Polisitiri (PS) plastiki bɛ yɔrɔ bɛɛ. K’a ta pakew dilanni na ka se ɛntɛrinɛti ma, a jɔyɔrɔ ka bon kosɛbɛ an ka don o don ɲɛnamaya kɔnɔ. Nka mun de b’a to a bɛ baara kɛ kosɛbɛ?

Nin barokun in kɔnɔ, an bɛna PS Plastic ka nafolo sɛgɛsɛgɛ , mun na a nafa ka bon izini suguya caman na, ani a bɛ baara kɛ cogo min na. Aw bɛna a ka baarakɛcogo, a ka fɛn caman sɛmɛntiya, ani a bɛ gɛlɛya minnu jira, aw bɛna olu dɔn.

Polisitiri (PS) plastiki ye mun ye?

PS ye polimɛri sintetiki ye. A bɛ dilan ni stirilɛni ye, o ye hidrɔkarɔbɔni jilama ye. Styrene ka kemikaliya formula ye C8H8 ye. Ni stirilɛni mɔlikulu caman bɛ ɲɔgɔn na, u bɛ polistirini dilan.

A bɛ baara kɛ cogo min na, o filɛ nin ye:

Styrene monomɛriw bɛ bɔ petoroli la.

O monomɛriw bɛ polimerizasiyɔn sɔrɔ.

O kɔlɔlɔ ye? Styrène unitéw ka cakɛda janw, ka polisitiri dilan.

PS ka kemikaliya cogoya bɛ i n’a fɔ nin:

[-CH(C6H5)-CH2-]N .

Min:

CH bɛ karɔbɔli ni idɔrɔzi atomu jira .

C6H5 ye Benzene bololanɛgɛ ye .

n ye repeating units hakɛ ye .

PS Plastiki bɛ sɔrɔ cogoya wɛrɛw la:

Plastiki solide (transparent et rigide) .

Fomu (a ka nɔgɔn ani a bɛ a tanga) .

Filimu (min ka ɲi ani a bɛ se ka wuli ka bɔ a nɔ na) .

Foroko kelen-kelen bɛɛ bɛ ni jogo kɛrɛnkɛrɛnnenw ye. U bɛ Kɛ baara suguya caman na, k’a Tà pakew dilanni na ka Taa Se u jɔli ma.

PS bɛ dɔn a ka:

O jogo ninnu bɛ PS kɛ sugandili ye min bɛ fɔ kosɛbɛ izini caman kɔnɔ. A ka nɔgɔn, a dilanni ka nɔgɔn, wa a dilanni musaka ka dɔgɔ.

Dakun nataw la, an bɛna an yɛrɛ Dòn PS ka nafaw, a ka baarakɛcogo ani a ka baarakɛcogo la. I bɛna a ye mun na nin polimɛri nɔgɔman in jɔyɔrɔ ka bon kosɛbɛ an ka don o don ɲɛnamaya kɔnɔ.

Polisitirini ka jogo ɲumanw .

PS Plastique farikolo yɔrɔw .

Polisitiri (PS) Plastiki bɛ farikolo yɔrɔ kɛrɛnkɛrɛnnen caman jira minnu b’a to a bɛnnen don izini baara suguya caman ma.

density ani yecogo .

PS ka nɔgɔn, a density ye 1,05 g/cm⊃3 ye;. O ye tad girinya dɔrɔn ye ka tɛmɛ ji kan!

A cogo gɛlɛn na, PS ye:

Jɛlen

Kulɛri tɛ .

Glossy .

O jɛya in b’a Kɛ dafalen ye baarakɛminɛnw na yɔrɔ minnu na yecogo nafa ka bon kosɛbɛ.

thermal characteristics .

PS bɛ ni funteni nafama dɔw ye:

O kɔrɔ ye mun ye? PS bɛ daminɛ ka nɔgɔya 100°C la. A bɛ wuli ka ɲɛ 240°C la.

A ka funteni-taama-cogo ka dɔgɔn ni 0,033 W/(m·k) ye. O bɛ PS kɛ insulatɛri ɲumanba ye.

Kuranko nafaw .

PS bɛ yeelen bɔ i n’a fɔ kuran insulatɛri. A ka teli ka kɛ ɛntɛrinɛti yɔrɔw ni so kɔnɔ.

Optical Properties .

PS bɛ waso ni kɛnɛya sabatili ye. A ka refractive index ye 1,59 ye, a ka ca ni plastiki caman wɛrɛw ye.

