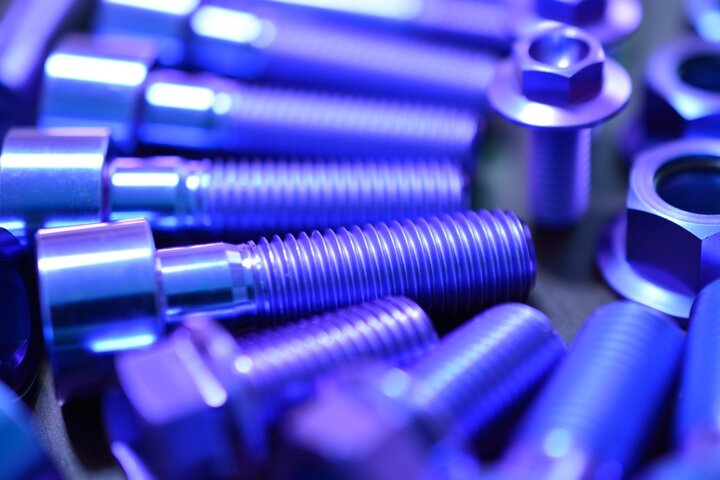

Shin ka taɓa yin mamakin yadda sassan ƙarfe a cikin samfuran yau da kullun suna kula da bayyanarsu mai haske kuma suna tsayayya da lalata? Amsar tana kwance a cikin dabarun gama gari kamar aniding da electiplating. Wadannan hanyoyin inganta kaddarorin na kayan ƙarfe, amma suna aiki a hanyoyi daban-daban.

Anodizing da baza'a da ba za a yi amfani da su guda biyu da aka yi amfani da su don inganta karko ba, juriya na lalata jiki, da bayyanar da sassan ƙarfe. Duk da yake duka dabarun biyu sun haɗa da matakai masu amfani, sun bambanta a cikin hanyarsu da sakamakon da suka fito.

A cikin wannan labarin, zamu bincika mahimman bambance-bambance tsakanin iredizing da electroplating. Za ku koya game da halaye na musamman na kowane tsari, ana iya amfani da karafa da za a iya amfani da su, da kuma aikace-aikace na saba a masana'antu daban daban. Ta hanyar fahimtar wadannan bambance-bambancen, za ku fi wadatattun kayan da za ku zabi dabarun karewa na dama don takamaiman bukatunku, ko kuna kan masana'antu, ƙirar samfur, ko injiniyanci ne, ko injiniya.

Fahimtar ADDIZID

Tsarin Adizing

Anodizing tsari ne na gari wanda ke inganta yanayin atide na halitta akan saman karfe, musamman aluminum. Ya ƙunshi ƙasa da ƙarfe a cikin wanka na lantarki da kuma amfani da wutar lantarki. Wannan yana haifar da iskar oxygen don amsawa tare da farfajiyar karfe, ƙirƙirar kauri, mafi yawan rarar jabu.

A lokacin anizing, karfe na karfe kamar yadda take a cikin sel na lantarki. A lokacin da ake amfani da wutar lantarki, ion oxygen daga electrollyte tare da kayan zina na aluminum a farfajiya. Suna samar da aluminium oxide wanda ke da wahala da ƙari a lalata da yawa fiye da ƙarfe kanta.

Tsarin lantarki wanda ya gina Layer na oxide ta hanyar sarrafawa a hankali:

Aluminum a cikin wayoyin hannu na saki kuma sun zama tilas a yi masa alkawarin ions.

Wadannan ions suna ƙaura zuwa cikin Layer na iri-iri na data kasance masu amfani.

A lokaci guda, mara kyau cajin Oions oions daga electrolyte zuwa saman ƙarfe.

Oxygen da aluminumenumiyar da aka amsa, suna samar da aluminum oxide (Al2o3) a farfajiya.

Kamar yadda wannan tsari yana ci gaba, da oxide cerse yana girma da kauri, samar da ingantaccen kariya da karkara.

