Pikiri mɔli ye fɛn dilanni ye min bɛ se ka kɛ fɛn caman na, min bɛ plastiki yɔrɔw dilan minnu ka ɲi kosɛbɛ ni u ɲɛda cogoya ka ɲi. Yɔrɔ dɔ min dilannen don, o sanfɛla laban jɔyɔrɔ ka bon kosɛbɛ a cɛɲi, a baarakɛcogo, ani a musakabɔlaw ka faamuyali la. Ka se ka yɔrɔ dafalen ɲininen sɔrɔ, o bɛ ɲini ka faamuyali sɔrɔ kosɛbɛ sariyaw ni fɛɛrɛ suguya caman kan minnu bɛ sɔrɔ.

Sosiyete min bɛ Plastics Industry (SPI) la, o ye laadilikanw sigi senkan walasa ka nɔgɔw labɛn ka kɛɲɛ ni plastiki ye. Nin SPI ka laadilikanw tara ka caya kabini u daminɛna san 1960 waatiw la, ka kan kelen di dilanbagaw, ɛntɛrinɛti dilannikɛlaw ani fɛn dilannikɛlaw ma walasa u ka se ka surface finish wajibiyalenw fɔ ka ɲɛ.

SPI Surface Finish Standards .

SPI Finish ye mun ye?

SPI fini, n’a bɛ fɔ fana ko SPI mɔli fini walima SPI Surface Finish, o bɛ tali kɛ sanfɛ finitigiw ka laadilikanw na minnu bɛ sigi senkan, minnu sigilen bɛ sosiyete ka plastiki baarakɛlaw fɛ (SPI). Nin laadilikan ninnu bɛ kan di diɲɛ bɛɛ ma walasa ka plastiki yɔrɔw ɲɛfɔcogo n’u cogoya ɲɛfɔ.

SPI Finish sariyaw ka bon kosɛbɛ pikiri kɛli la kun caman na:

l Ka da a kan a bɛ kɛ cogo basigilen na mɔni ni fɛn dilannikɛlaw danfaralenw cɛ .

l Ka kumaɲɔgɔnya jɛlen nɔgɔya dilanbagaw, ɛntɛrinɛti kalanbagaw ani baarakɛminɛnw dilanni na .

l min bɛ se ka kɛ sababu ye ka fɛn dilannikɛlaw dɛmɛ u ka se ka fini dafalen sugandi u ka baarakɛcogo la .

l Optimisation (Baarakɛcogo) Fɛn laban ka ɲɛnajɛko ni a ka baarakɛcogo ɲuman .

SPI Finish sariyaw tilalen don kuluba naani ye, u kelen-kelen bɛɛ bɛ ni kulu fitinin saba ye:

Suguya | subcategories . | Cogojirali |

A. Glossy . | A-1, A-2, A-3. | Finishes minnu ka nɔgɔn ani minnu bɛ manamana . |

B. Semi-glossy . | B-1, B-2, B-3. | cɛmancɛ nivo de glossiness . |

C. Matte . | C-1, C-2, C-3. | Finish minnu tɛ ɲɛ, olu tɛ ɲɛ . |

D. texturé . | D-1, D-2, D-3. | Finitigiw ka gɛlɛn, minnu bɛ kɛ ni misali ye . |

dakun fitinin kelen-kelen bɛɛ bɛ ɲɛfɔ ka taa a fɛ a ka surface roughness range kɛrɛnkɛrɛnnen fɛ, min bɛ suman micromɛtiriw (μM) la, ani finidoncogo minnu bɛ bɛn o ma minnu bɛ kɛ ka sɔrɔ ɲininen sɔrɔ.

Ni u bɛ tugu nin jatebɔsenw na minnu bɛ kɛ ka kɛɲɛ ni sariya ye, fɛn dilannikɛlaw bɛ se k’a lajɛ ko pikirijikɛlanw bɛ se ka kɛ sababu ye ka fɛnw dafa minnu bɛ se ka kɛ, minnu bɛ kɛ ka fɛnw dafa, minnu bɛ kɛ ni fɛnw ye minnu ka ɲi, minnu bɛ mɔgɔ ɲɛnajɛ, ani minnu bɛ baara kɛ ka ɲɛ.

SPI fini 12 kala .

SPI Finish Standard bɛ kɛ ni jateden 12 ye minnu bɛ danfara la, minnu labɛnna ka kɛ kuluba naani ye: Glossy (A), Semi-Glossy (B), Matte (C), ani Textured (D). Jateden kelen-kelen bɛɛ bɛ Kɛ dakun fitinin saba ye, minnu bɛ Jira ni jateden 1, 2 ani 3 ye.

O dakunba naani n’u cogoya ye :

1. Glossy (A) : A bɛ kɛ ni fini ye min ka nɔgɔn ani min ka nɔgɔn, a bɛ sɔrɔ ni diamant buffing ye.

2. Semi-glossy (b) : Glosiness cɛmancɛ hakɛ, min bɛ sɔrɔ grit papier polishing fɛ.

3. Matte (C) : Finish minnu tɛ ɲɛ, minnu bɛ jɛnsɛn, olu dabɔra ni kabakurunw ye.

4. Textured (d) : fini gɛlɛnw, minnu bɛ kɛ ni misali ye, minnu bɛ sɔrɔ ni fiɲɛ jalen ye ni kunnafonidilan suguya caman ye.

Nin ye SPI ka fini 12 ka jatebɔw tiɲɛni ye, ka fara u ka finidoncogo kan ani surface roughness ranges typiques kan:

SPI grade . | Finish (Type) . | Finishing fɛɛrɛ . | Surface Roughness (RA) range (μm) . |

A-1 . | Super high glossy . | Kalanso #3, 6000 Grit Diamant Buff . | 0,012 - 0,025 . |

A-2 . | Glossy haute . | Kalanso #6, 3000 Grit Diamant Buff . | 0,025 - 0,05 . |

A-3. | Normal glossy . | Kalanso #15, 1200 Grit Diamant Buff . | 0,05 - 0,10 . |

B-1 . | Semi-glossy fine . | 600 Grit Paper . | 0,05 - 0,10 . |

B-2. | cɛmancɛ semi-glossy . | 400 Grit Paper . | 0,10 - 0,15 . |

B-3. | Normal semi-glossy . | 320 Grit Paper . | 0,28 - 0,32 . |

C-1. | Matte fine . | 600 Grit kabakurun . | 0,35 - 0,40 . |

C-2. | Matte moyenne . | 400 Grit kabakurun . | 0,45 - 0,55 . |

C-3 ye. | Matte normal . | 320 Grit kabakurun . | 0,63 - 0,70 . |

D-1. | Satin texturé . | Blast glass bead #11. | 0,80 - 1,00 . |

D-2. | Dull texturé . | Blast jalen #240 oxide . | 1,00 - 2,80 . |

D-3. | texturé rough . | Blast jalen #24 oxide . | 3,20 - 18,0. |

I n’a fɔ a jiralen bɛ cogo min na ja in na, SPI hakɛ kelen-kelen bɛɛ bɛ bɛn laban suguya kɛrɛnkɛrɛnnen dɔ ma, finidoncogo, ani dugukolo sanfɛla gɛlɛya hakɛ. Misali la, A-1 fini bɛ jate super high glossy ye, min bɛ sɔrɔ ni grade #3, 6000 grit diamant buff ye, o bɛ na ni a sanfɛla gɛlɛya ye 0,012 ni 0,025 μm cɛ. Faan wɛrɛ fɛ, D-3 fini bɛ jate fɛn gɛlɛn ye, min bɛ sɔrɔ ni #24 oxide ye, o bɛ na ni yɔrɔ gɛlɛnba ye min ka RA hakɛ bɛ se 3,20 fo 18,0 μm ma.

Ni SPI hakɛ bɛnnenw bɛ sɔrɔ, dilanbagaw ni ɛntɛrinɛti injiniyɛriw bɛ se k’a lajɛ ko pikirijikɛlanw bɛ se ka yɔrɔ laban wajibiyalenw dafa, ka fɛn laban cɛɲi, a baarakɛcogo ani a jogo ɲuman sɔrɔ.