Nin nafolo in bɛ PS kɛ fɛn ɲuman ye:

Lenses optiques .

Diffusées de light .

Display Cases .

| nafolo | nafa . |

| Hakɛ | 1,05 g/cm³ |

| Yecogo | transparent, glossy . |

| Point de melting . | 240°C (464°F) |

| Glass transition température . | 100°C (212°F) |

| Sumaya min bɛ kɛ ni funteni ye . | 0,033 w/(m·k) . |

| Kuranko insulasi . | Ɲuman ɲuman |

| Optical Properties . | Transparence (Fɛnɲɛnabɔli) ka bon . |

| Index de réfraction . | 1.59 |

PS Plastique ka baarakɛcogo masinw .

Fanga ni fɛn caman sɛgɛsɛgɛli .

PS Plastiki bɛ fanga kabakoma jira:

Nka a tɛ se ka wuli ka bɔ a nɔ na kosɛbɛ. A janya bɛ Kɛ 1-2,5% dɔrɔn ye.

Gɛlɛya ni nɔ min bɛ sɔrɔ a la .

PS ka gɛlɛn, ni Rockwell ka gɛlɛya ye R75-105 ye. O b’a to a bɛ se ka sɔgɔsɔgɔninjɛ ni ɲinw furakɛ.

Nka, a bɛ kari ni fanga dɔgɔyali ye. Aw bɛ PS fɛn dɔ fili, a bɛ se ka kari walima ka a tiɲɛ.

gɛlɛya .

PS bɛ dɔn a ka gɛlɛya ka bon. O ye fɛn gɛlɛn ye, min b’a cogoya mara cogoya fanba la.

Nin ye PS ka masinko nafaw sumacogo teliya ye:

| nafolo | nafa . |

| Tensile fanga . | 30-55 MPa . |

| Flexural fanga . | 48-76 MPA . |

| Elongation ka break . | 1-2,5% . |

| Gɛlɛya (Rockwell) . | R75-105 . |

| Impact fanga . | Fɛ́gɛn |

| gɛlɛya . | Jamanjan |

O nafolo ninnu bɛ PS kɛ fɛn ɲuman ye baara dɔw kama:

PS Plastique ka fɛnɲɛnamafagalan ( resistance chimique ) .

PS Plastic ka kemikaliya ye bɔrɔ ɲagaminen ye. A bɛ jɔ fɛn dɔw la nka a bɛ jɔrɔ dɔw la.

Fura minnu bɛ sɔrɔ ɲɔgɔn fɛ .

PS bɛ resistance ɲuman jira:

Asidiw (Dilute) .

Bases .

dɔlɔw .

O b’a to a bɛnnen don du ni izini caman ma.

Barika dɔgɔya .

Nka, PS b’a ka Akilisi ta. A bɛ se ka wuli:

PS fana tɛ se ka kɛ ka ɲɛ:

Asidi caman bɛ sɔrɔ .

Esters .

Ketones .

Olu bɛ se ka kɛ sababu ye ka PS tiɲɛ walima ka a wuli.

UV resistance .

PS ka UV kɛlɛli man ɲi. Ni tile yeelen bɛ a la, a bɛ teli ka kɛ:

Nɛrɛmuguman

Aw ka kɛ brittle ye .

A bɛ dɔgɔya waati kɔnɔ .

O bɛ dan Kɛ a baara la kɛnɛyako la.

Nin ye tabali teliyalen ye min bɛ tali kɛ a la:

| Kimikɛ kulu | ka rezisti . |

| Asidi dilute . | Duman |

| Bases . | Duman |

| dɔlɔw . | Duman |

| hidrɔkarɔbɔni aromatikiw . | Faantan |

| hidrɔkarbonw kulorilenw . | Faantan |

| Asidi caman bɛ sɔrɔ . | Faantan |

| Esters . | Faantan |

| Ketones . | Faantan |

| UV yeelen . | Faantan |

PS Plastique baarakɛcogo .

PS Plastiki ye fɛn ye min bɛ se ka kɛ fɛn caman ye. A bɛ kɛ izini suguya caman na, k’a ta pakew dilanni na ka se furakɛli minɛnw ma. An k’a ka baarakɛminɛnw sɛgɛsɛgɛ minnu bɛ yɔrɔ caman na.

pakew dilanni .

PS bɛ fanga sɔrɔ pakew dilanni diɲɛ kan. Aw bɛna a sɔrɔ:

Dumunikɛminɛnw ni tasaw .

Fomu min bɛ a tanga, o bɛ kɛ .

Clamshells ani Blister pakew .

