Yala aw delila k’aw yɛrɛ ɲininka cogo min na nɛgɛ yɔrɔw bɛ u cogoya manamanananw mara ani ka u ka nɔgɔw kunbɛn wa? Jaabi bɛ sɔrɔ surface finishing fɛɛrɛw la i n’a fɔ anodizing ani electroplating. O wale ninnu bɛ nɛgɛ yɔrɔw cogoyaw bonya, nka u bɛ baara kɛ cogoya wɛrɛw la.

Anodizing ni electroplating ye fɛɛrɛ fila ye minnu bɛ kɛ tuma caman na walasa ka nɛgɛ yɔrɔw muɲu, ka u sɔgɔ, ani ka u cogoya ɲɛ. Hali ni o fɛɛrɛ fila bɛɛ bɛ tali kɛ kuran-sɛnɛcogo la, u bɛ danfara don u ka taabolo la ani u bɛ nɔ minnu bɔ.

Nin barokun in kɔnɔ, an bɛna danfara jɔnjɔnw Sɛgɛsɛgɛ anodizing ni electroplating cɛ. Aw bɛna a dɔn baara kelen-kelen bɛɛ cogoya kɛrɛnkɛrɛnnenw kan, u bɛ se ka baara kɛ ni nɛgɛ minnu ye, ani u kɛcogo danma ye izini suguya caman na. Ni i ye o danfara ninnu faamuya, i bɛna se ka surface finishing technique ɲuman sugandi i mago kɛrɛnkɛrɛnnenw kama, i mana kɛ fɛn dilanni na, fɛn dilanni na, walima injiniyɛri la.

Faamuyali anodizing .

Anodizing taabolo .

Anodizing ye kuran-sɛnɛcogo ye min bɛ ɔkisizɛni nafama lamini nɛgɛw kan, kɛrɛnkɛrɛnnenya la aluminiyɔmu. A bɛ kɛ ni nɛgɛ su ji la ni kuran ye ani ka kuran kɛ. O bɛ kɛ sababu ye ka ɔkisizɛni ionw kɛ ni nɛgɛ ye, ka oksizɛni layɛrɛ dɔ dilan min ka bon, min bɛ se ka wuli.

Anodizing waati la, nɛgɛ bɛ kɛ i n’a fɔ anɔdi min bɛ electrolytic cellule kɔnɔ. Ni kuran bɛ don, oksizɛni ionw bɛ bɔ elekitorolite sirili la ni aluminiyɔmu atomu ye a sanfɛ. U bɛ kɛ aluminiyɔmu ɔkisidi layɛrɛ ye min ka gɛlɛn ani min bɛ se ka sɔgɔ ka tɛmɛ nɛgɛ yɛrɛ kan.

Electrochimique (elektrokimika) fɛɛrɛ bɛ oksidan layɛrɛ jɔ ni fɛɛrɛ ye min bɛ kɔlɔsi kosɛbɛ:

Aluminiyɔmu atomu minnu bɛ surface la, olu bɛ elekitɔnw Bɔ ka Kɛ ion chargement positif ye.

O ionw bɛ Taa ɔkisizɛni layini min bɛ yen, olu bɛ Bɔ ka Taa elekitoroliti fan fɛ.

O waati kelen na, oksizɛni ionw charge négatifs bɛ bɔ elekitoroliti la ka taa nɛgɛ sanfɛla la.

Oksizɛni ni aluminiyɔmu ionw bɛ ɲɔgɔn sɔrɔ, ka aluminiyɔmu ɔkisidi (AL2O3) kɛ a sanfɛ.

Ni o kɛcogo bɛ ka taa ɲɛ, oksizɛni layɛrɛ bɛ bonya ka taa a fɛ, o bɛ lakana ni muɲuli bonya di.

Anodizing suguyaw .

Anodizing suguya saba bɛ yen, u kelen-kelen bɛɛ ka nafaw ni u ka baarakɛcogo tɛ kelen ye:

A suguya fɔlɔ: Asidi kuromiki anodize (CAA) .

