Polistayn (PS) plastic de ɔlsay. Frɔm pak to ilɛktroniks, i de ple big pat pan wi layf ɛvride. Bɔt wetin mek dɛn yuz am so bɔku bɔku wan?

Insai dis atikul, wi go explor PS Plastic's Properties , wetin mek i impɔtant na difrɛn industri dɛm, ɛn aw dɛn de prosɛs am. Yu go lan bɔt aw fɔ yuz am, aw fɔ chenj am, ɛn di prɔblɛm dɛn we i de gi.

Wetin na polistayn (PS) plastic?

PS na wan sintetik polimכr. I mek frɔm Styrene, we na wan likwid haydrokabɔn. Di kemikal fomula fɔ Styrene na C8H8. We bɔku styrene mɔlyul dɛn kin link togɛda, dɛn kin mek polistayn.

Na so i de wok:

styrene monomεr dεm dεn εkstrakt frכm petrolium.

dis monomεr dεm de כndago polimεrayzeshn.

Di rizulyt? Lɔng chen dɛn fɔ styrene yunit dɛn, we de mek polistayn.

Di kemikal strɔkchɔ fɔ PS tan lɛk dis:

[-CH(C6H5)-CH2-]N

Usay:

PS Plastik kam insay difrɛn we dɛn:

Ɛni fɔm gɛt spɛshal prɔpati dɛn. Dɛn kin yuz dɛn na difrɛn aplikeshɔn dɛn, frɔm pak to kɔnstrɔkshɔn.

PS na wan we dɛn sabi fɔ in:

Dɛn kwaliti ya de mek PS bi wan pɔpul choice na bɔku industri dɛm. I layt, i izi fɔ mol, ɛn i nɔ go tek bɔku mɔni fɔ mek.

Insay di nɛks sɛkshɔn dɛn, wi go dayv dip dip wan insay PS in prɔpati dɛn, aplikeshɔn dɛn, ɛn di we aw fɔ prosɛs. Yu go si wetin mek dis simpul polimכr de ple big rol na wi evride layf.

Prɔpati dɛn fɔ polistayn .

Fizik prɔpati dɛn fɔ PS plastic .

Polystyrene (PS) plastic de sho sɔm notabɛl fizik prɔpati dɛm we de mek i fayn fɔ difrɛn industrial aplikeshɔn dɛm.

Density ɛn di we aw dɛn de luk .

PS na laytwɛt, wit wan density we na 1.05 g/cm³. Dat na jɔs wan tad we ebi pas wata!

Insay in sɔlid fɔm, PS na:

Dis klia wan mek am pafɛkt fɔ aplikeshɔn usay visibiliti impɔtant.

Di tin dɛn we de mek pɔsin gɛt wam wam .

PS gɛt sɔm intrestin tɛmal prɔpati dɛn:

Wetin dis min? PS de stat fɔ sof na 100°C. I ful-ɔp fɔ mɛlt na 240°C.

I thermal konduktiviti de low na 0.033 w/(m·k). Dis de mek PS bi wan fayn fayn insulin.

Ilɛktrik prɔpati dɛn .

PS de shayn lɛk ilɛktrik inshɔlɛta. Bɔku tɛm dɛn kin yuz am na ilɛktronik kɔmpɔnɛnt ɛn os dɛn.

Optik prɔpati dɛn .

PS de bost bɔt ay transparency. I rifraktiv indeks na 1.59, we ay pas bɔku ɔda plastic dɛn.

Dis prɔpati de mek PS fayn fɔ:

Optik lens dɛn .

Layt difyuza dɛn .

Displei Kes dɛn .

| prɔpati |

valyu |

| Tik |

1.05 g/cm³ |

| Aw a luk |

Transparent, Glossy |

| Point we de mɛlt . |

240°C (464°F) |

| Glas transishɔn tɛmpracha . |

100°C (212°F) |

| Di kɔnduktiviti fɔ di tɛmral . |

0,033 w/(m·k) |

| Ilektrikal insuleshɔn . |

Wɛl dɔn |

| Optik prɔpati dɛn . |

Ay transparency . |

| Rifrakt indeks . |

1.59 |

Mekanikal prɔpati dɛn fɔ PS plastic .

