Short Shot in Injection Molding: Kɔz, Aydentifikeshɔn, ɛn Sɔlwɛshɔn

Di we aw yu de si di pikchɔ dɛn: 0

Aks fɔ aks kwɛstyɔn dɛn .

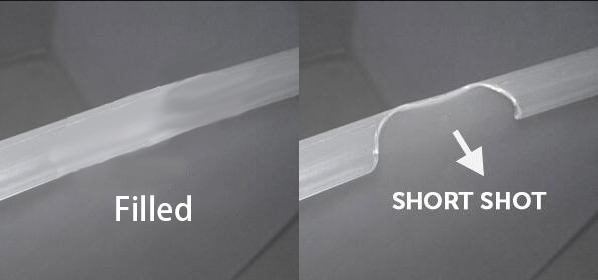

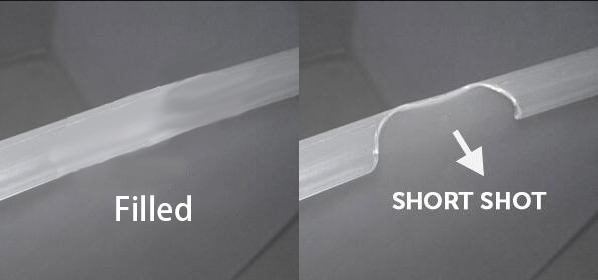

Yu dɔn ɛva mit wit plastic pat dɛn we nɔ kɔmplit ɔ we nɔ kɔmplit frɔm yu . Injɛkshɔn moldin prɔses? Dis isyu, we dɛn kɔl 'short shot,' kin rili impɔk di prɔdak kwaliti ɛn prodakshɔn efyushɔn. Insay injɛkshɔn moldin, shɔt shot kin apin we di plastic we dɔn rɔtin nɔ ebul fɔ ful di wan ol mold kaviti, we kin mek di tin dɛn we nɔ kɔmplit ɔ we nɔ de na di las pat.

Fɔ adrɛs shɔt shot kwɛstyɔn dɛn na impɔtant tin fɔ mek yu kɔntinyu fɔ gɛt ay kwaliti autput ɛn fɔ mek yu nɔ west bɔku na yu injɛkshɔn moldin ɔpreshɔn dɛn. Insai dis post, wi go daiv insay di kɔz dɛm fɔ shɔt shot, aw fɔ no dɛn, ɛn fɛnɔt ifɛktiv sɔlvishɔn fɔ protɛkt ɛn trabulshut dis kɔmɔn prɔblɛm.

Wetin na shɔt shot na injɛkshɔn moldin?

Short shot na wan kɔmɔn dɛfɛkt na injɛkshɔn moldin. I kin apin we di plastic we dɔn rɔtin nɔ ful-ɔp di mold kaviti kɔmplit wan. Dis kin mek di las tin we dɛn mek wit tin dɛn we nɔ de ɔ we nɔ kɔmplit.

Short shot kin apin insay difrɛn we dɛn pan pat dɛn we dɛn dɔn mol:

Inkɔmplit filin fɔ tin sɛkshɔn ɔ ɛj dɛn .

Di tin dɛn we nɔ de ɔ di ditil dɛn .

visible voids ɔ gap dɛn na di sɔfa .

Inkɔnsistɛns wɔl tik ɔ pat dimɛnshɔn dɛn .

Di impak we shɔt shot kin gɛt kin bi impɔtant:

Ridyus di kwaliti fɔ di prɔdak ɛn di wok we dɛn de du .

Inkris skrap ret ɛn matirial west .

Lɔwa prodakshɔn efyushɔn ɛn truput .

Pɔtɛnɛshɛl dilɛys in ɔda fulfilment .

Di ay ɔvala manufakchurin kɔst dɛn .

Di tin dɛn we kin mek pɔsin gɛt shɔt shot na injɛkshɔn moldin .

Bɔku tin dɛn kin ɛp fɔ mek dɛn shot shɔt pan injɛkshɔn moldin. Lɛ wi fɛn di kɔmɔn tin dɛn we kin mek tin apin we gɛt fɔ du wit matirial, mold dizayn, ɛn mashin sɛtin.

Di tin dɛn we gɛt fɔ du wit di tin dɛn we gɛt fɔ du wit matirial .

