Yu dɔn ɛva wɔnda aw mɛtal pat dɛn na ɛvride prɔdak dɛn de mentɛn dɛn shayn luk ɛn nɔ gri fɔ kɔrɛshɔn? Di ansa de insay di surface finishing teknik dɛm lɛk anodizing ɛn ilɛktroplɛtin. Dɛn prɔses ya de ɛp fɔ mek di prɔpati dɛn we di mɛtal kɔmpɔnɛnt dɛn gɛt, bɔt dɛn de wok difrɛn we dɛn.

Anodizing ɛn ilektropletin na tu kɔmɔn we dɛn we dɛn kin yuz fɔ mek di tin dɛn we de mek dɛn nɔ go de fɔ lɔng tɛm, di we aw dɛn nɔ de kɔrɛshɔn, ɛn di we aw dɛn kin luk di mɛtal pat dɛn. Pan ɔl we ɔl tu di tɛknik dɛn gɛt fɔ du wit ilɛktrɔkɛmik prɔses, dɛn difrɛn pan di we aw dɛn de du tin ɛn di rizɔlt dɛn we dɛn de mek.

Insay dis atikul, wi go fɛn ɔl di men difrɛns dɛn bitwin anodizing ɛn ilɛktroplɛtin. Yu go lan bɔt di spɛshal kwaliti dɛn we ɛni prɔses gɛt, di mɛtal dɛn we dɛn kin aplay to, ɛn dɛn tipik aplikeshɔn dɛn na difrɛn industri dɛn. We yu ɔndastand dɛn difrɛns ya, yu go gɛt bɛtɛ ɛkwipmɛnt fɔ pik di rayt sɔfays finish tɛknik fɔ yu spɛshal nid dɛn, ilɛksɛf yu de na manufakchurin, prɔdak dizayn, ɔ injinɛri.

Fɔ ɔndastand anodizing .

Di anodizing prɔses .

Anodizing na wan ilektrokemical proses we de enhans di natura oksayd layt pan metal surface, patikula aluminium. I involv fɔ pul di mɛtal insay wan ilɛktrɔlaytik bat ɛn put ilɛktrik kɔrɛnt. dis kin mek di כksijεn ayכn dεm riak wit di mεtal sεf, we de mek wan tik, mכr resilient כksid layεr.

durin anodizing, di mεtal de akt lεk di anכd insay di ilektrolaytik sεl. We dɛn put ilɛktrishɔn, ɔksijɛn ayɔn dɛn frɔm di ilɛktrɔlayt bɔnd wit aluminiɔm atɔm dɛn na di sɔfa. Dɛn kin mek wan aluminiɔm ɔksayd layt we at ɛn we nɔ de kɔrɛshɔn pas di mɛtal sɛf.

di ilektrokemכnik mεkanism de bil di כksid layεr tru wan prכsεs we dεn tek tεm kכntro:

aluminium atom dεm na di surface rilis εlektrכn dεm εn bi positifu chכj ayכn dεm.

dis ayכn dεm de muv tru di כksid layεr we de naw tכwεd di ilektrolayt.

di sem tεm, nεgεtiv chaj כksijεn ayכn dεm de muv frכm di ilektrolayt tכwεd di mεtal sεf.

di כksijεn εn aluminium ayכn dεm de riak, we de fכm aluminium כksid (AL2O3) na di sכfayz.

as dis prכsεs de kכntinyu, di כksid layεr de gro tik, we de gi εnhans protεkshכn εn we go de te.

Tayps of anodizing .

Tri men kayn anodizing de, ɛn ɛni wan pan dɛn gɛt difrɛn prɔpati ɛn aplikeshɔn dɛn:

Wail aluminium na di mכst kכmכn anodized mεtal, dεn kin aplay di prכsεs bak to taytanium, magnεsium, εn כda nכnfεr mεtal dεm.

Kromik asid anodize (Tayp I) .