A suguya II: Asidi sulfuriki anodize (SAA) .

suguya III: Anodize gɛlɛn .

Hali ni aluminiyɔmu ye nɛgɛ ye min bɛ sɔrɔ ka caya, o kɛcogo bɛ se ka kɛ fana titaniyɔmu, manje ani nɛgɛ wɛrɛw la minnu tɛ nɛgɛ ye.

Asidi chromique anodize (Type i) .

Asidi chromique anodize (CAA), walima suguya fɔlɔ anodizing, o bɛ ɔkisizɛni layɛrɛ finman, dense dilan ni asidi kromiki ye i n’a fɔ elektrɔli. Filimu min bɛ sɔrɔ o la, o ka nɔgɔn ka tɛmɛ anodizing suguya tɔw kan nka a bɛ corrosion resistance ɲuman di. CAA bɛ kɛ ka caya aerospace baara la yɔrɔ min na, a bɛ ɲini ka kɛ fɛn finman ye, min bɛ a tanga.

Anodize sulfuric (suguya II ani IIB) .

Asidi sulfuriki anodize (SAA), walima anodizing suguya II, o ye suguya ye min ka ca. A bɛ baara kɛ ni asidi sulfuriki ye i n’a fɔ elekitoroliti, o bɛ na ni ɔkisizɛni sɔgɔlen ye ka tɛmɛ suguya fɔlɔ kan. suguya II anodizɛli bɛ sɛgɛn ni sɔgɔli kɛcogo ɲuman di, o b’a to a bɛnnen don fɛn dilanni, mobili ani fɛn feeretaw ma.

suguya IIB ye suguya II suguya ye, a bɛ kɛ fɛn ye min ka fin ka tɛmɛ suguya II kan. A bɛ balansi Di suguya fɔlɔ filimu finman ni suguya filanan ka 'yɔrɔ min ka bon.

Anodize gɛlɛn (suguya III) .

Anodize gɛlɛn, walima suguya III anodizing, bɛ baara kɛ ni asidi sulfuriki elekitoroliti ye min ka ca ni elekitoroli ye ani ka wuli ka caya walasa ka ɔkisizɛni caman sɔrɔ. O yɔrɔ min bɛ sɔrɔ o la, o bɛ se ka sɛgɛn kosɛbɛ, wa a bɛ mɛn, o b’a to a ka ɲi kosɛbɛ izini baara la i n’a fɔ aerospace yɔrɔw, masinw yɔrɔw, ani fini caman.

Anodizing gɛlɛn bɛ abrasion ni corrosion resistance ɲuman di ni a bɛ tali kɛ suguya wɛrɛw la. A bɛ fini dɔ di min bɛ mɛn sen na, min bɛ a tanga, min bɛ se ka sigida gɛlɛnw ni masinw degunw muɲu.

Nafaw ni dantigɛliw anodizing .

Nafa minnu bɛ sɔrɔ anodizing .

Anodizing bɛ nafa jɔnjɔn caman di:

Fɛn min bɛ se ka kɛ sababu ye ka fɛnw tiɲɛ : oksizɛnimugumugu bɛ nɛgɛ min bɛ a jukɔrɔ, o tanga nɔgɔ ma, hali sigida gɛlɛnw na.

Surface hardness ani ears resistance : anodized surfaces ka gɛlɛn ani u bɛ se ka sɔgɔsɔgɔ ni sɛgɛn, ka nɛgɛ ɲɛnamaya janya.

Kulɛri suguya masirilenw ka tɛmɛn kalali fɛ : ɔkisizɛni porose bɛ se ka kalali minɛ, o bɛ se ka kɛ sababu ye ka kulɛri fini caman dilan.

Kuranko gɛlɛyaw : layɛrɛ anodizelenw tɛ se ka wuli, o b’a to u bɛnnen don kuran sɛnɛcogo ma.

Sigida lakanani taabolo : Anodizing ye wale ye min saniyalen don kosɛbɛ ani min tɛ sigida lakana ni a bɛ tali kɛ yɔrɔ furakɛli wɛrɛw la.

