Aw bɛ a lajɛ cogo di ko masin yɔrɔw bɛ bɛn ɲɔgɔn ma cogo dafalen na ani ko u bɛ baara kɛ ka ɲɛ? Fitini ɲuman sugandili ye ko kɔrɔba ye ɛntɛrinɛti kan. Fit tigitigi bɛ nɔ bila fɛnw ka baarakɛcogo la, u ka muɲuli la, ani u ka lakana.

Fitini suguya wɛrɛw faamuyali nafa ka bon yɔrɔw dilanni na minnu bɛ lamaga, ka wuli, walima ka sɛgɛn.

Nin sɛbɛn in kɔnɔ, aw bɛna a dɔn ko clearance, transition ani interference fits. An bɛna aw bilasira ni aw ka poroze ye min bɛnnen don kosɛbɛ ka da baarakɛcogo kan, tiɲɛni, ani budget kan.

Faamuyali Engineering Fits: A jɔnjɔnw .

Engineering fits jɔyɔrɔ ka bon kosɛbɛ bi fɛn dilanni na. O jɔnjɔnw faamuyali bɛ ɛntɛrinɛti kalanbagaw dɛmɛ u ka masinw ka lajɛ tigitigiw da.

Engineering fitinin ye mun ye?

Engineering fit bɛ dimensionnel jɛɲɔgɔnya ɲɛfɔ furuɲɔgɔnya yɔrɔ fila ni ɲɔgɔn cɛ. A bɛ yɔrɔw bɛ ɲɔgɔn sɔrɔ cogo min na ni u lajɛlen don ɲɔgɔn fɛ, o de bɛ o latigɛ. Engineering Fits A b'a jira ko:

Mekaniki jɛɲɔgɔnya tigitigiw bɛ sɔrɔ yɔrɔw ni ɲɔgɔn cɛ ka tɛmɛ dimensionnels contrôlées (hakɛw ni ɲɔgɔn cɛ jɛɲɔgɔnyaw) fɛ .

Baara kɛcogo ɲuman ni jɛya walima ɲɔgɔndan ye furuɲɔgɔnya yɔrɔw ni ɲɔgɔn cɛ .

Lajɛ kɛcogo minnu bɛ se ka da u kan, minnu sinsinnen bɛ dantigɛli sariyaw kan minnu bɛ kɛ ka kɛɲɛ ni sariya ye .

Fɛn min bɛ bonya ka taa a fɛ, o ka ɲɛnamaya janya ni a yɔrɔw ka jɛɲɔgɔnya ɲuman ye ani ka a don .

Daɲɛ kolomaw bɛ sɔrɔ ɛntɛrinɛti kan.

Daɲɛ nafamaw faamuyali bɛ ɛntɛrinɛti kalanbagaw dɛmɛ u ka kumaɲɔgɔnya kɛ koɲuman fitininw kan:

Basi yɔrɔw:

DON : Yɔrɔ dɔ kɔnɔna na (silindrique walima non-cylindrical) .

Shaft : Kɛnɛmafɛn min dabɔra ka jɛ ni dingɛ ye .

Hakɛ tɔgɔlama : Dimension dafalen teoritiki min bɛ kɛ i n’a fɔ a bɛ baara kɛ ni min ye .

Dimension (hakilila) Daɲɛw:

Tolerance : Yɛlɛma min bɛ sɔn ka bɔ dimensions kofɔlenw na .

Clearance : Yɔrɔ min bɛ cɛnimusoya yɔrɔw ni ɲɔgɔn cɛ .

Interference : Dafalenw ni ɲɔgɔn cɛ yɔrɔw hakɛw ni ɲɔgɔn cɛ .

Deviation : Danfara bɛ hakɛ tɔgɔlama la .

Fits jɔyɔrɔ masinaw ka lajɛbaw la .

Engineering Fits bɛ baara caman kɛ masinw na:

Lamaga-lamagali kɔlɔsili .

Regulate component motion .

Aw bɛ se ka baara kɛ cogo nɔgɔman na .

Contrôle mécanique friction .

doni jiginni .

Aw ye aw jija fanga jiginni ka ɲɛ .

Ka sigicogo dafalen mara .

Aw bɛ a yɔrɔw dɛsɛ bali .

Lajɛba ɲɛnabɔli .

Guide ka fɛn dilanni taabolo .

Standardize component relationships .

Aw bɛ ladonni kɛcogo nɔgɔya .

Dimension jɛɲɔgɔnyaw sariyakolo jɔnjɔnw .

Injiniyɛri ka jusigilan bɛ tali kɛ sariyakolo jɔnjɔn caman na:

| sariyakolo | ɲɛfɔli | baarakɛcogo . |

| Hole basis system . | Dingɛw hakɛ jɔlenw, shaft hakɛ bɛrɛbɛrɛ . | Fɛn dilanni fɛɛrɛ min ka ca kosɛbɛ . |

| Shaft Basis System . | Shaft dimensions fixe, , , hole size variable . | Aplikasi kɛrɛnkɛrɛnnenw . |

| Tolerance Zones . | Dimensional variations acceptables ɲɛfɔlenw . | Quality Control Standard . |

Jɛɲɔgɔnya kɔrɔfɔlenw:

Componentw ka jɛɲɔgɔnya .

furuɲɔgɔnya yɔrɔw ka kan ka bɛn tolerances kofɔlenw kɔnɔ .

