Yin gyare-gyaren allura wani tsari ne na masana'anta wanda ke samar da sassan filastik masu inganci tare da kyakkyawan yanayin gamawa.Ƙarshen saman ɓangaren da aka ƙera yana taka muhimmiyar rawa a cikin kyawun sa, aikinsa, da fahimtar mabukaci.Cimma ƙarshen saman da ake so yana buƙatar cikakken fahimtar ma'auni da dabaru daban-daban da ake da su.

Society of the Plastics Industry (SPI) ya kafa wani sa na jagororin don daidaita mold gama a cikin robobi masana'antu.Waɗannan jagororin SPI an karɓe su sosai tun farkon gabatarwar su a cikin 1960s, suna ba da harshe gama gari don masu zanen kaya, injiniyoyi, da masana'antun don sadarwa da buƙatun ƙarewar saman yadda ya kamata.

SPI Surface Kare Matsayi

Menene SPI Gama?

SPI Finish, wanda kuma aka sani da SPI Mold Finish ko SPI Surface Finish, yana nufin daidaitattun jagororin gamawar saman da Society of the Plastics Industry (SPI) ta kafa.Waɗannan jagororin suna ba da yare na duniya don siffanta siffa da nau'in sassan filastik gyare-gyaren allura.

Matsayin Ƙarshe na SPI yana da mahimmanci a cikin gyaran allura saboda dalilai da yawa:

l Tabbatar da daidaiton ingancin farfajiya a cikin sassa daban-daban da masana'antun

l Samar da bayyananniyar sadarwa tsakanin masu zanen kaya, injiniyoyi, da masu yin kayan aiki

l Ba da damar masu ƙira don zaɓar mafi dacewa gama don aikace-aikacen su

l Haɓaka ƙaya da ayyuka na samfurin ƙarshe

Ma'aunin Ƙarshe na SPI an raba su zuwa manyan rukunai huɗu, kowannensu yana da rukunai uku:

Kashi | Rukunin rukuni | Bayani |

A. Mai sheki | A-1, A-2, A-3 | Mafi santsi kuma mafi kyalli |

B. Semi-mai sheki | B-1, B-2, B-3 | Matsakaicin matakin sheki |

C. Matte | C-1, C-2, C-3 | Ba mai sheki ba, yana gamawa |

D. Rubutu | D-1, D-2, D-3 | M, tsari ya ƙare |

Ana ƙara fayyace kowane rukuni ta hanyar ƙayyadaddun ƙayyadaddun yanayin yanayin sa, wanda aka auna shi a cikin micrometers (μm), da kuma hanyoyin gamawa daidai da ake amfani da su don cimma sakamakon da ake so.

Ta bin waɗannan madaidaitan nau'ikan, masana'antun za su iya tabbatar da cewa sassan da aka ƙera allura sun cika ƙayyadaddun buƙatun ƙarewar saman, wanda ke haifar da ingantattun samfura, sha'awar gani, da ingantattun samfuran aiki.

Maki 12 na SPI Gama

Ma'aunin Ƙarshe na SPI ya ƙunshi maki 12 daban-daban, an tsara su zuwa manyan rukunai huɗu: Glossy (A), Semi-Glossy (B), Matte (C), da Textured (D).Kowane nau'i ya ƙunshi ƙananan rukunai guda uku, waɗanda lambobi 1, 2, da 3 ke nunawa.

Manyan rukunan guda hudu da halayensu sune:

1. Glossy (A) : Mafi santsi da kyalli, wanda aka samu ta amfani da buffing lu'u-lu'u.

2. Semi-Glossy (B) : Matsayin matsakaici na sheki, wanda aka samu ta hanyar goge takarda.

3. Matte (C) : Ba mai sheki ba, yana ƙarewa, an ƙirƙira ta amfani da gogewar dutse.

4. Rubutun rubutu (D) : M, ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun busassun fashewa tare da kafofin watsa labarai daban-daban.

Anan akwai cikakkun bayanai na 12 SPI Gama maki, tare da hanyoyin gama su da kuma yanayin yanayin yanayin sama:

Babban darajar SPI | Gama (Nau'i) | Hanyar Ƙarshe | Rage Tsayin Sama (Ra) Range (μm) |

A-1 | Super High Glossy | Daraja #3, 6000 Grit Diamond Buff | 0.012 - 0.025 |

A-2 | Babban mai sheki | Daraja #6, 3000 Grit Diamond Buff | 0.025 - 0.05 |

A-3 | Al'ada mai sheki | Darasi #15, 1200 Grit Diamond Buff | 0.05 - 0.10 |

B-1 | Kyakkyawan Semi-mai sheki | 600 Grit Paper | 0.05 - 0.10 |

B-2 | Matsakaici Semi-mai sheki | 400 Grit Paper | 0.10 - 0.15 |

B-3 | Semi-mai sheki na al'ada | 320 Grit Paper | 0.28 - 0.32 |

C-1 | Mafi kyawun Matte | 600 Grit Stone | 0.35 - 0.40 |

C-2 | Matsakaici Matte | 400 Grit Stone | 0.45 - 0.55 |

C-3 | Al'ada Matte | 320 Grit Stone | 0.63 - 0.70 |

D-1 | Satin Textured | Dry Blast Glass Bead #11 | 0.80 - 1.00 |

D-2 | Dull Textured | Busasshiyar fashewa #240 Oxide | 1.00 - 2.80 |

D-3 | Rough Textured | Bushewar fashewa #24 Oxide | 3.20 - 18.0 |

Kamar yadda aka nuna a cikin ginshiƙi, kowane matakin SPI ya yi daidai da takamaiman nau'in gamawa, hanyar ƙarewa, da kewayon ƙarancin ƙasa.Misali, an rarraba ƙarshen A-1 a matsayin Super High Glossy, wanda aka samu ta amfani da Grade #3, 6000 Grit Diamond Buff, yana haifar da rashin ƙarfi tsakanin 0.012 da 0.025 μm.A gefe guda, an rarraba ƙarewar D-3 azaman Rough Textured, wanda aka samu ta bushewar fashewa tare da #24 Oxide, wanda ke haifar da ƙasa mai tsananin ƙanƙara tare da kewayon Ra na 3.20 zuwa 18.0 μm.

Ta hanyar ƙididdige ƙimar SPI da ta dace, masu zanen kaya da injiniyoyi za su iya tabbatar da cewa sassan da aka ƙera allura sun cika buƙatun gama saman da ake so, suna haɓaka ƙaya, aiki, da ingancin samfurin ƙarshe.