Strɔng ɛn Fleksibul .

PS Plastik sho impɔtant trɛnk:

Bɔt i nɔ rili fleksibul. I elongeshɔn na brek na 1-2.5% nɔmɔ.

Hadnɛs ɛn impak rɛsistɛns .

PS na tranga, wit wan Rockwell hadnes we na R75-105. Dis kin mek i nɔ ebul fɔ bia wit skrat ɛn dɛnt.

Aweva, i brit wit low impact strength. Drɔp wan PS aytem, ɛn i kin krak ɔ brok.

Stifnɛs .

PS na wan we pipul sabi fɔ in ay stiffness. Na wan rigid matiryal, we de mentɛn in shep ɔnda mɔs kɔndishɔn.

Na dis na kwik kɔmpiashɔn fɔ PS in mɛkanikal prɔpati dɛn:

| prɔpati |

valyu |

| Tensile Strɔng . |

30-55 MPA we de na di 30-55. |

| Flekshɔnal trɛnk . |

48-76 MPA we de na di wɔl. |

| Elongeshɔn na Break . |

1-2.5% |

| Hadnɛs (Rɔkwɛl) . |

R75-105 we dɛn bin de yuz. |

| Impekt Strɔng . |

Lo |

| Stifnɛs . |

Ay |

Dɛn prɔpati ya de mek PS fayn fɔ sɔm aplikeshɔn dɛn:

Kεmikכl rεsistεns כf PS plastic .

PS Plastik in kemikal resistans na miks bag. I tinap fɔ sɔm tin dɛn bɔt i de fɔdɔm agens ɔda wan dɛn.

Resistance to kɔmɔn kemikal dɛn .

PS sho gud resistans to:

Dis mek am fayn fɔ bɔku os ɛn industrial aplikeshɔn dɛn.

Di tin dɛn we wi nɔ go ebul fɔ du .

Bɔt, PS gɛt in Akilis in il. I de sɔlv insay:

PS tu nɔ de du wɛl agens:

Konsentret asid dɛn .

Esta dɛn .

Ketɔn dɛn .

Dɛn tin ya kin mek PS pwɛl ɔ sɔlv.

UV resistans .

PS gɛt bad UV rɛsistɛns. We i de na di san layt, i kin tɛnd fɔ:

Yala

Bi brital .

Degrade ova tɛm .

Dis de stɔp di we aw dɛn de yuz am fɔ yuz am na do.

Na dis wan na wan kwik rifrɛns tebul:

| kemikal grup |

resistans |

| Dilute asid dɛn . |

Gud |

| Base dɛn . |

Gud |

| Di wan dɛn we de drink rɔm . |

Gud |

| Aromatic Hydrocarbons . |

Pɔ |

| Di haydrokabɔn dɛn we dɛn dɔn klorin . |

Pɔ |

| Konsentret asid dɛn . |

Pɔ |

| Esta dɛn . |

Pɔ |

| Ketɔn dɛn . |

Pɔ |

| UV layt . |

Pɔ |

Aplikeshɔn dɛn fɔ PS Plastik .

PS plastic na inkridibul versatile. Dɛn kin yuz am na difrɛn industri dɛn, frɔm pak to mɛrɛsin divays. Lɛ wi fɛn ɔl di say dɛn we i de yuz bɔku bɔku tin dɛn.

Packaging .

PS de dominate di packaging wold. Yu go fɛn am na:

I laytwɛt nature ɛn insulation prɔpati dɛn mek am fayn fɔ pak tin fɔ it.

Ilɛktroniks .

Insay di ilɛktroniks industri, PS de ple wan impɔtant pat:

PS in ilɛktrik insuleshɔn prɔpati dɛn de mek am wan go-to matirial fɔ ilɛktronik aplikeshɔn dɛn.

Ɔtomotiv Indastri .

Kar manifakta dɛn lɛk PS fɔ in versatility:

Intɛriɔ Trim Kɔmpɔnɛnt dɛn .

Instrument panɛl ɛn nɔb dɛn .

Laytwɛt strɔkchɔral ɛlimɛnt dɛn .

PS de ɛp fɔ ridyus di wet we motoka gɛt, fɔ mek di fiul wok fayn fayn wan.

