Jiri, n’a bɛ fɔ a ma ko jurukisɛ, o ye fɛn ye min bɛ kɛ ka fɛn dɔ siri ni nɛgɛ ye min bɛ kɛ ka a lamini ni silinda walima koniki ye. A b’a To 'yɔrɔ-yɔrɔ-ko-yɛrɛ-yɛrɛ-yɛrɛ-yɛrɛ-yɛrɛ-yɛrɛ bɛ 'yɔrɔ-yɔrɔ-ko-yɛrɛ-yɛrɛ-yɛrɛ-yɛrɛ-yɛrɛ-yɛrɛ-yɛrɛ-yɛrɛ-yɛrɛ-yɛrɛ-yɛrɛ-yɛrɛ-yɛrɛ-yɛrɛ-yɛrɛ-yɛrɛ-yɛrɛ-yɛrɛ-yɛrɛ-yɛrɛ-yɛrɛ-yɛrɛ SUMA ƝƐSIN ƝƐSIN ƝƐSIN ƝƐSIN ƝƐSIN ƝƐSIN ƝƐSIN ƝƐSIN ƝƐSIN ƝƐSIN ƝƐSIN ƝƐSIN ƝƐSIN ƝƐSIN ƝƐSIN ƝƐSIN ƝƐSIN ƝƐSIN ƝƐNAJƐ NI ƝƐNAMAYA ƝƐNABƆ. Filɛriw nafa ka bon ɛntɛrinɛti la walasa ka yɔrɔw fara ɲɔgɔn kan, ka lamaga dabɔ, ani ka fanga lase mɔgɔw ma.

Tariku ni nafa minnu bɛ dilan injiniyɛri la .

Filɛriw kɛra fɛn nafamaba ye masinko la kabini san kɛmɛ caman. O jirisun in hakilina bɛ Bɔ kɔrɔlen na waati min na a tùn bɛ Kɛ ka 'sèn Bɔ a sirili ni a kɔrɔtacogo jɔnjɔnw na. I n’a fɔ iziniw dilanni bɛ ka yiriwa cogo min na, jiri suguya minnu bɛ kɛ ka kɛɲɛ ni sariya ye, olu donna senkan walasa ka bɛnkan ni ɲɔgɔn falen-falen sabati. Bi, jirisunw nafa ka bon kosɛbɛ ɛntɛrinɛti seko ni dɔnko siratigɛ la, k’a ta aerospace la ka se mobili baarakɛlaw ma. U bɛ jɛɲɔgɔnya barikamaw sabati, minnu bɛ se ka bɔ ani ka se ka lamaga-lamagali tigitigi kɛ.

Thread baarakɛcogo suguyaw .

Filɛriw bɛ baara kɛ kun suguya caman na ka kɛɲɛ ni ɛntɛrinɛti wajibiyalenw ye. Thread applications minnu ka ca kosɛbɛ olu ye:

sirilanw : olu bɛ kɛ ka fɛn fila walima u caman minɛ ɲɔgɔn na ka ɲɛ. Bolo ni nuguw ye misali kɔrɔw ye minnu bɛ sirilanw siri. U bɛ sɔrɔ ka caya masinw, mɔbiliw, ani jɔli porozɛw la k’a sababu kɛ u fanga n’u lajɛli nɔgɔya ye.

Lamaga-lamagali jiriw : O jirisunw bɛ wuli-wuli-yɔrɔ-yɛrɛ-yɛrɛ Yɛlɛma ka Kɛ lamaga-lamagali ye. Lead screws in machines and jackscrew in heavy equipment ye misali ɲumanw ye. U dilanni tigitigi b’a to u bɛ se ka jiginni baara kɛ ka kɛ lamagacogo ɲuman ye, min bɛ kɔlɔsi, o b’a to u nafa ka bon kosɛbɛ masinw ka sigida la minnu bɛ tiɲɛni wajibiya.

Transport threads : A ka ca a la, a bɛ sɔrɔ conveyor systems ani screw conveyors la, o jiriw bɛ dɛmɛ ka taa ni fɛnw ye walima ka ji bɔ. U ka spirali min bɛ to senna, o bɛ kɛ sababu ye ka fɛnw bila sira kan ni fanga kɔrɔsilen ye, k’u kɛ nafama ye iziniw kɔnɔ i n’a fɔ sɛnɛ ani fɛn dilanni.

geometri ani dilanw .

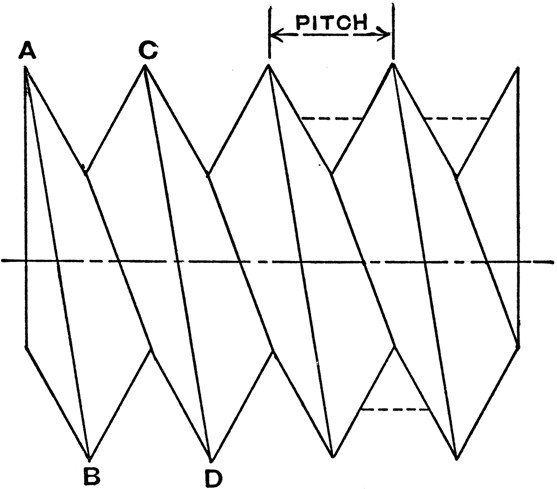

Thread geometry jɔyɔrɔ ka bon kosɛbɛ a ka baara kɛcogo n’a bɛnnenya dɔnni na baara suguya caman kama. Paramɛtɛrɛ kelen-kelen bɛɛ bɛ nɔ bila jiriw la, fanga jiginni, ani u jɔcogo dafalen sabatili cogo la. An ka jateminɛ kɛcogo kɔrɔlenw ni baarakɛminɛnw sɛgɛsɛgɛ minnu bɛ kɛ ka jiriw suman.

geometric paramètres de thread .

Nin jateminɛ paramɛtɛrɛ ninnu bɛ jirisun dɔ cogoya n’a kɛcogo ɲɛfɔ:

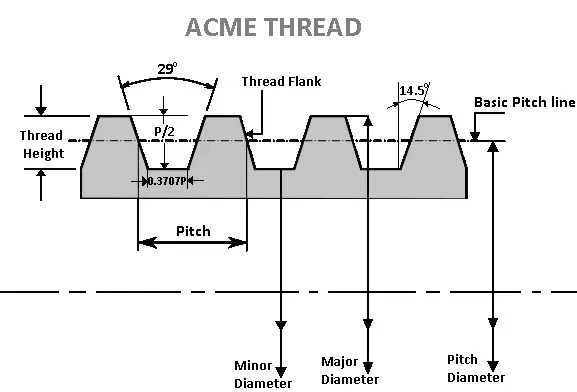

Diamètre (janya)ba : Filɛri janya ka bon, min bɛ suman kɛnɛma jiriw sanfɛla la walima kɔnɔna jiriw duguma. A bɛ jiribolo-yɔrɔ bɛɛ bonya n’a fanga bɛɛ Labɛn.

A cɛmancɛ fitinin : a cɛmancɛ ka dɔgɔn, a bɛ suman kɛnɛma jiri juw cɛ walima kɔnɔna jiri sanfɛla. A bɛ fɛn in girinya ɲɛfɔ min bɛ sirilan walima bolokɔni kɔnɔna na.

Pitch diamètre (a diamètre effectif) : Silinda miirilen dɔ cɛmancɛ bɛ tɛmɛ jiri flankɛw fɛ. A nafa ka bon walasa ka bɛnkan ni jɛɲɔgɔnya sabati furuɲɔgɔnya jiriw ni ɲɔgɔn cɛ, ka nɔ bila u ka mesh sirilen na cogo min na.

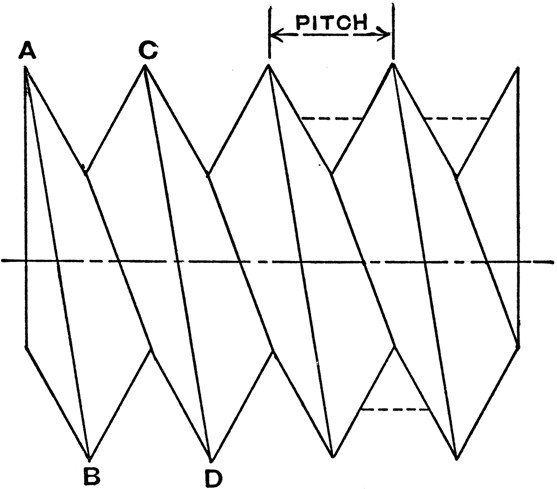

Pitch : Axial distance ni points correspondants sur les trees avances. Fɔɔnɔ min ka bon, o bɛ sira Di lamaga teliya ma jiginni kelen na, k’a sɔrɔ fɔlisen fitinin bɛ kɔrɔsicogo ɲuman di ani ka nafa sɔrɔ masin na.

