Wetin mek di pat dɛn we dɛn kɔl injɛkshɔn kin gɛt layn rawnd dɛn? Dis 'parting line' na impɔtant tin fɔ mek. We yu ɔndastand am, dat kin mek yu dizayn dɛn bɛtɛ.

Insai dis post, yu go lan wetin na parting line en wai e bi essential. Wi go tɔk bɔt in impak pan di kwaliti fɔ di prɔdak ɛn di wok we i de du.

Wetin na wan pat we de pat pan injɛkshɔn moldin?

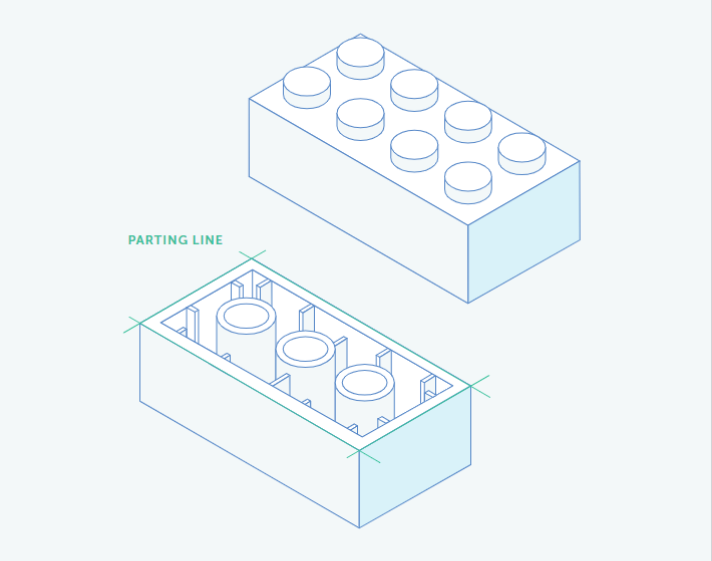

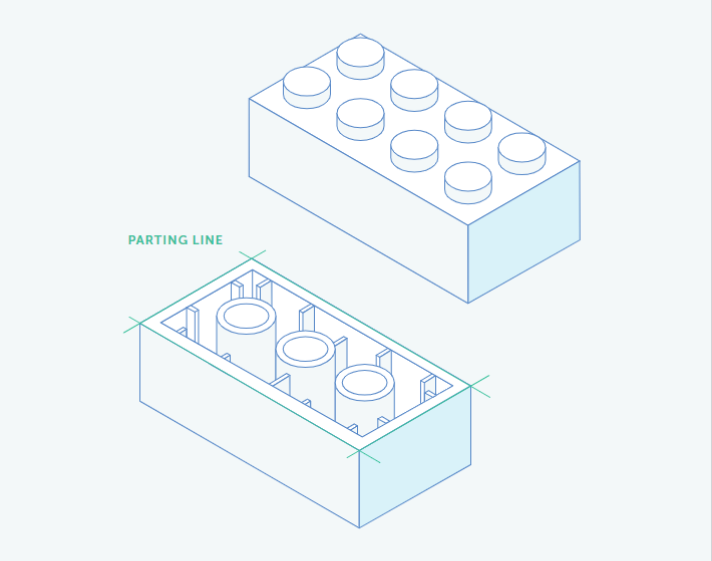

Wan layn we de kɔmɔt na di say we dɛn de, na di say we tu pat dɛn we gɛt mol kin mit. I de apin as tin layn na di say we dɛn injɛkshɔn-mɔld pat dɛn de. Dis layn nɔ go ebul fɔ avɔyd bɔt dɛn kin stɔp am ɔ ayd am. Bɔku tɛm, di wan dɛn we de mek dizayn kin put am na say dɛn we dɛn nɔ kin notis bɛtɛ.

Aw dɛn kin mek layn dɛn we de sheb .