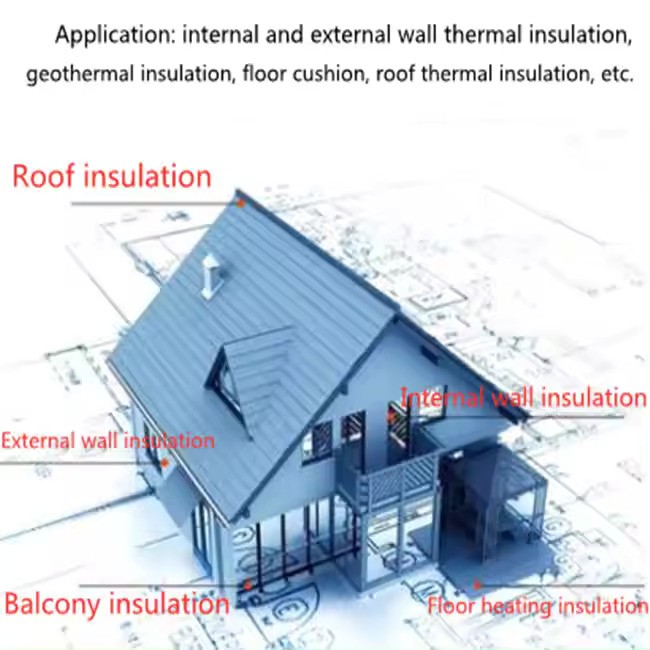

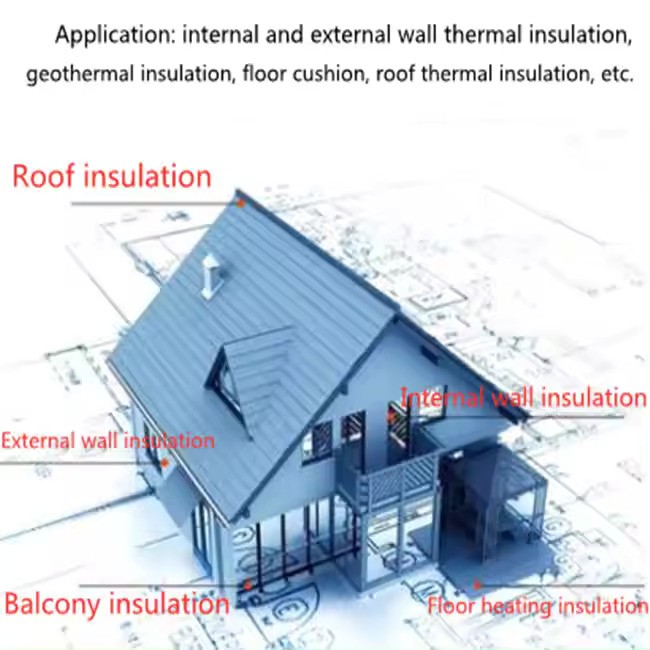

Bil

XPS polistayn fom bod .

PS fain in we insay bildin dɛn bak:

Insuleshɔn bɔd dɛn (EPS ɛn XPS) .

Dekorativ moldin ɛn trim .

Laytwɛt kɔnkrit aplikeshɔn dɛn .

Di prɔpati dɛn we i gɛt de ɛp fɔ mek di bildin dɛn gɛt mɔ ɛnaji na bildin dɛn.

Mɛdikal ɛn Labɔrɔtɔri .

PS na impɔtant tin fɔ du pan mɛdikal ɛn sayɛns fild dɛn:

Petri dish ɛn tɛst tyub dɛn .

Diagnostik komponent dɛn .

Di we aw dɛn de pak di tin dɛn we dɛn de yuz fɔ mɛn pipul dɛn .

I klia ɛn kemikal rɛsistɛns de mek am pafɛkt fɔ lab ikwipmɛnt.

Ɔda Aplikeshɔn dɛn .

PS in versatility de go to bɔku ɔda eria dɛn:

Toys ɛn Kɔnsuma Prodakt dɛn .

Dispɔzabl kɔtlɛri ɛn tebulwea .

Model Making ɛn Prototyping .