Kwatanta da Sauran Ƙimar Ƙarshen Sama

Duk da yake SPI Finish shine mafi girman ma'auni da aka sani don kammala aikin allura, sauran matakan masana'antu sun wanzu, kamar VDI 3400, MT (Moldtech), da YS (Yick Sang).Bari mu kwatanta SPI Gama da waɗannan hanyoyin:

1. VDI 3400 :

a. VDI 3400 misali ne na Jamusanci wanda ke mai da hankali kan rashin ƙarfi na sama maimakon bayyanar.

b. Ya ƙunshi maki 45, kama daga VDI 0 (mafi santsi) zuwa VDI 45 (ƙananan).

c. VDI 3400 na iya zama kusan alaƙa da SPI Gama maki, kamar yadda aka nuna a cikin tebur da ke ƙasa:

SPI Ƙarshe | Farashin 3400 |

A-1 zuwa A-3 | 0 zuwa VDI 15 |

B-1 zuwa B-3 | VDI 16 zuwa VDI 24 |

C-1 zuwa C-3 | VDI 25 zuwa VDI 30 |

D-1 zuwa D-3 | VDI 31 zuwa VDI 45 |

2. MT (Moldtech) :

a. MT wani ma'auni ne wanda Moldtech ya haɓaka, wani kamfani na Sipaniya wanda ya ƙware a cikin rubutun ƙira.

b. Ya ƙunshi maki 11, daga MT 0 (mafi laushi) zuwa MT 10 (mai ƙazanta).

c. Makin MT ba su misaltuwa kai tsaye da maki na SPI Gama maki, saboda suna mai da hankali kan takamaiman laushi maimakon rashin ƙarfi.

3. YS (Yick Sang) :

a. YS misali ne da wasu masana'antun Asiya ke amfani da su, musamman a China da Hong Kong.

b. Ya ƙunshi maki 12, daga YS 1 (mafi santsi) zuwa YS 12 (ƙananan).

c. Makin YS sun yi daidai da maki SPI Gama, tare da YS 1-4 daidai da SPI A-1 zuwa A-3, YS 5-8 zuwa SPI B-1 zuwa B-3, da YS 9-12 zuwa SPI C-1 ku D-3.

Duk da kasancewar waɗannan madadin ma'auni, SPI Finish ya kasance mafi yawan amfani da ma'auni don gyare-gyaren allura a duk duniya.Wasu mahimman fa'idodin amfani da SPI Gama sun haɗa da:

l Babban karbuwa da masaniya tsakanin masu zanen kaya, injiniyoyi, da masana'anta a duniya

l Bayyanar da taƙaitaccen rarrabuwa na ƙarewar saman bisa duka bayyanar da roughness

l Sauƙi na sadarwa da ƙayyadaddun buƙatun ƙarewar saman

l Daidaita tare da nau'ikan kayan gyare-gyaren allura da aikace-aikace

l Abubuwan albarkatu masu yawa da abubuwan tunani akwai, kamar SPI Katin Kammala da jagororin

Ta hanyar ɗaukar ma'aunin Ƙarshe na SPI, kamfanoni za su iya tabbatar da daidaito, inganci mai inganci don ɓangarorin allurar su yayin da suke sauƙaƙe sadarwa mai inganci da haɗin gwiwa tare da masu kaya da abokan tarayya a duk duniya.

Zaɓi Ƙarshen SPI Dama

Abubuwan da za a yi la'akari da su Lokacin Zaɓin Ƙarshen SPI

Lokacin zabar Ƙarshen SPI don sassan allurar ku, dole ne a yi la'akari da mahimman abubuwa da yawa don tabbatar da kyakkyawan sakamako mai yiwuwa.Waɗannan abubuwan sun haɗa da ƙaya, aiki, dacewa da kayan aiki, da abubuwan farashi.

1. Aesthetics :

a. Siffar gani da ake so na samfurin ƙarshe shine muhimmiyar mahimmanci wajen zaɓar Ƙarshen SPI.

b. Ƙarshe mai sheki (A-1 zuwa A-3) yana ba da santsi, ƙasa mai sheki wanda ke haɓaka bayyanar ɓangaren, yana sa ya dace don aikace-aikace inda kayan ado ke da fifiko.

c. Matte ya ƙare (C-1 zuwa C-3) yana ba da bayyanar da ba ta da kyau, mai yaduwa wanda zai iya taimakawa wajen ɓoye kurakuran saman da rage ganuwa na yatsa ko smudges.

2. Ayyuka :

a. Amfani da aikin da aka yi niyya na sashin gyare-gyaren allura ya kamata ya yi tasiri sosai kan zaɓin SPI Gama.

b. Ƙarshen rubutu (D-1 zuwa D-3) yana ba da ƙarin riko da juriya, yana sa su dace da aikace-aikace inda mu'amala ko hulɗar mai amfani ke da mahimmanci, kamar na'urorin hannu ko kayan haɗin mota.

c. Ƙarƙasa mai laushi (A-1 zuwa B-3) sun fi dacewa da sassan da ke buƙatar tsabta, siffa mai laushi ko waɗanda za a yi wa fenti ko lakabi bayan gyaran fuska.

3. Dacewar Abu :

a. Dole ne a yi la'akari da dacewa tsakanin kayan da aka zaɓa da Ƙarshen SPI da ake so.

b. Wasu kayan, irin su polypropylene (PP) ko thermoplastic elastomers (TPE), ƙila ba za su dace da cimma kyakkyawan haske ba saboda ƙayyadaddun kayan kayansu.

c. Tuntuɓi shawarwarin mai kaya ko gudanar da gwaji don tabbatar da cewa zaɓaɓɓen SPI Gama za a iya samun nasara tare da abin da aka zaɓa.

4. Tasirin Farashin :

a. Zaɓin Ƙarshen SPI na iya tasiri sosai ga ƙimar juzu'in gyare-gyaren allura.

b. Ƙare mafi girma, kamar A-1 ko A-2, yana buƙatar ƙarin gogewa da sarrafawa, wanda zai iya ƙara yawan kayan aiki da farashin samarwa.

c. Ƙarshen ƙananan ƙira, kamar C-3 ko D-3, na iya zama mafi tsada-tasiri ga aikace-aikace inda bayyanar saman ba ta da mahimmanci.

d. Yi la'akari da ma'auni tsakanin ƙarshen saman da ake so da farashin haɗin gwiwa don ƙayyade mafi dacewa SPI Ƙare don aikin ku.

