PPS walima polifenilɛni sulfure daminɛna fɔlɔ san 1960 waatiw la i n’a fɔ polimɛri min bɛ baara kɛ kosɛbɛ. A bɛ danfara don plastiki jɔnjɔnw ni fɛn kɔrɔw cɛ, ka nafolo kɛrɛnkɛrɛnnenw di minnu b’a to a nafa ka bon izini suguya caman na.

Nin sɛbɛn in kɔnɔ, an bɛna PPS ka nafolo kɛrɛnkɛrɛnnenw sɛgɛsɛgɛ, baarakɛcogo suguya caman, a labɛncogo, ani mun na a bɛ kɛ fɛn nafamaba ye izini suguya caman na.

PPS ka kemikaliya cogoya .

Polifenilɛni sulfide (PP) bɛ funteni caman sɔrɔ, ka gɛlɛya, ani ka kɛ cogo ye min tɛ ye i n’a fɔ semi-kirisitalini thermoplastique.

Molecules ka sigicogo .

PPS kɔkolo bɛ kɛ para-fenilɛni unitw ye minnu bɛ ɲɔgɔn falen ni sulfure jɛɲɔgɔnyaw ye. O bɛ PPS ka jogo ɲumanw di.

Kibaruya atomu bɛ kɛ ɲɔgɔndɛmɛ kelen ye bɛnzɛni bololanɛgɛw ni ɲɔgɔn cɛ. U bɛ ɲɔgɔn Dòn para (1,4) labɛnni na, ka cakɛda 'kɔnɔ.

Kristali jɔcogo .

PPS bɛ kɛ semi-crystalline structures ye, ka dɛmɛ don a ka funteni sabatili la ani a ka kemikaliya la.

Orthorhombic Unit Cell .

PPS ka unit cellule ye orthorhombic ye, ni nin hakɛ ninnu ye:

A = 0,867 nm .

B = 0,561 nm .

C = 1,026 nm .

Fusion ka funteni jatebɔlen PPS kristalɛ ɲuman na o ye 112 J/g ye. O jɔcogo in bɛ PPS ka wuliyɔrɔba di PPS ma min ye 280°C ye.

degree de cristallinité .

Kristali hakɛ PPS la, o bɛ bɔ 30% na ka se 45% ma. A bɛ bɔ:

Kristali caman bɛ bonya:

Barika

gɛlɛya .

kemikɛli resistance .

Sumaya kɛlɛli .

Kristali duguma bɛ ɲɛ:

Impact resistance .

Elongation .

Aw bɛ se ka PPS amorphes ni crosslinked labɛn ni:

Sumaya sanfɛ funteni funteni na .

Nɛnɛ bɛ se 30°C ma min bɛ wuli yɔrɔ la .

Minɛni ka kɛ lɛrɛ caman kɔnɔ fiɲɛ na .

O jɔcogo in bɛ PPS nafa ɲumanw di i n’a fɔ funteni caman kɛlɛli ani kemikoro inertness.

PPS plastiki suguyaw .

PPS resin bɛ sɔrɔ cogoya wɛrɛw la, u kelen-kelen bɛɛ ni u ka jogo kɛrɛnkɛrɛnnenw bɛ labɛn ka kɛɲɛ ni baara kɛrɛnkɛrɛnnenw ye.

PPS lineaire .

A bɛ se ka kɛ PPS basigilenw ka molekiyɔmu girinya ye siɲɛ fila .

A bɛ na ni timinandiya ye ka caya, ka janya, ani ka nɔ bila fanga la .

PPS kɛnɛyalen .

A bɛ sɔrɔ PPS basigilenw sumaya fɛ fiɲɛ (O2) sɔrɔli la .

Furakɛli bɛ cakɛda molekiyɔmuw janya ani ka bolofara dɔw dilan .

A bɛ molekiyɔmu girinya bonya ani ka thermoset ɲɔgɔnna jogo di .

PPS bolofara .

A girinya ka bon ni PPS basigilen ye .

A bɛ ni polimɛri cakɛda janyalenw ye minnu bɛ bɔ kɔkolo la .

A bɛ masinw ka baarakɛcogo, u ka timinandiya ani u ka ductility ɲɛ .