Aw bɛ a suma ni Surface Finish Standards wɛrɛw ye .

Hali ni SPI Finish ye sariya ye min bɛ dɔn kosɛbɛ pikiri kɛli la, o bɛ kɛ, izini sariya wɛrɛw bɛ yen, i n’a fɔ VDI 3400, MT (MoldTech), ani YS (Yick Sang). An ka SPI Finish ni nin fɛɛrɛ wɛrɛw suma ɲɔgɔn na:

1. VDI 3400 : .

kelen. VDI 3400 ye Alemaɲi ka sariya ye min bɛ sinsin dugukolo sanfɛla gɛlɛya kan sanni a ka kɛ cogoya la.

B. A bɛ Kɛ 45 ye, k'a Tà VDI 0 (smoothest) la ka Taa VDI 45 la (a ka gɛlɛn).

C. VDI 3400 bɛ se ka ɲɔgɔn sɔrɔ ni SPI finimugu hakɛw ye, i n’a fɔ a jiralen bɛ cogo min na ja in na:

SPI Finish . | VDI 3400 . |

A-1 ka A-3 . | VDI 0 ka VDI 15 . |

B-1 ka B-3. | VDI 16 ka VDI 24 . |

C-1 ka C-3. | VDI 25 ka VDI 30 . |

D-1 ka D-3. | VDI 31 ka VDI 45 . |

2. MT (MoldTech) ye :

kelen. MT ye sariya ye min dilanna Moldtech fɛ, Ɛsipaɲi ka baarakɛyɔrɔ min ka baara ɲɛsinnen bɛ mɔli ma.

B. A bɛ Kɛ 11 ye, k'a Tà MT 0 (smoothest) la ka Taa Mt 10 (a ka gɛlɛn).

C. MT kalasi tɛ se ka suma ni SPI Finish Grades ye, bawo u bɛ u sinsin fɛn kɛrɛnkɛrɛnnenw kan sanni ka u sinsin surface roughness kan.

3. YS (Yick Sang) :

kelen. YS ye sariya ye min bɛ baara kɛ ni Azi fɛn dilannikɛla dɔw ye, kɛrɛnkɛrɛnnenya la Sinuwa ani Hong Kong.

B. A bɛ Kɛ kàla 12 ye, k’a Tà ys 1 (smoothest) la ka Taa ys 12 (a ka gɛlɛn).

C. YS hakɛw bɛ bɛn SPI laban hakɛw ma, ni YS 1-4 bɛ bɛn SPI A-1 ma ka se A-3 ma, YS 5-8 ka se SPI B-1 ma ka se B-3 ma, ani YS 9-12 ni SPI C-1 ka se D-3 ma.

Hali ni nin sariya wɛrɛw bɛ yen, SPI Finish bɛ to ka baara kɛ ni a ye kosɛbɛ ani min bɛ dɔn kosɛbɛ pikiri kɛcogo kan diɲɛ kɔnɔ. Nafa jɔnjɔn dɔw minnu bɛ SPI Finish baara la, olu dɔw ye:

l sɔnni ni dɔnniya caman dilanbagaw, ɛntɛrinɛti kalanbagaw ani fɛn dilannikɛlaw cɛ diɲɛ kɔnɔ .

l Clear and concise categorization of surface finiw ka da a cogoya ni a gɛlɛya fila bɛɛ kan .

l kumaɲɔgɔnya nɔgɔya ani surface fini wajibiyalenw ɲɛfɔli .

l Bɛn ni pikirijikɛlanw ni a kɛcogo caman ye .

l Nafolo caman ani kunnafoni minnu bɛ sɔrɔ, olu bɛ sɔrɔ, i n’a fɔ SPI Finish Cards ani Guides .

Ni u ye SPI finish standard ta, tɔnw bɛ se ka u ka pikiri kɛcogo yɔrɔw labɛn minnu bɛ bɛn ɲɔgɔn ma, minnu ka ɲi, k’a sɔrɔ u bɛ kumaɲɔgɔnya ɲuman ni jɛkafɔ nɔgɔya ni feerekɛlaw ni jɛɲɔgɔnw ye diɲɛ fan bɛɛ.

SPI fini ɲuman sugandili .

Fɛn minnu ka kan ka jateminɛ ni SPI Finish sugandi .

Ni aw bɛ SPI fini dɔ sugandi aw ka pikirijikɛlan yɔrɔw la, fɛn jɔnjɔn caman ka kan ka jateminɛ walasa ka a jira ko a bɛ se ka kɛ cogo ɲuman na. O kow ye ɲɛnajɛko ye, baarakɛcogo, fɛnw bɛrɛbɛnni, ani musaka nɔfɛkow.

1. Aesthetics :

kelen. Fɛn laban in yecogo ɲininen ye fɛn nafamaba ye SPI fini sugandili la.

B. Finishes glossy (A-1 to A-3) bɛ yɔrɔ nɔgɔlen ni kɛnɛman di min bɛ yɔrɔ in yecogo ɲɛ, o b’a to a ka ɲi kosɛbɛ baarakɛyɔrɔw la, aesthetics ye ɲɛtaa kunba ye yɔrɔ minnu na.

C. Matte Finishes (C-1 to C-3) bɛ yecogo dɔ di min tɛ yeli ye, min bɛ jɛnsɛn, min bɛ se ka dɛmɛ don ka yɔrɔw dafabaliya dogo ani ka bolokɔniw walima nɔgɔw yecogo dɔgɔya.

2. Baarakɛcogo : .

kelen. Pikiri kɛlen yɔrɔ in baaracogo n’a baara laɲininen ka kan ka nɔba bila SPI fini sugandili la.

B. textured finishes (D-1 to D-3) bɛ dɔ fara minɛcogo ni sɛgɛn kan, o b’a to u bɛnnen don baarakɛminɛnw ma yɔrɔ minnu na u minɛcogo walima u baarakɛlaw ka jɛɲɔgɔnya nafa ka bon, i n’a fɔ bololafɛnw walima mobili yɔrɔw.

C. Finimugu nɔgɔlenw (A-1 ka se B-3 ma) bɛnnen don kosɛbɛ yɔrɔw ma minnu bɛ yecogo saniyalen ni nɔgɔlen de wajibiya walima minnu bɛna penta walima ka u tɔgɔ sɛbɛn ko u kɔfɛ.

3. Materiel Compatibilité : .

kelen. Bɛnkan min bɛ sɔrɔ fɛn sugandilen ni SPI finimugu ɲininen cɛ, o ka kan ka jateminɛ kosɛbɛ.

B. Fɛn dɔw, i n’a fɔ poliporopilini (PP) walima elastomɛriw (TPE) bɛ se ka kɛ ko u man ɲi ka se ka finiw sɔrɔ minnu ɲɛ ka bon kosɛbɛ k’a sababu kɛ u ka fɛnw cogoya ye minnu tɛ u la.

C. Aw ye fɛn dilanbaga ka ladilikanw lajɛ walima ka sɛgɛsɛgɛli kɛ walasa ka a dɔn ko SPI fini sugandilen bɛ se ka sɔrɔ ka ɲɛ ni fɛn sugandilenw ye.

4. musaka minnu bɛ bɔ a la : .

kelen. SPI fini sugandili bɛ se ka nɔba bila pikiri kɛlen yɔrɔ bɛɛ musaka bɛɛ la.

B. Fini minnu ka bon, i n’a fɔ A-1 walima A-2, olu bɛ polisi ni baarakɛcogo caman de wajibiya, o bɛ se ka dɔ fara baarakɛminɛnw ni fɛn dilanni musakaw kan.

C. Finish minnu ka dɔgɔn, i n’a fɔ C-3 walima D-3, olu bɛ se ka kɛ musaka dɔgɔyali ye baarakɛcogo la, yɔrɔ minnu na sanfɛla cogoya ka gɛlɛn.