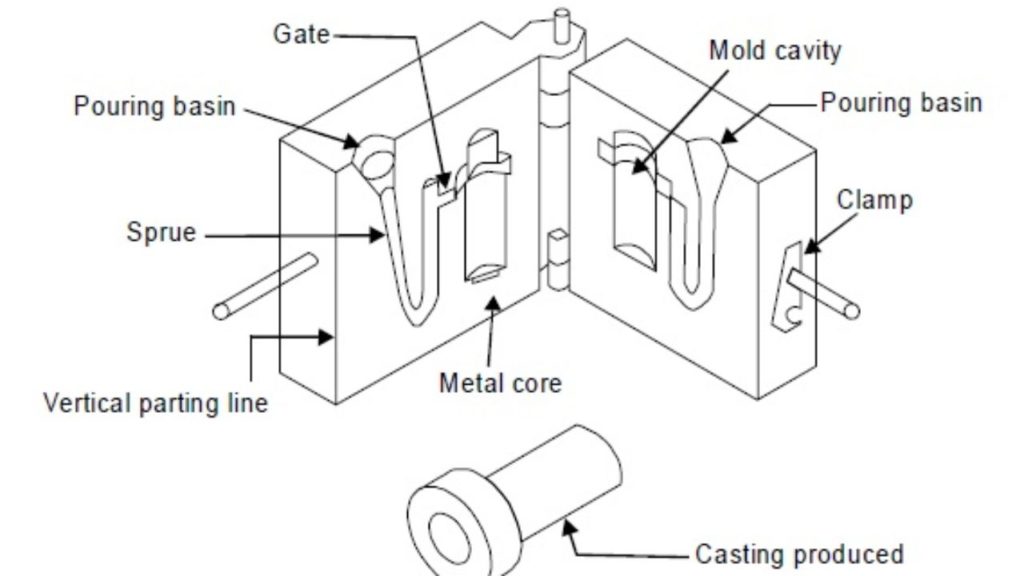

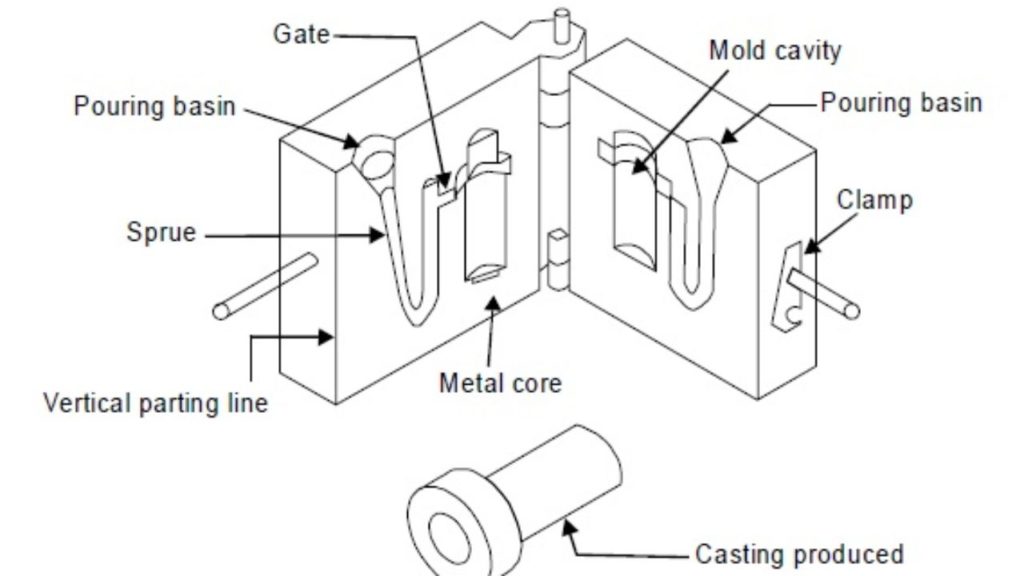

Fɔ ɔndastand aw layn dɛn de fɔm, wi nid fɔ tek tɛm luk di . Injekshɔn moldin prɔses sɛf. Ɔl dis bigin wit di mol, we gɛt tu af dɛn: di kɔr ɛn di kaviti.

Di tu pat dɛn na di mol de klamp togɛda .

Molten plastic de injekt insay di mold cavity ɔnda ay prɛshɔn .

Di plastic kol ɛn solidify, tek di shep fɔ di mold .

Di mold opin, ɛn di pat we dɔn dɔn, dɛn kin pul am kɔmɔt .

Na durin dis proses na im di parting lain de fom. We di tu pat dɛn na di mol kam togɛda, dɛn kin mit along wan patikyula layn ɔ plen. Dɛn kin kɔl dis as di layn we de sheb.

Di rilayshɔn bitwin di layn dɛn we de kɔmɔt ɛn di mold af dɛn .

