Mun na ABS (Acrylonitrile Butadiene Styrene) tora taa-ka-segin ye 3D sɛbɛnniko la kabini san tan ni saba ni kɔ? A ka masina cogoya danmadɔw, funteni bɛ se ka se 105°C ma, ani a bɛ se ka baara kɛ ni a ye cogo caman na, o b’a kɛ sugandili nafamaba ye dilanbagaw ni fɛn dilannikɛlaw bɛɛ fɛ.

I mana kɛ baarakɛla ye min bɛ waati kɔnɔ walima i ye ɲɛnajɛko ɲɛnabɔbaga ye min bɛ se kosɛbɛ, ABS sɛbɛnni nuancɛw faamuyali bɛ se ka i ka 3D sɛbɛnni sekow bonya kosɛbɛ. Nin bulɔgu in kɔnɔ, an bɛna aw bilasira ka don 3D sɛbɛnni diɲɛ majigilen na ni ABS filament ye, faamuyali, baarakɛcogo, ani nafaw walasa ka sugandili ɲuman kɛ.

ABS plastiki ye mun ye?

Acrylonitrile Butadiene Styrene (ABS) ye fɛn caman sɛmɛntiya fɛn dilanni na ka sɔrɔ ka bɔ kɛnɛ kan ka kɛ fɛn ye min bɛ se ka kɛ 3D sɛbɛnni fɛɛrɛw la. A ka molekiyɔmu jɔcogo kɛrɛnkɛrɛnnen, n’o ye monomɛri saba danfaralenw faralen ye ɲɔgɔn kan, o bɛ masinw cogoya danfaralenw Di. Kɔlɔsiliw y’a jira ko ABS yɔrɔw bɛ sigicogo dafalen mara funteni na fo ka se 105°C ma, min bɛ tɛmɛ kosɛbɛ fɛn wɛrɛw kan minnu bɛ se ka baara kɛ.

ABS 3D sɛbɛnni baarakɛcogo .

Industriw ka dɔnnikɛlaw bɛ ABS dɔn don o don fɛn caman na:

Mobili yɔrɔw (20% suguya sɔrɔta) .

Consumer Electronics (35% suguya sɔrɔta) .

Du kɔnɔ minɛnw (25% suguya sɔrɔta) .

Industriw ka minɛnw (15% suguya sɔrɔta) .

Aplikasi wɛrɛw (5% suguya sɔrɔta) .

Industriw ka fɛn dilanni bɛ ABS sɛbɛnni fɛɛrɛw tali jira kosɛbɛ. Fɛn dilanyɔrɔw leverage abs for:

Baarakɛminɛnw ni fɛnw labɛncogo minnu bɛ kɛ ka kɛɲɛ ni mɔgɔw sago ye, olu bɛ dɔ bɔ sɛnɛfɛnw musakaw la ni 40% ye .

Functional prototypes muɲuni diɲɛ kɔnɔ sɛgɛsɛgɛli cogoyaw la .

Yɔrɔ minnu bɛ falen u nɔ na minnu dilannen don ni u bɛ kɛ ka kɛɲɛ ni u ɲinini ye, ka fɛnmarayɔrɔ musakaw tigɛ .

Assembly Line Optimisation Baarakɛminɛnw bɛ baarakɛcogo ɲɛ ka ɲɛ ni 25% ye .

Mobili baarakɛminɛnw bɛ ABS ka muɲuli ni a ka funteni kunbɛncogo jira:

| yɔrɔ suguya | baarakɛcogo nafaw | baarakɛcogo jateminɛw . |

| Kɔnɔna yɔrɔw . | Funteni bɛ sabati fo ka se 105°C ma . | 95% bɛ se ka muɲu . |

| brackets customs . | Resistance de resistance haute . | 200 J/M Impact fanga . |

| Prototype yɔrɔw . | Iterasiyɔn teliya . | 70% waati dɔgɔyali . |

| Baarakɛminɛnw . | A musaka ka dɔgɔ . | 60% musaka dɔgɔyali . |

Consumer Electronics bɛ nafa sɔrɔ ABS ka fɛn caman na:

Minɛnw ka dakunw ni impact resistance ɲumanba .

Fɛn minnu bɛ se ka funteni kɛlɛ, olu ye ɛntɛrinɛti lajɛw ye .

Solutions de montagne custom .

Prototype casings ka ɲɛsin fɛn dilanni ma .