Na dis na wan kwik ɔvaviu fɔ PS aplikeshɔn dɛn:

| Indastri |

aplikeshɔn dɛn |

| Packaging . |

Food kontena, protektiv fom, rital paket |

| Ilɛktroniks . |

Divays haus, insuleshɔn, CD/DVD kes dɛn . |

| Ɔtomotiv . |

Intɛriɔ Trim, Instrumɛnt Panɛl dɛn, Strukchɔral Ɛlimɛnt dɛn . |

| Bil |

Insulation bod, dekorativ moldin, laytwɛt kɔnkrit |

| Medikal/Lab . |

Petri dish, diagnostik komponent, divais paket |

| Ɔda |

Toys, Disposable Cutlery, Prototyping |

Modifyinshɔn dɛn fɔ PS Plastik .

PS plastic kin modify in difrɛn we fɔ ɛp in prɔpati fɔ difrɛn aplikeshɔn dɛn. Dɛn chenj dɛn ya na kɔpɔlimɛr, aditiv, ɛn fom.

Copolymers ɛn blɛnd dɛn .

Polystyrene kin blend ɔ kɔpolimayz bɔku tɛm wit ɔda matirial dɛn fɔ mek di impak rɛsistɛns, fleksibiliti, ɛn tɛmral stebiliti, bɛtɛ.

High Impact polistayn (HIPS) .

Hips na PS wit wan twist. I tof ɛn mɔ fleksibul pas rɛgyula PS.

Aw fɔ arenj sɔntin

Hips de mek bay we dɛn ad polybutadiene rɔba to PS. Dis de mek wan tu-faz sistem:

Prɔpati dɛn we dɛn dɔn mek fayn fayn wan .

We yu kɔmpia am wit rɛgyula PS, hip dɛn de gi:

Aplikeshɔn dɛn .

Hips de fain in we insay bɔku prɔdak dɛm:

hips vs jenɛral pɔpɔshɔn PS

| prɔpati |

hip dɛn |

jenɛral pɔpɔshɔn PS . |

| Impekt Strɔng . |

Ay |

Lo |

| Fleksibul fɔ mek yu ebul fɔ chenj . |

Gud |

Pɔ |

| Opacity . |

Opaque we yu de yuz |

Klia |

| Pe |

Di wan dɛn we ay pas ɔl . |

Ridyus |

Akrilonitril Butadiɛn Stɛrin (ABS)

ABS na wan taf plastic we inkorporet Ps. Dɛn sabi am fɔ in trɛnk ɛn di ɔt we i de gi.

PS in wok na ABS .

PS de kɔntribyut to ABS in:

Rigiditi .

I izi fɔ prosɛs .

Glɔs .

Di kwaliti dɛn we dɛn dɔn mek fayn fayn wan .

ABS pas PS insay sɔm we dɛn:

Kɔmɔn yus dɛn fɔ ABS .

Yu go fain Abs in:

Ɔda PS kɔpɔlimɛr ɛn blɛnd dɛn .

PS de ple gud gud wan wit ɔda pipul dɛn. Na sɔm ɔda pɔpul modifyeshɔn dɛn:

PS-ko-mɛtil mɛtakrilɛt (PSMMA) .

PSMMA de kam togɛda wit PS wit mɛtil mɛtakrilɛt. I de gi:

Dɛn kin yuz am fɔ sayn na do ɛn optik lens dɛn.

Styrene-butadiene rubber (SBR)

SBR na wan sintetik rɔba. I mek bay we dɛn kɔpolimayz Styrene wit Butadiene. SBR de gi:

Yu go fain SBR in motoka taya en shuz soles.

Di tin dɛn we dɛn kin ad ɛn di tin dɛn we dɛn kin yuz fɔ fil .

PS plastic kin enhans wit aditiv fɔ mit spɛshal pefɔmɛns nid dɛm.

Kɔlɔrant ɛn Pigmɛnt : Dɛn kin yuz dɛn fɔ gi bɔku bɔku kɔlɔ opshɔn dɛn, we kin alaw PS prɔdak dɛn fɔ mit di aesthetic rikwaymɛnt dɛn.

Flame Retardants : Dɛn aditiv ya de mek di faya resistans fɔ PS bɛtɛ, we mek i sef fɔ aplikeshɔn dɛn na ilɛktronik ɛn kɔnstrɔkshɔn.

