Lwaki ABS (Acrylonitrile Butadiene Styrene) esigadde nga egenda mu maaso mu mulimu gw’okukuba ebitabo mu ngeri ya 3D okumala emyaka egisukka mu makumi asatu? Ebyuma byayo eby’enjawulo, okuziyiza ebbugumu okutuuka ku 105°C, n’obusobozi obw’okukola ebintu mu ngeri nnyingi oluvannyuma lw’okukola bifuula okulonda okw’omuwendo ennyo eri abakola n’abakola ebintu byonna.

Oba oli seasoned professional oba omuyiiya alina ebirowoozo ebinene, okutegeera nuances za ABS okukuba ebitabo kiyinza okugaziya mu ngeri ey’ekitalo obusobozi bwo obw’okukuba ebitabo mu ngeri ya 3D. Mu blog eno, tujja kukulungamya mu nsi ey’amagezi ey’okukuba ebitabo mu ngeri ya 3D ne ABS filament, okutegeera ennyonyola, okukozesa, n’ebirungi okusobola okusalawo obulungi.

Akaveera ka ABS kye ki?

Acrylonitrile Butadiene Styrene (ABS) yakyusa amakolero g’amakolero nga tannavaayo ng’ekintu eky’oku nsonda mu tekinologiya w’okukuba ebitabo mu ngeri ya 3D. Ensengekera yaayo ey’enjawulo eya molekyu, ng’egatta monomera ssatu ez’enjawulo, egaba eby’obutonde eby’enjawulo. Okunoonyereza kulaga nti ebitundu bya ABS bikuuma obulungi bw’enzimba ku bbugumu okutuuka ku 105°C, nga bisinga nnyo ebintu ebirala.

Okukozesa ABS 3D Printing .

Abakugu mu by'amakolero bamanyi ABS mu bintu bingi ebya bulijjo:

Ebitundu by'emmotoka (20% ku katale)

Abakozesa ebyuma (35% ku katale)

Ebikozesebwa mu maka (25% akatale)

Ebikozesebwa mu makolero (15% akatale)

Okusaba okulala (5% ku katale) .

Okukola ebintu mu makolero kulaga okwettanira ennyo tekinologiya w’okukuba ebitabo mu ABS. Ebifo eby'amakolero leverage ABS for:

Custom Tooling ne fixtures Okukendeeza ku nsaasaanya y’okufulumya ebitundu 40% .

Enkola ezikola (functional prototypes) zigumira embeera z’okugezesa ez’ensi entuufu .

Ebitundu ebikyusibwamu ebikoleddwa ku bwetaavu, okusala ku nsaasaanya y'ebintu

Ebikozesebwa mu kulongoosa layini y’okukuŋŋaanya okulongoosa obulungi ebitundu 25% .

Automotive Applications Showcase ABS's okuwangaala n'okuziyiza ebbugumu:

| ekitundu ky'ekitundu | Enkozesa Emigaso | performance metrics |

| Ebitundu by'omunda . | Heat stable okutuuka ku 105°C . | 95% Obuwangaazi Ekipimo . |

| custom brackets . | Okuziyiza okukuba kwa waggulu . | 200 J/M Amaanyi g'okukuba . |

| Ebitundu bya Prototype . | Okuddiŋŋana okw’amangu . | 70% Okukendeeza ku budde . |

| Ebikozesebwa mu kuweereza . | Ekendeeza ku ssente . | 60% okukekkereza ku nsaasaanya . |

Ebikozesebwa mu byuma bikalimagezi biganyulwa mu ABS's versatility:

Enzigi z'ebyuma nga zirina okuziyiza okulungi ennyo okw'okukuba .

Ebitundu ebigumira ebbugumu ku nkuŋŋaana ez’amasannyalaze .

Ebizibu ebiteekebwa mu nkola custom .

Prototype casings okukola ebintu .

Okusaba kw ‟obujjanjabi n‟ebyobulamu kussa essira ku butuufu: Okusaba okukulu:

Ebikozesebwa mu kulongoosa mu mubiri .

Ebintu ebikozesebwa mu by'obujjanjabi eby'ennono .

Ebitundu by'ebikozesebwa mu laboratory .

Enkola z'okutendeka n'okusomesa .

Ebitundu by’ebizimbe n’okukola dizayini bikozesa ABS ku:

Ebitundu bya minzaani ebyetaagisa okuwangaala .

Ebintu eby'omulembe eby'okuzimba .

