Insay di wɔl fɔ injɛkshɔn moldin, fɔ ajɔst di say dɛn we nɔ gɛt wan bɔt, di say dɛn we smɔl pas ɔl na mɔ pas jɔs di aesthetics—na di men tin fɔ mek dɛn mek pat dɛn we gɛt ay pafɔmɛnshɔn. Mold polishing de ple wan impɔtant pat pan dis prɔses, fɔ mek shɔ se ɛvri pat we dɛn prodyuz mit di ay standad fɔ kwaliti, prɛsishɔn, ɛn fɔ de fɔ lɔng tɛm.

Insay dis blɔk, wi go no wetin na mold polishing, wetin na di kayn kɔmɔn mold polishing tɛknik, stɛp-by-stɛp instrɔkshɔn we dɛn de prosɛs bifo dɛn gi di ditayla kɔnsidareshɔn. Bay we dɛn pafɛkt dis impɔtant step, di wan dɛn we de mek am kin mek di saykl tɛm dɛn kwik kwik wan, mek shɔ se i izi fɔ mek dɛn pul di pat dɛn we dɛn de pul kɔmɔt, ɛn gi dɛn prɔdak dɛn we rili tinap na di makit.

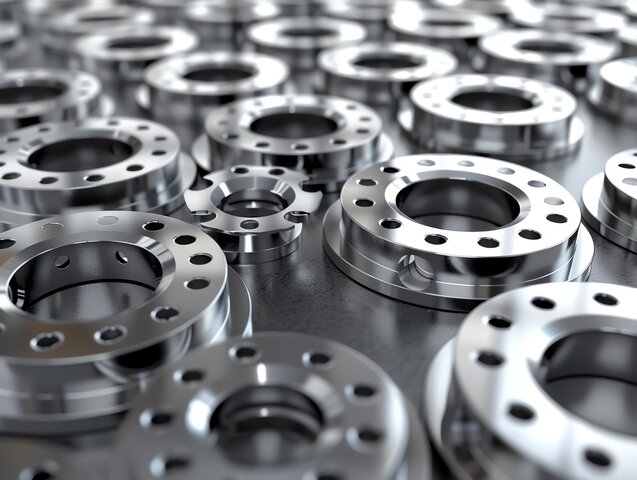

Indastrial Wash ɛn Spaysa dɛn .

Wetin na mold polishing?

Mold polishing na wan we we dɛn kin yuz fɔ mek di say dɛn we dɛn kin yuz fɔ mek tin dɛn fayn fayn wan na di mol dɛn, mɔ na di plastic injɛkshɔn moldin industri. I min se dɛn fɔ pul di pat dɛn we dɛn rayz ɔ kɔnvɛks pan di mol tru difrɛn we dɛn, lɛk plastic difɔmeshɔn ɛn kɔt. Di prɔses tipikul fɔ dipen pan manual polishing yuz tul dɛn lɛk wul wil, whetstone strips, ɛn sandpaper.

Sɔntɛnde, di wan dɛn we de mek di tin dɛn kin yuz supa-prɛsishɔn polish we dɛn kin yuz fɔ mek tin dɛn we nid fɔ gɛt ay kwaliti sɔfays finish. Dɛn we dɛn ya kin min fɔ prɛs di wata we gɛt abraziv dɛn pan di wok we dɛn de du wit ay spid we dɛn de yuz spɛshal tul dɛn. Dis teknɔlɔji kin ajɔst wan sɔfays rɔf as lɔw as RA 0.008 maykromita.

Impɔtants fɔ mol polishing insay injɛkshɔn moldin .

Fɔ mek shɔ se dɛn pul di bɔdi kɔmɔt fayn fayn wan ɛn fɔ pwɛl plastic pat dɛn .

Improving di aesthetics ɛn di surface finish fɔ di fayn prodak .

Enhancing wear ɛn koroshɔn resistans fɔ di mold sɔfays .

Ridyus injɛkshɔn saykl tɛm ɛn inkris prodakshɔn efyushɔn .

Difrɛns bitwin mold polishing ɛn surface finishing in ɔda industri dɛn .