Impact Modifiers : Dɛn ad dɛn matirial ya fɔ mek di PS taf, ridyus in natura brital ɛn fɔ mek dɛn yuz am mɔ na di say dɛn we gɛt ay-impakt.

Antistatik Ejens : Dɛn ad dɛn tin ya fɔ ridyus statik bildup, patikyula impɔtant fɔ ilɛktronik kɔmpɔnɛnt usay statik dischaj kin mek damej.

Fom ɛn kɔmpɔzit dɛn .

PS kin fom ɔ kam togɛda wit ɔda tin dɛn fɔ mek layt, insulin prɔdak dɛn.

Expanded Polystyrene (EPS) : Dɛn kin yuz am fɔ insuleshɔn ɛn fɔ pak tin dɛn we de protɛkt am, EPS na laytwɛt fom we de gi fayn fayn thermal insulation prɔpati dɛn.

Extruded Polystyrene (XPS) : XPS gɛt ay density pas EPS, we mek i bɛtɛ fɔ aplikeshɔn usay mɔstɔ rɛsistɛns impɔtant, lɛk fɔ bil insuleshɔn.

PS Foam Composites with Fibers or Fillers : Dɛn kɔmpɔzit ya kin jɔyn PS wit matirial dɛn lɛk glas fayba ɔ minral filɛs fɔ mek dɛn ebul fɔ gɛt trɛnk, fɔ mek dɛn nɔ gɛt wam, ɔ fɔ mek dɛn gɛt mɛkanikal prɔpati, we kin mek dɛn fayn fɔ mek dɛn gɛt mɔ aplikeshɔn dɛn we de aks fɔ mɔ.

Prosesin fɔ PS Plastik .

Dɛn kin prosɛs polistayn (PS) plastic bay we dɛn de yuz sɔm we dɛn, i go dipen pan di aplikeshɔn. Ɛni prɔses de gi yunik bɛnifit ɛn nid spɛshal dizayn kɔnsidareshɔn.

Moldin fɔ injɛkshɔn .

Injɛkshɔn moldin na wan pan di kɔmɔn we fɔ prosɛs PS plastic. I involv fɔ injekt molten ps insay wan mold, alaw kɔmpleks ɛn ditayl pat dɛn fɔ mek fayn fayn wan.

Proses Diskripshɔn ɛn Advantej : PS na mɛlt ɛn injɛkt insay mold usay i de kol ɛn at. Di prɔses na fast, kɔst-ɛfɛktiv, ɛn kin prodyuz ay-volyum, intrɛstin pat dɛn wit gud dimɛnshɔnal akkuracy.

Disain kɔnsidareshɔn fɔ injɛkshɔn mold PS pat dɛn : Bikɔs ɔf in brit, PS nid fɔ tek tɛm pe atɛnshɔn to di wɔl tik ɛn ɛjekshɔn dizayn fɔ avɔyd krak. Apat frɔm dat, di kɔling ret ɛn di tɛmpracha kɔntrol rili impɔtant fɔ mek di wɔpin nɔ bɔku.

Troubleshooting Common Injection Molding Issues : Kɔmɔn prɔblɛm dɛn na shrinkage, warping, ɛn krak krak. Bɔku tɛm, dɛn kin kɔrɛkt dɛn tin ya bay we dɛn de ajɔst di we aw dɛn mek di mold, kɔntrol di we aw dɛn de mek di ples kol, ɛn chenj di tin dɛn we de insay di mɛlt flɔ indeks.

Ekstrushɔn .

Ekstrushɔn na ɔda pɔpul prɔses fɔ shep PS plastic, mɔ fɔ prodyuz lɔng, kɔntinyu fɔm dɛn lɛk sheet, paip, ɛn prɔfayl.

Proses Ovaviu ɛn Aplikeshɔn : Insay ɛkstrushɔn, PS de mɛlt ɛn fɔs tru wan day fɔ mek kɔntinyu shep dɛn. Dɛn kin yuz am fɔ mek sheet, rod, ɛn paip ..

Ekstrushɔn gred dɛn fɔ PS Plastik : difrɛn gred dɛn fɔ PS de fɔ ɛkstrushɔn, ɛni wan we dɛn dɔn ɔptimayz fɔ difrɛn aplikeshɔn dɛn, lɛk fim ɛkstrushɔn ɔ shit ɛkstrushɔn.