A ka nɔgɔn cogoya n’a ka fɛnw dilanni na, o b’a to a ka ɲi kosɛbɛ dumuni pakew kɔnɔ.

Elektroniki .

Elektroniki baara la, PS jɔyɔrɔ ka bon kosɛbɛ:

PS ka kuran-sɛnɛfɛnw b’a Kɛ ‘fɛn ye min bɛ Taa ‘ɲɛ ‘kɔnɔ ‘elektɔriki baarakɛcogo la.

Mobili industrie .

Mobili dilannikɛlaw bɛ PS kanu a ka fɛn caman na:

PS bɛ dɛmɛ don ka mobili girinya dɔgɔya, ka sɛnɛfɛnw sɛnɛcogo ɲɛ.

Sojɔ

XPS Polystyrène foam board .

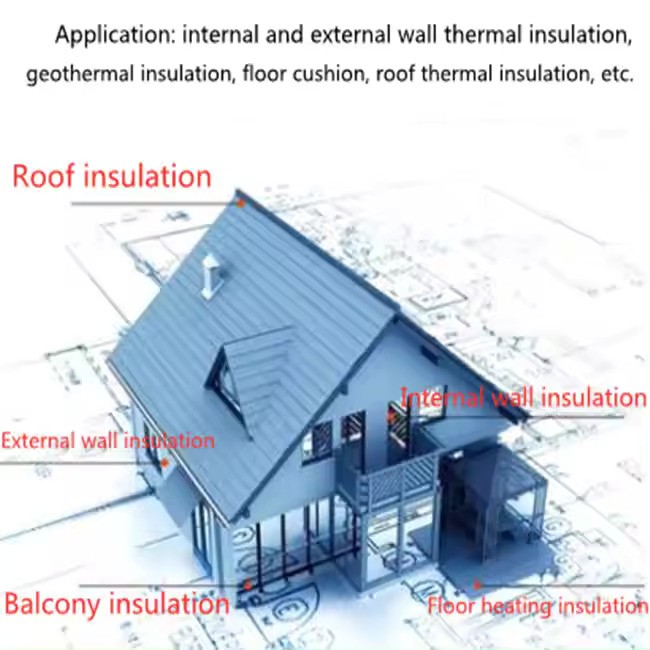

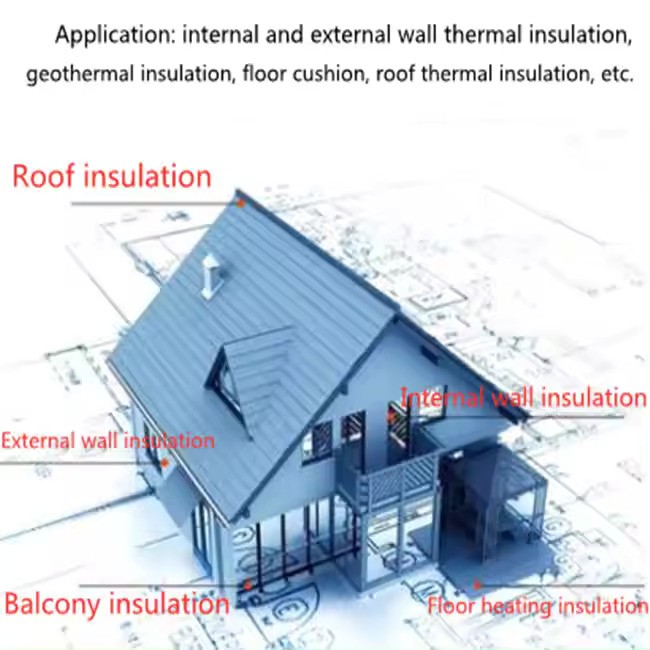

PS bɛ sira sɔrɔ ka don sow kɔnɔ fana:

Insulation boards (EPS ani XPS) .

Decoratif mouldings ani trim .

Béton applications nɔgɔmanw .

A ka insulasi nafaw bɛ dɛmɛ ka fanga sɔrɔcogo ɲɛ sow kɔnɔ.

Dɔgɔtɔrɔso ni laboratuwari .

PS nafa ka bon kosɛbɛ furakɛli ni dɔnniya siratigɛ la:

A jɛlen ni a kemikaliya b’a to a dafalen don laboratuwaari minɛnw kama.

Aplikasi wɛrɛw .

PS ka fɛn caman kɛli bɛ taa fo yɔrɔ caman wɛrɛw la:

Tulonkɛfɛnw ni fɛn minnu bɛ kɛ ka fɛnw feere .