D. Aw ye balansi jateminɛ surface fini ɲininen ni o musakaw cɛ walasa ka SPI fini bɛnnenba dɔn aw ka poroze kama.

Ni u ye nin ko kelen-kelen bɛɛ sɛgɛsɛgɛ koɲuman ani u bɛ se ka nɔ min bila fɛn laban na, o bɛ se ka kɛ sababu ye ka fɛɛrɛ tigɛ ni kunnafoni ye, ni u bɛ SPI fini dɔ sugandi. Nin fɛɛrɛ bɛɛjɛfanga in b’a to pikiri kɛcogo yɔrɔw ka bɛn cɛɲi, baarakɛcogo ani sɔrɔko sariyaw ma minnu wajibiyalen don ka sɔrɔ ka bɛnkan mara ni fɛn sugandilen ye.

SPI Finish ani Material Compatibilité .

Fɛn ɲuman sugandili nafa ka bon kosɛbɛ walasa ka SPI laban ɲininen sɔrɔ pikiri kɛlen yɔrɔw la. Fɛn min bɛ kɛ ni fɛn ye, o ni fini sugandilen cɛ, o bɛ se ka nɔba bila fɛn dilannen yecogo laban na, a baarakɛcogo la, ani a kɛcogo ɲuman na. Nin ye hakilina jɔnjɔn dɔw ye minnu ka kan ka jateminɛ:

1. Fɛn minnu bɛ kɛ ni fɛnw ye:

kelen. Plastiki fɛn kelen-kelen bɛɛ bɛ ni jogo kɛrɛnkɛrɛnnenw ye minnu bɛ nɔ bila a seko la ka SPI fini dɔw sɔrɔ.

B. Misali la, fɛn minnu ka dɔgɔyali hakɛ ka bon walima minnu ka jibɔcogo ka dɔgɔn, olu bɛ se ka gɛlɛya ka tɛmɛ ka u sɔgɔ ka ɲɛ ka se fini jɛmanw ma.

2. Fɛn minnu bɛ fara a kan:

kelen. Fɛn minnu bɛ fara ɲɔgɔn kan, i n’a fɔ kulɛriw, fasaw, walima barikalanw, olu sɔrɔli bɛ se ka nɔ bila fɛn in ka bɛnkan na ni SPI fini kɛrɛnkɛrɛnnenw ye.

B. Fura dɔw bɛ se ka dɔ fara u ɲɛda gɛlɛya kan walima ka dɔ bɔ fɛn na min bɛ se ka kɛ fɛn ye min bɛ se ka sɔgɔ.

3. Mold design and processing:

kelen. Moli dilanni n’a baaracogo paramɛtɛrɛw, i n’a fɔ da yɔrɔ, kogo janya, ani nɛnɛ hakɛ, olu bɛ se ka nɔ bila fɛn in bolicogo n’a sanfɛla cogoya la.

B. Mold design ani process optimisation ɲuman bɛ se ka dɛmɛ ka SPI fini ɲininen sɔrɔ tuma bɛɛ.

Walasa ka dɛmɛ don ka fɛnw sugandili ɲɛminɛ, aw ye nin bɛnkan sɛbɛn in lajɛ min bɛ kɛ ka ɲɛsin plastiki jɛlenw ma ani u bɛnnenya ma SPI hakɛ kelen-kelen bɛɛ la:

Minɛ | A-1 . | A-2 . | A-3. | B-1 . | B-2. | B-3. | C-1. | C-2. | C-3 ye. | D-1. | D-2. | D-3. |

ABS . | ○ . | ○ . | ● . | ● . | ● . | ◎ . | ◎ . | ◎ . | ◎ . | ◎ . | ◎ . | ● . |

PP . | ✕ | △ | △ | ● . | ● . | ◎ . | ◎ . | ◎ . | ◎ . | ◎ . | ◎ . | ◎ . |

PS . | △ | △ | ● . | ◎ . | ◎ . | ◎ . | ◎ . | ◎ . | ◎ . | ◎ . | ◎ . | ● . |

HDPE . | ✕ | △ | △ | ● . | ● . | ◎ . | ◎ . | ◎ . | ◎ . | ◎ . | ◎ . | ◎ . |

Nylon . | △ | △ | ● . | ● . | ◎ . | ◎ . | ◎ . | ◎ . | ◎ . | ◎ . | ◎ . | ● . |

PC . | △ | ● . | ◎ . | ● . | ● . | △ | △ | ✕ | ✕ | ◎ . | ✕ | ✕ |

TPU . | ✕ | ✕ | ✕ | ✕ | △ | △ | ● . | ● . | ● . | ◎ . | ◎ . | ● . |

Acrylique . | ◎ . | ◎ . | ◎ . | ● . | ● . | ● . | ● . | ● . | ● . | △ | △ | △ |

Lezandi:

L ◎: A bɛ se ka kɛ cogo ɲuman na .

L ●: Bɛnkan ɲuman .

L △: Bɛnkan hakɛ danmadɔ .

L ○: A bɛ se ka kɛ ko a bɛ se ka kɛ ko a bɛ se ka kɛ .

L ✕: A ma fɔ .

Fɛn minnu bɛ kɛ ka fɛnw ni ɲɔgɔn cɛ, olu sugandicogo ɲuman:

1. Aw bɛ taa fɛnw feerelaw ni pikiri kɛcogo dɔnbagaw lajɛ walasa ka ladilikanw sɔrɔ ka da aw ka baarakɛcogo kɛrɛnkɛrɛnnen n’aw ka ɲininiw kan.

2. Aw bɛ prototype testing kɛ ni fɛn sugandilenw ye ani SPI finish ye walasa ka a yecogo ni a kɛcogo ɲininen tiɲɛ.

3. Aw ye baara laban sigida jateminɛ ani baara kɔfɛko wajibiyalenw, i n’a fɔ ja walima finimugu, ni aw bɛ fɛn sugandi ani ka a ban.

4. Aw bɛ SPI fini ɲininen ni fɛn musaka, sɔrɔli, ani baarakɛcogo ɲuman balansi walasa ka baara kɛcogo dɔ sɔrɔ min musaka ka dɔgɔ ani min bɛ se ka da a kan.

Ni an ye bɛnkan faamuya fɛnw ni SPI finiw cɛ, dilanbagaw ni ɛntɛrinɛti injiniyɛriw bɛ se ka latigɛw kɛ minnu bɛ u ka pikiri kɛcogo, u baarakɛcogo ani u kɛcogo ɲɛ.

Ladilikanw dicogo kɛrɛnkɛrɛnnenw .

SPI fini ɲuman sugandili aw ka pikirijikɛlanw na, o bɛ bɔ a kɛcogo laɲininen na kosɛbɛ ani a ka kan ka kɛ cogo min na kɛrɛnkɛrɛnnenya la a yecogo, a baarakɛcogo ani a baarakɛlaw ka jɛɲɔgɔnya kama. Ladilikan dɔw filɛ nin ye minnu bɛ kɛ ka ɲɛsin baarakɛcogo ma minnu bɛ kɛ ɲɔgɔn fɛ:

1. Finishes glossy (A-1 ka se A-3 ma) :

kelen. A bɛnnen don baarakɛcogo ma minnu bɛ kɛ ni ɲɛda cogoya ɲuman ye, min bɛ polisi .

B. A ka ɲi yɔrɔw ma minnu ka kan ka kɛ ni ɲɛ ye, i n’a fɔ lensɛriw, yeelen datugulanw, ani filɛlikɛlanw .

C. Sugandili ɲumanba don fɛnw na minnu bɛ ye walima minnu jɛlen don, i n’a fɔ jiralanw walima lakanani datugulanw .

D. Misaliw: Mobili yeelen, ɲɛgɛnw dilanni, ani fɛnw minnu bɛ mɔgɔw dɛmɛ .

2. Semi-glossy finiw (B-1 ka se B-3 ma) :

kelen. A bɛnnen don baarakɛminɛnw ma minnu bɛ balansi ɲini ɲɛnajɛko ni baarakɛcogo cɛ .

B. A ka ɲi kosɛbɛ mɔgɔw ka fɛnw ma, sow, ani dasiriw ma minnu bɛ nafa sɔrɔ kɛnɛya hakɛ danmadɔ la .

C. Sugandili ɲuman kɛ yɔrɔw la minnu bɛna penta walima ka da kɔfɛ ka bɔ .

D. Misaliw: Du kɔnɔ minɛnw, ɛntɛrinɛti minɛnw, ani furakɛli minɛnw dasiriw .

3. Matte finiw (C-1 ka C-3) :

kelen. A bɛnnen don baarakɛcogo ma yɔrɔ minnu na, a ɲɛda cogoya tɛ ye, a ɲɛ ka dɔgɔ, a bɛ ɲini .

