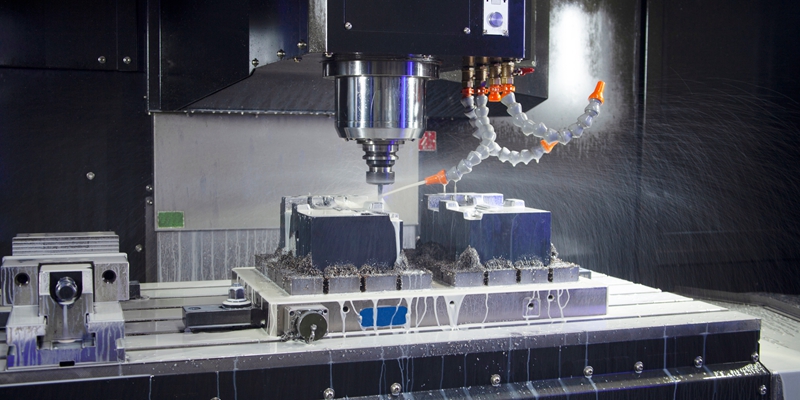

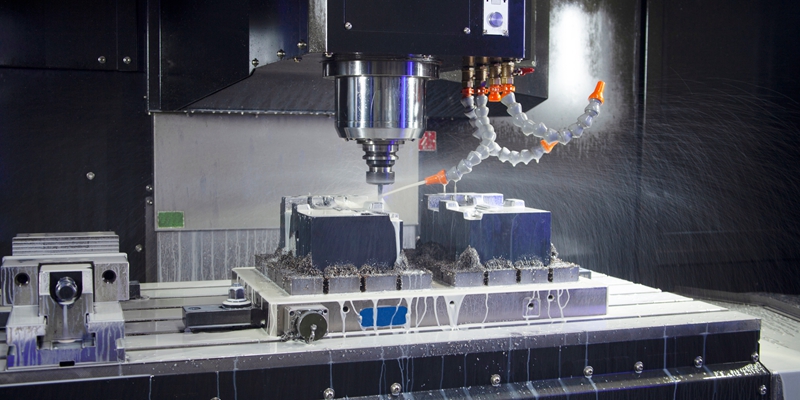

Lɛk ɛni ɔda tin we dɛn de yuz fɔ yuz ilɛktrishɔn, CNC mashin dɛn fɔ wok na say we sef fɔ mek dɛn kɔntinyu fɔ wok di bɛst we. Yuz CNC kulant na impɔtant tin fɔ kip di mashin ikwipmɛnt na lɔwa tɛmpracha di tɛm we dɛn de du ay-intɛnsiv mashin wok. I kin mek dɛn nɔ ɔt pasmak ɛn gi difrɛn ɔda bɛnifit dɛn, lɛk fɔ lɛf fɔ yuz lɔbrik ɛn fɔ mek dɛn nɔ pwɛl di kɔrɛshɔn.

Di rizin fɔ yuz CNC kulant .

as di ikwipmɛnt dɛn we kin wok bɔku tɛm we di tɛmpracha ay, . CNC mashin nid fɔ gɛt wan rili kɔling sistɛm fɔ mek dɛn kɔntinyu fɔ wok ɔltɛm. CNC kulant dɛn de wok as di kɔling sistɛm we CNC ikwipmɛnt dɛn nid fɔ mek shɔ se di CNC mashin dɛn wok fayn fayn wan we dɛn de du dɛn . Rapid manufakchurin opareshon dem. Na dis na di rizin fɔ yuz CNC kulant:

• CNC kulant kin mek mashin ɛn wokpies eria nɔ ɔva ɔt.

Ova ɔt kin mɛs di ɔl CNC ɔpreshɔn sistɛm, we kin mɛs di kɔmand dɛn we dɛn dɔn program ɛn di hadwɔd we yu de yuz fɔ mek di ɔpreshɔn dɛn. Yu kin mek yu nɔ ɔt pasmak na di CNC ikwipmɛnt ɛn di wokpies eria bay we yu aplay CNC kɔlant. Fɔ kip wan wɛlbɔdi tɛmpracha rawnd di wokples eria kin mek bak difɔmeshɔn dɛn nɔ de na di matirial wokpies bikɔs ɔf di ɔva ɔt.

• SMƆL TƆK: I nɔ de mek di ikwipmɛnt nɔ wok fayn.