Tablo min bɛ duguma, o bɛ PPS suguya wɛrɛw ka molekiyɔmu girinya suma ɲɔgɔn na:

| PPS suguya | molekiyɔmu girinya sumacogo . |

| PPS basigilen . | Baseline . |

| PPS lineaire . | A bɛ se ka kɛ ko PPS bɛ kɛ tuma bɛɛ siɲɛ fila . |

| PPS kɛnɛyalen . | Dɔ farala PPS basigilenw kan ka da cakɛda janya ni bolofaraw kan . |

| PPS bolofara . | A ka ca ni PPS sabatilenw ye . |

PPS ka molekiyɔmu girinya jɔyɔrɔ ka bon kosɛbɛ a ka nafaw dɔnni na. A ka c’a la, molekiyɔmu girinya bɛ na ni:

Mekaniki fanga ɲɛnabɔli .

A ka fisa ka impact resistance .

ka dɔ fara ductility ni elongation kan .

Nka, a bɛ se ka kɛ sababu ye fana ka dɔ fara fɛnw sɔgɔli kan, o bɛ kɛ sababu ye ka baara kɛcogo gɛlɛya.

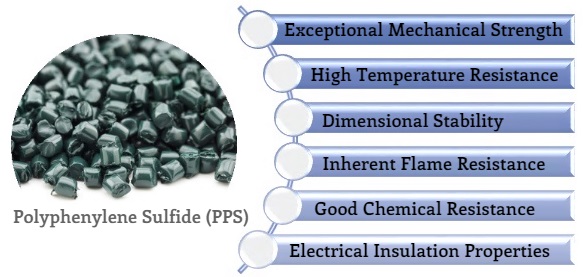

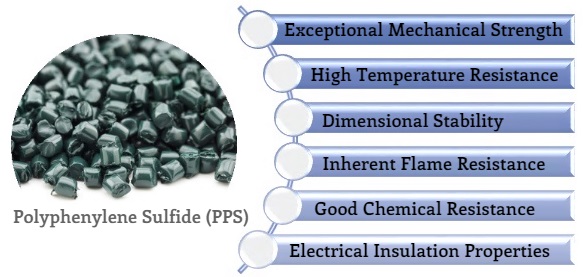

PPS(polyphenylene sulfide) plastiki ka jogo .

PPS Plastiki bɛ jogo dɔw jira minnu bɛ kɛ ɲɔgɔn fɛ cogo kɛrɛnkɛrɛnnen na minnu b’a to a bɛnnen don baara suguya caman ma.

Mekaniki jogo .

PPS bɛ waso ni masinw ka nafolo ye min bɛ bɔ kɛnɛ kan, o b’a to a bɛ kɛ fɛn ɲumanw ye minnu bɛ kɛ ka baara ɲini.

Tensile strength (Tensile fanga): Ni tension (janya) fanga ye 12.500 psi (86 MPa) ye, PPS bɛ se ka doni nafamaw muɲu k’a sɔrɔ a ma kari.

Impact resistance: Hali n’a ka gɛlɛn, PPS ka IZOD impact fanga ye 0,5 ft-lbs/in (27 j/m) ye, o b’a to a bɛ se ka sɔgɔsɔgɔninjɛ barikamaw minɛ.

Flexural modulus of elasticity: at 600.000 psi (4.1 GPA), PPS bɛ fanga kɔrɔtalenw kɛlɛ kosɛbɛ, k’a cogoya n’a jɔcogo dafalen mara.

Dimension Stabilité: PPS b’a hakɛw mara hali ni funteni ni nɛnɛba bɛ a la, o b’a to a bɛnnen don yɔrɔw ma minnu bɛ se ka kɛ fɛn ye min bɛ se ka kɛ ni muɲuli gɛlɛnw ye.

thermal properties .

PPS bɛ tɛmɛ funteni sabatili ni a kɛlɛli kan, o nafa ka bon kosɛbɛ funteni caman na.

Funteni funteni hakɛ: PPS bɛ se ka funteni muɲu fo ka se 260°C ma (500°F) ni 1,8 MPa (264 psi) ani 110°C (230°F) ye 8,0 MPa (1160 psi) la.

Coefficient de expansion médiature linéaire : PPS bɛ fɛn fitininw jira minnu hakɛ bɛ yeli kɛ ni funteni caman ye 4,0 × 10⁻⁵ in/in/°F (7,2 × 10⁻⁵ m/m/°C).