Lead : Jiri bɛ taa ɲɛ yɔrɔ min na, o bɛ taa ɲɛ dafalen kelen na. Daminɛ kelen-kelenw kan, plɔmu bɛ bɛn fɔlikan ma, nka daminɛ multi-start threads kan, lead ye multiple of the pitch ye.

Thread Starts : o bɛ tali kɛ jiri kelen-kelenw hakɛ la buruburu kan. A daminɛ-yɔrɔ kelen bɛ ni helical groove kelen ye min bɛ to sen na, ka sɔrɔ threads multi-stards bɛ lamaga teliyalen di jiginni kelen na.

Helix angle : Angle min bɛ dilan jiri in ka helix cɛ ani layini min bɛ jɔ ni jiri in ka aksidan ye. Helix angle min ka jan, o bɛ dɔ bɔ ɲɔgɔnkanu na nka a bɛ se ka dɔ bɔ a minɛcogo la.

Thread angle : Angle min bɛ sɔrɔ jiribolo kɛrɛfɛlanw ni ɲɔgɔn cɛ. O bɛ nɔ bila fanga tilacogo la ani ka nɔ bila jiri ka baarakɛcogo ɲuman na doni jiginni na.

ɲin angle : jiri kelen-kelen bɛɛ ɲinw cogoya n’u kɛrɛ, minnu bɛ ɲɔgɔn ta ka da jiri dilanni n’a kuntilenna kan. ɲin yɔrɔw bɛ se ka kɛ trapezoidal, square, walima triangulaire ye, ka nɔ bila jiri fanga ni a sɔgɔli cogoyaw la.

Sumanikɛminɛnw ka ɲɛsin jiriw ma .

Filɛli sumani tigitigi nafa ka bon walasa ka bɛnkan sɔrɔ furuɲɔgɔnya yɔrɔw ni ɲɔgɔn cɛ. Baarakɛminɛn fɔlɔ fla minnu bɛ Kɛ o baara in na olu ye:

Caliper : Baarakɛminɛn caman bɛ yen minnu bɛ se ka cɛ (kɛnɛma) ni muso (kɔnɔna) fila bɛɛ janya suman. A ka ɲɛfɔli bɛ kɛ sababu ye ka injiniyɛriw dɛmɛ u ka se ka jiri hakɛ suman joona ani ka u kɛ cogo bɛnnen na.

Pitch gauge : Baarakɛminɛn kɛrɛnkɛrɛnnen min dabɔra walasa ka jirikurunw ni ɲɔgɔn cɛ janya suman. A nafa ka bon kosɛbɛ walasa ka jiri in fɔcogo dɔn wa a bɛ kɛ ka jiri suguya fila bɛɛ kɛ.

Identifier threads .

Filɛri dɔnni tigitigi nafa ka bon kosɛbɛ yɔrɔw sugandili ɲuman na ani sistɛmu bɛnkan na. Aw bɛ nin wale ninnu kɛ walasa ka jiriw dɔn:

Fɛn minnu bɛ kɛ ka jiriw dɔn .

1. Cɛ ni muso ka jiriw .

Cɛw ka jiriw: kɛnɛma jiriw bɛ kɛ bolokɔniw kan, juruw kan, walima pipew kan.

Musow ka jiriw: Kɔnɔnatumuw bɛ kɛ nuguw la, dingɛw kɔnɔ, walima fɛnw na minnu bɛ kɛ ka fɛnw don.

Sɛgɛsɛgɛli yelen bɛ se ka kɛ; Cɛya ni musoya tɛ nɔ bila baarakɛcogo la nka a bɛ cɛnimusoya yɔrɔw latigɛ.

2. Tapered vs parallel jiriw .

Parallel jiriw bɛ janya basigilen mara janya la.

Tapered threads bɛ dɔgɔya a cɛmancɛ la ka taa a laban na.

Aw bɛ baara kɛ ni kalifaw ye walasa ka a dafa: paralɛli jiriw bɛ ɲɔgɔn sɔrɔ janya dafalen na, jirimuguw fara.

3. Sumanikɛlanw ka fɔta .

Baara kɛ ni pitch gauge ye walasa ka yɔrɔjan dɔn jirikurunw ni ɲɔgɔn cɛ.

Ka ɲɛsin mansamara jiriw ma, aw bɛ jiriw jate insitiri kelen kɔnɔ (TPI).

Walasa ka mɛtɛrɛw kɛ, aw bɛ janya suman krecɛnw ni ɲɔgɔn cɛ milimɛtɛrɛw la.

4. Sumanikɛlanw bonya .

Fila hakɛ sumani bɛ bɔ jiri suguya de la:

| Fila suguya | sumanikɛcogo . |

| Pipe Filaw . | A bɛ se ka kɛ ni tɔgɔ ye min bɛ se ka kɛ . |

| Fila minnu tɛ pipe ye . | Aw bɛ kɛnɛma cɛmancɛ suman ni kalifa ye . |

5. Ka jiri suguya sariya jira .

Aw bɛ sumanikɛlanw suma ni taabolow ye minnu bɛ kɛ ka kɛɲɛ ni sariya ye:

NPT/NPTF ka ɲɛsin Ameriki pipe fila ma .

BSP ka ɲɛsin tubabukan na pipe threads ma .

Metric ka ɲɛsin diɲɛ sariyaw ma .

ONU/UNF ka ɲɛsin jamana ka jiriw ma .

Thread Standards and Specifications .

Injiniyɛri la, jirisunw ka sariyaw n’u ka fɛnsɛbɛnniw bɛ bɛnkan, ɲɔgɔnfaamu, ani tigitigiya sabati sigida ni izini suguya caman kɔnɔ. Standard kelen-kelen bɛɛ bɛ jiri in ka jateminɛ, a ka fɔcogo ani a ka muɲuli ɲɛfɔ. Yan, an bɛna kuma sariyaw kan minnu bɛ baara kɛ kosɛbɛ, i n’a fɔ ISO metric threads, Unified Threads, British Standard Threads, ani American Pipe Thread Standards.

ISO ka metriki jiriw (m) .

ISO metric thread ye thread standard ye min ka ca diɲɛ kɔnɔ. A bɛ baara Kɛ ni mɛtɛrɛ sumanikɛlanw ye a cɛmancɛ ni a fɔcogo bɛɛ la, a bɛ sariyaw nɔgɔya maraw kɔnɔ.

Thread profile and dimensions : ISO metric threads bɛ ni 60-degree V-shaped profile ye, min ɲɛfɔlen don ni tɔgɔ tɔgɔla ani pitch ye. O hakɛ fila bɛɛ bɛ suman milimɛtiriw la.

Coarse and Fine Pitch Series : Koarse pitch series (misali la, M10 × 1.5) bɛ baara kɛ ni fɛn bɛɛ ye min bɛ kɛ ka fɛn bɛɛ kɛ, ka fɛn dilanni nɔgɔya. Fine pitch series (misali la, M10 × 1.0) bɛ kɛ ni a ka gɛlɛn ani ni a ka ɲi kosɛbɛ.

Tolerance classes and fits : ISO metric threads bɛ tila ka kɛ muɲuli kalanw ye, i n’a fɔ 6G ani 6H, o bɛ a jira ko a bɛ se ka kɛ ko a bɛ se ka kɛ ko a bɛ se ka kɛ ko a bɛ se ka kɛ ko a bɛ se ka kɛ ko a bɛ se ka kɛ ko a bɛ se ka kɛ ko a bɛ se ka kɛ ko a bɛ se ka kɛ ko a bɛ se ka kɛ ko a bɛ se ka kɛ ko a bɛ se ka kɛ ko a bɛ se ka kɛ ko a bɛ se ka kɛ ko a bɛ se ka kɛ ko a bɛ se ka kɛ ko a bɛ se ka kɛ ko a bɛ se ka kɛ ko a bɛ se ka kɛ ko a bɛ se ka kɛ ko a bɛ se ka kɛ ko a bɛ se ka kɛ. Tolerances coarser bɛ fɛnw di minnu ka surun, ka sɔrɔ muɲuli ɲumanw bɛ fitininw di minnu ka gɛlɛn.