B. A ka ɲi bololafɛnw ni fɛn dilannenw ma minnu bɛ to ka maga u la, bawo u bɛ bolokɔniw ni nɔgɔw bɔcogo dɔgɔya .

C. Sugandili ɲuman ka ɲɛsin izini yɔrɔw ma walima yɔrɔ minnu bɛ ɲɛda cogoya nɔgɔlen, min bɛ dɔgɔya, o de bɛ kɛ .

D. Misaliw: Seko ni dɔnko baarakɛminɛnw, yɔrɔjan fɛɛrɛw, ani mobili kɔnɔna yɔrɔw .

4. textured finiw (D-1 ka se D-3 ma) :

kelen. A bɛnnen don baarakɛcogo ma minnu bɛ minɛ ka ɲɛ walima ka sɛgɛn .

B. A ka ɲi yɔrɔw ma minnu bɛ to ka minɛ walima minnu bɛ kɛ ka fɛnw sɛgɛsɛgɛ, i n’a fɔ bololanɛgɛw, nɛgɛberew, ani switchw .

C. Sugandili ɲuman kɛ mobili yɔrɔw la minnu bɛ surface non slip de wajibiya, i n’a fɔ bolifɛn walima girinw sɛgɛsɛgɛlikɛlanw .

D. Misaliw: dumunikɛminɛnw, bololabaarakɛminɛnw, ani farikoloɲɛnajɛ minɛnw .

Ni aw bɛ SPI Finish sugandi aw ka baarakɛminɛn kama, aw bɛ nin fɛn ninnu jateminɛ:

l yelifɛn ye min bɛ ɲini ka kɛ fɛn ye min bɛ se ka ye ani min bɛ ye ka ɲɛ .

l Baarakɛlaw ka jɛɲɔgɔnya ni u ka baarakɛcogo hakɛ wajibiyalen .

l Mako min bɛ kɛ ka fanga sɔrɔ min bɛ se ka minɛ walima ka sɛgɛn .

l Ka bɛn ni fɛnɲɛnamafagalanw ye minnu bɛ kɛ ka fɛnw kɛ ka caya, i n’a fɔ ja walima lajɛ .

l Fɛnw sugandili n’a bɛnnen don fini sugandilen na .

Waleyali | SPI finiw minnu bɛ fɔ . |

Optical components . | A-1, A-2. |

Electronics consommateurs . | A-2, A-3, B-1. |

Du kɔnɔ minɛnw . | B-2, B-3, C-1. |

Bololabaarakɛminɛnw . | C-2, C-3. |

Industriw ka yɔrɔw . | C-3, D-1. |

Motomotive Interiors . | C-3, D-1, D-2. |

bololanɛgɛw ni nɛgɛberew . | D-2, D-3. |

Ni aw ye nin laadilikan kɛrɛnkɛrɛnnenw jateminɛ ani ka aw ka fɛn dilannen ka wajibi kɛrɛnkɛrɛnnenw jateminɛ, aw bɛ se ka SPI fini bɛnnen sugandi min bɛ cɛɲa, baarakɛcogo, ani musaka kɛcogo bɛn.

Achieving the perfect spi fini .

Pikiri kɛcogo fɛɛrɛw walasa ka ɲɛtaa ɲuman sɔrɔ .

Walasa ka SPI fini ɲininen sɔrɔ tuma bɛɛ, a nafa ka bon ka i ka pikiri kɛcogo ɲumanw kɛ. Nin ye fɛɛrɛ tigɛlenw ye walasa ka SPI fini suguya wɛrɛw nafa bonya:

1. Mold Design : .

kelen. Aw bɛ aw jija ka fiɲɛ sama ka ɲɛ walasa fiɲɛ ka ja ni jeninida taamasiɲɛw kana kɛ, o bɛ se ka nɔ bila a sanfɛla fini na .

B. Aw bɛ da yɔrɔ ni a bonya ɲɛnabɔ walasa ka jibɔ siraw dɔgɔya ani ka dugukolo sanfɛla cogoya ɲɛ .

C. Aw bɛ kogo janya kelen kɛ walasa ka nɛnɛ basigilen sɔrɔ ani ka dugukolo yɔrɔw tiɲɛniw dɔgɔya .

2. Material Selection : .

kelen. Aw bɛ fɛnw sugandi minnu ka jibɔcogo ka ɲi ani minnu ka dɔgɔyali ka dɔgɔn walasa ka yɔrɔw dafabaliya dɔgɔya .

B. Aw bɛ a lajɛ ka baara kɛ ni farankanw ye, i n’a fɔ tulumafɛnw walima fɛn minnu bɛ bɔ a la, walasa ka a sanfɛla cogoya ɲɛ .

C. Aw bɛ a lajɛ ko fɛn bɛ bɛn SPI finimugu ɲininen ma (aw ye sɛbɛn ɲɛ 3.2 lajɛ min bɛ bɛn ɲɔgɔn ma)

3. Baarakɛcogo paramɛtɛrɛw : .

kelen. Aw bɛ pikiri teliya, tansiyɔn ani funteni kɛ ka ɲɛ walasa ka a fa ka ɲɛ ani ka a sanfɛla fiɲɛw dɔgɔya .

B. Aw bɛ mɔli funteni hakɛ basigilen mara walasa ka nɛnɛ kɛ kelen ye ani ka Warpage dɔgɔya .

C. Aw bɛ degun ni waati ladilan walasa ka jibolisira taamasiɲɛw dɔgɔya ani ka yɔrɔw cogoya ɲɛ .

Gafe ɲɛ kelen-kelen bɛɛ bɛ se ka SPI fini suguya caman sɔrɔ:

SPI Finish . | Fɛɛrɛw . | Minɛnw |

A-1 ka A-3 . | - diamant buffing . - Polishing teliyaba . - Ultrasonic saniya . | - diamant compound . - Polisi teliyaba . - Ultrasonic saniyalan . |

B-1 ka B-3. | - Grit Paper Polishing . - Sandingɛ jalen . - Sandingɛ jilama . | - Paper min bɛ kɛ ka a sɔgɔ (600, 400, 320 grit) . - Sander orbital . - Sanding Block . |

C-1 ka C-3. | - Kabakurunw polisili . - Bead blasting . - Vapor Honing . | - Kabakurunw (600, 400, 320 Grit) . - Bead blasting minɛnw . - Vapor Honing Machine . |

D-1 ka D-3. | - Blasting jalen . - Etching . - texturing inserts . | - Blasting media (Glass biɲɛw, aluminiyɔmu ɔkisidi) . - Etching kemikaliw . - textured mold inserts . |

DFM sariyakolow ni SPI sariyaw faralen ɲɔgɔn kan .

Design for Manufacturability (DFM) sariyakolow ka kan ka don a daminɛ na fɛn dilanni na walasa ka a jira ko SPI laban ɲininen bɛ se ka sɔrɔ musaka la ani cogo basigilen na. Nin ye DFM ni SPI Finish sugandili cogo ye:

1. Baarakɛɲɔgɔnya daminɛni:

kelen. Aw bɛ pikiri kɛcogo dɔnbagaw ni a dilannikɛlaw sen don a dilanni daminɛ na .

B. Aw ye baro kɛ SPI Finish Requirements kan ani u bɛ nɔ min bila yɔrɔ dɔw dilanni na ani u dilanni na .

C. Gɛlɛya minnu bɛ se ka sɔrɔ ani dantigɛli minnu bɛ tali kɛ finidoncogo sugandilen na .

2. Design optimisation:

kelen. Yɔrɔ jateminɛcogo nɔgɔya walasa ka modubility ɲɛ ani ka surface defects dɔgɔya .