Di say we di pating layn de, na di we aw dɛn mek di mold af dɛn. Dɛn tek tɛm mek di kɔr ɛn kaviti fɔ mek di shep we dɛn want fɔ di pat we dɔn dɔn.

Usay dɛn tu pat ya kin mit, dɛn kin mek di say we dɛn de sheb di tin dɛn. Na essentially wan seam we de ron along di entire perimeter of di part.

| Mold Haf | Fɔnkshɔn . |

| Men | Fɔm dɛn Intanɛt ficha dɛn . |

| Kaviti . | Fɔm dɛn we de na do fɔ mek dɛn gɛt ɛksternal ficha dɛn . |

Di say we di parting layn de kin gɛt impɔtant impak pan di we aw di pat we dɔn dɔn ɛn di we aw i de wok. Na dat mek i impɔtant fɔ mek dizayna ɛn injinia dɛn tek tɛm tink bɔt fɔ tek pat pan layn ples we dɛn de du di dizayn prɔses.

Tayps of parting lines in injekshɔn moldin .

Naw we wi dɔn kɔba di bɛsis fɔ pat layn, lɛ wi fɛn di difrɛn kayn dɛn we yu go mit pan injɛkshɔn moldin. Ɛni kayn gɛt in yon spɛshal kwaliti ɛn aplikeshɔn dɛn.

Vɛtikal Pating Layn dɛn .

Vɛtikal pati layn dɛn na di kayn we we dɛn kin yuz mɔ. Dɛn de rɔn pɔrpindikul to di say we di mol go opin ɛn lɔk. Bɔku tɛm yu go fɛn dɛn pan pat dɛn we gɛt stret jɔyometri, lɛk kɔp ɔ kɔntena.

Advantej ɛn disavantej

| Advantej | Disadvantej dɛn |

| Simpul ɛn kɔst-ɛfɛktiv . | kin bi pɔsin we de si am klia wan . |

| I fayn fɔ bɔku pat dizayn dɛn . | kin nid fɔ gɛt ɔda tin dɛn fɔ dɔn . |

Beveled parting lines .

Beveled parting lines feature angled or sloped edges pas strait wan dɛn. Dɛn kin yuz dɛn fɔ ridyus di visibiliti fɔ di pating layn ɛn minimiz flash fɔmɛshɔn.

We yu de yuz beveled parting lines .

Tink bɔt aw fɔ yuz layn dɛn we gɛt bɛvɛl we:

Aesthetics na wan tɔp prayoritɛd .

Yu nid fɔ minimiz flash .

Di pat gɛt intrikɛt ditil dɛn nia di pating layn .

Di layn dɛn we dɛn kɔba wit kɔba .

As di nem sho, di kɔba we dɛn kɔba fɔ pat layn dɛn de fala di kɔnto dɛn fɔ wan pat in kɔba sɔfays dɛn. Dɛn kin kɔmpleks pas di layn dɛn we de kɔmɔt stret ɛn dɛn nid spɛshal mold dizayn.

Aplikeshɔn fɔ kɔba pat dɛn we dɛn kɔba .

Curved parting lines na fayn tin fɔ:

Pat dɛn we gɛt kɔmpleks kɔv ɔ kɔnto .

Dizayn dɛn we nid fɔ mek dɛn luk lɛk se dɛn nɔ gɛt wan prɔblɛm .

Prodakt dɛn we gɛt ergonomic features .

Steps parting lines .

Step parting lines ficha multiple levels or 'steps' along di parting line. Dɛn kin yuz dɛn fɔ akɔmod pat dɛn we gɛt difrɛn difrɛn tik dɛn na di wɔl ɔ fɔ balans di klamp fɔs na di mol.

Rizin dɛn fɔ yuz step parting lines .

Yu kin pik step parting lines wen:

Di pat gɛt impɔtant chenj dɛn na di wɔl tiknes .

Yu nid fɔ sheb klamp fɔs ivin .

Di dizayn nid fɔ gɛt bɔku bɔku layn dɛn we de sheb .

Kɔmprɛhɛnsif parting layn dɛn .

Kɔmprɛhɛnsif pat layn dɛn na wan kɔmbaynshɔn fɔ vertikal, bɛvɛl, kɔba, ɛn step parting layn dɛn. Dɛn na di kayn we kɔmpleks pas ɔl ɛn dɛn kin yuz dɛn fɔ pat dɛn we gɛt bɔku bɔku jɔyometri dɛn.