Minɛnw ni tabali minnu bɛ kɛ siɲɛ kelen .

Modeli dilanni ani prototyping .

Nin ye PS baarakɛminɛnw ɲɛfɔli teliya ye:

| Industriw | ka baarakɛminɛnw . |

| pakew dilanni . | Dumunikɛminɛnw, Fomu min bɛ mɔgɔ tanga, a bɛ kɛ ka fɛnw feere. |

| Elektroniki . | Minɛnw ka so, insulasi, CD/DVD ko . |

| Mobili . | Kɔnɔna trim, minɛnw pannew, fɛnw jɔcogo . |

| Sojɔ | Insulation boards, decoratif mouldings, bɛton nɔgɔman . |

| Dɔgɔtɔrɔso/Lab . | Petri minɛnw, sɛgɛsɛgɛli yɔrɔw, minɛnw pakew . |

| Dɔ wɛrɛ | Tulonkɛfɛnw, minɛnw minnu bɛ kɛ siɲɛ kelen, prototyping . |

PS Plastiki caman bεε bε bεn .

PS Plastiki bɛ se ka fɛn caman sɛmɛntiya cogoya caman na walasa k’a ka nafaw yiriwa baara suguya caman na. O bεε bε bεn kopolimɛriw, farankanw ani fomuw ma.

Kopolimɛriw ni u ɲagaminenw .

Polisitirini ka teli ka ɲagami walima ka kopolimɛri kɛ ni fɛn wɛrɛw ye walasa ka a ka fɛnw minɛcogo ɲɛ, ka u sɛgɛsɛgɛ, ani ka u ka funteni sabati.

Polisitirini min bɛ se ka nɔba bila mɔgɔ la (HIPS) .

Hips ye PS ye ni twist ye. A ka gɛlɛn ani a bɛ se ka wuli ka tɛmɛ PS kan tuma bɛɛ.

Kɛ fɛnw

Hips bɛ dilan ni polibutadiyɛni lastikuw farali ye PS kan. O bɛ kɛ sababu ye ka fasa fila-fila kɛ:

Propriétés en trouvés .

Ni i ye a suma ni PS basigilen ye, hips bɛ o di:

Aplikasi .

Hips bɛ sira sɔrɔ ka don fɛn caman na:

hips vs générale public PS

| property hips | general | kuntilenna PS . |

| Impact fanga . | Jamanjan | Fɛ́gɛn |

| Flexibilité . | Duman | Faantan |

| Opacity . | Opaque . | Jɛlen |

| Sɔngɔ | sanfɛ . | Ka lajigin |

Acrylonitrile Butadiene Styrene (ABS) .

ABS ye plastiki gɛlɛn ye min bɛ PS. A bɛ Dɔn a ka fanga n'a ka funteni-ko la.

PS jɔyɔrɔ ABS la .

PS bɛ dɛmɛ don ABS ta la:

rigidité .

A baara nɔgɔya .

Gloss .

jogo ɲumanw .

ABS bɛ tɛmɛ PS kan cogo caman na:

ABS baarakɛcogo minnu bɛ kɛ tuma caman na .

Aw bɛna ABS sɔrɔ:

Mobili yɔrɔw .

Elektronikiw ka so .

Pipe Systems .

LEGO birikiw .

PS Kopolimɛri wɛrɛw ni a ɲagaminenw .

PS bɛ tulon kɛ koɲuman ni mɔgɔ wɛrɛw ye. Yɛlɛma wɛrɛw filɛ nin ye minnu bɛ fɔ kosɛbɛ:

PS-Co-methyl methacrylate (PSMMA) .

PSMMA bɛ PS ni methél methacrylate fara ɲɔgɔn kan. A bɛ nin fɛn ninnu di:

A bɛ kɛ kɛnɛma taamasiyɛnw na ani ɲɛkisɛw la.

Styrène-butadiene ka lastikuw (SBR) .

SBR ye lastikuw ye minnu dilannen don. A bɛ dilan ni copolimerizing styrene ye ni butadiene ye. SBR bɛ:

I bɛ SBR sɔrɔ mobili pankurunw ni sanbara soles kɔnɔ.

farankanw ni filɛriw .

PS plastiki bɛ se ka bonya ni faralifɛnw ye walasa ka baara kɛcogo kɛrɛnkɛrɛnnenw ɲɛnabɔ.

Kulɛriw ni ɲɛgɛnw : Olu bɛ kɛ ka kulɛri suguya caman di, o bɛ kɛ sababu ye ka PS fɛnw kɛ ka ɲɛnajɛko wajibiyalenw dafa.