Nau'in tsinkaye

Akwai manyan nau'ikan nau'ikan aniding guda uku, kowannensu tare da keɓaɓɓun kaddarorin da aikace-aikace:

Yayin da aluminum shine mafi yawan ƙarfe ƙarfe, tsari kuma ana iya amfani da shi zuwa Titanium, magnesium, da sauran karafa masu ba da labari.

Chromic acid Anodize (nau'in i)

Chromic acid Anodize (CAA), ko nau'in i giri, yana haifar da bakin ciki, m, m, m, + m m amfani da compom acid. A sakamakon fim ya fi girma fiye da sauran nau'ikan anning amma yana ba da kyakkyawan juriya na lalata. Ana amfani da Caa a aikace-aikacen Aerospace inda ake so Layer.

Sulfurcic ii (nau'in II da IIB)

Acid acid andodize (saa), ko nau'in ii anizing, shine nau'in yau da kullun. Yana amfani da sulfuric acid kamar yadda waƙar lantarki, sakamakon shi da tabo iide na II, sanya shi dace da samfurori na lalata.

Rubuta IIB wani bambance ne na nau'in II, yana samar da wani nau'in bakin ciki fiye da Standard Pype II. Yana ba da ma'auni tsakanin fim ɗin bakin ciki ni da kuma alkalami Layer na II.

Hard Aododize (nau'in III)

Wornize mai wuya, ko nau'in girudizing, yana amfani da ƙarin mai da hankali sulfuric acid actrololyte da mafi girman ƙarfin lantarki don samar da lokacin farin ciki, wuya oxide Layer. A sakamakon farfajiya yana da matukar tsayayya da kuma mawadewa, yana sa ya dace da aikace-aikacen masana'antu kamar kayan haɗin Aerospace, sassan kayan masarufi, sassan kayan masarufi, da kuma manyan sassan.

Hard Areodized yana ba da babbar juriya da juriya da lalata jiki idan aka kwatanta da sauran nau'ikan. Yana ba da dadewa, ƙarewar kariya wanda zai iya tsayayya da matsanancin yanayin da damuwa na inji.

Fa'idodi da iyakoki na aniding

Fa'idodin Anodiz

Anodized yana ba da fa'idodi masu yawa:

Inganta Layer juriya : The Swead ohinside Layer yana kare ƙarfe mai rauni daga lalata, har ma a cikin matsanancin mahalli.

Ingantaccen tsananin ƙarfi da kuma sanya juriya : anodized saman suna da wahala kuma mafi jure wa farrasion da sa, shimfida rayuwar ƙarfe.

Zaɓuɓɓukan launuka masu dorawa ta hanyar dye : opide na opide Layer na iya ɗaukar distes, ba da izinin kewayon launi mai kyau na ado.

Abubuwan rufe wutar lantarki na wutar lantarki : shimfidar riga ba mai warwarewa bane, sanya su dace da aikace-aikacen shigowar wutar lantarki.

Tsarin tsabtace muhalli : Anodizing shine mai tsabta mai tsabta da kuma sada zumonin tsabtace muhalli idan aka kwatanta da sauran jiyya.

Iyakantarwa na Anodizing

Duk da amfanin sa, anodizing yana da wasu iyakoki:

Litaizin wasu ƙananan ƙarfe : Anodizing aiki mafi kyau akan aluminium da titanium. Ba shi da tasiri ko bai dace da sauran karafa ba.

Layer na bakin ciki idan aka kwatanta da wasu mayuka : yayin da kayan girke-girke yana ba da kariya mai kyau, oxide Layer ya kasance mai bakin ciki idan aka kwatanta da wasu sauran jiyya.

Ya karu da rikice-rikice a wasu allures : tasirin hardening na aniding na iya sa wasu aluminium sun fi soji da ƙarfi ga fatattaka.

Babban farashi na adadi kaɗan : Anodizing na iya zama mafi tsada fiye da sauran abubuwan fitarwa saboda ƙarancin kuɗin da aka tsara.

