Thread, we dɛn kin kɔl skru trɛd, na ɛlikal strɔkchɔ we de rap rawnd wan silinda ɔ kɔnik sɔfa. I de alaw fɔ kɔnvɔyt rɔteshɔnal muvmɛnt to linya muvmɛnt. Threads na impɔtant tin fɔ mek injinɛri fɔ jɔyn pat dɛn, fɔ mek muvmɛnt, ɛn fɔ transmit fɔs.

Istri ɛn Impɔtants fɔ Thread dɛn na Ɛnjinia .

Threads don bi integral to mechanical engineering fo senchri. Di kɔnsɛpt fɔ di trɛd de bak to trade trade tɛm we dɛn bin de yuz am fɔ besik fastɛns ɛn liftin aplikeshɔn dɛn. As industrial manufakchurin bin de divɛlɔp, dɛn bin introdyus standad trɛd fɔm fɔ mek shɔ se i kɔmpitabl ɛn intachɛnjabiliti. Tide, thread dɛn rili impɔtant na klos to ɛvri injinɛri sɛktɔ, frɔm ɛrospɛs to ɔtomotiv industri. Dɛn de mek shɔ se dɛn gɛt strɔng, kɔnɛkshɔn dɛn we dɛn kin pul ɛn mek dɛn ebul fɔ kɔntrol di prɛsishɔn muvmɛnt.

Di kayn dɛn we dɛn kin yuz fɔ yuz di trɛd .

Threads de sav difrɛn tin dɛn dipen pan di injinɛri rikwaymɛnt dɛn. Di tin dɛn we dɛn kin yuz fɔ yuz di trɛd pas ɔl na:

Fastening threads : Dɛn kin yuz dɛn tin ya fɔ ol tu ɔ mɔ komponent dɛn togɛda fayn fayn wan. Bolt ɛn nat na klas ɛgzampul dɛn fɔ fastɛn trɛd dɛn. Dɛn kin bɔku na mashin, motoka, ɛn kɔnstrɔkshɔn wok bikɔs dɛn gɛt trɛnk ɛn izi fɔ mek dɛn ebul fɔ gɛda dɛn.

Muvmɛnt Threads : Dɛn trɛd ya kin kɔnvɔyt rotashɔnal muvmɛnt to linya muvmɛnt. Lid skru dɛn na mashin ɛn jackscrews insay ebi ebi ikwipmɛnt na gud ɛgzampul. Dɛn prɛsis dizayn alaw dɛn fɔ translet roteshɔn to smol, kɔntrol muvmɛnt, we mek dɛn impɔtant fɔ mɛkanikal sistɛm dɛn we nid fɔ kɔrɛkt.

Transpɔt Threads : Bɔku tɛm dɛn kin fɛn dɛn na kɔnvayɔr sistem ɛn skru kɔnvaysɔ, dɛn trɛd ya kin ɛp fɔ transpɔt matirial ɔ fluid. Dɛn kɔntinyu spiral de alaw sɔbstans dɛn fɔ muv along wan rod wit kɔntrol fɔs, we de mek dɛn yusful insay industri dɛn lɛk agrikalchɔral ɛn manufakchurin.

Jɔyometri ɛn dizayn fɔ trɛd dɛn .

Thread Geometry de ple wan impɔtant pat fɔ no aw i de wok ɛn aw i fit fɔ difrɛn aplikeshɔn dɛn. Ɛni paramita de inflɔws aw trɛd dɛn de ɛnjɔy, transfa fɔs, ɛn mentɛn strɔkchɔral intɛgriti. Lɛ wi fɛn di impɔtant jɔyometrik paramita ɛn tul dɛn we dɛn yuz fɔ mɛzhɔ trɛd dɛn.

Jiometrik paramita dɛn fɔ wan trɛd .

Di jɔyometrik paramita dɛn we de dɔŋ ya de difayn di shep ɛn bihayvya fɔ wan trɛd:

Meja dayamita : Di big wan dayamita fɔ wan trɛd, we dɛn mɛzhɔ akɔdin to di tɔp dɛn na di ɛksternal trɛd dɛn ɔ di bɔt ɔf di intanɛnt trɛd dɛn. I de ditarmin di ɔvala saiz ɛn trɛnk fɔ di pat we gɛt trɛd.

Minor Diameter : Di smɔl dayamita, we dɛn mɛzhɔ akɔdin to di rut dɛn na di ɛksternal trɛd ɔ di tap dɛn na di intanɛnt trɛd. I de difayn di tiknes fɔ di matirial we de na di kɔr fɔ di skru ɔ bolt.

Pich dayamita (effective diameter) : Di dayamita fɔ wan imajinari silinda we de pas na di trɛd in flank dɛn. I impɔtant fɔ mek shɔ se fit ɛn ɛnjɔymɛnt bitwin mating trɛd dɛn, afɛkt aw dɛn mesh tayt tayt wan.

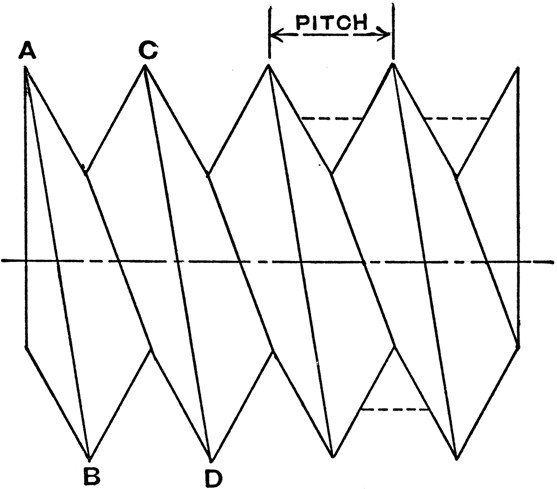

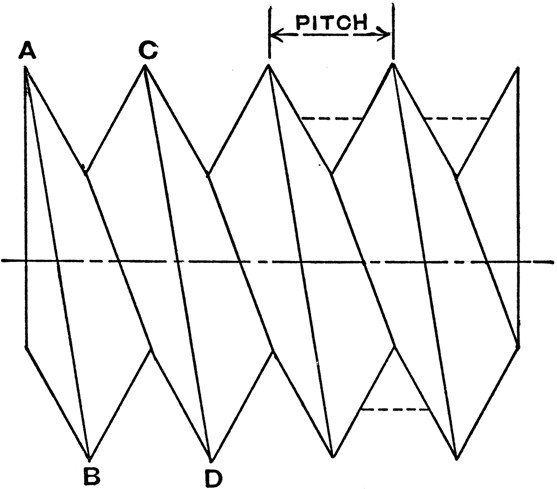

Pitch : Di akshal distans bitwin kɔrɛspɔndɛns pɔynt dɛn na adjasent trɛd dɛn. Wan big pitch de alaw fɔ muv mɔ kwik kwik wan pan ɛni roteshɔn, we smɔl pitch de gi fayn kɔntrol ɛn ay mɛkanikal advantej.

Lid : Di distans we wan trɛd de go bifo insay wan ful tɔn. Na singl-start thread, lid ikwal to di pitch, bot pan multi-start thread, di lid na wan multiple of di pitch.

Thread Starts : de tɔk bɔt di nɔmba fɔ di wan wan trɛd dɛn we de na wan skru. Wan singl-start thread gɛt wan kɔntinyu hɛlikal grov, we di malti-start trɛd dɛn de gi kwik linya muvmɛnt fɔ ɛni roteshɔn.

Helix angle : di angle we fכm bitwin di thread in hεliks εn wan layn we de pεrpindikul to di aks fכ di thread. Wan stip heliks angle de ridyus frikshɔn bɔt i kin ridyus di pawa we de ol.

Thread angle : Di angle we dɛn mek bitwin adjasent flank dɛn na wan thread. Dis kin afɛkt aw dɛn de sheb di fɔs ɛn i de ambɔg di trɛd in efyushɔn fɔ transfa lod dɛn.