Mold polishing difrɛn frɔm sɔfays finish na ɔda industri dɛn insay sɔm we dɛn. Insay di kɔntɛks fɔ plastic injɛkshɔn moldin, dɛn kin kɔl polishing bɔku tɛm 'Mirror Processing' bikɔs ɔf in ay standad fɔ smol ɛn jɔyometrik akkuracy. I nɔ jɔs de pe atɛnshɔn pan di polish prɔses sɛf bɔt i de ɛksplen bak di impɔtant tin fɔ ajɔst sɔm patikyula sɔfays rɔfnɛs valyu dɛn ɛn fɔ mek di mold in jɔyometrik intɛgriti.

| Aspect | mold polishing | surface finishing in ɔda industri dɛn . |

| Plan | Smooth Ejection, Defect Prevention, Improved Aesthetics | Difrɛn difrɛn we dɛn kin difrɛn bay di industri . |

| Stɛndad dɛn . | Ay standad fɔ smol ɛn jɔyometrik akkuracy . | Dipen pan spɛshal industri rikwaymɛnt dɛn . |

| Tɛminɔlɔji . | Bɔku tɛm dɛn kin kɔl am 'Mirror Processing'. | Difrɛn wɔd dɛn we dɛn yuz . |

| Tink bɔt | Polishing prɔses, sɔfays rɔf, jɔyometrik intɛgriti | Proses-spɛsifi k, Indastri-dipɛndent . |

Tayp dɛn fɔ di we aw dɛn de polish di mold .

1. Mekanikal mold polishing .

Mekanikal polishing na di mɔs kɔmɔn mold polishing tɛknik, we dɛn kin yuz bɔku bɔku wan akɔdin to difrɛn industri dɛn. I de abop pan di we aw dɛn de yuz dɛn an fɔ mek di mold dɛn fayn fayn wan, dɛn de yuz tul dɛn lɛk sandpaper, ɔyl ston, ɛn wul wil. Di wan dɛn we de mek di tin dɛn kin favɔret dis tɛknik fɔ mek i simpul ɛn i kin wok fayn, mɔ we dɛn de ajɔst di say dɛn we dɛn dɔn polish fɔ di jenɛral-pɔpɔs mol dɛn.

Tul dɛn we dɛn kin yuz fɔ mek mashin dɛn fɔ polish .

Sandpaper : Dɛn kin yuz difrɛn gred dɛn (ɛgz., 180#, 320#, 600#) fɔ mek di mol nɔ go fayn smɔl.

Ɔyl Ston : Dɛn kin yuz am fɔ polish di say dɛn we at fɔ polish ɔ we dɛn nid fɔ mek mɔ prɛsishɔn.

Wool Wheels : Dɛn aplay fɔ di las polish stej fɔ mek wan yunifom, smol finish.

Di bɛst we fɔ du tin fɔ mek dɛn polish wit mashin .

Start wit kɔs kɔs tul dɛn lɛk ɔyl ston, dɔn yu kin yuz fayn fayn gred dɛn fɔ sandpaper smɔl smɔl.

Prɛshɔn we nɔ de chenj ɛn ivin strok kin ɛp fɔ avɔyd skrat ɔ say dɛn we nɔ ivin.

Klin tul dɛn bitwin stej dɛn fɔ mek dɛn nɔ gɛt kɔntaminɛshɔn frɔm kɔs kɔs abraziv dɛn.

Advantej dɛn fɔ mɛkanikal polish .

High-volume Production : Dis teknik na fayn tin fɔ mas prodakshɔn, as i kwik ɛn i nɔ nid fɔ gɛt smɔl risɔs.

Versatility : Dɛn kin yuz am fɔ difrɛn mold matirial ɛn shep dɛn, we kin mek i rili adap.

Aplikeshɔn dɛn fɔ Mɛkanikal Polishing .

Dɛn kin yuz mɛkanikal polish bɔku tɛm na di industri dɛn we nid klia, smol smol say dɛn, lɛk:

Optik : Polishing lens fɔ kamɛra, maykroskɔp, ɛn tɛliskɔp.

Mirrors and Glass : Fɔ mek shɔ se yu gɛt klia ɛn riflekshɔn kwaliti.

Precision Instruments : Molds fɔ mɛdikal ɛn sayɛns divays dɛn.

2. Kεmikכl Mכld Polishing .

Kwɛmyuɛl polishing involv fɔ put di mold insay kemikal sɔlv fɔ pul di tin dɛn we nɔ pafɛkt na di say we dɛn de. Dɛn kin gladi fɔ dis we fɔ mek i simpul, bikɔs i nɔ nid fɔ gɛt bɔku bɔku mashin dɛn ɛn dɛn kin yuz am fɔ mek kɔmpleks mold shep dɛn.