Dɔgɔtɔrɔso ni kɛnɛyako baarakɛminɛnw bɛ sinsin tigitigi: a kɛcogo jɔnjɔnw:

Anatomical models for opere planning .

custom medical device housings .

Laboratoire minɛnw yɔrɔw .

Kalan ni kalanko misaliw .

Architectural and design sectors bɛ baara kɛ ni ABS ye ka ɲɛsin:

Scale model components minnu bɛ muɲuli wajibiya .

architecture architectures .

Ɲɛjirali yɔrɔw .

Functional prototypes for building systems .

Kalan porozɛw bɛ ABS ka nafolo sɔrɔ:

Engineering jirali misaliw .

Science Lab ka minɛnw .

Kalankɛminɛnw ni ɲɔgɔn cɛ .

Kalandenw ka dilan porozew .

Sɛgɛsɛgɛli ni yiriwali baarakɛcogo dɔw ye:

| Foro | baarakɛcogo | Key Advantage . |

| Material Science . | Kɔrɔbɔli kɛcogo . | Propriétés consistens . |

| Engineering . | Baarakɛcogo prototypes . | Iterasiyɔn teliya . |

| Product Design . | Hakilila modɛliw . | A musaka ka dɔgɔ . |

| Biomedical . | Custom minɛnw . | Dilancogo sɛgɛsɛgɛli . |

Industries spécialisés trouve uniques:

Aerospace component prototyping .

Sɔrɔdasi ka minɛnw ladamuni .

Kɔgɔjida la fɛnɲɛnamafagalanw yiriwali .

Spor minɛnw bεε bε bεn .

Nafa minnu bɛ 3D sɛbɛnni na ni ABS filament ye .

Mekaniki jogo ɲumanw bɛ bɔ kɛnɛ kan i n’a fɔ ABS sɛbɛnnenw yɔrɔ ɲɛfɔlen. O fɛn in bɛ fɛn dɔw jira minnu bɛ se ka kɛ sababu ye ka se ka fɛn caman kɛ, ka se 200 J/m ma, ka tɛmɛ 3D sɛbɛnnikɛlanw kan minnu ka ca kosɛbɛ. A ka fanga bɛ daminɛ 40-50 MPa la, o bɛ kɛ sababu ye ka baarakɛminɛnw dilan minnu bɛ mɛn sen na, minnu bɛ se ka degunba muɲu masinw na.

Funteni kunbɛncogo ɲuman bɛ ABS kɛ sugandili ɲuman ye baarakɛcogo caman na. O fɛn bɛ sigicogo dafalen mara fo ka se 105°C ma, o bɛ PLA (60°C) ani PETG (85°C) sɔrɔ min ka ca kosɛbɛ. O funteni muɲuni sanfɛla bɛ a to yɔrɔ sɛbɛnnenw ka to u cogo la funteni kɔrɔtalen kɔrɔ, o b’a to u bɛnnen don mobili yɔrɔw ma ani kɛnɛma fɛnw ma.

Seko ni dɔnko kɔfɛ sugandiliw bɛ ABS ni sɛbɛnnifɛn wɛrɛw danfara bɔ ɲɔgɔn na. O kunnafoni bɛ jaabi nɔgɔya la:

Asetone Vapor Smoothing, Achieving Injection-Molded Surface Quality

Sanding fɛɛrɛw bɛ taa ɲɛ, minnu bɛ kɛ sababu ye ka dugukolo sanfɛla kunbɛn .

Penti adhesion, min bɛ se ka finidoncogo suguya caman kɛ .

Mekanikini poliyali, min bɛ na ni yɔrɔw ye minnu bɛ yeelen bɔ kosɛbɛ .

Cost-effectiveness positions ABS iko sugandili min bɛ se ka kɛ sɔrɔko siratigɛ la. Sugu sɛgɛsɛgɛli y’a jira ko:

| musaka hakɛ | nafa . |

| Matériel raw . | $20-25/kg . |

| baarakɛwaati . | 15% teliya ka tɛmɛ PLA kan . |

| Nɔgɔ dɔgɔyali . | 10% ka dɔgɔn dɛmɛnanw ma . |

| Post-processing musaka . | 30% ka dɔgɔn ni fɛn wɛrɛw ye . |

A kɛcogo caman bɛ ABS ka ladamuni jira iziniw kɔnɔ. O fɛn in bɛ tɛmɛ nin kan:

Mobili yɔrɔw bɛ ɲini ka se ka u yɛrɛ tanga kosɛbɛ .

