Akwatin, wanda aka saba sansu da zaren dunƙule, tsari ne mai haske da ke kunshe da siliki ko kuma condic. Yana ba da damar motsi da za a canza shi zuwa motsi na layi. Zaren suna da mahimmanci a cikin injiniya don shiga sassan, ƙirƙirar motsi, da kuma karfi.

Tarihi da Muhimmancin zaren a Injiniya

Ra'ayoyin sun kasance alaƙa da injiniyan injiniya na ƙarni. Manufar kwanakin da aka yi wa tsoffin lokutan da aka yi amfani da shi lokacin da aka yi amfani da shi don haɓaka haɓaka da kuma ɗaga aikace-aikace. Kamar yadda masana'antu masana'antu ke ci gaba, an gabatar da tsarin siffofin zaren don tabbatar da jituwa da rashin canji. A yau, zaren suna da mahimmanci a kusan kowane ɓangaren injiniya, daga Aerospace zuwa masana'antar mota. Sun tabbatar da karfi, haɗi masu fasa kuma suna kunna madaidaicin motsi.

Nau'in aikace-aikacen zaren

Heates suna bauta wa dalilai daban-daban dangane da bukatun injiniya. Aikace-aikacen da aka fi amfani da su na yau da kullun sun haɗa da:

Ana amfani da subanni : Waɗannan ana amfani da waɗannan don riƙe abubuwan biyu ko fiye tare tare cikin amintattu. Kamanni da kwayoyi sune misalai na gargajiya na kusurwar zaren. An samo su a cikin masarufi, motoci, da ayyukan gini saboda ingantattun taro.

Motsa makasudin motsi : waɗannan zaren suna canza motsi zuwa motsi na layi. Jakadun manyan sukurori a cikin injuna da jacksks a cikin kayan aiki sune misalai masu kyau. Daidai ƙirar su yana ba su damar fassara juyawa zuwa santsi, motsi mai sarrafawa, yana sa su zama da muhimmanci ga tsarin injin na buƙatar daidaito.

Safar jigilar kaya : galibi ana samunsu a cikin tsarin masu isar da isar da iskar ruwa, waɗannan zaren suna taimakawa kayan sufuri ko ruwa. Su ci gaba da karkace su ba da damar abubuwa don motsawa tare da ƙarfi tare da ƙarfi da ƙarfi, yana sa su amfana a masana'antu kamar noma.

Geometry da tsara zaren

Zaren geometry yana taka muhimmiyar rawa wajen tantance aikinta da dacewa don aikace-aikace daban-daban. Kowane siga yana tasiri yadda zaren ya yi aiki, canja wurin karfi, da kuma kiyaye tsarin tsari. Bari mu bincika sigogi masu mahimmanci da kayan aikin da aka yi amfani da su don auna zare.

Geometric sigogi na zaren

Abubuwan da ke biye da geometric sun ayyana yanayin da halayyar zaren:

Babban diamita : Mafi girma diamita na zaren, auna a saman fi na waje na zaren ko kuma kasan zaren ciki. Yana ƙayyade girman gaba ɗaya da ƙarfin suttura.

Oran ƙaramin diamita : mafi ƙarancin diamita, auna a cikin tushen zaren waje ko saman zaren ciki. Ya fassara da kauri daga kayan a cikin zuciyar dunƙule ko aron.

Pitch Diamita (Ingantaccen diamita) : diamita na silinda ke wucewa ta hanyar zaren zaren. Yana da mahimmanci don tabbatar da dacewa da sa hannu tsakanin masu canzawa, wanda ya shafi yadda suke mish.

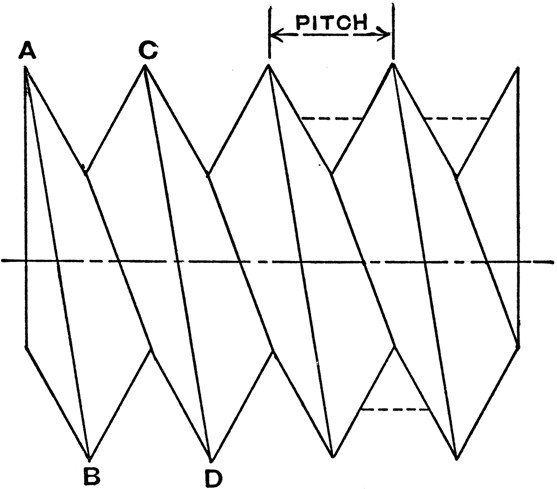

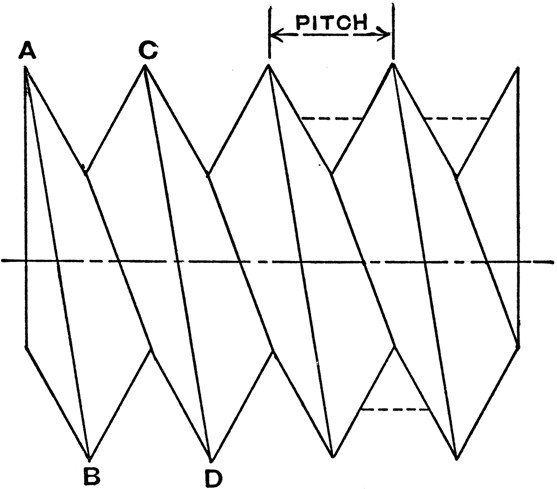

Filin wasan kwaikwayo : Nisa naxial tsakanin maki masu dacewa akan zaren kusa da kusa. Wani matakin da ya fi girma yana ba da damar mama mai sauri a kowane juyawa, yayin da ƙananan ƙaramin fa'ida yana samar da tsari mai kyau da haɓaka na injiniya.

Jagora : Distance zaton ci gaban daya cikakken juyawa. A kan zaren-fara, kai tsaye daidai da farar, amma a kan zaren da yawa na fara, jagora muhimmin filin wasan ne.

Zaren yana farawa : Yana nufin yawan zaren zaren akan dunƙule. Wani zaren farawa guda daya yana da ci gaba mai ci gaba, yayin da mahimmin zaren da yawa suna ba da motsi mai laushi a kowace juyawa.

Gelier kusurwa Baki na Steeperper na rage gogewa amma zai iya rage riƙe iko.

An kafa kusurwa ta zaren : kusurwar kafa tsakanin flanks na kusa da zaren. Wannan yana shafar yadda ake rarraba karfi da kuma tasiri ingancin zaren da ake mayar da kaya.