Dantigɛli minnu bɛ kɛ anodizing kan .

Hali n’a nafa ka bon, dan dɔw bɛ anodizing na:

Dan bɛ nɛgɛ dɔw la : Anodizing bɛ baara kɛ ka ɲɛ aluminiyɔmu ni titanium kan. A man ɲi walima a man ɲi nɛgɛ wɛrɛw ma.

Oksizɛni finman ni a bɛ tali kɛ finimugu wɛrɛw la : hali ni anodizɛli bɛ lakana ɲuman di, oksizɛni layɛrɛ ka fin kosɛbɛ ni a bɛ tali kɛ a sanfɛla furakɛli wɛrɛw la.

Ni dɔ farala bɔgɔmugu dɔw kan : anodizing ka gɛlɛya bɛ se ka aluminiyɔmu nɛgɛma dɔw kɛ kari ka caya ani ka u ka kari.

Musaka caman bɛ sɔrɔ hakɛ fitininw na : Anodizing bɛ se ka sɔngɔ gɛlɛya ka tɛmɛ fini wɛrɛw kan minnu bɛ kɛ ka ɲɛsin baara misɛnninw ma minnu bɛ kɛ ka da a sigicogo musakaw kan ani a baarakɛwaati kan.

Faamuyali min bɛ kɛ ni kuran ye .

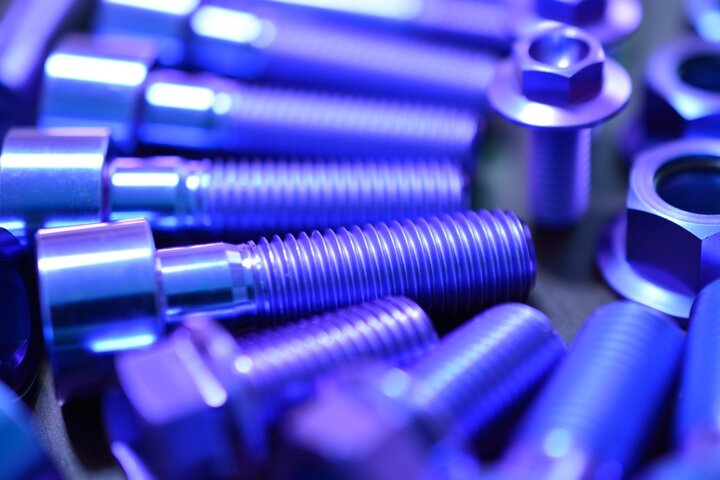

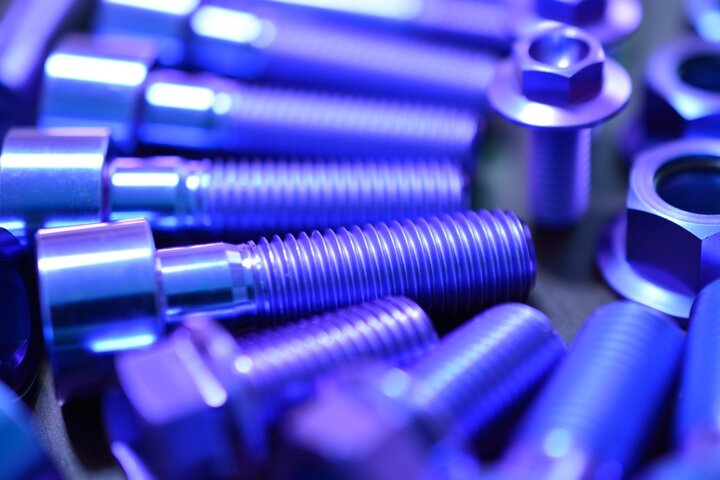

Elektɔri-plati kɛcogo .

Kuranko ye fɛɛrɛ ye min bɛ baara kɛ ni kuran ye walasa ka nɛgɛfɛn dɔ ko ni nɛgɛ wɛrɛ ye min ka fin. A bɛ substrat cogoya, a sɔgɔli, a kɛcogo ani a jogo wɛrɛw bonya. Nɛgɛ minnu bɛ Kɛ ka caya ni kuran ye, olu ye chrome, nickel, copper, sanu ani warijɛ ye.