Flame Retardants : O farankanw bɛ PS tasuma kunbɛn, o b’a to a bɛ lakana ɛntɛrinɛti ni jɔli la.

Impact modifiers : O fɛnw bɛ fara a kan walasa ka PS gɛlɛya bonya, ka dɔ bɔ a ka tiɲɛni na ani ka a baara bonya yɔrɔw la minnu bɛ se ka fɛn caman kɛ.

Antistatic Agents : olu bɛ fara ɲɔgɔn kan walasa ka dɔ bɔ static buildup la, kɛrɛnkɛrɛnnenya la min nafa ka bon ɛntɛrinɛti yɔrɔw la yɔrɔ minnu na static bɔli bɛ se ka tiɲɛni kɛ.

Fomuw ni fɛnɲɛnamafagalanw .

PS bɛ se ka fomu walima ka fara fɛn wɛrɛw kan walasa ka fɛnw dilan minnu ka nɔgɔn, minnu bɛ mɔgɔ tanga.

Polisitiri (EPS) min bɛ bonya : A bɛ kɛ ka caya ka ɲɛsin fɛnw ma minnu bɛ u tanga ani u lakanani, EPS ye fomu nɔgɔman ye min bɛ funteni insulasicogo ɲumanw di.

Polisitiri (XPS) min bɛ bɔ kɛnɛma (XPS) : XPw ka ca ni EPS ye, o b’a to a bɛnnen don kosɛbɛ baarakɛcogo ma yɔrɔ minnu na ji bɛ se ka wuli ka bɔ a nɔ na, i n’a fɔ insulasi jɔli.

PS Foam Composites with fibres walima fillers : Nin composites ninnu bɛ PS ni fɛnw fara ɲɔgɔn kan i n’a fɔ gilasi fiyɛw walima minerali falenfɛnw walasa ka fanga, funteni kunbɛn, walima masinw cogoyaw ɲɛ, o b’a to u bɛnnen don baara caman kɛli ma.

PS Plastique baarakɛcogo .

Polisitiri (PS) plastiki bɛ se ka baara kɛ ni fɛɛrɛ caman ye, ka kɛɲɛ ni a kɛcogo ye. Taabolo kelen-kelen bɛɛ bɛ nafa kɛrɛnkɛrɛnnenw di, wa a bɛ jateminɛ kɛrɛnkɛrɛnnenw de wajibiya.

Pikirili Molidali .

Pikiri kɛli ye PS plastiki baaracogo ye min ka teli ka kɛ. O ye ka PS mɔlenw pikiri kɛ fɛn dɔ la, ka a to yɔrɔ gɛlɛnw ni yɔrɔ ɲɛfɔlenw ka dilan ka ɲɛ.

Taabolo ɲɛfɔli ni nafa : PS bɛ wuli ka pikiri kɛ mɔbiliw la a bɛ nɛnɛ ani ka gɛlɛya yɔrɔ minnu na. O kɛcogo bɛ teliya, a musaka ka dɔgɔ, wa a bɛ se ka yɔrɔw dilan minnu ka bon kosɛbɛ, minnu ka gɛlɛn, ni u hakɛ bɛ se ka kɛ cogo ɲuman na.

Dilancogo jateminɛ minnu bɛ kɛ PS yɔrɔw la minnu dilannen don ni pikiri ye : k’a sababu kɛ a karicogo ye, PS bɛ a ɲini ka jateminɛ kɛ kosɛbɛ kogo janya ni a bɔli dilancogo la walasa a kana kari. Ka fara o kan, nɛnɛ hakɛ ni funteni hakɛ kunbɛnni nafa ka bon kosɛbɛ walasa ka kirinni dɔgɔya.

Gɛlɛyaw ɲɛnabɔli pikiri kɛli ko la min bɛ kɛ tuma caman na : Gɛlɛya minnu bɛ sɔrɔ tuma caman na, olu ye dɔgɔyali, kirinni, ani kari. Olu bɛ se ka latilen tuma caman na ni mɔbili dilanni ladilanni ye, ka nɛnɛ kɛcogo kɔrɔsi, ani ka fɛn in ka nɔgɔjibɔlan sɛgɛsɛgɛli kɛ.

Extrusion .

Extrusion ye fɛɛrɛ wɛrɛ ye min bɛ fɔ kosɛbɛ PS plastiki labɛnni na, kɛrɛnkɛrɛnnenya la, ka cogoya janw, minnu bɛ to senna i n’a fɔ sɛbɛnw, pipew, ani profilew.

