Yala i delila k’i yɛrɛ ɲininka mun na PVC plastiki bɛ yɔrɔ bɛɛ wa? K’a ta pibilikiw la ka se furakɛli minɛnw ma, o fɛn caman bɛ se ka fɛn caman sɛmɛntiya. A sɔrɔla balawu la san 1872 Alemaɲi furakɛlikɛla Eugen Baumann fɛ, kabini o waati, PVC kɛra fɛn jɔnjɔn ye diɲɛ kɔnɔ.

Nin sɛbɛn in kɔnɔ, an bɛna PVC plastiki nafaw, a dilanni taabolo, ani a suguyaw sɛgɛsɛgɛ. Aw bɛna a baarakɛcogo n’a caman caman caman caman caman caman caman caman caman caman caman caman caman caman caman caman caman caman caman caman caman caman caman caman caman caman caman caman caman caman caman caman caman caman caman caman caman caman caman caman caman caman caman caman caman caman caman caman caman caman caman caman caman caman caman caman caman caman caman caman caman caman caman caman caman caman caman caman caman caman caman caman caman caman caman caman caman caman caman caman caman caman caman caman caman caman caman caman caman caman caman min bɛ se ka kɛ fɛn caman ye.

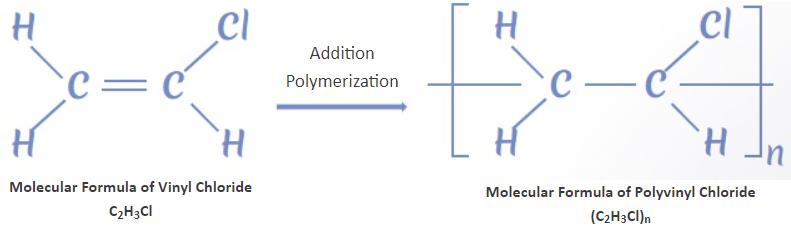

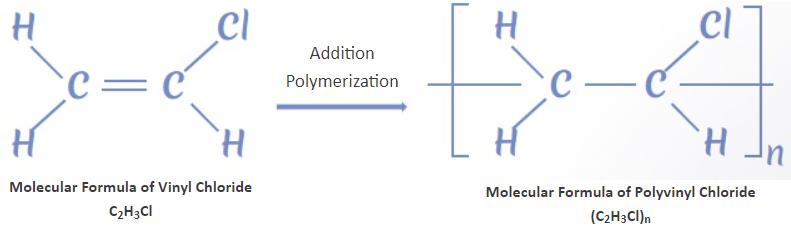

Faamuyali polivinili kuloridi (PVC) .

PVC (polyvinyl chlorure) ye mun ye?

PVC, walima polivinili kuloridi, a bɛ fɔ fana ko vinyl, o ye polimɛri ye min bɛ se ka kɛ fɛn caman ye. A bɛ dɔn a ka muɲuli, a ka se ka sɔrɔ, ani a ka se ka a yɛrɛ tanga kemikɛli ma. Baara bɛ kɛ ni iziniw ye i n’a fɔ jɔli, kɛnɛyako ani ɛntɛrinɛti, PVC ka fisa a ka seko ma ka se ka bana juguw muɲu. A tɛ i n’a fɔ plastiki dɔw, PVC bɛ se ka wuli walima ka gɛlɛya, ka kɛɲɛ ni farankanw ye minnu bɛ kɛ a dilanni senfɛ.

PVC ye fɛn ye min ka nɔgɔn. A ka nɔgɔn ka baara kɛ n’a ye wa a bɛ se ka dilan ka kɛ cogoya suguya caman ye, o b’a to a bɛ kɛ sugandili ye baara caman na. A ka kuran-sɛnɛcogo ɲumanba fana b’a to a ka ɲi nɛgɛ ni kabali dilanni ma.

PVC sɔrɔli ni a yiriwali tariku surun .

PVC ka sɔrɔ kɛra kasaara ye min kɛra nisɔndiyako ye. San 1872, Alemaɲi furakɛlikɛla Eugen Baumann ye gazi vinili kuloridi bɔ tile yeelen na, ka fɛn finman dɔ dilan — PVC. Nka, san 1913 de la, Friedrich Klatte ye fɛɛrɛ dɔ sigi sen kan walasa ka PVC polimɛrize ni tile yeelen ye, ka sira dabɔ jago kama.

Diɲɛ kɛlɛ fɔlɔ waati la, Alimanjamana ye PVC fɛnw dilan minnu bɛ se ka wuli ka bɔ u nɔ na ani minnu ka gɛlɛn, minnu ye nɛgɛw bila u nɔ na minnu bɛ se ka nɔgɔ bɔ. San kɛmɛ 20nan cɛmancɛ la, PVC kɛra plastiki ye min bɛ dilan kosɛbɛ diɲɛ kɔnɔ.

PVC Plastique ka jogo ɲumanw .