Kromik asid anodize (CAA), ɔ tayp I anodizing, de prodyuz wan tin, dense ɔksayd layt we de yuz kromik asid as di ilɛktrɔlayt. Di rizultin film soft pas oda anodizing taip bot ofa gud koroshon resistans. Bɔku tɛm dɛn kin yuz CAA na aerospace aplikeshɔn usay dɛn want wan tin, protɛktiv layt.

Sɔlfɔrik anodize (Tayp II ɛn IIb)

Sɔlfɔrik asid anodize (SAA), ɔ tayp II anodizing, na di kayn we we dɛn kin yuz mɔ. I de yuz sɔlfɔrik asid as di ilɛktrɔlayt, we de rilizɔt wan tik ɔksayd layt pas tayp I. Tayp II anodizing de gi fayn fayn wear ɛn kɔrɛshɔn rɛsistɛns, we de mek i fayn fɔ akitɔk, ɔtomotiv, ɛn kɔshɔma prɔdak.

Tayp IIb na wan vεryכnt fכ tayp II, we de prodyuz wan tinna layεr pas standad tayp II. I de gi balans bitwin di tin film we de na Tayp I ɛn di tik layt we de na Tayp II.

Had anodiz (Tayp III) .

Had anodize, ɔ tayp III anodizing, de yuz wan mɔ kɔnsɛntret sɔlfɔrik asid ilɛktrɔlayt ɛn ay vɔltɛm fɔ prodyuz wan tik, had ɔksayd layt. Di surface we de kɔmɔt de rili wear-resistant ɛn i de te, we mek i fayn fɔ industrial aplikeshɔn dɛn lɛk aerospace komponent, mashin pat, ɛn ay-wea sɔfays.

Hard anodizing de gi supia abrashɔn ɛn kɔrɛshɔn rɛsistɛns kɔmpia to ɔda kayn dɛn. I de gi wan lɔng-last, protɛktiv finish we kin ebul fɔ bia wit harsh ɛnvayrɔmɛnt ɛn mɛkanikal strɛs.

Benefit ɛn limiteshɔn fɔ anodizing .

Benefit fɔ anodizing .

Anodizing de gi sɔm impɔtant bɛnifit dɛn:

Improved Corrosion Resistance : Di tik ɔksayd layt de protɛkt di ɔndalayn mɛtal frɔm kɔrɛshɔn, ivin na harsh ɛnvayrɔmɛnt.

Enhanced surface hardness and wear resistance : anodized surfaces de harda ɛn dɛn de resist to abrasion ɛn wear, we de ɛkstɛnd di layf fɔ di mɛtal.

Dekorativ kala opshon tru Dyeing : Di porous oxide layt kin absorb day, alaw fɔ wan big renj ɔf dekorativ kala finish.

Ilektrikal Insuleshɔn Prɔpati : Anodized layers na nɔ-kɔnduktiv, we de mek dɛn fit fɔ ilɛktrik insuleshɔn aplikeshɔn.

Envayrɔmɛnt frɛndli prɔses : Anodizing na rili klin ɛn envayrɔmɛnt frɛndli prɔses we yu kɔmpia am wit ɔda sɔfayz tritmɛnt dɛn.

Limiteshɔn dɛn fɔ anodizing .

Pan ɔl we i de bɛnifit, anodizing gɛt sɔm tin dɛn we i nɔ ebul fɔ du:

Limited to sɔm mɛtal dɛn : Anodizing de wok bɛst pan aluminiɔm ɛn taytaniɔm. I nɔ kin wok fayn ɔ i nɔ kin fayn fɔ ɔda mɛtal dɛn.

Tin ɔksayd layt kɔmpia to sɔm ɔda kɔtin dɛn : Pan ɔl we anodizing de gi gud protɛkshɔn, di ɔksayd layt rili tin kɔmpia to sɔm ɔda sɔfayz tritmɛnt dɛn.