Kɔmpleks pat dɛn we nid fɔ gɛt kɔmprɛhɛnsif pat pan layn dɛn .

Ɛgzampul dɛn fɔ di pat dɛn we kin nid fɔ gɛt kɔmprɛhnsiv pat layn dɛn we gɛt bɔku bɔku pat dɛn na:

Ɔtomotiv Kɔmpɔnɛnt dɛn wit bɔku bɔku ficha dɛn .

Medikal divays dɛn we gɛt prɛsis tolɛreshɔn dɛn .

Konsuma prodakt wit komplex shep en ditel .

Disain fɔ pat pan layn dɛn .

We i kam pan injɛkshɔn moldin, fɔ pat layn plesmɛnt na jɔs di biginin. Fɔ mek shɔ se yu gɛt ay kwaliti pat dɛn, yu nid fɔ tink bɔt wan arenjmɛnt fɔ dizayn tin dɛn we go ambɔg di we aw yu prɔdak dɔn tan ɛn aw yu de wok.

Faktɔ dɛn fɔ mek mold .

Di dizayn fɔ yu mol de ple impɔtant pat fɔ no usay di layn dɛn we de fɔ pat ɛn di we aw i de luk. Na sɔm impɔtant tin dɛn we wi fɔ tink bɔt:

Kaviti ɛn kɔr alaynɛshɔn: Di we aw di tu af-af dɛn na di mol kam togɛda kin afɛkt di visibiliti fɔ di pating layn. Prɔpa alaynɛshɔn impɔtant fɔ minimiz flash ɛn mek shɔ se dɛn dɔn klin, we nɔ gɛt wan bɔt.

Surface Finish: Di tɛkstɔr ɛn finish fɔ yu mold surface kin ɛp fɔ kamoflaj parting lines. Bɔku tɛm, di tin dɛn we dɛn dɔn mek ɔ di tin dɛn we dɛn dɔn mek, nɔ kin bɔku fɔ mek dɛn nɔ tɔk bɔt di layn dɛn we de pat pas di say dɛn we smɔl ɛn we gɛt glos.

Mold Flow: Di flɔ fɔ molten plastic insay di mold kin impɔk bak fɔ pat layn apinans. Stratejik get plesmɛnt ɛn flɔ simulshɔn kin ɛp fɔ ɔptimayz matirial distribyushɔn ɛn minimiz visible flɔ layn dɛn.

| Factor | Impact pan Parting Lines |

| Kaviti ɛn kɔr alaynɛshɔn . | Afɛkt Visibiliti ɛn Flash Fɔmeshɔn . |

| Surface Finish . | I kin ɛp fɔ mek di layn dɛn we dɛn kin yuz fɔ mek tin dɛn we dɛn kin yuz fɔ mek tin dɛn we dɛn kin yuz fɔ mek tin dɛn we dɛn kin yuz fɔ mek tin dɛn we dɛn kin yuz fɔ mek tin dɛn we dɛn kin yuz . |

| Mold Flɔ . | Influɛns matirial distribyushɔn ɛn flɔ layn dɛn . |

Kul ɛn shearing ret .

Di we aw yu pat kol ɛn solidify insay di mold kin gɛt impɔtant impak pan in kwaliti ɛn fɔ lɔng tɛm. Na dis yu nid fɔ no:

Di kol we yu de kol: Di kol we yu de kol kin mek yu gɛt wɔping, shrinkage, ɛn ɔda dɛfekt dɛm we kin kɔmprɔmis di integriti fɔ yu pat. Prɔpa kɔling sistɛm dizayn impɔtant fɔ mek dɛn kɔntinyu fɔ gɛt kɔnsistɛns tɛmpracha ɔlsay na di mol.

Shearing rate: As molten plastic de flɔ tru di mold, i de ɛkspiriɛns shia fɔs dɛn we kin afɛkt in prɔpati dɛn. di ay shia ret kin mek di dεgradashכn εn wik, patikyular along di parting layn dεm. Optimizing flow rates ɛn get locations kin ɛp fɔ minimiz dɛn ifɛkt ya.