B. Aw bɛ aw yɛrɛ tanga nkɔni nɔgɔlenw ma, minnu bɛ duguma, ani kogo finmanw minnu bɛ se ka nɔ bila u sanfɛla la .

C. Aw bɛ a kɛrɛw don a kɔnɔ walasa ka yɔrɔ dɔw bɔli nɔgɔya ani ka surface tiɲɛni bali .

3. Prototyping ani sɛgɛsɛgɛli:

kelen. prototype molds ni SPI fini ɲininenw dilan walasa ka dilancogo ni baarakɛcogo sɛmɛntiya .

B. Aw bɛ sɛgɛsɛgɛli kɛ ka ɲɛ walasa ka dugukolo sanfɛla cogoya, a kɛcogo ɲuman ani a muɲuni jateminɛ .

C. Iterate (segin) dilancogo ni taabolo paramɛtɛrɛw kan ka da prototyping jaabiw kan .

DFM seginnkanniw ni lajɛw daminɛni nafa:

l Ka ko minnu bɛ se ka kɛ SPI Finish ye, olu dɔn ani k’u ɲɛnabɔ, u dilanni daminɛ na .

l Optimiser part design ka mou modulabilité ani surface qualité .

l ka dɔ bɔ farati la min bɛ sɔrɔ fɛn dilanni caman na ani fɛn dilanni waati latɛmɛni .

l Aw ye aw jija SPI fini sugandilen ka se ka sɔrɔ cogo basigilen na ani musaka-nafa .

SPI Finish ɲɛfɔli i ka dilancogo la .

Walasa ka jaabiw sɔrɔ minnu bɛ bɛn ɲɔgɔn ma ani ka kumaɲɔgɔnya jɛlen kɛ ni fɛn dilannikɛlaw ye, a nafa ka bon kosɛbɛ ka SPI fini ɲininenw ɲɛfɔ ka ɲɛ i ka dilan sɛbɛnw kɔnɔ. Nin ye wale ɲuman dɔw ye:

1. SPI Finish Callouts don a kɔnɔ:

kelen. Aw bɛ SPI laban hakɛ ɲininen jira ka jɛya (misali la, A-1, B-2, C-3) yɔrɔ ja kan walima 3D modɛli kan .

B. SPI Finish Requirement (SPI Finish Finish Requirement) ɲɛfɔ surface (yɔrɔ) kelen walima fɛn kelen-kelen bɛɛ la, ni fini wɛrɛw bɛ ɲini .

2. Aw bɛ sɛgɛsɛgɛli kɛlenw di:

kelen. Supply physical samples or SPI finish finiw minnu bɛ Surface Finish ɲininen jira .

B. Aw ye aw jija ka misaliw sɛbɛn ka ɲɛ ani ka SPI hakɛ kofɔlen bɛn .

3. Aw bɛ sariyaw fɔ ka jɛya:

kelen. Aw bɛ baro kɛ SPI Finish Requirements kan ni a dilabaga ye walasa ka faamuyali sɔrɔ ɲɔgɔn fɛ .

B. Kunnafoni caman di baarakɛcogo laɲininen kan, baarakɛcogo wajibiyalenw kan, ani baara kɔfɛ magoɲɛfɛnw kan .

C. Aw bɛ sɔnni sariyaw sigi sen kan minnu bɛ se ka kɛ ka ɲɛsin surface finish quality ani consistance ma .

4. Aw bɛ a kɔlɔsi ani ka a sɛgɛsɛgɛ:

kelen. Aw bɛ to ka surface finiw cogoya lajɛ ani ka a suman a dilanni waati .

B. Aw bɛ baara kɛ ni sumanikɛlanw ye minnu bɛ kɛ ka kɛɲɛ ni sariya ye, i n’a fɔ surface roughness gauges walima optique comparateurs .

C. Aw bɛ fɛn o fɛn bɔ SPI fini kofɔlen na , aw bɛ o ɲɛnabɔ joona walasa ka bɛnkan mara .

Ni aw ye nin wale ɲumanw kɛ ani ka SPI Finish wajibiyalenw lase mɔgɔw ma ka ɲɛ, aw bɛ se k’a lajɛ ko aw ka pikirijikɛlanw yɔrɔw bɛ se ka kɛ sababu ye ka fɛnw sɔrɔ minnu bɛ kɛ ka ɲɛ, o bɛ na ni fɛnw ye minnu ka ɲi kosɛbɛ, minnu bɛ mɔgɔ ɲɛnajɛ, ani minnu bɛ baara kɛ ka ɲɛ.

SPI Finish baarakɛminɛnw ni nafolo .