Process Overview and Applications : Extrusion kɔnɔ, PS bɛ wuli ani ka jagoya ka tɛmɛ die fɛ walasa ka siginidenw kɛ minnu bɛ to senna. A bɛ kɛ ka caya walasa ka sɛbɛnw, berew ani pipew dilan ..

PS Plastic ka Extrusion Grades : PS suguya wɛrɛw bɛ sɔrɔ ka bɔ kɛnɛ kan, u kelen-kelen bɛɛ bɛ ɲɛ ka ɲɛsin baara suguya wɛrɛw ma, i n’a fɔ filimu bɔli walima sheet extrusion.

Coextrusion ni polimɛri wɛrɛw ye : PS fana bɛ se ka kɛ ɲɔgɔn fɛ ni plastiki wɛrɛw ye walasa ka baara kɛcogo ɲɛ, i n’a fɔ a bɛ se ka kɛ cogo min na ka ɲɛ walima a bɛ se ka muɲu. Coextrusion bɛ sira di fɛn caman ma minnu bɛ fɛnw nafa fara ɲɔgɔn kan.

thermoforming .

thermoforming bɛ PS sɛbɛnw sumaya ani k’u cogoya kɛ ka u kɛ nɔgɔw kan. Nin fɛɛrɛ in ka ɲi kosɛbɛ walasa ka yɔrɔbaw dilan minnu ka nɔgɔn i n’a fɔ pakew ni sarɛtiw.

Vacuum formation and pressure formation techniques : Ni vacuum formation, PS sɛbɛn min bɛ funteni na, o bɛ ja nɔgɔ kan ni vacuum ye. Degun sɔrɔli la, degun wɛrɛw bɛ kɛ walasa ka kunnafoni ɲumanw sɔrɔ ani ka nkɔni nɔgɔlenw sɔrɔ.

Sheet extrusion and roll stock production : PS sɛbɛnw bɛ sɔrɔ cogoya la extrusion fɛ ka sɔrɔ ka baara kɛ ni u ye thermoforming process kɔnɔ. Roll Stock ye foroko wɛrɛ ye min bɛ kɛ ka caya ka ɲɛsin mass production ma.

thermoforming design guidelines : Ni PS yɔrɔw bɛ dilan ka ɲɛsin thermoforming ma, u janya kelen ani u draft angles bɛnnenw nafa ka bon yɔrɔ bɔli la ani ka u tanga ka dɔgɔya nkɔni na.

Baarakɛcogo wɛrɛw .

Fɛɛrɛ kunbabaw kɔfɛ, PS plastiki bɛ se ka baara kɛ ni fɛɛrɛ wɛrɛw ye walasa ka mago kɛrɛnkɛrɛnnenw ɲɛnabɔ.

Blow Molding : PS bɛ wuli ka a fiyɛ ka kɛ bɔgɔ ye walasa ka yɔrɔ dogolenw dilan, i n’a fɔ buteliw ni minɛnw.

Rotational Molding : Nin fɛɛrɛ in bɛ kɛ ni PS sumayalen ye fɛn dɔ la min bɛ wuli ka wuli, ka fɛnw dilan minnu kɔnɔna bɛ wuli, minnu tɛ fɛn tiɲɛ i n’a fɔ tanki belebelew walima minɛnw.

Compression moulding : compression molding kɔnɔ, PS bɛ bila module sumayalen na, degun bɛ kɛ yɔrɔ min na walasa ka fɛn in cogoya. Nin fɛɛrɛ in man ca PS la nka a bɛ kɛ ka baara kɛrɛnkɛrɛnnenw kɛ minnu bɛ yɔrɔ barikamaw ɲini minnu ka gɛlɛn.

PS Plastiki ka fɛnw lasegincogo ani u ka sigida laminiko .

PS Plastiki bɛ kɛ ka caya, nka a ka sigida laminiko ye haminanko ye min bɛ ka bonya. An ka don fɛnw lasegincogo gɛlɛyaw la ani sigida koɲɛw la minnu bɛ PS lamini.

PS Plastique ka baara kɛcogo kura .

PS bɛ se ka segin a cogo kɔrɔ la, nka a tɛ tilennen i n’a fɔ plastiki tɔw. Aw ka kan ka min dɔn, o filɛ nin ye:

PS bɛ se ka segin a cogo kɔrɔ la siɲɛ caman ni a ka jogoɲini nafama tɛ .