PVC bɛ waso ni nafolomafɛnw ye minnu tɛ ɲɔgɔn ta, minnu b’a kɛ fɛn caman ye baara suguya caman kama.

| Property | nafa . |

| Hakɛ | 1,3-1,45 g/cm³ |

| Ji minɛcogo (24h sutura) . | 0,06% ye . |

| Tensile fanga . | 7500 psi . |

| Modulus flexural . | 481000 PSI . |

| notched izod impact fanga . | 1,0 ft-lbs/in . |

| Funteni funteni hakɛ (264 psi) . | 158°F . |

| Coefficient de expansion thermal . | 3,2 x 10-5 in/in/°F . |

| Dielektriki fanga . | 544 V/MIL . |

Farikolo yɔrɔw .

Density : PVC ka density ye 1,3-1,45 g/cm⊃3 ye; ka ɲɛsin PVC gɛlɛn ma. O densité (dansi) min ka bon kosɛbɛ, o bɛ dɔ fara a ka barika kan ani a ka muɲu.

Ji minɛcogo : PVC ji minɛcogo ka dɔgɔn. Ni a sunnen don sanga 24 kɔnɔ, a bɛ ji 0,06% dɔrɔn de minɛ. O b’a to a bɛ se ka ji kɛlɛ ani a bɛnnen don kɛnɛma.

Mekaniki jogo .

Tensile fanga : PVC ka tension fanga ye 7500 psi ye. O fangaba in b’a to a bɛ se ka degunba muɲu k’a sɔrɔ a ma tiɲɛ. A ka ɲi kosɛbɛ baarakɛminɛnw na minnu bɛ gɛlɛya de wajibiya.

Flexural modulu : PVC ka flexural modulu ye 481000 psi ye. Nin gɛlɛya sumanikɛlan in b’a to PVC bɛ se k’a cogoya mara doni kɔrɔ.

Notched IZOD Impact Strength : PVC ka IZOD impact fanga ye 1,0 ft-lbs/in ye. O b’a jira ko a bɛ se ka fanga sɔrɔ fanga la ani ka a yɛrɛ tanga karili ma.

thermal properties .

Sumaya-yɔrɔ-ko funteni : 264 psi la, PVC ka funteni-yɔrɔ-yɔrɔ-ko funteni ye 158°F ye. O ye funteni ye a bɛ da Minɛ min na ka Bɔ doni kɔrɔ. PVC b’a cogoya mara ka ɲɛ funteni hakɛ danmadɔ jukɔrɔ.

Coefficient de la expansion thermal : PVC ka coefficient de temps de temps 3,2 x 10-5 in/in/°F. O bɛ a ka bonya hakɛ jateminɛ ni funteni caman yeli ye. PVC ka nafa dɔgɔyali kɔrɔ ye ko a bɛ dimension stabilité mara.

Kuranko nafaw .

kemikɛli nafaw .

Furakɛli : PVC bɛ se ka fura caman kɛlɛ, i n’a fɔ asidiw, basiw, kɔgɔw, ani alifatiki hidrɔkarbɔnw. O b’a to a bɛnnen don ka baara kɛ ni a ye sigidaw la minnu bɛ fɛnw tiɲɛ.

Weathering resistance : PVC bɛ se ka tile yeelen ni waati yɔrɔ wɛrɛw lajɛ. Nin yɔrɔ in bɛ sira di a ma ka baara kɛ ni a ye kɛnɛma baarakɛcogo la.

Nafaw ni dɛsɛw .

PVC ka nafolo bɛ nafa caman di:

Nka, nafa dɔw fana b’a la:

Funteni sabatili jugu: PVC bɛ se ka tiɲɛ funteni caman na.

Plastikiw ka jiginni: Waati tɛmɛnen kɔfɛ, plastiki bɛ se ka bɔ, o bɛ nɔ bila PVC ka nafaw la.

Toxicité potentiel : Klori bɛ PVC la, o bɛ se ka bagajiw bɔ a dilanni walima a filituma na.

PVC plastiki dilanni taabolo .

Yala i delila k’i yɛrɛ ɲininka PVC plastiki dilannen don cogo min na wa? O ye wale ye min bɛ mɔgɔ ɲɛnajɛ, min bɛ kɛ ni fɛɛrɛ caman ye. An ka nin fɛn caman dilanni taama in sɛgɛsɛgɛ.

Fɛn minnu bɛ kɛ ni fɛnɲɛnamafagalanw ye .

PVC dilanni na, fɛn fɔlɔ minnu bɛ sɔrɔ, olu ye:

Vinyl chloride monomer (VCM) : VCM bɛ sɔrɔ kulori (min bɛ bɔ kɔgɔ la) ni etilɛni (ka bɔ gazi walima tulu la). Etilɛni dikuloridi bɛ sɔrɔ. O kɔfɛ, a bɛ sumaya ka bɔ kariyɔrɔ la walasa ka VCM bɔ.

Fàrafinna : farankan suguya caman bɛ Kɛ ka PVC ka nafaw bonya:

Stabilisateurs (Stabilizatɛriw): A bɛ tiɲɛni bali baarakɛtuma na .