Surface finish bɛ nɔ bila fit baarakɛcogo la kosɛbɛ .

Material properties bɛ nɔ bila fit jogo la .

Fɛn dilanni jateminɛw .

Sɛnɛfɛnw dilanni sekow bɛ muɲuli minnu bɛ se ka kɛ .

musaka bɛ bonya ni muɲuli gɛlɛnw ye .

Lajɛ fɛɛrɛw bɛ nɔ bila fit sugandili la .

Baarakɛcogo wajibiyalenw .

Baarakɛcogo bɛ nɔ bila Fit Selection la .

Load Requirements A’ ye fitinin suguya bɛnnenw de latigɛ .

sigida koɲɛw bɛ nɔ bila bɛnkan sabatili la waatijan kɔnɔ .

O faamuyali jɔnjɔn bɛ injiniyɛriw dɛmɛ ka fitininw sugandi minnu bɛnnen don baara kɛrɛnkɛrɛnnenw kama. U bɛ se ka yɔrɔw jɛɲɔgɔnyaw ɲɛnabɔ ka ɲɛ ka sɔrɔ ka jateminɛ kɛ fɛn dilanni seko ni musaka gɛlɛyaw la.

Ka dingɛ ni shaft basis sitɛmu faamuya .

Ɲɛfɔli min bɛ kɛ dingɛ ni shaft basis system kan .

Hole and Shaft Basis System ye injiniyɛri ka fitininw ɲɛfɔli jusigilan ye. A b’a jira ko jamalajɛ yɔrɔ jumɛn — dingɛ walima jiribolo — o bɛna kɛ ni fɛn ye min bɛ to ka kɛ. O kɔfɛ, a yɔrɔ tɔ kelen in hakɛ bɛ ladilan walasa ka se ka bɛnkan ɲininen sɔrɔ. Nin cogoya in nafa ka bon kosɛbɛ walasa ka a dɔn kosɛbɛ yɔrɔw bɛna don ɲɔgɔn na cogo min na kosɛbɛ walima ka u lafiya.

Hole-Basis System: Dingɛ hakɛ min bɛ to ka kɛ, a bonya bɛ danfara .

Dingɛ-basi-sistɛm kɔnɔ, dingɛ in bonya bɛ Labɛn ka sɔrɔ a jiribolo bonya bɛ Yɛlɛma walasa ka se ka fitinin wajibiyalen Sɔrɔ. O fɛɛrɛ in bɛ fɛn dilanni nɔgɔya bawo dingɛ bonya bɛ nɔgɔya ka tɛmɛ baara kɛcogo jɛlenw fɛ i n’a fɔ jirituru. O kɔfɛ, shaft’s dimensions bɛ se ka fin-tuned walasa ka fitting requirement tigitigiw dafa.

Hole-basis system ka jogo jɔnjɔnw:

Shaft-Basis System: Shaft hakɛ basigilen, dingɛ hakɛw bɛ danfara .

Shaft-basis system kɔnɔ, shaft in dimension bɛ to a cogo la, wa dingɛ bonya bɛ ladilan walasa ka se ka bɛn. Nin fɛɛrɛ in bɛ kɛ tuma caman na ni jiribolo hakɛ caman cili ka gɛlɛn, i n’a fɔ a bɛ kɛ cogo min na, o bɛ kɛ fɛn ye min bɛ wuli teliya la, yɔrɔ minnu na, mass balannako nafa ka bon kosɛbɛ. Dingɛ hakɛ ladilanni bɛ fɛn caman sɛgɛsɛgɛli kɛ ni jiribolo tɛ se ka Changé.

Shaft-basis system ka jogo jɔnjɔnw:

Nafa minnu bɛ sɔrɔ ka baara kɛ ni Hole-Basis System ye .

Hole-basis system ye sugandili ye min bɛ kɛ ka caya injiniyɛri la. A nafaw ye:

Nɔgɔya : dingɛw ka nɔgɔn ka tɛmɛ u dilanni kan.

musaka kɛcogo ɲuman : A bɛ dɔ bɔ dingɛw dilanni kɛrɛnkɛrɛnnen na.

Versatility : A bɛ se ka ladilanni nɔgɔya ni a shaft dimensions caman cili ye.

| Sisitɛmu suguya | jɔlenw ka | fɛn caman sɛgɛsɛgɛli | yɔrɔ jɛlenw . |

| Hole-basis system . | Dingɛ | Shaft . | gears, bushings, machine parts . |

| Shaft-basis system . | Shaft . | Dingɛ | Fɛn minnu bɛ wuli teliya la . |

Tolerances ani u jɔyɔrɔ in Engineering Fits .