Omwoleso okwolesebwa ebitundu .

Ebikozesebwa mu kukola enkola z’okuzimba .

Pulojekiti z'ebyenjigiriza zikozesa ebintu bya ABS:

Ebikolwa eby'okwolesebwa mu by'obuyinginiya .

Ebikozesebwa mu Laabu ya Sayansi .

Ebikozesebwa mu kuyiga ebikwatagana .

Pulojekiti z'abayizi abakola dizayini .

Okusaba okunoonyereza n’okukulaakulanya mulimu: Enkozesa

| mu nnimiro | y’okukozesa | Enkizo . |

| Sayansi w'ebintu . | Ebigezo by’okugezesa . | Ebintu ebikwatagana . |

| Engineering . | Ebikozesebwa mu kukola emirimu egy’enjawulo . | Okuddiŋŋana okw’amangu . |

| Design y'ebintu . | Ebikolwa by'endowooza (Concept Models) . | Ekendeeza ku ssente . |

| Obujjanjabi obw'obulamu . | Ebyuma ebikoleddwa ku mutindo . | Okukyukakyuka mu kukola dizayini . |

Amakolero ag'enjawulo gafuna emigaso egy'enjawulo:

Okukola ebikozesebwa mu bbanga (Aerospace component prototyping) .

Okulongoosa ebyuma by'amagye .

Enkulaakulana y'ebikozesebwa mu nnyanja .

Okukyusa mu byuma by'emizannyo .

Ebirungi ebiri mu kukuba ebitabo mu ngeri ya 3D ne ABS Filament .

Ebintu eby’oku ntikko eby’ebyuma bisinga okulabika ng’engeri etegeeza ebitundu ebikubiddwa mu ABS. Ekintu kino kiraga okuziyiza okukosebwa okw’enjawulo, okutuuka ku 200 J/M, okusinga ebisinga obungi mu kukuba ebitabo mu 3D. Amaanyi gaayo ag’okusika gava ku 40-50 MPa, ekisobozesa okukola ebitundu ebikola ebiwangaala ebisobola okugumira okunyigirizibwa okw’amaanyi okw’ebyuma.

Obuziyiza bw’ebbugumu obw’enjawulo bufuula ABS okulonda okulungi ennyo okukozesebwa mu kusaba. Ekintu kino kikuuma obulungi bw’enzimba okutuuka ku 105°C, nga kisinga nnyo PLA (60°C) ne PETG (85°C). Okugumiikiriza kuno okw’ebbugumu okw’ekika ekya waggulu kukakasa nti ebitundu ebikubiddwa bisigala nga binywevu wansi w’ebbugumu eri waggulu, ekigifuula esaanira ebitundu by’emmotoka n’okuteekebwa ebweru.

Ebintu ebikozesebwa mu kukola emirimu egy’enjawulo oluvannyuma lw’okukola eby’okukola byawula ABS ku biwandiiko ebirala eby’okukuba ebitabo. Ebintu bino biddamu mangu:

Acetone vapor smoothing, okutuuka ku mutindo gw’okungulu ogubuumbiddwa empiso

Obukodyo bw’okusenda okugenda mu maaso, okusobozesa okufuga obulungi ku ngulu .

Okunyweza langi, okusobozesa okumaliriza okw’enjawulo .

Okusiimuula mu makanika, ekivaamu ebitundu ebimasamasa ebingi .

Ebifo eby’enjawulo eby’okukendeeza ku nsaasaanya y’ensimbi ABS ng’okusalawo okuyinza okukolebwa mu by’enfuna. Okwekenenya akatale kulaga:

| gw'ensaasaanya omuwendo . | omuwendo |

| Ebintu ebisookerwako . | $20-25/KG . |

| Obudde bw’okukola . | 15% ku sipiidi okusinga PLA . |

| Okukendeeza ku kasasiro . | 10% Ebintu Ebiwagira Ebitono . |

| Oluvannyuma lw’okukola ku ssente z’okukola . | 30% wansi okusinga ku ndala . |

Wide application versatility eraga ABS's adaptability mu makolero gonna. Ekintu kino kisukkulumye mu:

Ebitundu by'emmotoka ebyetaagisa okuziyiza okukuba ennyo .

Ebintu ebikozesebwa mu byuma ebikozesebwa mu byuma ebikozesebwa mu byuma ebyetaagisa okutebenkeza ebbugumu .

Ebikozesebwa mu makolero n'ebikozesebwa .

