CNC wud router mashin na stet-ɔf-di-at teknɔlɔji insay wud wok, we de chenj di we aw fɔ mek wud ɛlimɛnt dɛn. Dis na kɔmpyuta kɔntrol routin sistem dɛn – frɔm smɔl CNC router tebul dɛn to big wud routin mashin dɛn usay prɛsishɔn ɔspitul kɔt de kɔpl wit manufakchurin sɛnta dɛn.

Ilɛksɛf na fɔnicha we de mek fɔ yuz CNC router bits ɔ ɔndatak akitɔk trim wok, dɛn wud CNC routing sɔlvishɔn ya dɔn bi wan nid fɔ impɔtant efyushɔn insay prodakshɔn ɛn ivin insay dizayn fɔ wud woka ɛn wud manufakchurin kɔmni dɛn ɔl tu.

Insay dis blɔk, wi go tɛl yu bɔt difinishɔn, aplikeshɔn, ficha ɛn mentɛn tips pan CNC wud routers, we de gi yu prɔfɛshɔnal sɔgzhɛshɔn fɔ pik di bɛst CNC wud router mashin fɔ mek.

Wetin na CNC Wood Router?

Ɔndastand CNC Wood Router .

Di CNC (kɔmpyuta nɔmba kɔntrol) Wud routin teknɔlɔji de yuz kɔmpyuta dijital prɔses fɔ divɛlɔp difrɛn kɔt wud pat dɛn frɔm simpul to kɔmpleks dizayn dɛn. Dɛn kin yuz di router mashin fɔ rid CAD/CAM fayl dɛn ɔ programin kɔd dɛn, we kin dayrɛkt di tin dɛn we dɛn kin yuz fɔ kɔt di tin dɛn we dɛn dɔn pik fɔ di tin dɛn we dɛn dɔn pik fɔ mek di kɔrɛkt dizayn dɛn.

Di kɔntempɔral wud router sistem dɛn de bays pan di prinsipul dɛn fɔ tri-aks kɔntrol ɛn di muvmɛnt dɛn de mek insay X, Y ɛn Z kɔdinɛt fɔ mek wan 3D ifɛkt kɔt patɛn. Di wɔd nɔ jɔs de tɔk bɔt wud wok bɔt i de tɔk bak bɔt intagreshɔn fɔ kɔmpyuta kɔntrol ɛn mashin dɛn fɔ ajɔst di wud wok prɔses dɛn we nɔ biliv ivin fɔ ripit di tawzin dɛn pan wan inch.

Komponent dɛn fɔ CNC wud router .

Gantry System : Na wan robust framework wit wan ovahed bim, we de sopot di spindle muvment wen de stebul am ivin durin agresiv routing spid.

Spindle Unit : Na asembli we dɛn de drɛb bay spindle moto wit 13000 to 24,000 rivɔlɔshɔn fɔ wan minit, we dɛn kin yuz fɔ drɛb di tin dɛn we dɛn kin yuz fɔ kɔt fɔ mek dɛn pul di tin dɛn we dɛn nid fayn fayn wan.