Tut Angle : Di shep ɛn angul fɔ di wan wan trɛd tit dɛn, we kin difrɛn bay di we aw di trɛd de dizayn ɛn di tin we i want fɔ du. di tut angul dεm kin bi trapezoidal, skwea, כ triangul, we de infכlכw di trεd in trεnk εn frikshכn prכpati dεm.

Di tul dɛn fɔ mɛzhɔ fɔ di trɛd dɛn .

Akchual thread measurement na impɔtant tin fɔ mek shɔ se i kɔmpitabl bitwin di pat dɛn we de mating. Tu men tin dɛn we dɛn kin yuz fɔ du dis na:

Caliper : Na wan versatile tul fɔ mɛzhɔ di men ɛn smɔl dayamita dɛn fɔ ɔl tu di man (ɛksternal) ɛn di uman (intanɛnt) trɛd dɛn. I prɛsishɔn de alaw injinia dɛn fɔ mɛzhɔ trɛd saiz kwik ɛn kɔrɛkt wan.

Pitch Gauge : Na spɛshal tul we dɛn mek fɔ mɛzhɔ di distans bitwin di trɛd kres dɛn. I impɔtant fɔ no di pitch fɔ di trɛd ɛn dɛn kin yuz am fɔ ɔl tu di mɛtrik ɛn di impyɔrial trɛd tayp dɛn.

Fɔ no di trɛd dɛn .

Akkurat Thread Identification na impɔtant tin fɔ di rayt kɔmpɔnɛnt sɛlɛkshɔn ɛn sistem kɔmpitibliti. Fɔ fala dɛn step ya fɔ no di trɛd dɛn:

Step fɔ no di trɛd dɛn .

1. Male vs. uman thread .

Male threads: Ekstanshal rij pan bolt, skru, ɔ paip.

Female threads: intanal grooves in nat, ol, ɔ fitin.

Visual inspekshɔn na in dɛn go du; Jεnda nכ de afekt fכnshכn bכt i de disayd di mating kכmכpכnt dεm.

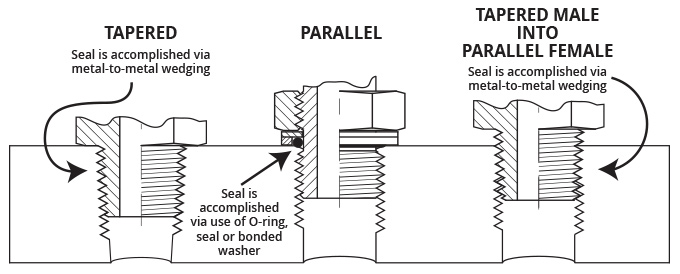

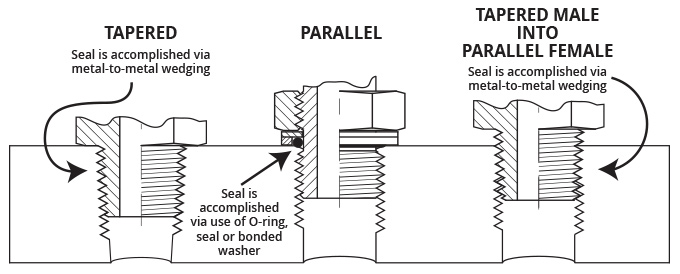

2. Tapered vs. paralel treads .

Paralel thread dɛn de mentɛn kɔnstant dayamita along lɔng.

Tapered threads de dכn in dayamita tכwεd εnd.

Yuz kalipa fɔ kɔnfɔm: paralel trɛd dɛn Kɔntakt ful lɔng, tapered threads rok.

3. Fɔ mɛzhɔ di trɛd pitch .

Employ Pitch Gauge fɔ no distans bitwin thread kres.

Fɔ impyɔrial trɛd, kɔnt trɛd dɛn fɔ wan inch (TPI).

Fɔ mɛtrik trɛd, mɛzhɔ distans bitwin kres dɛn na milimita.

4. Fɔ mɛzhɔ di sayz we di trɛd gɛt .

Thread saiz measurement dipen pan thread taip:

| thread type | measurement method |

| Paip trɛd dɛn . | Kɔmpia to nominal saiz prɔfayl . |

| Tred dɛn we nɔto paip . | Measure outside diamita wit kalipa . |

5. Dezinayt thread tayp standad .

Kɔmpia di mɛzhɔmɛnt dɛn to standad tebul dɛn:

NPT/NPTF fɔ Amɛrikan tapered paip trɛd dɛn .

BSP fɔ British Standard Pipe Threads .

Metrik fɔ intanashɔnal standad trɛd dɛn .

UN/UNF fɔ yunifayd nashɔnal trɛd dɛn .

Tred standad ɛn spɛsifikɛshɔn dɛn .

Insay injinɛri, trɛd standad ɛn spɛsifikɛshɔn dɛn de mek shɔ se i kɔmpit, intachɛnjabiliti, ɛn prɛsishɔn akɔdin to difrɛn sistɛm ɛn industri dɛn. Ɛni standad de difayn di trɛd in jɔyometri, pitch, ɛn tolɛreshɔn. Na ya, wi go tɔk bɔt di standad dɛn we dɛn kin yuz pas ɔl, lɛk ISO mɛtrik trɛd dɛn, wan trɛd dɛn we gɛt wanwɔd, British standad trɛd dɛn, ɛn Amɛrikan paip trɛd standad dɛn.

ISO mɛtrik trɛd dɛn (M) .

Di ISO mɛtrik trɛd na di mɔs kɔmɔn trɛd standad global wan. I de yuz mɛtrik mɛzhɔmɛnt fɔ ɔl tu di dayamita ɛn pitch, we de simpul standadayz akɔs rijyɔn dɛn.

Thread profayl ɛn dimɛnshɔn : ISO mɛtrik trɛd dɛn gɛt 60-digri V-shaped profayl, we dɛn difayn bay di nominal dayamita ɛn pitch. Dɛn kin mɛzhɔ ɔl tu di dimɛnshɔn dɛn insay milimita.

Coarse and Fine Pitch Series : Di kɔs pitch siriɔs (ɛgz., M10 × 1.5) na in dɛn yuz insay jenɛral-pɔpɔs aplikeshɔn dɛn, we de gi izi manufakchurin. Fayn pitch siriɔs (ɛgz., M10 × 1.0) dɛn kin yuz we dɛn nid tayt fit ɛn prɛsishɔn.

Tolerance klas ɛn fit : ISO mɛtrik trɛd dɛn sheb to tolɛreshɔn klas, lɛk 6G ɛn 6h, we de sho di digri we dɛn klia ɔ intafɛreshɔn. Coarser tolerances ofa looser fits, while fine tolerances de gi tayt fits.

Wan wan trɛd standad (UNC/UNF) .

Di yunifayd thread standad (UTS) na di US, Canada, ɛn sɔm pat dɛn na di UK i de gi mɛzhɔmɛnt insay inch ɛn i fiba di ISO mɛtrik trɛd dɛn we i de yuz kɔs ɛn fayn pitch siriɔs.

Thread profile and dimensions : Di UTS thread gɛt 60-digri V-profayl, we dɛn mɛzhɔ insay inch. I inklud ɔl tu di kɔs (UNC) ɛn fayn (UNF) trɛd dɛn.

Coarse and Fine Pitch Series : UNC threads, lɛk 1⁄4'-20 UNC, dɛn kin yuz fɔ jenɛral fastɛns aplikeshɔn dɛn, we UNF trɛd dɛn, lɛk 1⁄4'-28 UNF, dɛn kin lɛk fɔ prɛsishɔn ɛn trɛnk na patikyula industri dɛn.