Consumer Electronics Sow minnu mago bɛ funteni sabatili la .

Industriw ka baarakɛminɛnw ni u ka fɛnw .

Prototype yiriwali demand durability .

Solutions de fabrications de la , minnu bɛ kɛ ka kɛɲɛ ni mɔgɔw sago ye .

O nafolo faralen ɲɔgɔn kan, o bɛ ABS bila sugandili fɔlɔ la 3D sɛbɛnni baara ɲɛtaa kama, kɛrɛnkɛrɛnnenya la, fanga, funteni kɛlɛli, ani musaka dɔgɔyali ye jateminɛ fɔlɔw ye.

ABS plastiki dantigɛliw ni gɛlɛyaw .

Funteni hakɛ jateminɛnanw:

Warping Threshold: 3°C/Minute Nɛnɛ hakɛ .

Lamini funteni hakɛ ɲuman: 50-60°C .

Diferentiel température (15°C) ye funteni hakɛ gɛlɛn ye.

Sigida haminankow ye :

VOC bɔli bɛ se 200 μg/m⊃3 ma; sɛbɛnni waati .

Ji minɛcogo hakɛ: 0,3% sanga 24 kɔnɔ 50% RH la .

Sumaya hakɛ min bɛ sɔrɔ funteni na: 95 × 10^-6 mm/mm/°C .

Minɛnw sigicogo nafamaw .

3D sɛbɛnnikɛlan ka sariyaw .

ABS sɛbɛnni ɲɛtaa bɛ fɛn kɛrɛnkɛrɛnnenw ɲini minnu bɛ kɛ ni fɛnɲɛnamafagalanw ye:

A yɔrɔ nafamaw:

Dilan min bɛ funteni na (a ka ca ni 110°C ye) .

So min datugulen don (funteni hakɛ <5°C) .

All-Metal hotend (a bɛ tali kɛ >260°C la) .

Active Air Filtration System .

Print surface labɛnni .

ABS nɔrɔli min bɛ ɲɛ sɔrɔ, o bɛ kɛ sababu ye ka sanfɛla labɛnni ɲuman kɛ. Sɛgɛsɛgɛliw y’a jira ko dilan labɛnni ɲuman bɛ se ka dɔ fara a ka ɲɛtaa hakɛ fɔlɔ kan ni 85% ye.

Surface Options Comparaison:

| Surface suguya | nɔrɔli hakɛ | funteni | sabatili musaka nafa . |

| Glass + ABS SURRY . | 95% . | Ɲuman ɲuman | Jamanjan |

| PEI sɛbɛn . | 90% . | A kaɲi kɔsɛbɛ | Hakɛ |

| Kapton kase . | 85% . | Duman | Fɛ́gɛn |

| Buildtak . | 80% . | Duman | Hakɛ |

Labɛnni kunbabaw:

Surface saniya (isopropil alcool >99%) .

Funteni sabatili (miniti 15 ka kɔn funteni ɲɛ) .

Adhesion promoteur application .

Nivo sɛgɛsɛgɛli (±0,05mm tolerance) .