Ay viskɔsiti matirial ɔ di wan dɛn we nɔ gɛt fayn flɔ prɔpati nɔ kin ful di mold kaviti kɔmplit wan. Dis kin mek dɛn shot dɛn fɔ shɔt tɛm.

Di tin dɛn we nɔ gri wit di tin dɛn we dɛn gɛt, lɛk di difrɛns dɛn we de na di mɔstɔ kɔntinyu ɔ di kɔntaminɛshɔn, kin mek bak flɔ prɔblɛm ɛn i kin mek dɛn shot shɔt.

Di tin dɛn we kin mek pɔsin gɛt mɔl we gɛt fɔ du wit mold .

If yu nɔ gɛt fayn vent ɔ ɛya trap dɛn na di mol, dat kin mek yu nɔ fil fayn fayn wan. If di briz nɔ ebul fɔ rɔnawe, i de stɔp di flɔ we di plastic we dɔn rɔtin de flɔ.

Di get saiz, di say we di get nɔ fayn, di say we dɛn de, ɔ di we aw dɛn mek am kin mek di tin nɔ flɔ. Get dɛn we tu smɔl ɔ we dɛn nɔ put fayn kin mek dɛn shot shɔt.

Tin wɔl ɔ kɔmpleks jɔyometri dɛn na di prɔdak dizayn kin mek i nɔ izi fɔ di matirial fɔ ful ɔl di eria dɛn na di mol.

Mashin sɛtin ɛn prɔses-rilayt

Lɔw injɛkshɔn prɛshɔn ɔ spid nɔ kin gi inof fɔs fɔ ful di mold kaviti kɔmplit wan. Dis kin mek dɛn shot shɔt.

If yu nɔ mɛlt ɔ mold di tɛmpracha, dat kin mek di tin strɔng tumɔs kwik kwik wan, ɛn dis kin mek yu nɔ fil kɔmplit wan.

If dɛn nɔ shot di sayz ɔ di kusɛn sɛtin dɛn, dat kin mek dɛn nɔ injɛkt di tin dɛn we nɔ go du fɔ di mold.

Inkɔnsistɛns saykl tɛm ɔ intarapshɔn na prodakshɔn kin ambɔg di flɔ fɔ matirial ɛn mek shɔt shot.

| Kɔz Kɔz Kategori |

Ɛgzampul dɛn . |

| Tin dɛn |

- Ay viskɔsiti

- po flɔ prɔpati dɛn

- prɔpati dɛn we nɔ kɔrɛkt |

| Dizain fɔ mold . |

- Inadequate venting

- Improper get dizain

- tint wol ɔ kɔmpleks jɔyometri |

| Mashin Sɛtin dɛn . |

- Lɔw injɛkshɔn prɛshɔn/spid

- Insufishɛnt tɛmpracha

- Improper shot saiz/kushion |

We yu no di patikyula tin dɛn we kin mek yu gɛt shɔt shot na yu injɛkshɔn moldin prɔses, yu kin tek stɛp dɛn we yu want fɔ adrɛs fɔ adrɛs dɛn ɛn mek yu prodakshɔn kwaliti bɛtɛ.

Aw fɔ no di shɔt shɔt shot dɛn na di injɛkshɔn mold pat dɛn .

Fɔ no di shɔt shot dɛn na impɔtant tin fɔ mek dɛn kɔntinyu fɔ kɔntrol di kwaliti we dɛn de yuz fɔ mek dɛn gɛt injɛkshɔn. Na sɔm we dɛn ya we yu kin yuz fɔ no di shɔt shɔt shot dɛn na yu pat dɛn we dɛn dɔn mol.

Di we dɛn we dɛn de yuz fɔ inspɛkt di tin dɛn we dɛn de si .

Di tin dɛn we nɔ kɔmplit ɔ di tin dɛn we nɔ de apin ɔ di tin dɛn we nɔ de na di say dɛn we dɛn kin sho na di tɛltal sayn dɛn we de sho se dɛn shot shɔt. Inspek yu pat dɛn wit yay fɔ si ɛni say we tan lɛk se dɛn nɔ dɔn ɔ dɛn nɔ gɛt ditil.

difεk dεm we de na di sɔfays ɔ di tin dεm we nɔ rayt, lɛk di sink mak ɔ di voids, kin sho bak se dɛn shot shɔt. Luk gud wan na di pat fɔ ɛni inkɔnsistens.