Standard kelen min bɛ kɛ ni jiri ye (UNC/UNF) .

The Unified Thread Standard (UTS) bɛ baara kɛ kosɛbɛ Ameriki, Kanada, ani Angletɛri yɔrɔ dɔw la a bɛ sumanikɛlanw di insitiriw la ani a bɛ tali kɛ ISO metriki jiriw la a ka baara kɛcogo la min bɛ wele ko coarse and fine pitch series.

Thread profile and dimensions : UTS Thread bɛ ni V-profile 60 ye, a bɛ suman insitiriw la. A bɛ ni jirisunw ye minnu ka gɛlɛn (UNC) ani Fine (UNF) fila bɛɛ.

Coarse and Fine Pitch Series : UNC threads, i n’a fɔ 1⁄4'-20 UNC, olu bɛ kɛ ka ɲɛsin fɛn bɛɛ sirili baarakɛcogo ma, ka sɔrɔ UNF jiriw, i n’a fɔ 1⁄4'-28 UNF, olu de ka fisa ni fɛn kɛrɛnkɛrɛnnenw ye ani fanga ye izini kɛrɛnkɛrɛnnenw na.

Tolerance classes and fits : UTS bɛ muɲuli kalan suguya caman di, ni kalan minnu bɛ kɛ ka caya, olu ye kalanso 1 ye (loose fit), kalasi 2 (standard), ani kalasi 3 (tight fit).

British Standard Threads .

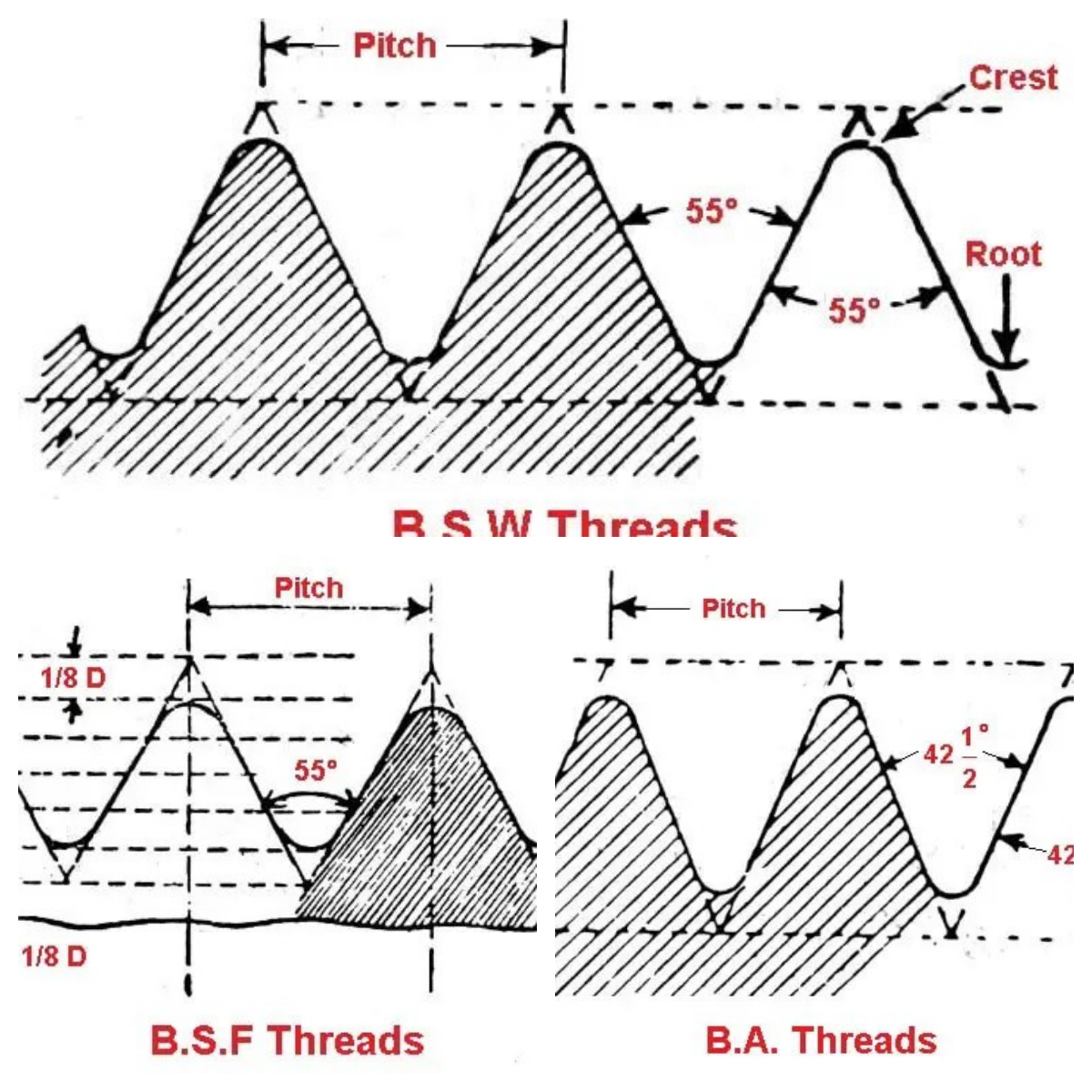

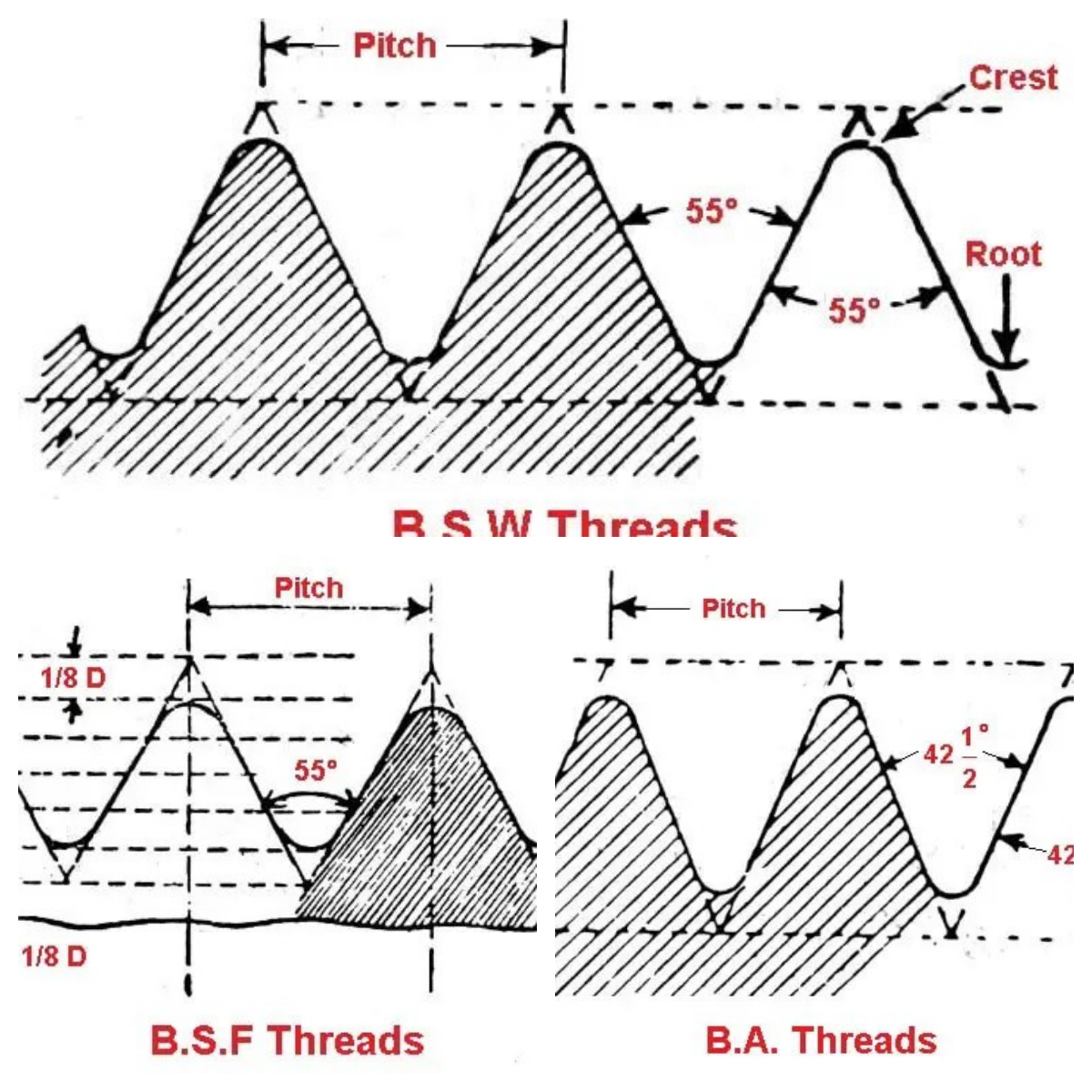

Angilɛw ka jiriw ye ciyɛn ye, hali bi u bɛ baara kɛ kosɛbɛ Angletɛri ani Commonwealth jamanaw na. O jirisun ninnu ye Whitworth, Fine ani Pipe jiriw ye.