Bayanan haƙoran haƙori : siffar da kusurwa na ɗayan hakora, wanda ya bambanta dangane da ƙirar zaren da kuma manufa. Motar hakori na iya zama trapezoidal, murabba'i, ko triangular, tasiri, ƙarfin ƙarfin zaren da kuma abubuwan tashin hankali.

Auna kayan aiki don zaren

Cikakken ma'aunin zare na da mahimmanci don tabbatar da daidaituwa tsakanin abubuwan dabbar dabbar ta hanyar canjin. Kayan aikin farko da aka yi amfani da su don wannan dalilin sune:

Caliper : kayan aiki mai ma'ana don auna manyan da ƙananan diamita na maza biyu (waje) da kuma mata (na ciki). Daidai ya ba da injiniyoyi don auna girman zare da sauri kuma daidai.

Bitch Get : Kayan aiki na musamman da aka tsara don auna nesa tsakanin crest. Yana da mahimmanci don gano rami na zaren kuma ana amfani dashi don nau'ikan awo da na sarƙoƙi.

Gano zaren

Cikakken gyaran ma'anar zaren yana da mahimmanci ga zaɓin da ya dace da daidaitaccen tsarin. Bi waɗannan matakan don gano zaren:

Matakai don gano zaren

1. Namiji vs. Mace Mata

Male zaren: harkokin waje a kan bolts, sukurori, ko bututu.

Mace zaren: Grooves na ciki a cikin kwayoyi, ramuka, ko kayan aiki.

Binciken gani; jinsi ba ya tasiri aiki amma suna ƙayyade abubuwan haɗin taɗi.

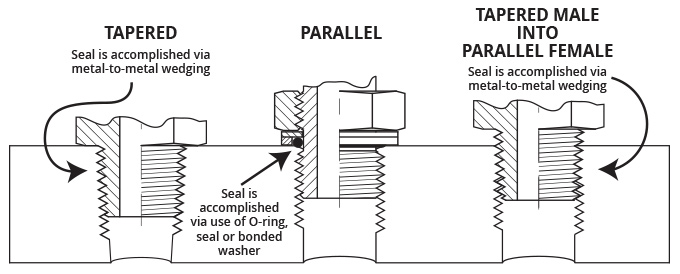

2. Cire vs. layi daya

Parallel threads kula da sauƙin diamita tare tsawon lokaci.

Sauke zaren saukarwa a diamita zuwa ƙare.

Yi amfani da calipers don tabbatarwa: Daidaitaccen zaren lamba cikakke, Rocks Rock.

3. Ada

Yi amfani da filin wasan kwaikwayon don tantance nesa tsakanin crest locate.

Ga zaren aji na aji, ƙidaya zaren kowace inch (tpi).

Don zaren awo, auna nesa tsakanin crests a milimita.

4. Gyara girman zaren

Matsakaicin girman ma'aunin zare ya dogara da nau'in zare na zaren:

| sauƙin | Hanyar daidaita |

| PIPE Flers | Kwatanta bayanin girman martaba |

| Rarraba marasa-bututu | Auna waje na diamita tare da da'ira |

5. Tsararren nau'in nau'in zare

Kwatanta ma'aunai ga daidaitattun tebur:

NTT / NTTF don zaren bututun dan adam

BSP ga Standard Pie Stread

Awo ga ma'aunin ƙasa na duniya

Un / unt for fadeled na kasa

Dokokin Kula da Bayani

A cikin Injiniya, ka'idojin zaren da bayanai don tabbatar da daidaituwa, musiya, da kuma daidaitawa a cikin tsarin daban-daban da masana'antu. Kowane ma'auni yana bayyana geometry zaren, farar ƙasa, da haƙuri. Anan, zamu tattauna ka'idodi da aka fi amfani da su, gami da kungiyar awo na awo, da aka kafa a cikin zaren Birtaniya, da kuma bututun dan kasar Burtaniya.

Iso awoms (m)

ISO 'Zaurciyar ISO ita ce mafi kyawun yanayin yanayin duniya. Yana amfani da ma'aunin etrics ga duka diamita da farar fata, daidaitawa a cikin yankuna.

Bayanin Bayanai da girma : ISO 'Zazzage Hyitoci suna da bayanin martaba na digiri na biyu, an bayyana shi da diamita na noma da farar ƙasa. Dukkan girma ana auna shi cikin milimita.

M da kyau pitch jerin sunayen: og, m10 × 1.5) ana amfani dashi a aikace-aikacen gaba ɗaya, yana samar da mafi yawan masana'antu. Lafiya mai kyau pitch jere (misali, m10 × 1.0) ana amfani da shi lokacin da ake buƙatar dace da daidaito da daidaito da daidaito.

Matsayi na haƙuri kuma ya yi daidai : ISO Suraye 'yan uwallu an raba shi cikin juriya, kamar 6g da 6h, tantance matakin rarrabuwa ko tsangwama. Tsarkakakken haƙuri yana ba da izinin tafiya, yayin da wadatar haƙuri ta ba da damar kawo wuri.

An haɗa da daidaitaccen daidaito (or ba un uni ba

An yi amfani da daidaitattun daidaitattun daidaitattun abubuwa (UTTs) a cikin Amurka, Kanada, da ɓangarorin Ingila suna ba da ma'auna cikin inci kuma suna kama da zaren awo da aka yi amfani da su da kyau.

Bayanin Bayani da girma : zaren uts yana da cikakkiyar bayanin martaba na 30, an auna shi cikin inci. Ya ƙunshi duka m (or ba uri ba da lafiya (ba na hanya ba.

M da act Pitch Serp : Kamar ¼ 'yayin da ba a yi amfani da zaren ba, kamar yadda ¼ , 28 UV da ba su da daidaito da ƙarfi a cikin takamaiman masana'antu.

Misalai na haƙuri kuma sunyi daidai : Uts yana ba da wasu azuzuwan haƙuri, tare da azuzuwan da ake amfani da shi waɗanda suka hada da aji 1 (Sako-sako), aji na 2 (m dacewa).