Plastikiw: Aw bɛ se ka fɛn caman sɛgɛsɛgɛ .

Filɛriw: Ka masinw ka baarakɛcogo ɲɛ .

tulumafɛnw : dɛmɛ don a labɛnni na .

UV Stabilizers: Aw bɛ aw tanga tile yeelen tiɲɛni ma .

Polimerizi fɛɛrɛw .

PVC bɛ sɔrɔ VCM ka polimɛrisiyɔn fɛ. Fɛɛrɛba fla ye ninnu ye:

Polimerizasiyɔn suspension : .

VCM bɛ jɛnsɛn ji la ni daminɛfɛnw ni farankanw ye.

Mixing continue bɛ suspension ni particule hakɛ kelen mara.

A bɛ kɛ 80% ye PVC sɔrɔli la diɲɛ kɔnɔ.

Polimerizasiyɔn emulsion : .

VCM bɛ mara soap micelles kɔnɔ ji la.

Baara bɛ kɛ ni daminɛfɛnw ye minnu bɛ se ka ji bɔ.

A bɛ PVC Bɔ ni a fɛnɲɛnamafagalan hakɛ ka dɔgɔn (0,1-100 μm).

O fɛɛrɛ fila bɛɛ bɛ funteni de la walasa ka polimerizasiyɔn daminɛ. PVC resin min bɛ sɔrɔ o la, o ye fin ye, a bɛ brittle solide.

compounding ani peletizing .

PVC resin bɛ ɲagami ni faralifɛnw ye wale dɔ la min bɛ wele ko compounding. O bɛ kɛ ɲagamifɛnw walima fɛn wɛrɛw la walasa ka ɲagami kelen sɔrɔ.

O kɔfɛ, PVC faralen ɲɔgɔn kan, o bɛ kɛ peleti ye. A bɛ Bɔ die la k'a Tigɛ ka Kɛ peleti misɛnninw ye. O kurukuruw minɛcogo ka nɔgɔn ani u labɛnnen don ka baara kɛ ka taa a fɛ.

Jogoɲumanya ni sɛgɛsɛgɛli .

Jogoɲini fɛɛrɛ gɛlɛnw bɛ waleya fɛn dilanni taabolo bɛɛ la. O bɛ PVC ka nafaw ni a ka baarakɛcogo sabati.

Kɔrɔbɔli minnu bɛ kɛ tuma caman na, olu dɔw ye:

density sumani .

Tensile fanga sɛgɛsɛgɛli .

Impact resistance sɛgɛsɛgɛli .

Sumaya sabatili sɛgɛsɛgɛli .

Kimikɛ ka rezisti sɛgɛsɛgɛli .

Nin sɛgɛsɛgɛliw bɛ dɛmɛ ka a sɛgɛsɛgɛ ko PVC bɛ fɛn wajibiyalenw dafa a kɛcogo laɲininen na.

Tablo min bɛ duguma, o bɛ PVC ka fɛn dilanni fɛɛrɛw kunbabaw lajɛ:

| STEP | ɲɛfɔli . |

| Fɛn minnu bɛ kɛ ni fɛnɲɛnamafagalanw ye . | VCM (ka bɔ kulori ni etilɛni na) ani farankanw . |

| Polimerizasiyɔn . | Suspension (80% ka bɔ a la) walima emulsion . |

| compounding . | PVC resin ni farankanw ɲagamini walasa ka nafolo bonya . |

| Peletizing . | PVC faralen ɲɔgɔn kan ka bɔ a kɔnɔ ani ka a tigɛ ka don a kɔnɔ . |

| Quality Control & Testing . | Nafaw ni baarakɛcogo sɛgɛsɛgɛli sɛgɛsɛgɛli suguya caman fɛ . |

PVC plastiki suguyaw .

PVC bɛ sɔrɔ suguya caman na, u kelen-kelen bɛɛ bɛ ni jogo ni baarakɛcogo kɛrɛnkɛrɛnnenw ye.

PVC gɛlɛn (UPVC) .

A bɛ fɔ fana ko PVC walima PVC-U min tɛ se ka kɛ .

A ka gɛlɛn ani a musaka ka dɔgɔ .

A bɛ se ka a yɛrɛ tanga kosɛbɛ fɛnw ma minnu bɛ se ka kɛ, ji, waati, ani sigida nɔgɔlenw .

Density: 1,3-1,45 g/cm³

Baarakɛcogo: pibilikiw, finɛtiriw, ani jɔlifɛnw .

PVC min bɛ se ka wuli ka bɔ a nɔ na .

PVC pipe flexible .

Plastikiw bɛ sɔrɔ a kɔnɔ minnu bɛ se ka fɛnw sɛgɛsɛgɛ .

Danfara min bɛ kɛ ka da plasticizer kɔnɔkow kan:

Density: 1,1-1,35 g/cm³

Baarakɛcogo: Kabilaw, hosew, ani fɛn minnu bɛ se ka wuli .

PVC properties flexibles .

A ka musaka ka dɔgɔ .

Flexible ani high impact strength .