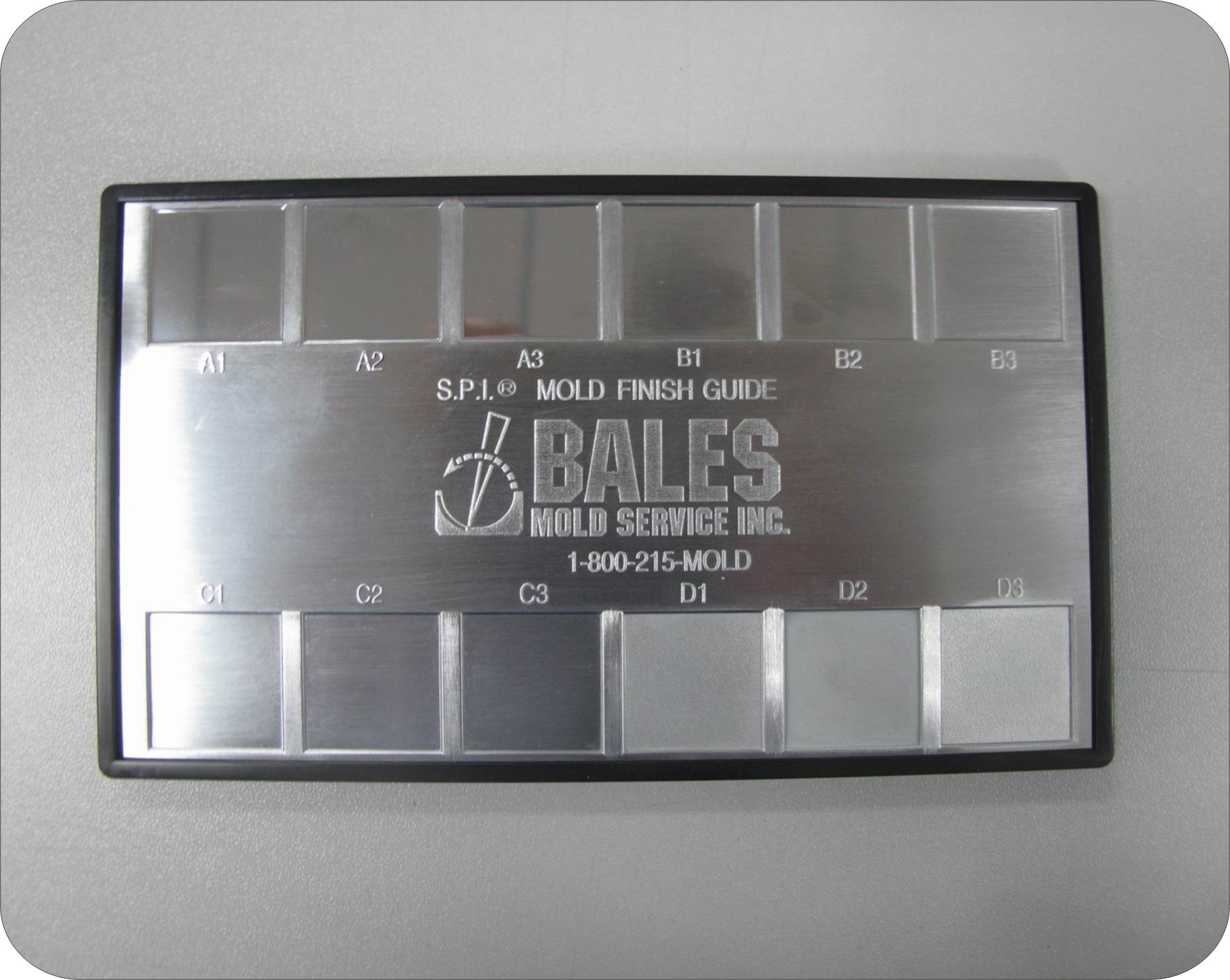

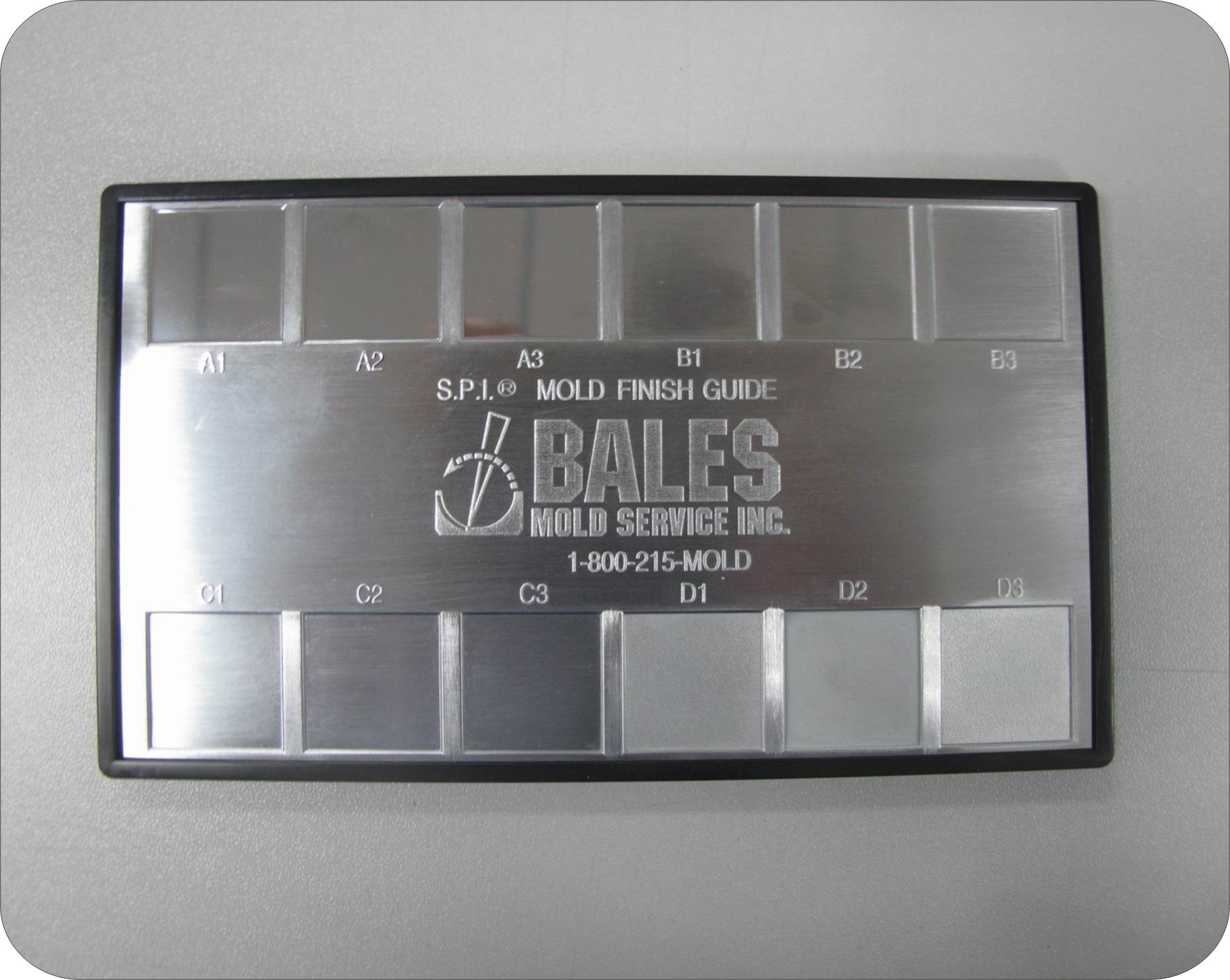

SPI finitigiw ka kartiw ni u ka sɛbɛnw .

SPI Finish Cards ani Plaques ye fɛn nafamaw ye minnu bɛ tali kɛ dilanbagaw, ɛntɛrinɛti dilannikɛlaw ani fɛn dilannikɛlaw bolo minnu bɛ baara kɛ ni pikirijikɛlanw ye. O misali farikolomaw bɛ SPI laban suguya wɛrɛw jiracogo yelen di, o bɛ kɛ sababu ye ka baarakɛlaw bila u ka se ka u ɲɛda cogoya n’u kɛcogo jateminɛ ni ɲɛ ye ani ka se ka kuma.

Nafa minnu bɛ sɔrɔ SPI Finish Cards ni Plaques la:

1. Kumaɲɔgɔnya min ɲɛnabɔra:

kelen. Aw bɛ kunnafoni yɔrɔ kelen di walasa ka baro kɛ surface finitigiw ka ɲininiw kan .

B. Daɲɛw ɲɛfɔli ni u kɔrɔfɔcogo jugu ban .

C. Faamuyali jɛlen nɔgɔya dilanbagaw, fɛn dilannikɛlaw ani kiliyanw cɛ .

2. A bɛ tali kɛ ɲɔgɔn na cogo min na tiɲɛ na:

kelen. Aw bɛ a to SPI Finish Grades suguya wɛrɛw ka ɲɔgɔn sanga kɛrɛfɛ .

B. Dɛmɛ don ka fini dafalen sugandi min bɛ se ka kɛ baarakɛminɛn kɛrɛnkɛrɛnnen dɔ ye .

C. A bɛ se ka kɛ sababu ye ka surface finish ni fɛn dilannenw wajibiyalenw bɛn tigitigi .

3. Quality Control:

kelen. A bɛ kɛ jateminɛ ye walasa ka pikirijikɛlanw cogoya jateminɛ .

B. Aw bɛ yecogo ni fɛn yecogo jira walasa ka surface finish consistance sɛgɛsɛgɛ .

C. Aw ye dɛmɛ don ka fɛn dɔw dɔn ani ka u ɲɛnabɔ ka bɔ finimugu ɲininen na .

SPI finitigiw ka kartiw ni u ka sɛbɛnw dilanbagaw:

1. Plastiki industriw ka tɔnw:

kelen. Sosiyete ka plastiki baarakɛlaw (SPI) - sisan a bɛ fɔ a ma ko Plastics Industry Association (Plastics) .

B. Ameriki ka tɔnba min bɛ sɛgɛsɛgɛli ni fɛnw kan (ASTM) .

C. Dugukolo kan jɛkulu min bɛ wele ko « Organisation internationale » (ISO) .

2. Pikiriw dilanni baarakɛlaw:

kelen. Ekipu MFG .

B. Protolabs .

C. Fictiv .

D. icomold .

e. Xometri .

3. Mold polishing ani texturing sociétés:

kelen. Boride engineered abrasives .

B. Mold-Tech .

C. Aultra textured surfaces .

Walasa ka SPI finitigiw ka kartiw walima u ka sɛbɛnw komandi, i bɛ se ka kuma dilanbagaw fɛ k’u ɲɛsin u ma walima ka taa u ka sitiw kan walasa ka kunnafoni wɛrɛw sɔrɔ sugandiliw kan minnu bɛ sɔrɔ, sɔngɔko, ani komandi kɛcogo.

Case Studies: SPI finiw waleyali ɲɛtaa .

Dɔgɔtɔrɔso minɛnw ka so .

L Fɛn min bɛ dilan : Bololabaarakɛlaw ka furakɛli minɛnw ka so .

L Material : ABS (Acrylonitrile Butadiene Styrene) .

L SPI Finish : C-1 (matte ɲuman) .

L RAUTILE : C-1 fini bɛ yɔrɔ di min tɛ ye, min bɛ se ka bolokɔniw ta, min bɛ minɛcogo ɲɛ ani ka minɛnw saniyacogo ɲɛ. Matte yecogo fana bɛ kɛ sababu ye ka ɲɛnajɛ kɛcogo ɲuman ni cogoya ɲuman sɔrɔ.

l Kalansenw : C-1 fini bɛ sɔrɔ tuma bɛɛ ni pikiri kɛcogo paramɛtiriw ɲɛnabɔli ye ani ka baara kɛ ni ABS fɛn ye min ka ɲi kosɛbɛ, min bɛ se ka kɛ furakɛli ye. Nɔgɔ ladonni ɲuman ani finitigiw ka sɛgɛsɛgɛli basigilenw tun nafa ka bon kosɛbɛ walasa ka a jira ko a sanfɛla ka ɲi cogo kelen na.