Ta hanyar yin nazarin kowane ɗayan waɗannan abubuwan a hankali da tasirin su akan samfurin ƙarshe, masu ƙira da injiniyoyi za su iya yanke shawarar da aka sani lokacin zabar Ƙarshen SPI.Wannan cikakkiyar dabarar tana tabbatar da cewa sassan alluran da aka ƙera su sun dace da ƙaya, aiki, da ka'idojin tattalin arziƙi da ake buƙata yayin kiyaye dacewa da kayan da aka zaɓa.

Ƙarshen SPI da Daidaituwar Abu

Zaɓin kayan da ya dace yana da mahimmanci don cimma abin da ake so SPI Gama a cikin sassa na allura.Daidaituwa tsakanin kayan da ƙarewar da aka zaɓa na iya tasiri sosai ga bayyanar ƙarshe, aiki, da ingancin samfurin.Ga wasu mahimman abubuwan da ya kamata a yi la'akari:

1. Kaddarorin kayan aiki:

a. Kowane kayan filastik yana da ƙayyadaddun kaddarorin da ke shafar ikon sa don cimma wasu Ƙarshen SPI.

b. Misali, kayan da ke da girman raguwar ƙima ko ƙananan halayen kwarara na iya zama mafi ƙalubale don goge goge zuwa kyakkyawan gamawa.

2. Tasirin ƙari:

a. Kasancewar abubuwan ƙari, kamar masu canza launi, masu cikawa, ko ƙarfafawa, na iya yin tasiri akan dacewar kayan tare da takamaiman SPI Ƙare.

b. Wasu abubuwan da ake ƙarawa na iya ƙara ƙin ƙura ko rage ƙarfin kayan aikin gogewa.

3. Zane da sarrafawa:

a. Ƙirar ƙira da sigogin sarrafawa, kamar wurin ƙofa, kaurin bango, da ƙimar sanyaya, na iya yin tasiri ga kwararar kayan da bayyanar saman.

b. Ƙirar ƙira mai kyau da haɓaka tsari na iya taimakawa wajen kammala SPI da ake so akai-akai.

Don taimakawa jagorar zaɓin abu, koma zuwa wannan taswirar dacewa don robobi na gama gari da dacewarsu ga kowane maki SPI:

Kayan abu | A-1 | A-2 | A-3 | B-1 | B-2 | B-3 | C-1 | C-2 | C-3 | D-1 | D-2 | D-3 |

ABS | ○ | ○ | ● | ● | ● | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ● |

PP | ✕ | △ | △ | ● | ● | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ |

PS | △ | △ | ● | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ● |

HDPE | ✕ | △ | △ | ● | ● | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ |

Nailan | △ | △ | ● | ● | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ● |

PC | △ | ● | ◎ | ● | ● | △ | △ | ✕ | ✕ | ◎ | ✕ | ✕ |

TPU | ✕ | ✕ | ✕ | ✕ | △ | △ | ● | ● | ● | ◎ | ◎ | ● |

Acrylic | ◎ | ◎ | ◎ | ● | ● | ● | ● | ● | ● | △ | △ | △ |

Labari:

l ◎: Kyakkyawan dacewa

l ●: Kyakkyawan dacewa

l △: Matsakaicin dacewa

l ○: Ƙarfafa daidaitawa

l ✕: Ba a ba da shawarar ba

Mafi kyawun ayyuka don zaɓar mafi kyawun haɗin kayan - gamawa:

1. Tuntuɓi masu samar da kayan aiki da ƙwararrun gyare-gyaren allura don samun shawarwari dangane da takamaiman aikace-aikacenku da buƙatunku.

2. Gudanar da gwajin samfuri ta amfani da kayan da aka zaɓa da SPI Ƙare don tabbatar da bayyanar da aikin da ake so.

3. Yi la'akari da yanayin ƙarshen amfani da kowane buƙatun aiwatarwa, kamar fenti ko sutura, lokacin zabar kayan da gamawa.

4. Daidaita SPI da ake so Ƙarshe tare da farashin kayan, samuwa, da iya aiki don tabbatar da tsarin samar da farashi mai inganci kuma abin dogaro.

Ta hanyar fahimtar dacewa tsakanin kayan aiki da SPI Ƙare, masu zanen kaya da injiniyoyi na iya yanke shawarar yanke shawara waɗanda ke inganta bayyanar, aiki, da ingancin sassan allurar su.

Aikace-aikace-Takamaiman Shawarwari

Zaɓin madaidaicin SPI Ƙare don sassan allurar ku ya dogara da ƙayyadaddun aikace-aikacen da aka yi niyya da takamaiman buƙatun don bayyanar, aiki, da hulɗar mai amfani.Anan akwai wasu shawarwari don aikace-aikacen gama gari:

1. Ƙarshe mai sheki (A-1 zuwa A-3) :

a. Ya dace da aikace-aikacen da ke buƙatar ingantaccen inganci, bayyanar da aka goge

b. Mafi dacewa ga sassa masu buƙatun gani, kamar ruwan tabarau, murfin haske, da madubai

c. Kyakkyawan zaɓi don madaidaitan abubuwan da aka gyara ko bayyanannu, kamar surukan nuni ko murfin kariya

d. Misalai: hasken mota, marufi na kwaskwarima, da nunin kayan lantarki

2. Semi-mai sheki ya ƙare (B-1 zuwa B-3) :

a. Ya dace da aikace-aikacen da ke buƙatar ma'auni tsakanin kayan ado da ayyuka

b. Mafi dacewa don samfuran mabukaci, gidaje, da ƙullawa waɗanda ke amfana daga matsakaicin matakin haske

c. Kyakkyawan zaɓi don sassan da za a fenti ko mai rufi bayan gyare-gyare

d. Misalai: kayan aikin gida, gidaje na na'urar lantarki, da wuraren da na'urorin likitanci

3. Matte ya ƙare (C-1 zuwa C-3) :

a. Ya dace da aikace-aikace inda ake son bayyanar da ba ta da kyau, ƙarancin haske

b. Mafi dacewa don na'urorin hannu da samfuran da ake yawan taɓawa, yayin da suke rage bayyanar alamun yatsa da ɓarna.