Tolerances bɛ fɛn dɔ ɲɛfɔ min bɛ se ka kɛ yɔrɔ dɔ bonya la ka bɔ a tɔgɔla hakɛ la. U bɛ dan minnu Kɛ, yɔrɔ minnu bɛ Se ka Dilan k’a sɔrɔ u ma nɔ Blà u ka baara la. Engineering fits la, tolerances bɛ a jira ko deviation hakɛ min bɛ sɔn ni furuɲɔgɔnya yɔrɔw lajɛlen don.

Tolerances nafa ka bon ka se ka kɛ cogo bɛnnen na .

Muɲuli nafa ka bon walasa ka a lajɛ ni a yɔrɔw bɛ bɛn ka ɲɛ. Ni muɲuli tigitigiw tɛ, a yɔrɔw bɛ se ka lafiya kojugu walima ka u siri kojugu, o bɛ na ni baara kɛcogo koɲɛw ye walima hali ka dɛsɛ. Tolerances kofɔlenw bɛ se ka kɛ sababu ye ka injiniyɛriw dɛmɛ u ka se ka Fit ka cogoya kɔlɔsi ani ka dannaya sɔrɔ baara suguya caman kɔnɔ.

Jɛɲɔgɔnya min bɛ muɲuni ni fitinin suguyaw cɛ .

Fit suguya wɛrɛw bɛ tolerance ranges kɛrɛnkɛrɛnnenw de wajibiya:

| fit type | typique tolerance range | application application |

| Clearance . | +0,025mm ka se +0,089mm ma . | Assemblées rotatifs . |

| Furancɛfanga | +0,023mm ka -0,018mm . | Yɔrɔ-kɔrɔ-yɔrɔw . |

| Interference . | -0,001mm ka se -0,042mm ma . | Assemblies permanents . |

Toleransiw ɲɛfɔlen don cogo min na ɛntɛrinɛti jaw kɔnɔ .

Injiniyɛri ja la, muɲuli bɛ jira tuma caman na ni jateminɛ hakɛ ni muɲuli (GD&T) taamasiyɛnw ye. O taamasiyɛnw bɛ dɛmɛ ka yɔrɔ hakɛw ɲɛfɔ minnu bɛ sɔn, ka kɛɲɛ ni ɲɔgɔndɛmɛ ye fɛn dilanni na. Tolerances bɛ jira linear ani angular measurement fila bɛɛ la, ka dilanbagaw dɛmɛ u ka se ka fit bɛnnen sɔrɔ.

Fɛn kolomaw minnu bɛ tolerances ɲɛfɔli la olu ye:

Dimension nominal : A yɔrɔ hakɛ ɲuman .

Sanfɛla ni duguma danw : A hakɛ bɛ se ka kɛ hakɛ min na ani a hakɛ fitinin .

GD&T taamasiyɛnw : taamasiyɛnw sariyalenw walasa ka tolerance zones ni geometric constraints ɲɛfɔ .

| Fit type | tolerance requirement | Misali Baarakɛcogo . |

| Clearance fit . | Tolerances looses ka ɲɛsin hɔrɔnya lamagacogo ma . | pivots, sliding joints . |

| Interference fit . | Tolerances sirilenw ka ɲɛsin presse-fit assemblies ma . | gears, bushings, birikiw jɔlenw . |

| Tɛmɛsira fitinin . | Tolerances moderate ka ɲɛsin ɲɔgɔndan tigitigi ma . | Moteur shafts, pulley assemblies . |

Tolerances ɲɛfɔlenw ka ɲɛ, o bɛ a to fitinin ɲininen bɛ se ka sɔrɔ, o bɛ na ni baara kɛcogo ɲuman ye ani ka ɲɛnamaya janya.

Engineering fits suguya jɔnjɔn saba .

Engineering (ɛntɛrinɛti) la, ka Fit (Fit) ɲuman sugandi, o bɛ a to masinw ka lajɛw ka baara kɛcogo ɲuman. Fitini suguya saba bɛ yen: clearance fits, interference fits, ani transition fits. Sugu kelen-kelen bɛɛ bɛ baara kɛ ni kuntilenna wɛrɛw ye ani a bɛ sugandi ka kɛɲɛ ni aplikasiɔn ka ɲininiw ye.

1. Clearance fits .

Clearance fits bɛ danfara ɲuman sigi senkan ɲɔgɔndan yɔrɔw ni ɲɔgɔn cɛ, ka hɔrɔnya lamagacogo sabati.

Koorilenw ka jogo:

jiribolo janya bɛ to ka dɔgɔya ka tɛmɛ dingɛ cɛmancɛ kan .

O yɔrɔ min dilannen don, o bɛ se ka kɛ sababu ye ka lamagacogo kɛrɛnkɛrɛnnenw kɛ fɛnw ni ɲɔgɔn cɛ .

Lajɛ kɛcogo bɛ fanga walima baarakɛminɛn kɛrɛnkɛrɛnnenw de wajibiya .

A suguya minnu bɛ sɔrɔ tuma caman na:

Fit de run de running (H11/C11) .