Kuranko la, fɛn min ka kan ka kɛ (substrate) o bɛ su ji la elekitoroliti jilama kɔnɔ, nɛgɛ ion wulilen bɛ min kɔnɔ. Kuran tilennen bɛ Kɛ, ni substrat bɛ Kɛ katodi ye ani nɛgɛ elekitorode (plating metal) i n’a fɔ anɔdi. Kuran bɛ kɛ sababu ye ka plating metal ionw wuli ka taa substrat la ka kɛ layɛrɛ finman ye, min bɛ nɔrɔ a la.

Kuranko taabolo bɛ tali kɛ nin wale ninnu na:

Substrat surface saniya ni a labɛnni .

Substrat ni anode su ji la elektrɔliji la .

Kuran tilennen waleyali walasa ka nɛgɛ ion jiginni daminɛ .

Plating nɛgɛ bilali substrat surface kan .

Koli ni furakɛli kɔfɛ fɛn min bɛ kɛ ka fɛnw ko .

Kuranko ni a kɛcogo suguyaw .

Kuranko bɛ se ka tila ka caya ka kɛ suguya fila ye:

Decorative electroplating : A bɛ fɛnw yecogo ɲɛ ni nɛgɛ ye min bɛ kɛ ni nɛgɛ ye min bɛ mɔgɔ sama, min bɛ manamana, walima min ɲɛw ye ɲɛgɛn ye. Misaliw ye mobili trim ye min bɛ kɛ ni chrome ye ani biye sanulama.

Baarakɛminɛnw : a bɛ substrat ka jogo kɛrɛnkɛrɛnnenw ɲɛ, i n’a fɔ sɔgɔli, sɛgɛnbaliya, walima kuran taabolo. Nin suguya in bɛ baara kɛ kosɛbɛ iziniw kɔnɔ.

Plating suguya wɛrɛ, plating électroless, o tɛ kɛnɛma current source wajibiya. O nɔ na, a bɛ da kemikaliya dɔgɔyali wale kan walasa ka nɛgɛ bila substrat kan.

Nikɛri plating .

Nikɛri plati bɛ kɛ ka caya izini suguya caman na a ka sɔgɔli ni a ka sɛgɛncogo ɲuman na. A bɛ nɛgɛ yɔrɔw lakanani ni u masirili di mobili, aerospace, elekitoroniki, ani fɛnw feereli fɛnw na. Nikɛri plati fana bɛ kɛ jukɔrɔlafini ye plating kɛcogo wɛrɛw la, i n’a fɔ chrome plating.

chromium plating .

Kɔrɔmu plating bɛ fini jɛlen, manamana, ani min bɛ mɛn, o bɛ fɛnw ɲɛnajɛcogo ɲɛ ka sɔrɔ ka u sɔgɔli ni u sɛgɛncogo ɲuman di. A bɛ kɛ ka caya mobili yɔrɔw, saniyafɛnw, ani izini yɔrɔw kan. Kɔrɔmu plating bɛ se ka kɛ decorative ye walima ka gɛlɛn, ka kɛɲɛ ni a kɛcogo ye.

Kupu ni warijɛ plating .

Kupu plati bɛ baara kɛ kosɛbɛ ɛntɛrinɛti baara la k’a sababu kɛ a ka kuran taabolo ɲuman n’a jɔli ye. A bɛ kɛ ka ɲɛsin ciriw ma minnu sɛbɛnnen don, ɲɔgɔndanw, ani ɛntɛrinɛti yɔrɔ wɛrɛw. Kupu plati fana bɛ kɛ fɛn ye min bɛ kɛ ka plati kɛcogo wɛrɛw kɛ, i n’a fɔ nikɛri ni chrome.