Fɔ mek yu ebul fɔ kol ɛn ridyus strɛs pan yu pat dɛn, tink bɔt dɛn tɛknik ya:

Inkorporet konformal kul chanel dem we de fala di konto dem fo yu pat .

Yuz ay-kɔnduktiviti matirial dɛn lɛk Berylum kɔpa fɔ insɛt ɛn kɔr dɛn .

Minimize variations in wall thickness fɔ mek ivin kol .

Adjɔst injɛkshɔn spid ɛn prɛshɔn fɔ kɔntrol shia ret .

Ejekshɔn prɔses .

We yu pat dɔn kol ɛn strɔng, i nid fɔ kɔmɔt na di mol. Dis na di say we ejekta pin dɛn kin kam insay. Bɔt if dɛn nɔ mek am fayn, dɛn kin lɛf mak ɔ mek i pwɛl along di say we dɛn de sheb.

Fɔ mek di impak we di ejekta pin dɛn gɛt pan di layn dɛn we de na yu pat pan di layn nɔ bɔku, tink bɔt dɛn strateji dɛn ya:

Pin plesmɛnt: Pozishɔn ɛjɛkta pin dɛn away frɔm krichɔl sɔfays ɔ ficha dɛn ɛnitɛm we i pɔsibul. Dis kin ɛp fɔ mek yu nɔ si mak dɛn we pɔsin kin si ɛn mek yu kɔntinyu fɔ gɛt di rayt we yu de yuz fɔ mek yu nɔ gɛt wanwɔd.

PIN Dizayn: Yuz ejekta pin wit smɔl dayamita ɛn wan smol, polish sɔfa fɔ ridyus di risk fɔ damej ɔ flash fɔmɛshɔn. Specialized pin dizain lek Blade Ejectors or Valve Gate pins kin yus tu fo spesifik aplikeshon.

Mold rilis: Put wan fayn mold rilis ejen to di say dɛn we yu mol de fɔ mek i izi fɔ pul pat izi wan ɛn fɔ mek di pawa we dɛn nid fɔ pul kɔmɔt na di bɔdi nɔ bɔku. Dis kin ɛp fɔ ridyus strɛs na di say we dɛn de pat ɛn fɔ mek flash nɔ kam.

Chalenj dɛn wit di layn dɛn we de kɔmɔt .

Pan ɔl we fɔ pat layn na pat we nid fɔ de pan injɛkshɔn moldin, dɛn kin prɛzɛnt sɔm spɛshal prɔblɛm dɛn, mɔ we dɛn de dil wit kɔmpleks pat dɛn ɔ tray fɔ ajɔst wan flawlɛs finish. Lɛ wi tek tɛm luk sɔm pan dɛn prɔblɛm dɛn ya ɛn aw fɔ win dɛn.

Handling komplex shep dɛn .

Intrikɛt dizayn dɛn wit kɔv, ɔnda-kɔt, ɔ bɔku bɔku ficha dɛn kin mek parting layn plesmɛnt nɔ izi. Na sɔm strateji dɛn fɔ dil wit kɔmpleks shep dɛn:

Multi-step parting: Insted of wan single strait parting line, yuz wan multi-step aprɔch we de fala di kɔnto dɛm fɔ di pat. Dis kin ɛp fɔ mek di vijual impak we di pat pan di layn gɛt nɔ bɔku ɛn mek shɔ se di mold alaynɛshɔn fayn.

Sayd Akshɔn: Inkɔrej sayd akshɔn ɔ slaydin kɔr insay di mold dizayn fɔ mek ɔndakat ɔ ficha dɛn we nɔ go pɔsibul wit simpul tu-pat mol. Dɛn ɔda mold kɔmpɔnɛnt dɛn ya kin ɛp fɔ mek klin, prɛsis parting layn dɛn na kɔmpleks eria dɛn.

3D Printed Inserts: Fɔ patikyula chalenj jɔyometri, tink bɔt fɔ yuz 3D print insɛt ɔ cavities we kin izi fɔ swap ɔ riples. Dis kin gi big dizayn fleksibiliti ɛn alaw fɔ mɔ prɛsis pat layn kɔntrol.

| Strategy | Advantage |

| malti-step parting . | Fɔ fala kɔnto, minimiz vijual impak |

| Sayd Akshɔn dɛn . | Krio Undercuts ɛn Kɔmpleks Ficha dɛn . |

| 3D insɛt dɛn we dɛn print . | Gi dizayn fleksibiliti ɛn prɛsishɔn . |

I nɔ mata di strateji we yu pik, prɛsis mold alaynɛshɔn na impɔtant tin. Ivin di smɔl misalaynmɛnt kin mek pɔsin nɔ ebul fɔ waka fɔ pat layn dɛn, flash, ɔ ɔda tin dɛn we nɔ fayn.