If yu yuz di CNC kulant, i go ɛp bak fɔ mek di CNC ikwipmɛnt nɔ wok fayn we yu de yuz am. Di ay-tɛmpracha CNC mashin ikwipmɛnt kin briŋ tumɔs ɔt to ɛni CNC kɔmpɔnɛnt, we kin mek i nɔ ebul fɔ wok lɛk aw i fɔ wok. kip wan ekstrimli ay tempɔret pan di . CNC pat dɛn kin pwɛl bak ɔl tu di hadwɔd ɛn kɔmpyuta aspek dɛn fɔ di CNC mashin.

• SMƆL TƆK: Nɔ mek dɛn ridyus di pefɔmɛns na CNC ɔpreshɔn.

Ha tempɔret kin du mɔ bad pas gud fɔ yu CNC mashin ɔpreshɔn. If yu yuz di CNC kulant wan wan tɛm we yu de du ay-spid ɛn ay-intɛnsiv ɔpreshɔn, dat kin ɛp fɔ mek di tɛmpracha na di ikwipmɛnt nɔ bɔku. Dis we ya, yu kin kip bak wan ay levul fɔ pefɔmɛns fɔ di ɔvala CNC ikwipmɛnt.

• CNC kulant kin mentɛn di rayt tul yuz.

Fɔ CNC aplikeshɔn, fɔ gɛt wok kɔt tul dɛn go impɔtant fɔ mek yu manufakchurin projɛkt go bifo. Yu nɔ go ebul fɔ mek di CNC kɔt ɔ miling tul dɛn pwɛl we dɛn de du di opareshɔn bikɔs dɛn nɔ de mek dɛn fayn ɔ dɛn nɔ gɛt bɔku ɔt. Fɔ dis, CNC kulant kin ɛp fɔ mentɛn di rayt tul yuz insay CNC ikwipmɛnt wit in kɔling ɛn klin prɔpati.

• Lubrik di mashin kɔmpɔnɛnt dɛn.

CNC Coolant na fayn bak fɔ lubrik difrɛn mashin kɔmpɔnɛnt dɛn, we mek am izi fɔ dɛn kɔmpɔnɛnt dɛn ya fɔ du di kɔt ɛn ɔda CNC ɔpreshɔn dɛn. Yu kin aplay di CNC kulant rawnd di mashin kɔta, chips, ɛn ɔda pat dɛn na di CNC ikwipmɛnt. Apat frɔm dat, wata-based kulant dɛn kin wok bak fɔ klin di matirial wokpies frɔm ɛni dɔti we dɛn de yuz CNC aplikeshɔn.

• SMƆL TƆK: I nɔ de mek di tul dɛn ɛn di CNC kɔmpɔnɛnt dɛn nɔ rɔsti.

Rɔst ɛn kɔrɛshɔn kin krip ɔp di kɔt tul dɛn ɛn CNC kɔmpɔnɛnt dɛn if yu nɔ du di rayt mentenɛns. If yu put di CNC kulant pan di mashin ikwipmɛnt, dat kin ɛp fɔ mek di tin dɛn we dɛn de kɔt ɛn di CNC kɔmpɔnɛnt dɛn nɔ go de rɔst we dɛn de yuz am ɛvride. Rɔst ɛn kɔrɛshɔn kin ambɔg di wok we di CNC ikwipmɛnt dɛn de du ɔltɛm, so kɔlant na fayn fayn sɔlv fɔ mek di ikwipmɛnt kɔntinyu fɔ rɔn fayn fayn wan.

• CNC kulant kin mek difɔmeshɔn dɛn nɔ de fɔ di matirial wokpies.

Na possibiliti de fɔ difɔmeshɔn fɔ di matirial wokpies we yu ɛksplɔz am to ɔva ɔt tɛmpracha we yu nɔ kol di wokpies eria dɔŋ. CNC kulant kin kip di wokpies matirial na low temperecha fɔ avɔyd fɔ pwɛl am di tɛm we dɛn de du mashin ɔpreshɔn we dɛn dɔn ɔt.

Prekoshɔn bifo yu yuz CNC kulant .

As wan impɔtant ɛlimɛnt na yu CNC mashin ɔpreshɔn, yu fɔ ɔltɛm tek ekstrim prɛkoshɔn bifo yu yuz di mashin kulant. Na sɔm tin dɛn fɔ tek tɛm wit fɔ mɛmba bifo yu yuz CNC kulant:

• Ɔndastand di difrɛn kayn CNC kɔlant dɛn.

CNC Coolant gɛt difrɛn kayn dɛn, we dɛn kategoriz insay wata-bɛs ɛn nɔ-wata-bɛs CNC kɔling sɔlvishɔn dɛn. Ɛni kayn gɛt in bɛnifit ɛn prɔblɛm dɛn, ɛn dɛn kin afɛkt aw CNC mashin dɛn de wok. Ɔltɛm no aw fɔ yuz di kɔlant ɛn di bɛnifit dɛn we i kin briŋ to yu manufakchurin ɔpreshɔn.