UV, asidi, alkaliw ani tuluw bɛ se ka kɛ ka ɲɛ .

Non-Flammable .

Performance versatile .

PVC kulori (CPVC) .

A bɛ sɔrɔ PVC resin kulori la .

Klori hakɛ cayara ka bɔ 56% la ka se 66% ma .

A bɛ se ka muɲu, a bɛ sabati kemikaliya la, ani tasuma kunbɛnni .

A bɛ se ka funteni hakɛ caman muɲu ka tɛmɛ PVC basigilen kan .

A bɛ kɛ cogo min na: Ji funteni pibilikiw ani iziniw ka ji minɛcogo .

PVC min ɲɛsinnen bɛ o ma (PVC-O) .

A dilannen don ni PVC-U pipes stretching ye .

A bɛ amorofɔri sigicogo labɛn kokura ka kɛ fɛn ye min bɛ kɛ ni layɛrɛ ye .

A bɛ farikolo cogoyaw bonya:

gɛlɛya .

Sɛgɛn resistance .

Lightweight .

A kɛcogo: Tansiyɔn pipew minnu bɛ baara kɛ kosɛbɛ .

PVC sɛmɛntiyalen (PVC-M) .

PVC ka ɲɔgɔndɛmɛ min bɛ sɔrɔ fɛnɲɛnamafagalanw farali fɛ .

A bɛ gɛlɛya ni Impact Properties ɲɛ .

Aplikasi: Ducts, conduits, ani fittings minnu bɛ ɲini ka muɲuli sabati .

Tablo min bɛ duguma, o bɛ PVC suguya jɔnjɔnw n’u jogo jira:

| suguya | ɲɛfɔli | Key Properties | Applications . |

| PVC rigide . | A ma kɛ ni ɲɛ ye, a ka gɛlɛn . | Impact, weather ani chimique resistance . | Pipes, Fenɛtiriw, jɔli . |

| PVC min bɛ se ka wuli ka bɔ a nɔ na . | Plastikiw bɛ sɔrɔ a kɔnɔ walasa ka se ka fɛnw sɛgɛsɛgɛ . | UV, asidi, alkali, ani tulu bɛ se ka kɛ . | Kablonw, hoses, inflatables . |

| PVC kulori . | Klori hakɛ cayara ka se 66% ma . | A bɛ se ka muɲu, ka funteni kunbɛn . | Ji funteni pipew, izini ji minɛcogo . |

| PVC min ɲɛsinnen bɛ o ma . | PVC-U pipes stretched . | Gɛlɛya min bɛ sɔrɔ a la, o bɛ sɛgɛn, sɛgɛnbaliya . | Preformance pressure pipes minnu bɛ baara kɛ kosɛbɛ . |

| PVC sɛmɛntiyalen . | PVC Alloy ni fɛn caman sɛmɛntiyalanw . | Dɔ farala gɛlɛya kan ani ka nɔ bila fanga la . | Ducts, conduits, fittings . |

PVC plastiki baarakɛcogo fɛɛrɛw .

PVC ka fɛn caman kɛli tɛ a ka nafaw dɔrɔn na, nka a bɛ se ka baara kɛ cogo minnu na fana. An ka don fɛɛrɛ suguya caman na minnu bɛ kɛ ka nin fɛn in kɛ fɛn nafamaw ye.

Extrusion .

Extrusion ye wale ye min bɛ taa ɲɛ, min bɛ profile janw dilan, minnu bɛ kɛ kelen ye. PVC bɛ wuli ani ka jagoya ka tɛmɛ die fɛ walasa ka cogoya ɲininen dilan.

Pikirili Molidali .

Pikiriw dilanni bɛ kɛ ka yɔrɔ gɛlɛnw dilan, yɔrɔ saba. PVC mɔlen bɛ pikiri kɛ nɔgɔbɔlan kɔnɔ yɔrɔ min na a bɛ nɛnɛ ani ka sabati.

Taabolo paramɛtɛrɛw : .

Funteni hakɛ: 170-210°C .

Moli funteni hakɛ: 20-60°C .

O paramɛtiriw bɛ PVC ka jibɔ ni a nɛnɛni sabati ka ɲɛ .

Jateminɛw : .

thermoforming .

thermoforming bɛ PVC sɛbɛn dɔ sumaya fo a ka se ka wuli ka sɔrɔ k’a cogoya kɛ ka a kɛ nɔgɔ ye. O kɔfɛ, sɛbɛnfura bɛ nɛnɛ walasa a cogoya kura ka to a la.

Blow Molding .

Blow molding bɛ kɛ ka fɛn nɔgɔlenw dilan i n’a fɔ buteliw ni minɛnw. PVC molten (PVC) tuubu min bɛ wele ko Parisson, o bɛ fiɲɛ bila mɔni kɔnɔ.

CalEndering .

Jatebɔ ye wale ye min bɛ sɛbɛnw walima filimuw bɔ minnu bɛ taa ɲɛ, minnu bɛ taa ɲɛ. PVC bɛ tɛmɛ ni wulilanw ye minnu bɛ funteni sɔrɔ, minnu bɛ a degun ani k’a cogoya.