A bɛ dɔn ni recyclage taamasiyɛn #6 ye .

Segin-ka-bɔnye kɛyɔrɔ caman tɛ sɔn PS ma k’a sababu kɛ baarakɛcogo gɛlɛyaw ye .

Gɛlɛyaw bɛ sɔrɔ fɛnw lasegincogo la .

Recyclage PS tɛ ko nɔgɔn ye. Balifɛn damadɔw b’a to a man teli ka kɛ ni plastiki tɔw ye:

Nɔgɔya: Dumuni tolenw ka teli ka PS dumunikɛminɛnw nɔgɔ .

Density: PS ye yeelen ye, o b’a to a bɛ se ka ta ka taa ni a ye .

Sugu ɲinini: Sugu danma ka ɲɛsin PS fɛnw ma minnu bɛ segin ka kɛ fɛn wɛrɛw ye .

Baarakɛcogo: Minɛn kɛrɛnkɛrɛnnen minnu ka kan ka kɛ PS lasegincogo la .

O gɛlɛyaw b’a to PS lasegincogo sɔrɔko siratigɛ la, fɛn caman bɛ se ka kɛ minnu na.

Sigida haminankow .

PS bɛ sigida ko caman jira:

Non-biodegradable .

PS tɛ tiɲɛ a yɛrɛ la. A bɛ se ka to sigida la san kɛmɛ caman kɔnɔ.

Ɲaman

PS fɛn nɔgɔmanw bɛ kɛ nɔgɔ ye nɔgɔya la. U bɛ sɔrɔ tuma caman na nbɛdaw la ani sigida la.

Kɔgɔjida nɔgɔli .

PS ye dɛmɛba ye kɔgɔjida nɔgɔli la. A bɛ kari ka kɛ fɛn misɛnninw ye, ka kɔgɔji kɔnɔ fɛnɲɛnamaw tiɲɛ.

Fɛɛrɛ wɛrɛw ani fura sabatilenw .

Walasa ka nin haminankow ɲɛnabɔ, fɛɛrɛ wɛrɛw ni furakɛli caman bɛ ka bɔ kɛnɛ kan:

Fɛn wɛrɛw minnu bɛ se ka tiɲɛ biodigradable .

Fɛɛrɛ kuraw minnu bɛ se ka kɛ ka fɛnw lasegin u cogo kɔrɔ la .

Dɔgɔyali fɛɛrɛw .

PS minnu bɛ kɛ ka baara kɛ ni u kelen ye, olu balili ye mara dɔw kɔnɔ .

Dusu donna baara wɛrɛw la minnu bɛ se ka baara kɛ ni u ye kokura .

Nafa kura minnu bɛ sɔrɔ PS recyclés la .

jɔli minɛnw .

Lumber synthétique .

Seko ni dɔnko fɛnw .

Nin ye PS suma ye ni fɛɛrɛ wɛrɛw ye:

| fɛnw | biodegradable | recyclable | relative cost . |

| PS . | Ayi | Ɔwɔ (gɛlɛya) . | Fɛ́gɛn |

| PLA . | Awɔ | Awɔ | Hakɛ |

| PBS . | Awɔ | Awɔ | Jamanjan |

| Papiye | Awɔ | Awɔ | Fɛ́gɛn |

PS bɛ se ka nɔ min bila sigida la, o nafa ka bon kosɛbɛ. Nka ni fɛɛrɛ kuraw ni fɛɛrɛ wɛrɛw ye, an bɛ ka taa ɲɛnabɔli sabatilenw na.

Aw bɛ a suma ni plastiki wɛrɛw ye .

Polisitiri (PS) ka teli ka suma ni plastiki wɛrɛw ye minnu bɛ fɔ kosɛbɛ, u kelen-kelen bɛɛ bɛ jogo danfaralenw di. Nin ye PS stack up ye PP , PET , ani PVC kan ..

PS ni PP (polypropylene)

Density : PS ka density ( 1,05 g/cm³ ) bɛ a la ni a bɛ tali kɛ PP la, o min ka nɔgɔn ( 0,91 g/cm³ ). O bɛ kɛ sababu ye ka PP bɛnnen don kosɛbɛ baarakɛcogo nɔgɔmanw na.

Flexibilité : PP bɛ se ka wuli ka bɔ a nɔ na ani a tɛ tiɲɛ ka tɛmɛ PS kan, o b’a to a ka fisa ni baara kɛtaw ye minnu bɛ se ka muɲu ani ka se ka nɔ bila a la, i n’a fɔ pakew ni mobili yɔrɔw.

