Quid est abs (Acryonitrile Butadiene styrene) manserunt ad materiam in 3D printing industria in tres decennia? Eius eximia mechanica proprietatibus, æstus resistentia ad CV ° C, et versatile Post-processus capabilities facere quod invaluable choice pro fabri et manufacturers idem.

Utrum tibi a seasoned professionalem vel ambitiosus Hobbyist, intellectus in Nuaces of Absit printing potest dramatically expand 3D printing elit. In hoc blog, nos in magicis mundi 3D printing cum abs Fibernam, intelligentiam definitionem, applications, et commoda ut melius arbitrium.

Quid est Plastic?

Acryonitrile Butadiene styrene (Abs) revolutionized vestibulum industries ante emergentes ut lapidem angulare materia in 3D printing technology. Sua unique mulge structuram, combining tres distincta monomers, liberat eximia mechanica proprietatibus. Studiis indicant abs String Structural integritas temperaturis ad CV ° C, significantly outperforming alternative materiae.

Applications of Abs 3D printing

Industria Periti recognize Abs in numerosis quotidie items:

Automotive Components (XX% Market Share)

Consumer Electronics (XXXV% foro participes)

Domus appliances (XXV% foro participes)

Industrial Equipment (XV% Market Share)

Alia Applications (V% Market Share)

Industrial vestibulum demonstrat significant adoptionem de abs Typting technology. Vestibulum Facilities Leverage Abs pro:

Custom Tooling et Fixtures reducing productio costs per XL%

Eget Prototypes withstanding realis-Mundus testing conditionibus

Postea partes fabricari in-demand, cutsing inventory costs

Conventus linea Optimization Tools Improving Efficens a XXV%

Automotive Applications Showcase Abs scriptor Diuturitatem et æstus Resistentia:

| Component Type | Usage Benefits | perficientur metrics |

| Interiora | Calor firmum ad CV ° C | XCV% diuturnitatem Rating |

| Custom Brackets | Maximum impulsum resistentia | CC J / m impulsum vires |

| Prototype partes | Iteration | LXX% tempus reductionem |

| Service Tools | ECFECTUS | LX% cost peculi |

Consumer Electronics prodest beneficium a Abs scriptor versatility:

Cogitatus inclusis optimis impulsum resistentia

Calor, repugnans components ad electronic coetus

Consuetudo ascendens solutions

Prototype Casings pro Product Development

Medical et curis Applications Precision: Key Applications:

Anatomical exempla pro chirurgicam planning

Custom medicinae fabrica housings

Laboratory apparatu components

Disciplina et educational exempla

Architecturae consilio sectores utilitas abs for:

Scale exemplar components requiring diuturnitatem

Custom Architecturae Elementa

Pre se ferre ostentationem pieces

Eget prototypes pro aedificationem systems

Educational Projects Leverage Abs proprietatibus:

Research and Development Applications includit:

| Field | Application | Key commodum |

| Materia | Test specimens | Consistent proprietatibus |

| Engineering | Eget prototypes | Iteration |

| Product Design | Conceptum exemplum | ECFECTUS |

| Biomedical | Consuetudo | Design flexibilitate |

Specialized Industries Reperio unique usus:

Aerospace pars prototyping

Military Equipment Aliquam

Marine Hardware Development

Sports Equipment immutatio

3D printing cum abs Fibernas

Mechanica proprietatibus stare ut definitio proprium de abs typis partes. In materia exhibet eximia impulsum resistentia, perveniens ad CC J / m, excedens maxime commune 3D printing materiae. Eius tensile viribus iugis ex 40-50 MPa, enabling productio de duratione eget components capaces ad impedimenta significant mechanica accentus.

Outstanding æstus resistentia facit abs an specimen arbitrium ad postulans applications. Et materiam maintains structural integritas usque ad CV ° C, significantly outperforming Pla (LX ° C) et petg (LXXXV ° F). Huiusmodi calor tolerantia ensures typis partes manent firmum sub elevatur temperaturis, faciens ea idoneam automotive components et velit installations.