Baara kɛcogo funteni hakɛ min bɛ to sen na: PPS bɛ se ka kɛ ka to fiɲɛ na funteni na fo ka se 220°C ma (428°F).

kemikɛli resistance .

PPS bɛ dɔn a ka kemikoro-kɛlɛ-kɛlɛli danma-danma fɛ, o b’a to a bɛnnen don sigida gɛlɛnw ma.

Ji kɛlɛli : PPS bɛ to a nɔ na ji fɛ, a bɛ to ka muɲu ani ka da a la ko nɛnɛ bɛ a la.

Fura suguya caman kɛlɛli: PPS bɛ se ka fura juguw ta, i n’a fɔ asidi barikamaw, basiw, fɛnɲɛnamafagalanw, oksidanw, ani hidrɔkarbɔnw.

Kuranko nafaw .

PPS ka kuran sɛgɛsɛgɛli kɛcogo b’a to a bɛnnen don ɛntɛrinɛti baarakɛcogo ma.

Resistivité volume haute : PPS bɛ insulation resistance caman mara hali ni humimite caman bɛ sigidaw la, ni volume resistivity ye 10⊃1;⁶ Ω·cm ye.

Dielektriki fanga : ni dielektriki fanga ye 450 v/mil (18 kV/mm) ye, PPS bɛ insulation ɲuman sɔrɔ.

Propriétés wɛrɛw .

PPS bɛ nafolo caman wɛrɛw di:

Tasuma kunbɛn: PPS furakisɛ fanba bɛ tɛmɛ UL94V-0 sariya kan ni tasuma kunbɛnnan wɛrɛw tɛ.

Modulu sanfɛ ni a barika ka bon: PPS hakɛ barikamaw bɛ modulu caman jira, ka masina fanga bonya.

Ji minɛcogo dɔgɔyali : Ni ji minɛcogo ye 0,02% dɔrɔn ye sanga 24 kɔnɔ, PPS ka ɲi kosɛbɛ, o bɛ kɛ sababu ye ka ji caman ta.

Nin ja in bɛ PPS plastiki ka jogo jɔnjɔnw lajɛ:

| nafolo | nafa . |

| Tensile fanga (ASTM D638) . | 12 500 psi (86 MPa) . |

| IZOD Impact fanga (ASTM D256) . | 0,5 ft-lbs/in (27 J/M) . |

| Modulu flexural (ASTM D790) . | 600.000 psi (4,1 GPA) . |

| Funteni de bɛ se ka kɛ funteni de la (ASTM D648) . | 500°F (260°C) @ 264 psi |

| Coefficient de expansion thermal lineaire . | 4,0 × 10⁻⁵ in/in/°F . |

| Baara kɛcogo funteni hakɛ min bɛ to sen na . | 428°F (220°C) |

| Volume resistivity (ASTM D257) . | 10⊃1;⁶ Ω·cm . |

| Dielektriki fanga (ASTM D149) . | 450 V/MIL (18 kV/mm) . |

| Ji minɛni (ASTM D570, 24h) . | 0,02% . |

O nafolo ninnu bɛ PPS kɛ sugandili ɲuman ye baarakɛminɛnw na minnu bɛ baara kɛcogo ɲuman, muɲuli, ani dannaya ɲini sigida gɛlɛnw na.

PPS plastiki dilanni taabolo .

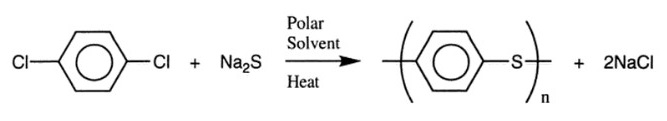

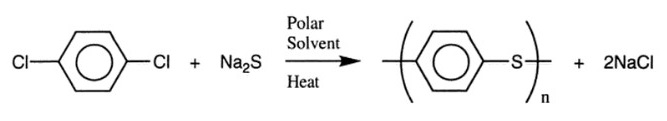

Sulfure sodium ni dichlorobenzene ka ɲɔgɔn sɔrɔli polari furaji la walasa ka polifenilɛni sulfure (PP) sɔrɔ .

Kokuraw daminɛni PPS dilanni na .

PPS maana daminɛna san 1967 ni Edmonds ni Hill ye Philips Petroleum la. U ye jagokɛcogo fɔlɔ labɛn ni tɔgɔ ye ko Ryton.