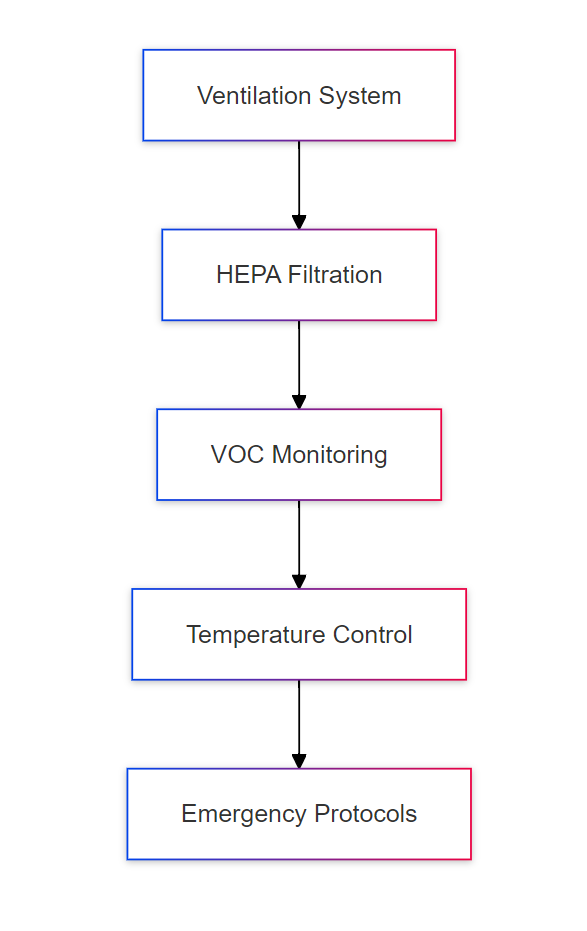

sigida kɔlɔsili .

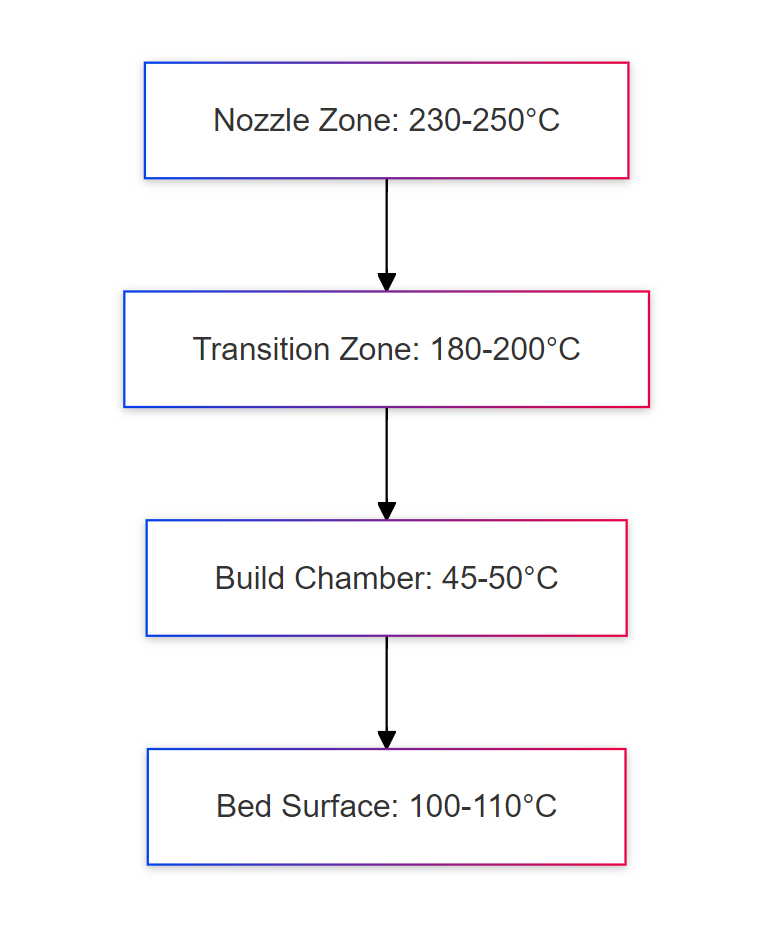

Funteni hakɛ ɲɛnabɔli bɛ kɛ ko kɔrɔba ye ABS sɛbɛnni ɲɛtaa kama. Kɔlɔsiliw y’a jira ko sow datugulenw bɛ se ka warping dɔgɔya ni 78% ye.

Laminiko paramɛtiri nafamaw:

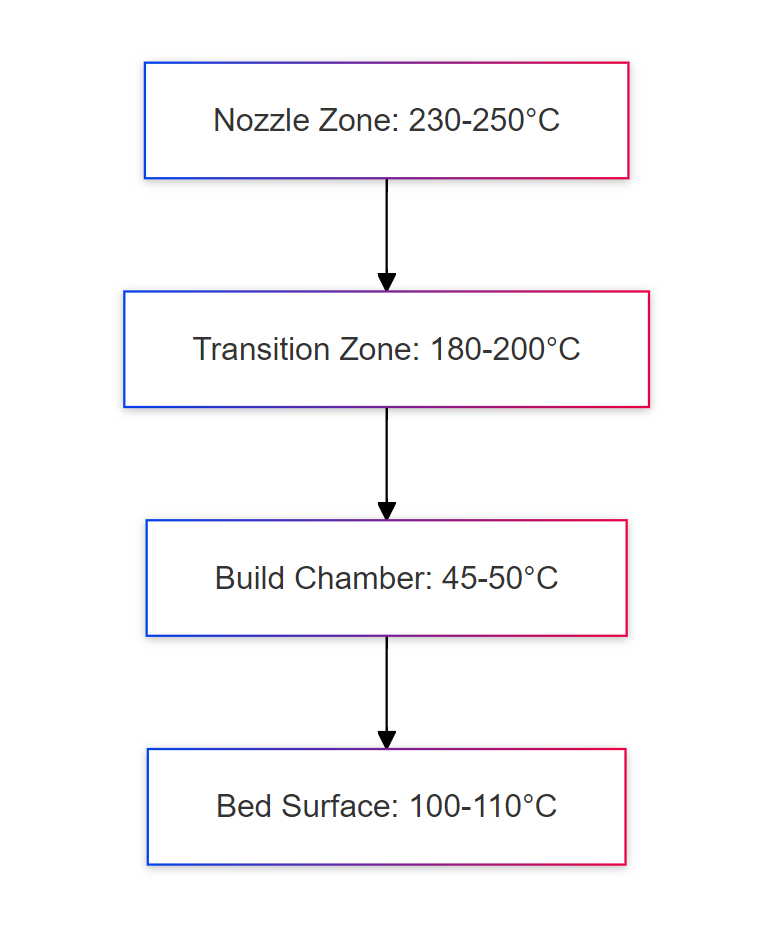

Chambre funteni hakɛ: 45-50°C .

Funteni hakɛ jiginni: <2°C/lɛrɛ .

A ka nɛnɛ hakɛ: 30-40%

Fiɲɛbɔlan: 0,1-0,2 m/s .

3D sɛbɛnni paramɛtiriw ni a sigicogo ni ABS .

Funteni ɲɛnabɔli .

Funteni hakɛ kunbɛnni ɲuman bɛ nɔba bila sɛbɛnni jogo la. Sɛgɛsɛgɛliw y’a jira ko funteni kunbɛncogo ɲuman bɛ se ka fiɲɛw dɔgɔya ni 65% ye.

Funteni yɔrɔw:

Fɛn minnu nafa ka bon kosɛbɛ:

Nozzle funteni sabatili (±2°C) .

Dilan funteni kelenya (±3°C) .

Chambre température consistance .

Sumaya gradient management .

Sɛbɛnni kɛcogo .

Sɛgɛsɛgɛli min bɛ kɛ ni fɛnw ye, o bɛ sɛbɛnni kɛcogo ɲumanw jira ABS la:

| Paramɛtiri | bɛ se ka kɛ cogo min na, | o bɛ se ka kɛ fɛn ye min bɛ se ka kɛ fɛn ye min bɛ se ka kɛ fɛn ye . |

| sɛbɛnni teliya . | 30-50 mm/s . | Jamanjan |

| Layɛrɛ janya . | 0,15-0,25mm . | Hakɛ |

| Koli janya . | 1,2-2,0mm . | Jamanjan |

| Densité infill . | 20-40% . | Hakɛ |

Fan teliya ladilikanw:

Layɛrɛ fɔlɔ: 0% .

Bridges: 15-20%

Overhangs: 10-15%

Layers standards: 5-10%

Layɛrɛ fɔlɔ jateminɛw .

Fɔlɔ layɛrɛ ɲɛtaa bɛ nɔba bila sɛbɛnni bɛɛ lajɛlen jogo la. Jateminɛw y’a jira ko layɛrɛ fɔlɔ sigicogo ɲuman bɛ dɔ fara ɲɛtaa hakɛw kan ni 90% ye.

Sumanikɛlanw:

z-offset: 0,1-0.15mm Layɛrɛ janya: 0,2-0,3mm Layini bonya: 120-130% dilan hakɛ: ±0,02mm

Gɛlɛyaw ɲɛnabɔli 3D sɛbɛnni ni ABS ka koɲɛw la minnu bɛ kɛ tuma bɛɛ .

Print qualité gɛlɛyaw .

Sɛgɛsɛgɛli bɛ dɛsɛcogo fɔlɔw ni a furakɛcogo jira:

Defaults commun Analysis:

| Issue | frequency | Primaire de procédure | de fixe après |

| Warping . | 45% . | Delta de température . | 85% . |

| Layɛrɛ danfara . | 30% . | Adhesion jugu . | 90% . |

| Surface defauts . | 15% . | Bugun | 95% . |

| Dimensionnel inaccuracy . | 10% . | Calibration . | 98% . |

Ko minnu bɛ tali kɛ fɛnw na .

