Aw yu go mek shɔ se mashin pat dɛn fit fayn fayn wan ɛn wok fayn fayn wan? Fɔ pik di rayt fit na impɔtant tin na injinɛri. Wan prɛsis fit de impɔk di pefɔmɛns, durabiliti, ɛn sef fɔ di prɔdak dɛn.

Fɔ ɔndastand difrɛn kayn fit dɛn impɔtant fɔ disayn kɔmpɔnɛnt dɛn we de muv, rɔta, ɔ slayd.

Insay dis post, yu go lan bɔt kliarens, transishɔn, ɛn intafɛreshɔn fit. Wi go gayd yu fɔ pik di bɛst fit fɔ yu prɔjek bay we yu de du di wok, di prɛsishɔn, ɛn di badjɔt.

Fɔ ɔndastand injinɛri fit dɛn: Di fawndeshɔnal tin dɛn .

Ɛnjinia fit dɛn de ple impɔtant pat pan di mɔdan manufakchurin. We dɛn ɔndastand dɛn fawndeshɔnal ya, i de ɛp injinia dɛn fɔ mek prɛsis, rilibul mɛkanikal asɛmbli dɛn.

Wetin na injinɛri fit?

Wan injinɛri fit de difayn di dimɛnshɔnal rilayshɔn bitwin tu mating kɔmpɔnɛnt dɛn. I de disayd aw pat dɛn kin intarakt we dɛn gɛda togɛda. Engineering Fits Mek shɔ se:

Prɛsis mɛkanikal kɔnɛkshɔn bitwin kɔmpɔnɛnt dɛn tru kɔntrol dimɛnshɔnal rilayshɔnship dɛn .

Optimal pefomans tru spesifik kliarens ɔ intafɛreshɔn bitwin mating pat dɛn .

Riliable asembli proses we bies pan standad dimenshonal spesifikeshɔn dɛn .

Enhansed prodakt longevity tru prɔpa kɔmpɔnɛnt intarakshɔn ɛn wear kɔntrol .

Ki Tɛminɔlɔji insay Ɛnjinia Fits .

We yu ɔndastand impɔtant tɛminɔlɔji, dat de ɛp injinia dɛn fɔ tɔk fayn bɔt di fit dɛn:

Di komponent dɛn we de na di bays:

Hol : Di intanal ficha fɔ wan kɔmpɔnɛnt (silindrikal ɔ nɔ-silinda)

Shaft : Di ekstenal ficha we dɛn mek fɔ mate wit wan ol .

Nominal Size : Di tiorikal pafɛkt dimɛnshɔn we dɛn yuz as rɛfrɛns

Dimenshɔnal Tɛm dɛn:

Tolerance : Akseptabl vεryushכn frכm spεsifi k dimenshכn dεm .

Kliarens : Spays bitwin di komponent dɛn we de mating .

Intɛfɛreshɔn : ɔvalap bitwin kɔmpɔnɛnt dimɛnshɔn dɛn .

Deviation : Difrɛns frɔm nominal saiz .

Rol fɔ fit dɛn na mɛkanikal asɛmbli dɛn .

Engineering Fits de sav bɔku tin dɛn na mɛkanikal sistem dɛn:

Muvmɛnt Kɔntrol .

Rigyulet Kɔmpɔnɛnt Moshɔn .

Enable Smooth Opareshɔn .

Kontrol Mekanikal Frikshɔn .

Lod Transf ɔ r .

Mek shɔ se yu gɛt di rayt fɔs transmishɔn .

Mentɛn strɔkchɔral intɛgriti .

Prɛvent Kɔmpɔnɛnt Fayla .

Asɛmbli Manejmɛnt .

Gayd fɔ mek di tin dɛn we dɛn de yuz fɔ mek tin dɛn .

Standartayz Kɔmpɔnɛnt Rilayshɔnship dɛn .

Fɔ mek am izi fɔ mek dɛn du di mentenɛns wok .

Besik prinsipul dɛm fɔ dimɛnshɔnal rilayshɔnship dɛm .

Di fawndeshɔn fɔ injinɛri fit dɛn de dipen pan sɔm impɔtant prinsipul dɛn:

| Prinsipul | Diskripshɔn | Aplikeshɔn Aplikeshɔn |

| Hol Basis Sistem . | Fiks ol dimenshon, variebul shaft saiz | Mɔs kɔmɔn we fɔ mek tin dɛn . |

| Shaft besis sistem . | Fiks shaft dimenshon, variebul hol saiz | Speshal Aplikeshɔn dɛn . |

| Tolerance Zones . | Difain akseptabl dimɛnshɔnal vɛryushɔn dɛn . | Kwaliti kɔntrol standad . |

Krio Rilayshɔnship dɛn:

Komponent Intarakshɔn .