Trim intérieur automobile .

L Product : decorative intérieur trim pour luxe vehicles .

L Fɛn : PC/ABS (polycarbonate/acrylonitrile butadiene styrene blend) .

L SPI Finish : A-2 (a bɛ yeelen bɔ kosɛbɛ) .

L RAUTILE : A-2 fini bɛ yeli kɛ ɲɛnajɛba la, min bɛ yeelen bɔ kosɛbɛ, min bɛ mobili kɔnɔna dilancogo ɲuman dafa. O yɔrɔ nɔgɔlen fana bɛ saniya nɔgɔya ani k’a cɛɲi diyabɔ waati kɔnɔ.

l Kalansenw : A-2 fini sɔrɔli tun bɛ kunbɛnni gɛlɛn de wajibiya pikiri kɛcogo kan, i n’a fɔ fɛn dilanni funteni, pikiri teliya, ani nɛnɛ waati. PC/ABS fɛn min bɛ se ka yeelen bɔ kosɛbɛ, o baara ye a to a ka kɛ yɔrɔ ye min bɛ mɛn sen na ani a kulɛri sabatili.

Consumer Electronics enclosure .

L Product : Smartphone Protective Case .

L Material : TPU (Polurethane thermoplastique) .

L SPI Finish : D-2 (Dull Textured) .

L RAUTILE : D-2 fini bɛ yɔrɔ di min tɛ slip ye, min bɛ kɛ ni sɛbɛnni ye min bɛ minɛcogo ɲɛ ani ka telefɔni bali ka sɛgɛn ka bɔ baarakɛla bolo la. O yecogo dulen fana bɛ dɛmɛ ka sɔgɔsɔgɔninjɛ misɛnniw ni u doncogo dogo waati tɛmɛnen kɔ.

l Kalansenw : D-2 fini donna ka ɲɛ ni baara kɛli ye ni sɛbɛnni kɛcogo kɛrɛnkɛrɛnnen ye, i n’a fɔ kemikɛli walima laser texturing, moule surface kan. TPU material grade sugandili ɲuman ye a jira ko flow properties ɲumanw ani a texture ɲininen replication tigitigi.

Nin ko kɛlenw bɛ SPI fini suguya wɛrɛw waleyacogo ɲuman jira izini suguya caman na, k’a jira ko a nafa ka bon ka finimugu bɛnnen sugandi ka da fɛn dilannenw wajibiyalenw kan, fɛnw cogoyaw, ani fɛn dilanni taabolo. Ni aw ye nin misaliw kalan ani ka aw ka poroze mago kɛrɛnkɛrɛnnenw jateminɛ, aw bɛ se ka kunnafoni sɔrɔ ni aw bɛ SPI finiw ɲɛfɔ aw ka pikiri kɛcogo yɔrɔw la.

Jateminɛ ɲɛtaalenw ani siniko taabolo .

SPI Finish in high-end applications .

SPI finiw jɔyɔrɔ ka bon kosɛbɛ baarakɛcogo kɔrɔw la, i n’a fɔ aerospace ani furakɛli minɛnw, yɔrɔ minnu na dugukolo sanfɛla cogoya ni a cogoya bɛ kɛ fɛn bɛɛ la belebele ye. O iziniw kɔnɔ, SPI fini ɲuman bɛ se ka nɔba bila fɛn dilannenw ka baarakɛcogo la, u ka lakana, ani u ka sariyaw labatoli la.

1. Aerospace applications:Fuel system components .

kelen. kabini kɔnɔna yɔrɔw .

B. structurel components .

Kow sɛgɛsɛgɛli: Aerospace dilanko tɔnba dɔ min ka baara ɲɛsinnen bɛ fɛnɲɛnamafagalanw ma, o y’a jira ko ni baara kɛra ni A-2 fini ye yɔrɔ gɛlɛnw kan, o ye sɛnɛfɛnw bolicogo ɲuman ɲɛnabɔ ani ka dɔ bɔ nɔgɔko farati la. O yɔrɔ min bɛ yeelen bɔ kosɛbɛ, min bɛ ji wuli, o bɛ ji wulilen dɔgɔya ani ka saniya ni sɛgɛsɛgɛli nɔgɔya.

2. Dɔgɔtɔrɔso minɛnw baarakɛcogo:Fɛn minnu bɛ se ka don .

kelen. Opereli minɛnw .

B. Diagnostic minɛnw .

Kow sɛgɛsɛgɛli: Dɔgɔtɔrɔso minɛnw baarakɛyɔrɔ dɔ ye opereli minɛnw sinsinni kura dɔ labɛn ni C-1 matte fini ye. O yɔrɔ min tɛ yeli ye, o ye dɔ bɔ ɲɛgɛnɛsira la walew senfɛ, ka operelikɛlaw yecogo ɲɛ. O laban fana ye minɛnw ka se ka sɔgɔsɔgɔ ni sɔgɔli kɛ, o bɛ a to a bɛ mɛn sen na waati jan kɔnɔ ani ka yeli kɛ cogo jɛlen na.

Aerospace ni furakɛli minɛnw baarakɛcogo fila bɛɛ la, SPI fini bɛnnen sugandili bɛ tali kɛ sɛgɛsɛgɛli, tiɲɛni ani sɛbɛnniw kɛcogo gɛlɛn na. Dilanbagaw ka kan ka baara kɛ ɲɔgɔn fɛ ni fɛnw feerelaw ye, finitigiw, ani sariyasunbatigiw ye walasa ka a jira ko finidoncogo sugandilen bɛ baara kɛcogo ni lakana sariyaw bɛɛ dafa.

Kokuraw ni siniɲɛsigiw bɛ sɔrɔ surface finidoncogo la .

Ni fɛɛrɛ kuraw bɛ ka taa ɲɛ ani iziniw ka ɲininiw bɛ ka taa ɲɛ, a ka c’a la, SPI finiw bɛ se ka fɛn caman Changements significatifs ani ko kura sɔrɔ. Nin ye ko dɔw ye minnu bɛ ka bɔ kɛnɛ kan ani k’a jira ko u bɛ ka ɲɛsin surface finishing nata ma:

1. Nanotechnologie-enhanced finiw:

kelen. Nanoscale coatings ni textures yiriwali .

B. Scratch resistance, anti-fouling properties, ani yɛrɛ saniya sekow ɲɛnabɔ .

C. A bɛ se ka kɛ SPI Finish Grades kura ye minnu dabɔra kɛrɛnkɛrɛnnenya la nanoteknoloji baarakɛminɛnw kama .

2. Finishing kɛcogo sabatilenw ani minnu bɛ kɛ ni eko ye:

kelen. Sinsin kɛli ka caya sigida nɔfɛkow dɔgɔyali kan .

B. Ji-la-ko-kɛcogo-fɛɛrɛw tali labancogo fɛɛrɛw .

C. Fɛn minnu bɛ kɛ ni biyo-based ani biodegradable ye, olu ɲinini ka ɲɛsin surface finidoncogo ma .

3. Nizɛri Surface Finishing ani Quality Control:

kelen. 3D sɛgɛsɛgɛli ni hakililataw donni ka ɲɛsin dugukolo sɛgɛsɛgɛli ma .

B. Finishing taabolo kɔlɔsili ni a ladilanni waati yɛrɛ la ni IoT sensɛriw ye .

C. Nizɛri SPI Finish Standards ani Virtual Reference Samples yiriwali .

4. ladamuni ni mɔgɔya:

kelen. Demande min bɛ ka bonya ka ɲɛsin surface finiw ma minnu tɛ kelen ye ani minnu bɛ kɛ ka kɛɲɛ ni mɔgɔw sago ye .