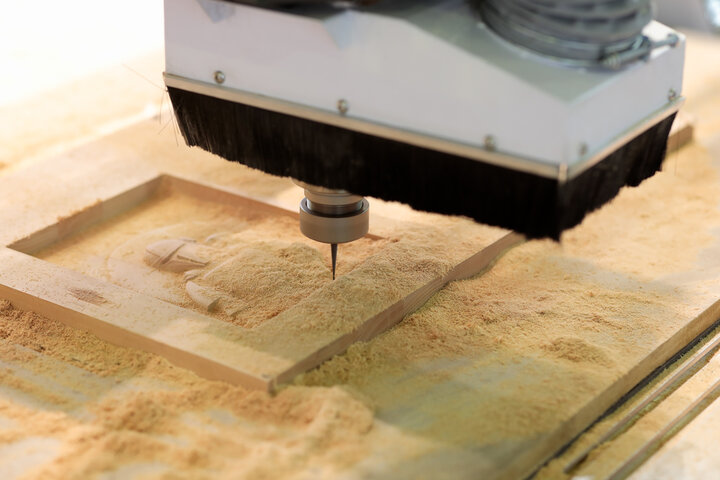

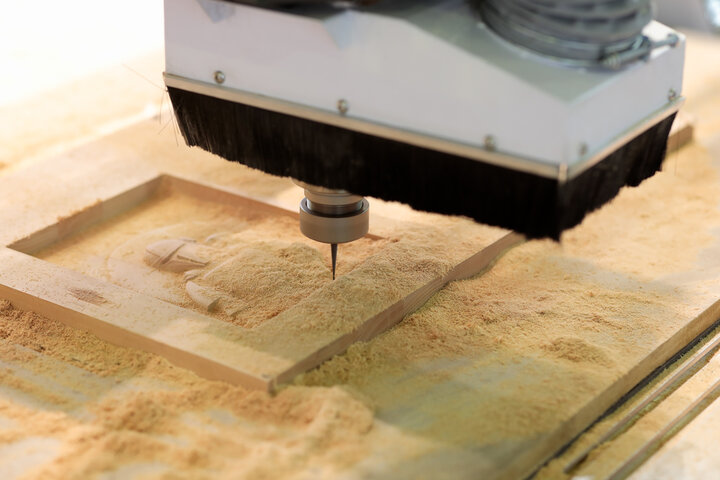

Router Table : wan big saiz woktebul we in surface gɛt inbuilt vacuum chanɛl ɛn kin sɔpɔt wok pies dɛn we de lɛk 5' bay 10' ɛn ivin big.

Tul ɔlda dɛn : Kwik chenjable, ɔpreshɔn bit shank fastɛns fɔ ISO-30 ɔ HSK – 63 intafɛs.

Dust Collection : Dust extraction system we dɛn dɔn instɔl wit saiz dɛn we de bitwin 6-10 inch fɔ pul wud chips ɛn ɔda west dɛn we dɛn de kɔt di prɔses.

Kontrol Sistem : Di intafeys we de alaw di yuza fɔ ɔpreshɔn kɔmpyuta we dɛn ataya to wan NC mashin fɔ mek i ebul fɔ kɔt to skel akɔdin to wan dizayn pan wan CAD.

Mekanism fɔ CNC wud router .

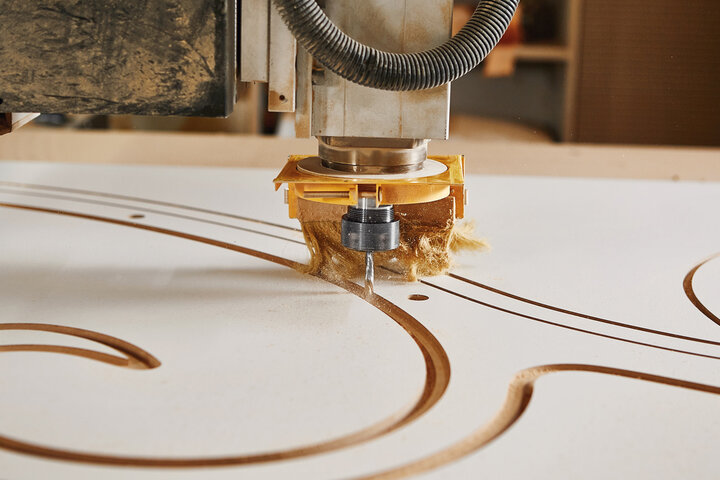

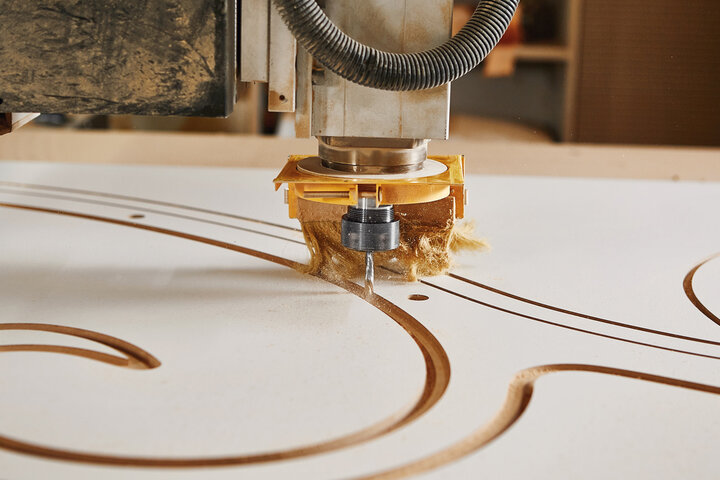

We dɛn de ɛksɛkutiv ɛni kɔt wok, wan wud routa mashin de jɔyn togɛda di rɔtin we di spindle de rɔtin ɛn di muvmɛnt we di tul de muv na di wokples. Di routin proses de employ router bits we kot insay di matirial na fiks fid ret, ɛn mentɛn aprɔpriet kɔt spid fɔ difrɛn kayn wud.