3D sɛbɛnni .

3D sɛbɛnni, walima fɛn wɛrɛw dilanni, o ye fɛɛrɛ kura ye min bɛ kɛ ka PVC baara. O ye ka fɛn dɔ jɔ ni layɛrɛ ye ka bɔ modeli numɛriki la.

| Baarakɛcogo fɛɛrɛ | ɲɛfɔli | yɔrɔ kolomaw . |

| Extrusion . | Taabolo min bɛ to senna walasa ka profiles (profilw) dilan . | pipe, tubing, sɛbɛnw; Funteni minnu bɛ dɔgɔya ka tɛmɛ pikiri kɛli kan . |

| Pikirili Molidali . | A bɛ yɔrɔ gɛlɛnw dilan ni pikiri kɛli ye mɔni na . | temp: 170-210°C, Mold Temp: 20-60°C; Moliw minnu bɛ se ka kɛ ni nɔgɔ ye . |

| thermoforming . | PVC sɛbɛnw minnu bɛ funteni sɔrɔ, olu cogoya . | a bɛ se ka kɛ 120-150°C ye; pakew, taamasiyɛnw, mobili yɔrɔw . |

| Blow Molding . | A bɛ fɛnw dilan minnu kɔnɔna bɛ kɛ ni fɛnw ye . | buteliw, minɛnw; A bɛnnen don kemikɛli ma . |

| CalEndering . | A bɛ sɛbɛnw walima filimuw dilan minnu ka fin, minnu bɛ taa ɲɛ . | Filimuw ka ɲɛsin pakew ma, labeliw; Sɛbɛn minnu bɛ kɛ ka duguma, so sanfɛla . |

| 3D sɛbɛnni . | A bɛ fɛnw jɔ layɛrɛ la layɛrɛ la ka bɔ modeli numɛriki la . | PVC filaninw kura; Tiɲɛni minnu bɛ se ka kɛ sɛbɛnnikɛlan yɔrɔw la . |

O baarakɛcogo ninnu bɛ PVC ka ladamuni jira. Fɛɛrɛ kelen-kelen bɛɛ n’a ka nafaw n’a ka jateminɛw don. Baarakɛcogo sugandili bɛ bɔ labanfɛn ɲininen na ani a wajibiyalenw na.

Yɛlɛma minnu bɛ kɛ PVC plastiki la .

PVC man teli ka kɛ a cogo saniyalen na. A ka c’a la, a bɛ fɛn caman sɛmɛntiya ni farali suguya caman ye walasa k’a ka nafaw n’a ka baarakɛcogo ɲɛ.

| Modification | misaliw | nɔfɛkow . |

| Plastikiw . | Ftalatiw, adipates, trimellitates . | Aw bɛ dɔ fara fɛnw sɛgɛsɛgɛli kan, ka fanga dɔgɔya . |

| Sumaya sabatilifɛnw . | Calcium-Zinc, Tin-based | Aw bɛ tiɲɛni bali a baara waati la ani a baara waati . |

| Fillers . | Karɔbɔni kalisiyɔmu, dioksidi titaniyɔmu, gilasi fiyɛw . | Masinaya cogoyaw ɲɛ, musaka dɔgɔyali . |

| tulumafɛnw . | Paraffin sizo, asidi stɛariki . | Processability (Baarakɛcogo ɲuman) ɲɛ, ka dɔ bɔ ɲɔgɔnkanu na . |

| UV stabilisateurs . | Hals, Benzotriazoles . | Aw bɛ aw tanga UV tiɲɛni ma . |

| Impact modifiers . | Acrylique, MBS . | Toughness ani Impact resistance bonya . |

| Flame retardants . | Antimony trioxide, aluminiyɔmu idɔrɔkisidi . | Tasuma kunbɛncogo ɲɛ . |

| Baarakɛminɛnw labɛnni . | Akiriliki-based, silicone-based . | Processability ani surface quality (Sɔrɔcogo ɲuman) bonya . |

| Blends . | PVC/PolyEster, PVC/PU, PVC/NBR . | Fɛn kɛrɛnkɛrɛnnenw ɲɛnabɔli baarakɛcogo laɲinitaw la . |

Plastikiw .

Plastikiw ye faralifɛnw ye minnu bɛ dɔ fara PVC ka fɛn caman sɛgɛsɛgɛli kan ani a ka baarakɛcogo kan. U bɛ dɔ bɔ polimɛri ka kristalɛ la, o b’a to a bɛ se ka wuli ka bɔ a nɔ na.

Sumaya sabatilifɛnw .

Funteni sabatili furaw bɛ PVC tiɲɛni bali a baara waati ni a baara waati la. U bɛ asidi klorokini (HCL) min bɛ sɔrɔ ni PVC bɛ a la, o kɛ ka funteni sɔrɔ.

Fillers .