Fɔ mek shɔ se dɛn alaynɛs fayn, tink bɔt dɛn tin ya:

Yuz gayd pin ɛn bush fɔ mek dɛn kɔntinyu fɔ gɛt prɛsis alaynɛshɔn bitwin mold af dɛn .

Inkorporet intalɔk ɔ alaynɛshɔn ficha dɛn insay di mold dizayn .

Inspek ɛn mentɛn di mold kɔmpɔnɛnt dɛn ɔltɛm fɔ mek dɛn nɔ wear ɛn misalignment .

Fɔ mek flash nɔ apin .

Flash, ɔ ɛksɛs matirial we de fɔm along di parting layn, na kɔmɔn chalenj fɔ injɛkshɔn moldin. I nɔ jɔs de ambɔg di we aw di pat de apia, bɔt i kin ambɔg di fit ɛn di wok we i de du. So, wetin de mek flash, ɛn aw yu go mek i nɔ apin?

Di tin dɛn we kin mek flash fɔmɛshɔn inklud:

Poor mold alaynɛshɔn ɔ wear .

Insufisient klamp fɔs .

Injɛkshɔn prɛshɔn ɔ spid we pasmak .

Inadequate venting ɔ kol .

Fɔ ridyus ɛn pul flash, tray dɛn we ya:

Mold Maintenance: Ɔltɛm inspɛkt ɛn mentenɛt yu mold fɔ mek shɔ se dɛn alaynɛs fayn ɛn mek dɛn nɔ west. Riples di komponent dɛn we dɔn pwɛl as nid de ɛn kip di say dɛn we dɛn dɔn pwɛl klin ɛn nɔ gɛt dɔti.

Proses Optimization: Adjust injekshɔn prɛshɔn, spid, ɛn ɔda prɔses paramita fɔ minimiz flash fɔmɛshɔn. Yuz simulshɔn softwe fɔ no di say dɛn we yu go ebul fɔ gɛt prɔblɛm ɛn fɔ mek yu wok fayn fayn wan akɔdin to dat.

Flash Trap: Inkorporet flash trap ɔ ɔvaflɔ wɛl insay yu mold dizayn fɔ kech ɛksɛs matirial ɛn mek i nɔ spre along di parting layn. Dɛn ficha dɛn ya kin ɛp fɔ kɔntinyu fɔ flash ɛn mek am izi fɔ pul we dɛn de du post-prɔsɛsin.

Sɛkɔndari Ɔpreshɔn: If Flash apin, bɔku tɛm dɛn kin pul am tru sɛkɔndari ɔpreshɔn dɛn lɛk fɔ trim, sand, ɔ tumbling. Krayojen deflash, we de yuz ekstrim kol fɔ embrittle di flash, kin bi bak ifɛktiv fɔ sɔm matirial dɛn.

Teknik fɔ ridyus di visibiliti fɔ pat layn dɛn .

Pan ɔl we fɔ pat layn na pat we nɔ go ebul fɔ avɔyd fɔ injɛkshɔn moldin, dɛn nɔ nid fɔ bi ays-ɔ we pɔsin kin si. Bɔku tɛknik dɛn de we yu kin yuz fɔ mek dɛn nɔ luk fayn ɛn mek dɛn dɔn mek wan prɔdak we nɔ gɛt wan prɔblɛm.

Surface texture kamouflalajn .

Wan ifektiv we fɔ ayd pat layn na bay we yu yuz sɔfays tɛkstɔr we de ɛp fɔ brok di vijual kɔntinyuiti fɔ di layn. Na so i de wok:

Tekstɔr sɛlɛkshɔn: Pik wan tɛkstɔr we de kɔmplit di dizayn ɛn di wok we yu pat de du. di opshכn dεm de kכmכt frכm di sכft mat finish dεm to mכr agrεsiv patεn dεm lεk stipples כ grooves.