Moisture Impact Metrics:

A tali hakɛ: 0,2-0,3% tile kɔnɔ .

Fanga dɔgɔyali: fo ka se 40% ma .

Surface Quality Degradation: A bɛ ye ji hakɛ 2% kɔfɛ .

Print dɛsɛ bɛ caya: 65% ni filament ɲiginnen ye .

A maracogo minnu bɛ fɔ:

Funteni: 20-25°C Nɔgɔya hakɛ: <30% Fiɲɛ hakɛ: Minɛn fitinin suguya: fiɲɛ tɛ don a la ni a jalen don

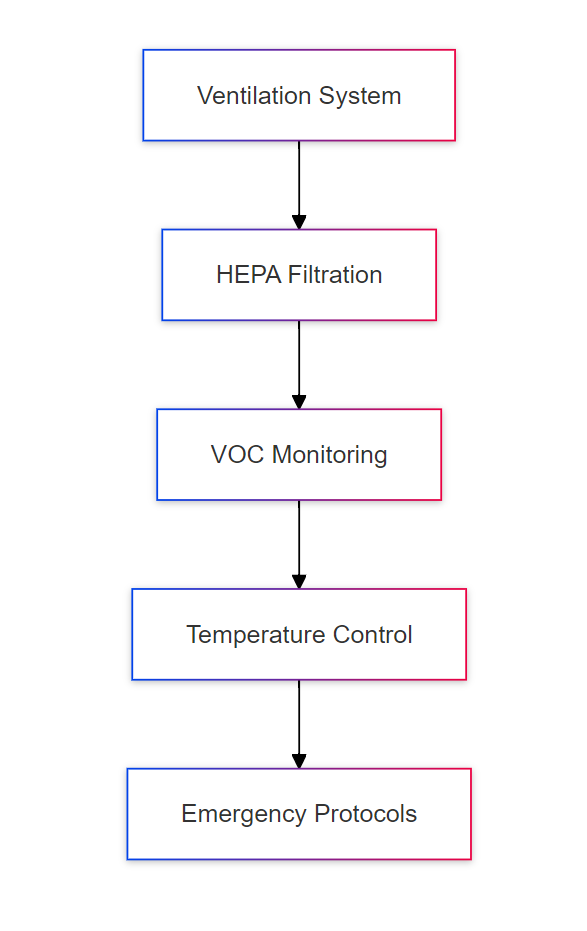

Sigida gɛlɛyaw .

Sigida kɔlɔsili bɛ nɔba bila sɛbɛnni ɲɛtaa la:

Fɛn minnu bɛ na ni nɔ ye:

Funteni jiginni (±5°C = 70% Dɛsɛ hakɛ)

A ye sɛgɛsɛgɛli kɛ (>0,3 m/s = 85% dɛsɛ hakɛ)

Nɛnɛ caman ɲɔgɔnna (>50% RH = 60% jogo dɔgɔyali) .

VOC dalajɛli (>100 ppm = kɛnɛya farati)

Baara kɔfɛ fɛɛrɛw ABS sɛbɛnnenw kama .

Surface Finishing .

Progressive Sanding protocole bɛ kɛ surface refinement jusigilan ye. Aw bɛ a daminɛ ni 120-grit sandpaper ye walasa ka layini fɔlɔ bɔ, ka taa ɲɛ dɔɔni dɔɔni ka tɛmɛ 240, 400 ani 800 grits fɛ. Nin fɛɛrɛ sigilen in bɛ dugukolo sanfɛla yiriwali kelen de sabati k’a sɔrɔ a ma sigicogo dafalen tiɲɛ.

Baarakɛminɛn nafamaw ani fɛn nafamaw minnu ka kan ka kɛ walasa ka baarakɛlaw ka jaabiw sɔrɔ olu ye:

| Baarakɛminɛn suguya | kɛrɛnkɛrɛnnenw | kuntilenna |

| Abrasives . | Sandpaper ɲiginnen/jalen (120-2000 grit) . | Nivoya surface . |

| Seko ni dɔnko baarakɛminɛnw . | Sander min bɛ teliya orbital orbital . | Yɔrɔba baarakɛcogo . |

| Bolo baarakɛminɛnw . | Sanding blocs, files . | Detail baara . |

| Fɛn minnu bɛ se ka kɛ . | Polishing compounds, microfibre finiw . | Finishing laban . |

Polishing fɛɛrɛ minnu bɛ taa ɲɛ, olu bɛ dugukolo sanfɛla cogoya bonya ka tɛmɛ basigilen kan:

Buffing mécanique bɛ kɛ ni wotoroninw ye .