Matin sɔfays fɔ alayns insay spɛsifikɛd tolɛreshɔn dɛn .

Surface finish de afɛkt fit pefɔmɛns siriɔs wan .

Material Properties Influence Fit Karakta dɛn .

Di tin dɛn we dɛn fɔ tink bɔt .

Prodakshɔn kapabiliti dɛn de ditarmin achievable tolerances .

Kost inkris wit tayt tolerans .

Di we aw dɛn go ebul fɔ mek di Asɛmbli Afɛkt fit sɛlɛkshɔn .

Di tin dɛn we dɛn nid fɔ du .

Opareshɔn Kɔndishɔn dɛn Influɛns Fit Sɛlɛkshɔn .

Di tin dɛn we dɛn nid fɔ du fɔ lod Ditarmin di rayt fit tayp .

Di tin dɛn we de apin na di envayrɔmɛnt de afɛkt di lɔng tɛm fit stebiliti .

Dis fundamental ɔndastandin de ɛp injinia dɛn fɔ pik di rayt fit fɔ spɛshal aplikeshɔn dɛn. Dɛn kin optimize kɔmpɔnɛnt rilayshɔn dɛn we dɛn de tink bɔt manufakchurin kapabiliti ɛn kɔst kɔnstrakshɔn.

Ɔndastand di ol ɛn shaft besis sistem .

Ɛksplen di ol ɛn shaft besis sistem .

Di hol ɛn shaft besis sistem na di fawndeshɔn fɔ difayn injinɛri fit dɛn. I de establish us pat pan di asɛmbli—we na di ol ɔ di shaft—go gɛt dimenshɔn ɔltɛm. Dɔn dɛn kin ajɔst di ɔda kɔmpɔnɛnt in dimɛnshɔn fɔ mek dɛn ebul fɔ du di fit we dɛn want. Dis sistɛm rili impɔtant fɔ no aw di pat dɛn go jɔyn tayt ɔ lɔs wan go jɔyn.

Hol-Basis sistem: kɔnstant ol saiz, shaft dimɛnshɔn dɛn kin difrɛn

Insay di ol-besis sistem, di ol in dimɛnshɔn de fiks we di shaft in saiz de chenj fɔ ajɔst di fit we dɛn nid. Dis aprɔch de mek di manufakchurin prɔses simpul bikɔs di ol in saiz izi fɔ kɔntrol tru kɔmɔn prɔses lɛk drɔlin. Di shaft in dimɛnshɔn dɛn kin dɔn fayn-tyun fɔ mit prɛsis fitin rikwaymɛnt dɛn.

Ki kwaliti dɛm fɔ di ol-bɛsis sistɛm:

Shaft-basis sistem: kɔnstant shaft saiz, ol dimɛnshɔn dɛn kin difrɛn

Insay di shaft-besis sistem, di shaft in dimɛnshɔn de kɔntinyu fɔ de, ɛn dɛn chenj di ol in saiz fɔ mek i fit. Bɔku tɛm dɛn kin yuz dis we we dɛn de chenj di shaft saiz, i nɔ kin izi, lɛk insay ay-spid rotating shaft usay mas balansin na impɔtant tin. We yu ajɔst di ol saiz, dat de mek yu ebul fɔ chenj mɔ we yu nɔ ebul fɔ chenj di shaft.

Ki kwaliti dɛm fɔ di shaft-bɛsis sistɛm:

Advantej fɔ yuz di ol-bɛsis sistɛm .

Di hol-besis sistem na di opshɔn we dɛn kin yuz mɔ na injinɛri. I advantej dɛn na:

I izi fɔ mek : ol dɛn simpul fɔ kɔntrol we dɛn de prodyuz mas.

Kost Efisiensi : Ridyus di nid fɔ spɛshal mashin fɔ ol.

Versatility : Alaw fɔ mek i izi fɔ ajɔst bay we yu chenj di shaft dimɛnshɔn dɛn.

| Sistem Tayp | Fiks Kɔmpɔnɛnt | Variɛbul Kɔmɔnt | Kɔmɔn Aplikeshɔn dɛn |

| Hol-Basis sistem . | Ol | Shaft we dɛn mek | gia, bushing, mashin pat . |

| Shaft-Basis sistem we de wok fɔ di kɔmni . | Shaft we dɛn mek | Ol | High-speed rotating komponents . |

Tolerances ɛn dɛn wok na injinɛri fit .