Segin-ka-bɔnye : Hali ni plastiki fila bɛɛ bɛ se ka segin ka kɛ fɛn wɛrɛw ye, PP ka nɔgɔn ani a musaka ka dɔgɔ caman na ka tɛmɛ PS kan, o min bɛ gɛlɛyaw sɔrɔ a jɔcogo n’a tiɲɛni kosɔn.

| ka nafolo | PS | PP . |

| Hakɛ | 1,05 g/cm³ | 0,91 g/cm³ |

| Flexibilité . | brittle, less flexibles . | A bɛ se ka wuli ka bɔ a nɔ na kosɛbɛ . |

| Segin-ka-bɔnyew . | A ka gɛlɛn ka tɛmɛ o kan . | A ka nɔgɔn ani a ka ca . |

PS vs. PET (Polyéthylène Terephthalate)

Kɛnɛya : PS ni PET fila bɛɛ bɛ kɛnɛ kan, nka PET bɛ jɛya ɲuman di, o b’a to a bɛ kɛ fɛn ye min bɛ se ka sugandi jifilenw ni dumuniw foroko kɔnɔ, yɔrɔ minnu na yecogo nafa ka bon.

Fanga : PET barika ka bon ani a bɛ se ka a yɛrɛ tanga ka tɛmɛ PS kan. A fana bɛ se ka farikolo funteni caman wuli ka ɲɛ, o b’a to a ka ɲi kosɛbɛ sigida funteni ni nɛnɛma bɛɛ la.

A kɛcogo : PS ka fisa ni furaw ye i n’a fɔ CD kow ani fɛnw labɛncogo, ka sɔrɔ PET bɛ kɛ minfɛnw minɛnw na, u foroko dilanni na, ani fini fiyɛw la.

| Propriété | PS | PET . |

| Transparence . | transparent, jɛlen . | Sanuya sanfɛla . |

| Barika | brittle, less durable . | A barika ka bon, a bɛ mɛn ka ɲɛ . |

| Baarakɛcogo caman . | CD ka banaw, insulasi . | Minfɛn buteliw, fiyɛw . |

PS ni PVC (polyvinyl chlorure)

Flexibilité : PVC ka ca ni PS ye, o ye brittle ye. O b’a to PVC bɛnnen don pɔmpiw ma, kuran sɔgɔli, ani a foroko caman.

Furakɛcogo : PVC bɛ kemikaliya kunbɛncogo ɲuman di, kɛrɛnkɛrɛnnenya la asidiw ni alkaliw kama, o b’a to a bɛnnen don ka kɛ yɔrɔ minnu na, fura gɛlɛnw bɛ sɔrɔ yɔrɔ minnu na.

Laminiko gɛlɛya : PVC bɛ se ka sigida laminiko gɛlɛya kosɛbɛ ka da a kan kulori toxic (toxic) bɔli bɛ kɛ a dilanni ni a bɔli waati la, k’a sɔrɔ PS ka sigida gɛlɛyaba ye a lasegincogo ye.

| ka nafolo | PS | PVC . |

| Flexibilité . | brittle . | Labilalen |

| kemikɛli resistance . | Ka bɛrɛbɛn | Jamanjan |

| Sigida laminiko gɛlɛya . | A ka gɛlɛn ka segin a cogo kɔrɔ la . | Toxic sɔrɔli ni a filili . |

Kuncɛli

PS plastiki ye fɛn caman ye ani a bɛ kɛ ka caya. A bɛ Dɔn a ka jɛya, a ka gɛlɛya, ani a ka insulasi cogoyaw fɛ. PS bɛ baarakɛcogo sɔrɔ pakew, ɛntɛrinɛti ani jɔli la.

Yɛlɛma minnu bɛ kɛ i n’a fɔ hips ani ABS bɛ a ka baara kɛcogo ɲɛ. Baarakɛcogo suguya caman, i n’a fɔ pikiri kɛcogo ani thermoforming, olu bɛ PS kɛ fɛn suguya caman ye.

PS grade ni baarakɛcogo ɲuman sugandili nafa ka bon kosɛbɛ. A bɛ baara kɛcogo ɲuman sabati baara kɛrɛnkɛrɛnnenw na. Aw ye fɛnw jateminɛ i n’a fɔ fanga, fɛnɲɛnamafagalanw tali, ani sigida laminiko ni PS sugandili ye.

Ladilikanw: A bɛ se ka kɛ ko aw bɛ a fɛ ka a bɛɛ kɛ plastiki ye .