A dabɔra baarakɛminɛnw kama minnu bɛ lamaga hɔrɔnyaba de wajibiya ka sɔrɔ ka jɔyɔrɔko jɛɲɔgɔnya jɔnjɔnw mara masinw ni ɲɔgɔn cɛ .

A ka fisa sigidaw ma minnu bɛ nɔgɔba sɔrɔ, funteni caman ɲɔgɔnna, walima ladonni bolodalen minnu tɛ kɛ tuma bɛɛ .

Fit de run de running (H9/D9) .

A bɛ sɛgɛsɛgɛli dafalen di min bɛ se ka baara kɛ ka ɲɛ teliya la baarakɛcogo la ka sɔrɔ ka bɛnkanw mara minnu bɛ sɔn ka kɛ fɛnw ye minnu bɛ wuli ka wuli .

A ka ɲi kosɛbɛ sistɛmuw ma minnu bɛ tulumafɛnw ɲini minnu bɛ to ka kɛ ani ka tiɲɛni hakɛ danmadɔ sɔrɔ izini masinw sigicogo la .

Fit running close (H8/F7) .

A bɛ fɛnw cɛsira tigitigiw mara yɔrɔw ni ɲɔgɔn cɛ k’a sɔrɔ u bɛ se ka lamagacogo kɔrɔsilenw kɛ masinw na minnu bɛ kɛ ka ɲɛ .

A bɛnnen don masin baarakɛminɛnw sɔgɔli ma ani sliding mechanisms precision ma min bɛ jɔyɔrɔko tigitigi de wajibiya baara kɛtuma na .

Sliding fit (H7/G6) .

A bɛ se ka kɛ cogo la min bɛ kɛ ka ɲɛ walima ka wuli ka bɔ ɲɔgɔn na ka sɔrɔ ka dimension control strict mara furuɲɔgɔnya yɔrɔw ni ɲɔgɔn cɛ cogo la min bɛ kɛ ka ɲɛ .

A bɛ sɔrɔ jiko siratigɛ la, ɲɛjirali kɛcogo tigitigiw la, ani masin kɛrɛnkɛrɛnnenw na minnu bɛ lamagacogo kɔrɔsilenw de wajibiya .

Yɔrɔ min bɛ yɔrɔ la (H7/H6) .

A bɛ yɔrɔw jɔyɔrɔ tigitigi sigi sen kan ka sɔrɔ ka sira di lamaga ma min ka kan ka kɛ walasa ka lajɛ ani ka baara kɛ ni fɛnw ye minnu bɛ kɛ ka ɲɛ.

A nafa ka bon ɲɛminɛlanw ni jɔyɔrɔfalen minɛnw na minnu bɛ segin-ka-bɔ ɲɔgɔndɛmɛ na lajɛ ni ladonni waatiw la .

Aplikasi Matrix:

| Fit suguya | Baarakɛcogo | Sigida cogoyaw | Lajɛli wajibiyalenw . |

| Loose running . | Minɛn girinmanw . | A nɔgɔlen don/a bɛ se ka fɛn caman sɛmɛntiya . | fanga fitinin . |

| Bololabaara fu . | Sistɛmuw jiginni . | Saniya/kɔlɔsili . | Alignment basigilen . |

| Boli surun . | Baarakɛminɛnw tigitigi . | Saniya/stable . | A minɛcogo ɲuman . |

| Sliding . | Lamaga-lamagali liniyali . | Saniya/lubrifié . | Setup tigitigi . |

| Yɔrɔ in . | positionnement . | Kɔlɔsili . | Labɛnni tigitigi . |

2. Tɛmɛsira fitininw .

Tɛmɛsira fitininw bɛ cɛmancɛ-yɔrɔ-ko jɛɲɔgɔnyaw jira clearance ni interference cogoyaw cɛ.

Fɔlɔw danfara:

O ɲɔgɔnna fitinin (H7/K6) .

A bɛ bɛnkanw dilan minnu bɛ bɛn ɲɔgɔn ma, minnu bɛ sira di walasa ka se ka fɛnw bɔ ɲɔgɔn na dɔɔnin walima ka dankarili dɔɔnin kɛ ka kɛɲɛ ni fɛn dilanni fɛn caman ɲɔgɔnna ye .

A bɛ se ka kɛ sababu ye ka jɔyɔrɔfalen kɛ ka sɔrɔ ka lajɛli sɛgɛsɛgɛli sabati masinw na minnu bɛ se ka kɛ fɛn ye min bɛ se ka minɛ ka ɲɛ.

Fixe fit (H7/N6) .

A bɛ dantigɛli dafalen caman sigi sen kan ka sɔrɔ ka to ka ɲɛnabɔ lajɛw la ani ladonni nataw la minnu bɛ se ka kɛ .

A bɛ jɔyɔrɔ sabatili sabati ni a bɛ tali kɛ fitininw na minnu bɛ tali kɛ ɲɔgɔn na ka sɔrɔ ka lajɛ fanga wajibiyalenw mara cogo bɛnnen na .

Nafa jɔnjɔnw:

Balannako ɲuman jɔyɔrɔ tiɲɛni ni ɲɔgɔnjɛ waleyali cɛ .