Polishing ɲiginnen ni diamant pastes .

Micro-mesh padding ka ɲɛsin ultra-smooth fini ma .

Rotary Tool techniques ka ɲɛsin yɔrɔw ma minnu ɲɛfɔlen don .

kemikoro furakɛli .

AsetOne smoothing processus bɛ kɛ sababu ye ka professional-grade surface fini:

Basic Parameters:Temperature: 45-50°C A bɛ sɔrɔ a la ko a bɛ kɛ waati min na: miniti 15-30 fiɲɛbɔ waati: miniti 60+ So kɔnɔ Volume: 2L 100cm⊃ fan

Vapor Smoothing Safety Protocols bɛ tugu kosɛbɛ ka tugu ɲɔgɔn kɔ:

Aplikasi fɛɛrɛw bɛ danfara ka kɛɲɛ ni a yɔrɔ dɔw ka gɛlɛya ye:

Directe vapor exposition ka ɲɛsin jateminɛ nɔgɔmanw ma .

Furakɛli min bɛ kɛ ni so kɔnɔ yɔrɔ gɛlɛnw ye .

Brush application ka ɲɛsin sugandili ma .

Dipping technique ka ɲɛsin furakɛli kelen ma .

Lajɛ ni finidoncogo .

Bonding Techniques Selection Criteria:

| Fɛɛrɛ | Fanga | waleyali waati | Baarakɛcogo ɲuman ko . |

| Solvent welding . | Kosɛbɛ sanfɛ . | 5-10 min . | Jogindaw sigicogo . |

| Bonding thermal . | Jamanjan | 15-20 min . | Surfaces belebelebaw . |

| adhesive joining . | Hakɛ | 30-45 min . | Assemblées complexes . |

Surface labɛnni sinsinni walasa ka ɲɛtaa ɲuman sɔrɔ:

Mekaniki saniya (120-grit abrasion) .

Degreasing chimique .

Surface activation furakɛli .

Primer application .

penti labɛnni .

Lajɛ laban ka laadilikanw bɛ baarakɛlaw ka sɔrɔw sabati:

Alignment verification ni jigs ye .

Sequential Assembly Planning .

Stress Point barika bonya .

Quality Control checkpoints .

Baarakɛcogo sɛgɛsɛgɛli taabolo .

Surface furakɛli suganditaw bɛ finidoncogo suguya caman di:

primer application techniques .

penti bɛnkan jateminɛw .

Coat lakanani fɛɛrɛw jɛlen .

Texture application procedures .

A kɛcogo ɲumanw ni a kɛcogo ɲumanw .

Materiel (fɛnw) minɛcogo .

Storage Environment Metrics:

Optimal Conditions:Siya: 20-22°C Nɛnɛ hakɛ: 25-30% Yeelen yeelen: <50 Lux Fiɲɛ hakɛ: 0,5-1,0 ACH

Jogoɲumanya ladonni sariyaw:

Dɔgɔkun kɔnɔ ji kɔnɔkow sɛgɛsɛgɛli .

Saman o kalo saba fɛnw sɛgɛsɛgɛli .

Sigida kɔlɔsili sabatili .

A bɛ kɛ tuma bɛɛ desicant replacement .

Print optimisation .

Baarakɛcogo ɲɛtaa kunnafoniw:

| Optimisation Step | Quality Impact | Time Investissement | ROI Rating . |

| Funteni hakɛ jateminɛ . | +40% | sanga 2 . | Jamanjan |

| Tuning retraction . | +25% | 1 lɛrɛ . | Hakɛ |

| Teliya optimisation . | +20% | sanga 3 . | Jamanjan |

| Flow rate adjustment . | +15% . | Miniti 30 . | Kosɛbɛ sanfɛ . |

Kɔrɔbɔli sɛbɛnw sɛgɛsɛgɛli:

Funteni sankanso (miniti 45) .