B. Ɲɛtaa minnu kɛra 3D sɛbɛnni na ani prototyping teliya la ka ɲɛsin misɛnw dilanni ma .

C. Se ka SPI Finish Standards ka don a kɔnɔ ka kɛɲɛ ni mɔgɔw sago ye .

5. Baarakɛcogo dakunw:

kelen. Finishw yiriwali ni baarakɛcogo wɛrɛw ye, i n’a fɔ banakisɛfagalanw walima fɛnw minnu bɛ kɛ ka fɛnw kɛ ka ɲɛ .

B. Sensɔrɔlan hakilitigiw ni ɛlektronikiw donni surface finiw kɔnɔ .

C. SPI Finish sariyaw bonya walasa ka baarakɛcogo sariyaw don .

Nin ko kura ninnu ni taabolo ninnu bɛ ka taa ɲɛ ka ɲɛsin dugukolo sanfɛla labɛnni ma, a nafa ka bon kosɛbɛ dilanbagaw, ɛntɛrinɛti kalanbagaw ani fɛn dilannikɛlaw bolo ka to kunnafoni na ani k’u ka walew bɛrɛbɛn ka kɛɲɛ n’o ye. Ni u ye fɛɛrɛ kuraw minɛ ani ka jɛ ka baara kɛ ni izini dɔnbagaw ye, tɔnw bɛ se ka baara kɛ ni nin ɲɛtaa ninnu ye walasa ka fɛn ɲumanw, fɛn kuraw dilan minnu bɛ se ka kɛ sababu ye ka kiliyanw magow ni sariyaw wajibiyalenw dafa.

Taabolo | Impact on SPI finiw . |

nanoteknoloji . | Se bɛ SPI fini kura ye ka kɛɲɛ ni nanoscale applications ye . |

Mɛli | Eco-friendly finishing fɛɛrɛw ni fɛnw tali . |

Nizɛri . | Nizɛri SPI Finish Standards ani Virtual Reference Samples yiriwali . |

ladamuni . | ladamuni sugandiliw don SPI Finish sariyaw kɔnɔ . |

Baarakɛcogo . | SPI Finish sariyaw bonya walasa ka baarakɛcogo sariyaw don . |

Ni Surface Finishing Landscape bɛ ka taa ɲɛ, a ka c’a la, SPI Finish Standards bɛna lajɛw kɛ ani ka fɛn kuraw sɔrɔ walasa ka nin ko kɛlenw ni fɛɛrɛ kuraw labɛn minnu bɛ ka bɔ kɛnɛ kan. Ni u tora o yiriwaliw ɲɛfɛ, fɛn dilannikɛlaw bɛ se k’a lajɛ k’u ka pikirijikɛlanw yɔrɔw bɛ ka taa a fɛ ka jogoɲumanya, baarakɛcogo, ani kokuradonni sariyaw labato minnu ka bon kosɛbɛ.

Kuncɛli

Nin gafe in kɔnɔna bɛɛ la, an ye SPI Finish jɔyɔrɔba sɛgɛsɛgɛ pikiri kɛli la. K’a ta jateden 12 faamuyali la ka se fini ɲuman sugandili ma i ka baarakɛcogo la, SPI Finish mastering nafa ka bon walasa ka yɔrɔw dilan minnu ka ɲi, minnu bɛ mɔgɔ ɲɛnajɛ, ani minnu bɛ se ka baara kɛ ni u ye.

Walasa ka SPI fini don ka ɲɛ aw ka pikiri kɛcogo porozew kɔnɔ, aw ye nin wale ninnu jateminɛ:

1. Aw ye jɛ ka baara kɛ ni dɔnnikɛlaw ye walasa ka fini dafalen sugandi min bɛnnen don kosɛbɛ aw ka ɲinini kama .

2. Aw ka SPI Finish wajibiyalenw fɔ aw ka fɛn dilanni jɛɲɔgɔnw ye ka jɛya .

3. Leverage SPI Finish Cards ani Plaques walasa ka ɲɔgɔn sanga tigitigi ani ka jogoɲini kɛ .

4. Aw ka to kunnafoni na ko kɛlenw ni fɛɛrɛw kan minnu bɛ ka bɔ kɛnɛ kan, minnu bɛ sɔrɔ surface finishing kɔnɔ .

Ni aw ye nin wale ninnu kɛ ani ka jɛɲɔgɔnya kɛ ni baarakɛlaw ye minnu bɛ se kosɛbɛ i n’a fɔ Team MFG, aw bɛ se ka dannaya kɛ ka SPI Finish diɲɛ taama ani ka ɲɛtaa ɲuman sɔrɔ aw ka pikiri kɛcogo la.

Ɲininkaliw jaabiw .

J: SPI Finish Finish Grade min ka ca ni tɔw bɛɛ ye, o ye mun ye?

A: SPI laban hakɛ minnu ka ca kosɛbɛ olu ye A-2, A-3, B-2, ani B-3 ye, minnu bɛ kɛ sababu ye ka ɲɛkisɛ jɛlen di.

J: Ne bɛ se ka fini ɲuman sɔrɔ ni plastiki fɛn o fɛn ye wa?

A: Plastiki minɛnw bɛɛ man ɲi ka se ka finiw sɔrɔ minnu ɲɛ ka bon. Aw ye sɛbɛn ɲɛ Materiel Compatibilité Chart lajɛ sigida 3.2 kɔnɔ walasa ka bilasirali sɔrɔ.

J: SPI fini bɛ nɔ jumɛn bila pikiri kɛli musaka la?

A: SPI fini minnu ka bon (misali la, A-1, A-2) caman bɛ dɔ fara baarakɛminɛnw ni fɛn dilanni musakaw kan ka da baara wɛrɛw kan minnu ka kan ka kɛ.

J: Yala a bɛ se ka kɛ ko SPI finiw tɛ kelen ye a yɔrɔ kelen kan wa?

A: Ɔwɔ, a bɛ se ka kɛ ka SPI fini suguya wɛrɛw ɲɛfɔ yɔrɔw la minnu tɛ kelen ye walima minnu bɛ kɛ ni pikirijikɛlan ye.

J: Danfaraba jumɛnw bɛ SPI A ni Spi D finiw cɛ?

A: SPI A Finishes ye glossy ye ani u bɛ nɔgɔya, ka sɔrɔ Spi D Finishes ye textured ye ani u ka gɛlɛn. U bɛ baara kɛ ni kuntilenna ni wajibiw ye minnu tɛ kelen ye.

J: Yala SPI finiw bɛ se ka ladilan ka tɛmɛ sariyaw kan wa?

A: SPI finiw labɛnni ka tɛmɛ hakɛ dantigɛlenw kan, o bɛ se ka kɛ, ka kɛɲɛ ni a dilabaga ka wajibi kɛrɛnkɛrɛnnenw ni a sekow ye.

J: Ne bɛ se ka kow latigɛ cogo di ne ka fɛn dilannen na?

A: Aw ye jateminɛ kɛ ɲɛnajɛko, baarakɛcogo, ani baara laban lamini na ni aw bɛ fini jɛlenw ni fini jɛlenw sugandi. Aw ye sigida 3.3 lajɛ walasa ka ladilikanw sɔrɔ minnu bɛ kɛ ka ɲɛsin furakɛli ma.

J: musaka danfara minnu bɛ SPI fini suguya caman cɛ, olu ye jumɛnw ye?

A: SPI finiw musaka danfara bɛ bɔ fɛnw na i n’a fɔ fɛnw, yɔrɔ jateminɛcogo, ani fɛn dilanni hakɛ. A ka c’a la, fini minnu ka bon (misali la, A-1) olu sɔngɔ ka gɛlɛn ka tɛmɛ fini minnu ka dɔgɔn (misali la, D-3).

J: A ka c’a la, a ka teli ka kɛ ko SPI fini dɔ bɛ kɛ ka a kɛ fɛn dɔ la?

A: Waati min ka kan ka kɛ ka SPI fini dɔ kɛ nɔgɔ la, o bɛ danfara ka kɛɲɛ ni nɔgɔ ka gɛlɛya ye ani finiko kɛrɛnkɛrɛnnen ye. A bɛ se ka kɛ lɛri damadɔw la ka se tile damadɔ ma.