Silver plating, i n’a fɔ kuran, a bɛ kuran caman di, wa a bɛ kɛ ni kuran ye, switchw, ani fɛnw dontaw. Aerospace industry bɛ baara kɛ ni warijɛ plating ye a ka funteni jiginni ɲuman n’a ka galling anti-galling nafaw kama.

Nafa ni dɛsɛ bɛ sɔrɔ kuran na .

Nafa minnu bɛ sɔrɔ kuran na .

Electroplating bɛ nafa caman di:

Nɛgɛ suguya caman bɛ se ka bila, o bɛ kɛ sababu ye ka fɛn caman kɛ baarakɛcogo la.

Fɛn minnu bɛ kɛ ka fɛnw sɔgɔ, olu ka ɲɛnamaya kɛcogo ɲɛ.

Kuranko ɲɛnabɔli min bɛ bonya, o b’a to a ka ɲi kosɛbɛ ɛntɛrinɛti yɔrɔw la.

Decoratif finiw ni nɛgɛ suguya caman bɛ aesthetic appeal di.

Yɔrɔ minnu sɛgɛnnen don, olu dilancogo n’u lasegincogo bɛ se ka sɔrɔ ni kuran ye.

Nafa minnu bɛ sɔrɔ kuran na .

Hali n’a nafa ka bon, kuran-sɛnɛfɛnw nafa dɔw bɛ yen:

O kɛcogo bɛ kɛ ni kemikɛlifɛn bagajiw ni nɛgɛ gɛlɛnw ye, minnu bɛ se ka kɛ sababu ye ka sigida faratiw lase sigida ma ni u ma ɲɛnabɔ ka ɲɛ.

Kuranko bɛ kuran fanga caman dun, o b’a to a fanga ka bon.

Baarakɛlaw bɛ se ka faratiw sɔrɔ kɛnɛyako la ka a sababu kɛ fura faratilenw ye. 4.Stringent nɔgɔw kunbɛncogo wajibiyalenw ka kan ka kɛ walasa ka sigida nɔgɔli bali.

Sɛgɛsɛgɛli min bɛ kɛ ni ɲɔgɔn ye .

Danfaraba minnu bɛ anodizing ni electroplating cɛ .

Anodizing . Surface finish ani electroplating ye surface furakɛli taabolo danfaralenw ye ni danfara jɔnjɔnw ye u ka fɛɛrɛw n’u ka sɔrɔw la. Anodizing bɛ kɛ ɔkisizɛni lakananen ye nɛgɛ sanfɛ, ka sɔrɔ kuran bɛ nɛgɛ wɛrɛ bila substrat kan.

Anodizing bɛ kɛ fɔlɔ aluminiyɔmu ni titaniyɔmu na, k’a sɔrɔ kuran bɛ se ka kɛ nɛgɛ suguya caman na, i n’a fɔ nɛgɛ, nɛgɛ ani nɛgɛ. Anodizing (anodizing) kɛcogo bɛ ɔkisizɛni layɛrɛ finman dɔ Bɔ n’i y’a Jira ko nɛgɛ-yɔrɔ min Dònna ni kuran ye.

Datugulanw cogoyaw fana bɛ danfara bɔ:

Laminiko siratigɛ la, a ka c’a la, anodizing bɛ jate ko a ka fisa, bawo a tɛ nɛgɛ gɛlɛnw sen don a la. Nka, kuran bɛ se ka kɛ sababu ye ka sigida ni kɛnɛyako faratiw lase mɔgɔ ma ka da a kan a bɛ kɛ ni bagajiw ye.

| Aspect | anodizing | electroplating . |

| Baarakɛcogo fɛɛrɛ . | A bɛ kɛ ɔkisizɛni layɛrɛ ye . | Deposits métal layer . |

| Nɛgɛ minnu bɛ baara kɛ . | Fɔlɔ aluminiyɔmu ni titaniyɔmu . | Nɛgɛ suguya caman (nɔgɔ, nɛgɛ, a ɲɔgɔnnaw) . |

| Datugulan janya . | Layɛrɛ finmanw . | Layɛrɛ minnu ka bon . |

| gɛlɛya . | sanfɛ . | Ka lajigin |

| Aw bɛ resistance don . | sanfɛ . | Ka lajigin |

| Conductivité . | Ka lajigin | sanfɛ . |

| Sigida laminiko gɛlɛya . | A ka ca a la a ka fisa . | Farati minnu bɛ se ka sɔrɔ kemikɛliw la . |

Anodizing ni electroplating baarakɛcogo .