A kɛcogo fɔlɔ yɔrɔ kolomaw:

A bɛ sɔrɔ PPS molekiyɔmuw ka dɔgɔn .

A ka ɲi kosɛbɛ ka ɲɛsin finiw dilanni ma .

Furakɛli wajibiyalen don ka ɲɛsin molding grades ma .

Bi fɛn dilanni fɛɛrɛw .

Bi PPS bɔli yiriwara kosɛbɛ. Bi taabolow laɲini ye ka :

Aw bɛ furakɛli kɛcogo ban .

Aw bɛ furaw labɛn ni masin fanga ɲɛnabɔli ye .

Aw bɛ dɔ fara baarakɛcogo ɲuman kan ani ka sigida nɔfɛkow dɔgɔya .

kemikɛli ka waleyali ani a ka sinti .

PPS bɔli bɛ kɛ ni chimie hakilitigi ye. Nin ye a furakɛcogo jɔnjɔn ye:

Aw bɛ sulfure sodium ni dikulorobɛnzɛni ɲagami .

Aw bɛ furaji polari dɔ fara a kan (misali la, n-methylpyrrolidone) .

Aw bɛ a sumaya fo ka se 250°C ɲɔgɔn ma.

Aw ye maaɲɛmaaya kɛ!

Furakɛli taabolo n’a nɔfɛkow .

Furakɛli nafa ka bon kosɛbɛ PPS sɛnɛcogo la. A bɛ Kɛ 'yɔrɔ lamini na ni fiɲɛ ye.

Furakɛli nɔ minnu bɛ sɔrɔ:

A bɛ dɔ fara molekiyɔmu girinya kan .

Toughness boostes .

A bɛ dɔ bɔ solubilité la .

A bɛ dɔ bɔ melt flow la .

A bɛ kristalɛni dɔgɔya .

Dibi bɛ kulɛri la (Hello, brownish hue!)

Polar solvents jɔyɔrɔ PPS sɔrɔli la .

Polar solvents ye PPS bɔli jatigɛwalew ye minnu ma fɔ. Olu:

Aw bɛ sulfure sodium ni dichlorobenzene ka ɲɔgɔn sɔrɔli nɔgɔya .

Aw bɛ dɛmɛ don ka polimɛri ka molekiyɔmu girinya kunbɛn .

nɔ bila PPS ka jogo labanw na .

Solvents polaires commune minnu bɛ kɛ:

Solvant kelen-kelen bɛɛ bɛ na n’a ka daamu ye PPS parti la, o bɛ nɔ bila fura laban na.

Polifenilɛni sulfide(pps) plastiki tali iziniw kɔnɔ .

PPS plastiki bɛ baara kɛ ni baara suguya caman ye k’a sababu kɛ a ka nafolo faralen ɲɔgɔn kan cogo kɛrɛnkɛrɛnnen na.

Mobili ni aerospace .

Mobili ni aerospace seko ni dɔnko siratigɛ la, PPS bɛ kɛ fɛnw ye minnu bɛ se ka muɲu, ka funteni kunbɛn, ani ka kemikaliya sabati.

Motɛri yɔrɔw : PPS bɛ kɛ ɲɔgɔndanw na, so kɔnɔ, ani fɛnw kolanw na, yɔrɔ minnu na a ka funteni ka bon ani a ka masina fanga ka bon kosɛbɛ.

Fuel System Parts: PPS yɔrɔw bɛ kɛ fɛnɲɛnamafagalanw na k’a sababu kɛ u ka kemikaliya ye ani u bɛ se ka funteni caman muɲu.

Avionw kɔnɔna : PPS bɛ sɔrɔ awiyɔnw kɔnɔ fɛnw na ani kɔnɔna brackets, yɔrɔ min na a ka nɔgɔn ani a ka to ka mɛn, o nafa ka bon.

Elektroniki ni kuran yɔrɔw .

PPS ka kuran sɛgɛsɛgɛli kɛcogo b’a to a ka ɲi kosɛbɛ ɛntɛrinɛti ni kuran baara kama.

Connecteurs et insulateurs : PPS bɛ kɛ ɲɔgɔndanw ni insulatɛriw la k’a sababu kɛ a dielektriki fanga ka bon ani a ka funteni sabatili.

Circuit boards: PPS bɛ baara kɛ kafoda la, ka miniaturisation ani baara kɛcogo ɲuman dɛmɛ.