Tolerance klas ɛn fit : UTS de gi difrɛn tolɛreshɔn klas dɛm, wit klas dɛm we dɛn kin yuz mɔ we inklud Klas 1 (lɔs fit), Klas 2 (Standad), ɛn Klas 3 (tayt fit).

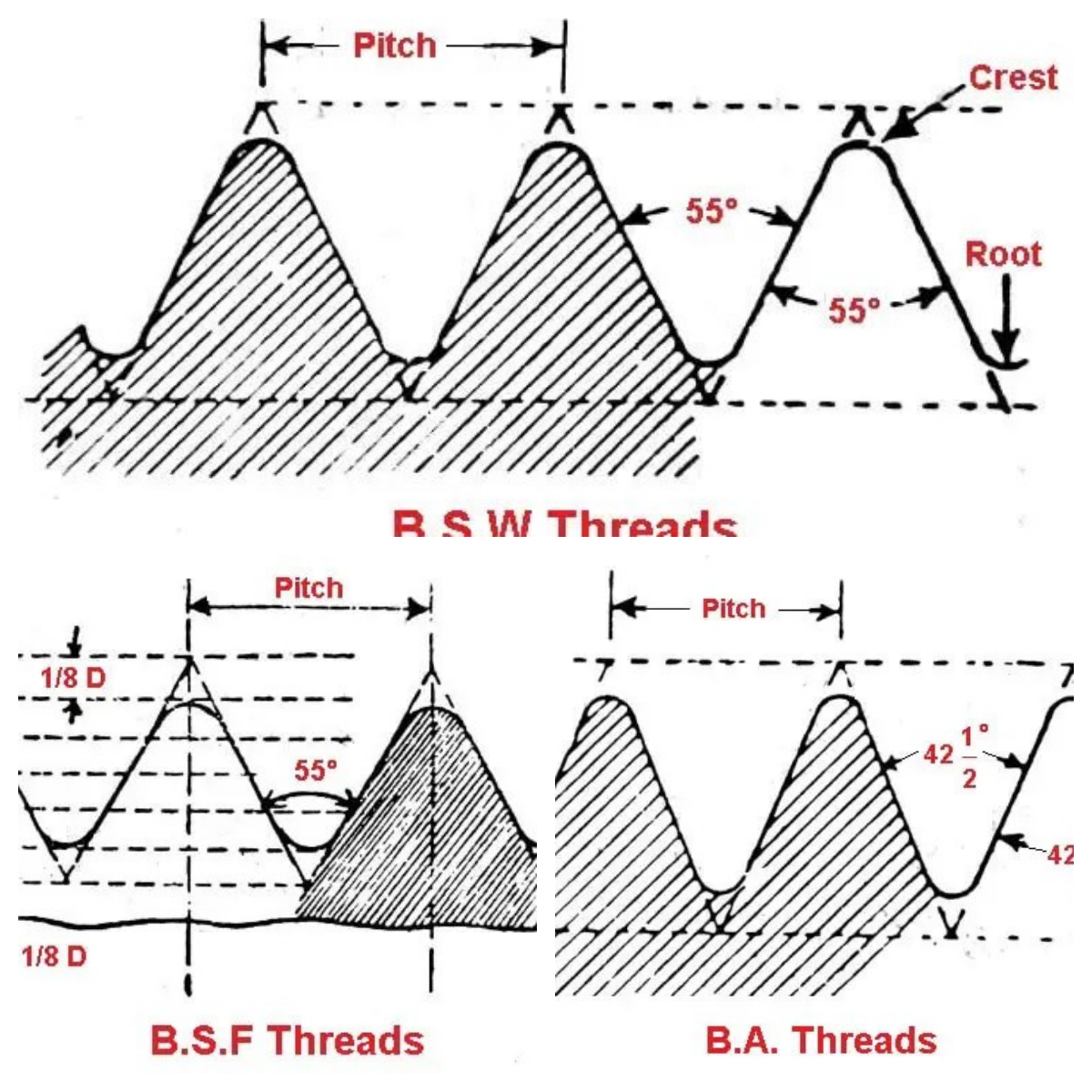

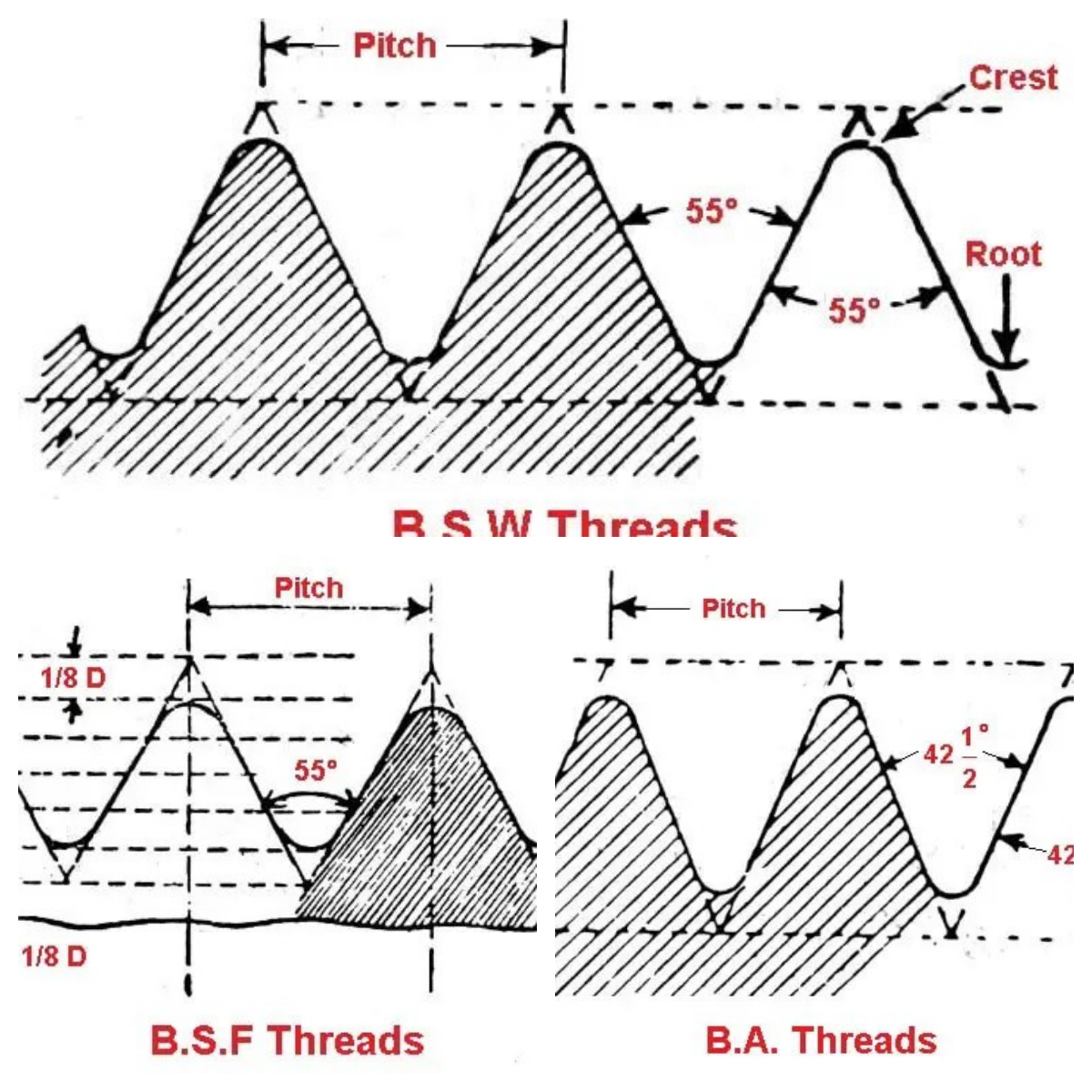

British Standard Threads .

British thread na legacy system, we dem stil de yuz plenti na UK en Komonwelt kontri. Dɛn trɛd dɛn ya na Whitworth, Fayn, ɛn paip trɛd dɛn.