Enkulaakulana ey’ekyokulabirako nga esaba okuwangaala .

Ebizibu by’okukola ebintu eby’ennono .

Omugatte guno ogw’ebintu guteeka ABS nga eky’okulonda eky’omulembe eky’okukozesa mu kukuba ebitabo mu ngeri ey’omulembe mu 3D, naddala ng’amaanyi, okuziyiza ebbugumu, n’okukendeeza ku nsimbi bye bisinga okulowoozebwako.

Ebikoma n'okusoomoozebwa kwa ABS obuveera .

Ebipimo by’okutegeera ebbugumu:

Warping Threshold: 3°C/Eddakiika Okunyogoza

Ebbugumu erisinga obulungi mu kifo: 50-60°C

Enjawulo mu bbugumu ery’omugaso: <15°C .

Ebintu ebikwata ku butonde bw’ensi mulimu:

omukka gwa VOC ogufuluma nga gutuuka ku 200 μg/m³ Mu kiseera ky'okukuba ebitabo .

Omuwendo gw’okunyiga obunnyogovu: 0.3% buli ssaawa 24 ku 50% RH

Omugerageranyo gw’okugaziya ebbugumu: 95 × 10^-6 mm/°C .

Okuteekawo ebyuma ebikulu .

Ebyetaago bya 3D printer .

Okukuba ebitabo kwa ABS okuwangudde kwetaaga ensengeka za Hardware ezenjawulo:

Ebitundu ebikulu:

Ekitanda ekibuguma (ekitono 110°C obusobozi)

Ekisenge ekiggaddwa (Enjawulo y’ebbugumu <5°C) .

All-Metal Hotend (Eraboddwa >260°C)

Enkola y’okusengejja empewo ekola .

Okuteekateeka ku ngulu ku lupapula .

Okunyweza ABS okuwangula kyetaagisa okuteekateeka kungulu okulungi. Okunoonyereza kulaga nti okuteekateeka obulungi ekitanda kiyinza okwongera ku buwanguzi mu layeri esooka ebitundu 85%.

Okugerageranya eby’okulonda ku ngulu:

| Ekika ky’okungulu | okunyweza | okugereka ebbugumu | Okutebenkera omuwendo gw’ensimbi |

| Endabirwamu + ABS Slurry . | 95% . | Suffu | Waggulu |

| Ekipande kya PEI . | 90% . | Kilungi nyo | Midiyamu |

| Akatambi ka Kapton . | 85% . | Kirungi | Wansi |

| BuildTak . | 80% . | Kirungi | Midiyamu |

Emitendera emikulu egy’okuteekateeka:

Okwoza kungulu (Isopropyl Omwenge >99%) .

Okutebenkeza ebbugumu (eddakiika 15 nga tonnaba kubuguma) .

Okusaba kwa adhesion promoter .

Okukakasa ku ddaala (±0.05mm okugumiikiriza) .

Ebifuga obutonde bw’ensi .

Enzirukanya y’ebbugumu eraga nti kikulu nnyo mu buwanguzi mu kukuba ebitabo mu ABS. Okunoonyereza kulaga nti ebisenge ebiggaddwa bisobola okukendeeza ku kuwuguka ebitundu 78%.

Ebipimo ebikulu eby’obutonde:

Ebbugumu ly’ekisenge: 45-50°C

Ebbugumu eriweweeza ku bbugumu: <2°C/essaawa

Obunnyogovu: 30-40%

Entambula y’empewo: 0.1-0.2 m/s .

Printing parameters n'ensengeka z'okukuba ebitabo mu ngeri ya 3D ne ABS .