Microélectronique applications: PPS bɛnnen don microélectronique baarakɛcogo ma, a bɛ dimensions stabilité ɲuman ni insulation properties di.

kemikɛli baarakɛlaw ka baarakɛyɔrɔ .

PPS ka kemikaliya bɛ se ka kɛ sababu ye a ka bɛn fɛnw ma minnu bɛ kɛ kemikɛlifɛnw na minnu bɛ se ka kɛ fɛn ye.

Valves ani pompes: PPS bɛ kɛ valves, pompes, ani fittings la kemikaliya baara la bawo a bɛ kemikaliya juguw muɲu funteni jiginni na.

Filɛriw ka so: PPS bɛ kɛ filɛri so kɔnɔ, ka a to a ka muɲu ani ka a kɛ a ka kemikaliya la filɛriw kɔnɔ.

Seals and Gaskets: PPS ka ɲi sigilanw ni gaziw ma kemikɛli sigidaw la, o bɛ baara kɛ waati jan kɔnɔ ani ka se ka tiɲɛni kɛ.

Industriw ka minɛnw .

PPS bɛ baara kɛ izini minɛnw na walasa a ka sɛgɛn ani a ka masina fanga.

Gears and Bearings: PPS bɛ kɛ girinw na, birikiw la, ani fɛn wɛrɛw minnu bɛ se ka sɛgɛn, olu bɛ kɛ ni masin fanga ni hakɛ sabatili ye.

Komɛsi yɔrɔw: PPS bɛ kɛ komɛsi-minɛnw na bawo a bɛ fanga ni muɲuli caman di izini baara gɛlɛnw na.

Baara minnu bɛ se ka kɛ ni sɛgɛn ye: PPS yɔrɔw bɛ baara kɛ ni sɛgɛnlafiɲɛbɔlanw ni bushings ye, o bɛ kɛ sababu ye ka ɲɔgɔn sɔgɔsɔgɔ ani ka sɛgɛnba di izini masinw na.

Semiconductor industrie .

PPS bɛ baara sɔrɔ semikɔndukiri baara la k’a sababu kɛ a saniyacogo n’a ka insulation properties ye.

Semiconductor Machinery Components: PPS bɛ kɛ kafoɲɔgɔnyaw la, ka ɲɔgɔn sɔrɔ nɛgɛw la, ka funtenibɔlanw, ani ka ɲɔgɔn sɔrɔ degun disikiw la semikɔndukiri dilanni minɛnw kɔnɔ.

Kalansen kɛrɛnkɛrɛnnenw ka ɲɛsin semikɔndukiri baarakɛcogo ma: PPS kɛrɛnkɛrɛnnenw hakɛ i n’a fɔ Tecatron SE ani SX, olu dabɔra semikɔndukiri baarakɛminɛnw kama, minnu bɛ saniya ni nafolo caman di.

Mekanikini injiniyɛri .

PPS bɛ baara kɛ ni masinko baara suguya caman ye.

Komɛsi ni pɔnpe yɔrɔw : PPS bɛ kɛ komɛsi ni pɔnpe yɔrɔw la ka da a ka kemikaliya ni a ka masin fanga kan.

Cakɛda ɲɛminɛbagaw ni basigilanw: PPS bɛ baara kɛ cakɛda ɲɛminɛbagaw ni basigilanw na, o bɛ sɛgɛnbaliya ni hakɛ sabatili di.

Industriw wɛrɛw .

PPS plastiki bɛ kɛ baarakɛyɔrɔ caman wɛrɛw la:

Textile Machinery: PPS yɔrɔw bɛ kɛ kalali, sɛbɛnni ani baarakɛminɛnw na, minnu bɛ muɲu ani ka kɛ ni kemikɛli ye.

Furakɛcogo : PPS bɛ kɛ opereli minɛnw yɔrɔw la ka da a ka kemikaliya kan ani a ka se ka sterilize kɛcogo muɲu.

Tumu ni gazi minɛnw : PPS bɛ kɛ jiginɛ minɛnw na, sigilanw na, ani ɲɔgɔndanw na, yɔrɔ minnu na a ka kemikaliya ni a ka funteni caman sabatili nafa ka bon.