Anodizing bɛ baara caman sɔrɔ aerospace, mobili, fɛn dilanni, ani fɛnw feereli baarakɛyɔrɔw la. Aluminiyɔmu yɔrɔ anodizelenw bɛ sɔrɔ awiyɔn yɔrɔw la, fɛn dilanni ɲɛda la, ani fɛnw feereli la. O kɛcogo bɛ sɔgɔli, muɲuli, ani cɛɲi sugandiliw di o baarakɛcogo ninnu na.

Kuranko bɛ kɛ ka caya mobili, kuran, biye ani aerospace baarakɛyɔrɔw la. Misaliw ye:

Mobili trim ni wotoro min bɛ ni chrome ye .

Bijoux ni électroniques sanulama .

Aerospace components nickel-plates .

Circuit boards imprimées (Circuit) minnu bɛ kɛ ni nɛgɛ ye .

Sugandili min bɛ kɛ anodizing ni electroplating cɛ, o bɛ bɔ a kɛcogo kɛrɛnkɛrɛnnen na, i n’a fɔ substrat nɛgɛ, a ka nafolo ɲininenw, a musaka, ani a sigida jateminɛw.

Desizɔn minnu bɛ sɔrɔ sugandili la anodizing ni electroplating cɛ .

Ni aw bɛ a latigɛ anodizing ni electroplating cɛ, aw bɛ nin ko ninnu jateminɛ:

Substrate Metal: Anodizing bɛnnen don aluminiyɔmu ni titaniyɔmu ma, ka sɔrɔ kuran bɛ se ka kɛ nɛgɛ suguya caman na.

Fɛn minnu bɛ ɲini: Anodizing bɛ sɛgɛn ni gɛlɛya ɲuman di, ka sɔrɔ kuran-minɛnw bɛ se ka kɛ ni fɛnw ye minnu bɛ se ka kɛ ka fɛnw ta ka ɲɛ ani ka fɛnw masiri.

Muɲu : Anodizing (anodizing) caman bɛ musaka bɔ baarabaw la, k’a sɔrɔ kuran bɛ se ka kɛ sɔrɔko ye batch (batch) misɛnninw na.

Sigida laminiko : Anodizing ka teli ka fisaya k’a sababu kɛ a ka sigida ni kɛnɛyako faratiw ka dɔgɔn ni a bɛ tali kɛ kuran na.

Anodizing de ka fisa ni:

Substrat ye aluminiyɔmu walima titanium ye.

A ka kan ka kɛ ni sɛgɛnba ye ani a ka gɛlɛn.

Fini min bɛ mɛn, min bɛ se ka sɔgɔsɔgɔ, o de ka kan ka kɛ.

Sigida haminankow ye ko ye min bɛ bila ɲɛfɛ.

Elektɔri ka fisa ni:

Substrat ye nɛgɛ ye min tɛ aluminiyɔmu walima titaniyɔmu ye.

Kuranko ɲɛnabɔli ye ko kɔrɔba ye.

Fini masirilen caman bɛ ɲini.

Aw bɛ finimugumuguw kɛ minnu ka bon, minnu bɛ u tanga.

Tuma dɔw la, o kɛcogo fila bɛɛ bɛ se ka fara ɲɔgɔn kan, i n’a fɔ ka anodizɛli kɛ furakɛli ɲɛfɛ sani kuran ka kɛ. O faralen ɲɔgɔn kan, o bɛ se ka kɛ sababu ye ka kuran dacogo ni a muɲuni sabati.