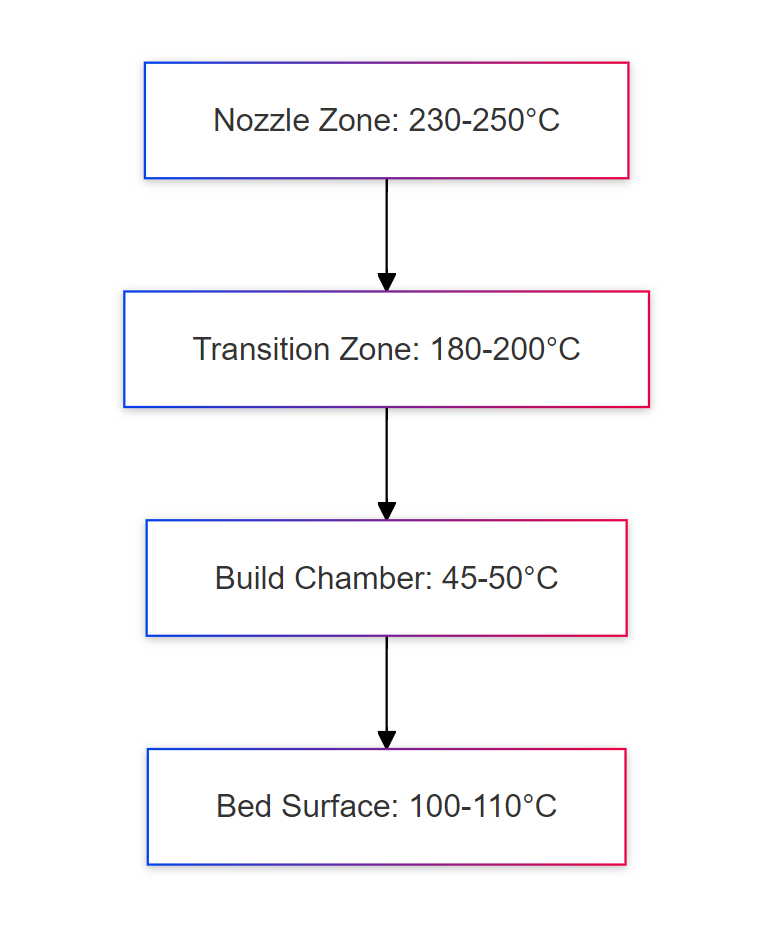

Enzirukanya y’ebbugumu .

Okufuga ebbugumu erisinga obulungi kukwata nnyo ku mutindo gw’okukuba ebitabo. Okunoonyereza kulaga nti okuddukanya ebbugumu mu ngeri entuufu kuyinza okukendeeza ku bulema ebitundu 65%.

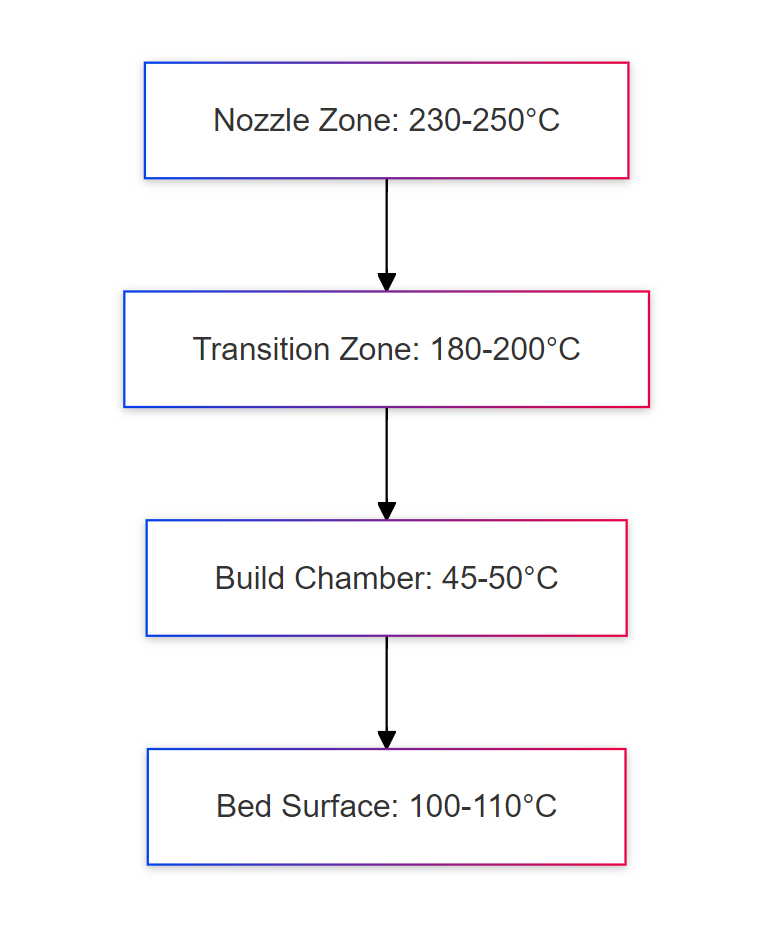

Zooni z’ebbugumu:

Ensonga enkulu:

Obunywevu bw’ebbugumu ly’entuuyo (±2°C) .