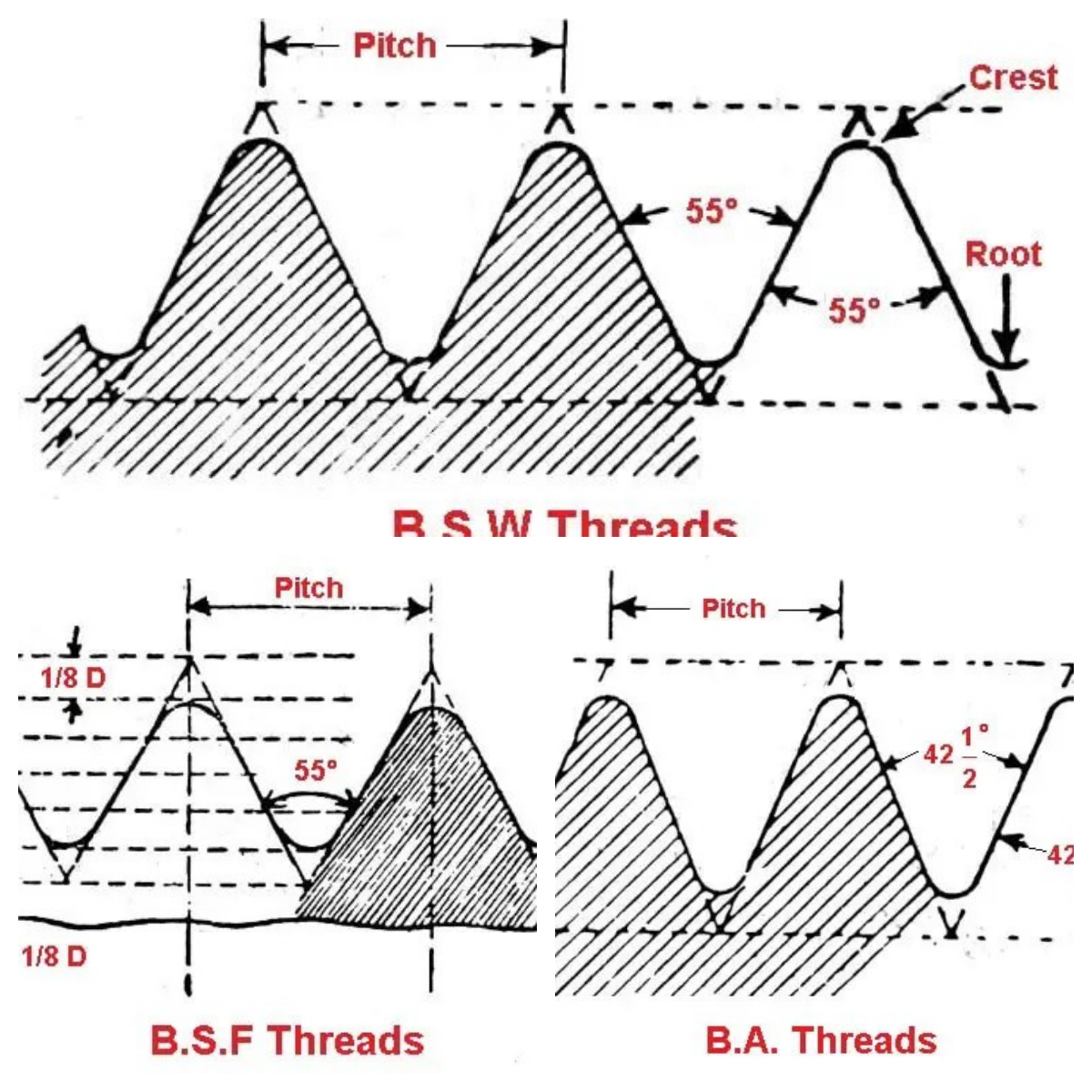

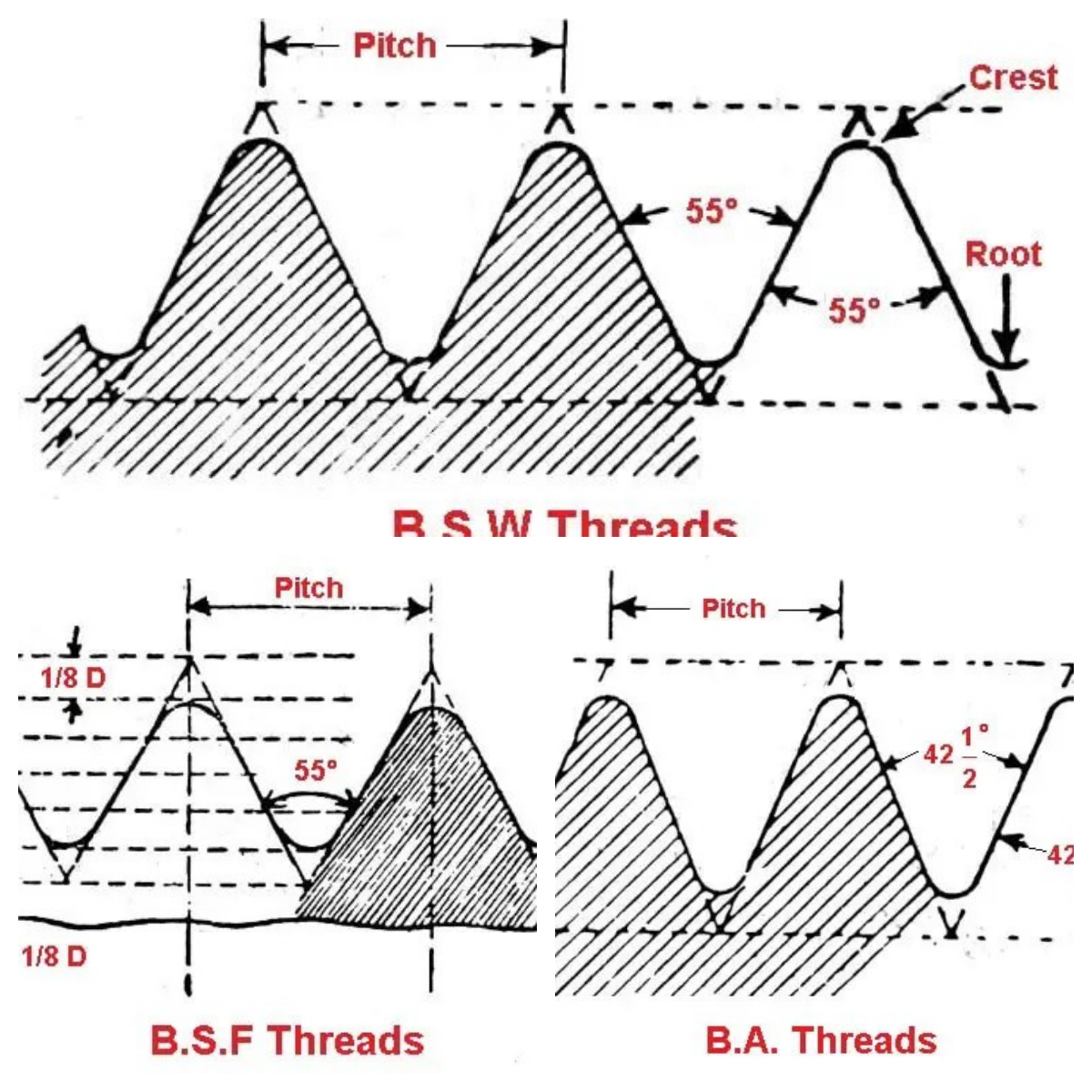

British Standars

Hannun Burtaniya tsarin gado ne, har yanzu ana amfani dashi a cikin Burtaniya da Cometilalalth. Wadannan zaren sun hada da cewa, lafiya, da kuma bututu.