Di kɔmpyuta gɛt di abiliti fɔ kɔntrol dɛn sistem ya, ɛn dipen pan di tɛm we dɛn de kɔt di prɔses, di sistɛm de chenj di paramita dɛn fɔ di kɔt prɔses akɔdin to di we aw di tul dɛn ɔ ɔda tin dɛn de wear. Wan sofistikeyt dip/finish kɔntrol sistɛm dɔn impruv bitwin di spindle ɛn wok pies fɔ mek dɛn ebul fɔ du dis kayn kɔntrol di tɛm we dɛn de du ɛvri kɔt saykl.

Aw CNC Wood Routing de wok?

Progrɛm CNC wud patɛns .

In ɔda wɔd, CNC router mashin dɛn de tɔn di dijital layout fɔ wan dizayn to in kɔrɛspɔndɛns wud kɔt instrɔkshɔn dɛn. Wan CAD-CAM sistem we ful-ɔp wit pawaful wud router softwea de import CAD drɔin ɛn divɛlɔp optimized tul pat, we di CNC Wud Routing Program de invɛstigat bak aw fɔ yuz matirial dɛn di bɛst we insay kɔmpleks wud router wok dɛn.

Mashineri we de yuz fɔ wok .

CNC Wood Router Bits : Rɛnj na strayt shank kɔta, V-kat bit, prɔfayl bit ɛn ɔda wan dɛn fɔ routin pɔpɔshɔn.

Speed of Wood Router : Adjustable precision frɔm tɛn tawzin to twɛnti 4 tawzin rivɔlɔshɔn fɔ wan minit izi fɔ kɔt we dɛn mek fɔ difrɛn wud router wok dɛn.

Fid ret fɔ wan CNC router : Self ajɔstmɛnt fɔ di fid ret fɔ di router de mek shɔ se dɛn kɔt klin wan wit difrɛn wud router kɔmpɔzit dɛn.

Cutting Depth of the Router : Multi-pass programming alaw intricate dizain dɛn we dɛn mek wit 3D wud router.

Wud router wok tebul : Vacuum based workholding alaw fɔ fiks wokpies we dɛn de rout bay CNC mashin.

KONTROLIN Material Muvmɛnt .

Muvmɛnt fɔ di wokpies dɛn de kɔntrol kɔrɛkt wan bay we dɛn de yuz wan nɔmba kɔntrol freym ɛn wan muvmɛnt kɔntrol softwe we de yuz wan aks sistɛm we dɛn put na di sɔfays na di wud router tebul. Ɔl di aks dɛn na industrial servo moto dɛn de drɛb dɛn we ebul fɔ ol spɛshal pozishɔn ivin di tɛm we dɛn de du kɔmpleks kɔva prɔses dɛn na di wud routin mashin.

Wit dis advans wud CNC router mashin, sistem de we de enable pefomans measurement in rial-taym en adjustments of di router parameters dipen pan di kain matiryal we dem de yuz. Di kɔntrol yunit de garanti bak fɔ kɔntrol di kwaliti fɔ kɔt insay difrɛn rɛnj dɛn fɔ wud routa dɛn, inklud di wan dɛn we dɛn yuz fɔ mek fɔnicha pat ɛn akitɔk ditil dɛn.

Wetin na CNC Wood Router in advantej ɛn prɔblɛm dɛn?

Advantej dɛn fɔ Router Wood CNC .

Akkurat & Yunifɔmiti .

CNC wud routers achiv ekstra odinari levuls of akkuracy en opereyt insaid tolerances of op to 0.001 inch or ivin leser. Dis mɛkanikal akkuracy na bɛnifit insay dat i de mek shɔ se yunifɔmiti in di rizɔlt dɛn ova wan rɛnj ɔf wan pis dɛn so dat i go pul mɔtalman inflɛns we prodakshɔn dɛn de rɔn fɔ du. Ilɛksɛf na kɔmplit pat pan art ɔ fɔnicha ɛlimɛnt dɛn, i nɔ go nid fɔ se ɛni wan pan di kɔva dɛn de ɛksɛkutiv wit di sem lɛvul fɔ prɛsishɔn.

Awtomatik tɛm de .