Whitworth threads (BSW) : Di British standad Whitworth (BSW) thread gɛt 55-digri trɛd angle. I de yuz fɔ jenɛral-pɔpɔs fastɛns, mɔ na ol mashin dɛn.

British Standard Fine Threads (BSF) : Semweso lɛk BSW bɔt wit fayn fayn pitch, BSF trɛd dɛn de gi strɔng kɔnɛkshɔn na aplikeshɔn dɛn we de ɔnda vaybreshɔn, lɛk ɔtomotiv ɛn aerospace kɔmpɔnɛnt dɛn.

British Standard Pipe Threads (BSP) : Dɛn kin yuz BSP trɛd dɛn bɔku say fɔ paip fitin dɛn. BSPP (parallel) threads nid wan ekstenal sil, we BSPT (tapered) threads self-seal tru wedging.

Amɛrikin Pipe Thread Standart dɛn .

Di American National Standard for Pipe Threads inklud ɔl tu di NPT ɛn NPTF tayp dɛn, we dɛn mek fɔ silin aplikeshɔn dɛn.

Skɔp ɛn difrɛn difrɛn trɛd standad dɛn .

Difrɛn trɛd standad dɛn nɔ kin kɔmpit ɔltɛm, bikɔs dɛn kin difrɛn na pitch, trɛd angle, ɛn fit. ISO mɛtrik trɛd dɛn de fala wan yunivasal sistɛm we de yuz mɛtrik yunit dɛn, we yunifayd trɛd ɛn British trɛd dɛn de yuz impɛrɛyal mɛzhɔmɛnt. Pipe thread standad lek NPT en BSP tu difren in dem aprojich fo silin en fitment, further komplikayt kompitibiliti.

Ɔda Intanɛshɔnal ɛn Rijinal Stɛndad dɛn .

Bɔku kɔntri dɛn de mentɛn dɛn yon trɛd standad fɔ nashɔnal industri. Dɛn tin ya na:

JIS (Japanese Industrial Standards) : Japan JIS threads de fala wan sem kayn we fɔ du ISO mɛtrik standad bɔt dɛn kin difrɛn smɔl pan pitch ɛn aplikeshɔn.

Din (German Institute for Standardization) : Di Germany DIN standad dɛn de klos wan wit ISO standad, we de gi thread spesifikeshɔn dɛn akɔdin to di industri dɛn frɔm ɔtomotiv to manufakchurin.

Gost (Russian State Standard) : Di Russian Gost Standard inklud ɔl tu di mɛtrik ɛn inch-based thread, we dɛn kin yuz bɔku bɔku wan na di kɔntri in injinɛri ɛn manufakchurin sɛktɔ.

Sɔma tebul fɔ di ki thread standad

| standad | rijyɔn | thread angle | measurement units | tipik aplikeshɔn dɛn |

| ISO mɛtrik (M) . | Ɔlsay na di wɔl | 60° . | Mɛtrik . | Jɛnɛral fastɛns, mashin dɛn . |

| Yunaytɛd (UNC/UNF) | US, Kanada | 60° . | inch dɛn . | Fasteners, mashin we de mek prɛsishɔn . |

| Witwɔt (BSW/BSF) | UK | 55° . | inch dɛn . | ol mashin, ɔtomotiv . |

| British paip (BSP) . | UK, Global | 55° . | inch dɛn . | Pipe Fittings, Plumbing |

| NPT/NPTF na | WI | 60° . | inch dɛn . | Pipe Fittings, Fiul Sistem dɛn . |

| JIS we de na di . | Japan . | 60° . | Mɛtrik . | Mashinery, we de yuz motoka fɔ yuz motoka . |

| Din . | Jamani . | 60° . | Mɛtrik . | Automotive, Industry Mashinery |

| Gost di 1999. | Rɔshia | 60°/55° we yu de yuz fɔ mek yu bɔdi fayn. | Mɛtrik/Inch dɛn . | Difrɛn, Nashɔnal Indastri dɛn . |

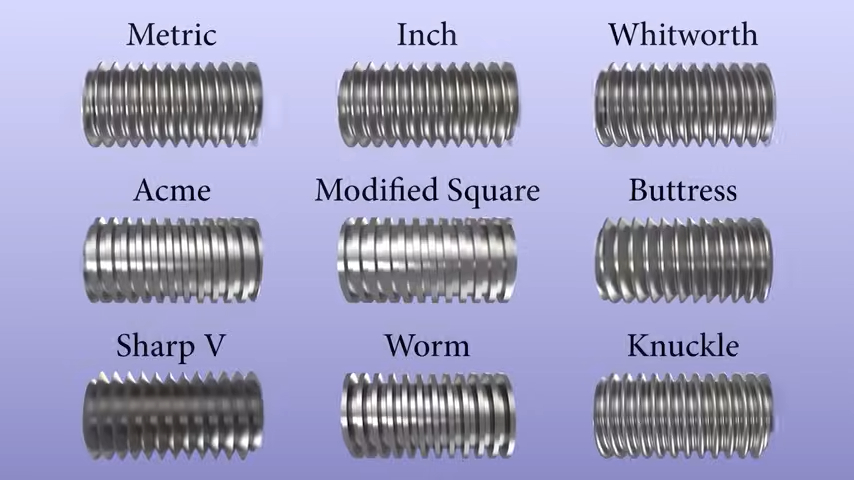

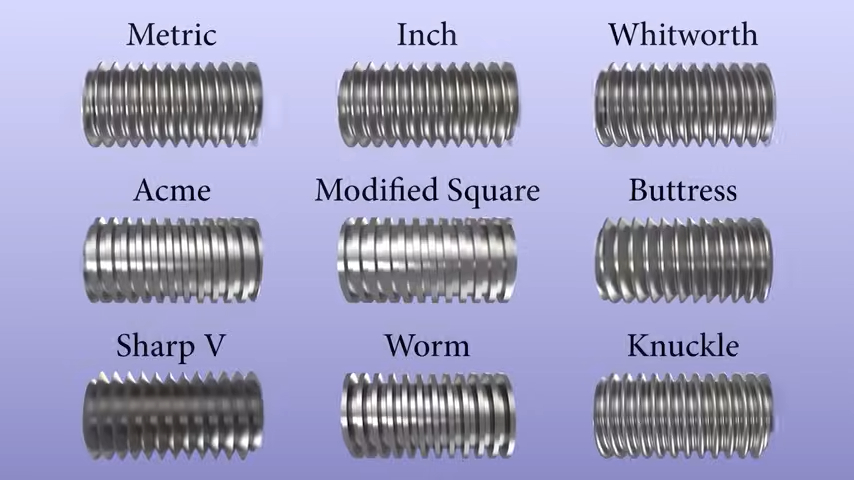

Tayp dɛn fɔ di trɛd dɛn .

Thread dɛn gɛt difrɛn we dɛn, ɛn dɛn mek ɛni wan pan dɛn fɔ sɔm patikyula injinɛri aplikeshɔn dɛn. Fɔ ɔndastand di difrɛn kayn trɛd dɛn impɔtant fɔ pik di rayt wan fɔ yu prɔjek. Lɛ wi fɛn ɔl di kɔmɔn trɛd tayp dɛn bay di dairekshɔn, prɔfayl, ɛn standad.

Rayt-an ɛn lɛft-an trɛd dɛn .

Dɛn kin kategoriz trɛd bay di dairekshɔn we dɛn tɔn fɔ ɛnjɔy.

Rayt-an (RH) Threads : Dis na di kayn trɛd dɛn we kɔmɔn pas ɔl. Dɛn kin tayt we dɛn de rɔta kloksayz. Klose to ɔl di jenɛral-pɔpɔs fastɛns dɛn, lɛk skru ɛn bolt, de yuz RH trɛd fɔ mek i izi fɔ yuz.