Whitworth Threads (BSW) : British Standard Whitworth (BSW) jiri bɛ ni jiri ye min bɛ se ka kɛ 55 ye. A bɛ kɛ ka fɛn bɛɛ lajɛlen sirilanw kɛ, kɛrɛnkɛrɛnnenya la masin kɔrɔw la.

British Standard Fine Threads (BSF) : A bɛ tali kɛ BSW la nka ni a fɔcogo ka ɲi, BSF jiriw bɛ jɛɲɔgɔnya barikamaw di baarakɛminɛnw na minnu bɛ yɛrɛyɛrɛ, i n’a fɔ mobili ni aerospace yɔrɔw.

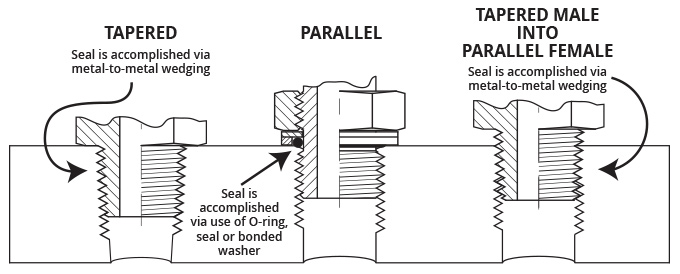

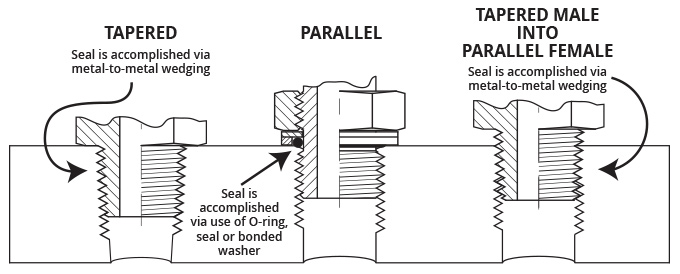

British Standard Pipe Threads (BSP) : BSP jiriw bɛ kɛ ka caya pipe fitininw kama. BSPP (parallel) jiriw bɛ kɛnɛma sigilan de wajibiya, ka sɔrɔ BSPT (tapered) jiriw bɛ u yɛrɛ datugu ni wuluwulu ye.

Ameriki ka pipe thread standards .

Ameriki jamana ka sariya min bɛ pipew ka jiriw kan, o bɛ NPT ni NPTF suguyaw fila bɛɛ lajɛlen na, minnu dabɔra sigili kama.

NPT ni NPTF danfara : NPT (National Pipe Tapered) Filɛliw bɛ sigilan dɔ dilan ka tɛmɛn jirisunw kan ani tuma caman na, u bɛ sigilan wɛrɛw wajibiya. NPTF (National Pipe Tapered Fuel) Filaw dilannen don walasa u ka sigi ni fɛn wɛrɛw tɛ u la, u kɛtɔ ka nɛgɛ ni nɛgɛ ɲɔgɔn sɔrɔ.

Thread sariya suguya caman bonya ani u danfara .

Filɛli sariyaw tɛ kelen ye tuma bɛɛ, bawo u bɛ ɲɔgɔn ta u fɔcogo la, u bɛ ɲɔgɔn sɔrɔ cogo min na, ani u bɛ bɛn ɲɔgɔn ma. ISO metriki jiriw bɛ tugu diɲɛ bɛɛ ka sigida la ni mɛtɛrɛ unitw ye, ka sɔrɔ jirisunw ni tubabu jirisunw bɛ baara kɛ ni Imperial sumanikɛlanw ye. Pipe Thread sariyaw i n’a fɔ NPT ani BSP fana bɛ danfara don u ka sigicogo la sigili ni u labɛncogo la, o bɛ bɛnkan gɛlɛya ka taa a fɛ.

Dugukolo kan ani mara sariya wɛrɛw .

Jamana damadɔw b’u yɛrɛ ka dilan sariyaw mara jamana ka iziniw kan. Olu dɔw ye:

JIS (Japon Industrial Standards) : Japon ka JIS jiriw bɛ tugu o cogo kelen na ISO jateminɛcogo sariyaw la nka a bɛ se ka danfara dɔɔnin don a fɔcogo ni a kɛcogo la.

DIN (Alemaɲi ka sariyasunba) : Alimanjamana ka DIN sariyaw bɛ bɛn kosɛbɛ ISO sariyaw ma, ka jiriw ɲɛfɔcogo di iziniw bɛɛ kɔnɔ k’a ta mobili la ka taa a bila fɛn dilanni na.

GOST (Russie State Standard) : Risi GOST ka sariyasun kɔnɔ, jirisunw ni inch-based threads fila bɛɛ bɛ yen, minnu bɛ baara kɛ kosɛbɛ jamana ka ɛntɛrinɛti ni fɛn dilanni siratigɛ la.

Tabali kuncɛlen Key Thread Standards

| Standard | Region | Angle | Sumanikɛlanw Baarakɛcogo | misali . |

| ISO métrique (M) . | Fanbɛ | 60° . | Metriki . | General Fasteners, Masina . |

| Unifié (UNC/UNF) . | Ameriki, Kanada | 60° . | inci . | Fasteners, machines précisions . |

| Whitworth (BSW/BSF) . | Angletɛri . | 55° . | inci . | Masina kɔrɔw, Mobili . |

| British Pipe (BSP) . | Angletɛri, diɲɛ kɔnɔ . | 55° . | inci . | Pipe fitininw, plomberie . |

| NPT/NPTF . | AN | 60° . | inci . | Pipe Fittings, Sɔgɔsɔgɔninjɛw . |

| JIS . | Japon . | 60° . | Metriki . | Masina, Mobili . |

| Din . | Alimanjamana . | 60° . | Metriki . | Mobili, izini masinw . |

| GOST . | Irisi jamana na . | 60°/55° . | Metriki/insi . | Jamana ka izini suguya caman, jamana ka iziniw . |