A laban na, sugandili min bɛ kɛ anodizing ni electroplating cɛ, o bɛ bɔ a kɛcogo ɲinini kɛrɛnkɛrɛnnenw na. Aw ye fɛnw, nafolo ɲininenw, musaka ani sigida fɛnw jateminɛ walasa ka fɛɛrɛ min bɛnnen don kosɛbɛ aw magow ma, aw ye o sugandi.

Ɲininkaliw jaabiw .

J:Nɔgɔw ni nɛgɛ tɛ minnu na, olu fila bɛɛ bɛ se ka kɛ anodize ye wa?

Ayi, nɛgɛ dɔw dɔrɔn i n’a fɔ aluminiyɔmu, titaniyɔmu ani manje bɛ se ka kɛ anodi ye. Nɛgɛ minnu tɛ nɛgɛw ye ani nɛgɛ wɛrɛw i n’a fɔ nɛgɛ tɛ se ka kɛ ɔkisizɛni wajibiyalen ye anodize waati la.

J:Anodizing vs. electroplating sigida laminiko ye mun ye?

A ka c’a la, anodizing bɛ jate sigida lakanani ye ka tɛmɛ kuran kan. A tɛ nɛgɛ gɛlɛnw ni kemikɛli bagajiw ta, o b’a to a ka fisa baarakɛlaw ma ani a tiɲɛniw ɲɛnabɔli ka nɔgɔn.

Q:Anodizing musaka bɛ se ka kɛ cogo di ni electroplating ye porozebaw kama?

Anodizing bɛ se ka musaka bɔ ka tɛmɛ kuran kan porozebaw kama. Setup musakaw ni baarakɛwaati min bɛ kɛ ka anodizing kɛ, olu ka teli ka dɔgɔya, kɛrɛnkɛrɛnnenya la ni aluminiyɔmu yɔrɔw bɛ baara kɛ.

J:Gɛlɛyaw furakɛcogo fila ye mun ye minnu bɛ kɛ ka caya o wale fila bɛɛ la?

Anodizing ni electroplating fila bɛɛ la, surface labɛnni ɲuman nafa ka bon kosɛbɛ. Aw bɛ aw jija a yɔrɔw ka saniya ani ka nɔgɔ bɔ u la. Aw bɛ elekitoroliti hakɛ kɔlɔsi ani ka sisan density ni température bɛnnen mara walasa ka ɲɛtaa ɲuman sɔrɔ.

Kuncɛli

Anodizing ani electroplating bɛ nafa danfaralenw di nɛgɛ sanfɛla labɛnni na. Anodizing bɛ kɛ ɔkisizɛni lakanani layɛrɛ ye, ka sɔrɔ kuran bɛ nɛgɛ layɛrɛ dɔ bila substrat kan. Sugandili bɛ bɔ fɛnw na i n’a fɔ nɛgɛ basigilen, nafolo ɲininenw, musaka, ani sigida laminiko.

Fɛɛrɛ kelen-kelen bɛɛ bɛ baara kɛrɛnkɛrɛnnenw kɛ iziniw kɔnɔ i n’a fɔ aerospace, mobili, ɛntɛrinɛti, ani fɛnw feereli fɛnw.

Aw ye aw ka wajibi kɛrɛnkɛrɛnnenw jateminɛ ni aw bɛ surface finishing kɛcogo dɔ sugandi. Aw ye ɲininkali kɛ ni dɔnnikɛlaw ye walasa ka fɛɛrɛ ɲuman dɔn aw ka poroze kama.

Aw bɛ anodizing sugandi aluminiyɔmu walima titanium yɔrɔw la minnu mago bɛ sɔgɔsɔgɔninjɛ kunbɛnni na ani a muɲuni na. Aw bɛ kuran sugandi ni a bɛ se ka kɛ ko a bɛ se ka kɛ ni fɛn wɛrɛw ye walima ni a bɛ fɛnw masiri, o nafa ka bon kosɛbɛ nɛgɛ wɛrɛw la.

Danfara minnu bɛ anodizing ni electroplating cɛ, olu faamuyali bɛ se ka kɛ sababu ye ka latigɛw latigɛ minnu bɛ baara kɛcogo, musaka ani sabatili ɲɛ.