c. Kyakkyawan zaɓi don abubuwan masana'antu ko sassan da ke buƙatar da hankali, yanayin da ba a bayyana ba

d. Misalai: kayan aikin wuta, sarrafawar nesa, da abubuwan ciki na mota

4. Ƙarshen rubutu (D-1 zuwa D-3) :

a. Ya dace da aikace-aikacen da ke buƙatar ingantaccen riko ko juriyar zamewa

b. Mafi dacewa ga sassan da ake sarrafa su akai-akai ko sarrafa su, kamar su hannuwa, dunƙulewa, da maɓalli.

c. Kyakkyawan zaɓi don abubuwan haɗin mota waɗanda ke buƙatar ƙasa maras zamewa, kamar ƙafafun tuƙi ko masu canza kaya.

d. Misalai: kayan dafa abinci, kayan aikin hannu, da kayan wasanni

Lokacin zabar SPI Gama don aikace-aikacen ku, la'akari da waɗannan:

l Ƙaunar gani da ake so da ingancin samfurin

l Matsayin hulɗar mai amfani da kulawa da ake buƙata

l Bukatar ingantaccen riko ko juriyar zamewa

l Daidaituwa tare da matakai na gyare-gyare, kamar fenti ko taro

l Zaɓin kayan da ya dace da zaɓaɓɓen gamawa

Aikace-aikace | Shawarwari SPI ya ƙare |

Abubuwan abubuwan gani | A-1, A-2 |

Kayan lantarki masu amfani | A-2, A-3, B-1 |

Kayan aikin gida | B-2, B-3, C-1 |

Na'urorin hannu | C-2, C-3 |

Abubuwan masana'antu | C-3, D-1 |

Motoci na ciki | C-3, D-1, D-2 |

Hannu da dunƙulewa | D-2, D-3 |

Ta la'akari da waɗannan ƙayyadaddun shawarwarin aikace-aikacen da kimanta keɓaɓɓen buƙatun samfuran ku, zaku iya zaɓar mafi dacewa SPI Ƙare wanda ke daidaita ƙaya, ayyuka, da ingancin farashi.

Samun Cikakkar Ƙarshen SPI

Dabarun Gyaran allura don Mafi kyawun Sakamako

Don cimma abin da ake so SPI Gama a kai a kai, yana da mahimmanci don inganta dabarun gyaran allurar ku.Anan akwai wasu nasihu na fasaha don haɓaka tasiri na Ƙarshen SPI daban-daban:

1. Tsarin Tsara :

a. Tabbatar da iska mai kyau don guje wa tarkon iska da alamun ƙonewa, wanda zai iya rinjayar ƙarewar saman

b. Haɓaka wurin ƙofa da girman don rage yawan layukan gudana da haɓaka bayyanar ƙasa

c. Yi amfani da kaurin bango iri ɗaya don tabbatar da daidaiton sanyi da rage lahani

2. Zaɓin kayan aiki :

a. Zaɓi kayan da ke da kyawawan kaddarorin kwarara da ƙananan raguwa don rage ƙarancin ƙasa

b. Yi la'akari da yin amfani da abubuwan da ake ƙarawa, kamar masu mai ko masu sakin jiki, don haɓaka ingancin saman

c. Tabbatar cewa kayan sun dace da Ƙarshen SPI da ake so (koma zuwa ginshiƙi a sashe na 3.2)

3. Ma'aunin sarrafawa :

a. Haɓaka saurin allura, matsa lamba, da zafin jiki don tabbatar da cikawa mai kyau da rage lahani na saman

b. Kula da daidaitaccen zafin jiki don tabbatar da sanyaya iri ɗaya da rage yanayin yaƙi

c. Daidaita matsa lamba da lokaci don rage alamun nutsewa da haɓaka daidaiton saman

Jagoran mataki-mataki kan cimma Ƙarshen SPI iri-iri:

SPI Ƙarshe | Dabaru | Kayan aiki |

A-1 zuwa A-3 | - Diamond buffing - goge-goge mai sauri - Ultrasonic tsaftacewa | - Diamond fili - Mai saurin gogewa - Mai tsabtace Ultrasonic |

B-1 zuwa B-3 | - Grit takarda goge - bushewar yashi - Yashi rigar | - Takarda mai lalacewa (600, 400, 320 grit) - Orbital sander - Sanding block |

C-1 zuwa C-3 | - Gyaran dutse - Ƙwaƙwalwar ƙaya - Tururi honing | - Duwatsu masu goge (600, 400, 320 grit) - Kayan aikin fashewar bead - Injin honing tururi |

D-1 zuwa D-3 | - Busassun fashewa - Etching - Abubuwan saka rubutu | - Kafofin watsa labarai masu fashewa (gilashin beads, aluminum oxide) - Sinadaran da ke lalata - Textured mold abun da ake sakawa |

Haɗa ƙa'idodin DFM tare da Ka'idodin SPI

Ya kamata a haɗa ƙa'idodin ƙira don ƙira (DFM) da wuri a cikin tsarin haɓaka samfuran don tabbatar da kammalawar SPI da ake so za a iya cimma ta yadda ya kamata kuma akai-akai.Ga yadda ake haɗa DFM tare da zaɓin gama SPI:

1. Haɗin Kan Farko:

a. Haɗa ƙwararrun gyare-gyaren allura da masana'anta a farkon tsarin ƙira

b. Tattauna SPI Kammala buƙatun da tasirin su akan ƙira da gyare-gyare

c. Gano yuwuwar ƙalubale da iyakoki masu alaƙa da ƙarewar da aka zaɓa

2. Haɓaka ƙira:

a. Sauƙaƙe juzu'i don haɓaka gyare-gyare da rage lahani

b. Ka guje wa sasanninta masu kaifi, ƙasƙantattu, da bangon sirara waɗanda zasu iya shafar ƙarewar saman

c. Haɗa daftarin kusurwoyi don sauƙaƙe fitar da sashi da hana lalacewa ta sama

3. Samfura da Gwaji:

a. Ƙirƙirar ƙirar ƙira tare da Ƙare SPI da ake so don inganta ƙira da iya aiki

b. Gudanar da cikakken gwaji don tantance ingancin saman, daidaito, da karko

c. Maimaita kan ƙira da sigogin tsari dangane da sakamakon samfuri

Fa'idodin bita da shawarwari na DFM na farko:

l Gano da magance yuwuwar al'amurran da suka shafi SPI Gama da wuri a cikin tsarin ƙira

l Haɓaka ƙirar sashi don ingantattun moldability da ingancin saman

l Rage haɗarin sauye-sauyen ƙira masu tsada da jinkirin samarwa

l Tabbatar da zaɓaɓɓen Ƙarshen SPI za a iya samun ci gaba da ƙima da tsada

Ƙayyadaddun Ƙarshen SPI a Ƙirar ku

Don tabbatar da daidaiton sakamako da bayyananniyar sadarwa tare da masana'antun, yana da mahimmanci don tantance ƙaƙƙarfan SPI da ake so a cikin takaddun ƙirar ku.Ga wasu kyawawan ayyuka:

1. Haɗa SPI Gama kiran kira:

a. A sarari nuna ƙimar Ƙarshe SPI da ake so (misali, A-1, B-2, C-3) akan zanen ɓangaren ko ƙirar 3D

b. Ƙayyade buƙatun Ƙarshen SPI don kowane saman ko fasali, idan ana son ƙare daban-daban

2. Bayar da samfuran tunani:

a. Bayar da samfurori na zahiri ko SPI Katin Ƙarshe waɗanda ke wakiltar ƙarshen saman da ake so

b. Tabbatar cewa samfuran ana yiwa alama daidai kuma sun dace da ƙayyadaddun darajar SPI

3. Sadar da buƙatun a sarari:

a. Tattauna SPI Gama buƙatun tare da masana'anta don tabbatar da fahimtar gama gari

b. Bayar da cikakkun bayanai kan aikace-aikacen da aka yi niyya, buƙatun aiki, da kowane buƙatun aiwatarwa

c. Kafa fayyace ma'aunin karbuwa don inganci da daidaito

4. Saka idanu kuma tabbatarwa:

a. Duba akai-akai da auna ingancin ƙarewar saman yayin samarwa

b. Yi amfani da ingantattun dabarun aunawa, kamar ma'aunin ma'auni ko kwatancen gani

c. Cire duk wani sabani daga ƙayyadadden SPI Gama da sauri don kiyaye daidaito

Ta bin waɗannan ingantattun ayyuka da sadarwa na SPI Gama buƙatun yadda ya kamata, zaku iya tabbatar da cewa sassan allurar ku sun cika ka'idodin gamawar saman da ake so akai-akai, wanda ke haifar da inganci, sha'awar gani, da ingantattun samfuran aiki.