Fahimtar jimla

Tsarin Lawiri

Lalacewar tsari ne wanda ke amfani da wutar lantarki don ɗaukar abu mai ƙarfe tare da bakin ciki na wani ƙarfe. Yana haɓaka bayyanar substrate ta, juriya na lalata cuta, gudanarwa, da sauran kaddarorin. Abun da aka fi amfani da su da aka fi amfani da su a cikin leleplating ne chromium, nickel, jan ƙarfe, zinariya, da azurfa.

A cikin eleconating, abin da za a buga (substrate) ya nutse cikin mafita na lantarki wanda ya ƙunshi narkar da ƙwararrun ƙirar karfe. Ana amfani da kai tsaye na yanzu, tare da substrate yana aiki kamar Katasa da electrode na ƙarfe (ƙarfe na ƙarfe) kamar yadda take. A halin yanzu da ke haifar da ions mara karfe don yin ƙaura zuwa substrate kuma samar da bakin ciki, mai mahimmanci.

Tsarin leleplating ya shafi wadannan matakai:

Tsaftacewa da shiri na substrate surfrate

Nutsewa na substrate da obinode a cikin wanka na lantarki

Aikace-aikacen kai tsaye don fara hiona na karfe

Ajiya na pla m karfe a kan subrate surfrate

Rinsing da kuma bayan-magani na abun ciki

Nau'in da bautar da aikace-aikace

Za'a iya rarrabe masu ba da hankali cikin nau'ikan biyu:

Abubuwan da ke ado na ado : Haɓaka bayyanar abubuwa da kyan gani, mai haske, ko karfe mai launi na gama gari. Misalai sun haɗa da datsa daskararren motoci da kayan adon zinare.

Ayyukan ruwa na aiki : Inganta takamaiman kaddarorin na substrate, kamar juriya na lalata, sanadin juriya, ko keta hali. Ana amfani da wannan nau'in sosai a aikace-aikacen masana'antu.

Wani nau'in parring, kayan ado maraƙi, baya buƙatar asalin yanayin yanzu. Madadin haka, ya dogara ne akan ɗaukar sinadarai don adan ƙarfe a kan substrate.

Nickel farantin

Nickel farantin ana amfani dashi sosai a cikin masana'antu daban-daban don kyakkyawan lalata da kuma sanya juriya. Yana ba da kariya da kayan ado gamawa ga sassan ƙarfe a cikin mota, Aerospace, kayan lantarki, da samfuran masu amfani. Nickel Plating shima yana aiki a matsayin inccoat na sauran hanyoyin shirya, kamar chromium play.

CHromium play

Chromium playing yana ba da haske, mai haske, da kuma gamsuwa da cewa inganta abubuwan da suka dace da abubuwa yayin samar da juriya. Ana amfani dashi akan sassan motoci na kayan gida, kayan santsi, da kayan masana'antu. Chromium play na iya zama ado ko wahala, dangane da bukatun aikace-aikacen.

Jan ƙarfe da silver na azurfa

An yi amfani da faranti mai ƙarfi a cikin masana'antar lantarki saboda kyakkyawan aikinsa da kyakkyawan aikin sa da sashen. Ana amfani da shi ga allon katako, masu haɗin, da sauran abubuwan haɗin lantarki. Plating na ƙarfe kuma yana aiki azaman inccoat na sauran hanyoyin shirya, kamar nickel da chromium.

Azurfa ta azurfa, kamar jan ƙarfe, yana ba da babban aikin lantarki kuma ana amfani da shi a cikin lambobin lantarki, sauya, da masu haɗin kai. Masana'antar Aerospace tana amfani da suturar sutura don kyakkyawan aikinsa da kayan anti-galling kaddarorin.

Fa'idodi da rashin amfanin karfin zuciya

Abbuwan amfãni na da ba da karanci

Baƙi yana ba da fa'idodi da yawa:

Za'a iya ajiye kayan ƙarfe da yawa, suna ba da izinin ɗaukakawa a aikace-aikace.

Inganta lalata juriya yana shimfida rayuwa ta kayan kwalliya.

Inganta aikin lantarki yana sa ya dace da kayan aikin lantarki.

Kayan ado na ado tare da makamai daban-daban na samar da roko na musamman.