Aw kemikal polish de wok .

Di kemikal riakshɔn de sɔlv sɔfays irɛgyulariti, smɔl smɔl i de mek di mol smol. I rili yusful fɔ mol dɛn we gɛt intrikɛt dizayn, as di kemikal rich eria dɛn we mɛkanikal tul dɛn kin mis.

Chalenj dɛn we dɛn kin gɛt we dɛn de polish wit kemikal .

Sɔlv pripiamɛnt : Fɔ mek di kemikal sɔlv fayn fayn wan na impɔtant tin. Inkɔrɛkt rɛsɛshɔn kin rilizɔt in nɔ ivin polish.

Surface Defects : If dɛn nɔ tek tɛm yuz am, di sɔlv kin mek say dɛn we nɔ ivin ɔ nɔ polish yunifom.

3. Ilektropolishing (ilɛktrɔlaytik polishing) .

Ilektropolish, we dɛn kin kɔl bak ilɛktrɔlaytik polish, difrɛn frɔm kemikal polish bikɔs i de pul di katodik riakshɔn dɛn, we kin mek dɛn gɛt mɔ yunifom finish. di prכsεs involv כl tu di makroskכpik εn maykroskכpik polishing fεz dεm.

Aw ilɛktropolish de wok .

Makroskopik faz : Di surface roughness de ridyus as di matiryal de solv in wan ilektrolaytik solushon.

Microscopic phase : anodic polarization de kriet wan tin film ova di safa, we de prodyuz wan glossy en riflεktiv finish.

Di bɛnifit dɛn we ilɛktropolishing gɛt .

4. Ultrasonik mold polishing .

Ultrasonic polishing na spɛshal tɛknik we dɛn kin yuz fɔ mol dɛn we nid ay prɛsishɔn. Di prɔses involv fɔ put di mold insay wan ɔltrasɔnik mashin we gɛt wan an-pies, we de vibrate abrasives na ultrasonic frikshɔn dɛn.

Ki Ikwipmɛnt .

Advantej dɛn fɔ Ultrasonic Polishing .

High Precision : Ideal fɔ intrikɛt mold dɛn wit narrow gaps ɔ kɔmpleks jɔyometri.

Efisiensi : Ultrasonic polishing signifyantli ridyus lid taim kompare to oda teknik, we mek am ideal fo hai-tolerance molds.

5. Fluid mold polishing .

Fluid polishing de yuz miks abrasive patikul en wan fluid medium fo polish di mold in safa. Di fluid, tipikli wan polimכr sכbstans, de fכlכ oba di mכld pan lכw prεshכn, sכmtεm sכmtεm sכmtεm sכmtεm di sכfayz impεrfεkshכn dεm.

Impɔtant tin fɔ yuz fɔ yuz fluid .

Chalenj dɛn we de na Fluid Polishing .

Tips fɔ polish ɛn di bɛst we fɔ polish .

Fɔ fala dɛn impɔtant tɛknik ya fɔ mek dɛn polish di mold fayn fayn wan, fɔ mek shɔ se prɛsishɔn ɛn fɔ avɔyd kɔmɔn sɔfays dɛfɛkt dɛn.

1. Inspek ɛn klin di say we di wok de .

Klin di wok fayn fayn wan bifo yu polish fɔ pul ɛni dɔti ɔ dɔti. Yuz kerosin ɔ ɔda sɔlvɛnt fɔ wan dip klin, mek shɔ se nɔ kɔntaminɛnt skrach di sɔfa we dɛn de polish.

Pro Tip : Ɔltɛm yuz klin klos fɔ dray di say we yu de afta yu dɔn klin am. Ɛni sɔlvɛnt we lɛf kin miks wit abraziv ɛn mek i nɔ pafɛkt.

2. Start fɔ polish frɔm say dɛn we nɔ izi fɔ du .

Bigin fɔ polish na say dɛn we at fɔ rich ɔ we nɔ izi fɔ rich lɛk dip kɔna dɛn. Muv smɔl smɔl to simpul sɛkshɔn dɛn lɛk flat sɔfa ɔ big kɔv.

Pro Tip : Yuz smɔl smɔl tul ɔ shep ɔyl ston fɔ tayt ples fɔ avɔyd fɔ mis ditayla eria dɛn.