A bɛnnen don sigida cogoya caman ma .

A bɛ se ka ladilan ka kɛɲɛ ni doni wajibiyalenw caman ye .

3. Interference fits .

Interference fits bɛ mekaniki jɛɲɔgɔnya barikamaw dilan ni dimension overlap contrôlé ye yɔrɔw ni ɲɔgɔn cɛ.

A waleyali fɛɛrɛw:

Aw bɛ Fit (H7/P6) digi.

A bɛ ɲɔgɔndan banbaliw sigi sen kan ni dimension contrôlée contrôlée contrôlées ye ɲɔgɔndɛmɛ yɔrɔw ni ɲɔgɔn cɛ assemblies critiques kɔnɔ .

A bɛ lajɛminɛn kɛrɛnkɛrɛnnenw de wajibiya ani baarakɛcogo kɔlɔsili ɲuman walasa ka ɲɛtaa ɲuman sɔrɔ k’a sɔrɔ a yɔrɔ dɔw tiɲɛna .

Shrink fit .

A bɛ baara kɛ ni funteni bonya ni a jiginni sariyakolow ye walasa ka masinw sirili barikamaba dɔw sigi sen kan fɛnw ni ɲɔgɔn cɛ minnu bɛ se ka baara kɛ ni fɛnw ye minnu bɛ se ka baara kɛ .

A bɛ funteni hakɛ kɔlɔsili tigitigi ɲini ani a kɛcogo kɛrɛnkɛrɛnnenw lajɛli ni ladonni baara minnu bɛ se ka kɛ .

Sugandili jateminɛw:

Baarakɛyɔrɔ funteni hakɛ minnu bɛ nɔ bila hakɛ sabatili la .

Load transmission wajibiyalenw bɛ sɔrɔ sigida lajɛlenw kɔnɔ .

Ladonni sɔrɔli wajibiyalenw baara nataw kama .

fɛn dilanni seko ni musaka gɛlɛyaw .

Material Properties ani Surface Finish Specifications .

Fit suguya ɲuman sugandi cogo .

Fit suguya ɲuman sugandili injiniyɛri la, o nafa ka bon kosɛbɛ walasa ka a jira ko masinw yɔrɔw bɛ baara kɛ i n’a fɔ a laɲininen don cogo min na. Sugandili bɛ bɔ fɛn caman na, i n’a fɔ baarakɛcogo magow, a tiɲɛni, ani a sigida cogoyaw. Nin ko ninnu faamuyali bɛ ɛntɛrinɛti kalanbagaw dɛmɛ u ka se ka latigɛw kɛ walasa ka baara kɛcogo ɲuman sɔrɔ.

Fɛn minnu ka kan ka jateminɛ .

Ni aw bɛ fitinin sugandi, a nafa ka bon ka fɛn kolomaw jateminɛ minnu bɛ nɔ bila a yɔrɔw dilanni n’u baarakɛcogo la:

Baarakɛcogo wajibiyalenw : Aw bɛ a dɔn ni yɔrɔw bɛna taa, ka wuli, walima ka to u cogo la.

Baarakɛcogo : Aw bɛ fɛnw jateminɛ i n’a fɔ funteni, nɛnɛ, ani fɛn minnu bɛ se ka kɛ buguri walima nɔgɔ la.

A lajɛ ni a tiɲɛni magow : Aw bɛ a jateminɛ ko a yɔrɔw ka kan ka lajɛ walima ka u fara ɲɔgɔn kan siɲɛ joli, o bɛ nɔ bila fitinin sirili la.

Muɲu jateminɛw : Tolerances sirilenw ni precision fits bɛ dɔ fara fɛn dilanni musakaw kan cogoya la, o la balansi baarakɛcogo ni budget ye.

Precision requirements : Baarakɛminɛn dɔw bɛ muɲuli gɛlɛnw de wajibiya walasa ka baarakɛcogo sabati, kɛrɛnkɛrɛnnenya la sigida minnu bɛ degunba lase mɔgɔw ma.

Fɛnw nafa : Fɛn suguya bɛ nɔ bila yɔrɔw bɛ ɲɔgɔn sɔrɔ cogo min na, u ka funteni bonya, u doncogo, ani u muɲuni doni kɔrɔ.

Sugandili sariyaw .

Ni u bɛ Fit suguya laban, ɛntɛrinɛti injiniyɛriw ka kan k’u ka latigɛw sinsin sugandili sariyaw kan minnu ɲɛfɔlen don kosɛbɛ:

Load Requirements : Aw bɛ fitinin dɔ sugandi min bɛ se ka doni makɔnɔnen kunbɛn, kɛrɛnkɛrɛnnenya la yɔrɔw la minnu bɛ degun basigilen kɔnɔ.

Lamaga-lamagali wajibiyalenw : A’ ye a dɔn ni Fit bɛ sira Di lamaga-lamagali hɔrɔnyalen ma, lamaga-lamagali ma, walima lamaga-lamagali tɛ min na hali dɔɔnin.