Dɛn kin rɔn dɛn mashin dɛn ya we dɛn nɔ gɛt brek, ɛn dɛn kin kɔmplit ful-skel vishɔn insay di las prɔdak na wan tɛm we rili smɔl pas di tɛm we an dɛn kin yuz. Wan mashin ebul fɔ wok pan sɔm wok dɛn di sem tɛm, if di kwaliti stil de di sem. Dis kayn wokflɔ de pul di tɛm ɛn di kɔst dɛn we dɛn bin fɔ dɔn gɛt fɔ du di sem wok dɛn wit an insay di prɔfɛshɔnal wokshɔp dɛn.

Disain Adapabiliti fɔ di .

Di laytst CNC Technologies komfotabl intaprit wan imej dijital wan ɛn prodyuz di sem; frɔm wan stret fɔdɔm kɔt to wan ditayl 3D skapul. Wit di mɔdan injinɛri tul dɛm, wan disayna nɔ de kɔnfyus fɔ mek ɔl di bɛst dizayn dɛn bikɔs chenj dɛn kin mek te to di las minit we nɔ gɛt ɛni matirial kɔst. Dis min se dɛn kin du ɔva kɔmplikɛt shep, dizayn ɛn kɔstɔmayshɔn dɛn we nɔ gɛt di limiteshɔn fɔ mek dɛn rɛnd di an.

Di wan dɛn we de mek tin dɛn we nɔ gɛt bɔku mɔni .

Di kɔnsidabul ɛkspɛns apfrɔnt kin jɔstifay bay CNC routers bay we dɛn deliv pɔsitiv ritɔn afta sɔm tɛm bikɔs ɔf less leba fɔs ɛn less matirial west . Di mɛkanayz prɔses fɔ prodyus gɛt in bɛnifit dɛn as i de briŋ dɔŋ di kɔst mistek dɛn ɛn di prodakshɔn wok we dɛn kin avɔyd. Di opareshɔnal ret in turn de ɛp fɔ maksimayz di kapasiti fɔ di wokshɔp.

Disadvantages van Router Wood CNC .

Ay initial invɛstmɛnt .

Di sɛtup fɔ wan CNC routin sistem de kɔl fɔ bɔku mɔni, we inklud fɔ bay mashin, ɛn fɔ prokyur di softwe laysens ɛn plus instɔleshɔn kɔst. Ɔda kɔst dɛn na fɔ tren di wan dɛn we de wok ɛn fɔ bay di tin dɛn we dɛn nid lɛk di tin dɛn we dɛn nid lɛk fɔ gɛda di dɔst. Dis kayn faynɛns kɔmitmɛnt kin rili at fɔ smɔl ɔganayzeshɔn dɛn as dɛn de bigin dɛn ɔtomɛshɔn joyn.

Spɛshal skil dɛn we dɛn nid fɔ gɛt .

Wan nid fɔ sabi ɔl tu di wud wok ɛn kɔmpyuta tɛnkɔlɔji dɛn fɔ yuz di CNC mashin dɛn. Di ɔpreshɔn dɛn fɔ no bɔt CAD/CAM sistem ɛn aw fɔ program dɛn, ɛn fɔ wok wit difrɛn kayn ikwipmɛnt dɛn. Dis kayn tin we dɛn nid fɔ no bɔt tɛknikal tin dɛn, min se ay levul skil de we di wan dɛn we de wok wit wud we nɔ ebul fɔ wok ɔtomɛtik wan dɛn kin izi fɔ fes we dɛn de lan fɔ yuz dɛn.

Wetin na di industrial aplikeshɔn dɛn fɔ CNC Wood Router?

Kastom fɔnicha manufakchurin .

Di yus fɔ wud CNC router mashin dɛn kin chenj di fɔnicha prodakshɔn prɔses fɔ bɛtɛ ɛn mɔ sistamɛnt we dɛn. Di mɔdan router wud sistem dɛn de mek shɔ se dɛn kin kɔt kɔmplikɛt jɔyn ɛn patɛn dɛn kɔrɛkt wan. Di CNC router fɔ wud kip wan fayn lɛvɛl fɔ prɛsishɔn akɔdin to ɔl di fɔnicha router wok dɛn, we standad wud router bit dɛn we dɛn impruv insay ɔl di prɔjek dɛn bin briŋ bɔt dɛkɔretiv ficha dɛn.

Kabinɛt Mek ɛn Kichin Instɔlɛshɔn dɛn .