Filɛlikɛlanw bɛ kɛ ka PVC ka masinw cogoya ɲɛ ani ka musakaw dɔgɔya. U bɛ se ka dɔ fara u ka gɛlɛya kan, u fanga ani u bonya sabatili kan.

Karɔbɔni kalisiyɔmu : .

Titanium dioxide : .

Glass fibres : .

tulumafɛnw .

tulumafɛnw bɛ fara PVC kan walasa k’a baaracogo ɲɛ. U bɛ dɔ bɔ ɲɔgɔnkanu na bɔli ni mɔli waati la, ka nɔrɔli bali ani ka jibɔ nɔgɔya.

kɛnɛma tulumafɛnw : .

Kɔnɔna tulumafɛnw : .

UV stabilisateurs .

UV sabatilifɛnw bɛ PVC tanga tiɲɛni ma min bɛ sɔrɔ tile yeelen fɛ. U bɛ kulɛri caman bɔli bali, ka kretiɛnw ka fɛnw bɔ ɲɔgɔn na, ani ka u bali ka kɛ masinw ye.

Impact modifiers .

Impact modifiers bɛ PVC ka gɛlɛya ni a ka se ka a yɛrɛ tanga. U bɛ fɛn in ka seko ɲɛ ka fanga minɛ k’a sɔrɔ u ma kari.

Flame retardants .

Tasuma-fanga-minɛnw bɛ PVC ka tasuma-fanga-minɛn ɲɛ, o b’a to a bɛ kɛ ka ɲɛ ka tɛmɛ baara suguya caman kan.

Baarakɛminɛnw labɛnni .

Baarakɛda minnu bɛ baara kɛ, olu ye faralifɛnw ye minnu bɛ PVC ka baarakɛcogo n’a ka yɔrɔ cogoya ɲɛ.

A bɛ ɲagami ni thermoplastiques wɛrɛw ye .

PVC ni thermoplastique wɛrɛw ɲagamini bɛ se k’a ka nafaw ɲɛ ka ɲɛ baara kɛrɛnkɛrɛnnenw kama.

O fɛn caman b’a jira ko PVC bɛ se ka ladamu cogo min na, o tɛ se ka da a la. Ni u bɛ farankanw sugandi koɲuman, fɛn dilannikɛlaw bɛ se ka PVC ka nafaw labɛn ka kɛɲɛ ni baara suguya caman ye.

PVC Plastiki baarakɛcogo ani a baarakɛcogo .

PVC ka fɛn caman kɛli b’a kɛ taa-ka-segin ye baara jatebaliya la. K’a ta jɔli la ka se kɛnɛyako ma, k’a ta mobili la ka taa a bila fɛnw na, PVC bɛ yɔrɔ bɛɛ.

Baara min bɛ kɛ ni jɔli ye .

PVC ye baarakɛ-so ye jɔli siratigɛ la. A ka muɲuli, a ka se ka waati kɛ, ani a sigili ka nɔgɔn, o b’a kɛ sugandili ɲuman ye baara suguya caman na.

PVC pipew ni a fitininw : .

A bɛ kɛ ka pɔmpi, nɔgɔ, ani ji don .

A bɛ se ka kɛ sababu ye ka fɛnw tiɲɛ ani ka u kɛlɛ kemikaliw la .

A ka nɔgɔn ani a sigili ka nɔgɔn .

Fenɛtiriw ka ɲɛfɔliw ni daaw :

Aw bɛ insulasi ni waati bɛɛ labɔli ɲumanw di .

A bɛ ladonni fitinin de wajibiya .

A bɛ sɔrɔ kulɛriw ni finiw caman na .

Dugukolo ni kogo datugulanw : .

A bɛ mɛn ani a saniya ka nɔgɔn .

Offer ɲuman slip resistance .

A bɛ sɔrɔ cogoya ni dilancogo suguya caman na .

Kuran ni elekitoroniki .

PVC ka fɛn ɲumanw ni tasumafagalanw b’a kɛ sugandili ye min ka di kuran ni ɛntɛrinɛti baara ye.

Kɛnɛyako ni furakɛli minɛnw .

PVC ka biyocompatibilité, clarity, ani se ka sterilize, o b’a kɛ fɛn nafamaba ye kɛnɛyako la.

Mobili Sekɔrɔ .

PVC ka muɲuli, a ka kemikaliya, ani a ka modulability b’a to a nafa ka bon mobili baara suguya caman na.

pakew dilanni .

PVC ka jɛya, a ka kemikaliya, ani a ka se ka mɔ, o b’a to a bɛ kɛ sugandili ye min ka di a ye kosɛbɛ.

Consumer Goods .

