek POM pafɛkt fɔ bia ɛn slaydin kɔmpɔnɛnt dɛn.

Fɔd-grɛd modifyeshɔn .

Sef fɔs! Fɔd-grɛd POM mit strikt rigyuletɔri rikwaymɛnt dɛn. Wi kin ajɔst dis bay we wi:

Yuz FDA-apruv aditiv dɛn .

Implimɛnt spɛshal prɔsesin tɛknik dɛn .

Rigorous Testing ɛn Sɛtifiket .

Fɔd-grɛd POM impɔtant fɔ it prɔsesin ikwipmɛnt ɛn pak.

UV resistans modifyeshɔn .

Mek wi mek pom san-pruf. Wi de ad UV stabiliza ɛn absɔba dɛn to:

Nɔ mek di kɔlɔ nɔ chenj di kɔlɔ .

Mentɛn mɛkanikal prɔpati dɛn .

Ɛkstɛnd di layf we dɛn de liv na do .

UV-resistant POM na impɔtant tin fɔ ɛkstirian ɔtomotiv pat ɛn ɔda ikwipmɛnt.

Nanocomposite modifyin di .

Taim fo som hai-tech tweaks. Wi inkorporet nanomaterials laik:

Dɛn smɔl smɔl tin dɛn ya we dɛn ad kin mek dɛn ebul fɔ mek big big tin dɛn bɛtɛ:

Enhansed Mechanical Properties .

Impɔtant tɛmral stebiliti .

Bɛtɛ barɛri prɔpati dɛn .

Nanocomposite POM de push di bɔda dɛn fɔ pefɔmɛns insay diman aplikeshɔn dɛn.

Na dis wan na wan kwik ɔvaviu fɔ POM modifyeshɔn dɛn:

| modifyeshɔn | ki aditiv dɛn | Men bɛnifit dɛn |

| Afɛkt | Elastomers . | Toughness, Fleksibul . |

| Riinfɔsmɛnt . | Glass/Kabɔn Fayba dɛn . | Strɔng, Stifnɛs . |

| Low-friction . | PTFE, silikon . | Ridyus Wear, Bɛtɛ Lubrikeshɔn |

| Fɔd-grɛd . | Di aditiv dɛn we FDA dɔn gri fɔ ad pan . | Sef fɔ kɔntakt it . |

| UV-Isistɛnt . | UV stɛbyulayza dɛn . | Di Durability we de na do fɔ lɔng tɛm . |

| Nanocomposite na na na na na na na na na na na na na na na na na na na na na na na na na na na na na na na | Nanomaterials na di . | Oval Pɛfɔmɛns Boost . |

Dɛn modifyeshɔn ya de ɛkspɛn Pom in kapabiliti, we mek i ivin mɔ versatile ɛn valyu akɔdin to industri dɛm.

POM Plastik Prosɛsin Mɛtɔd dɛn .

Pom plastic kin bi proses tru difrɛn we dɛn, ɛni wan de gi spɛshal bɛnifit fɔ difrɛn aplikeshɔn dɛn. Dis dɔŋ ya na di kɔmɔn tɛknik dɛn we dɛn kin yuz fɔ shep ɛn prodyuz POM kɔmpɔnɛnt dɛn.

Moldin fɔ injɛkshɔn .

Injɛkshɔn moldin na di we we dɛn kin yuz pas ɔl fɔ POM. I fayn fɔ mek dɛn prodyuz ay-volyum ɛn i de mek dɛn ebul fɔ mek kɔmpleks jɔyometri wit ay prɛsishɔn. Dis we aw dɛn de du tin kin wok fayn ɛn dɛn kin yuz am bɔku tɛm na industri dɛn lɛk ɔtomotiv ɛn ilɛktroniks.

| Advantej dɛn fɔ injɛkshɔn moldin | ditil dɛn . |

| Di prodakshɔn we gɛt ay vɔlyum . | Kost-effektiv fɔ mas manufakchurin . |

| Kɔmpleks jɔyometri dɛn . | Enables intricate shep ɛn dizayn dɛn . |

| Tayt Tolerances . | Achieves high akchualiti fɔ prɛsishɔn kɔmpɔnɛnt dɛn . |

Ekstrushɔn .

Dɛn kin yuz di ɛkstrushɔn prɔses fɔ mek shit, rod, ɛn tiub frɔm POM. Bɔku tɛm dɛn pat ya kin sɛmi-finish ɛn dɛn kin nid fɔ mek mɔ mashin lɛk fɔ kɔt, tɔn, ɔ mil fɔ mit prɛsis spɛsifikɛshɔn dɛn.

| Advantej dɛn fɔ | di ditel dɛn bɔt ɛkstrushɔn . |

| Kɔntinyu fɔ prodyuz . | I de mek lɔng lɔng tin dɛn fɔ yuz . |

| versatile shep dɛn . | I fayn fɔ mek rod, sheet, ɛn tiub . |

| Fɔ mek mashin dɛn go bifo mɔ . | Bɔku tɛm dɛn kin nid am fɔ di las pat we de shep . |

Machining .