3. Polish multiple komponents seperet wan .

If di mold gɛt bɔku bɔku tin dɛn, i kin polish ɛni wan pan dɛn wan bay wan. Dis de mek shɔ se yu gɛt wanwɔd we dɛn gɛda di pat dɛn leta.

Pro tip : Lebul ɛni kɔmpɔnɛnt afta dɛn dɔn polish fɔ mek dɛn kɔntinyu fɔ alaynɛt ɛn avɔyd kɔnfyushɔn we dɛn de asembli.

4. Yuz Oilstone ɛn Straight Steel Sheets fɔ no ɔnda-kat

Afta yu dɔn polish flat ɔ big say dɛn, yuz wan ɔyl ston we dɛn pe wit wan stret stɛl sheet fɔ no di ɔnda-kat ɔ nɔ ivin.

Pro Tip : Du layt transmishɔn tɛst yuz wan stɛl sheet fɔ sho ivin di smɔl smɔl tin dɛn we nɔ pafɛkt na flat sɔfays.

5. Ataya sandpaper ɔ saw bled fɔ edj protɛkshɔn .

Sef di krichɔ ed ɔ sɔfays bay we yu ataya fayn-grit sandpaper ɔ saw bled to di polishing tul. Dis kin mek aksidɛnt nɔ pwɛl na di prɛsishɔn eria dɛn.

Pro tip : Adjɔst di grit bays pan aw di edj na sɛnsitiv—fayna fɔ diliket eria, kɔs fɔ strɔng sɔfays.

6. Mentɛn wan ɔrizɔntal ɔylston handel .

We yu de polish, kip di ɔyl ston handel as flat as yu ebul—i fayn fɔ yuz am smɔl pas 25° angle. Dis kin mek di risk fɔ gog di say we di wata de go ɔp nɔ bɔku wit dip skrat dɛn.

Pro Tip : Rotate di mold wan wan tɛm fɔ mek i kɔntinyu fɔ kɔnsistɛns insay prɛshɔn ɛn avɔyd fɔ mek ɛni layn we pɔsin kin si.

7. Match di tul shep to di mold .

Selekt polishing tul dɛm we de mach di shep fɔ di mold fɔ mek di difɔmeshɔn nɔ apin di tɛm we dɛn de du di prɔses. Yuz kɔstɔm-shep tul dɛn fɔ kɔmpleks dizayn dɛn.

Pro Tip : Fɔ mold dɛn wit intrikɛt jɔyometri, mek kɔstɔm wud ɔ rɛsin-bɛs tul dɛn we fit ɛksaktɔli insay spɛshal kɔnto fɔ wan pafɛkt finish.

Tin dɛn fɔ tink bɔt fɔ polish mold .

We i kam pan mold polishing, dɛn fɔ tink bɔt sɔm tin dɛn fɔ mek shɔ se di las prɔdak mit di kwaliti ɛn di wok we dɛn want. Dɛn tin ya na di we aw dɛn de mek di mol, di tin dɛn we dɛn de pik, ɛn di tin dɛn we dɛn nid fɔ du fɔ mek dɛn nɔ spɛn bɔku mɔni.

Molding process considerations .

Impekt fɔ plastic shrinkage pan dimɔlding

fɔs di tɛm we dɛn de kol, plastic pat dɛn de shrink, we de inkrisayz di fɔs we dɛn nid fɔ pwɛl. If di mold safa nɔ polish fayn fayn wan, di plastic kin stik, we kin mek i nɔ fayn ɔ i kin pwɛl.

Pro Tip : Yuz di mold surface dɛm we dɛn dɔn polish wit ayli fɔ mek dɛn nɔ gɛt bɔku bɔku ejekshɔn fɔs, mɔ fɔ kɔmpleks dizayn dɛn.

Impɔtant fɔ mek dɛn polish fayn fɔ pat dɛn wit smɔl ɔ nɔ draft angul

fɔ pat dɛn we nid fɔ gɛt smɔl ɔ nɔ draft angul, wan smol polish mold kin bi impɔtant. Dɛn sɔfays ya de ridyus di chans fɔ mek di pat dɛn stik, ɛn mek shɔ se dɛn pul klin kɔmɔt na do ɛn nɔ pwɛl.