Left-han (LH) Threads : Dɛn trɛd ya kin tayt we dɛn tɔn kɔntraklɔksayz. Dɛn kin yuz LH trɛd dɛn na say dɛn usay kloksayz roteshɔn kin mek wan pat lus, lɛk insay sɔm mɛkanikal asɛmbli dɛn lɛk baysikul pedal ɔ spɛshal ɔtomotiv pat dɛn.

Di prɔfayl dɛn we de na di trɛd .

Thread profayl dɛn de tɔk bɔt di shep we di trɛd dɛn gɛt ɛn inflɔws dɛn trɛnk, efyushɔn, ɛn wok.

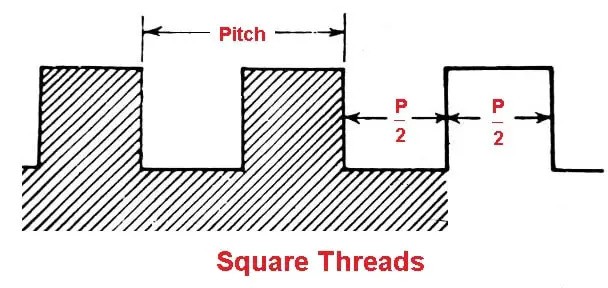

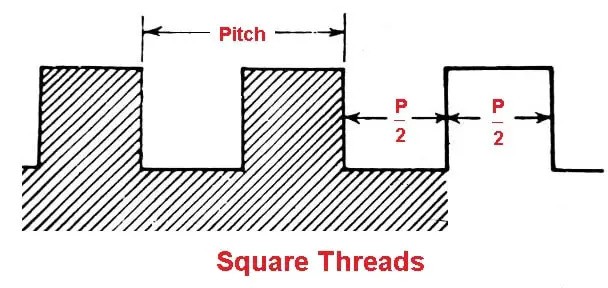

Square threads : skwea thread dem efishɔnal in pawa transmishɔn, wit minimal frikshɔn. Bɔku tɛm dɛn kin yuz dɛn fɔ jackskru, lid skru, ɛn ɔda ebi ebi mɛkanikal divays dɛn.

Tapered ɛn paralel trɛd dɛn .

trεd dεm kin kכl dεm bak bay aw dεn dayamita de chenj along di lεngth.

Taper threads : Dɛn trɛd ya de dɔŋ smɔl smɔl in dayamita to di ɛnd, we de mek wan wedj we de mek wan sil. Tapred thread na kɔmɔn tin na paip fitin ɛn dɛn de sɛlf-sil pan lɔw prɛshɔn. Ɛgzampul dɛn na NPT (National Pipe Thread) ɛn BSPT (British Standard Pipe tapered).

Paralel thread : paralel threads de mentɛn wan kɔnstant dayamita ɔlsay. Dɛn nid fɔ gɛt ɔda we dɛn fɔ sidɔm, lɛk O-ring ɔ trɛd tep, fɔ mek dɛn gɛt wata-tayt kɔnɛkshɔn. Di kɔmɔn kayn dɛn na BSPP (British standad paip paralel) ɛn NPTF (nashɔnal paip tapered fiul).

Speshal Tayp dɛn we dɛn kin yuz fɔ mek trɛd .

Bɔku standad dɛn de gi spɛshal trɛd fɔ yuz na difrɛn industri dɛn, wit notabɛl ɛgzampul dɛn na:

Yunaytɛd Nashɔnal Threads (UNC, UNF, UNS) : Dɛn kin mɛzhɔ di wan dɛn we dɛn kin yuz na di US ɛn Kanada, dɛn kin mɛzhɔ di yunifayd trɛd dɛn insay inch. UNC threads (coarse) dɛn de yuz fɔ jenɛral-pɔpɔs fastɛns, we UNF threads (Fine) na dɛn kin lɛk fɔ yuz am na ay-strɛng aplikeshɔn dɛn. UNS threads na nɔ-standad thread dɛn we dɛn tayl fɔ spɛshal nid dɛn.

British Standard Threads (BSW, BSF, BSP) : Dɛn kin yuz British Standard Whitworth (BSW) trɛd dɛn mɔ na ol mashin dɛn. British Standard Fine (BSF) threads de gi strɔng, fayn kɔnɛkshɔn ɛn dɛn de yuz dɛn na vaybreshɔn-prone ɛnvayrɔmɛnt. British Standard Pipe (BSP) threads na impɔtant tin fɔ paip fitin dɛn na plaba ɛn gas sistem, inklud ɔl tu paralel (BSPP) ɛn tapered (BSPT) fɔm dɛn.

Sɔma tebul fɔ di Tayp dɛn we dɛn kin yuz fɔ mek

| di trɛd trɛd dɛn | prɔfayl | aplikeshɔn dɛn . |

| Rayt-an (RH) trɛd dɛn . | Kloksayz . | Jɛnɛral-pɔpɔs fastɛns dɛn . |

| Left-han (LH) trɛd dɛn . | Kɔntraklɔksayz . | Pat dɛn kin prone fɔ lus ɔnda roteshɔn . |

| V-shaped thread dɛn . | Triangul we de na di wɔl . | Fastening, Jɛnɛral mashin dɛn . |

| Square thread dɛn . | Skwaya | Pawa transmishɔn, jack, hevi mashin |

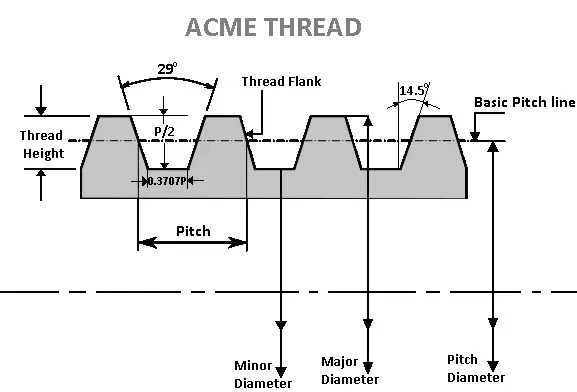

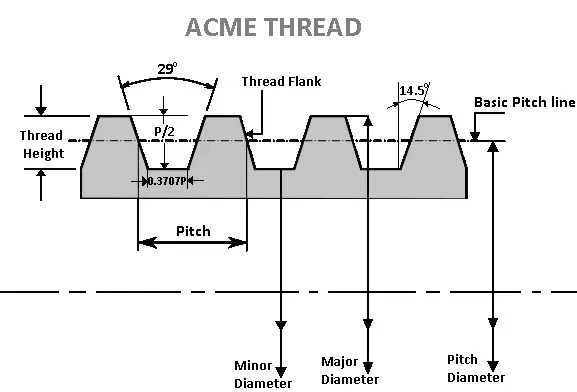

| Acme Thread dɛn . | Trapezoidal we de na di wɔl . | Hevi lod, mashin tul dɛn . |

| Trapezoidal thread dɛn . | Trapezoidal we de na di wɔl . | Pawa transmishɔn, Yuropian mashin dɛn . |