PVC ka fɛn caman kɛli ni a muɲuni b’a kɛ fɛn ye min bɛ kɛ fɛn caman na, fɛn minnu bɛ kɛ ka mɔgɔw balo.

| Aplikasi yɔrɔ | misaliw | nafa jɔnjɔnw . |

| Sojɔ | Pipes, Fenɛtiriw, dugumalanw . | Durabilité, resistance de temps, a sigili ka nɔgɔn . |

| Kuranko & Elektroniki . | Kablon insulation, conduits . | insulasi, tasuma kɛlɛli, kemikɛli resistance . |

| Kɛnɛyako . | Joli forokow, opereli ganw . | BioCompatibilité, Clarité, Stérilizabilité . |

| Mobili . | Kɔnɔna yɔrɔw, farikolo jukɔrɔla lakanani . | Durability, resistance chimique, modulabilité . |

| pakew dilanni . | Dumunifɛnw foroko, Blister pakew . | jɛya, kemikɛli resistance, modulabilité . |

| Consumer Goods . | Fini, sennasanbara, tulonkɛfɛnw . | versatility, muɲu, lakana . |

Ninnu ye misali damadɔw ye PVC ka baarakɛcogo jatebaliya kan. A ka nafolo faralen ɲɔgɔn kan, o b’a kɛ fɛn ye min nafa ka bon kosɛbɛ an ka bi diɲɛ kɔnɔ.

sigida laminiko jateminɛw .

Fɛn minnu bɛ se ka kɛ baga ye .

PVC dilanni n’a baara bɛ se ka fɛn juguw bɔ, kɛrɛnkɛrɛnnenya la a dilanni n’a filituma na. Diokisini ni kuloridi vinili ye PVC sɔrɔli kɔfɛfɛnw ye, olu bɛ faratiba lase sigida ni kɛnɛyako ma. Ni PVC jeni walima ni a ma baara kɛ ka ɲɛ, a bɛ se ka nin furakisɛ bagajiw bɔ, ka kɛ sababu ye ka fiɲɛ nɔgɔli ni kɛnɛya faratiw lase baarakɛlaw ma.

Plastikiw ka jiginni ni u tolenw .

PVC min bɛ se ka wuli, o ka teli ka kɛ plastiki ye walasa a ka se ka a ka fɛn caman sɛgɛsɛgɛ. Waati tɛmɛnen kɔfɛ, o plastikibɔlanw bɛ se ka bɔ o fɛn na, o bɛ se ka tolenw to yen. Kɔlɔsiliw y’a jira ko ftalatiw , n’o ye plastiki suguya ye min ka ca, o bɛ se ka hadamadenw ka kɛnɛya tiɲɛ, ka nɔ bila ɔrimɔni ni bangekɔlɔsi fɛɛrɛw la. O kɛra sababu ye ka haminankow bonya PVC sɛgɛsɛgɛli la min bɛ se ka wuli ka bɔ a nɔ na, fɛn minnu bɛ se ka wuli ka bɔ u nɔ na.

Sumaya sabatilikɛlan minnu sinsinnen bɛ nɛgɛ gɛlɛnw kan, olu nɔfɛkow .

Tariku kɔnɔ, PVC y’a jigi da nɛgɛ gɛlɛnw kan minnu sinsinnen bɛ nɛgɛ kan, kɛrɛnkɛrɛnnenya la plɔmu , walasa ka tiɲɛni bali baara kɛtuma na. Hali ni a bɛ se ka kɛ, o sabatilifɛnw bɛ faratiba lase mɔgɔ ma ni PVC filila walima ni a bɛ segin ka kɛ fɛn wɛrɛ ye. Plomb nɔgɔli PVC nɔgɔw la, o bɛ kɛ sababu ye ka fɛnw lasegin u cogo kɔrɔ la, wa o bɛ faratiba lase sigida ma sigida la.

| Funteni sabatili | bɛ se ka kɛ farati minnu na . |

| Stabilisateurs minnu bɛ bɔ plɔmu na . | Sigida nɔgɔli, gɛlɛyaw lasegincogo gɛlɛyaw . |

| Tin-based stabilisateurs . | A ka fisa nka a musaka ka bon . |

| kalisiyɔmu-zinki sabatili . | A tɛ baga ye, a bɛ se ka kɛ fɛn wɛrɛw ye minnu bɛ se ka kɛ fɛn ye . |

Fɛn minnu tɛ baga ye, olu yiriwali .

O haminankow jaabi la, o baara in jiginna ka taa farankanw kan minnu tɛ baga ye ani minnu tɛ fɛn tiɲɛ . Fɛɛrɛ wɛrɛw kalisiyɔmu-zinki sabatilifɛnw walasa ka nɛgɛ gɛlɛnw bila u nɔ na. tigɛra i n’a fɔ Nin farankan kura ninnu bɛ PVC ka baara kɛcogo sabati k’a sɔrɔ u ma sigida walima hadamadenw ka kɛnɛya tiɲɛ. Cɛsiriw fana bɛ sen na walasa ka bio-based plasticizers da minnu tɛ farati kelenw lase ni laadala fthalates ye.

dagalenw lasegincogo siraw .