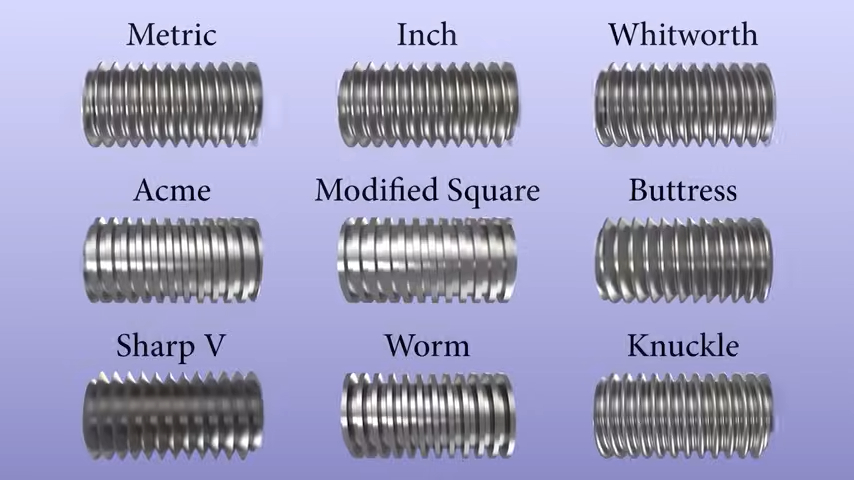

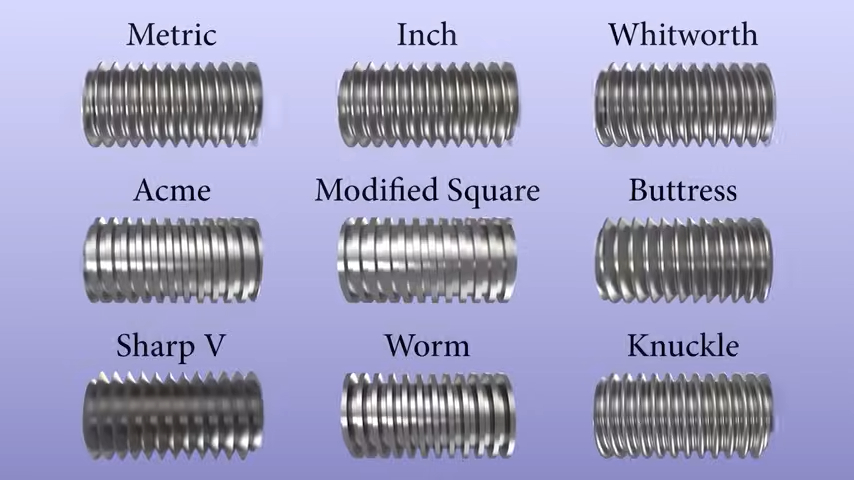

Filɛli suguyaw .

Filɛriw bɛ sɔrɔ cogoya caman na, u kelen-kelen bɛɛ dabɔra ɛntɛrinɛti baara kɛrɛnkɛrɛnnenw kama. Filɛli suguya wɛrɛw faamuyali nafa ka bon walasa ka se ka min bɛnnen sugandi i ka poroze kama. An ka jiri suguya caman sɛgɛsɛgɛ ka da u ɲɛsincogo, u cogoya ani u kɛcogo kan.

Nɛgɛbere ni numanbolow .

Filɛriw bɛ se ka tila ka kɛɲɛ ni u bɛ taa sira min fɛ.

Nɛgɛbere (RH) Filaw : Ninnu ye jiri suguya ye min ka ca. U bɛ gɛlɛya ni u bɛ wuli ka u wuli waatibolo fɛ. A bɛ se ka fɔ ko fɛn bɛɛ lajɛlen sirilanw, i n’a fɔ juruw ni bololanɛgɛw, olu bɛ RH jiriw kɛ ka baara nɔgɔya.

Nɛgɛbere (LH) Filaw : Nin dilan ninnu bɛ siri ni u jiginna ɲɔgɔn kɔ. LH jiriw bɛ kɛ cogoyaw la minnu na waati cogoya bɛ se ka kɛ sababu ye ka yɔrɔ dɔ lajɔ, i n’a fɔ masinw ka lajɛ dɔw la i n’a fɔ bisikili pedaliw walima mobili yɔrɔ kɛrɛnkɛrɛnnenw.

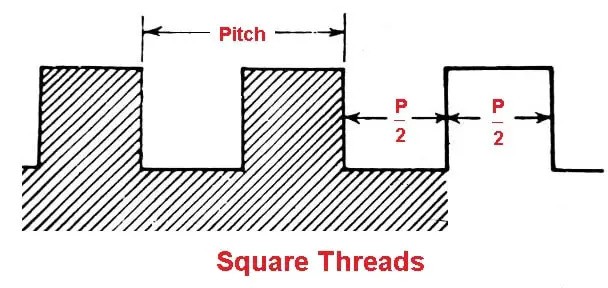

Profiles de tray .

Filɛriw ka ɲɛfɔliw bɛ jiriw cogoya ɲɛfɔ ani ka nɔ bila u fanga la, u ka baarakɛcogo ɲuman na, ani u ka baarakɛcogo la.

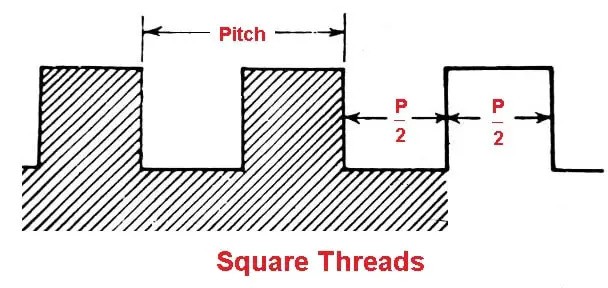

Square threads : Square threads bɛ baara kɛ ka ɲɛ fanga jiginni na, ni friction fitinin ye. A ka ca a la, u bɛ kɛ ni jakiw ye, ni nɛgɛberew ye, ani masin girinman wɛrɛw.

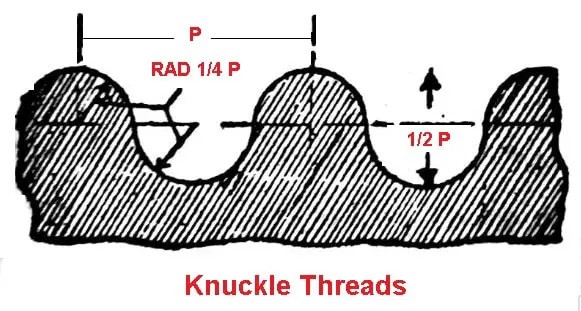

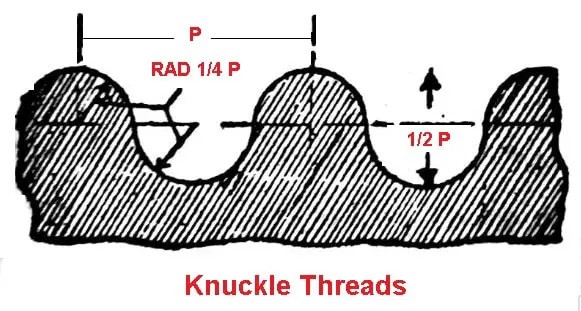

Knuckle threads : A bɛ dɔn u ka kretiɛnw ni u juw fɛ, Knuckle jiriw dilannen don walasa u ka se ka baara gɛlɛn muɲu ani u ka ɲi kosɛbɛ ko dɔw la, nɔgɔ walima tiɲɛni bɛ kɛ yɔrɔ minnu na, i n’a fɔ nɛgɛso sirili walima buteli dakunw.

Threads tapered ani parallèles .

Filɛriw fana bɛ Se ka Jate u cɛmancɛ bɛ Yɛlɛma cogo min na u janya la.

Taper threads : Nin jiri ninnu cɛmancɛ bɛ dɔgɔya dɔɔni dɔɔni ka taa a laban fan fɛ, ka wedge dɔ da min bɛ kɛ sigilan ye. Filɛriw bɛ kɛ pibilikiw la minnu bɛ kɛ ka u yɛrɛ datugu ni u bɛ u yɛrɛ datugu ni degun dɔgɔmanw ye. Misaliw ye NPT (National Pipe Thread) ani BSPT (British Standard Pipe Tapered) ye.

Parallel Threads : Parallel threads Aw bɛ a cɛmancɛ basigilen mara a fan bɛɛ la. U bɛ da tugucogo wɛrɛw de wajibiya, i n’a fɔ O-rings walima thread tape, walasa ka jɛgɛnsira sɔrɔ minnu tɛ ji bɔ. A suguya caman ye BSPP (British Standard Pipe Parallel) ani NPTF (National Pipe Tapered Fuel) ye.

Tire suguya kɛrɛnkɛrɛnnenw .

Sariya caman bɛ jiri kɛrɛnkɛrɛnnenw di walasa ka baara kɛ ni u ye izini suguya caman na, ni misali kɛrɛnkɛrɛnnenw ye:

Unified National Threads (UNC, UNF, UNS) : A ka ca a la, a bɛ kɛ Ameriki ani Kanada, jiri kelenw bɛ suman insitiriw la. UNC jiriw (coarse) bɛ kɛ ka fɛn bɛɛ siri, ka sɔrɔ UNF jiriw (fine) ka fisa ni fanga caman ye. UNS jiriw ye jirisunw ye minnu tɛ sariya ye, minnu bɛ labɛn mago kɛrɛnkɛrɛnnenw kama.