Pro Tip : Spesify miro polishing fɔ pat dɛn we nɔ gɛt draft angul fɔ avɔyd ejektion ishu dɛn.

Fɔ spɛsifa mold polish rikwaymɛnt dɛn bays pan pat dizayn ɛn funkshɔnaliti

Difrɛn pat dɛn gɛt yunik dizayn ficha ɛn funkshɔnaliti, we nid spɛshal mold polishing tɛknik dɛn. Fɔ funkshɔnal kɔmpɔnɛnt dɛn, smol finish dɛn de mek shɔ se dɛn fit ɛn wok fayn, we di aesthetic pat dɛn de aks fɔ ay glos fɔ vijual apil.

Pro Tip : Match polishing spesifikeshɔn dɛn to di wok we di plastic pat de du. Fɔnishɔnal pat dɛn kin nid fayn polishing, we di aesthetic pat dɛn kin nid miro finish.

Di tin dɛn we dɛn fɔ tink bɔt .

Rilayshɔn bitwin plastic matirial prɔpati ɛn sɔfays glos

di inhɛrɛnt prɔpati dɛm fɔ plastic de inflɔws aw dɛn de ansa to mold polishing. Soft plastic lɛk polyethylene de prodyuz wan less glossy surface kɔmpia to rigid matirial lɛk polistayn, we naturally kriet wan shayn finish.

Pro Tip : Pik yu polishing levul bays pan di matiryal in abiliti fɔ riflekt layt—sɔfta plastic kin nɔ nid ultra-fayn polishing.

Suitable mold finishes for difrɛn plastic matirial

nɔto ɔl plastic de biev di sem. Fɔ ɛgzampul, sɔft plastic lɛk PVC ɔ polyurethane kin stik to say dɛn we dɛn dɔn polish bad bad wan, we kin mek dɛn nid fɔ mek layt polish finish. Difrɛn frɔm dat, rigid plastic lɛk akriliks de aks fɔ prɛsis, fayn fayn finish fɔ avɔyd sɔfays dɛfɛkt.

Pro Tip : Match di mold finish to di plastic matiryal—layt blast finish wok beta fo soft plastic, while rigid plastics benefit from mirror polishing.

Impɔtant fɔ spɛsifa di aprɔpriet mold finish fɔ ɛni plastic matirial we

de spɛsifa di rayt mold finish de ɛp fɔ mek di prɔblɛm dɛn nɔ apin we dɛn de mol. Fɔ ɛgzampul, if yu yuz di rɔng finish, dat kin mek plastic pat dɛn stik to di mol ɔ mek di say we di wata de na di wɔl nɔ fayn.

Pro Tip : Tɔk bɔt di matirial prɔpati dɛn wit di mold mek fɔ mek shɔ se di finish we dɛn pik de sɔpɔt ɔl tu di pefɔmɛns ɛn di ɛstitiks.

Di tin dɛn we wi fɔ tink bɔt we wi de pe fɔ di kɔst .

Stepwise nature of di mold polishing process

mold polishing de apin in step, stat frɔm kɔs polishing ɛn muv to fayn fayn finish. Di nɔmba fɔ di step dɛn we dɛn nid fɔ du, de dipen pan di finish we dɛn want—rough finishes nid smɔl step, we di ay-glos finish dɛn nid mɔ.

Pro Tip : Fɔ ridyus di kɔst, pik fɔ kɔs kɔs fɔ dɔn if yu pat dɛn nɔ nid ay-glɔs sɔfays.

Rilayshɔn bitwin di finish we dɛn nid ɛn di nɔmba fɔ di polish stɛp dɛn

di ay we di sɔfa kwaliti nid, na di mɔ polishing stɛp dɛn de insay. Fɔ ɛgzampul, miro finish kin involv bɔku bɔku rawnd dɛn fɔ polish wit fayn fayn abrasives.

Pro Tip : Tink bɔt aw di sɔfays finish impɔtant to di wok we di pat de du bifo yu pik fɔ ay polish lɛvɛl.

Impekt fɔ mold polishing pan ɔvala mold kɔst

ay-prɛsishɔn mold polishing de inkrisayz di ɔvala kɔst fɔ mold manufakchurin. Fɔ dɔn di step dɛn nɔmɔ kin ripresent 10% ɔ mɔ pan di ɔl di mold kɔst, mɔ fɔ di mol dɛn we de prodyuz ay-klariti pat dɛn lɛk lens.