Ebbugumu ly’ekitanda ery’enjawulo (±3°C) .

Obugumu bw’ebbugumu mu kisenge .

Enzirukanya y’ebbugumu (thermal gradient) .

Enteekateeka z’okukuba ebitabo .

Okugezesa okuyitira mu bumanyirivu (empirical testing) kulaga ebipimo ebisinga obulungi eby’okukuba ebitabo ku ABS:

| parameter | recommended range | impact on quality . |

| Sipiidi y’okukuba ebitabo . | 30-50 mm/s . | Waggulu |

| Obugulumivu bwa layeri . | 0.15-0.25mm . | Midiyamu |

| Obugumu bw’ekisusunku . | 1.2-2.0mm . | Waggulu |

| indill density . | 20-40% . | Midiyamu |

Okuteesa ku sipiidi y’abawagizi:

Ebilowoozebwako mu layeri esooka .

Obuwanguzi bwa layeri esooka bukwata nnyo ku mutindo gw’okukuba ebitabo okutwalira awamu. Okwekenenya mu bibalo kulaga nti enteekateeka entuufu ey’okuteekawo layeri esooka eyongera ku miwendo gy’obuwanguzi ebitundu 90%.

Ebipimo ebikulu:

Z-offset: 0.1-0.15mm Obugulumivu bw’olutimbe: 0.2-0.3mm Obugazi bwa layini: 120-130% Obuliri bw’ekitanda: ±0.02mm

Okugonjoola ebizibu ebitera okubaawo mu kukuba ebitabo mu ngeri ya 3D ne ABS .

Ebizibu by'omutindo gw'okukuba ebitabo .

Okunoonyereza kuzuula engeri z’okulemererwa okusookerwako n’okugonjoola ebizibu:

Okukebera obulema obutera okubeerawo:

| okufulumya | emirundi | primary cause | success rate oluvannyuma lw'okutereeza . |

| Okuwuguka . | 45% . | Ebbugumu Delta . | 85% . |

| Okwawukana kwa layeri . | 30% . | Okunywerera obubi . | 90% . |

| Obulema ku ngulu . | 15% . | Amazzi | 95% . |

| Obutabeera butuufu bwa bipimo . | 10% . | Okupima okupima . | 98% . |

Ensonga ezikwata ku bintu .

Ebipimo by’okukosa obunnyogovu:

Omuwendo gw'okunyiga: 0.2-0.3% buli lunaku

Okukendeeza ku maanyi: okutuuka ku bitundu 40% .

Okuvunda kw’omutindo gw’okungulu: kulabika oluvannyuma lw’obunnyogovu bwa 2% .

Okulemererwa mu kukuba ebitabo kweyongera: 65% nga nnyogovu filament .

Embeera eziteeseddwa ez’okutereka:

Ebbugumu: 20-25°C Obunnyogovu obw’enjawulo: <30% Okulaga empewo: Ekika ky’ekintu ekitono: empewo eyingiramu n’okukkakkanya

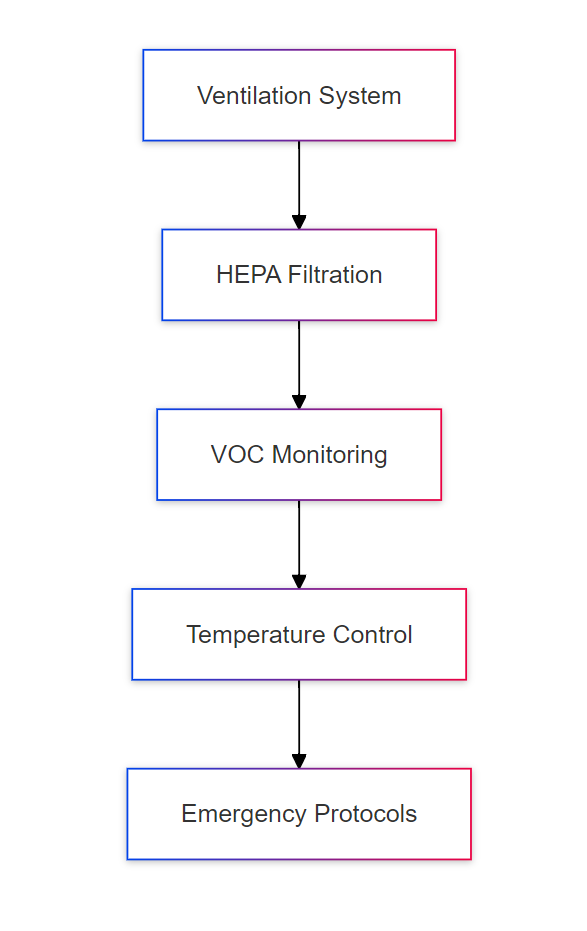

Okusoomoozebwa mu butonde bw’ensi .