Mɔdan wud kɔt CNC routers dɔn introdyus ɔtomɛshɔn insay prɔses lɛk drɔlin, izi fɔ prosɛs di kabin panɛl dɛn. Di wud routin mashin akchuali posishun di sistem hols of 32mm wen dem mobiliz di 32mm routing sistem of oda tuls. Indastrial-grɛd CNC routers de fasilit di manufakchurin fɔ kabinɛt fes ɛn di insay pat dɛn insay wan mɔ ɔganayz we.

Akitekchɔral mil wok .

CNC wud router sistem wit ay pawa gɛt di kapasiti fɔ prodyuz akitekchral ditel. Di router mashin fɔ wud moldin de prodyuz moldin ɛn panɛl dɛn we gɛt ay kɔmplisiti. ayli advans dizayn fɔ CNC wud router involv furnishings lɛk trim wok ɛn embellishment dɛn we dɛn mek pan di wud yuz kɔstɔm-mɛd router bits.

Myuzik Instrumɛnt Prodakshɔn .

Prɛsishɔn CNC routers fɔ wud dɛn mek fɔ kraft difrɛn wud pat dɛn na di inschrumɛnt dɛn. Di wud router mashin de gi supia pefomans in kontriol of dimenshons fo akostik purposes. Apat frɔm dat, kɔmpleks router wud tul tɛnkɔlɔji dɛn de yuz spɛshal wud CNC routin strateji fɔ jenarayz sɔfays wit kɔmplikɛt kɔv dɛn.

Ɛgzibit ɛn Displei Manufakchurin .

Kastom displei fɔ rital pɔpɔshɔn dɛn de mek bay we dɛn de yuz kɔmɛshɔnal wud routa mashin dɛn. Di yus ɔf CNC routin teknɔlɔji alaw fɔ fast mɔdelin fɔ displei pat dɛn. Ɛgzampul dɛn fɔ pɔshɔnal router projɛkt dɛn na wudwɔk dɛn inklud intalɔk framing sistem ɛn displei bɔd dɛn we dɛn mek pan vertikal CNC wud router tebul dɛn.

Doa ɛn Windo Manufakchurin .

Nesting CNC sistem fɔ wud alaw fɔ ful ɔtomatik domɔt ɛn winda freym fabrikeshɔn layn dɛn. Di moulder mashin de kɔt mɔtis ɛn tɛnɔn timba jɔyn dɛn kɔrɛkt wan. Sofistikeyt CNC timba routin sistem dɛn de alaw bak fɔ di mɔlti-dayrɛkshɔn prɔsesin fɔ timba routa pat dɛn.

Pattern making ɛn prototyping .

Wit advans Tommorow in teknɔlɔji, CNC wud routers de ɛnabul fɔ mek patɛns fɔ industrial yuz. Di wud routin teknɔlɔji de alaw fɔ simpul chenj fɔ dizayn dɛn insay shɔt tɛm. Prodakshɔn wud router mashin dɛn we gɛt spɛshal router bits, kin mek kɔmpakt ɛn kɔmpleks patɛn wit shap akkuracy.

Aw fɔ Mentɛn CNC Wud Router Sistem dɛn?

Fɔ du mentenɛns ɔltɛm .

Wan kɔnsistɛns chɛk-ɔp schedule na di router bits observ se dɛn kɔtin edj dɛn de stil shap, we wan periodik klinin fɔ di wud router tebul surface de mek shɔ se no debris bild up. Spindle bearings of di wood routing system fɔ bi lubrik na intaval lɛk aw di manifakta in rɛkɔmɛndishɔn se.

We yu tek kia ɔf di kɔlɛkshɔn sistɛm as dɛn bin want fɔ mek shɔ se di CNC router fɔ wud de insay pafɛkt opareshɔn kɔndishɔn. Vakyum sil dɛn na router wud tebul dɛn fɔ de chɛk ɔltɛm bay di ɔpreshɔn dɛn, ɔl di kɔntaminɛshɔn kɔntrol ɛlimɛnt dɛn fɔ klin, ɛn di lɛvɛl dɛn we dɛn chɛk di sukshɔn fɔ mek shɔ se di wok-pies nɔ displeys di tɛm we dɛn de du wud CNC routing prɔses.

Sɔlv fɔ kɔmɔn tin dɛn .

Di ay-ɛnd wud router mashin dɛn kin dɔn bak fɔ alaynɛshɔn ɛn dɛn go gɛt fɔ kalibrayt am afta wan patikyula tɛm. Di CNC router ɔpreshɔn fɔ chɛk fɔ ɛni indikashɔn fɔ aks muvmɛnt wear ɛn di tɛnsiɔn fɔ bɛlt dɛn na di router wud sistem dɛn, ɛn bak di tul ɔfset akkuracy. Periodik asesmɛnt fɔ di waya ɛn kɔnɛkshɔn dɛn fɔ di wud routin mashin de ɛp bak fɔ avɔyd ilɛktrik sistɛm malfunctions.