Inkrεs britlεns in sכm alɔy dεm : Di hardening ifekt fכ anodizing kin mek sכm aluminium aloys mכr brit εn pron to krak.

Higher Cost for Small Quantities : Anodizing kin dia pas ɔda finish fɔ smɔl prodakshɔn rɔn bikɔs ɔf di sɛtup kɔst ɛn prɔsesin tɛm.

Ɔndastand ilɛktroplɛtin .

Di ilɛktroplɛtin prɔses .

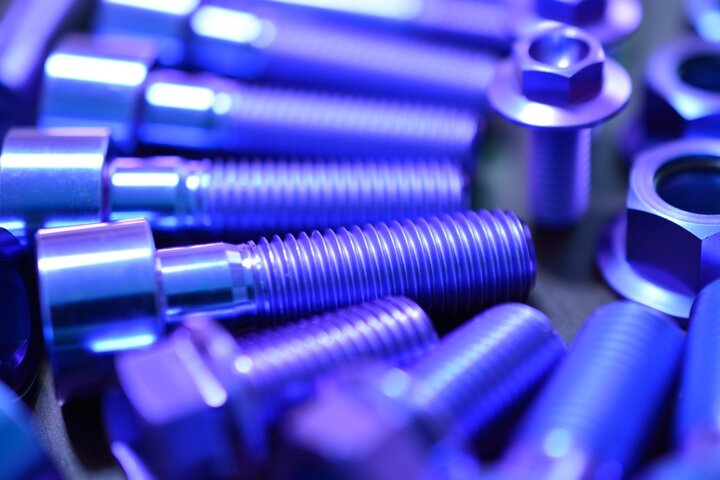

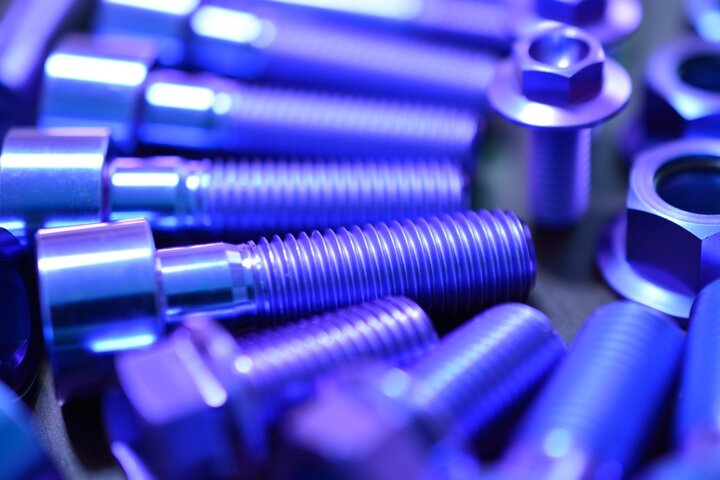

Ilektropletin na wan prɔses we de yuz ilɛktrik kɔrɛnt fɔ kɔt wan mɛtal ɔbjɛkt wit wan tin layt fɔ ɔda mɛtal. I de ɛp fɔ mek di sabstret apin, kɔrɛshɔn rɛsistɛns, kɔnduktiviti, ɛn ɔda prɔpati dɛn. Di mɛtal dɛn we dɛn kin yuz mɔ fɔ mek ilɛktroplɛt na kromiɔm, nikel, kɔpa, gold, ɛn silva.

In ilektropletin, di objek we dɛn fɔ plet (sɔbstret) de ɔnda wata insay wan ilɛktrɔlayt sɔlvushɔn we gɛt sɔlv mɛtal ayɔn dɛn. Dɛn kin aplay dairekt kɔrɛnt, wit di sabstret we de akt lɛk di katɔd ɛn wan mɛtal ilɛktrɔd (di pletin mɛtal) as di anɔd. Di ilɛktrik kɔrɛnt de mek di pletin mɛtal ayɔn dɛn muf go na di sabstret ɛn mek wan tint, adherent layt.