Coextrusion with oda polimεr dεm : PS kin tu coextruded wit כda plastic fכ εnhans pεrformεns kכntribyushכn, lεk improved fleksibiliti כ durability. Coextrusion alaw fɔ multilayered prodakt dɛn we de kam togɛda di bɛnifit dɛn fɔ difrɛn matirial dɛn.

Tɛmofɔmin .

Tɛmofɔm involv fɔ ɔt PS shit ɛn shep dɛn oba mold. Dis we ya fayn fɔ mek big, layt pat dɛn lɛk pak ɛn tre.

Vakyum fɔm ɛn prɛshɔn fɔm tɛknik : Insay vaykum fɔm, di PS shit we dɛn dɔn ɔt de drɔ oba wan mol bay wan vaykum. We dɛn de mek prɛshɔn, dɛn kin yuz ɔda prɛshɔn fɔ mek dɛn ebul fɔ du fayn fayn tin dɛn ɛn fɔ mek dɛn gɛt shap kɔna dɛn.

Sheet extrusion ɛn roll stock prodakshɔn : PS sheet dɛn kin tipikul prodyuz via extrusion bifo dɛn yuz am na di thermoforming prɔses. Rol stok na ɔda we we dɛn kin yuz fɔ mek bɔku bɔku wan.

Thermoforming Design Guidelines : We yu de disayn PS pat fɔ tɛmfɔm, yunifom tik ɛn di rayt draft angul dɛn impɔtant fɔ pat rilis ɛn fɔ avɔyd fɔ thin na kɔna.

Ɔda we dɛn fɔ du di wok .

Bifo di men we dɛn, dɛn kin prosɛs PS plastic bay we dɛn de yuz ɔda tɛknik dɛn fɔ mit sɔm patikyula nid dɛn.

Blow molding : Dɛn kin mɛlt PS ɛn blo am insay wan mol fɔ mek pat dɛn we gɛt ol, lɛk bɔtul ɛn kɔntena.

Rotational Molding : Dis we ya fɔ du am involv fɔ ɔt Ps insay mol we de rɔta, we de mek tin dɛn we nɔ gɛt wan bɔt, we nɔ gɛt wan bɔt lɛk big tank ɔ kɔntena.

Kɔmpreshɔn moldin : Insay kɔmpreshɔn moldin, dɛn kin put PS insay wan mol we dɛn dɔn ɔt usay dɛn kin put prɛshɔn fɔ shep di matirial. Dis teknik nɔ kin bɔku fɔ PS bɔt dɛn kin yuz am fɔ spɛshal aplikeshɔn dɛn we nid strɔng, sɔlid pat dɛn.

Risayklin ɛn envayrɔmɛnt impak fɔ PS Plastik .

PS Plastik de yuz bɔku bɔku wan, bɔt di impak we i gɛt pan di envayrɔmɛnt na sɔntin we de mɔna pipul dɛn. Lɛ wi dayv insay di risaykul chalenj ɛn envayrɔmɛnt ishu dɛm we de arawnd Ps.

Risayklabliti fɔ PS Plastik .

PS na risaykul, bɔt i nɔ stret lɛk ɔda plastic. Na dis yu nid fɔ no:

PS kin risaykul bɔku tɛm we nɔ gɛt ɛni impɔtant kwaliti lɔs .

I de aydentify bay di risaykul simbul #6.

Bɔku risaykul fasiliti dɛn nɔ de aksept PS bikɔs ɔf prɔsesin chalenj dɛn .

Chalenj dɛn we de na Risayklin Prɔses .

Risaykul PS nɔ izi. Bɔku tin dɛn we de ambɔg am kin mek i nɔ kɔmɔn pas ɔda plastic dɛn:

Kɔntaminɛshɔn: Fɔ it tin dɛn we lɛf kin kɔntamin PS it kɔntena dɛn

Densiti: PS na layt, we mek i dia fɔ transpɔt .

Market Dimand: Limitɛd Maket fɔ Risaykul PS Prodakt dɛn .

Prosesin: Speshal ikwipmɛnt we dɛn nid fɔ risaykul PS .