Suraye Ana amfani dashi don gabaɗaya-manufa, musamman a cikin manoma inji.

Mace fannoni na Burtaniya (BSF) : Kamari da BSW amma tare da fina-finai na finh, bsf sililin suna ba da haɗin haɗi mai ƙarfi a aikace-aikacen da ke ƙarƙashin rawar jiki, kamar kayan aiki da Aerospace.

Rediyon BIGH Standard Streas Streate (BSP) : Ana amfani da zaren BSS sosai don bututun bututun. BSPP (a layi daya) Rayu na na bukatar hatimi na waje, yayin da zaren da aka buga) ta hanyar da aka yi wa aure.

Ba'amurke na Amurka

Asali na Kasa na Ba'amurke na Ba'amures na bututun bututun ya hada da npt da nttf iri, wanda aka tsara don aikace-aikacen slokations.

Iyakoki da bambance-bambance na ƙa'idodi daban-daban

Ka'idodin zaren daban-daban ba su dace da kullun ba, yayin da suke bambanta cikin rami, kusurwar zaren, da dacewa. Iso awo na awo suna bin tsarin duniya ta amfani da raka'a naúrar, yayin da aka ba da sanarwar zaren amfani da hanyoyin Ingila suna amfani da ma'aunin sarki. Standarfin bututun mai kamar npt da kuma BSP kuma sun bambanta da tsarinsu don ɗaukar hoto da dacewa, ƙarin karfinsa ƙarin rikice-rikice.

Sauran ka'idojin ƙasa da na ƙasa

Kasashe da yawa suna kula da ka'idodin zaren su na masana'antu na kasa. Waɗannan sun haɗa da:

JIS (ka'idojin masana'antu na Jafananci) : Japan zaren Japan )

Din (Cibiyar Jamusawa ta daidaito) : Ka'idojin Din na Jamus suna da alaƙa da ka'idodin ISO, samar da ƙayyadaddun zaren a kan masana'antu zuwa masana'antu.

GOSS (Standard State Standard) : Standardaran ƙasar Rasha ta haɗa da zaren awo da Inch-tushen, waɗanda aka yi amfani da su a cikin injiniyan masana'antu.

Tafurin Takaital na Kogi Ka'idodin

| Standard | Standard | Standard | Standary | Standardaka |

| Iso aworict (m) | Na duniya | 60 ° | Awo | Janar Fasterners, injina |

| An haɗa (UNC / uni) | Amurka, Kanada | 60 ° | Inci | Gaisuwa, kayan masarufi |

| Whitworth (BSW / BSF) | Na UK | 55 ° | Inci | Maɓallin tsofaffi, Automototive |

| Bututun Burtaniya (BSP) | UK, Duniya | 55 ° | Inci | Bututun mai, bututun ƙarfe |

| NTT / NTTF | Mana | 60 ° | Inci | PIPE SUTINGS, Tsarin Manufofin |

| JIS | Japan | 60 ° | Awo | Injina, kayan aiki |

| In | Jamus | 60 ° | Awo | Automotive, injallar masana'antu |

| Tafiya | Russia | 60 ° / 55 ° | Awo awo / inci | Masana'antu, masana'antu na ƙasa |

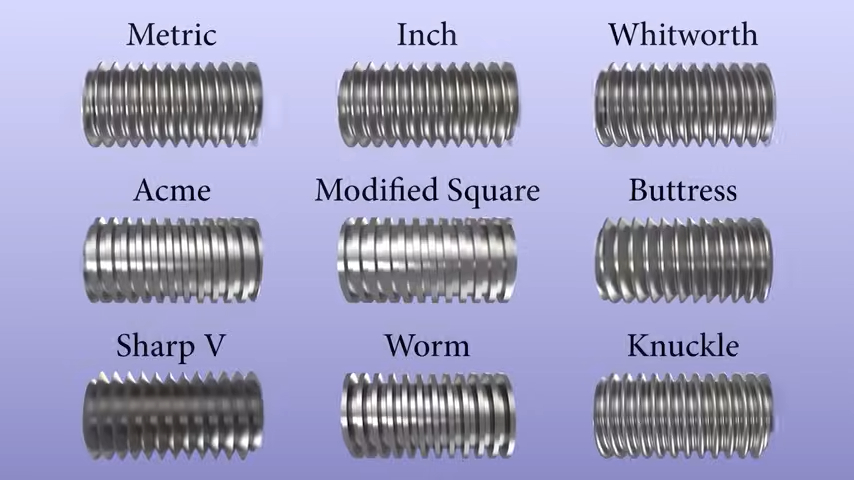

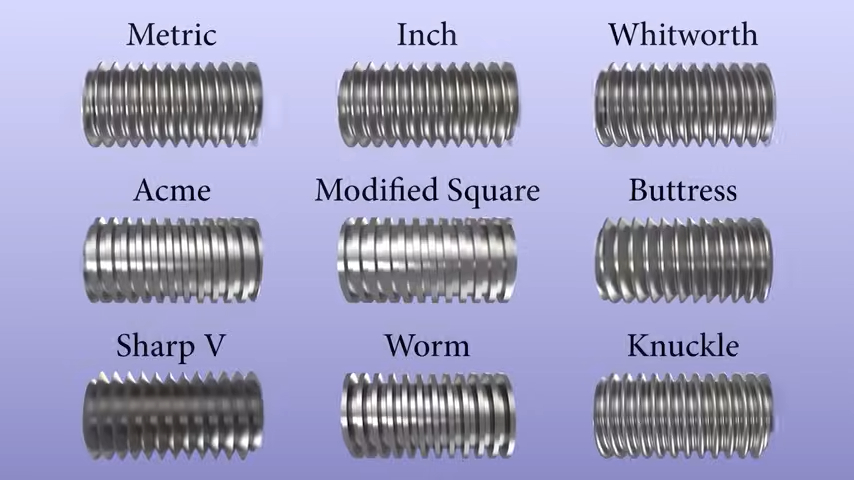

Nau'in zaren

Zoben sun shigo da siffofi daban-daban, kowannensu da aka tsara don takamaiman aikace-aikacen injiniya. Fahimtar nau'ikan zaren suna da mahimmanci don zaɓin wanda ya dace don aikinku. Bari mu bincika nau'ikan zaren gama gari dangane da shugabanci, bayanin martaba, da na misali.