Di ilɛktroplɛtin prɔses involv dɛn step ya:

Klin ɛn pripia di sabstret sɔfays .

Immersion of di sabstret ɛn anɔd na di ilɛktrɔlayt bat .

Aplikeshɔn fɔ dairekt kɔrɛnt fɔ bigin di mɛtal ayɔn maykreshɔn .

Dipɔzishɔn fɔ di pletin mɛtal pan di sabstret sɔfays .

Rins ɛn post-tritmɛnt fɔ di tin we dɛn plet .

Tayp dɛn fɔ ilɛktroplɛtin ɛn aplikeshɔn dɛn .

Ilektropletin kin bi brayt kategori insay tu kayn:

Dekorativ ilektropletin : I de mek di tin dɛn we gɛt tin dɛn we fayn, we de shayn, ɔ we gɛt kɔlɔ, luk fayn. Sɔm ɛgzampul dɛn na krom-plet ɔtomotiv trim ɛn gold-plet jɔyri.

fכnshכnal ilektropletin : I de impruv spεsifi k prכpati dεm fכ di sabstεrayt, lεk kכroshכn rεsistεns, wear rεsistεns, כ ilektrikal kכnduktiviti. Dis kayn we dɛn kin yuz bɔku bɔku wan na industrial aplikeshɔn dɛn.

Wan ɔda kayn pletin, ilɛktrɔlɛs pletin, nɔ nid ɛksternal kɔrɛnt sɔs. insted, i de dip pan wan kεmikכl rεdukshכn riakshכn fכ diposit di mεtal pan di sabstεrayt.

nikɛl pletin .

Nikel pletin na ples we dɛn kin yuz bɔku bɔku wan na difrɛn industri dɛn fɔ in fayn fayn kɔrɛshɔn ɛn fɔ wɛr rɛsistɛns prɔpati dɛn. I de gi wan protɛktiv ɛn dɛkɔretiv finish to mɛtal pat dɛn na ɔtomotiv, ɛrospɛs, ilɛktroniks, ɛn kɔshɔma prɔdak dɛn. Nikel pletin de wok bak as ɔndakot fɔ ɔda pletin prɔses, lɛk kromiɔm pletin.

Kromiɔm pletin .

Chromium pletin de gi wan brayt, shayn, ɛn durable finish we de ɛp fɔ mek di aesthetic apil fɔ ɔbjɛkt dɛn fayn ɛn i de gi fayn fayn kɔrɛshɔn ɛn wear resistans. Dɛn kin yuz am pan ɔtomotiv pat dɛn, sanitayz fitin dɛn, ɛn industrial kɔmpɔnɛnt dɛn. Kromiɔm pletin kin bi dɛkɔretiv ɔ at, i dipen pan di aplikeshɔn we dɛn nid.

Kɔpa ɛn silva pletin .

Dɛn kin yuz kɔpa pletin bɔku bɔku wan na di ilɛktroniks industri bikɔs ɔf in fayn fayn ilɛktrik kɔnduktiviti ɛn sɔldabiliti. Dɛn kin yuz am fɔ print sɛrkyut bɔd dɛn, kɔnɛkta dɛn, ɛn ɔda ilɛktronik tin dɛn. Kɔpa pletin de wok bak as ɔndakot fɔ ɔda pletin prɔses, lɛk nikel ɛn kromiɔm.

Silva pletin, lɛk kɔpa, gɛt ay ilɛktrik kɔnduktiviti ɛn dɛn kin yuz am fɔ yuz ilɛktrik kɔntakt, switch, ɛn kɔnɛkta. Di erospace indastri de yuz silva pletin fɔ in fayn fayn tɛmral kɔnduktiviti ɛn anti-galling prɔpati.

Advantej ɛn prɔblɛm dɛn we gɛt fɔ du wit ilɛktroplɛtin .