Gyara da kuma dawo da abubuwan da aka sa a saman abubuwan da aka sawa ta hanyar electiplating.

Rashin daidaituwa na lantarki

Duk da amfaninta, da baza'a da wasu halaka:

Tsarin ya ƙunshi sinadarai masu guba da ƙarfe masu nauyi, wanda zai iya haifar da haɗarin muhalli idan ba'a gudanar da shi sosai ba.

Baƙi yana cinye babban adadin kuzarin lantarki, yana sa shi kuzari-m.

Ma'aikata na iya fuskantar haɗarin kiwon lafiya yana fuskantar matsalolin kiwon lafiya saboda bayyanar da sunadarai masu haɗari. 4.Starinalan shawarwari na sharar 4.Starinent wajibi ne don hana gurbata muhalli.

Bincike na Comporative

Matsa bambance-bambance tsakanin ADDizing da electionating

Mai gadi Forcearshe da ba da jimawa ba sun bambanta hanyoyin magance hanyoyin ƙasa tare da bambance-bambancen asali a cikin hanyoyin su da sakamakon. Anodizing siffofin kariya na ganye na kariya a farfajiya, yayin da ba za a iya yin ajiyar abubuwa a cikin wani ƙarfe na wani ƙarfe ba a substrate.

Anodiz da farko ana amfani dashi ga aluminium da titanium, yayin da za'a iya amfani da electiplating da yawa, ciki har da ƙarfe, jan ƙarfe, da tagulla. Tsarin gyara yana samar da wani yanki mai laushi na bakin ciki idan aka kwatanta da karancin ƙarfe wanda ba za ~ eleflating ba.

Kayan kwalliyar sutturar sun banbanta:

Matsakaicin muhalli, Anodized an dauke shi da aminci, kamar yadda bai ƙunshi karafa masu yawa ba. Ba za a iya haifar da hatsarin muhalli da hatsarin lafiya ba saboda amfani da magungunan guba.

| Bangare | na | aske |

| Hanyar sarrafawa | Kimanin Layer na oxide | Aikata Layer Layer |

| Metals da aka yi amfani da shi | Prian aluminum da titanium | Karuwa daban-daban (karfe, jan ƙarfe, da sauransu) |

| Inating kauri | Yanayi na Thinner | Yadudduka masu kauri |

| Ƙanƙanci | Sama | Saukad da |

| Sa juriya | Sama | Saukad da |

| Yin aiki | Saukad da | Sama |

| Tasirin muhalli | Gabaɗaya mafi aminci | M haɗarin daga sunadarai |

Aikace-aikacen Anodizing da electroplating

Anodizing ya sami amfani sosai a cikin Aerospace, kayan aiki, da masana'antar kayan amfani da kayayyaki. Abubuwan aluminum na aluminum sun zama ruwan dare a cikin abubuwan haɗin jirgin sama, kayan aikin gine-gine, da kuma kayan lantarki. Tsarin yana ba da juriya na lalata, karkara, da zaɓuɓɓukan ban sha'awa ga waɗannan aikace-aikacen.

Ba'a amfani da ku ba da amfani sosai a cikin mota, lantarki, kayan ado, da masana'antu aeraspace. Misalai sun hada da:

CHROME-plated mota mota da ƙafafun

Kayan ado na zinariya da kayan lantarki

Nickel-plated Aerospace abubuwan

Jan ƙarfe-sanyi buga da'irar da'irar

Zabi tsakanin Anodizing da baza'a dogara da takamaiman bukatun aikace-aikace ba, kamar su substrate baƙin ƙarfe, abubuwan da ake so, da la'akari da la'akari da muhalli.

Abubuwan yanke shawara a cikin zaɓin tsakanin awo da ba da izini

A lokacin da yanke shawara tsakanin ayodizing da ba da damar, la'akari da waɗannan abubuwan:

Substrate Karfe: Anodizing ya dace da aluminium da titanium, yayin da za a iya amfani da leleplantating zuwa ga karafa daban-daban.

Properties da ake so: Anodized yana ba da mafi kyawun sa juriya da kuma taurin kai, yayin da electroplating ke ba da kyawawan ayyuka da zaɓuɓɓukan masu ado.