Kayayyakin Kammala SPI da Albarkatu

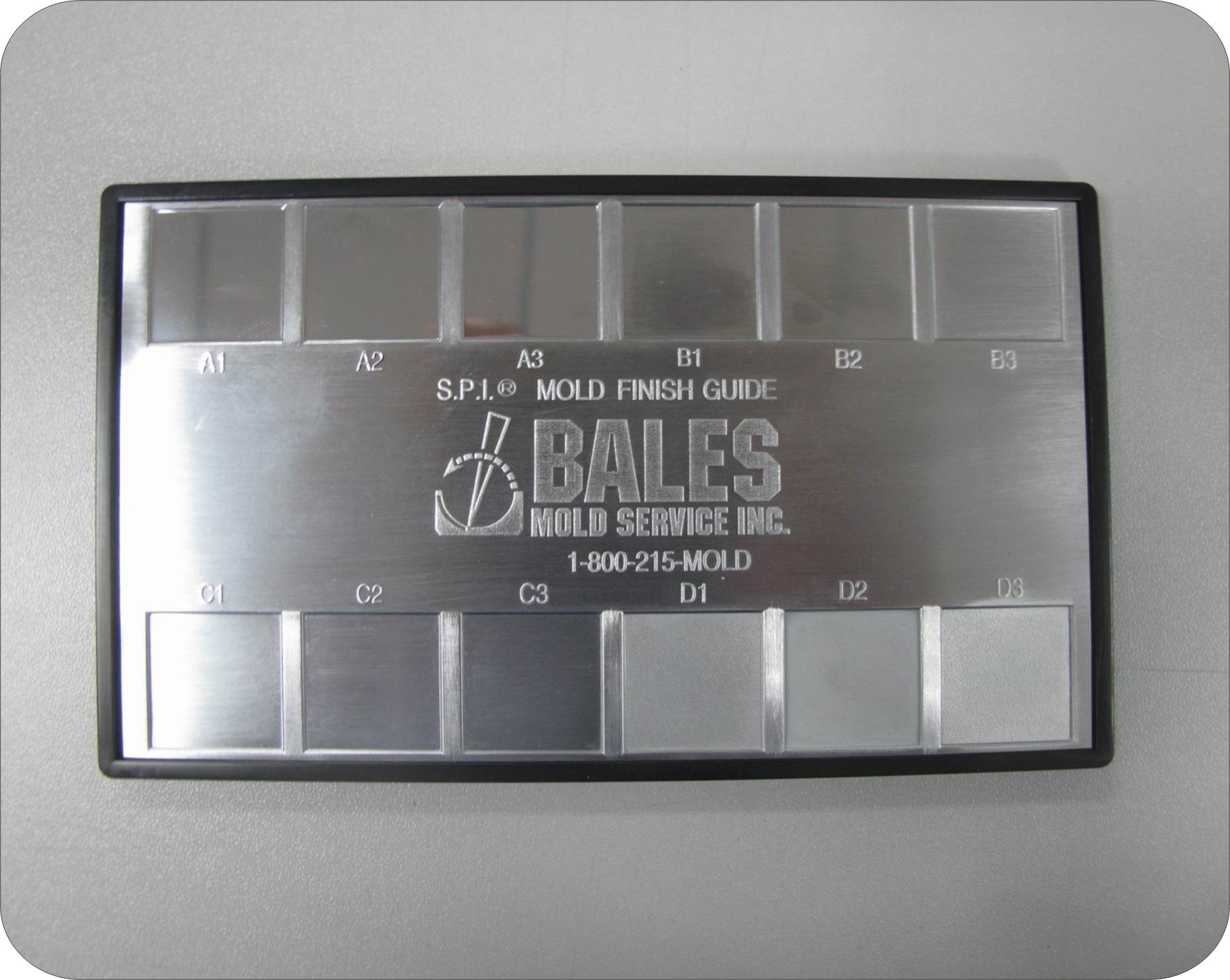

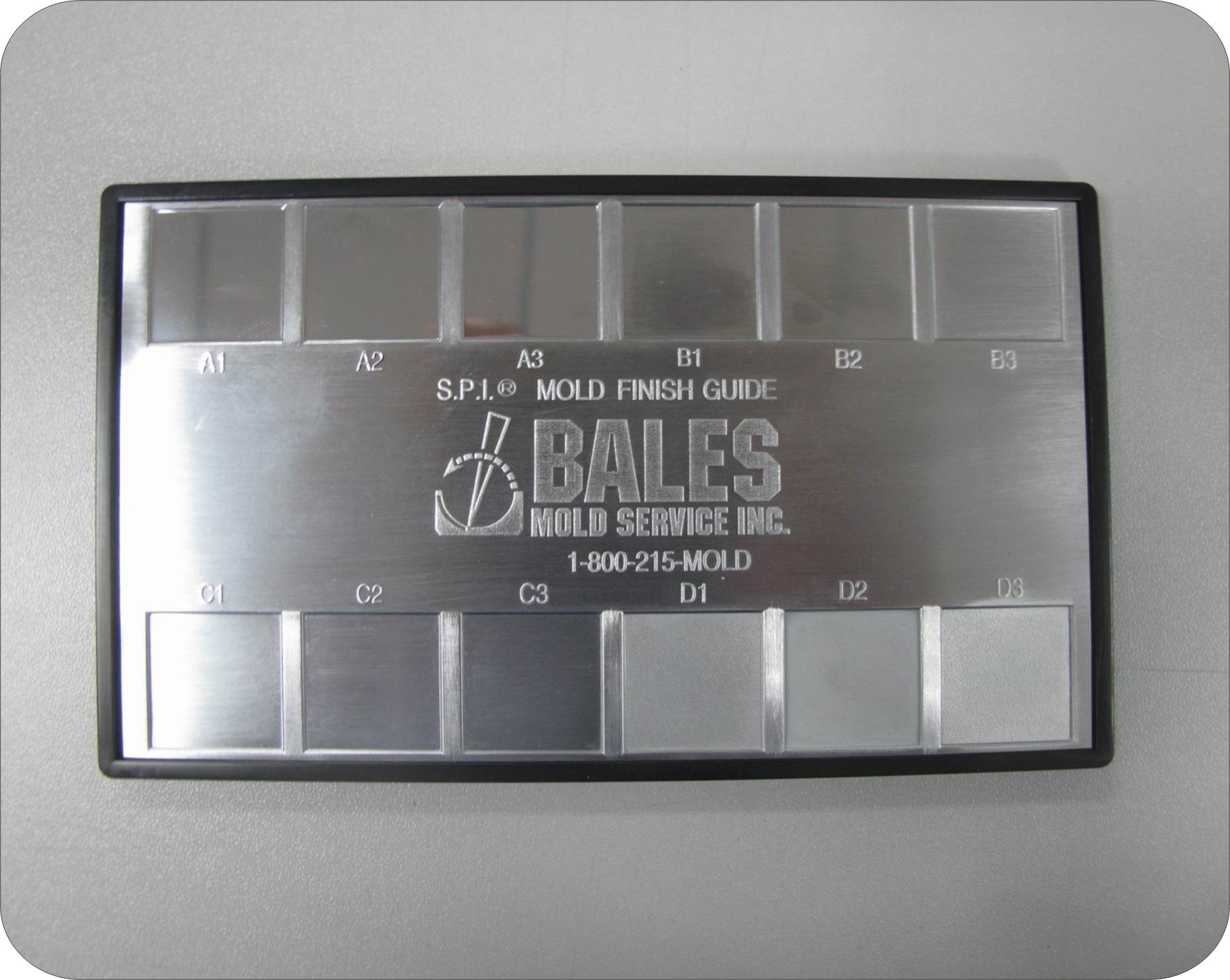

Katunan Ƙarshe na SPI da Plaques

Katunan Ƙarshe na SPI da allunan kayan aiki ne masu mahimmanci ga masu zanen kaya, injiniyoyi, da masana'antun da ke aiki tare da robobi na allura.Wadannan samfurori na jiki suna ba da wakilci na ainihi na daban-daban na SPI Gama maki, ƙyale masu amfani su iya gani da kuma tactilely tantance yanayin bayyanar da rubutu.

Fa'idodin amfani da SPI Ƙare katunan da alluna:

1. Ingantaccen sadarwa:

a. Samar da maƙasudin gama gari don tattaunawa game da buƙatun ƙare saman

b. Kawar da shubuha da rashin fahimta na siffantawa

c. Haɓaka bayyanannen fahimta tsakanin masu ƙira, masana'anta, da abokan ciniki

2. Daidaitaccen kwatance:

a. Bada damar kwatanta gefe-da-gefe na daban-daban SPI Gama maki

b. Taimaka wajen zaɓar mafi dacewa gama don takamaiman aikace-aikacen

c. Kunna madaidaicin madaidaicin ƙarshen saman zuwa buƙatun samfur

3. Kula da inganci:

a. Yi aiki azaman ma'auni don tantance ingancin sassan alluran da aka ƙera

b. Samar da ma'auni na gani da tactile don duba daidaiton ƙarewar saman

c. Taimaka wajen ganowa da magance duk wani sabani daga gamawar da ake so

Masu ba da katin gamawa na SPI da plaques:

1. Ƙungiyoyin Masana'antar Filastik:

a. Society of the Plastics Industry (SPI) - Yanzu da aka sani da Plastics Industry Association (PLASTICS)

b. Ƙungiyar Gwaji da Kayayyakin Amirka (ASTM)

c. Ƙungiyar Ƙididdiga ta Duniya (ISO)

2. Masu Bayar da Sabis ɗin Gyaran allura:

a. Tawagar Mfg

b. Protolabs

c. Fictiv

d. ICOMold

e. Xometry

3. Kamfanonin Rubutun Rubutun Mold:

a. Boride Injiniya Abrasives

b. Mold-Tech

c. Matsakaicin Rubutun Fuskoki

Don yin odar SPI Ƙare katunan ko alluna, tuntuɓi masu samarwa kai tsaye ko ziyarci gidajen yanar gizon su don ƙarin bayani kan samuwan zaɓuɓɓuka, farashi, da tsari na oda.

Nazarin Harka: Nasara Aikace-aikace na SPI ya ƙare

Gidajen Na'urar Likita

l Samfuri : Gidajen na'urar likita ta hannu

l Material : ABS (Acrylonitrile Butadiene Styrene)

L SPI Ƙarshe : C-1 (Fine Matte)

l Rationale : Ƙarshen C-1 yana ba da wani wuri mara kyau, mai jurewa da yatsa wanda ke haɓaka riko da inganta tsabtace na'urar.Hakanan bayyanar matte yana ba da gudummawa ga ƙwararrun ƙwararru da kyan gani.

l Darussan Koyo : An cim ma kammalawar C-1 akai-akai ta hanyar inganta sigogin gyare-gyaren allura da yin amfani da kayan ABS masu inganci, na likitanci.Kula da kyallen da ya dace da kuma duba kammalawa na yau da kullun sun kasance mahimmanci don tabbatar da ingancin saman bai ɗaya.