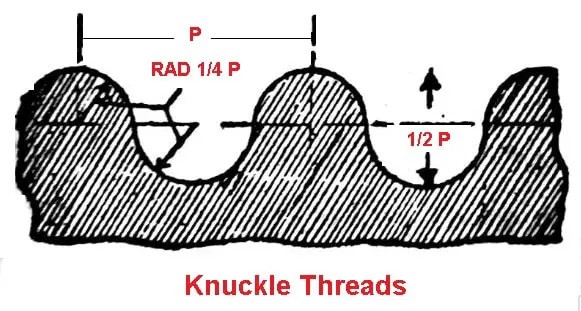

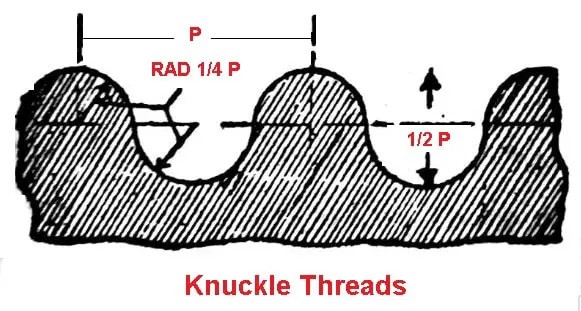

| Knuckle Thread dɛn . | Rounded . | Railway couplings, botul kaps |

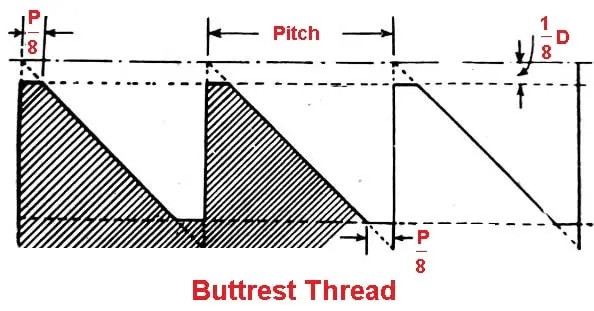

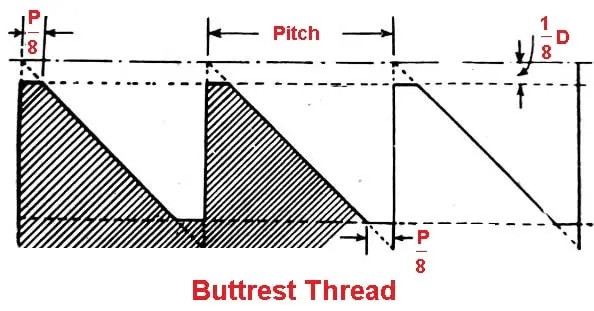

| Buttress threads . | Asymmetrical na di . | Divays dɛn we de klamp, pawa prɛs dɛn . |

| Wom Thread dɛn . | Hɛlikal . | Wom gia, rayt-ɛngl pawa transmishɔn |

| Taper trɛd dɛn . | Wedge-sealing na di . | Pipe Fittings (NPT, BSPT) |

| Paralel trɛd dɛn . | Di dayamita we dɛn kin gɛt kɔnstant . | Pipe Fittings we nid fɔ gɛt ɛksternal silin . |

| Yunaytɛd Nashɔnal trɛd dɛn . | Inch-based na | Fasteners, mashin we de mek prɛsishɔn . |

| British Standard Threads . | Inch-based na | Pipe Fittings, ola mashin |

Di we dɛn fɔ mek di trɛd .

Di prodakshɔn fɔ trɛd dɛn involv difrɛn tɛknik dɛn, ɛni wan de gi yunik advantej fɔ spɛshal aplikeshɔn ɛn matirial dɛn. Na dis na wan ɔvaviu fɔ di praymari trɛd manufakchurin we dɛn de yuz:

Thread cutting (Taps ɛn Days)

Thread cutting stil bi wan we dɛn kin yuz bɔku bɔku wan fɔ mek ɔl tu di intanɛnt ɛn ɛksternal trɛd dɛn:

Di bɛnifit dɛn we pɔsin kin gɛt:

I fayn fɔ mek dɛn mek smɔl smɔl tin dɛn .

we dɛn kin yuz fɔ bɔku bɔku tin dɛn .

Relatively low initial tul kɔst .

Di tin dɛn we yu nɔ fɔ du:

Tred we de rɔl .

Thread rolling forms threads tru plastic diformation of di wokpies:

Bɛnifit dɛn:

Di ay prodakshɔn ret dɛn .

Impɔtant trɛd trɛnk bikɔs ɔf wok hardening .

Eksɛlɛnt sɔfays finish ɛn dimɛnshɔnal akkuracy .

Di prɔblɛm dɛn we pɔsin kin gɛt:

Thread grindin .

Thread Grinding de yuz abrasive wil fɔ prodyuz ay-prɛsishɔn thread dɛn:

Di men tin dɛn we de insay:

Eksepshɔnal akkuracy ɛn sɔfays finish .

Suitabl fɔ thread afta ɔt tritmɛnt .

I ebul fɔ mek kɔmpleks trɛd fɔm dɛn .

Di tin dɛn we wi fɔ tink bɔt:

Thread mil di .

Thread Milling employ rotating cutting tools fɔ mek trɛd dɛn:

Di bɛnifit dɛn we pɔsin kin gɛt:

we ebul fɔ mek big big dayamita trɛd dɛn .

Minimal tul prɛshɔn, ideal fɔ tin-wɔl pat dɛn

kin mek ɔl tu di rayt-an ɛn lɛft-an trɛd dɛn wit di sem tul .

Di tin dɛn we yu nɔ fɔ du:

3D printin ɛn aditiv manufakchurin .

Di teknɔlɔji dɛn we de kam ɔp de gi nyu pɔsibul fɔ mek dɛn prodyuz trɛd:

Di bɛnifit dɛn we pɔsin kin gɛt:

Kɔmpleks jɔyometri dɛn we pɔsibul .

Di west we dɛn dɔn ridyus di tin dɛn we dɛn dɔn ridyus .

Rapid prototayping kapabiliti dɛn .

Chalenj dɛn:

Limitɛd matirial opshɔn dɛn .

Lɔw trɛnk we yu kɔmpia am wit tradishɔnal we dɛn fɔ du tin .

Surface finish kin nid fɔ gɛt post-prosɛsin .

Factors we de afɛkt di we aw di trɛd de wok .

Thread performance de inflɔws bay difrɛn tin dɛn we de sho in trɛnk, durabiliti, ɛn rilaybiliti insay injinɛri aplikeshɔn dɛn. Frɔm matirial sɛlɛkshɔn to envayrɔmɛnt kɔnsidareshɔn, fɔ ɔndastand dɛn tin ya rili impɔtant fɔ mek shɔ se di trɛd pefɔmɛns go fayn. Dis dɔŋ ya na di men tin dɛn we de afɛkt di we aw di trɛd de wok.

Di we aw dɛn de pik di tin dɛn we dɛn dɔn yuz

Thread pefɔmans rili dipen pan matirial prɔpati dɛn:

Strɔng: Ditarmin lod-bearing kapasiti .

Ductility: Afεkt trεd fכmeshכn εn rεsistεns to stripping .

Corrosion Resistance: I impɔtant fɔ mek pipul dɛn liv lɔng na di say dɛn we at fɔ liv na say dɛn we nɔ izi fɔ liv .

Di tritmɛnt dɛn we de na di wɔl ɛn di kɔtin dɛn .

Surface tritment dem de improve di longevity en functionality of threads bay we dem de ridyus wear, corrosion, en galling. Di tritmɛnt dɛn we dɛn kin gɛt na:

Zinc pletin : Protɛkt threads frɔm kɔrɛshɔn ɛn ɛp fɔ mek dɛn layfspan bɛtɛ.

Blak Ɔksayd Kɔtin : de gi mild kɔrɛshɔn rɛsistɛns ɛn i de ɛp fɔ mek di aestɛtiks bɛtɛ.

Fosfatin : I de impruv lubrication retention, we de mek am yusful insay ay-frikshɔn aplikeshɔn.

Anodizing : Dɛn kin yuz am fɔ aluminiɔm trɛd, i kin mek di kɔrɛshɔn rɛsistɛns bɔku ɛn wɛr trɛnk.

Dɛn tritmɛnt ya kin ɛp trɛd dɛn fɔ du dɛn wok fayn fayn wan na say dɛn we nɔ fayn ɔ we dɛn kin yuz fɔ wɛr ay klos.

Lubrikeshɔn ɛn Frikshɔn .