Nin ja in bɛ PPS plastiki baarakɛcogo jɔnjɔnw lajɛ izini suguya caman kɔnɔ:

| izini | baarakɛcogo . |

| Mobili ni aerospace . | Motɛri yɔrɔw, fɛnɲɛnamafagalanw yɔrɔw, awiyɔnw kɔnɔna . |

| Elektroniki . | Connecteurs, Insulateurs, Circuit Boards, Microélectroniques . |

| kemikɛli baarakɛcogo . | Valves, Pompes, Filtre so, sigilanw, gaziw . |

| Industriw ka minɛnw . | gears, birikiw, komɛsi yɔrɔw, yɔrɔw minnu bɛ se ka sɛgɛn . |

| Semiconducteur . | Masina yɔrɔw, Kalanso kɛrɛnkɛrɛnnenw ka ɲɛsin semikɔndukiri dilanni ma . |

| Mekanikini injiniyɛri . | komɛsi ni pɔnpe yɔrɔw, cakɛda ɲɛminɛlanw, basigilanw . |

| Textile . | Kalali ni sɛbɛnnikɛminɛnw, baarakɛminɛnw . |

| Furakɛli | Opereli minɛn yɔrɔw . |

| tulu ni gazi . | Downhole minɛnw, sigilanw, ɲɔgɔndanw . |

Polifenilɛni sulfide(pps) fɛnw ka baarakɛcogo ɲuman .

Fàraɲɔgɔnkan ni barikalan suguya caman bɛ Se ka Kɛ ka PPS plastiki nafaw bonya.

farankanw ni barikalanw .

Glass fibre barika bonya .

Glass fibres bɛ dɔ fara PPS ka sɔgɔli fanga kan, a ka flexural modulus, ani a ka bonya sabatili.

U bɛ PPS kɛ minnu bɛnnen don baara kɛtaw ma minnu bɛ kɛ ni masin fanga ka bon.

Fɛn minnu bɛ kɛ ka kɛɲɛ ni sariya ye i n’a fɔ PPS-GF40 ani PPS-GF MD 65, olu ka suguya caman bɛ u la.

Karɔbɔni fiyɛri barika bonya .

PTFE farankanw .

nanoparticules ani nanocomposites .

PPS-based nanocomposites bɛ se ka labɛn ni nanofillers carbone ye (misali la, graphite expanded, nanotubes carbone) walima nanoparticules inorganiques.

Nanofilɛriw bɛ fara PPS kan fɔlɔ walasa k’a ka masinw cogoya ɲɛ.

PPS nanocomposites fanba labɛnna ni melt-blending ye ka da PPS ka insolubilité kan common biologique solvents la.

Nin ja in bɛ PPS falen minnu falen don, minnu tɛ se ka don gilasi la, ani minnu falen don gilasi la, olu ka nafaw suma ɲɔgɔn na:

| nafolo (Unit) gilasi min | ma fa | (40%) | gilasi-minɛrilen falen* |

| densité (kg/l) . | 1.35 | 1.66 | 1,90 - 2,05 . |

| Tensile fanga (MPa) . | 65-85 . | 190 | 110-130 . |

| Elongation ka lafiɲɛbɔ (%) . | 6-8 . | 1.9 | 1,0-1,3 ye. |

| Module flexural (MPa) . | 3800 | 14000 | 16000-19000 . |

| Flexural strength (MPa) . | 100-130 . | 290 | 180-220 . |

| Izod notched impact strength (KJ/M⊃2;) | - | 11 | 5-6 . |

| HDT/A @ 1,8 MPa (°C) | 110 | 270 | 270 |

*Ka kɛɲɛ ni gilasi/mineral filler ratio ye .

farankan kɛrɛnkɛrɛnnenw ka ɲɛsin nafolo yiriwali ma .

Fɛn kɛrɛnkɛrɛnnenw bɛ se ka kɛ ka PPS ka jogo kɛrɛnkɛrɛnnenw laɲini ani k’u bonya:

Alkali nɛgɛ silikatiw ka ɲɛsin viscosité control ma .

Alkali nɛgɛ silikati, alkali nɛgɛ sulfitew, amino acides, ani oligomères de a silel ether bɛ se ka kɛ ka PPS ka nɔgɔya ni a ka nɔgɔya kunbɛn.

Klori kalisiyɔmu ka ɲɛsin molekiyɔmu girinya bonya ma .

bloki kopolimɛriw ka ɲɛsin Impact resistance ɲɛtaa ma .