Hannun dama da hagu-hagu

Za'a iya rarrabe zaren da aka danganta shi bisa allo da suka juya zuwa aiki.

Dama-hannun dama (RH RH) : Waɗannan su ne mafi yawan nau'ikan zaren. Suna ƙara ja da kullun juyawa agogo. Kusan duk gaba daya-manufa, kamar su skurs da kuma bolts, yi amfani da Rh Threads don sauƙin amfani.

Hagu-hagu (LH) Zanes : Wadannan zaren da aka fi karfafawa lokacin da aka juya su. Ana amfani da zaren LH a yanayi inda jujjuyawar agogo zai iya haifar da wani sashi don sassauta, kamar a cikin wasu manyan manyaniyoyin sarrafawa suna son ƙayyadaddun abubuwan sarrafawa.

Bayanan Bayanan martaba

Bayanan martaba na zaren zaren suna bayyana siffar zaren da kuma rinjayi karfin su, inganci, da aiki.

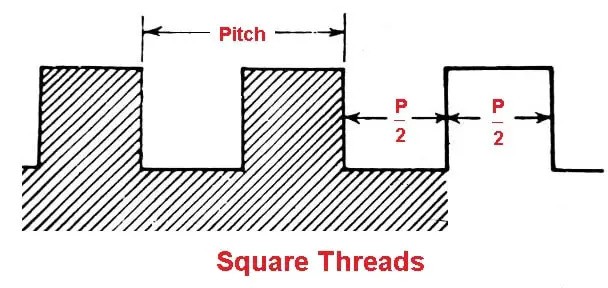

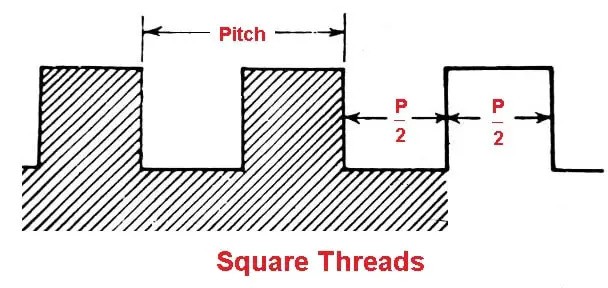

Square zaren : Square zaren suna da inganci a cikin watsa wutar lantarki, tare da karancin gogewa. Ana amfani dasu sau da yawa a cikin kwalkwalin kwalkwalin, jigogi, da sauran na'urorin injiniyoyi masu nauyi.

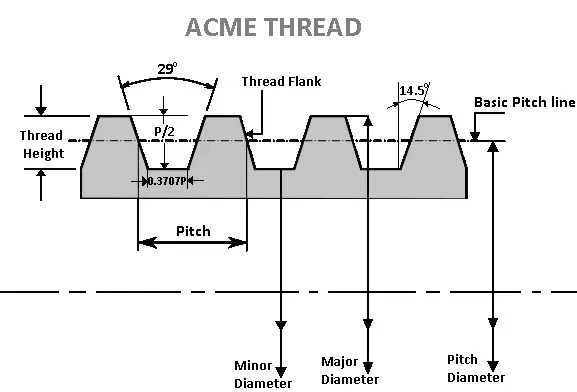

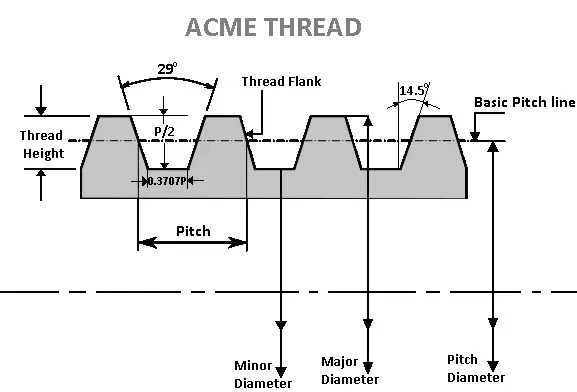

Akwatin ACME : Wani takamaiman nau'in zaren murabba'i, zaren kade, yana ba da ƙarfi mafi girma kuma ya fi sauƙi don kerawa. Ana amfani dasu a aikace-aikacen da ke buƙatar kaya masu nauyi, kamar kayan aikin injin da bawuloli.

Zaren da layi daya da layi daya

Hakanan za'a iya rarrabe su ta yadda diamita yake canzawa tare da tsawon.

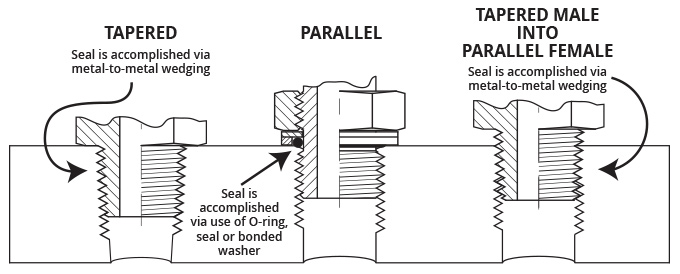

Taskar toner : Wadannan zaren suna raguwa a cikin diamita zuwa ƙarshen, ƙirƙirar da wedge da siffofin da ke kafa hatimi. Sayeled zare sun zama ruwan dare gama gari a cikin bututun bututun kuma suna da hatimin kansu a matsin lamba. Misalai sun hada da NTT (the bututun bututun kasa) da BSPT (Standary Pipe na Burtaniya).

Paralel Sadows : Randunan layi daya suna kula da diamita a ko'ina. Suna buƙatar ƙarin hanyoyin da aka ɗora, kamar O-zobba ko tef ɗin zare, don haɗin-m-m-m-m haɗe. Nau'in gama gari sun hada da BSPP (Standard Student bututun layi daya) da kuma NTTF (bututun bututun ƙasa).