Funteni cogoyaw : Fitini dɔw, i n’a fɔ ɲɔgɔndan fitininw, olu bɛ ɲini ka jateminɛ kɛ u bonya ni u jiginni kan ka da funteni caman yeli kan.

Ladonni magow : Fɛn minnu mago bɛ baara la tuma bɛɛ, olu ka kan ka baara kɛ ni fitininw ye minnu bɛ se ka ɲɔgɔn lajɛ nɔgɔya la ani ka u bɔ ɲɔgɔn na.

Fɛn dilanni sekow : Aw ye aw jija aw ka fɛn dilanni taabolo ka se ka tiɲɛniw dafa minnu ka kan ka kɛ walasa ka se ka kɛ.

| Fit Type | Ideal for | Common applications |

| Clearance fit . | Lamaga-lamagali hɔrɔnyalenw ni ɲɔgɔn cɛ . | pivots, sliding joints, low-load yɔrɔw . |

| Interference fit . | Jɛɲɔgɔnya lakananenw, banbaliw . | gears, bushings, bérés monts . |

| Tɛmɛsira fitinin . | A ka ca a la, a bɛ se ka kɛ ko a bɛ se ka kɛ . | Alignment précision, shafts, pulleys . |

Ni u ye o kow ni sariyaw jateminɛ, ɛntɛrinɛti injiniyɛriw bɛ se ka fitinin suguya ɲuman sugandi u ka porozɛ kɛrɛnkɛrɛnnen kama, ka baara kɛcogo ɲuman ni a muɲuni sabati.

Achieving dimension tolerances for fits .

Tolerances dimensionnels tigitigi sɔrɔli nafa ka bon kosɛbɛ injiniyɛri la walasa a yɔrɔw ka bɛn ɲɔgɔn ma ka ɲɛ ani ka baara kɛ i n’a fɔ a tun bɛ fɔ cogo min na. Fɛn dilanni fɛɛrɛ suguya caman bɛ ɛntɛrinɛti kalanbagaw dɛmɛ u ka se ka muɲuli wajibiyalenw dafa, ka masina yɔrɔw baaracogo n’u ɲɛnamaya janya.

Fɛn dilanni fɛɛrɛw walasa ka muɲuli gɛlɛnw sɔrɔ .

Fɛn dilanni taabolo caman bɛ kɛ ka caya walasa ka tiɲɛniba sɔrɔ yɔrɔw la, k’a lajɛ ko muɲuli minnu kofɔlen bɛ ɛntɛrinɛti dilanni na, olu ka dafa.

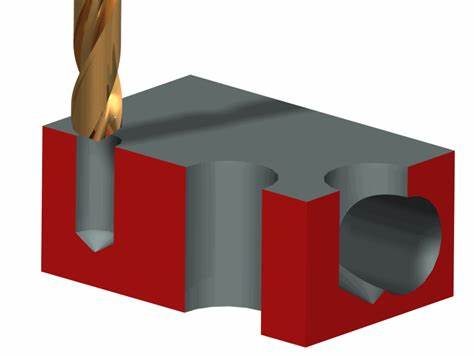

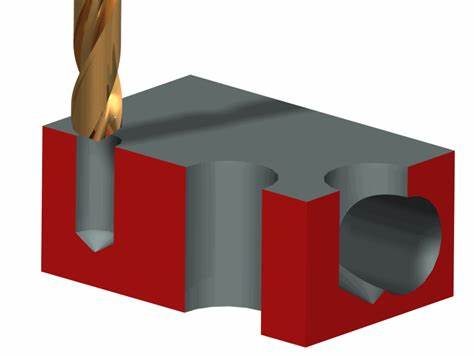

CNC ka machining précision .

CNC masinw bɛ tiɲɛni danma di, a ka c’a la, u bɛ muɲuli sɔrɔ ka gɛlɛn i n’a fɔ +/- 0,001 mm. U ka ɲi kosɛbɛ yɔrɔw la minnu bɛ kunnafoni gɛlɛnw walima fɛn fitininw de wajibiya u bonya la.

Nafaw : tigitigiyaba, segin-ka-bɔ, se ka kɛ ka siginiden gɛlɛnw dilan .

Aplikasi : shafts, gears, so .

Grinding .

Grinding ye finidoncogo ye min bɛ kɛ ka yɔrɔw sɔrɔ minnu ka nɔgɔn kosɛbɛ ani ka tolerances sirilen kosɛbɛ. A nafa ka bon kɛrɛnkɛrɛnnenya la yɔrɔw la, yɔrɔ minnu na, tiɲɛniba ka kan ka kɛ, i n’a fɔ fɛnw tiɲɛni.

Nafaw : A bɛ tiɲɛniba sɔrɔ fo ka se +/- 0,25 mikron ma .

Aplikasi : Bearing surfaces, press-fit parts .

Reaming .

Reaming ye fɛɛrɛ ye min bɛ kɛ ka dingɛw bonya, k’u laminicogo n’u tiɲɛni ɲɛ. A ka ca a la, a bɛ baara kɛ sɔgɔli kɔfɛ walasa ka dingɛw lase muɲuli tigitigiw ma minnu ka kan ka kɛ walasa ka ɲɔgɔn lajɛ.