Insay CNC Wudwɔks, di kwaliti fɔ kɔt de inflɔws bay di stet fɔ di router bit. So, staggered tool riplesmɛnt skim fɔ wud router bits ɛp fɔ manej di yus fɔ cuttingtools. Fɔ mek dɛn ebul fɔ mek shɔ se di kwaliti we dɛn de kɔt fayn, i impɔtant fɔ chɛk di spindle wan wan tɛm ɛn di kɔlet kɔndishɔn na wan wud router mashin.

Standart fɔ Sistem Kalibreshɔn .

Kalibreshɔn mɛtɔd fɔ wud CNC routers garanti yunifom mashin prɛsishɔn. Di sistem fɔ routin wud nid fɔ chɛk dɛn wan wan tɛm fɔ di pɔrpindikul we di aks dɛn de ɛn di ajɔstmɛnt dɛn fɔ di muvmɛnt kɔntrol sɛtin dɛn. Suitabl fɔ industrial yuz CNC router divays dɛn fɔ ɔnda tɛst fɔ posishun akkuracy ɛvri naw ɛn den wit di ɛp fɔ laser mɛzhɔmɛnt tul dɛn.

Sofistikeyt wud wok ikwipmɛnt dɛn kin gɛt ɔpdet dɛn wan wan tɛm bɔt di ficha dɛn we dɛn dɔn instɔl ɛn dɛn validɛshɔn. Di kɔntrol softwe fɔ wan CNC wud kɔt mashin nɔ fɔ fɔgɛt fɔ bak di mashin paramita dɛn inklud di tul dɛn we dɛn yuz. NJ Router Machine in ɔpreshɔn dɛn fɔ kip di rayt ɛn ɔpdet rɛkɔd dɛn fɔ ɔl di kalibreshɔn dɛn we dɛn du fɔ adherence to kwaliti kɔntrol standad dɛn.

Ki difrɛns bitwin CNC wud router ɛn mɛtal CNC mil .

Spid ɛn pawa kwaliti dɛn .

CNC routers fɔ wud wok alaw fɔ yuz ay spindle spid, we de bitwin 13,000 te to 24,000 rpm pan avɛj. Dɛn routin ɔpreshɔn ya we dɛn de du wit ay spid de ɛp fɔ ɛp fɔ mek di kwaliti fɔ kɔt insay wud matirial dɛn bɛtɛ. Na di ɔda say, mɛtal mil mashin dɛn de wok wit smɔl spid we avrej frɔm 2000 to 10,000 rpm fɔ mek dɛn ebul fɔ gi di mɛtal kɔt tɔk we dɛn nid.

Kɔmɛshɔnal gred routers de yuz spindle pawa in di renj bitwin 5 ɛn 15 hp usay sɔfayz spid de fav pas fɔ kɔt fɔs. Na di ɔda say, mɛtal CNC mil mashin dɛn gɛt bɔku mɔ pawaful spindle motoka dɛn, bɔku tɛm dɛn kin pas 20 ɔspawɛl, fɔ mek di spindle kɔt tru had mɛtal dɛn.

Tooling ɛn Holding Systems .

Mɛtal dɛn we de krank aut mashin dɛn de yuz mɔ rigid tulholdin sistem dɛn, lɛk BT40 ɔ CAT40 taper ikwipmɛnt, we kin bia bɔku bɔku kɔt fɔs dɛn. Di wud routin mashin kin mek yus to di wan dɛn we nɔ gɛt bɛtɛ hεvi-duti lɛk ISO-30 ɔ HSK-63 we fayn fɔ fast wud prɔsesin ɔpreshɔn.

CNC router bits fɔ wud nɔto di sem wit mɛtal kɔt kɔta bikɔs dɛn gɛt difrɛn jɔyometri, we gɛt dɛn yon rayk ɛn flut fɔ chip pul. Insay mɛtal mil, dɛn kin yuz kɔstɔm mek kabayd tul dɛn wit kɔtin tɛknik dɛn we kin bia wit ɔt ɛn lɔng layf insay kɔt stɛl.

wok eria ɛn kɔnstrɔkshɔn .