If yu gɛt di rayt lɔbrik, i de ridyus di frikshɔn we dɛn de asembli ɛn i de mek yu nɔ gɛt galling ɔ seiz, mɔ we yu de yuz ay-lod aplikeshɔn dɛn. Lubrikeshɔn:

Ridyus Wear : I de ɛp fɔ mek di damej nɔ bɔku we yu de tayt ɛn lɛf fɔ wok ɔltɛm.

Impruv torque control : I de mek shɔ se ivin lod distribushɔn akɔdin to trɛd, we de mek dɛn nɔ ebul fɔ bia pasmak.

Thread lubricants kin inklud ɔyl, gris, ɔ anti-seiz kɔmpawnd dipen pan di aplikeshɔn in spɛshal rikwaymɛnt dɛn.

Di tin dɛn we de apin na di envayrɔmɛnt .

Bɔku tɛm, dɛn kin gɛt trɛd to difrɛn envayrɔmɛnt kɔndishɔn dɛn, we kin afɛkt dɛn pefɔmɛns as tɛm de go. Di men tin dɛn we kin apin na:

Tempracha : Ay tempɔret kin mek matirial ɛkspɛnshɔn ɛn impak thread trɛnk. Low temperecha kin mek sɔm matirial dɛn kin brok.

Kɔroshɔn : trɛd dɛn we gɛt mɔstɔ, kemikal, ɔ sɔl kin kɔrɛd, wikɛd dɛn strɔkchɔ ova tɛm.

Vaybreshɔn : Kɔntinyu fɔ vaybrɛshɔn kin lɔs trɛd kɔnɛkshɔn, we kin mek i nɔ wok. Di we aw dɛn kin lɔk lɛk trɛd lɔka ɔ lɔk nat kin ɛp fɔ stɔp dis.

Fɔ adrɛs dɛn envayrɔmɛnt chalenj ya impɔtant fɔ mek dɛn kɔntinyu fɔ gɛt di intagriti fɔ di kɔnɛkshɔn dɛn we gɛt trɛd.

Di we aw dɛn go ebul fɔ gɛda ɛn di we aw dɛn fɔ tayt .

Di we aw dɛn bin de yuz fɔ gɛda ɛn tayt di trɛd dɛn kin rili afɛkt dɛn pefɔmɛns. Di men we dɛn fɔ du am na:

Torque Control : Fɔ aplay di kɔrɛkt tɔk de mek shɔ se thread dɛn nɔto ɔva- ɛn ɔnda-tayt, dɛn de mentɛn dɛn integriti.

Preload Tension : Prɔpa prɛlɔd de ridyus di risk fɔ lus ɔnda dinamik lod ɛn mek shɔ se lod distribyushɔn akɔdin to di trɛd prɔfayl.

Fastening Tools : Tul dɛn lɛk di tork wrench dɛn de gi prɛsishɔn taytin, we de ridyus di chans fɔ mek di trɛd nɔ wok.

Yuz kɔrɛkt asɛmbli tɛknik dɛn de ɛp fɔ mek di kɔnɛkshɔn dɛn we gɛt trɛd go te ɛn trɛnk.

Load types ɛn dɛn impak pan thread trɛnk .

Dɛn kin put trɛd dɛn pan difrɛn kayn lod dɛn, ɛn ɛni wan pan dɛn kin afɛkt di we aw di trɛd de wok difrɛn we:

Statik Loads : Dɛn kin aplay am stedi ɔva tɛm, dɛn kin jɔs nɔ kin mek trɛd nɔ wok pas di lod pas di matirial in yield trɛnk.

Dynamic Loads : kin chenj ova tɛm ɛn i kin mek trɛd lɛf ɔ taya if dɛn nɔ mek am fayn.

Fatigue Loads : Ripit lod ɛn ɔndo saykl dɛn kin wik trɛd dɛn ova tɛm, we kin mek dɛn nɔ wok. Dɛn kin lɛk fɔ yuz matirial dɛn we gɛt ay fatigue resistans na dɛn kayn aplikeshɔn dɛn de.

Ɔndastand di lod kɔndishɔn dɛn de mek shɔ se dɛn pik di rayt trɛd tayp ɛn matirial fɔ di aplikeshɔn we dɛn want fɔ yuz.

Silin Pɔfɔmɛnshɔn Rikwaymɛnt dɛn .

Insay bɔku aplikeshɔn dɛn, dɛn kin nid trɛd fɔ gi wan sil, mɔ na di wata ɔ gas sistɛm. Tepred threads lɛk NPT ɛn BSPT de gi sɛlf-sil prɔpati bay we dɛn de mek wan tayt fit as dɛn tayt dɛn. Fɔ trɛd dɛn we nɔ de sial fɔ dɛnsɛf (ɛgz., paralel trɛd dɛn lɛk BSPP), dɛn nid fɔ gɛt ɔda sil dɛn lɛk O-ring ɔ trɛd tep fɔ mek dɛn nɔ lik.

| Thread Type | Siling Abiliti | Aplikeshɔn dɛn . |

| NPT trɛd dɛn . | Self-sealing . | Pipe Fittings, Fluid sistem dɛn . |

| BSPT trɛd dɛn . | Self-sealing . | Gas ɛn Fluid Aplikeshɔn dɛn . |

| BSPP trɛd dɛn . | I nid fɔ gɛt ɔda silin (O-ring ɔ tep) | Plumbing, Low-Pressure Systems . |

Fɔ adrɛs di tin dɛn we dɛn nid fɔ silin na impɔtant tin fɔ mek shɔ se dɛn gɛt kɔnɛkshɔn dɛn we nɔ de mek fluid-tayt insay injinɛri aplikeshɔn dɛn.

Aplikeshɔn dɛn fɔ trɛd dɛn na injinɛri .

Threads de ple wan impɔtant pat pan difrɛn injinɛri aplikeshɔn dɛn, we de gi impɔtant wok dɛn akɔdin to bɔku bɔku industri dɛn. Dɛn versatility ɛn efficiency de mek dɛn indispensable kɔmpɔnɛnt dɛn na mɔdan injinɛri.

Fastɛns dɛn .

Threaded fasteners fɔm di bakbon fɔ mɛkanikal asɛmbli dɛn:

Bolts: ay-strɛng kɔnɛkshɔn dɛn na strɔkchɔral aplikeshɔn dɛn .

Skru dɛn: Bɔku bɔku tin dɛn we dɛn kin yuz fɔ fast fɔ bɔku bɔku tin dɛn .

Nuts: Gi sikyuɔr, adjɔstabl klamp fɔs

Dɛn komponent ya de mek am izi fɔ asembli, disassembly, ɛn mentenɛns fɔ injinɛri sistɛm dɛn.

Pawa transmishɔn .

Threads excel in kɔnvɔyt rotary muvmɛnt to linya muvmɛnt:

Dɛn efyushɔn ɛn akkuracy de mek thread dɛn fayn fɔ pawa transmishɔn aplikeshɔn dɛn.

Fluid ɛn gas silin .

Threaded connections na impɔtant tin we de insay di fluid handling sistem dɛn:

Pipe Fittings: Sikyu, lik-pruf jɔyn dɛn na plaba ɛn industrial paip

Valv dɛn: Prɛsis flɔ kɔntrol na haydrolik ɛn nyumɛtik sistem dɛn .

Tepred threads kin gi self-sealing prɔpati, ɛnhans sistem intɛgriti.

Pozishɔn ɛn ajɔstmɛnt .

Threads de mek yu ebul fɔ ajɔst fayn fayn wan insay prɛsishɔn inschrumɛnt dɛn:

Maykromita dɛn: Di kɔrɛkt we aw dɛn de mɛzhɔ di tin dɛn we dɛn de yuz fɔ mek di tin dɛn we dɛn de yuz fɔ mek di tin dɛn we dɛn de yuz fɔ mek di tin dɛn we dɛn de yuz fɔ mek di tin dɛn we dɛn de yuz fɔ mek di tin dɛn we dɛn de

Adjɔstmɛnt skru dɛn: Kalibreshɔn fɔ optik inschrumɛnt ɛn mashin dɛn .