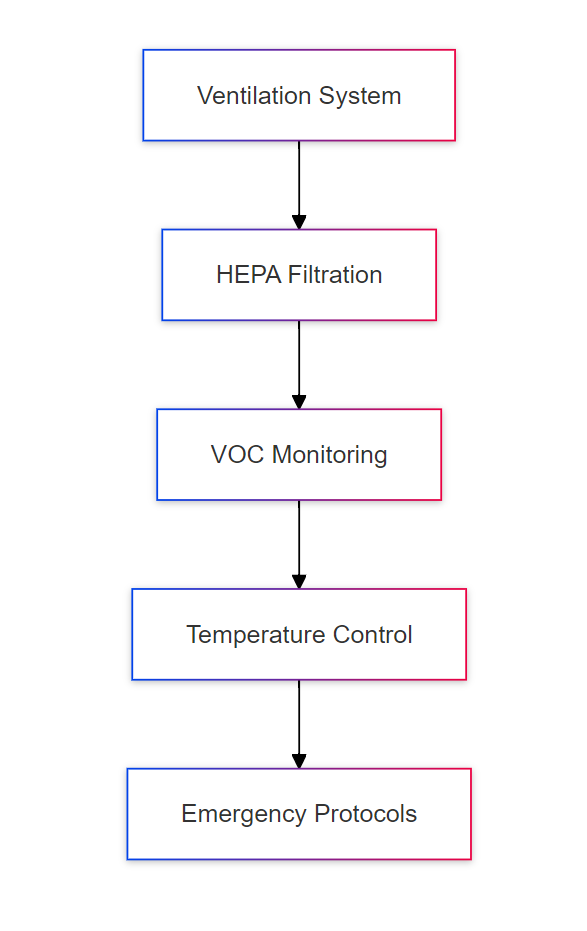

Okufuga obutonde bw’ensi kikwata nnyo ku buwanguzi mu kukuba ebitabo:

Ensonga ezikosa:

Enkyukakyuka mu bbugumu (±5°C = 70% okulemererwa) .

Ebbago ly’okulaga (>0.3 m/s = 85% omuwendo gw’okulemererwa) .

Enjawulo mu bunnyogovu (>50% RH = 60% Okukendeeza ku mutindo)

Okukuŋŋaanyizibwa kwa VOC (>100 ppm = Obulabe bw’obulamu) .

Obukodyo bw'okukola oluvannyuma lw'okukola ebitundu ebikubiddwa mu ABS .

Okumaliriza ku ngulu .

Progressive sanding protocol ekola omusingi gw’okulongoosa kungulu. Tandika ne 120-grit sandpaper okusobola okuggyawo layeri mu kusooka, mpolampola okugenda mu maaso okuyita mu 240, 400, ne 800 grits. Enkola eno entegeke ekakasa enkulaakulana y’okungulu ey’enjawulo awatali kukosa butuukirivu bwa nsengeka.

Ebikozesebwa ebikulu n’ebikozesebwa ebyetaagisa mu bivaamu eby’ekikugu mulimu:

| Ekika ky’ebikozesebwa | Ebintu ebitongole | ekigendererwa . |

| Ebintu ebiziyiza . | Omusenyu omubisi/omukalu (120-2000 grit) | Okutereeza ku ngulu . |

| Ebikozesebwa mu maanyi . | Variable Sipiidi Enzitoya Sander . | Okulongoosa ekitundu ekinene . |

| Ebikozesebwa mu ngalo . | Ebiziyiza okusenda, fayiro . | Omulimu gw'okukola mu bujjuvu . |

| Ebikozesebwa . | Ebirungo ebirongoosa, engoye za microfiber . | Okumaliriza okusembayo . |

Enkola ez’omulembe ez’okusiimuula zitumbula omutindo gw’okungulu okusukka okusenda okusookerwako:

Okuzimba ebyuma nga tukozesa nnamuziga ezikozesebwa .

Okusiimuula mu mazzi nga mulimu ebikuta bya dayimanda .