Gyaran Cikin Mota

l Samfurin : Kayan ado na ciki na kayan ado don motocin alatu

l Material : PC/ABS (Polycarbonate/Acrylonitrile Butadiene Styrene saje)

l SPI Ƙarshe : A-2 (Maɗaukaki Mai sheki)

l Rationale : Ƙarshen A-2 yana haifar da ƙaƙƙarfan ƙaƙƙarfan kamanni mai sheki wanda ya dace da ƙirar ciki na abin hawa.Filaye mai santsi kuma yana sauƙaƙe tsaftacewa mai sauƙi kuma yana kula da ƙayatarwa a kan lokaci.

l Darussan da Aka Koyi : Cimma ƙarshen A-2 na buƙatar kulawa mai ƙarfi akan tsarin gyaran allura, gami da zafin jiki, saurin allura, da lokacin sanyaya.Yin amfani da babban mai sheki, UV-resistant PC/ABS abu ya tabbatar da tsawon lokaci mai inganci da kwanciyar hankali na launi.

Wurin Lantarki na Mabukaci

l Samfurin : Kariyar kariya ta wayar hannu

l Abu : TPU (Thermoplastic Polyurethane)

L SPI Ƙarshe : D-2

l Rationale : Ƙarshen D-2 yana ba da wani wuri mara zamewa, mai laushi wanda ke haɓaka ƙugiya kuma yana hana wayar daga zamewa daga hannun mai amfani.Siffar maras kyau kuma tana taimakawa wajen ɓoye ƙanƙanta da lalacewa akan lokaci.

l Darussan Koya : An cimma nasarar kammala D-2 ta hanyar yin amfani da wani tsari na musamman na rubutu, kamar sinadarai etching ko Laser texturing, a kan mold surface.Zaɓin da ya dace na ƙimar kayan TPU ya tabbatar da kyawawan kaddarorin kwarara da ingantaccen kwafin rubutun da ake so.

Waɗannan nazarin shari'o'in suna nuna nasarar aikace-aikacen SPI daban-daban a cikin masana'antu daban-daban, suna nuna mahimmancin zaɓin ƙarewar da ta dace dangane da buƙatun samfur, kaddarorin kayan aiki, da hanyoyin masana'antu.Ta hanyar koyo daga waɗannan misalan da kuma la'akari da takamaiman buƙatun aikinku, zaku iya yanke shawara mai fa'ida lokacin ƙayyadaddun SPI Gama ga sassan allurar ku.

Nau'ukan Ci gaba da Abubuwan Gaba

SPI Gama a cikin Manyan Aikace-aikace

SPI Finishes suna taka muhimmiyar rawa a cikin manyan aikace-aikace, kamar sararin samaniya da na'urorin likitanci, inda ingancin saman da daidaito ke da mahimmanci.A cikin waɗannan masana'antu, Madaidaicin SPI Finish na iya tasiri ga aikin samfur, aminci, da bin ka'idoji.

1. Aikace-aikacen sararin samaniya: Abubuwan tsarin man fetur

a. Cabin ciki sassa

b. Abubuwan da aka gyara

Nazarin Harka: Wani mai kera sararin samaniya da ya ƙware a sassan tsarin man fetur ya gano cewa yin amfani da ƙarewar A-2 akan sassa masu mahimmanci ya inganta ingantaccen kwararar mai kuma ya rage haɗarin gurɓatawa.Babban mai sheki, santsi mai laushi ya rage yawan tashin hankali na ruwa kuma ya sauƙaƙe tsaftacewa da dubawa.

2. Aikace-aikacen Na'urar Likita: Na'urorin da za a dasa

a. Kayan aikin tiyata

b. Kayan aikin bincike

Nazarin Harka: Kamfanin na'urar likitanci ya haɓaka sabon layin kayan aikin tiyata ta amfani da matte C-1.Fuskar da ba ta nuna haske ta rage haske a lokacin hanyoyin, haɓaka ganuwa ga likitocin fiɗa.Ƙarshen ya kuma inganta juriyar kayan aikin ga karce da lalata, yana tabbatar da dorewa na dogon lokaci da kuma kula da siffa mai kyau.

A cikin duka sararin samaniya da aikace-aikacen na'urar likitanci, zaɓin gamawar SPI da ta dace ta ƙunshi ƙaƙƙarfan tsari na gwaji, tabbatarwa, da takaddun shaida.Dole ne masu sana'anta suyi aiki tare da masu samar da kayan aiki, ƙwararrun ƙwararrun ƙwararru, da ƙungiyoyin tsari don tabbatar da cewa ƙarshen da aka zaɓa ya cika duk buƙatun aiki da aminci.

Sabuntawa da Abubuwan Gaba a cikin Ƙarshen Sama

Kamar yadda fasaha ta ci gaba da buƙatun masana'antu, ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙasa, gami da Ƙarshen SPI, na iya fuskantar manyan canje-canje da sabbin abubuwa.Anan akwai wasu abubuwan da suka kunno kai da tsinkaya don makomar ƙarewar saman:

1. Ƙarfafa Ƙarfafa Nanotechnology:

a. Ci gaban nanoscale coatings da laushi

b. Ingantattun juriya na karce, abubuwan hana lalata, da iya tsaftace kai

c. Mai yuwuwa don sabbin maki SPI Ƙarshe da aka tsara musamman don aikace-aikacen nanotechnology

2. Tsare-tsare masu Dorewa da Kammala Zaman Lafiya:

a. Ƙara ƙarfafawa akan rage tasirin muhalli

b. Amincewa da hanyoyin gamawa na tushen ruwa da rashin ƙarfi

c. Bincika abubuwan da suka dogara da halittu da kuma abubuwan da za su iya lalacewa don gamawa