British Standard Threads (BSW, BSF, BSP) : British Standard Whitworth (BSW) jiriw bɛ kɛ fɔlɔ masin kɔrɔw la. British Standard Fine (BSF) Filɛliw bɛ jɛɲɔgɔnya barikamaw di, minnu ka ɲi, wa u bɛ kɛ sigidaw la minnu bɛ yɛrɛyɛrɛ. British Standard Pipe (BSP) Filɛliw nafa ka bon pipe fitininw na pɔmpiw ni gaziw la, minnu bɛ tali kɛ paralɛli (BSPP) ani Tapered (BSPT) fila bɛɛ la.

Summaire table de tray types

| tray type | profile | applications . |

| Fila kininfɛ (RH) . | Waatibolodacogo . | Fasteners général-purpose . |

| Threads gauche (LH) . | counterclockwise . | Yɔrɔw ka teli ka lajɔ u ka wuli-wuli jukɔrɔ . |

| V-cogo fila . | Triangulaire . | A sirili, masinw bɛɛ lajɛlen . |

| Jiriw kare . | Kɛrɛnaani | fanga jiginni, jakiw, masin girinmanw . |

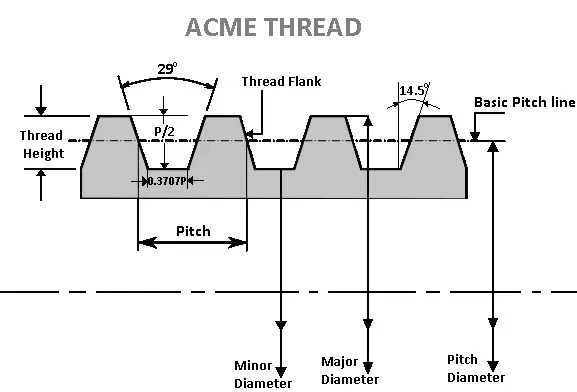

| ACME ka jiriw . | Trapezoidal . | doni girinmanw, masin baarakɛminɛnw . |

| Fila de trapezoidal . | Trapezoidal . | Seko ni dɔnko, Erɔpu masinw . |

| Knuckle jiriw . | Rounded . | Nɛgɛso ka ɲɔgɔndanw, buteliw . |

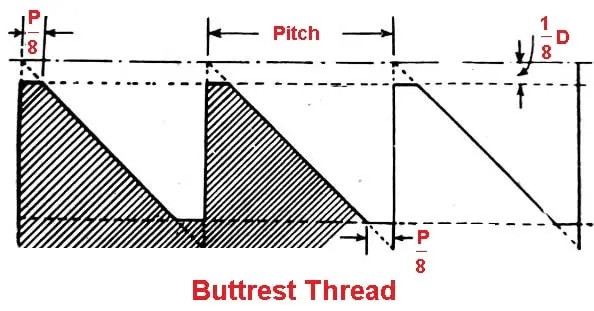

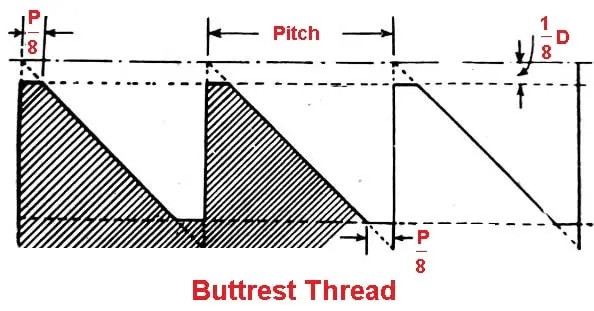

| Buttress Fils . | asimetriki . | CLAMPING MINƐNW, POWER presses . |

| Filɛriw . | Helical . | Worm girinw, kininfɛ-bolo-ci-yɔrɔ-yɔrɔ-ko . |

| Taper Filaw . | wedge-sealing . | Pipe fitininw (NPT, BSPT) . |

| Filɛriw paralɛli . | Diamètre constant . | Pipe fitininw minnu bɛ kɛnɛma datugu . |

| Jamana ka jiriw kelen-kelen . | Inch-based . | Fasteners, machines précisions . |

| British Standard Threads . | Inch-based . | Pipe fitininw, masin kɔrɔw . |

Thread dilanni fɛɛrɛw .

Filɛriw dilanni bɛ tali kɛ fɛɛrɛ suguya caman na, u kelen-kelen bɛɛ bɛ nafa kɛrɛnkɛrɛnnenw di baara kɛrɛnkɛrɛnnenw ni fɛnw ma. Nin ye jirisun fɔlɔ dilanni fɛɛrɛw lajɛlen ye:

Fila tigɛcogo (tasaw ni sa) .

Thread tigɛ bɛ to fɛɛrɛ ye min bɛ kɛ ka caya kɔnɔna ni kɛnɛma fila bɛɛ dilanni na:

Nafaw:

A bɛnnen don ka kɛ fɛn misɛnninw dilanni ye .

A bɛ tali kɛ fɛn caman na .

Baarakɛminɛn fɔlɔw musaka ka dɔgɔ kosɛbɛ .

Dantigɛliw:

Fila rolling .

Thread rolling forms threads through plastic deformation of the workpiece:

Nafaw:

Sɛnɛfɛnw dilanni hakɛ caman .

Thread fanga ɲɛnabɔlen ka da baara gɛlɛyali kan .

Surface Finish ani Dimensional ka tiɲɛni ɲumanba .

dɛsɛw: .

Thread grinding .

Thread grinding bɛ baara kɛ ni abrasive wheels ye walasa ka jiriw dilan minnu ka ɲi kosɛbɛ:

Fɛn minnu ye fɛnba ye:

A ka tiɲɛni ni a ka surface fini .

A bɛnnen don ka kɛ jiri ye funteni furakɛli kɔfɛ .

A bɛ se ka dilan ni jiri suguya gɛlɛnw ye .

Jateminɛw:

Filɛli min bɛ kɛ ni jiri ye .

Thread milling bɛ baara kɛ ni tigɛminɛnw ye minnu bɛ wuli ka wuli walasa ka jiriw labɛn:

Nafaw:

A bɛ se ka kɛ ka jiriw dilan minnu bɛ kɛ ni cɛmancɛ ye .

Baarakɛminɛnw tansiyɔn fitinin, a ka ɲi kosɛbɛ yɔrɔw la minnu kogow ka fin .

A bɛ Se ka kininfɛ-bolo-minɛnw bɛɛ Dabɔ ni baarakɛminɛn kelen ye .

Dantigɛliw:

A bɛ minɛn kɛrɛnkɛrɛnnenw ni porogaramuw de wajibiya .

A ka c’a la, a bɛ kɛ dɔɔnin dɔɔnin ka tɛmɛ a wulicogo kan walasa ka a sɔrɔ a bɛ se ka kɛ fɛn caman ye .

3D sɛbɛnni ni farankan dilanni .

Fɛɛrɛ kura minnu bɛ ka bɔ kɛnɛ kan, olu bɛ se ka kɛ cogo kura la jirisunw dilanni na:

Fɛn minnu bɛ kɛ ni jiri ye, olu sɛbɛnni tilennen .

post-processing ka . 3D sɛbɛnni yɔrɔw ka fara jiriw kan .

Nafa minnu bɛ se ka sɔrɔ olu la:

Gɛlɛyaw:

Fɛn minnu bɛ kɛ ka fɛnw sugandi .

Fanga dɔgɔyali ni laadala fɛɛrɛw ye .

Surface Finish bɛ se ka kɛ a ka baara ye .

Fɛn minnu bɛ tali kɛ jirisunw ka baarakɛcogo la .

Thread baarakɛcogo bɛ nɔ bila fɛn suguya caman na minnu b’a fanga, a muɲuni, ani a dannaya jira ɛntɛrinɛti baarakɛcogo la. K’a ta fɛnw sugandili la ka se sigida jateminɛw ma, nin ko ninnu faamuyali nafa ka bon kosɛbɛ walasa ka jiri baarakɛcogo ɲuman sabati. Fɛn kolomaw bɛ duguma minnu bɛ nɔ bila jirisunw ka baarakɛcogo la.

Material Selection .

Thread baarakɛcogo ka bon kosɛbɛ ka bɔ fɛnw cogoyaw la:

Fanga: A bɛ doni-ta-seko latigɛ .

Ductility: A bɛ nɔ bila jiri dilanni na ani a kɛlɛli la ka ɲɛsin stripping ma .

Corrosion resistance: A nafa ka bon kosɛbɛ sigida gɛlɛnw na .