Pro tip : We yu de badjɛt, factor in di ekstra kɔst fɔ pat dɛn we de aks fɔ wan polished, ay-gloss sɔfays.

Variabiliti in mold polishing kɔst bitwin injɛkshɔn moldin kɔmni dɛn

kɔst kin difrɛn bad bad wan dipen pan di mold maker in ɛkspiriɛns, tul dɛn, ɛn ikwipmɛnt dɛn. Sɔm kɔmni dɛn kin gi kɔmpitishɔn ret fɔ standad finish, bɔt ay-glɔs ɔ spɛshal finish kin rili inkrisayz di prayz.

Pro Tip : Rikwest ditayl kot frɔm bɔku spɔlayt dɛn fɔ ɔndastand kɔst difrɛns ɛn mek shɔ se dɛn inklud di lɛvɛl fɔ polish we dɛn nid fɔ yu prɔjek.

Dɔn

Fɔ dɔn, mold polishing na wan impɔtant aspek fɔ di injɛkshɔn moldin prɔses, dairekt impakt di kwaliti, di we aw i luk, ɛn di wok we di fayn prodak de du. Dis atikul dɔn fɛn difrɛn kayn we dɛn fɔ polish di mold, lɛk mɛkanikal, kemikal, ilɛktrɔlaytik, ɔltrasɔnik, fluid, ɛn magnɛtik polish, wit dɛn bɛnifit ɛn tin dɛn we dɛn fɔ tink bɔt. We dɛn ɔndastand di impɔtant tin dɛn we dɛn fɔ du fɔ polish di mold, di men tin dɛn we dɛn fɔ tink bɔt, ɛn di bɛst we fɔ fala, di wan dɛn we de mek di tin dɛn kin mek shɔ se dɛn gɛt di bɛst rizɔlt ɛn di tin dɛn we dɛn de mek fayn fayn wan.

Patnaship wit ɛkspiriɛns injɛkshɔn moldin savis provayda dɛm, lɛk Tim MFG, kin ɛp kɔmni dɛm fɔ ajɔst di autkam dɛm we dɛn want bay we dɛn de yuz ɛkspɛriɛns, di stet-ɔf-di-at tɛknɔlɔji, ɛn wan kɔmitmɛnt fɔ kwaliti. Fɔ embras mold polishing as wan impɔtant pat pan di injɛkshɔn moldin prɔses impɔtant fɔ sakrifays insay tide in kɔmpitishɔn manufakchurin land skay.

Kwɛstyɔn dɛn we dɛn kin aks bɔt mold polishing .

K: Wetin na di rizin fɔ mek dɛn polish mold?

A: Fɔ mek wan smol say na di mold kaviti fɔ impɔtant pat kwaliti ɛn izi ejeshɔn.

K: Wetin na di mɔs kɔmɔn mold polish tɛknik?

A: Mekanikal polishing, kemikal polishing, ilektropolishing, ɛn ultrasonic polishing.

K: Aw mold polishing de afɛkt di injɛkshɔn moldin prɔses?

A: I de ridyus di saykl tɛm dɛn, i de mek di prɔblɛm dɛn nɔ bɔku, ɛn i de mek di ɔl kwaliti fɔ di pat dɛn we dɛn dɔn mold bɛtɛ.

K: Us tin dɛn wi fɔ tink bɔt we dɛn de pik wan we fɔ polish fɔ polish?

A: Mold matirial, di surface finish we dɛn want, mold jɔyometri, prodakshɔn rikwaymɛnt, ɛn badjɛt.

K: Aw di lɛvɛl we dɛn de polish di mold kin afɛkt di las prɔdak?

A: Di ay polish lɛvɛl dɛn kin rili mek di say dɛn we smɔl, we gɛt glos, we di smɔl smɔl lɛvul dɛn kin mek dɛn gɛt mat ɔ tɛkstɔr finish.

K: Dɛn kin du mold polishing pan ɛni kayn mold matirial?

A: Yɛs, bɔt di we aw dɛn pik di tɛknik ɛn di abraziv dɛn kin difrɛn bay di tin dɛn we di mold matirial gɛt.

K: Aw ɔltɛm dɛn fɔ du mold polishing?

A: Ɔltɛm, bays pan tin dɛn lɛk mold matirial, plastic tayp, mold jɔyometri, ɛn prodakshɔn volyum.