Micro-mesh padding okusobola okumaliriza ultra-smooth .

Obukodyo bw'ebikozesebwa mu kukyusakyusa mu bitundu ebikwata ku nsonga eno mu bujjuvu .

Okulongoosa eddagala .

Enkola z’okugonza Acetone zituusa okumaliriza okw’omutindo ogw’ekikugu ku ngulu:

Basic parameters:Ebbugumu: 45-50°C Obuwanvu bw’okulaga: eddakiika 15-30 ekiseera ky’okuyingiza empewo: eddakiika 60+ Ekisenge ky’ekisenge: 2L buli 100cm³ ekitundu

Vapor smoothing safety protocols zeetaaga okunywerera ennyo:

Enkola entuufu ey’okufulumya empewo .

Enkozesa ya PPE eguziyiza eddagala .

Okulondoola ebbugumu .

Okuteekateeka okuddamu okw’amangu .

Okuddaabiriza embeera efugibwa .

Enkola z’okukozesa zaawukana okusinziira ku buzibu bw’ekitundu:

Okwolesebwa kw’omukka obutereevu ku geometry ennyangu .

Obujjanjabi bw’ekisenge obufugibwa ku bitundu ebizibu .

Okusiiga Brush Okulonda .

Enkola y’okunnyika mu kujjanjaba obujjanjabi obumu .

okukuŋŋaanya n’okumaliriza .

Enkola y’okulonda obukodyo bw’okukwatagana :

| Enkola | y’okukozesa | obudde bw’okukozesa | obulungi ensonga y’okukozesa obulungi . |

| Okuweta kwa kizimbulukusa . | waggulu nnyo . | eddakiika 5-10 . | Ebiyungo Ebizimba . |

| Okukwatagana kw’ebbugumu . | Waggulu | eddakiika 15-20 | Ebitundu ebinene . |

| adhesive okwegatta . | Midiyamu | Edakiika 30-45 | Enkuŋŋaana Enzibu . |

Omutendera gw’okuteekateeka ku ngulu okusobola okufuna ebivaamu ebisinga obulungi:

Okwoza ebyuma (120-grit abrasion) .

Okuggya Amasavu mu kemiko .

Enkola y’okukola ku ngulu .

Okusaba kwa Primer .

Okuteekateeka langi .

Endagiriro ezisembayo mu lukiiko zikakasa ebivaamu eby’ekikugu:

Okukakasa okulaganya nga okozesa Jigs .

Enteekateeka y’Olukiiko oluddirira .

Okunyweza ensonga ya situleesi .

Ebifo ebikebera omutindo .

Enkola z’okugezesa emirimu .

Enkola z’okulongoosa ku ngulu ziwa ebisoboka eby’enjawulo ebigenda mu maaso:

Obukodyo bw'okukozesa Primer .

Langi Okukwatagana Okulowoozebwako .

Enkola z'okukuuma ekkooti ezitangaavu .

Enkola z'okukozesa ebiwandiiko .

Enkola Ennungi N'obukodyo .

Enkwata y’ebintu .

Embeera y’okutereka Ebipimo:

Embeera ennungi:Ebbugumu: 20-22°C Obunnyogovu obw’enjawulo: 25-30% Okulaga ekitangaala: <50 LUX Omuwendo gw’okuwanyisiganya empewo: 0.5-1.0 ACH

Ebiragiro by’okuddaabiriza omutindo:

Okugezesa ebirimu obunnyogovu buli wiiki .

Okukakasa ebintu ebikozesebwa buli luvannyuma lwa myezi esatu .

Okulondoola obutonde obutasalako .

Okudda mu kifo kya Desiccant bulijjo .

Okulongoosa mu kukuba ebitabo .

Data y’okulongoosa mu nkola:

| Okulongoosa Omutendera | Omutindo Okukwata ku | budde okuteeka ssente mu kuteeka ssente | mu ROI |

| Okupima ebbugumu . | +40% . | Ssaawa 2 . | Waggulu |

| Okuzza emabega Tuning . | +25% . | essaawa 1 . | Midiyamu |

| Okulongoosa sipiidi . | +20% . | Ssaawa 3 . | Waggulu |

| Okutereeza omuwendo gw’amazzi agakulukuta . | +15% . | Eddakiika 30 . | waggulu nnyo . |

Okugezesa omutendera gw’okukuba ebitabo:

Omunaala gw’ebbugumu (eddakiika 45) .