A sanfɛla furakɛli ni a dacogo .

Surface furakɛli bɛ jiriw ka ɲɛnamaya janya ani u baaracogo ɲɛ ni u bɛ sɛgɛn, ka u sɔgɔ, ani ka u kɛ gala ye. Furakɛli minnu bɛ kɛ tuma caman na, olu ye:

Zɛnki plating : A bɛ jiriw tanga sɔgɔli ma ani ka u si hakɛ bonya.

Black Oxide Coating : A bɛ sɔgɔli nɔgɔya ani ka ɲɛnajɛko sabati.

Fositɛri : A bɛ tulumafɛnw marali ɲɛ, o b’a to a nafa ka bon baarakɛcogo la min bɛ kɛ ni fɛn caman ye.

Anodizing : A bɛ kɛ ka caya aluminiyɔmu jiriw la, a bɛ dɔ fara sɔgɔli kan ani ka fanga don.

O furakɛli ninnu bɛ jiriw dɛmɛ u ka se ka baara kɛ ni dannaya ye sigida gɛlɛnw na walima baarakɛcogo ɲumanw na.

Lubrication ani friction .

Lubrifiyen ɲuman bɛ dɔ bɔ ɲɔgɔn na ɲɔgɔnkanu waati la ani ka galon walima ka minɛ, kɛrɛnkɛrɛnnenya la doni caman tacogo la. Lubrication:

A bɛ dɔ bɔ sɛgɛn na : a bɛ dɛmɛ ka tiɲɛniw dɔgɔya minnu bɛ sɔrɔ a gɛlɛyali siɲɛ caman ani a lajɔli fɛ.

A bɛ torque control ɲɛ : A bɛ hali doni tila-tila jiriw cɛ, ka a bali ka tɛmɛ a dan kan.

Filɛlikɛlanw bɛ se ka tuluw, tuluw, walima tulumafɛnw kɛlɛ ka kɛɲɛ ni a kɛcogo kɛrɛnkɛrɛnnen ye.

Sigidako koɲɛw .

Tuma caman na, jirisunw bɛ bila sigida cogoya caman na, minnu bɛ nɔ bila u ka baara kɛcogo la waati kɔnɔ. Fɛn minnu ye nin ye, olu ye:

Funteni : Funteni caman bɛ se ka kɛ sababu ye ka fɛnw falen ani ka nɔ bila jiri la. Funteni dɔgɔyali bɛ se ka fɛn dɔw tiɲɛ.

Nɔgɔ : Jiri minnu bɛ kɛ ji la, kemikɛlifɛnw na, walima kɔgɔ la, olu bɛ se ka u jɔcogo dɔgɔya waati kɔnɔ.

Yɛrɛyɛrɛli : Yɛrɛyɛrɛli tɛmɛnen bɛ Se ka ɲɔgɔndanw Lajɔ, o bɛ Nà ni dɛsɛ ye. Datugulanw i n’a fɔ jirisunw walima da tugulenw, olu bɛ se ka dɛmɛ don ka o nɔgɔya.

O sigida gɛlɛyaw ɲɛnabɔli nafa ka bon walasa ka ɲɔgɔndanw dafalen sabati.

Lajɛ ni a siricogo fɛɛrɛw .

Fɛɛrɛ min bɛ kɛ ka jiriw lajɛ ani ka u siri, o bɛ nɔba bila u ka baara kɛcogo la. Fɛɛrɛ jɔnjɔnw ye:

Torque Control : Ni aw ye torque ɲuman kɛ a la, o bɛ a to jiriw kana tɛmɛ u dan kan, u tɛ u ka dafalenya mara.

Preload tension : Preload bɛnnen bɛ dɔ bɔ farati la ka lajɔ doni barikamaw kɔrɔ ani ka doni tilali sabati jiri profile kɔnɔ.

Fastening Tools : Baarakɛminɛnw i n’a fɔ torque wrenches bɛ fɛnw gɛlɛyacogo ɲuman di, o bɛ dɔ bɔ jiriw dɛsɛli hakɛ la.

Baara kɛli ni ɲɔgɔnkanu fɛɛrɛ ɲumanw ye, o bɛ ɲɔgɔndanw muɲuni ni u fanga bonya.

Load suguyaw n' u nɔfɛkow jiri fanga kan .

Filɛriw bɛ kɛ doni suguya wɛrɛw la, wa suguya kelen-kelen bɛɛ bɛ nɔ bila jiri in baarakɛcogo la cogo wɛrɛ la:

Static loads : Ni u bɛ kɛ ka ɲɛ waati kɔnɔ, a ka c’a la, u tɛ kɛ sababu ye ka jirituru kɛ fo ni doni tɛmɛna fɛn ka sɔrɔ fanga kan.

dynamique loads : A bɛ ɲɔgɔn ta waati kɔnɔ ani a bɛ se ka kɛ sababu ye ka jiriw lajɔ walima ka sɛgɛn ni u ma dilan ka ɲɛ.

Sɛgɛn doni : doni segin-seginni ni jigincogo cycles bɛ jiriw barika dɔgɔya waati kɔnɔ, o bɛ na ni dɛsɛ ye. Fɛn minnu ka sɛgɛn ka bon, olu de ka fisa o baara suguw la.

Faamuyali doni cogoyaw b’a to jiri suguya bɛnnen ani fɛn sugandilenw ka sugandi ka kɛ baarakɛminɛn ye.

Sealing baarakɛcogo wajibiyalenw .

Baara caman na, jiriw ka kan ka kɛ walasa ka sigilan di, kɛrɛnkɛrɛnnenya la ji walima gazi siratigɛ la. Filɛlikɛlanw i n’a fɔ NPT ani BSPT bɛ yɛrɛlabɛncogo ɲuman di u ma ni u bɛ se ka u siri ni u sirilen don. Ni jiri minnu tɛ siri u yɛrɛ la (misali la, jiri minnu bɛ ɲɔgɔn ta i n’a fɔ BSPP), olu bɛ kɛ ka ɲɛsigilan wɛrɛw kɛ i n’a fɔ O-rings walima jiri tapi ka kan ka kɛ walasa ka bɔgɔjiw bali.

| Thread suguya | sigili seko | baarakɛcogo . |

| NPT Filaw . | Yɛrɛ-da-yɔrɔ-ko . | Pipe fitininw, jibɔlanw . |

| BSPT Filaw . | Yɛrɛ-da-yɔrɔ-ko . | Gazi ni ji baarakɛcogo . |

| BSPP Fila . | A bɛ dasiri wɛrɛw de wajibiya (O-ring walima kase) . | Plomberie, systèmes de métassement . |

Sealing wajibiyalenw ɲɛnabɔli nafa ka bon kosɛbɛ walasa ka fɛnw sɔrɔ minnu tɛ se ka ji sɔrɔ ɛntɛrinɛti baarakɛminɛnw na.

Filɛriw baarakɛcogo injiniyɛri la .

Filɛriw jɔyɔrɔ ka bon kosɛbɛ ɛntɛrinɛti baara suguya caman na, minnu bɛ baara nafamaw di izini caman kɔnɔ. U ka fɛn caman kɛli n’u ka baarakɛcogo ɲuman b’a to u yɔrɔw nafa ka bon kosɛbɛ bi ɛntɛrinɛti la.

Fasteners .

Filɛlikɛlan minnu bɛ siri ni jiri ye, olu bɛ kɛ masinw ka lajɛw kɔkanna ye:

Boliw: Jɛɲɔgɔnya barikamaw bɛ sɔrɔ u jɔcogo la.

Vis: A bɛ se ka kɛ fɛn caman ye walasa ka fɛn caman kɛ .

Numuw: Aw bɛ fanga min bɛ se ka siri, min bɛ se ka ladilan, o di .

O yɔrɔw bɛ se ka kɛ sababu ye ka sigida injiniyɛriw lajɛ, k’u bɔ ɲɔgɔn na nɔgɔya la, ani k’u ladon.

Seko ni dɔnko .

Filaw bɛ tɛmɛ lamaga lamagacogo jiginni kan ka kɛ lamaga-lamagali ye:

U ka baarakɛcogo ɲuman n’u ka tiɲɛni bɛ kɛ sababu ye ka jiriw kɛ fɛn ɲumanw ye fanga jiginni baarakɛminɛnw na.

ji ni gazi sigili .