PVC baara in sinsinnanba dɔ ye ka segin-ka- bɔnyew sigi senkan minnu bɛ se ka kɛ ka fɛnw lasegin u cogo kɔrɔ la. O ye ka PVC bɔgɔw lasegin u cogo kɔrɔ la ka segin u dilanni na, ka dɔ bɔ fɛn kuraw mago la ani ka sigida laminiko gɛlɛya dɔgɔya. VinylPlus , n’o ye Erɔpu PVC lasegincogo ye, o ye ɲɛtaa sɔrɔ PVC ka fɛnw lajɛli n’u lasegincogo nɔgɔyali la. Ni PVC bɔgɔ bɛ se ka baara kɛ kokura ani ka baara kɛ ni a ye kokura, fɛn dilannikɛlaw b’a fɛ ka binkɛnɛw tiɲɛni dɔgɔya ani ka sɔrɔko sɛrɛkili dɔ yiriwa.

PVC ka segin-ka-bɔ ani a filili .

PVC seginni ye gɛlɛya ye ka da a kan farali ni nɔgɔw bɛ yen. PVC lasegincogo fɛɛrɛba fila bɛ yen:

Mekanikiw lasegincogo : o ye ka PVC bɔgɔw sɔgɔ ani ka u lasegin ka kɛ fɛn kuraw ye. Nka, nɔgɔw sɔrɔli bɛ se ka dɔ bɔ fɛn wɛrɛw la minnu bɛ segin ka kɛ fɛn wɛrɛw ye.

kemikorow lasegincogo : A bɛ PVC kari ka jigin a basigilen yɔrɔw la, minnu bɛ se ka baara kɛ kokura ni u dilanni taabolo kura ye. Nin fɛɛrɛ in ka gɛlɛn ka tɛmɛ nka a bɛ sira di ka segin ka kɛ fɛn wɛrɛ ye.

PVC filicogo jugu, kɛrɛnkɛrɛnnenya la, a jeni fɛ, o bɛ gazi juguw bɔ i n’a fɔ kulori idɔrɔzi . Fɛn minnu bɛ kɛ ka mɔgɔw bila ka taa yɔrɔ wɛrɛw la, olu filili fɛɛrɛw ka ɲi kosɛbɛ walasa ka sigida tiɲɛni dɔgɔya.

Fɛn dilanni taabolo sabatilen .

Walasa ka PVC ka sigida nɔfɛkow ɲɛnabɔ, fɛn dilannikɛlaw bɛ ka wale sabatilenw ta . Olu dɔw ye ka fɛnɲɛnamafagalanw bɔli dɔgɔya u dilanni senfɛ ani ka baara kɛ ni fanga sɔrɔyɔrɔw ye minnu bɛ se ka segin u cogo kɔrɔ la. Ni PVC laseginlen don fɛn kuraw kɔnɔ, o baara bɛ se ka dɔ bɔ a jigi la npogotigininw ka fɛnw kan. Kɔnpɔsitɛriw fana bɛ ka baaracogo sɛgɛsɛgɛ BIO-PVC , minnu bɛ sɔrɔ balofɛnw na minnu bɛ se ka segin u cogo kɔrɔ la, i n’a fɔ PVC kɔrɔlen wɛrɛ.

Fɛn wɛrɛw bɛ se ka kɛ PVC la .

Baara dɔw la, iziniw bɛ ka PVC wɛrɛw sɛgɛsɛgɛ. Fɛn minnu bɛ kɛ i n’a fɔ poliporopilini ani elastomɛri thermoplastic (TPE) olu bɛ o nafa kelenw di ni sigida nafa dɔgɔyali ye. Misali la, TPE bɛ se ka PVC sɛgɛsɛgɛlen nɔ na furakɛli tubabukan na, ka sɔrɔ poliyetilɛni bɛ kɛ ka caya pakew dilanni na. O fɛɛrɛ wɛrɛw ye cɛsiriba dɔ ye walasa ka dɔ bɔ fɛnw na minnu bɛ se ka kɛ fɛn ye min bɛ se ka mɔgɔ tɔɔrɔ.

Farankan

PVC plastiki ye fɛn caman ye, a bɛ mɛn, wa a bɛ kɛ ka caya iziniw kɔnɔ i n’a fɔ jɔli ni kɛnɛyako. A bɛ sɔrɔ cogo la min bɛ se ka wuli ka bɔ a nɔ na ani a ka gɛlɛn, a kɛcogo bɛ daminɛ pibilikiw la ka taa a bila furakɛli minɛnw na. Ɲɛtaa kura minnu bɛ kɛ ka fara fɛnw kan minnu bɛ se ka kɛ fɛn ye, ani ka fɛnw lasegin u cogo kɔrɔ la, olu kun ye ka PVC kɛ fɛn ye min bɛ sabati. Ni fɛɛrɛ kuraw bɛ ka ɲɛ, PVC min bɛ kɛ ni biyo ye ani fɛɛrɛ wɛrɛw minnu tɛ baga ye, olu bɛ ka bɔ kɛnɛ kan. Walasa ka sigida lakana, PVC furaw baaracogo ɲuman ani u filili ka ɲɛ, o nafa ka bon kosɛbɛ walasa u ka se ka u nɔfɛkow dɔgɔya.

Ladilikanw: A bɛ se ka kɛ ko aw bɛ a fɛ ka a bɛɛ kɛ plastiki ye .