Dimenshɔnal analisis tɛknik dɛn .

Measuring part dimensions against spesifikeshn kin rivεl sכt shot. Yuz kalipa ɔ ɔda tin dɛn fɔ mɛzhɔ fɔ chɛk if di pat mit di dimɛnshɔn dɛn we yu nid.

Varieshɔn dɛn na di wɔl tik ɔ shrinkage kin sho bak shɔt shot dɛn. Kɔmpia di tik we difrɛn pat dɛn na di pat gɛt fɔ no ɛnitin we nɔ gri wit wetin dɛn tɔk.

Ɔda tin dɛn we dɛn kin yuz fɔ no bɔt di sik ɛn di we aw dɛn kin du am .

Prɔses monitarin softwe ɔ sɛns kin ɛp fɔ no shɔt shot dɛn insay rial-taym. Dɛn tul ya de monitar injɛkshɔn prɛshɔn, spid, ɛn ɔda paramita fɔ no di prɔblɛm dɛn we kin apin.

Mold flow analysis ɔ simulations kin prɛdikt di chans fɔ shɔt shot bifo prodakshɔn bigin. Dɛn vayrɔyal tɛst ya kin ɛp fɔ mek di mold dizayn ɛn di prɔses sɛtin dɛn fayn.

Fɔ tɔk smɔl, yu kin no di shɔt shɔt shot dɛn tru:

Visual Inspekshɔn .

Dimenshɔnal analisis .

Proses Monitoring .

Mold Flow Analysis .

Trowe yuz wan kɔmbaynshɔn fɔ dɛn we ya, yu kin no kwik kwik wan ɛn adrɛs shɔt shot kwɛstyɔn dɛn na yu injɛkshɔn moldin prɔses.

Sɔlwɛshɔn fɔ protɛkt ɛn fɔ sɔlv prɔblɛm dɛn we dɛn kin shot shɔt shɔt shɔt shɔt shɔt shɔt shɔt shɔt shɔt shɔt shɔt shɔt shɔt shɔt shɔt shɔt shɔt shɔt shɔt shɔt shɔt shɔt shɔt shɔt shɔt shɔt shɔt shɔt shɔt shɔt shɔt shɔt shɔt shɔt shɔt shɔt shɔt shɔt shɔt shɔt shɔt shɔt shɔt shɔt shɔt shɔt shɔt shɔt shɔt shɔt shɔt shɔt shɔt shɔt shɔt shɔt shɔt shɔt shɔt shɔt shɔt shɔt shɔt shɔt shɔt shɔt shɔt shɔt shɔt shɔt shɔt shɔt shɔt shɔt shɔt shɔt shɔt shɔt shɔt shɔt shɔt shɔt shɔt shɔt shɔt shɔt shɔt shɔt shɔt shɔt shɔt shɔt shɔt shɔt shɔt shɔt shɔt shɔt shɔt shɔt shɔt shɔt shɔt shɔt shɔt shɔt shɔt shɔt shɔt shɔt shɔt shɔt shɔt shɔt shɔt shɔt shɔt shɔt shɔt naw n.

Fɔ mek yu nɔ gɛt shɔt shot ɛn fɔ sɔlv prɔblɛm dɛn, yu nid fɔ gɛt bɔku bɔku tin dɛn fɔ du. Lɛ wi fɛn sɔlv dɛn we gɛt fɔ du wit di we aw dɛn de pik di tin dɛn we dɛn de yuz, di we aw dɛn mek di mol, di we aw dɛn mek di mashin, ɛn di we aw dɛn de mek di ples nɔ pwɛl.

Material selekshɔn ɛn ɔptimayzeshɔn .

Pik matirial dɛn we gɛt di rayt flɔ prɔpati ɛn viskɔsiti fɔ yu aplikeshɔn. Dis kin ɛp fɔ mek shɔ se di mold kaviti fulɔp fayn fayn wan.

Di tin dɛn we dɛn ad ɔ di fil dɛn kin mek di tin dɛn we dɛn de yuz fɔ mek di tin dɛn we dɛn de yuz, bɛtɛ ɛn dɛn kin ridyus di prɔblɛm we kin mek dɛn shot shɔt. Tink bɔt fɔ put dɛn insay yu matirial fɔmyulashɔn.