Na musamman nau'in zaren

Matsayi da yawa suna ba takamaiman zaren don amfani dashi a cikin masana'antu daban-daban, tare da sanannun misalai kasancewa:

An haɗa da zaren na ƙasa (UNC, mara izini, un) : an saba amfani dashi a Amurka da Kanada, an auna zaren da aka haɗa a inci. Ana amfani da zaren UN (mara nauyi) don haɓaka manufa, yayin da masu yawa zaren (lafiya) an fi son su a aikace-aikace mai ƙarfi. Ba a daidaita zaren zaren da ba daidai ba ne don takamaiman bukatun.

British Standars na Burtaniya (BSW, BSF, BSP) : Ana amfani da Standard Street Whitworth (BSW) a cikin kayan BSW da farko a cikin kayan masarufi. Rundunar Burtaniya ta Burtaniya (BSF) suna ba da ƙarfi, haɗin haɗin gwiwa kuma ana amfani dasu a cikin mahalli-prone-prone-prone-prone-prone-prone mahalli. Macewar BPISH Standard (BSP) masu mahimmanci suna da mahimmanci don bututun bututun ruwa a cikin bututun gas da gas, gami da yanki ɗaya (BSPP).

Takaitacciyar tebur tebur na

| chardy | chard | daddy |

| Hannun dama (RH RH) | Kewaye iri na agogo | Gaba daya-manufa masu fasteners |

| Hagu-hannun (LH) zaren | Kaikiyo | Sassa mai yiwuwa don kwance a ƙarƙashin rotation |

| V-dimbin yawa | Triangular | Hanawa, Janar na'uroki |

| Square zaren | Filin gari | Isar da wutar lantarki, jacks, kayan masarufi |

| Acme zaren | Trapezoid | Kaya masu nauyi, kayan aikin injin |

| Trapezoidal zare | Trapezoid | Isar da wutar lantarki, kayan aikin Turai |

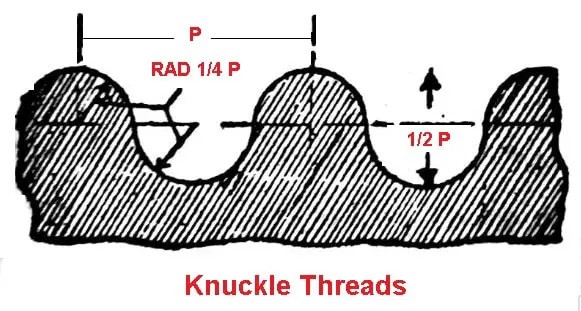

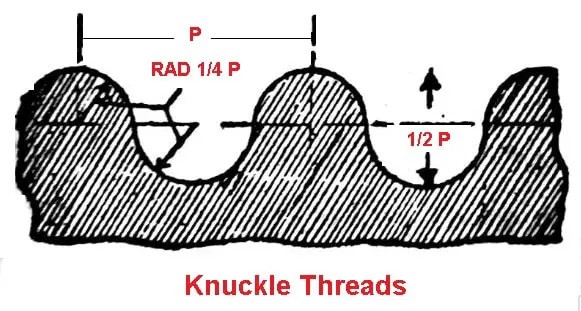

| Knuckle | Zagaye | Labaran jirgin ƙasa, iyakokin kwalban |

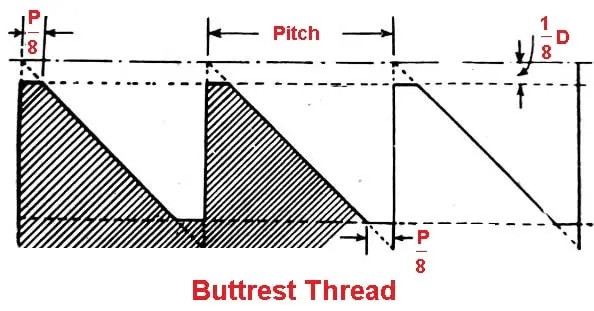

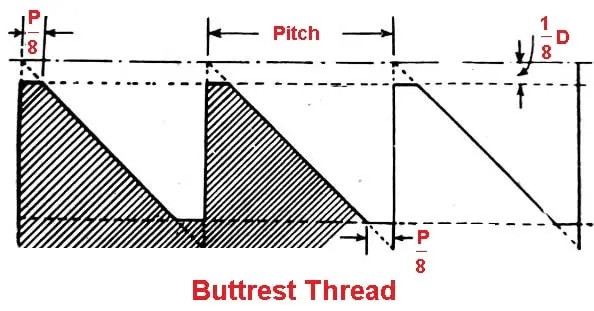

| Buttress zaren | Asymmetrical | Na'urorin clamping na'urori, coupsnes na coups |

| Raunin baƙin ciki | Helical | Tsutsotsi na ruwa, watsar da dama ta dama |

| Tarrayaya | Wedg-secking | PIPE SUTINGS (NTPT, BST) |

| Paralle zare | A zahiri diamita | PIPE FTTings na buƙatar hatimin waje |

| Ba a haɗa zaren na ƙasa | Inch-tushen | Gaisuwa, kayan masarufi |

| British Standars | Inch-tushen | PIPE SUTINGS, MAI GIRMA |

Hanyoyin masana'antu

Samun zaren ya ƙunshi dabaru daban-daban, kowane bayar da shawarwari na musamman don takamaiman aikace-aikace da kayan. Ga bayyanar da hanyoyin samar da kayan kera na farko:

Zakaran yankan (ya matsar da ciki)

Yankalin yankan ya kasance hanyar da ake amfani da ita don ƙirƙirar zaren na ciki da na waje:

Abvantbuwan amfãni:

Iyakantarwa:

Zare na rolling

Zaren mirgina siffofin da zaren filastik na filastik na aikin:

Fa'idodi:

Raunin:

Zaren gyaran

Zaren yana yin amfani da ƙafafun abar ƙyallen don haifar da zaren madaidaiciya:

Abubuwan da ke cikin Key:

Na musamman daidaito da ƙarewa

Ya dace da zaren bayan magani

Da ikon samar da rikice rikice-rikice

La'akari:

Zare na milling

Zaren Milling Milling yana da damar jujjuya kayan aiki don kare zaren:

Abvantbuwan amfãni:

Mai ikon samar da manyan zaren diamita

Mataki na Tourformance, manufa don sassan da ke bakin ciki

Na iya ƙirƙirar hannayen dama da hagu tare da kayan aiki tare da kayan aiki iri ɗaya

Iyakantarwa:

3D buga da masana'antu mai kida

Emering Fasaha suna ba da sabon damar don samarwa da zaren:

Za a sami fa'idodi:

Kalubale:

Iyakantaccen zaɓuɓɓukan abu

Ƙananan ƙarfi idan aka kwatanta da hanyoyin gargajiya

Farfajiya na iya buƙatar aiki

Dalilai da suka shafi aikin aikin

Ara aikin zaren yana tasiri da dalilai daban-daban wanda ke tantance ƙarfinsa, karkara, da aminci a aikace-aikacen injiniya. Daga Kayan Abubuwa don la'akari da muhalli, fahimtar waɗannan abubuwan suna da mahimmanci don tabbatar da kyakkyawan zaren aikin. Da ke ƙasa sune abubuwan mahalli waɗanda ke shafar aikin zaren.