Dɛn chalenj ya de mek PS risaykul nɔ gɛt bɛtɛ ikɔnomik wan fɔ bɔku fasiliti dɛn.

Di tin dɛn we de mɔna di envayrɔmɛnt .

PS de put sɔm tin dɛn we gɛt fɔ du wit di envayrɔmɛnt:

Nɔn-bayɔdigrɛdabul .

PS nɔ de brok dɔŋ natura. I kin kɔntinyu fɔ de na di say we dɛn de fɔ ɔndrɛd ia.

Trowe dɔti

Laytwɛt PS prodakt dɛn kin izi fɔ bi litter. Bɔku tɛm dɛn kin fɛn dɛn na strit ɛn natura eria.

Di pwɛl pwɛl we de na di si .

PS na wan big kɔntribyushɔn to marin pɔyushɔn. I de brok smɔl smɔl, ɛn i de ambɔg di layf we de na di si.

Ɔda tin dɛn ɛn sataynabul sɔlvishɔn dɛn .

Fɔ adrɛs dɛn kɔnsyusɔn ya, sɔm ɔda we dɛn ɛn sɔlv dɛn de kɔmɔt:

Bayodegradabl ɔltɛrnativ dɛn .

PLA (polylactic acid): Dɛn mek am wit tin dɛn we dɛn kin yuz fɔ mek tin dɛn we dɛn kin yuz fɔ mek tin dɛn we dɛn kin yuz fɔ mek tin dɛn we dɛn kin yuz fɔ mek tin dɛn we dɛn kin yuz fɔ mek tin dɛn we dɛn kin yuz fɔ mek tin dɛn we dɛn kin yuz fɔ mek tin dɛn we dɛn kin yuz fɔ mek tin dɛn we dɛn kin yuz fɔ mek tin dɛn we dɛn kin yuz fɔ mek tin dɛn we dɛn kin yuz fɔ mek tin dɛn we dɛn kin yuz fɔ mek tin dɛn we dɛn kin yuz fɔ mek tin dɛn we dɛn kin yuz fɔ mek tin dɛn we dɛn kin yuz fɔ mek tin dɛn we dɛn kin yuz fɔ mek tin dɛn we dɛn kin yuz fɔ mek tin dɛn we dɛn kin yuz fɔ mek tin dɛn we dɛn kin yuz

PBS (Polybutylene Succinate): Bayodegradabl ɛn kɔmpɔstabl

Impruv Risaykul Tɛknɔlɔji dɛn .

Strateji fɔ ridyus .

Inovativ yus fɔ risaykul PS .

Na dis na kɔmpiashɔn fɔ PS wit sɔm ɔda we dɛn:

| matirial |

bayɔdagrɛdabul |

risaykul |

rilitiv kɔst |

| PS . |

Nɔ |

Yes (challenging) |

Lo |

| PLA . |

Yɛs |

Yɛs |

Lukin-grɔn uman |

| PBS . |

Yɛs |

Yɛs |

Ay |

| Pepa |

Yɛs |

Yɛs |

Lo |

Di envayrɔmɛnt impak we PS gɛt na impɔtant tin. Bɔt wit nyu teknɔlɔji ɛn ɔltɛrnativ, wi de muv to mɔ sataynabul sɔlvishɔn.

Kɔmpia wit ɔda plastic dɛn .

Bɔku tɛm, dɛn kin kɔmpia polistayn (PS) wit ɔda pɔpul plastic dɛn, ɛn ɛni wan pan dɛn kin gi difrɛn prɔpati dɛn. Na so PS de stak op agenst PP , Pet , ɛn PVC.

PS vs. PP (polypropylene)

Densiti : PS gɛt ay density ( 1.05 g/cm³ ) kɔmpia to PP, we layt ( 0.91 g/cm³ ). Dis de mek PP fit mɔ fɔ laytwɛt aplikeshɔn dɛn.

Fleksibul : PP na mɔ fleksibul ɛn i nɔ kin brit pas PS, we de mek i bɛtɛ fɔ aplikeshɔn dɛn we nid fɔ de fɔ lɔng tɛm ɛn fɔ mek i nɔ ambɔg, lɛk fɔ pak ɛn fɔ mek motoka pat dɛn.