Di rayt we fɔ yuz di tin dɛn we dɛn de yuz, fɔ drɛy, ɛn fɔ kip tin dɛn rili impɔtant. Mɔstɔ ɔ kɔntaminɛshɔn kin afɛkt flɔ prɔpati ɛn mek dɛn shot shɔt.

Mold dizayn improvements .

Ad ɔ chenj di vent ɛn di ejekta pin fɔ mek i izi fɔ mek yu ebul fɔ pul di briz bɛtɛ. Dis kin mek di plastic we dɔn rɔtin ful-ɔp di say we dɛn dɔn mek am izi wan.

Optimize get saiz, lokeshɔn, ɛn tayp fɔ impɔtant flɔ. Big get ɔ bɔku get kin ɛp fɔ mek dɛn nɔ shot shɔt.

Adjɔst di wɔl tik ɛn pat jɔyometri fɔ mek i izi fɔ ful-ɔp. Yunifɔm wɔl tik ɛn smol transishɔn kin ridyus di flɔ rɛsistɛns.

Mashin Sɛtin ɛn Prɔses Adjɔstmɛnt dɛn .

Inkris injɛkshɔn prɛshɔn, spid, ɔ tɛm as nid de fɔ mek shɔ se dɛn ful-ɔp di filin ɔl. Ekspiriɛns wit difrɛn sɛtin dɛn fɔ fɛn di bɛst balans.

Optimize melt ɛn mold tempɔret fɔ di spɛshal matirial. Dis kin mek di flɔ go fayn ɛn mek i nɔ gɛt prɛmature solidification.

Adjɔst di saiz fɔ di shot, di kusɛn, ɛn ɔda mashin paramita dɛn fɔ mek yu ebul fɔ gi yu inof matirial fɔ ful di mol.

Impruv di prɔses monitarin ɛn kɔntrol sistem fɔ no ɛn kɔrɛkt shɔt shot dɛn insay rial-taym.

Preventiv Mentɛnans ɛn Trobul Sɔlv Tips

Klin ɛn chɛk di mold ɛn mashin kɔmpɔnɛnt dɛn ɔltɛm. Dis kin mek dɛn nɔ gɛt bɔku ɔ damej we kin mek dɛn shot shɔt.

Dokumɛnt ɛn analayz di prɔses data ɛn difɛkt tren dɛm. Dis infɔmeshɔn kin ɛp fɔ no di patɛn ɛn di rut kɔz dɛm fɔ shɔt shot.

Kɔndɔkt rut kɔz analisis ɛn impruv kɔrɛkt akshɔn dɛn. sistamatically address di andalayn ishu dem fo prevent fiuja shot shot.

| Sɔlwɛt Kategori |

Ki Akshɔn dɛn |

| Di we aw dɛn de pik di tin dɛn we dɛn dɔn yuz |

- Pik di rayt tin dɛn

- Yuz aditiv ɔ filɛs

- mek shɔ se dɛn de handle ɛn kip di rayt we |

| Dizain fɔ mold . |

- Impruv venting ɛn ejekshɔn

- Optimize get ɛn flɔ pat

- Adjɔst di wɔl tik ɛn jɔyometri |

| Mashin Sɛtin dɛn . |

- Adjɔst prɛshɔn, spid, ɛn tɛm

- ɔptimayz di tɛmpracha

- Impruv di prɔses monitarin ɛn kɔntrol |

| Prɛventiv Mentɛnans . |

- Rigyul klin ɛn inspekshɔn

- dɔkyumɛnt ɛn analayz data

- Kɔndɔkt rut kɔz analisis |

Di bɛst we fɔ avɔyd shɔt shot dɛn na injɛkshɔn moldin .

Fɔ mek di risk fɔ shɔt shot nɔ bɔku, i rili impɔtant fɔ fala di bɛst we fɔ du ɔl di injɛkshɔn moldin prɔses. Na sɔm impɔtant say dɛn fɔ pe atɛnshɔn pan.

Dizayn fɔ Manufakchurabiliti (DFM) prinsipul dɛn .

Inkorporet DFM gaydlain ali in di prodakt dizain stej. Dis kin ɛp fɔ mek shɔ se yu pat dɛn ɔptimayz fɔ injɛkshɔn moldin.

Tink bɔt tin dɛn lɛk di tik we de na di wɔl, di draft angul dɛn, ɛn di say dɛn we di get dɛn de fɔ mek dɛn go bifo bɛtɛ ɛn fɔ ridyus di chans fɔ mek dɛn shot shɔt.