POM na rili fayn fɔ mashin , we inklud prɔses lɛk fɔ tɔn , mil , ɛn drɔ . Bikɔs ɔf in dimɛnshɔnal stebiliti , POM na fayn fɔ pat dɛn we nid tayt tolɛreshɔn . Dis we ya na tin we dɛn kin yuz we prɛsishɔn impɔtant, lɛk na di aerospace ɛn medikal divays industri.

3D Printing we dɛn de yuz fɔ print .

POM kin bi bak we dɛn de yuz 3D printin tɛnkɔlɔji dɛn, mɔ di fuz filament fabrikeshɔn (FFF) ɛn sɛlɛktiv lɛsa sinta (SLS) . Pan ɔl we i nɔ bɔku, 3D printin de alaw fɔ mek kɔmpleks protɔtayp ɛn smɔl-smɔl prodakshɔn rɔn. I rili fayn fɔ yuz fɔ aplikeshɔn usay tradishɔnal moldin kin tu kɔst ɔ tek tɛm.

| Advantej dɛn fɔ 3D printin | ditil dɛn . |

| Prototayp Krieshɔn . | Ideal fɔ prodyuz kɔmpleks ɛn kɔstɔm dizayn dɛn . |

| Ridyus Lid Tayms . | Fasta prodakshɔn fɔ smɔl-smɔl rɔn dɛn . |

| Fleksibul dizayn modifyeshɔn dɛn . | I izi fɔ mek chenj dɛn to dizayn protɔtayp dɛn . |

Disain wit pom plastic .

We dɛn de disayn kɔmpɔnɛnt dɛn we de yuz POM plastic , we dɛn tek tɛm pe atɛnshɔn to sɔm patikyula dizayn ɛlimɛnt dɛn kin rili ɛp fɔ mek di pefɔmɛns ɛn di we aw dɛn de mek tin dɛn wok fayn fayn wan. Na di men tin dɛn we wi fɔ tink bɔt fɔ mɛmba.

Di tin dɛn we yu fɔ tink bɔt na di wɔl .

Fɔ mek di wɔl tik rayt na impɔtant tin. Na dis yu nid fɔ no:

Aim fɔ yunifom tik .

Di renj we dɛn kin advays: 1.5 to 3.0 mm

Di wɔl dɛn we tik pasmak kin mek di tɛm we dɛn kin kol kin mek dɛn kol ɛn dɛn kin mek dɛn gɛt mak dɛn we kin sink .

Tinna wɔl dɛn nɔ go ful-ɔp fayn fayn wan .

Pro Tip: Yuz rib ɔ gusset fɔ riinfɔs tin wɔl dɛn instead fɔ inkrisayz ɔl di tik.

Draft angles fɔ mol .

Draft angles na yu padi in injekshɔn moldin. Dɛn kin ɛp pat dɛn fɔ kɔmɔt na di mol izi wan.

Fɔ Pom, tink bɔt:

Minimum draft angle: 0.5°

Di draft angul we dɛn kin yuz: 1° to 2°

Inkris draft fɔ tɛkstɔr sɔfays dɛn .

Mɛmba: Mɔ draft min se i izi fɔ pul ɛn nɔ gɛt bɔku mak na yu pat.

Snap Fits ɛn Livin Hinges .

Pom in fleksibiliti mek am fayn fɔ snap fit ɛn liv hinj. Na dis na aw fɔ disayn dɛn:

Snap fit dɛn:

Livin hinj dɛn:

Dɛn tin ya kin ridyus di tɛm we dɛn kin kɔnt di pat ɛn di tɛm we dɛn kin gɛda.

Fɔ avɔyd shap shap kɔna dɛn .

Shap kɔna dɛn na strɛs kɔnsɛntreta dɛn. Dem na bad nyus fo pom parts. Bifo dat:

Yuz jenaros radii pan ɔl kɔna .

Minimum rekomend rayus: 0,5 mm

Big big radii de mek di flɔ go bifo ɛn ridyus strɛs .

Smooth curves mek fɔ strɔng, mɔ durable pat dɛn.

Akɔntin fɔ Shrinkage .

Pom de shrink as i de kol. Plan fɔ am na yu dizayn dɛn.