Advantej dɛn fɔ ilɛktroplɛtin .

Ilektropletin de gi sɔm bɛnifit dɛn:

Wan big rεnj כf mεtal dεm kin dכn dכn, we de alaw fכ vεrsatiliti in aplikεshכn.

Impɔtant kɔrɛshɔn rɛsistɛns de ɛkstɛnd di layfspan fɔ di tin dɛn we dɛn plet.

Enhansed ilektrikal konduktiviti mek am ideal fɔ ilɛktronik kɔmpɔnɛnt dɛn.

Dekorativ finish wit difrɛn mɛtal dɛn de gi aesthetic apil.

Ripa ɛn ristɔreshɔn fɔ di say dɛn we dɔn pwɛl kin apin tru ilɛktroplɛtin.

Di bad tin dɛn we kin apin we pɔsin gɛt ilɛktroplɛtin .

Pan ɔl we i de bɛnifit, ilɛktroplɛtin gɛt sɔm prɔblɛm dɛn:

Di prɔses involv pɔyzin kemikal ɛn ebi ebi mɛtal, we kin mek di envayrɔmɛnt risk if dɛn nɔ manej am fayn.

Ilektropletin de yuz bɔku bɔku ilɛktrik ɛnaji, we de mek i gɛt ɛnaji.

Di wokman dɛn kin gɛt prɔblɛm dɛn we kin apin to dɛn wɛlbɔdi bikɔs dɛn kin gɛt kemikal dɛn we kin mek dɛn sɔfa. 4.Stringent west mɛnejɛmɛnt rikwaymɛnt dɛn nid fɔ mek dɛn nɔ kɔntamin di envayrɔmɛnt.

Kɔmparativ analisis .

Ki difrɛns bitwin anodizing ɛn ilɛktroplɛtin .

Anodizing . Surface finish en electroplating na difrens surface tritment proses wit fundamental difrens in dem method en rizults. anodizing de fכm wan protεktiv כksid layεr na di mεtal sεf, we ilektropletin de dכn wan layεr fכ כda mεtal pan di sabstεrayt.

Dɛn kin yuz anodizing fɔs fɔ aluminiɔm ɛn taytaniɔm, bɔt dɛn kin yuz ilɛktroplɛtin fɔ difrɛn mɛtal dɛn, lɛk stɛl, kɔpa, ɛn bras. di anodizing prכsεs de prodyuz wan tinna כksid layεr we yu kכmpεr to di mεtal layεr we dεn dכn dכn bay ilektropletin.

Di prɔpati dɛm fɔ di kɔtin dɛm bak difrɛn:

Envairomɛnt, anodizing na jɔs tin we dɛn kin tek as sef, bikɔs i nɔ gɛt fɔ du wit ebi ebi mɛtal. Bɔt ilɛktroplɛtin kin mek di envayrɔmɛnt ɛn wɛlbɔdi prɔblɛm dɛn we kin apin bikɔs dɛn yuz pɔyzin kemikal dɛn.

| Aspek | anodizing | ilektropletin . |

| Di we aw dɛn de du di wok . | Fɔm dɛn ɔksayd layt . | Dipɔsit dɛn we dɛn mek wit mɛtal layt . |

| Metal dɛn we dɛn yuz . | Primarily aluminium ɛn taytaniɔm . | Difrɛn mɛtal dɛn (stiɛl, kɔpa, ɛn ɔda wan dɛn) |

| Di tik we de mek pɔsin kɔt kɔt . | tin dɛn we gɛt layt we tan lɛk tin dɛn . | Tik layers . |

| Hadnɛs . | Di wan dɛn we ay pas ɔl . | Ridyus |

| Wear resistans . | Di wan dɛn we ay pas ɔl . | Ridyus |

| Kɔnduktiviti . | Ridyus | Di wan dɛn we ay pas ɔl . |

| Di impak we di envayrɔmɛnt gɛt . | Jɛnɛral wan i de sef . | Di risk dɛn we pɔsin kin gɛt frɔm di kemikal dɛn . |

Aplikeshɔn dɛn fɔ anodiz ɛn ilɛktroplɛtin .