Asidi sulfonique esters ka ɲɛsin kristalize hakɛ bonya ma .

Nin ja in bɛ farankanw lajɛ minnu bɛ kɛ ka ɲɛsin nafolomafɛnw yiriwali kɛrɛnkɛrɛnnenw ma: Nafolomafɛnw

| wajibiyalenw | faralen ɲɔgɔn kan. |

| Flow melt dɔgɔman, viscosité sanfɛ . | Silikati alkali nɛgɛma, alkali nɛgɛ sulfitew, asidi aminikiw, oligomɛriw ka silili etɛri . |

| Molecules girinya caya . | Klori kalisiyɔmu faralen don polimɛrizi waati la . |

| Impact resistance (Impact resistance) ɲɛtaa . | Bloki kopolimɛriw donli a daminɛ na . |

| Kristali hakɛ cayalenba . | Asidi sulfonique esters ka fara nucleating fɛnɲɛnamafagalan kan . |

| Funteni sabatili ka caya, kristalize funteni dɔgɔyali . | Alkali nɛgɛ walima alkali dugukolo nɛgɛ dithionate . |

Baarakɛcogo fɛɛrɛw PPS plastiki la .

PPS resinw bɛ se ka baara kɛ ni fɛɛrɛ suguya caman ye, i n’a fɔ pikirijikɛlanw dilanni, u bɔli, u fiyɛli, ani u dilanni.

Pikirili Molidali .

Pikiriw dilanni ye PPS baarakɛcogo ye min bɛ kɛ tuma caman na, a bɛ baarakɛcogo ɲuman ni tiɲɛni di.

Extrusion .

PPS bɛ se ka bɔ kɛnɛ kan ka kɛ cogoya caman ye, i n’a fɔ fiɲɛw, filimuw, berew ani slab.

Blow Molding .

PPS bɛ se ka baara kɛ ni fiɲɛbɔlanw ye.

Machining PPS .

PPS bɛ se ka kɛ ni masin ye kosɛbɛ, a bɛ sira di a yɔrɔ dilanni tigitigi ni a gɛlɛn ma.

Nafa min bɛ a la ka ja dilan ka kɔn a ɲɛ .

PPS min bɛ ja ka kɔn o ɲɛ, o nafa ka bon kosɛbɛ walasa ka baarakɛcogo ɲumanw sɔrɔ.

Tablo nata bɛ baarakɛcogo fɛɛrɛw n’u jateminɛcogo jɔnjɔnw lajɛ:

| baarakɛcogo | jateminɛ kunbabaw . |

| Pikirili Molidali . | Aw bɛ ja, funteni ni tansiyɔn sigicogo, nɔgɔ gɛlɛya . |

| Extrusion . | Jali cogoyaw, funteni kunbɛncogo, fiɲɛ ani filimu bɔli . |

| Blow Molding . | Funteni hakɛw, jateminɛw ka ɲɛsin hakɛ falenw ma . |

| Machining . | Coolant selection, annealing processus, ka se ka tiɲɛni kɛ . |

Ni nin baarakɛcogo fɛɛrɛw faamuyara ani u ɲɛnabɔli, dilanbagaw bɛ se ka PPS yɔrɔw ni u yɔrɔw dilan minnu ka ɲi kosɛbɛ baara suguya caman kama.

Dilan jateminɛw PPS baarakɛcogo kan .

Ni aw bɛ PPS plastiki dilan, fɛn caman ka kan ka jateminɛ walasa ka baara kɛcogo ɲuman ni musaka dɔgɔyali sabati.

PPS sugandili baarakɛminɛn kɛrɛnkɛrɛnnenw kama .

PPS sugandili kɛcogo kɛrɛnkɛrɛnnen dɔ kama, o bɛ a ɲini ka jateminɛ kɛ kosɛbɛ a ka jogo kɛrɛnkɛrɛnnenw kan.

kemikɛli resistance .

PPS ka se ka kemikɛli juguw kunbɛn, o b’a to a bɛnnen don ka kɛ kemikɛlifɛnw dilanni na ani izini minɛnw na.

A bɛ se ka asidi barikamaw, basiw, fɛnɲɛnamafagalanw, oksidanw, ani hidrɔkarɔbɔniw sɔrɔ.

Sumayaba sabatili .

Dimensions sabatili .