Zabin Abinci

Zaren aikin da ya dogara da kayan kayan abu:

Turi: Kayyade yiwuwar ɗaukar nauyi

Cutararraki: Yana shafar samuwar zaren da juriya ga tsibi

Corroon jure: muhimmiyar tsawon rai a cikin yanayin m

Jiyya na tsari da cakuda

Jiyya na magunguna suna haɓaka tsawon rai da ayyukan zaren ta rage sutura, lalata, da galling. Jiyya gama gari sun hada da:

Zinc Plat : Yana kare zaren daga lalata da haɓaka salonsu.

Black oxide shafi : samar da juriya da m jemilta da inganta kayan ado.

Phosphating : Inganta riƙe lubrication, yana yin amfani a aikace-aikacen aikace-aikace.

Anodizing : Amfani da shi don zaren aluminium, yana ƙara maganin lalata cuta da sa ƙarfi.

Wadannan jiyya suna taimaka wa zaren yin dogaro da mawuyacin yanayi ko aikace-aikace mai girma.

Lubrication da kuma gogayya

Yancin da ya dace yana rage tashin hankali yayin taro da kuma hana gaɗi ko kama, musamman a cikin aikace-aikace na saukarwa. Saukar:

Rage sa : yana taimakawa rage lalacewa ta hanyar maimaita ƙarfi da kwance.

Inganta Ikon Torque : Yana tabbatar da har ma da rarraba rarraba a duk zaren, yana hana-da karfi.

Gudun lubricts na iya haɗawa da mai, man shafawa, ko anti-cockry mahadi dangane da takamaiman buƙatun aikace-aikacen.

Abubuwan Muhalli

Za a fallasa zaren da bambancin muhalli, wanda zai shafi wasan kwaikwayon su game da lokaci. Abubuwan da suka hada da:

Zazzabi : yanayin zafi na iya haifar da fadada abubuwa da karfin hadadden zaren. Low yanayin zafi na iya yin wasu abubuwan da suka lalace.

Corrous : zaren da aka fallasa su danshi, sunadarai, ko gishiri zai iya cinye tsarinsu akan lokaci.

Tsoro : Cigaba da rawar jiki na iya sassauta haɗi mai hoto, wanda ya haifar da gazawa. Kulle hanyoyin da ake kulle kamar wanda yasan zaren ko makullin kulle zai iya taimakawa rage wannan.

Magance waɗannan ƙalubalen muhalli yana da mahimmanci don kiyaye amincin haɗin haɗi.

A Majalisar Zango da Matsakaicin Hanyoyi

Hanyar da aka yi amfani da ita ta tara kuma a ɗaure zaren da muhimmanci yana shafar aikinsu. Mabuɗin maɓalli sun haɗa da:

Ikon Torque : Amfani da Daidai daidai yana tabbatar da zaren ba tare da zaren ba - ko kuma a ƙasƙantar da amincinsu.

Sanya tashin hankali : Tsare-tsare da ya dace yana rage haɗarin kwance a ƙarƙashin saƙo mai ƙarfi kuma yana tabbatar da rarraba kaya a fadin bayanan saƙo.

Kayan aiki masu sauri : kayan aikin kamar Wrrenches masu ƙarfi suna ba da madaidaicin tsauri, rage yiwuwar yiwuwar gazawar.

Yin amfani da ingantattun halaye na dabarun haɓaka haɓaka da ƙarfin haɗin haɗi.

Sauke nau'ikan da tasirinsu akan ƙarfin zaren

Zazzabi sun yi wa nau'ikan saukarwa daban-daban, kuma kowane nau'in yana shafar wasan kwaikwayon na zaren daban:

Abubuwan da ke tsaye : Aiwatar da kai tsaye a kan lokaci, gabaɗaya ba sa haifar da karancin zaren sai dai da nauyin ya wuce ƙarfin amfanin ƙasa.

Hanyoyi masu ƙarfi : sun bambanta akan lokaci kuma suna iya haifar da zaren da ake kwance ko gajiya idan ba a tsara shi da kyau ba.

Gajiya mai kyau : Maimaita Loading da Sauke Hycles Gudanar da Sadowa akan Lokaci, Jagoranci zuwa gazawa. Abubuwan da ke tare da manyan juriya mafi girma an fi son su a cikin irin waɗannan aikace-aikacen.

Fahimtar yanayin ɗaukar hoto yana tabbatar da nau'in da ya dace da kayan aikin da aka yi nufin.

Bukatar Bukatar Aiki

A cikin aikace-aikace da yawa, ana buƙatar zaren don samar da hatimi, musamman cikin tsarin ruwa ko gas. Reded Sadowa kamar NTPT da BSPT suna ba da kadarorin da kansu ta hanyar ƙirƙirar m Fit kamar yadda suke da ƙarfi. Ga zaren da ba sa saye da nasu (misali, zaren layi ɗaya kamar O-zobba ana buƙatar hana leaks.

| Aikace-aikacen | nau'in | aikace-aikacen |

| Npt zaren | Tedan zuma | Bututun mai, tsarin ruwa |

| RANAR BSPT | Tedan zuma | Gas da aikace-aikacen ruwa |

| BSPK CRECK | Na bukatar ƙarin ƙaye (o-zobe ko tef) | Bututun ƙarfe, tsarin matsin lamba |

Magana ka'idojin sutturar yana da mahimmanci wajen tabbatar da haɗin ruwa mai ƙarfi a aikace-aikacen injiniya.

Aikace-aikacen zaren a Injiniya

Relays suna taka muhimmiyar rawa a cikin aikace-aikace na injiniyoyi daban-daban, samar da ayyuka masu mahimmanci a kan masana'antu da yawa. Abubuwan da suka shafi su da inganci suna sanya su kayan haɗin kai a cikin injiniyanci na zamani.