Jɛɲɔgɔnya minnu bɛ kɛ ni jiri ye, olu nafa ka bon kosɛbɛ ji minɛcogo la:

Pipe Fittings: Joli minnu tɛ se ka bɔ, minnu tɛ se ka bɔ, olu bɛ sɔrɔ pɔmpiw ni iziniw kɔnɔ .

Valves: Flow control tigitigi bɛ sɔrɔ hydraulique ni pneumatique systèmes kɔnɔ .

Filɛriw ka teli ka kɛ sababu ye ka u yɛrɛ datugu, ka sistɛmu dafalen bonya.

JIGISƐMƐ NI ƝƐNAJƐW .

Filaw bɛ se ka ladilanni ɲumanw kɛ minɛnw na minnu bɛ se ka kɛ ka ɲɛ:

U ka se ka 'yɔrɔ-yɔrɔ-ko misɛnninw Kɛ 'yɔrɔ la min bɛ 'yɔrɔ la min bɛ 'yɔrɔ-yɔrɔ-ko-yɛrɛ-yɛrɛ-yɛrɛ-ko Kɛ, o tɛ Se ka Kɛ ni 'sèn ye.

Industrie applications spécifiques

| industry | application | type type . |

| Aerospace . | Fasteners fanga ka bon . | UNF, métrique fine . |

| Mobili . | Motɛri yɔrɔw . | Metriki, UNF . |

| Furakɛcogo minɛnw . | Implant fixation . | Custom, Fine Pitch . |

| tulu & gazi . | Degun-tight connections . | NPT, API |

Ko minnu kɛra .

Jɛɲɔgɔnya minnu bɛ kɛ ni bolo ye kosɛbɛ, olu bɛ sɔrɔ Bridge Construction kɔnɔ .

Gɛlɛya: Ka fara fɛnw kan minnu bɛ kɛ ka fɛnw jɔ .

Furakɛcogo: A cɛmancɛ ka bon, a fanga ka bon ni UNC jiriw ye .

O kɔlɔlɔ: Jɛɲɔgɔnya minnu bɛ mɛn, minnu bɛ se ka sɛgɛn, minnu bɛ se ka doni gɛlɛnw muɲu .

Precision plɔmu ka fɛnɲɛnamafagalan CNC masinw kɔnɔ .

Gɛlɛya: Tigɛminɛnw sigicogo tigitigi .

Fɛn min bɛ se ka kɛ: dugukolo, daminɛ caman trapezoidal jiriw ni anti-backlash nuts .

O kɔlɔlɔ: Submicron jɔyɔrɔ tiɲɛni ani lamagacogo ɲuman .

Yɛrɛlabɔli pibiliki ɲɔgɔndanw na minnu bɛ kɛ ni tansiyɔnba ye .

Gɛlɛya: Joli minnu tɛ bɔ ji la, olu bɛ sɔrɔ jibolisiraw la .

Fɛn min bɛ se ka kɛ: NPTF tapered threads ni contrôlé interference fit .

O jaabi: Segu minnu bɛ se ka da u kan, nɛgɛ bɛ minnu na, olu tɛ se ka kɛ ni sigilanw ye minnu bɛ se ka kɛ u la .

Thread dɛsɛ cogoyaw ani a kunbɛncogo .

Faamuyali Thread dɛsɛ cogoyaw nafa ka bon kosɛbɛ walasa ka jirisunw ɲɔgɔndanw dilan minnu bɛ se ka da u kan ani minnu bɛ lakana. Nin yɔrɔ in bɛ dɛsɛcogo caman sɛgɛsɛgɛ, u sababuw, ani u kunbɛncogo fɛɛrɛw.

Dɛsɛcogo minnu bɛ sɔrɔ tuma caman na .

Fɛn minnu bɛ kɛ ni jiri ye, olu bɛ se ka dɛsɛ cogoya caman na:

Stripping : Thread deformation jukɔrɔ doni tɛmɛnen .

Shearing : Filaw farali dafalen ka da fanga jugu kan .

Galling : Surface Tiɲɛni ka bɔ nɔrɔli sɛgɛnw ni ɲɔgɔn cɛ .

Seizing : Filaw bɛ ɲɔgɔn datugu, ka u bali ka wuli .

Sɛgɛn : kari ka bonya dɔɔnindɔɔnin doni cyclique jukɔrɔ .

Stress Corrosion Cracking : Degun degun ni sigida laminiw faralen ɲɔgɔn kan .

Thread dɛsɛ sababuw

| sababu bɛ | ɲɛfɔli sɔrɔ | min bɛ sɔrɔ . |

| Ka don | Materiel bɔnɛ dɔɔnin dɔɔnin ka bɔ friction na . | A ka ca a la, joginda minnu bɛ lajɛ ɲɔgɔn fɛ . |

| Corrosion . | Tigɛ tiɲɛni kemikaliw la . | Sigida minnu bɛ kɛnɛ kan walima minnu ka ɲi . |

| Sɛgɛn | Stress cycles segin-segin minnu bɛ na ni crack formation ye . | A yɔrɔw bɛ wuli walima u bɛ se ka kɛ sikɔlɔma ye . |

| Overload . | Thread ka doni-ta-seko seko ni dɔnko . | sirilanw sirilen don cogo bɛnbali la . |

| Lajɛ min man ɲi . | Cross-threading walima ka tɛmɛ a dan kan . | Bololabaara kɛcogo . |

Banakunbɛn fɛɛrɛw .

Walasa ka jirisunw dɛsɛw nɔgɔya:

Fɛnw sugandili ɲuman ka da sigida cogoyaw kan ani doni wajibiyalenw kan .

Aw bɛ furakɛli walima finimuguw kɛ minnu bɛ bɛn .

Baara kɛli ni jiriw ye minnu bɛ siri ni jiri ye walasa ka yɛrɛyɛrɛli kunbɛn .

Lubrication kɛcogo ɲumanw waleyali .

torque values kofɔlenw labatoli lajɛ waati .

Filɛri sugandili ni a dilanni ɲuman .

Optimiser thread performance through:

Ka jirituru sɛbɛncogo bɛnnen sugandi aplikasiɔn kama .

Jateminɛ kɛ doni tilali la ani degunw hakɛ fɛnw .

sigida koɲɛw jateminɛni (funteni, nɔgɔ seko) .

A ka fisa ka optimale thread engagement janya .

Sugandili bɛ kɛ ka ɲɛsin muɲuli kalanw ma minnu bɛnnen don furuɲɔgɔnw ma .

Jogoɲumanya kɔlɔsili ani sɛgɛsɛgɛli .

Aw ye jogoɲumanya fɛɛrɛ barikamaw waleya:

Dimension Inspection (Dimension Inspection) Ni jateminɛfɛnw ni sumanikɛlanw ye minnu bɛ se ka kɛ .

Kɔrɔbɔli fɛɛrɛw minnu tɛ tiɲɛni kɛ (misali la, ultrasonic, magnétique particulaire) ka ɲɛsin fɛn nafamaw ma .

Sɛgɛsɛgɛli ni ladonni bolodalenw bɛ kɛ waati ni waati walasa ka fɛnw lajɛ minnu bɛ kɛ ni jiri ye .

Sɛbɛnw dilanni taabolo sɛbɛnw ni u nɔfɛtaama .

Kalan bolodalenw ka ɲɛsin jamalajɛ kɛbagaw ma walasa u ka se ka sigi sen kan cogo bɛnnen na .

Endnots .

Filɛriw nafa ka bon ɛntɛrinɛti la, u bɛ kɛ ka fɛnw siri, ka u lamaga, ani ka fanga ci. U bɛ ɲɔgɔndan barikamaw sabati, minnu bɛ se ka da u kan masinw ka sigidaw la.

Filɛriw sugandili, u dilanni, ani u jogoɲini ka ɲɛ walasa ka dɛsɛw bali ani ka baara kɛcogo ɲɛ baara suguya caman na.

Ni aw ye jiri sariyaw, fɛnw, ani fɛn dilanni fɛɛrɛw sɛgɛsɛgɛ, o bɛ se ka jiriw baarakɛcogo faamuyali bonya kosɛbɛ.

Walasa ka kunnafoni wɛrɛw sɔrɔ, aw bɛ izini sariyaw ni nafolo lajɛ walasa ka baara kɛcogo ɲuman sɔrɔ aw ka ɛntɛrinɛti porozɛw kɔnɔ.