Okugezesa okuzza emabega (eddakiika 30) .

Okugezesebwa kw'okuziba (eddakiika 20) .

Okukebera okusukkiridde (eddakiika 25) .

Okulowooza ku byokwerinda .

Ebyetaago by’obukuumi mu kifo ky’okukoleramu:

Ebipimo ebikulu eby’obukuumi:

Omuwendo gw’ensimbi ezikyusibwa mu mpewo: 6-8 ACH

Ekipimo kya VOC: <50 ppm .

Okusengejja obutundutundu: 0.3μm ku 99.97% .

Obudde bw'okuddamu mu bwangu: <30 seconds .

Mu bufunzi

Olugendo oluyita mu kukuba ebitabo bya ABS 3D lulaga okusoomoozebwa kwalwo n’obusobozi bwalwo obw’ekitalo. Wadde nga kyetaagisa okufaayo ennyo ku kufuga ebbugumu, okuyingiza empewo, n’okuteeka mu mpapula, empeera z’okukuba ebitabo mu ABS mu ngeri ey’ekikugu zibeera nnene. Omugatte gwayo ogutalina kye gufaanana ogw’okuwangaala, okuziyiza ebbugumu, n’okukyukakyuka oluvannyuma lw’okukola kukyagenda mu maaso n’okuvuga obuyiiya mu makolero gonna.

Nga tekinologiya w’okukola eby’okwongerako agenda akulaakulana, ABS esigala ku mwanjo, ng’emanyiira enkola empya n’okusoomoozebwa. Ebiseera eby’omumaaso eby’okukuba ebitabo bya ABS birabika nga bisuubiza, nga waliwo enkulaakulana ezigenda mu maaso mu sayansi w’ebintu ne tekinologiya w’okukuba ebitabo ebisuubiza n’okusingawo ebisoboka ku filament eno ekola ebintu bingi.

Mwetegefu okusitula omuzannyo gwo ogw'okukuba ebitabo mu 3D ne ABS? Team MFG ekuleetera eby’okukola eby’okukuba ebitabo eby’omutindo ogw’ekikugu ebya ABS nga biwagirwa obukugu mu by’amakolero okumala emyaka mingi. Okuva ku prototype okutuuka ku production, tujja kukuyamba okusumulula obusobozi bwa ABS obujjuvu. Tuukirira abakugu baffe leero oba genda ku Team MFG okusobola okwebuuza ku bwereere.

Ensonda ezijuliziddwa .

Okukuba ebitabo mu ngeri ya 3D .

ABS pulasitiika .

Ebikozesebwa mu kukuba ebitabo mu ngeri ya 3D .

Ebibuuzo ebitera okubuuzibwa: Okukuba ebitabo mu ngeri ya 3D ne ABS

Q1: Lwaki abs print warp yange ekola?

A: Okuwuguka kubaawo okuva mu kunyogoza okutali kwa bwenkanya. Kozesa ekitanda ekibuguma (100-110°C), ekisenge ekiggaddwa, n’ebizigo ebituufu eby’okunyweza.

Q2: ABS erimu obutwa?

A: Yee, ABS efulumya omukka mu kiseera ky’okukuba ebitabo. Bulijjo kozesa empewo n’ekisenge ekizimbiddwa. Weewale okumala ebbanga eddene ng’omanyidde ddala.

Q3: Ebbugumu ly’okukuba ebitabo erisinga obulungi?

A: Entuuyo: 230-250°C

Obuliri: 100-110°C

Ekisenge: 45-50°C

Q4: Lwaki nneetaaga ekiyumba?

A: Enzigi zikuuma ebbugumu, ziziyiza okuwuguka, zirimu omukka, n’okulongoosa okunywerera kwa layeri.

Q5: Nsaanidde kutereka ntya ABS?

A: Mu bibya ebiziyiza empewo okuyingira nga biriko desiccant ku 20-25°C, wansi wa 30% obunnyogovu.

Q6: Engeri esinga obulungi ey’okugonzaamu ABS?

A: Oba acetone vapor smoothing (amangu, glossy) oba okusenda okugenda mu maaso (okusinga okufuga).

Q7: Lwaki ebiwandiiko ebikubibwa biba bifuuse bifuuse?

A: Ebiseera ebisinga biva mu filamenti ennyogovu, ebbugumu eri wansi, oba okunywerera ku layeri embi. Filamenti enkalu n’okwongera ku bbugumu okusobola okutereeza.