Dɛn ebul fɔ translet smɔl smɔl roteshɔn dɛn to minit linya muvmɛnt dɛn nɔ gɛt wan kɔmpitishɔn.

Spesifi k Indastri Aplikeshɔn

| Indastri | Aplikeshɔn | Thread Tayp . |

| Aerospace na di . | Fastɛns dɛn we gɛt ay strɛng . | UNF, Mɛtrik Fayn . |

| Ɔtomotiv . | Enjin komponent dɛn . | Metrik, UNF . |

| Divays dɛn fɔ mɛn pipul dɛn . | Implant fikseshɔn . | Kastom, Fayn Pich |

| Oil & Gas na di . | Prɛshɔn-tayt kɔnɛkshɔn dɛn . | NPT, API . |

Kes Stɔdi dɛn .

ay-strɛngth bolt kɔnɛkshɔn dɛn na brij kɔnstrɔkshɔn .

Chalenj: Fɔ jɔyn bɔku bɔku strɔkchɔral ɛlimɛnt dɛn .

Sɔlv: Big dayamita, ay-strɛng bolt dɛn wit UNC trɛd dɛn

Rizult: Kɔnɛkshɔn dɛn we nɔ de te, we nɔ de taya, we ebul fɔ bia wit di dinamik lod dɛn

Precision lead screw in CNC mashin dɛn .

Chalenj: Di kɔrɛkt we aw dɛn de put di tul dɛn we dɛn de kɔt .

Sɔlv: grɔn, mɔlti-start trapezoidal trɛd dɛn wit anti-baklash nat dɛn

Rizult: Sabmaykron posishunin akkuracy ɛn smol moshɔn kɔntrol

Self-sealing paip kɔnɛkshɔn dɛn na ay-prɛshɔn sistem dɛn .

Chalenj: Di jɔyn dɛn we nɔ gɛt lik na di haydrolik sistem dɛn .

Sɔlv: NPTF tapered trɛd dɛn wit kɔntrol intafɛreshɔn fit

Rizɔlt: Rilibul, mɛtal-to-mɛtal sil dɛn we nɔ gɛt ɔda kɔmpawnd dɛn we dɛn kin sial wit ɔda silin dɛn

Thread failure mods ɛn prɛvɛnshɔn .

Fɔ ɔndastand di trɛd fayl mɔd dɛn na impɔtant tin fɔ disayn kɔnɛkshɔn dɛn we dɛn kin abop pan ɛn we sef. Dis pat de tɔk bɔt di kɔmɔn we aw dɛn kin fil, di tin dɛn we kin mek dɛn nɔ ebul fɔ du wetin dɛn want, ɛn di tin dɛn we dɛn kin du fɔ mek dɛn nɔ du bad tin.

Kɔmɔn fayl mɔd dɛn .

Threaded components kin fel difrɛn we dɛn:

Stripping : Thread difɔmeshɔn ɔnda pasmak lod .

Shearing : Komplit separeshɔn fɔ trɛd dɛn bikɔs ɔf di ekstrim fɔs .

Galling : Surface damage frɔm adhesive wear bitwin mating threads .

Seizing : Threads lok togeda, prevent disassembly

Fatigue : smɔl smɔl krak gro ɔnda saykli lod .

Stress Corrosion Cracking : Kɔmbaynshɔn fɔ tɛnsiɛl strɛs ɛn kɔrosiv ɛnvayrɔmɛnt

Di tin dɛn we kin mek di trɛd nɔ wok fayn

| kin mek | diskripshɔn | kɔmɔn insay . |

| Wɛr | Smɔl smɔl matirial lɔs frɔm frikshɔn . | Bɔku tɛm dɛn kin gɛda jɔyn dɛn . |

| Kɔrɔshɔn . | Kεmikכl dεgradashכn כf trεd mεtirial . | Envayrɔmɛnt dɛn we de na do ɔ we gɛt bɔku bɔku wata . |

| Taya | ripit strεs saykl dεm we de lid to krak fכmeshכn . | Vaybrɛt ɔ saykli lod kɔmpɔnɛnt dɛn . |

| Ovalod . | pas di wan we de kɛr di tin dɛn we dɛn de yuz fɔ mek di tin dɛn we dɛn dɔn yuz fɔ bia wit di tin dɛn we dɛn dɔn lod. | Di fastɛns dɛn we dɛn nɔ tayt di rayt we . |

| Asɛmbli we nɔ rayt . | Krɔs-thrɛd ɔ ɔva-tayt . | Manual asɛmbli prɔses dɛn . |

Di tin dɛn we dɛn fɔ du fɔ mek dɛn nɔ gɛt di sik .

Fɔ mitigate thread failures:

Prɔpa matirial sɛlɛkshɔn bays pan envayrɔmɛnt kɔndishɔn ɛn lod rikwaymɛnt dɛn .

Aplikeshɔn fɔ di rayt tritmɛnt ɔ kɔtin dɛn we fit fɔ gɛt di sik .

Yuz ɔf thread-lɔk kɔmpawnd fɔ vaybreshɔn rɛsistɛns .

Implimɛnt fɔ kɔrɛkt lɔbrikeshɔn prɔsis .

Adherence to spesifik tork valyu dɛn we dɛn de asembli .

Prɔpa trɛd sɛlɛkshɔn ɛn dizayn .

Optimize thread pefomans tru:

Fɔ pik di rayt trɛd prɔfayl fɔ di aplikeshɔn .

We yu tink bɔt aw fɔ sheb di lod ɛn di tin dɛn we de mek yu gɛt strɛs kɔnsɛntreshɔn faktɔ dɛn .

Evaluate envairomɛnt factor dɛm (tɛmpracha, kɔrɛshɔn pɔtɛnɛshɔn)

Ditarmin optimal thread engagement length .

Fɔ pik fayn tolerans klas fɔ mating kɔmpɔnɛnt dɛn .

Kwaliti Kɔntrol ɛn Inspekshɔn .

Impliment robust kwaliti mɛzhɔ:

Dimensional inspekshɔn we yu de yuz prɛsishɔn gej ɛn mɛzhɔmɛnt inschrumɛnt dɛn .

Nɔn-dɛstruktiv tɛst mɛtɔd dɛn (ɛgz., ɔltrasɔnik, magnɛtik patikyula) fɔ impɔtant kɔmpɔnɛnt dɛn

Inspekshɔn ɛn mentenɛns schedule dɛn we dɛn kin gɛt wan wan tɛm fɔ di asɛmbli dɛn we gɛt trɛd .

Dokumɛnt ɛn traysabiliti fɔ thread manufacturing prɔses .

Trenin program fɔ asɛmbli pipul dɛn fɔ mek shɔ se dɛn instɔl di tin dɛn fayn fayn wan .

ENDNOTS .

Threads na impɔtant tin we dɛn de yuz fɔ mek injinɛri, we dɛn kin yuz fɔ fast, muv, ɛn gɛt pawa. Dɛn de mek shɔ se strɔng, rilibul kɔnɛkshɔn dɛn de na mɛkanikal sistɛm dɛn.

Prɔpa sɛlɛkshɔn, dizayn, ɛn kwaliti kɔntrol fɔ trɛd dɛn rili impɔtant fɔ avɔyd fɔ fel ɛn impruv pefɔmɛns insay difrɛn aplikeshɔn dɛn.

Fɔ fɛn ɔl di trɛd standad, matirial dɛn, ɛn di we aw dɛn de mek tin dɛn kin rili ɛp fɔ mek pipul dɛn ɔndastand di aplikeshɔn dɛn we dɛn kin yuz fɔ yuz trɛd.

Fɔ no mɔ, chɛk di industri standad ɛn risɔs fɔ mek shɔ se di bɛst pefɔmɛns na yu injinɛri prɔjek dɛn.