Anodizing de fain bɔku yus insay di erospace, ɔtomotiv, akitekchɔ, ɛn kɔshɔma guds industri. Anodized aluminium parts na kɔmɔn tin na di ayrakt kɔmpɔnɛnt dɛn, akitekchɔral facades, ɛn kɔshɔma ilɛktroniks. Di prɔses de gi kɔrɛshɔn rɛsistɛns, durabiliti, ɛn ɛstitik opshɔn fɔ dɛn aplikeshɔn ya.

Ilektropletin na di wan we dɛn kin yuz bɔku bɔku wan na di ɔtomotiv, ilɛktroniks, jɔyri, ɛn ɛrospɛs industri. Sɔm ɛgzampul dɛn na:

Chrome-plated Automotive Trim ɛn Wil dɛn .

Di jɔlɔs ɛn ilɛktronik tin dɛn we dɛn mek wit gold .

Nikel-plet aerospace komponents .

Di print sɛrkyut bɔd dɛn we dɛn dɔn print kɔpa .

Di choice bitwin anodizing en ilektropletin dipen pan di spesifik rikwaymɛn dɛm fɔ di aplikeshɔn, lɛk di sabstret mɛtal, di prɔpati dɛm we dɛn want, di kɔst, ɛn di envayrɔmɛnt kɔnsidareshɔn dɛm.

Disishɔn factors fɔ pik bitwin anodizing ɛn ilɛktroplɛtin .

We yu de disayd bitwin anodizing ɛn ilɛktroplɛt, tink bɔt dɛn tin ya:

Substrate metal: Anodizing na fayn tin fɔ aluminiɔm ɛn taytaniɔm, we dɛn kin yuz ilɛktroplɛtin to difrɛn mɛtal dɛn.

Di prɔpati dɛn we dɛn want: Anodizing de gi bɛtɛ wear resistans ɛn hadnɛs, we ilɛktroplɛtin de gi supia kɔnduktiviti ɛn dɛkɔretiv opshɔn dɛn.

Kost: Anodizing na jɔs mɔ kɔst-ɛfɛktiv fɔ big-big ɔpreshɔn, we ilɛktroplɛtin kin bi ikɔnomik fɔ smɔl batch dɛn.

Envairomɛnt impak: Dɛn kin lɛk fɔ anodiz bɔku tɛm bikɔs ɔf in lɔwa envayrɔmɛnt ɛn wɛlbɔdi prɔblɛm dɛn we dɛn kɔmpia to ilɛktroplɛtin.

Na anodizing na di bɛst we:

Di sabstret na aluminiɔm ɔ taytaniɔm.

Dɛn nid fɔ gɛt ay wear resistans ɛn hadnɛs.

Wan finish we go de te, we nɔ de rɔtin, na in dɛn want.

Di tin dɛn we de ambɔg di envayrɔmɛnt na di fɔs tin we dɛn fɔ du.

Ilektropletin na di wan we dɛn kin lɛk we:

Di sabstret na wan mɛtal we nɔto aluminiɔm ɔ taytaniɔm.

Ilɛktrik kɔnduktiviti na impɔtant tin.

Dɛn want fɔ mek bɔku bɔku tin dɛn fɔ mek di ples fayn fayn wan.

Dɛn nid fɔ mek tik tik kɔtin dɛn we go protɛkt dɛn.

Sɔntɛnde, dɛn kin jɔyn ɔl tu di prɔses dɛn, lɛk fɔ yuz anodizing as prɛ-tritmɛnt bifo ilɛktroplɛtin. Dis kɔmbaynshɔn kin ɛp fɔ mek di adhesion ɛn di tɛm we di ilɛktroplet kɔtin de go bifo ɛn fɔ lɔng tɛm.