Kɔrɔbɔli sɛgɛsɛgɛli (miniti 30) .

Bridging test (miniti 20) .

Jateminɛ kɛlen kɔfɛ (miniti 25) .

Lakanali jateminɛw .

Baarakɛyɔrɔ Lakanali sariyaw:

Lakanali jateminɛ nafamaw:

Fiɲɛ wari falen hakɛ: 6-8 ACH .

VOC dakun: <50 ppm .

Filtration particulaire : 0,3μm ni 99,97% ye .

Kɔrɔtɔko jaabi waati: <sekɔndi 30 .

Kuncɛli

Taama min bɛ kɛ ABS 3D sɛbɛnni na, o b’a ka gɛlɛyaw n’a seko kabakomaw bɛɛ jira. Hali ni a bɛ ɲini ka jateminɛ kɛ kosɛbɛ funteni hakɛ kunbɛnni na, fiɲɛ bilali la ani sɛbɛnni na, ABS sɛbɛnni mastering saraw ka bon kosɛbɛ. A ka muɲuli, a ka funteni kunbɛncogo, ani a ka baarakɛcogo kɔfɛ, o faralen ɲɔgɔn kan, o bɛ taa a fɛ ka kokuradonni bila senkan iziniw kɔnɔ.

Ni faralifɛnw dilanni fɛɛrɛ bɛ ka wuli, ABS bɛ to ɲɛfɛ, a bɛ ladamu baarakɛcogo kuraw ni gɛlɛyaw la. ABS sɛbɛnni nata bɛ i ko layidu talen, ni yiriwaliw bɛ senna fɛnw dɔnniya ni sɛbɛnni fɛɛrɛw la minnu bɛ layidu ta ko sekobaw bɛ se ka kɛ ka tɛmɛn fɔlɔ kan nin filament caman in na.

Aw labɛnnen don ka aw ka 3D sɛbɛnni tulon kɔrɔta ni ABS ye? Team MFG bɛ na ni ABS sɛbɛnni ɲɛnabɔcogo ye min bɛ kɛ ni baarakɛlaw ye, n’a bɛ dɛmɛ ni san tan caman dilanni dɔnniya ye. K’a ta prototype la ka se production ma, an bɛna aw dɛmɛ ka ABS ka seko bɛɛ da wuli. Aw bɛ se ka kuma an ka dɔnnikɛlaw fɛ bi walima ka taa bɔ . Ekipu MFG ka lajɛ fu.

Reference sources .

3D sɛbɛnni .

ABS Plastique .

3D sɛbɛnnikɛminɛnw .

Ɲininkali minnu bɛ kɛ tuma caman na: 3D sɛbɛnni ni ABS .

Q1: Mun na ne ka abs print warp?

A: Warping bɛ sɔrɔ ka bɔ nɛnɛmadacogo la min tɛ kelen ye. Aw bɛ dilan sumayalen (100-110°C) kɛ, ka a datugu, ani ka a siricogo ɲumanw kɛ.

Q2: Yala ABS ye baga ye wa?

A: Ɔwɔ, ABS bɛ sisi bɔ sɛbɛnni kɛtuma na. Aw bɛ fiɲɛ bila tuma bɛɛ ani ka a datugu. Aw bɛ aw yɛrɛ tanga fɛnw sɔrɔli ma minnu bɛ mɛn sen na.

Q3: Printing température ideale ye mun ye?

A: Nɔgɔ: 230-250°C

Dilan: 100-110°C

So: 45-50°C

Q4: Mun na ne mago bɛ dakun na?

A: Datugulanw bɛ funteni mara, ka warping bali, ka sisiw don u la, ani ka layɛrɛ nɔrɔli ɲɛ.

Q5: Ne ka kan ka ABS mara cogo di?

A: Minɛn minnu bɛ fiɲɛ bila u la, olu bɛ sɔrɔ 20-25°C la, u ka nɛnɛ hakɛ bɛ se 30% ma.

Q6: ABS nɔgɔyacogo ɲuman?

A: Asetɔni vapor smoothing (teliya, glossy) walima sanding progressive (contrôle more).

Q7: Mun na sɛbɛnniw bɛ kari?

A: A ka c’a la, a bɛ bɔ filament ɲiginnen na, funteni dɔgɔyali, walima layɛrɛ nɔrɔbaliya. Filament jalen ani ka dɔ fara funteni kan walasa ka a labɛn.