CNC routers we dɛn bil fɔ wud prɔsesin kin kam wit ay wok ɛnvilɔp we na mɔst 4' bay 8' ɔ 5' bay 10'. Dis na fɔ mek yu ebul fɔ wok pan sheet guds. Metal mil mashin dɛn fiba bikɔs dɛn gɛt wok ɛnvilɔp dɛn bak we smɔl pan dimɛnshɔn dɛn na di aktual mashin. Aweva dɛn mek dɛn kayn mashin ya bɔku ebi so dat dɛn go avɔyd ɛni vaybreshɔn we go afɛkt di kɔt prɔses.

Wudwok routers inkorporet som wok-holdin sistem we de wok pan vacuum prinsipul, while metal cutting routers mostly yuz mechanical clamping in t –slots en vises. Di freym strɔkchɔ fɔ di wud router mashin na fɔ tek in ɔva big fɔmat wokpies. Bɔt mɛtal mil dizayn inkɔrpɔret kɔnstrɔkt barɛri fɔ kɔt prɔses wit bɔku akkuracy.

Di we aw dɛn de pul di tin dɛn we dɛn dɔn yuz

CNC Wood routing alaw fɔ pul di matirial pan wan rili ay spid ɛn wit smɔl kɔt fɔs, we fit mɔ fɔ di kwaliti dɛn we wud fayba dɛn gɛt. Bɔt dis nɔto di kayn tin we dɛn kin du na mɛtal mil ɔpreshɔn usay dɛn kin yuz ay kɔt fɔs fɔ kɔt mɛtal pan lɔw spid fɔ mek dɛn ebul fɔ kɔntrol di ɔt we dɛn dɔn mek ɛn di chips dɛn we dɛn mek insay mɛtal.

Di wud router mashin na haili proficient in surface shear en cut-out pattern mek in flat woks as wel as in komplex tri-dimenshonal fom. Na di ɔda say, di mɛtal mil dɛn fit wit ay-spid rɔta kɔtin tul dɛn we dɛn mek fɔ pul matirial, kɔntɔring rili kɔrɛkt wan di matirial insay sɔm siriɔs ɔpreshɔn dɛn. Chip kulant sistem dɛn kin de fɔ dɛn kɔt yunit dɛn ya as pan ɔkashɔn kɔt kin tu dip ɛn tu hot fɔ pefɔm insay wan pas.

Table: CNC wud router vs metal cnc mil

| feature ctegori cnc wud | router | metal cnc mill |

| Spindle spid yu gi oh . | 13,000-24,000 rpm | 2,000-10,000 rpm |

| Pawa raytin . | 5-15 Ɔs pawa . | 20+ ɔspawɛl . |

| Di wan dɛn we gɛt tul dɛn . | ISO-30, HSK-63. | BT40, CAT40. |

| tebul saiz . | 4'x8' to 5'x10' Tipik | 2'x4' Tipik |

| Wokholding . | Vakum sistem . | Mekanikal klamp, T-slots . |

| Fram we dɛn de bil . | Aluminium/Stiɛl haybrid . | Sɔlid Kast Ayɔn . |

| Tipik Aplikeshɔn dɛn . | Shit guds, panɛl, fɔnicha . | pat, mold, day . |

| Strateji fɔ kɔt . | Ay spid, layt kot . | Low spid, hevi kot |

| Di tin dɛn we dɛn kin yuz fɔ pul di tin dɛn we dɛn dɔn yuz . | Surface Profiling . | Prɛsis dip kɔntrol . |

| Sistem we de mek yu kol . | Dust Kɔlɛkshɔn . | Liquid kulant . |

| muvmɛnt spid . | 1000+ inch/minit | 100-400 inch/minit |

| Akkurat R ɛnj . | ±0.005' tipik | ±0.0005' tipik |

| Di tin dɛn we dɛn kin yuz fɔ mek tin dɛn . | Wud, Plastik, Kɔmpɔzit | stɛl, aluminiɔm, alɔys . |

| Tul Layf Fɔs . | Surface finish kwaliti . | Hɛt/wear Resistance . |

| Machine Cost Range . | $20,000-100,000 | $50,000-500,000+ |

Yu rɛdi fɔ ɛlevɛt yu wud wok kapabiliti dɛn?

Team MFG bring yu profeshɔnal-grɛd CNC Wud routin sɔlvishɔn dɛn bak bay industri ɛkspɛriɛns. Wi dediket tim fɔ CNC spɛshal pipul dɛn de gi sɔpɔt arawnd-di-klɔk, ɛn mek shɔ se yu prodakshɔn nɔ ɛva stɔp. Kontakt wi tide fɔ diskɔba aw wi kɔt-ɛj wud CNC mashin dɛn kin transfɔm yu manufakchurin prɔses.