• SMƆL TƆK: Di bɛst tɛm fɔ chenj di CNC kɔlant.

Di bɛst tɛm fɔ chenj di kɔlant fɔ yu CNC mashin dɛn na wan tɛm ɛvri 6 to 12 mɔnt. I go dipen bak pan di yus intɛnsity. Ɔltɛm chenj di CNC kulant we i bigin fɔ west ɛn lɔs in yuz ɛfɛktiv. I kin fayn ɔltɛm fɔ yuz CNC kulant nɔmɔ frɔm kwaliti brand ɔ manifakta dɛn.

• SMƆL TƆK: Di bɛst tɛm fɔ yuz CNC kulant.

Di bɛst tɛm fɔ yuz CNC kulant na we yu de rɔn ay-intɛns ɛn ay-tɛmpracha CNC ɔpreshɔn. If yu yuz di CNC kulant na ay-intensity opareshon kin kip di mashin temperecha low. CNC Coolant kin ɛp fɔ mek di kɔt ɔ miling ɔpreshɔn dɛn smol we dɛn yuz am na di opareshɔn dɛn we nɔ gɛt bɔku mɔni.

CNC kulant types .

Sɔm CNC kulant tayp dɛn de fɔ difrɛn CNC mashin ikwipmɛnt dɛn wit difrɛn praymari fɛnshɔn dɛn. Na di kayn CNC kulant fɔ CNC mashin ikwipmɛnt dɛn de:

• CNC kulant - ɔyl dɛn we de sɔlv.

Sɔlbul ɔyl dɛn kin kɛr di ɔyl-bɛs sɔlvushɔn we gɛt minral ɔyl ɛn ɛmulshɔn we yu kin miks wit wata na in aplikeshɔn. We yu jɔyn di ɔyl dɛn we de sɔlv wit wata, dat de mek yu gɛt bɛtɛ ɔt transfa prɔpati dɛn. Di soluble-oil CNC kulant kompris di bes minral oil miks wit emulshon komponent.

• SMƆL TƆK: Ɔyl dɛn we stret.

Di strayt-ɔyl kɔlant fɔ CNC mashin dɛn kɔmprɛs di bays minral ɔyl we dɛn miks wit petrolium kɔmpɔnɛnt dɛn. I kin wok fayn as lɔbrik instead fɔ mek i kol. Atikul dɛn, lɛk vegjetabul fat, dɛnsɛf kin gɛt ad to strayt-ɔyl CNC kɔlant fɔ mek dɛn gɛt mɔ tin dɛn we dɛn kin yuz fɔ mek dɛn gɛt lɔbrik.

• CNC kulant - sintetik fluid dɛn.

Yu kin yuz sintetik-fluid CNC kulant fɔ ɛp fɔ mek ɛni rust nɔ rust pan di mashin ikwipmɛnt, tul, ɛn wokpies. Dɛn mek am wit inɔgɛnɛk ɔ ɔrganik alkaline matirial, yu kin yuz dis mashin kɔlant fɔ mek yu kɔntinyu fɔ gɛt di bɛst wok ikwipmɛnt fɔ yu CNC mashin opareshɔn dɛn. I kin gi yu wan robust kol prɔpati fɔ ay-intensity CNC aplikeshɔn dɛn.

• Sɛmi-sintetik fluid dɛn.

Fɔ di rɛgyula kɔling sɔlvishɔn, sɛmi-synthetic fluids kin bi di bɛst opshɔn. I de kam togɛda wit sɔlv ɔyl dɛn wit sintetik fluid fɔ gi wan supia ɔt-disipashɔn ficha fɔ CNC mashin dɛn.

Dɔn

Yuz di rayt kulant fɔ di CNC mashin dɛn we yu de wok ɛvride, bikɔs i kin ɛp fɔ mek i kɔntinyu fɔ wok na di ɔprɛtin tɛmpracha na wan lɔwa lɛvul. Dɔn bak, i bɛtɛ fɔ yuz difrɛn kayn kɔlant bay di gol we yu go lɛk fɔ ajɔst wit dɛn. Yu kin yuz difrɛn kulant dɛn fɔ lubrik di CNC mashin tul dɛn ɛn matirial wokpies dɛn, asaydɔm frɔm jɔs dɔŋ di tɛmpracha.

Team MFG de inves plenti CNC mashin fo mit yu Rapid prototypein ., Low Volume Manufacturing , ɛn Mas Prodcution nid dɛn. Kontakt wi tim tide fɔ aks fɔ fri kot naw!