Di rayt we fɔ pik di tin dɛn we dɛn nid ɛn tɛst .

Selekt matirial dɛn we fayn fɔ yu aplikeshɔn ɛn we gɛt di rayt flɔ prɔpati. Kɔndɔkt gud tɛst fɔ validet matirial pefɔmɛns.

Wok wit yu matirial spɔlayt fɔ mek shɔ se kɔnsistɛns kwaliti ɛn prɔpati dɛn de akɔdin to batch dɛn. Dis kin ɛp fɔ mek dɛn nɔ chenj di difrɛn difrɛn tin dɛn we kin mek dɛn shot dɛn shɔt tɛm.

Mold dizayn validɛshɔn ɛn ɔptimayzeshɔn .

Yuz mold flow analysis softwa fɔ simul di injɛkshɔn moldin prɔses. Dis kin ɛp fɔ no di pɔtɛnɛshɛl shɔt shot kwɛstyɔn dɛn bifo mold fabrikeshɔn.

Optimize di mold dizayn bays pan simulshɔn rizɔlt ɛn ɛkspɛkt input. Mek di ajɔstmɛnt dɛn we nid fɔ apin to di get dɛn, di vent dɛn, ɛn ɔda tin dɛn fɔ mek di flɔ go fayn ɛn fɔ ridyus di shɔt shɔt shot dɛn.

mashin ɛn prɔses paramita sɛtin dɛn bays pan sayɛns moldin prinsipul dɛn .

Put sayɛns moldin prinsipul dɛn fɔ no di bɛst mashin ɛn prɔses sɛtin dɛn. Dis involv fɔ mek dɛn du sistamɛnt ɛkspirimɛnt ɛn data analisis.

Dokumɛnt ɛn mentɛn wan strɔng prɔses winda we kin ɔltɛm prodyuz gud pat dɛn. Monito ɛn ajɔst di sɛtin dɛn as nid de fɔ mek dɛn nɔ shot shɔt.

Kwaliti kɔntrol ɛn kɔntinyu fɔ impɔtant tin dɛn we dɛn dɔn bigin fɔ du .

Impruv wan kɔmprɛhɛnsif kwaliti kɔntrol sistɛm fɔ no ɛn adrɛs shɔt shot dɛn kwik kwik wan. Dis kin inklud fɔ inspekshɔn fɔ si, fɔ chɛk di dimɛnshɔnal dimɛnshɔn, ɛn ɔda we dɛn fɔ tɛst.

Foster wan kɔlchɔ fɔ kɔntinyu fɔ impɔtant. Ɛnkɔrej di tim mɛmba dɛn fɔ no ɛn sɔlv prɔblɛm dɛn togɛda. Ɔltɛm rivyu di prɔses data ɛn difɛkt tren fɔ drɛb di ɛnhansmɛnt dɛn we de go bifo.

Trowe adhering to dis bes praktis, yu kin signifyantli ridyus di occurrence of short shots in yu injection molding operations. Mɛmba se, prɛvɛnshɔn na ki – invɛstismɛnt tɛm ɛn ɛfɔt apfrɔnt kin sev yu frɔm kɔst kwaliti ishu dɛm dɔŋ di layn.

Dɔn

Short shot in injection molding kin bi bikɔs ɔf difrɛn tin dɛn, frɔm matirial ishu to mashin sɛtin. Fɔ no ɛn adrɛs dɛn nid fɔ gɛt wan kɔmplit we fɔ du am. We yu impruv fayn fayn sɔlvishɔn ɛn di bɛst we fɔ du tin, yu kin mek di prɔdak kwaliti bɛtɛ, i go mek yu gɛt mɔ prɔdaktiviti, ɛn i go ɛp fɔ mek yu nɔ spɛn bɔku mɔni na yu injɛkshɔn moldin ɔpreshɔn dɛn.

Yu de strɛs wit shɔt shot dɛn na yu injɛkshɔn moldin prɔses? Tim MFG in ɛkspɛkt injinia dɛn kin ɛp. Kɔntakt wi tide fɔ lan aw wi kɔmprɛhɛnsif sɔlvishɔn dɛn kin impruv yu prɔdak kwaliti ɛn prodaktiviti. Mek Team MFG bi yu patna in injekshɔn moldin sakses.