Nafaw : Dingɛw dilanni tigitigi ni muɲuli sirilenw ye .

Aplikasi : birikiw, bushings, dowel dingɛw .

GD&T nafa (jateminɛ ni muɲuli) .

GD&T ye taamasiyɛnw ni kunnafonifalenw sigicogo ye minnu bɛ kɛ ɛntɛrinɛti ja la walasa ka fɛn caman caman ɲɔgɔnna ɲɛfɔ yɔrɔ hakɛw la. A bɛ dilanbagaw dɛmɛ u k’a faamu hakɛ minnu nafa ka bon kosɛbɛ walasa ka se ka fitinin ɲininen sɔrɔ. GD&T b’a to yɔrɔw ka jateminɛ wajibiyalenw mara, hali ni fɛn dɔw bɛ ɲɔgɔn falen-falen u dilanni na.

Elements critiques

| GD&T taamasiyɛn | kɛcogo | Tolerance range . |

| Silindriki . | Shaft/Hole Formulaire . | 0,01-0,05mm . |

| Concentricité . | Assemblée alignment . | 0,02-0,08mm . |

| jɔyɔrɔ lakika . | component yɔrɔ . | 0,05-0,10mm . |

| Roundness . | Circular features . | 0,01-0,03mm . |

Joli bɛ jogoɲini na walasa a ka se ka kɛ cogo bɛnnen na .

Jogoɲumanya kɔlɔsili jɔyɔrɔ ka bon kosɛbɛ fitininw ka tiɲɛni sabatili la. Sɛgɛsɛgɛliw ni sɛgɛsɛgɛli kɛli tuma bɛɛ, o b’a to yɔrɔw bɛ muɲuli wajibiyalenw dafa. Fɛɛrɛw i n’a fɔ koordinatɛri sumani masinw (CMM) ani optique comparateurs bɛ kɛ ka hakɛw sɛgɛsɛgɛ.

Dimensions inspections : Aw ye a lajɛ ni yɔrɔw bɛ bɛn tolerances kofɔlenw ma.

Fit testing : A bɛ yɔrɔw lajɛ ani ka ko dɔw lajɛ minnu bɛ Fit kɔnɔ.

Taabolow kɔlɔsili : A bɛ fɛn dilanni taabolo kɔlɔsi walasa ka fɛn caman ɲɔgɔnna dɔgɔya ani ka bɛnkan mara.

| Fɛn dilanni | fɛɛrɛ tigitigiw | . |

| CNC ka machining précision . | +/- 0,001 mm . | Gears, shafts, components complexes . |

| Grinding . | +/- 0,25 microns . | Bearings, Press-FIT yɔrɔw . |

| Reaming . | Dingɛ-dilancogo tigitigi . | Bushings, Dowel dingɛw . |

Ni baara kɛra ni nin fɛn dilanni fɛɛrɛ ninnu ye ani ka jogoɲini gɛlɛnw mara, ɛntɛrinɛti injiniyɛriw bɛ se ka muɲuli gɛlɛnw sɔrɔ minnu ka kan ka kɛ walasa ka bɛncogo ɲuman sɔrɔ, ka masinw ka lajɛbaw ka baarakɛcogo n’u ka dannaya sabati.

Gɛlɛyaw ɲɛnabɔli fit gɛlɛyaw .

Ko minnu bɛ kɛ ɲɔgɔn fɛ fit assemblies kɔnɔ .

1. Jɛɲɔgɔnya lafiyalenw .

Yɔrɔw ni ɲɔgɔn cɛ bɔli kojugu bɛ na ni lamaga-lamagali ye min man ɲi baarakɛ waati la .

Tolerance specifications (muɲuli) kɛcogo bɛnbali bɛ na ni ɲɔgɔnkanu sabatili dɔgɔyali ye waati kɔnɔ .

Fɛn minnu ma bɛn ɲɔgɔn ma, olu bɛ sɛgɛncogo bɛnbaliw dilan minnu bɛ nɔ bila sistɛmu baarakɛcogo la .

Fɛn dilanni caman bɛ tɛmɛ dantigɛli dantigɛli kofɔlenw kan baarakɛcogo laɲinitaw kama .

2. Gɛlɛya minnu bɛ sɔrɔ sɛgɛn na .

Tolerance specifications (muɲuli) ɲɛfɔli juguw bɛ yɔrɔw tiɲɛni teliya baarakɛwaatiw la .

Materiel gɛlɛya jogo minnu tɛ bɛn ɲɔgɔn ma, olu bɛ sɛgɛncogo bɛnbaliw dilan furuɲɔgɔnya yɔrɔw bɛɛ la .

Surface Finishularités bɛ kɛ sababu ye ka fɛnw dɛsɛ ka kɔn u waati ɲɛ lajɛw la .

Inadequate lubrication systems compound wear issues in dynamic applications .