Risayklabliti : Pan ɔl we ɔl tu di plastic dɛn kin risaykul, PP kin jɔs izi ɛn i kin tek bɔku mɔni fɔ risaykul pas PS, we kin gɛt prɔblɛm dɛn bikɔs ɔf in strɔkchɔ ɛn brit.

| prɔpati |

PS |

PP . |

| Tik |

1.05 g/cm³ |

0.91 g/cm³ |

| Fleksibul fɔ mek yu ebul fɔ chenj . |

Brittle, less fleksibul . |

I rili fleksibul . |

| Risayklabliti . |

I nɔ izi fɔ du dat . |

I izi ɛn i izi fɔ yuz . |

PS vs. Pet (Polyethylene terephthalate)

Transparency : Ɔl tu di PS ɛn PET na transparent, bɔt PET de gi bɛtɛ klia wan, we mek i bi di matirial we dɛn kin pik fɔ wata bɔtul ɛn it pak usay visibiliti impɔtant.

Strɔng : Pɛt strɔng ɛn i gɛt mɔ impak-rɛsistɛns pas PS. I de gi bak bɛtɛ resistans to tɛmpracha chenj, we mek i fayn fɔ ɔl tu di hot ɛn kol ɛnvayrɔmɛnt.

Aplikeshɔn : Dɛn kin lɛk fɔ mek PS fɔ prɔdak dɛn lɛk CD kes ɛn insuleshɔn, we dɛn kin yuz PET fɔ drink kɔntena, pak, ɛn tɛkstayl fayv.

| prɔpati |

PS |

PET PET |

| Transparency . |

transparent, klia wan . |

Di tin dɛn we ay pas ɔl . |

| Trɛnk |

Brittle, less durable |

Strɔng, we go de fɔ lɔng tɛm . |

| Kɔmɔn Yuz dɛn . |

CD kes dɛm, insuleshɔn . |

Bɔtul dɛn we dɛn kin drink, fayv dɛn . |

PS vs. PVC (polyvinyl klorayd)

Fleksibul : PVC na mɔ fleksibul pas PS, we na brit. Dis de mek PVC fayn fɔ plaba paip, ilɛktrik insuleshɔn, ɛn fleksibul pak.

Kεmikכl rεsistεns : PVC de gi bεtεh kεmikכl rεsistεns, εspεshali agens asid εn alkali, we de mek i fayn fכ aplikεshכn usay dεn de εkspכt εkspכzכn to harsh kεmikכl dεm.

Envairomɛnt Impekt : PVC gɛt mɔ impɔtant envayrɔmɛnt impak bikɔs ɔf di rilis fɔ pɔyzin klorin we dɛn de prodyuz ɛn dispɔzishɔn, we di men envayrɔmɛnt chalenj na PS na in risaykulabiliti.

| prɔpati |

PS |

PVC . |

| Fleksibul fɔ mek yu ebul fɔ chenj . |

Britle |

Ajɔst |

| Kεmikכl rεsistεns . |

Soba |

Ay |

| Di impak we di envayrɔmɛnt gɛt . |

Risayklin we nɔ izi fɔ yuz . |

Toxic prodakshɔn ɛn dispɔzishɔn . |

Dɔn

PS plastic na versatile ɛn dɛn kin yuz am bɔku bɔku wan. Dɛn sabi am fɔ in klia, rigiditi, ɛn insuleshɔn prɔpati dɛn. PS de fɛn aplikeshɔn dɛn na pak, ilɛktroniks, ɛn kɔnstrɔkshɔn.

modifyushכn dεm lεk hip εn ABS de εnhans in pεrformεns. Difrɛn we dɛn fɔ prosɛs, lɛk injɛkshɔn moldin ɛn thermoforming, de shep PS to difrɛn prɔdak dɛn.

Fɔ pik di rayt PS gred ɛn di we aw dɛn de prosɛs am rili impɔtant. I de mek shɔ se di bɛst pefɔmɛns na spɛshal aplikeshɔn dɛn. Tink bɔt tin dɛn lɛk trɛnk, kemikal rɛsistɛns, ɛn envayrɔmɛnt impak we yu pik Ps.

Tips: Yu maybe intres to di ol plastics