Mold Texturing: Dɛn kin put di tɛkstɔr we dɛn pik dairekt to di mold safa, ɔ tru etch, engraving, ɔ ɔda we dɛn. We di plastic we dɔn rɔtin ful-ɔp di mol, i kin tek di tɛkstɔr we di mol de.

Parting Line Placement: Stratejik plesmɛnt fɔ di pating layn insay di tɛkstɔr eria kin ɛp fɔ mek i nɔ luk mɔ. Di tɛkstɔr de ɛp fɔ brok di layn ɛn mek i nɔ notis.

Ɛgzampul dɛn fɔ di fayn fayn tɛkstɔr aplikeshɔn dɛn na:

Leda grain tekstur pan otomotiv intɛriɔ pat dɛn .

Brushed Metal Finish pan Ilɛktronik Hausin dɛn .

Woodgrain tekstur pan furniture komponents .

| Tɛkstɔr | Aplikeshɔn |

| LƐDA GRƐN . | Otomotiv Intɛriɔ dɛn . |

| Metal we dɛn dɔn brɔsh . | Ilɛktronik Hausin dɛn . |

| Wudgrain we dɛn mek wit wud . | Furniture komponent dɛn . |

Sɛkɔndari prɔsesin tɛknik dɛn .

Ivin if dɛn tek tɛm disayn ɛn mold fɔ teks, sɔm layn dɛn we nɔ de tek pat kin stil de we pɔsin kin si ɔ nid fɔ gɛt ɔda tin dɛn fɔ dɔn. Na de sɛkɔndari prɔsesin tɛknik dɛn de kam in. Na sɔm opshɔn dɛn ya:

Vibratory Tumbling: Dɛn kin put pat dɛn na tumbler wit abrasive midia ɛn dɛn kin vibrate fɔ wan sɛt tɛm. Di abrasive akshɔn de ɛp fɔ mek di layn dɛn we de kɔmɔt ɛn ɔda tin dɛn we nɔ pafɛkt na di wɔl smol smol.

Krayojen deflash: pat dεm de εkspכz to ekstrimli kol tεmprachכ, tipikכs yuz likwid naytrכjen. Dis kin mek ɛni flash ɔ ɛksɛs matirial along di parting layn bi brital ɛn izi fɔ pul.

Han trim: Fɔ smɔl smɔl rɔn ɔ dilik pat, manual trim wit shap bled ɔ siza kin wok fayn fɔ pul pating layn flash. Dis mεtכd de alaw fכ big prεsishכn εn kכntrכl.

Midia Blasting: Dɛn kin bɔm di pat dɛn wit wan strim we gɛt abraziv midia, lɛk san, glas bid, ɔ plastic pellet. Dis de ɛp fɔ mek di layn dɛn we de pat pan di say dɛn we dɛn de wok smol smol ɛn gi yu mɔ yunifom sɔfays finish.

Di we aw dɛn kin pik sɛkɔndari prɔsesin tɛknik kin dipen pan sɔm tin dɛn, lɛk:

Material tayp ɛn durabiliti .

Pat jɔyometri ɛn kɔmplisiti .

Di tin dɛn we dɛn nid fɔ dɔn di say we dɛn dɔn .

Prodakshɔn volyum ɛn kɔst kɔnstrakshɔn .

Dɔn

Insay dis atikul, wi dɔn ɛksplɔrɔ di impɔtant wok we pat layn dɛn de du fɔ mek dɛn gɛt injɛkshɔn moldin. Frɔm ɔndastand wetin dɛn bi ɛn aw dɛn fɔm fɔ fɛn di difrɛn kayn ɛn dizayn kɔnsidareshɔn dɛn.

Bay we yu tink bɔt fɔ pat layn dɛn ali na di dizayn prɔses ɛn wok klos wit yu injɛkshɔn moldin patna, yu kin mek ay kwaliti pat dɛn we mit yu pefɔmɛns ɛn ɛstitik rikwaymɛnt dɛn.

Nid ɛp wit injɛkshɔn moldin ɛn parting layn dizayn? Team MFG in ekspiriens injinia dɛn dɔn rɛdi fɔ ɛp. Wi de gi komprehensiv savis, frɔm dizayn ɔptimayzeshɔn to mold manufakchurin ɛn prodakshɔn. Kontakt wi tide fɔ wan fri kɔnsultɛshɔn ɛn kot. Mek Team MFG bring yu vision to laif!