3. Dɛsɛ minnu bɛ sɔrɔ degunw fɛ,

| olu | sababu ye | fura ye . |

| component cracking . | ƝƐNAJƐW ƝƐFƆLI ƝƐFƆLI . | Aw bɛ se ka a ka fɛn ɲɛfɔlenw ladilan . |

| Surface Deformation . | Tansiyɔnba min bɛ lajɛ . | Modify installation processus . |

| Sɛgɛn min bɛ kɛ ni fɛn ye . | cyclique stress loading . | Segin ka kɛ fɛnw sugandili kan . |

| Assemblée tiɲɛni . | A sigicogo jugu . | Lajɛw kɛcogo ɲɛ . |

Fɛɛrɛ minnu bɛ se ka kɛ ka fɛnw ladilan .

A dilanni ka ɲɛsin fɛn dilanni ma .

Tolerance optimisation .

Jateminɛ kɛcogo kɔlɔsili fɛɛrɛw waleya walasa ka yɔrɔw hakɛ basigilenw mara .

Segin masinw paramɛtiriw kan walasa ka se ka dimension control tigitigi sɔrɔ .

Aw bɛ tigɛminɛn sugandili ladilan ka da fɛnw cogoyaw kan .

Surface furakɛli .

Aw bɛ surface finishing techniques kɛrɛnkɛrɛnnenw kɛ walasa ka yɔrɔw ka jɛɲɔgɔnya ɲɛ .

Fɛnw nafa bonya funteni furakɛli fɛ walima surface hardening fɛ .

Aw bɛ surface texture specifications (yɔrɔ min bɛ fɛnw ɲɛfɔ) caman sɛmɛntiya walasa ka baara kɛcogo ɲumanw sɔrɔ .

Solutions thermal .

Aw bɛ funteni hakɛ bɛnnenw jateminɛ walasa ka se ka fɛnw don ɲɔgɔn na minnu bɛ se ka kɛ sababu ye ka fɛnw don .

Monitɛri nɛnɛ hakɛw walasa ka fɛnw nafolo caman yeli bali minnu man ɲi .

Kɔlɔsili yiriwali hakɛw ka tɛmɛn funteni hakɛ maracogo tigitigiw kan .

Lubrication Strategies .

Assemblées ka sɛbɛnw .

Aw bɛ tulumafɛn bɛnnenw sugandi ka da fɛnw bɛnkan wajibiyalenw kan .

Aw bɛ tulumafɛnw kɛ minnu bɛ kɔrɔsi, olu bɛ kɛ yɔrɔ minnu na, olu lajɛ waatiw la .

Aw bɛ tulumafɛnw tiɲɛni nɔw kɔlɔsi lajɛ fanga wajibiyalenw kan .

Baarakɛcogo jateminɛw .

Aw bɛ tulumafɛnw ladonni bolodalenw sigi sen kan tuma bɛɛ walasa ka mɔgɔw ka lajɛw kɛ minnu bɛ se ka kɛ .

monitor lubrifiant degradation patterns waati la baara kɛcogo cycles .

Aw bɛ tulumafɛnw ɲɛfɔcogo ladilan ka da baarakɛcogo jaabiw kunnafoniw kan .

Banakunbɛnbagaw ka laadilikanw:

Aw bɛ sɛgɛsɛgɛli kɛ tuma bɛɛ fɛn dilanni waatiw la .

Sɛbɛnw lajɛcogo minnu bɛ kɛ ka ɲɛsin sigicogo sabatili ma .

Fit-related issues (ko minnu bɛ tali kɛ ɲɔgɔn na) sɛbɛn caman mara walasa ka kunnafoni nataw sɔrɔ .

Banakisɛfagalanw ladonni bolodalenw waleya ka da baarakɛcogo kunnafoniw kan .

Summary of Fit Selection for Engineering Projects .

Ka fitinin ɲuman sugandi ɛntɛrinɛti kan, o bɛ bɔ fɛn caman na. Baarakɛcogo wajibiyalenw, masinw tiɲɛni, ani musaka gɛlɛyaw bɛɛ jɔyɔrɔ ka bon. Tolerances ɲɛnabɔli bɛ a to yɔrɔw ka se ka dilancogo ɲɛfɔlenw dafa.

Walasa ka latigɛ kɛ clearance, transition ani interference fitw cɛ, injiniyɛriw ka kan ka jateminɛ kɛ lamaga, doni ani ɲɔgɔnjɛ magow la. Desizɔn jiri bɛ dɛmɛ ka taabolo ɲɛminɛ, ka tiɲɛni kɛ ni waleyali ye. Fit selection ɲuman bɛ baara kɛcogo ɲɛ, ka dɔ bɔ sɛgɛn na, ani ka a to a bɛ mɛn sen na. Ni nin laadilikan ninnu labatora, ɛntɛrinɛti injiniyɛriw bɛ se ka latigɛw kɛ minnu bɛ na ni masinw ka lajɛw ye minnu bɛ ɲɛ sɔrɔ.

Reference sources .

Engineering fits .

Dingɛ suguya wɛrɛw bɛ sɔrɔ ɛntɛrinɛti kan .

CNC Machining Tolerances .

Tansiyɔnba die casting .