3. Kammala Surface Dijital da Kula da Inganci:

a. Haɗe-haɗe na sikanin 3D da hankali na wucin gadi don duba ƙasa

b. Ainihin saka idanu da daidaita tsarin ƙarewa ta amfani da firikwensin IoT

c. Haɓaka ƙa'idodin SPI na dijital da samfuran ƙima

4. Keɓancewa da Keɓancewa:

a. Bukatar girma don keɓantacce kuma na musamman saman ƙare

b. Ci gaba a cikin bugu na 3D da saurin samfur don samar da ƙaramin tsari

c. Mai yuwuwa don ƙa'idodin gama SPI don haɗa zaɓuɓɓukan gyare-gyare

5. Ƙarshen Sama Mai Aiki:

a. Haɓakawa na gamawa tare da ƙarin ayyuka, kamar kayan antimicrobial ko sutura masu ɗaukar hoto

b. Haɗuwa da na'urori masu auna firikwensin da na'urorin lantarki zuwa ƙarshen saman

c. Fadada ma'auni na SPI don haɗa ma'aunin aikin aiki

Yayin da waɗannan sabbin abubuwa da abubuwan haɓaka ke ci gaba da siffanta masana'antar karewa, yana da mahimmanci ga masu ƙira, injiniyoyi, da masana'antun su kasance da masaniya da daidaita ayyukan su daidai.Ta hanyar rungumar sababbin fasahohi da haɗin gwiwa tare da masana masana'antu, kamfanoni za su iya yin amfani da waɗannan ci gaban don ƙirƙirar samfurori masu inganci, sababbin samfurori waɗanda suka dace da buƙatun abokin ciniki da kuma ka'idoji.

Trend | Tasiri kan Ƙarshen SPI |

Nanotechnology | Mai yuwuwa don sabbin maki SPI Gama da aka keɓe don aikace-aikacen nanoscale |

Dorewa | Amincewa da hanyoyin gamawa masu dacewa da kayan aiki |

Dijitalization | Haɓaka ƙa'idodin SPI na dijital da samfuran ƙima |

Keɓancewa | Haɗa zaɓuɓɓukan gyare-gyare cikin ma'aunin Ƙarshe na SPI |

Ayyuka | Fadada ma'auni na SPI don haɗa ma'aunin aikin aiki |

Yayin da shimfidar shimfidar wuri ke ci gaba da haɓakawa, ƙa'idodin Ƙarshen SPI za su yi yuwuwar yin bita da sabuntawa don ɗaukar waɗannan abubuwan da ke tasowa da fasaha.Ta kasancewa a sahun gaba na waɗannan abubuwan haɓakawa, masana'antun za su iya tabbatar da cewa sassan da aka ƙera musu allura sun ci gaba da saduwa da mafi girman ma'auni na inganci, aiki, da ƙirƙira.

Kammalawa

A cikin wannan cikakken jagorar, mun bincika mahimmancin rawar SPI Gama a cikin gyare-gyaren allura.Daga fahimtar maki 12 zuwa zaɓin gamawar da ya dace don aikace-aikacenku, ƙwarewar SPI Finish yana da mahimmanci don samar da ingantattun sassa, sha'awar gani, da ingantattun sassa.

Don samun nasarar haɗa SPI Gama cikin ayyukan gyare-gyaren allura, la'akari da waɗannan:

1. Haɗin kai tare da masana don zaɓar mafi dacewa gama don aikace-aikacen ku

2. Sadar da buƙatun Ƙarshen SPI ɗin ku a fili ga abokan haɗin gwiwar masana'anta

3. Yi amfani da SPI Ƙare katunan da plaques don ingantacciyar kwatance da sarrafa inganci

4. Kasance da masaniya game da abubuwan da suka kunno kai da fasahohi a cikin karewa

Ta bin waɗannan matakan aikin da haɗin gwiwa tare da ƙwararrun ƙwararru kamar Ƙungiyar MFG, za ku iya amincewa da kewaya duniyar SPI Finish kuma ku sami kyakkyawan sakamako a cikin ƙoƙarin ku na gyare-gyaren allura.

FAQs

Tambaya: Menene mafi yawan gama-gari na SPI?

A: Mafi yawan makin Ƙarshe na SPI sune A-2, A-3, B-2, da B-3, waɗanda ke ba da haske mai sheki zuwa siffa mai sheki.

Tambaya: Zan iya cimma babban mai sheki tare da kowane kayan filastik?

A: Ba duk kayan filastik ba ne masu dacewa don cimma kyakkyawan haske.Koma zuwa ginshiƙi daidaita kayan cikin sashe na 3.2 don jagora.

Tambaya: Ta yaya SPI Gama ke shafar farashin gyaran allura?

A: Ƙarshen SPI mafi girma (misali, A-1, A-2) gabaɗaya haɓaka kayan aiki da farashin samarwa saboda ƙarin aiki da ake buƙata.

Tambaya: Shin yana yiwuwa a sami Ƙarshen SPI daban-daban a bangare ɗaya?

A: Ee, yana yiwuwa a ƙayyade daban-daban SPI Ƙare don sassa daban-daban ko fasalulluka na ɓangaren allura iri ɗaya.

Tambaya: Menene babban bambance-bambance tsakanin SPI A da SPI D gama?

A: Ƙarshen SPI A suna da sheki da santsi, yayin da SPI D ya ƙare yana da laushi da ƙazanta.Suna hidima daban-daban dalilai da bukatun.

Tambaya: Za a iya ƙera SPI Ƙare fiye da ƙayyadaddun ƙayyadaddun ƙayyadaddun bayanai?

A: Keɓancewa na SPI Ƙare fiye da daidaitattun maki na iya yiwuwa, ya danganta da takamaiman buƙatu da iyawar masana'anta.

Tambaya: Ta yaya zan yanke shawara tsakanin mai sheki da matte gama don samfur na?

A: Yi la'akari da kyawawan abubuwan da ake so, ayyuka, da yanayin amfani na ƙarshe lokacin zabar tsakanin ƙare mai sheki da matte.Koma zuwa sashe na 3.3 don takamaiman shawarwarin aikace-aikace.

Tambaya: Menene bambance-bambancen farashi na yau da kullun tsakanin Ƙarshen SPI daban-daban?

A: Bambance-bambancen farashi tsakanin SPI Ƙare ya dogara da abubuwa kamar abu, juzu'i na sashi, da ƙarar samarwa.Gabaɗaya, mafi girma-sa ƙare (misali, A-1) sun fi tsada fiye da ƙananan darajar kammala (misali, D-3).

Tambaya: Yaya tsawon lokacin da aka saba ɗauka don amfani da Ƙarshen SPI zuwa wani tsari?

A: Lokacin da ake buƙata don amfani da Ƙarshen SPI zuwa ƙirar ƙira ya bambanta dangane da rikitarwa na ƙirar da ƙayyadaddun tsari na ƙarewa.Zai iya tafiya daga sa'o'i kaɗan zuwa kwanaki da yawa.