Versatile Post-dispensando options differentiate Abs ab aliis printing materiae. In materia libenter respondet:

Acetone vapor blandior, consequi iniectio-fingitur superficies qualis

Progressive Sanding Techniques, permittens denique superficiem imperium

Poena adhaesionem, enabling diverse consummatione options

Mechanica polising, unde in altum, glossa superficiebus

Effectivenity positions praeclarum sumptus- abs vel oeconomica viable arbitrium. Market Analysis reveals:

| pretium factor | valorem |

| Rudis materia | $ 20-25 / kg |

| Processing tempore | XV% velocius quam Pla |

| Perditio reductionem | X% minus auxilium materia |

| Post-processus sumptus | XXX% inferiore quam alternatives |

Wide Application Versatility Demonstrates abs de Adaptability trans Industries. In materia excellit in:

Automotive partibus requiring excelsum impulsum resistentia

Consumer Electronics Housings egens æstus stabilitatem

Industrial tooling et fixtures

Prototype Development Exsecutae diuturnitatem

Consuetudinem vestibulum solutions

Hoc compositum de proprietatibus locis abs AS ut a premier choice pro Advanced 3D printing applications, praesertim ubi vires, æstus resistentia, et sumptus-efficaciam sunt paramunt considerations.

Limitations et challenges de abs plastic

Temperatus sensitivity metrics:

Warping limine: III ° F / Minutum Rate Rate

Optimal Ambient Temperature: 50-60 ° C

Differentialium discrimine temperatus: <XV °

Environmental de includit:

Voc, emissiones pervenire CC μg / M⊃3; Dum printing

Humorem effusio rate: 0.3% per XXIV horas ad L% RH

Thermal expansion coefficient, XCV × X ^ -6 mm / mm / °

Essential Equipment Setup

3D printer iudicium

Prospera abs Trylocket Printing Personae specifica Hardware configurations:

Essential components:

Calefacit lectum (minimum C Cf Castry)

Inclusum camera (temperatus dissident <V ° F)

Omnes metallum Hotend (Rated> CCLX ° C)

Active Aeris Filtration System

Print superficiem praeparatio

Felix Abshaesio requirit meticulous superficiem praeparatio. Research indicat proprium lectulum praeparationem potest crescere primum-layer success rates per LXXXV%.

Superficiem Options Comparatio:

| Superficiem Type | Adhesionem Rating | Temperature Stabilitatem | Cost efficaciam |

| Vitrum + abs Slurry | XCV% | Praeclarus | Altum |

| Pei sheet | XC% | PERPLICENTER | Medium |

| Kapton tape | LXXXV% | Bonum | Humilis |

| Buildtak | LXXX% | Bonum | Medium |

Key praeparatio gradibus:

Superficies Purgato (Isopropyl Vocatus> XCIX%)

Temperatus stabilization (XV-minute pre-calefactio)

Adhaesionem Promoter Application

Level verificationis (± 0.05mm tolerantia)

Environmental controls

Temperature procuratio probat crucial pro absit printing victoria. Studies ostendere inclusum cellae potest reducere warping per LXXVIII%.

Essential environmental parametri:

Temperature cubiculum: 45-50 ° C

Temperatus CLIVUS: <II ° F / Hour

Umiditas range: 30-40%

Aeris circulation: 0.1-0.2 m / s

Printing parametri et occasus 3D printing cum abs

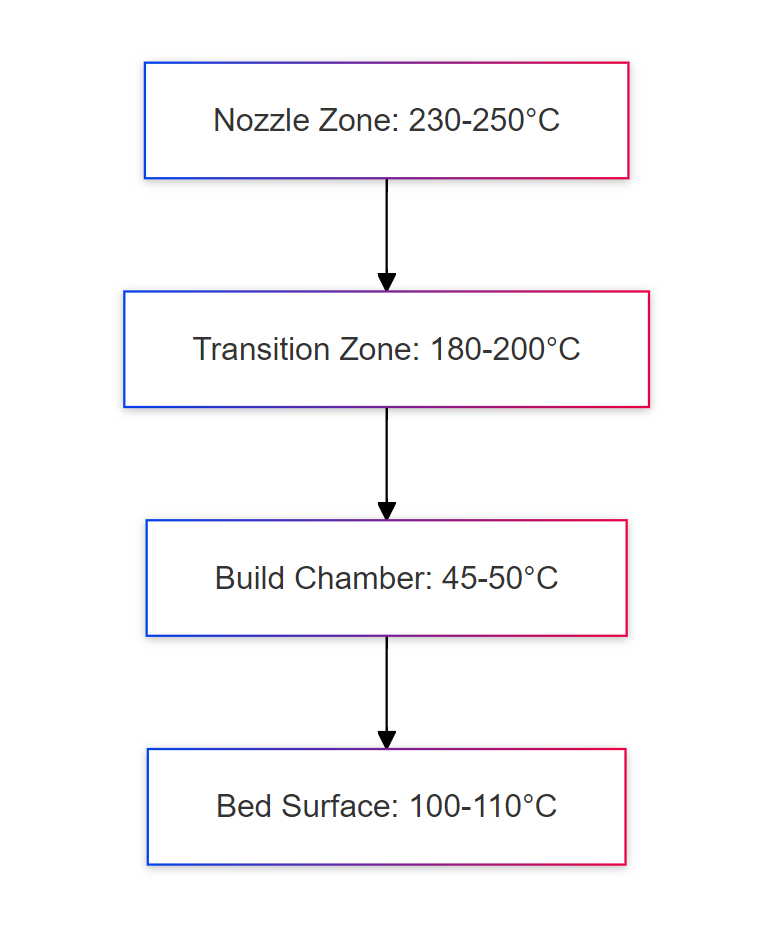

Temperatus Management

Optimal temperatus imperium significantly impingit print species. Research Demonstrates propriis temperatus procuratio potest reducere defectibus per LXV%.

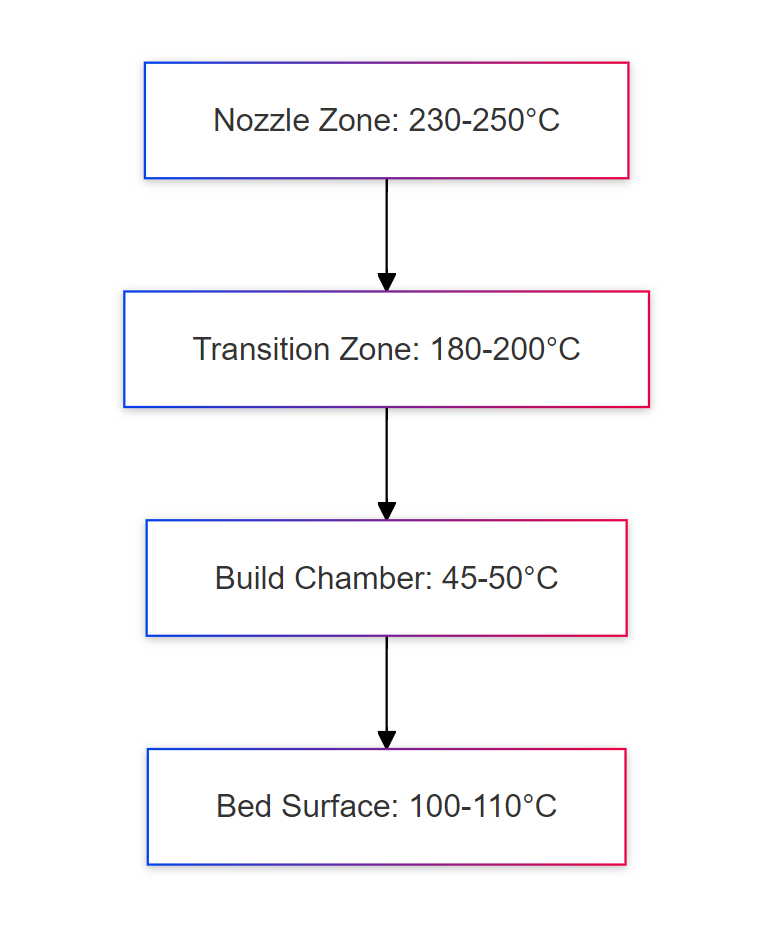

Temperature Zonas:

Critical Factors:

COLLUM Temzzle stabilitatem (± II ° F)

Tectum temperatus uniformitatem (± III ° F)

Tenebrarum temperatus consistency

Scelerisque gradient administratione

Print occasus

Vestibulum Procirical Testing reveals Optimal Print Parametri ad Abs:

| parametri | commendatur range | labefactum qualis |

| Print celeritate | 30-50 mm / s | Altum |

| Layer altitudo | 0.15-0.25mm | Medium |

| Testa crassitudine | 1.2-2.0mm | Altum |

| PROFILLUM | 20-40% | Medium |

Fan celeritas suasiones:

Primo iacuit: 0%

Pontes: 15-20%

Overhangs: 10-15%

Latin layers: 5-10%

Primo iacuit considerations

Initial stratum victoria dramatically influit altiore print species. Statistical Analysis ostendit propriis primum layer setup auget successu rates per XC%.

Critica mensuras:

Z-offset: 0,1-.15MM Layer Altitudo: 0.2-0.3mm linea latitudine: 120-130% lectum levelness: ± 0.02mm

Troubleshooting communis exitibus 3D printing cum abs

Print species problems

Research identifies prima defectum modis et solutions:

Communis defectus Analysis:

| Frequency | primaria | causa | victoria rate post fix |

| ADMITTATIO | XLV% | Temperature Delta | LXXXV% |

| Strepos | XXX% | Pauperes adhaesionem | XC% |

| Superficies defectus | XV% | Humor | XCV% |

| Dimensional Inaccuracy | X% | Calibration | XCVIII% |

Material-related exitibus

Humore impetus metrics:

Effusio rate: 0.2-0.3% per diem

Fortitudo Reduction: Usque XL%

Superficies species Degradation: Visibilis post II% humorem content

Print Deficiendi proventus: LXV% cum infectum filamento

Commendatur repono conditionibus:

Temperature: 20-25 ° C relative Umor <XXX% Air Exposure: Minimal Container Type: Airtight cum Desiccant

Environmental challenges

Environmental imperium significantly impingit print Success:

Impact factors:

Temperature fluctus (± V ° C LXX% defectum rate)

Duco nulla (> 0.3 M / S = LXXXV% defectum rate)

Umor Variations (> L% RH = LX% qualis reductionem)

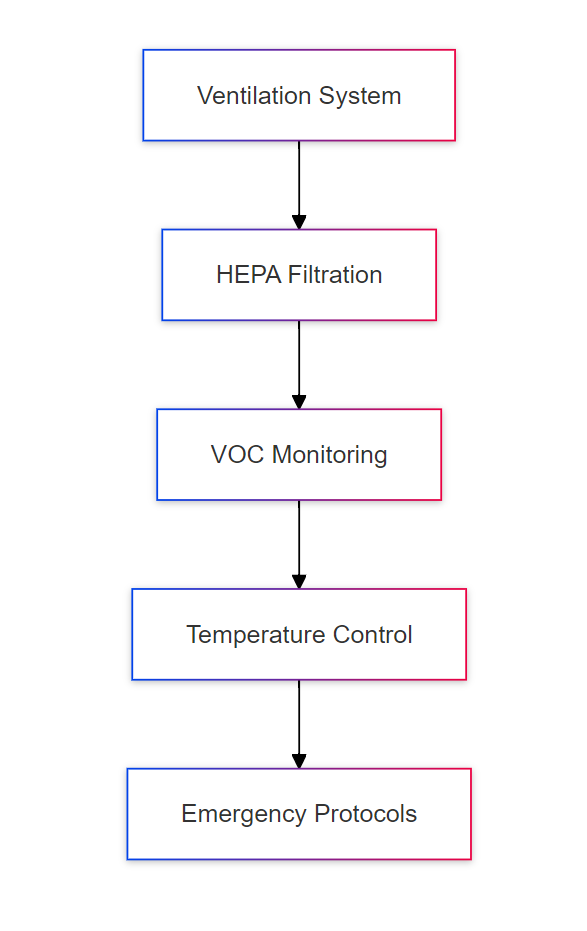

Voc cumulus (> C PPM = Health Periculum)

Post-Processing Techniques ad Abs typis partes

Superficies consummatione

Progressive Sanding Protocol format fundamenta superficiem elegantiam. Satus cum CXX-GRIRT Sandpaper ad initial Layer remotionem, paulatim progreditur per CCXL, CD, et DCCC - fermentum. Systematica accedat ensures uniformis superficiem progressionem sine compromising structural integritas.