Kudin: Anodizing shine mafi tsada mai tsada don ayyukan-sikelin, yayin da electiplating na iya zama tattalin arziƙi don ƙananan batir.

Tasirin muhalli: Anodizing ana son fi son haɗarin yanayin muhalli da kiwon lafiya idan aka kwatanta da ba da damar.

An fi son maganin lokacin da:

Subanium ne aluminum ko titanium.

Ana buƙatar babban abin juriya da wuya.

Mai dorewa, ana son cin nasarar lalata cututtuka.

Damuwa na muhalli muhimmin fifiko ne.

Ana fifita kuɗaɗe lokacin da:

Substrate shine ƙarfe ban da aluminium ko titanium.

Aikin lantarki yana da mahimmanci.

Ana so da yawa na kayan ado na ado.

Lokacin farin ciki, ana buƙatar coan kariya.

A wasu halaye, za a iya haɗe abubuwa biyu, kamar amfani da aniding azaman pre-jiyya kafin electroplating. Wannan hade zai iya inganta m da ƙwararrun mai da aka zaɓa.

Daga qarshe, zaɓi tsakanin Anodizing da baza'a dogara da takamaiman bukatun aikace-aikacen ba. Yi la'akari da kayan, kaddarorin da ake so, farashi, da dalilai na muhalli don zaɓar hanya mafi dacewa don bukatunku.

Faqs

Tambaya: Za a iya duka ƙarfe da marasa ƙarfe za'a riga andozed?

A'a, wasu ƙananan ƙarfe kamar aluminium, titanium, da magnesium za a iya girki. Rashin ƙarfe da sauran karafa kamar ƙarfe ba zai iya samar da Layer da ake buƙata ba, lokacin girka.

Tambaya: Menene tasirin tasirin muhalli da ba zaitin ba?

Anodized an yi la'akari da shi sosai fiye da tsabtace muhalli. Ba ya zama babban ƙarfe da sunadarai masu guba, suna sa ya fi aminci ga ma'aikata da sauƙi a sarrafa sharar gida.

Tambaya: Ta yaya farashin tanada ya kwatanta da zaɓar da zaɓar da zaɓar da za a iya kwatanta su da manyan ayyukan sikeli?

Anodizing na iya zama mafi tsada sosai fiye da electiplating don manyan ayyuka. Kudin saiti da lokacin sarrafawa don haɓakawa sau da yawa suna ƙasa, musamman lokacin da muke ma'amala da sassan aluminum.

Tambaya: Waɗanne ne shawarwarin warware matsalar gama gari don tafiyar matakai?

Don duka aniding da ba da damar, shirye-shiryen farfajiya yana da mahimmanci. Tabbatar da sassan suna da tsabta kuma kyauta daga ƙazantu. Saka idanu da abubuwan da ake ciki da kuma kula da yawan zafin jiki da zazzabi don ingantaccen sakamako.

Ƙarshe

Anodizing da bautar da ba da kyauta don ƙarin fa'idodi daban don ƙarfe farfajiya. Anodizing siffofin kariya na kaya na kariya, yayin da ba za a iya ba da damar adana kayan ƙarfe ba a kan substrate. Zabi ya dogara ne akan dalilai kamar gindin karfe, kayan da ake so, da kuma tasirin muhalli.

Kowane dabarar tana da takamaiman aikace-aikace a masana'antu kamar Aerospace, kayan aiki, lantarki, da kayayyakin masu amfani.

Yi la'akari da takamaiman bukatunku lokacin zaɓi tsari na gama gari. Yi shawara tare da masana don sanin mafi kyawun zaɓi don aikinku.

Zabi Anodizing don aluminium ko sassan titanium suna buƙatar juriya na lalata da karko. Ficewa don karfin liyaye lokacin da ake aiki ko roko na ado yana da mahimmanci ga sauran karafa.

Fahimtar bambance-bambance tsakanin Anodizing da ba da damar yanke shawara na sanar da sanarwar da ke inganta aiki, farashi da dorewa.