24/7 Tɛknikal Sɔpɔt .

Ɛkspɛkt kɔnsultɛshɔn .

️ Prɔfɛshɔnal instɔleshɔn .

✅ Rilibul afta-sɛl savis .

Kwɛshɔn dɛn we dɛn kin aks ɔltɛm (FAQ)

K: Aw a go pik di rayt router bit fɔ difrɛn wud dɛn?

We pɔsin de pik router bits, i fɔ tek tɛm tink bɔt di had we di wud de ɛn bak di say we di gren de. Fɔ ɛgzampul, Carbide Tipped CNC Wood Router Bits kin de fɔ lɔng tɛm ɛn dɛn kin bɛtɛ fɔ sav pɔshɔnal dɛn we de wok wit wud dɛn we at fɔ du. Pantap dat, di fid ret ɛn RPM fɔ difrɛn wit di dayamita ɛn di nɔmba fɔ di flut dɛn na di bit. I fayn fɔ yuz kɔmpreshɔn bit dɛn na plai wud aplikeshɔn fɔ mek dɛn ebul fɔ dɔn di wok fayn fayn wan.

K: Wetin na di opareshɔnal ɛn sefty ficha dɛn we a fɔ gɛt na CNC wud routers?

We i kam pan di bɛsis sefty ficha dɛn, ɔltɛm e-stɔp bɔtin dɛn de, dɛn kin lɔk di chɛmba ɔltɛm, ɛn dɔst kɔntinɛnt sistem dɛn de insay. Insay di mɔdan wud router mashin dɛn, akses panɛl sefty intalɔk ɛn ɔtomatik brek sistem fɔ di spindle dɔn bi wan rikwaymɛnt fɔ di sef fɔ di pɔsin we de yuz am.

K: Wetin mek mi CNC router de lɛf bɔn mak pan hadwud?

Bɔns we kin apin we dɛn de wok wit wud kin kɔmɔt frɔm we dɛn de yuz di rɔng fid ret ɔ yuz router wit wan bit we dɔn pwɛl. We dɛn de du di wud routin prɔses, dɛn kin mek ɔt ɛn dɛn fɔ kɔntrol am bay di rayt we aw dɛn kɔt am. Dɛn kin avɔyd dis kayn we aw dɛn kin bɔn di say dɛn we dɛn de mek di wɔl bay we dɛn de shap di tul dɛn ɔltɛm ɛn ajɔst di spid we dɛn de kɔt fayn fayn wan.

K: Aw bɔku ‘ɛfɛktiv’ spɛs a nid fɔ plesmɛnt fɔ wan CNC wudrɔuta sistɛm?

Kɔmɛshɔnal-grɛd CNC router instɔleshɔn dɛn de kɔl fɔ spɛs we pas di wan we di mashin in futprin gɛt. Wan standad 4'x8' wud router tebul nid, pan avɛj 15'x12', totɛl eria inkluziv fɔ dɔst kɔllɛkshɔn ɛn matirial stɔrɔj eria dɛn.

K: Us mashin apkip schedule a go nid fɔ observ fɔ mek shɔ se di mashin wok fayn fayn wan?

Di klin we dɛn de klin di router bits ɛn di chɛk dɛn we dɛn de chɛk na dɔst na sɔm pan di tin dɛn we dɛn de du ɛvride. Limbering di gayd rel ɛn chɛk bɛlt tɛnsiɔn na sɔm pan di aktiviti dɛn we dɛn kin du wan tɛm ɛvri wik. Inspekshɔn ɛn ri-kalibreshɔn fɔ di sistɛm in ɔl togɛda wit wan tul chɛk na wetin de involv wud CNC router mentenɛns afta ɛvri mɔnt.

K: I pɔsibul fɔ mek a ad ɔda fɛnshɔn dɛn to mi CNC router fɔ ivin mɔ kɔmpleks wud prɔjɛkt dɛn?

Mɔs pan di wud wok routa sistem dɛn de mek dɛn ebul fɔ ad-ɔn dɛn lɛk tul chenj, big spindl ɛn vaykum tebul zon ɛkstenshɔn dɛn. Di kɔntrol sistɛm fɔ di CNC routin divays kin bak ɛnhans wit sofistikieted softwea funkshɔnaliti fɔ advans wud router dizayn projɛkt dɛn.