Essential Tools and Materials required ad professional results include:

| tool genus | specifica items | ad |

| Abrasives | Udo / Arida Sandpaper (120-2000 GLARE) | Superficies adtritio |

| Power Tools | Variabilis celeritate orbital Sander | Magna area processus |

| Tools | Sanding caudices, files | Detail opus |

| Consumables | Polising componit, microfiber pannis | Finalis consummatione |

Provectus Polising modi augendae superficiem qualis ultra basic Sanding:

Mechanica Buffing per compositis rotae

Infectum politicandi cum adamas pastes

Micro-Mesh Padding pro Ultra-lenis metam

Gyratorius Tool Techniques pro detailed areas

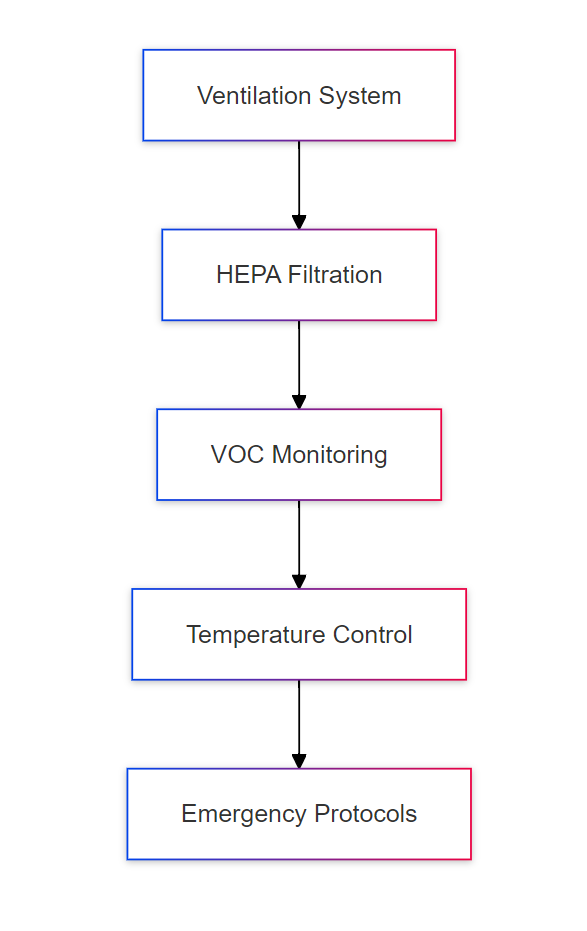

Chemical curatio

ACETONE Gradening Processes libera professional-gradus superficies consummavi:

Basic parametri: Temperature: 45-50 ° C Pope Duration: 15-30 Minutes Vollationum Period: 60 Duration Vol Vol Vol Vol Vol: pars

Vapor blanda salus protocols demonstrare stricte adhaerent;

Propriis VENTILATIO Systems

Chemical, repugnans PPE usus

Temperatus vigilantia

Subitis responsio Praeparatio

Imperium elit sustentationem

Applicationem methodologies variari secundum partem complexionem:

Direct vapor nuditate pro simplex geometries

Imperium camera treatment pro intricate partes

Peniculus applicationem selectivam levigans

Tingens ars enim uniformis curatio

Conventus et consummatione

Bonding Techniques Electio Criteria:

| Modus | Fortitudo | Application tempus | optimus Use Case |

| Solvendo WELDING | PERPREPIDUS | 5-10 min | Structural compagum |

| Scelerisque vinculum | Altum | 15-20 min | Magna superficiebus |

| Adhening joining | Medium | 30-45 min | Complexiones coetus |

Superficiem praeparatio sequence ad optimal results:

Mechanica Purgato (CXX-GLAREA abrasion)

Degreasing chemical

Superficies activation curatio

Primario applicationem

Pingor

Final Conventus Guidelines ut professional eventus:

ALIGRX verificationem per Jigs

Conventus sequentem congue

Suspendisse Point ReinForcement

Qualitas imperium checkpoints

Eget Testing ratio

Superficiem Treatment Options providere Diverse Consummatione possibilities:

Primer applicationem techniques

Aliquam compatibility considerations

Patet tunica tutela modos

Textura application procedendi

Optimus exercitia et tips

Materia tractantem

Repono environment metrics:

Optimal Conditions: Temperature: 20-22 ° C relative Umor 25-30% lux nuditate: <L Lux Aeris Exchange Rate: 0.5-1.0

Qualitas victum protocols:

Weekly humorem contentus temptationis

Quarterly materiae proprietas verificationem

Continuam environment magna

Ordinarius desiccant replacement

Print Optimization

Euismod Cultment data:

| Optimization step species | impulsum | tempus investment | Roi Rating |

| Calibration calibration | XL +% | II horis | Altum |

| Retraction tuning | + XXV% | I hora | Medium |

| Celeritate optimization | + XX% | III horas | Altum |

| Fluunt rate temperatio | + XV% | XXX minutes | PERPREPIDUS |

Test Print Sequence:

Temperatus Tower (XLV minutes)

Retractatione test (XXX minuta)

Ponging test (XX minutes)

Overhang Aestimatio (XXV minuta)

Salus considerations

Workspace Salus Requirements:

Metrics essential salutem:

Air Exchange Rate: 6-8 ACH

Voca limine: <L PPM

Particulatum filtration: 0.3μm at 99.97%

Subitis responsio Time: <XXX seconds

Conclusio

In itinere per abs 3D printing reveals et suum challenges et praeclara potentiale. Dum diligenter ad temperatus imperium, evacuatione et print occasus, praemia Maste Abs printing sunt substantial. Suavatu compositum ex diuturnitatem, æstus resistentia, et post-processus flexibilitate continues agitant innovation per industrias.

Sicut dictum est vestibulum technology evolves, abs manet in fronte, accommodatam ad novum applications et challenges. In futurum de Abs printing spectat promissum, cum ongoing progressionem in materia scientia et excudendi technology promissum etiam maior possibilities hoc versatile filamentum.

Promptus ad elevare 3D printing ludum cum abs? Team MFG brings vos professional-gradus abs Tryless Solutions backed per decennia de vestibulum peritia. Ex prototypum ad productionem, ut youll auxilium vobis unlock abs 's plena potential. Contact nostri peritos hodie vel visita Team MFG ad liberum consultationem.

Reference Sources

3D printing

St Plastic

3D printing materiae

Frequenter Interrogata Quaestiones: 3D Printing cum Abs

Q1: Quid meum Abs Print Warrior?

A: warping occurs a inaequaliter refrigerationem. Uti calefacta lectulo (100-110 ° F), inclusum camera et propriis adhaesionem solutions.

Q2: Est Abs toxicus?

A: Ita, ABS solvo fumus in printing. Semper usu evacuatione et clausuram. Vitare longum differentur nuditate.

Q3: Quid est idealis printing temperatus?

A: Ceo: 230-250 ° C

Bed: 100-110 ° F

Aethae: 45-50 ° C

Q4: Quid opus est clausura?

A: Clepsins ponere temperatus, ne warping, quae fumus, et amplio layer adhaesionem.

Q5: Quomodo si ego copia abs?

A: in airtight continentia cum desiccant at 20-25 ° C, sub XXX% humiditas.

Q6: Optimus ita ut lenis abs?

A: Aut Acetone vapor levigans (velox, nitidum) seu progressivum Sanding (magis potestate).

Q7: Quid sunt vestigia fragilis?

A solet ab infectum filamento humilis temperatus aut pauperum adhaesionem. Arida fibulam et crescere temperatus figere.