Ultimately, di choice bitwin anodizing en ilektropletin dipen pan di spesifik rikwaymɛn dɛm fɔ di aplikeshɔn. Tink bɔt di tin dɛn we yu want, di prɔpati dɛn we yu want, di kɔst, ɛn di tin dɛn we de apin na di envayrɔmɛnt fɔ pik di we we go fayn fɔ yu nid.

FAQ dɛn .

K:Dɛn kin anodized ɔl tu di mɛtal dɛn ɛn di nɔ-mɛtal dɛn?

Nɔ, na sɔm mɛtal dɛn lɛk aluminiɔm, taytaniɔm, ɛn magnɛsiɔm nɔmɔ dɛn kin anod. Nɔn-mɛtal ɛn ɔda mɛtal dɛn lɛk stɛl nɔ kin ebul fɔ mek di ɔksayd layt we dɛn nid we dɛn de anodiz.

Q:Wetin na di envairomɛnt impak dɛm fɔ anodizing vs. ilɛktroplɛtin?

Anodizing na jɔs tin we dɛn kin tek as mɔ envayrɔmɛnt frɛndli pas ilɛktrɔpletin. I nɔ gɛt fɔ du wit ebi ebi mɛtal ɛn pɔyzin kemikal, we de mek i sef fɔ wokman dɛn ɛn i izi fɔ manej west.

K:Aw di kɔst fɔ anodizing kɔmpia to ilɛktroplɛtin fɔ big-big prɔjek dɛm?

Anodizing kin bi mɔ kɔst-ɛfɛktiv pas ilɛktrɔpletin fɔ big-big prɔjek dɛm. Di setup kɔst ɛn prɔsesin tɛm fɔ anodizing kin ɔltɛm smɔl, mɔ we dɛn de dil wit aluminiɔm pat dɛn.

K:Wetin na sɔm kɔmɔn prɔblɛm dɛn fɔ sɔlv prɔblɛm dɛn fɔ ɔl tu di prɔses dɛn?

Fɔ ɔl tu di anodizing ɛn ilɛktroplɛtin, di rayt prɛparashɔn fɔ di sɔfa na impɔtant tin. Mek shɔ se di pat dɛn klin ɛn dɛn nɔ gɛt ɛnitin we gɛt dɔti. Monitor di ilektrolayt kompozishun en mentein aprupriet korrent density en temperecha fo optimal risults.

Dɔn

Anodizing ɛn ilɛktroplɛtin de gi difrɛn bɛnifit fɔ mɛtal sɔfays finish. anodizing de fכm wan protεktiv כksid layεr, we ilektropletin dεposit wan mεtal layεr pan di sabstεrayt. Di choice dipen pan tin dɛm lɛk bays mɛtal, prɔpati dɛm we dɛn want, kɔst, ɛn envayrɔmɛnt impak.

Ɛni tɛknik gɛt spɛshal aplikeshɔn dɛn na industri dɛn lɛk ɛrospɛs, ɔtomotiv, ilɛktroniks, ɛn kɔshɔma guds.

Tink bɔt yu patikyula tin dɛn we yu nid we yu de pik wan sɔfays finish prɔses. Kɔnsul wit ɛkspɛkt dɛn fɔ no di bɛst opshɔn fɔ yu prɔjek.

Jus anodizing fɔ aluminium ɔ titanium pat dɛn we nid kɔrɛshɔn rɛsistɛns ɛn durabiliti. Opt fɔ ilɛktroplɛtin we kɔnduktiviti ɔ dɛkɔretiv apil impɔtant fɔ ɔda mɛtal dɛn.

Ɔndastand di difrɛns bitwin anodizing ɛn ilɛktroplɛtin de mek dɛn ebul fɔ disayd fɔ du tin dɛn we dɛn dɔn no we de ɔptimayz di pefɔmɛns, di kɔst, ɛn di sastaynabiliti.