Hanji

Haske masu ɗaukar fansa suna samar da kashin bayan manyan kayan aikin yau da kullun:

Kafa: Haɗin kai mai ƙarfi a aikace-aikace na tsari

Sukurori: m sauri don wadatattun kayan da yawa

Kwayoyi: Bayar da amintaccen, ƙarfin matattara

Waɗannan kayan haɗin suna ba da damar daidaita taro, ratsuwa, da kuma kiyaye tsarin injiniya.

Watsa wutar lantarki

Zaren Excel a cikin Canza Motsi na Rotary zuwa Linear Motsa:

Ingancinsu da daidaito suna yin zaren da ke da kyau don aikace-aikacen watsawa na wutar lantarki.

Ruwa da hat na iskar gas

Haɗin Haɗin Mahalli yana da mahimmancin tsarin sarrafawa:

PIPE FTTings: Amintaccen, gidaje-tabbaci a cikin bututun kwafi da pippertiali na masana'antu

Bawuloli: Addinin Rundunar Runduna a cikin Tsarin Hydraulic da Tsarin Pnumatic

Sauke suttura sau da yawa suna ba da kaddarorin da kai, inganta mutuwar tsarin.

Matsayi da daidaitawa

Relays yana ba da damar daidaitawa a cikin kayan aikin daidai:

Iyakarsu don fassara kananan rotsi a cikin wuraren layin mintuna ba su da alaƙa.

Takamaiman aikace-aikacen masana'antu na

| masana'antu | aikace- | aikacen |

| Saidospace | Babban karfin kai | M, awo awo |

| Mayarwa | Abubuwan injiniyoyi | Awo, uni |

| Kayan aikin likita | Ingantaccen abu | Al'ada, filin mai kyau |

| Man & Gas | Haɗin kai tsaye | NTT, API |

Nazari na Case

High-ƙarfi hade da haɗin haɗin gwiwar a cikin Gina Gadarar

Kalubale: Shiga manyan abubuwa masu girma

Magani: Babban diamita, karfin kaji tare da rashin zaren UNL

Sakamakon: M, Figinu-Juriya zai iya tsayawa da yawa

Tsarin Jagora a cikin injunan CNC

Kalubale: cikakken matsayi na yankan kayan yankan

Magani: Groundasa, Ground Trapezoidal zaren da ke da ƙwayayen anti-baya

Sakamako: submicron sanya daidaito da sarrafawa mai motsi

Haɗin bututun kansa na rufe kansa a cikin tsarin matsin lamba

Kalubale: Haɗaɗɗun haɗin gwiwa a cikin tsarin hydraulc

Magani: NPTF ta sanya zaren da ke da kutse da ke sarrafawa

Sakamakon: amintattu, sutturar ƙarfe-karfe ba tare da ƙarin ƙwayoyin ido ba

Yanayin gajiyewa da rigakafin

Fahimtar wurin da aka gaza daidaito yana da mahimmanci ga tsara abin dogaro da ingantattun haɗi. Wannan sashin yana bincika hanyoyin gama gari, abubuwan da suke haifar da su, da matakan hana su.

Yanayin gazawa gama gari

Abubuwan da aka yi na Threaded na iya kasawa cikin hanyoyi daban-daban:

Tsawaita : nakastar dorormation a karkashin nauyin kima

Tearing : Cikakken rabuwa da zaren saboda matsanancin karfi

Galling : lalacewar farfajiya daga m sagation tsakanin suttura masu canzawa

Zane : zaren kulle tare, yana hana disasssebly

Gajiya : Karanta CRACK BING

Juyawar damuwa : hade da yanayin damuwa da yanayin lalata

Sanadin gazawar zaren

| yana haifar da | kwatancen | gama gari |

| Sa | Lamari na duniya daga rikici | Akai-akai tara gidajen abinci |

| Lahani | Lalata lalata kayan | Fallasa ko laima |

| Gajiya | Maimaita damuwa na damuwa wanda ke haifar da fasahar | Tsayawa ko cyclically couponed |

| Yi obalodi | Ya wuce karfin kaya mai nauyi | Ba daidai ba tsayayyen taimako |

| Taro mara kyau | Tsallake-threading ko sama-karfi | Taron Majija ta Majalisar |

Matakan kariya

Don rage gazawar Rarraba:

Zabi na kayan da ya dace ya dogara da yanayin muhalli da buƙatun kaya

Aikace-aikacen da suka dace da jiyya ko cox

Amfani da mahimman kayan kwalliyar zaren don juriya

Aiwatar da ayyukan ingantaccen ayyukan

Bin ka'idodin ƙimar Torque a lokacin taro

Zaɓin da ya dace da ƙira da ƙira

Inganta kayan aikin ta hanyar:

Zabi bayanan bayanan da suka dace don aikace-aikacen

La'akari da Rarraba Rage da Damuwa mai damuwa

Kimanta dalilai na muhalli (zazzabi, morrous m)

Tantance tsawan tsayin daka mafi kyau

Zabi azuzuwan haƙuri mai haƙuri da ya dace don abubuwan da aka gyara

Ingancin iko da dubawa

Aiwatar da matakan inganci mai ƙarfi:

Binciken girma ta amfani da ma'aunin daidaitattun abubuwa da kuma kayan aiki

Hanyoyin gwaji masu lalacewa (misali, ultrasonic, barbashi na magnetic) don mahimmin kayan aiki

Lokacin dubawa da kuma tsarin kula da taron kara

Tallafi da kuma rashin nasara na masana'antar kera

Shirye-shiryen horo don Majalisar Ma'aikatan don tabbatar da ingantaccen fasahohin shigarwa

Maharbi

Zaren suna da mahimmanci a cikin injiniya, wanda aka yi amfani da shi don sauri, motsi, da kuma watsa wutar lantarki. Sun tabbatar da karfi, amintattun hanyoyi a tsarin inji.

Zaɓin da ya dace, ƙira, da ikon ingancin zaren suna da mahimmanci don guje wa gazawa da haɓaka aikin aikace-aikace daban-daban.

Binciken ka'idojin zaren, kayan, da dabarun masana'antu na iya inganta fahimtar aikace-aikacen aikace.

Don ƙarin cikakkun bayanai, duba ƙa'idodi masana'antu da albarkatu don tabbatar da kyakkyawan aiki a cikin ayyukan injin ku.