Tipik shrinkage ret:

Pom homopolymer: 1,8% to 2,2%

Pom kopolimer: 1,5% to 2,0%

Factors we de afɛkt shrinkage:

Kɔmpɛns bay we yu ɔvasayz yu mold kaviti smɔl.

Na dis na wan kwik dizayn chɛklist fɔ POM pat dɛn:

| Dizayn Ɛlimɛnt | Rikɔmɛndishɔn |

| Tiknes fɔ di wɔl . | 1,5 - 3,0 mm |

| Draft angle . | 1° - 2° . |

| Radius we de na kɔna . | ≥ 0,5 mm |

| Snap Fit UnderCut | 1.0 - 1.5 × Tiknes |

| Livin hinge tiknes . | 0,3 - 0,5 mm |

| Shrinkage alawɛns . | 1.5% - 2.2% |

We yu kɔmpia POM plastic to ɔda matirial dɛn .

Mek wi stak pom op agenst som oda popular matiryal dem. Yu go si wetin mek bɔku tɛm na di tɔp chuk fɔ bɔku aplikeshɔn dɛn.

Pom vs. Nylon: Uswan bɛtɛ?

Pom ɛn naylon na ɔl tu versatile thermoplastics. Bɔt dɛn dɔn gɛt dɛn yon trɛnk:

POM Advantej dɛn:

Naylon Advantej dɛn:

Di trɛnk we gɛt ay impak .

Bɛtɛ kemikal rɛsistɛns to sɔm tin dɛn .

Bɔku tɛm dɛn kin pe smɔl mɔni .

Di wan dɛn we nɔ ebul fɔ fɛt ɔp .

Pik POM fɔ prɛsishɔn pat dɛn na wet ɛnvayrɔmɛnt. Go fɔ naylon we yu nid taf ɛn ɔt rɛsistɛns.

Pom plastic vs. polybutylene terephthalate (PBT)

POM ɛn PBT kin gɛt nɛk-ɛn-nɛk insay injinɛri aplikeshɔn dɛn. Mek wi brok am dɔŋ:

Pom Strɔng dɛn:

PBT Strɔng dɛn:

Bɛtɛ ilɛktrik prɔpati dɛn .

Di wan dɛn we nɔ ebul fɔ fɛt ɔp .

I izi fɔ mek dɛn mol .

Bɔku tɛm dɛn kin gɛt mɔ kɔst-ɛfɛktiv .

Pom de shayn insay mɛkanikal aplikeshɔn dɛn. PBT tek di lid in ilektrikal ɛn ay-ɔt sɛnɛriɔ.

Aw POM kɔmpia to ɔda injinɛri plastic dɛn .

Pom de ol in yon agens bɔku injinɛri plastic dɛn. Na dis wan na wan kwik kɔmpiashɔn:

| Prɔpati | Pom | Abs | PC | Peek |

| Trɛnk | Ay | Soba | Ay | Na rili ay . |

| Stifnɛs . | Ay | Soba | Ay | Na rili ay . |

| Wear resistans . | Wɛl dɔn | Pɔ | Soba | Wɛl dɔn |

| Kεmikכl rεsistεns . | Gud | Soba | Pɔ | Wɛl dɔn |

| Pe | Soba | Lo | Soba | Na rili ay . |

POM de gi wan balans miks fɔ prɔpati dɛn we gɛt rizin fɔ pe fɔ am. Bɔku tɛm na di go-to fɔ:

Pat dɛn we nid ay prɛsishɔn .

Komponent dɛn we gɛt pat dɛn we de muv .

Aplikeshɔn dɛn we nid lɔw frikshɔn .

Peek kin autperform pom in ekstrim kondishon, bot at a much higher prais. ABS na cheaper bot no kin mach Pom in mechanical propati.

Mɛmba se, di tin dɛn we yu go pik fɔ du, dipen pan di patikyula tin dɛn we yu nid. Tink bɔt tin dɛn lɛk:

Dɔn

Pom plastic , ɔ polyoxymethylene, de gi ay trɛnk , lɔw frikshɔn , ɛn fayn fayn dimɛnshɔnal stebiliti . Na wan impɔtant tin na industri dɛn lɛk ɔtomotiv , ilɛktroniks , ɛn mɛdikal divays dɛn . Di wok we Pom de du na di mɔdan manufakchurin de kɔntinyu fɔ gro bikɔs i gɛt bɔku tin dɛn fɔ du ɛn i go de fɔ lɔng tɛm . If yu nid komponent wit kemikal resistans ɔ prɛsishɔn , POM de deliver rilibul pefɔmɛns akɔs difrɛn aplikeshɔn dɛn.

Tips: Yu maybe intres to di ol plastics