Masini ni finiko jateminɛw .

PPS bɛ se ka kɛ masin ye walasa ka muɲuli da tugu, o b’a to a bɛnnen don yɔrɔw ma minnu ka gɛlɛn, minnu bɛ kɛ ka ɲɛ.

Masini bɛ se ka kɛ sababu ye ka dugukolo sanfɛla kari ani ka kɔnɔna degunw sɔrɔ PPS kɔnɔ.

O ko ninnu bɛ se ka nɔgɔya ni annealing ye ani ni nɛnɛmadalan bɛnnenw tali ye.

Non-aromatic, ji-solu bɛ nɛnɛ minnu na, i n’a fɔ fiɲɛ min bɛ degun na ani fiyɛli-minɛnw, olu ka ɲi walasa ka se ka dugukolo sanfɛla finiw sɔrɔ minnu ka ɲi kosɛbɛ.

Dimension (hakɛ) sabatili funteni bɛɛ la .

PPS bɛ hakɛ sabatili ɲuman mara funteni suguya caman na.

musaka jateminɛw ni fɛn wɛrɛw ye .

Hali ni PPS bɛ baara kɛcogo ɲuman di, a sɔngɔ ka bon ka tɛmɛ ɛntɛrinɛti plastiki caman kan.

Dilanbagaw ka kan ka PPS tali musaka ni nafa hakɛ jateminɛ.

Fɛn wɛrɛw, i n’a fɔ peek, olu bɛ se ka jateminɛ walasa ka baara kɛ ni u ye minnu tɛ fɛn caman kɛ.

Nka, PPS ka nafolo faralen ɲɔgɔn kan, a ka c’a la, a musaka ka bon baara kɛrɛnkɛrɛnnenw na.

Sigida ni lakana jateminɛw .

A ka ca a la, PPS bɛ jate farati ye ani a tɛ baga ye, nka a minɛcogo ɲuman ni a lakanani sariyaw ka kan ka labato.

PPS bɛ se ka faratiw lase hadamaden ka kɛnɛya ma ani sigida ma ni a ma ɲɛnabɔ ka ɲɛ walima ni a ma bɛn.

Lakanali sariyaw ni laadilikanw ka kan ka labato walasa ka faratiw dɔgɔya.

PPS ka UV tɛ se ka bana sɔrɔ, o b’a to a tɛ bɛn kɛnɛma baarakɛcogo ma ni a tɛ a yɛrɛ tanga.

Nin ja in bɛ PPS baarakɛcogo jateminɛ jɔnjɔnw lajɛ:

| Design Consideration | points points |

| PPS sugandili baarakɛminɛn kɛrɛnkɛrɛnnenw kama . | kemikɛli resistance, funteni caman sabatili, dimension stabilité . |

| Masini ni finidoncogo . | Annealing, coolant bɛnnenw, surface cracking ani kɔnɔna degunw dɔgɔyali . |

| Dimension (hakɛ) sabatili funteni bɛɛ la . | Yɛlɛma fitininw, baarakɛcogo dafalen na cogoya caman na . |

| musaka jateminɛw . | A musaka ka bon ni plastiki sariyalenw ye, musaka ni nafa jateminɛ, fɛn wɛrɛw . |

| Sigida ni lakana . | A ka c’a la, a minɛcogo ɲuman, a kɛcogo ɲuman ani a lakanacogo, UV resistance man ɲi . |

Kuncɛli

PPS Plastiki bɛ fɛn caman di ani baara kɛcogo ɲuman, o b’a to a ka ɲi kosɛbɛ baarakɛcogo caman na. A ka kemikaliya, a ka funteni sabatili, ani a ka masina fanga bɛ dannaya sabati iziniw kɔnɔ.

PPS ka fɛn caman b’a la ka fɛn caman sɛmɛntiya, ka fɛnw kɛcogo ɲɛfɔ, ani ka fɛnw dilacogo ɲɛfɔ, o nafa ka bon kosɛbɛ walasa k’a seko kɛ ka caya. Ni a kɛcogo ɲuman don, PPS bɛ fɛnw dilan minnu bɛ mɛn mobili, aerospace, ɛntɛrinɛti ani fɛn wɛrɛw la.

Ladilikanw: A bɛ se ka kɛ ko aw bɛ a fɛ ka a bɛɛ kɛ plastiki ye .