Tolerances define di alawable variation in wan pat in dimenshon frɔm in nominal saiz. Dɛn kin sɛt di limit dɛn insay we dɛn kin mek pat dɛn we nɔ afɛkt dɛn wok. Insay injinɛri fit, tolɛreshɔn dɛn kin disayd ɔmɔs dɛvyayshɔn dɛn kin aksept we dɛn kin gɛda pat dɛn.

Impɔtant tin fɔ tolɛreshɔn fɔ ajɔst di rayt fit dɛn .

Tolerances na impɔtant tin fɔ mek shɔ se di komponent dɛn fit fayn fayn wan. If dɛn nɔ gɛt prɛsis tolɛreshɔn, pat dɛn kin tu lɔs ɔ tu tayt, we kin mek dɛn gɛt prɔblɛm wit di pefɔmɛns ɔ ivin fɔlt. Di tolɛreshɔn dɛn we dɛn spɛsifa fayn fayn wan de alaw injinia dɛn fɔ kɔntrol di kwaliti fɔ di fit ɛn mek shɔ se dɛn rili abop pan difrɛn aplikeshɔn dɛn.

Rilayshɔn bitwin tolɛreshɔn ɛn fit tayp dɛn .

Difrɛn fit tayp dɛn nid spɛshal tolɛreshɔn rɛnj dɛn:

| fit tayp | tipik tolɛreshɔn rɛnj | aplikeshɔn ɛgzampul |

| Kliarens . | +0,025mm to +0,089mm | Di asɛmbli dɛn we de rɔn . |

| Chenj | +0,023mm to -0,018mm | Location-critical komponent dɛn . |

| Intɛfɛreshɔn . | -0,001mm to -0,042mm | Assemblies we go de sote go . |

Aw dɛn spɛsifa tolɛreshɔn dɛn na injinɛri drɔin dɛn .

Insay injinɛri drɔin, dɛn kin sho bɔku tɛm tolɛreshɔn dɛn we dɛn de yuz jɔyometrik dimɛnshɔn ɛn tolɛrans (GD&T) simbul dɛn. Dɛn simbul ya de ɛp fɔ difayn di akseptabl rɛnj fɔ pat dimɛnshɔn, fɔ mek shɔ se kɔnsistɛns de insay manufakchurin. Di tolerans dɛn de prɛzɛnt insay ɔl tu di linya ɛn angul mɛzhɔmɛnt dɛn, we de ɛp di manifakta dɛn fɔ ajɔst di kɔrɛkt fit.

Ki elemɛnt dɛn fɔ spɛsifa tolɛreshɔn dɛn na:

Nominal Dimension : Di ideal saiz fɔ di pat .

Upper and Lower Limits : Di maksimum ɛn minimum alawable dimɛnshɔn dɛn .

GD&T simbul : standad simbul fɔ spɛsifa tolɛreshɔn zon ɛn jɔyometrik kɔnstrakshɔn

| Fit Tayp | Tolɛreshɔn Rikwaymɛnt | Ɛgzampul Yuz |

| Kliarens Fit . | Loose tolerances fɔ fri muvmɛnt . | Pivots, jɔyn dɛn we de slayv . |

| Intɛfɛreshɔn fit . | Tayt tolerans fɔ prɛs-fit asɛmbli dɛn . | gia, bush, fiks biɛrin |

| Transishɔn Fit . | Modaret tolerans fɔ prɛsis alaynɛshɔn . | Moto shaft, pulley assemblies |

Di tolerans dɛn we dɛn dɔn difayn fayn fayn wan de mek shɔ se dɛn gɛt di fit we dɛn want, we go mek dɛn ebul fɔ du bɛtɛ wok ɛn fɔ mek dɛn gɛt lɔng pat layf.

Tri men kayn injinɛri fit dɛn .

Insay injinɛri, we yu pik di kɔrɛkt fit, dat de mek shɔ se di mɛkanikal asɛmbli dɛn wok fayn fayn wan. Tri men kayn fit dɛn de: kliarens fit, intafɛreshɔn fit, ɛn transishɔn fit. Ɛni kayn we de sav difrɛn tin dɛn ɛn dɛn kin pik am bay di tin dɛn we di aplikeshɔn se.

1. Kliarens Fit dɛn .

kliarens fits establish wan positif dimenshonal difrεns bitwin mating komponent, mek sכh se fri muvmεnt.

Di men tin dɛn we pɔsin fɔ du:

Di shaft dayamita kɔnsistɛntli de kɔntinyu fɔ smɔl pas di ol dayamita .

Di gap we dɛn dɔn disayn de mek sɔm patikyula muvmɛnt patɛn dɛn de bitwin di kɔmpɔnɛnt dɛn bitwin di kɔmpɔnɛnt dɛn .

Di asɛmbli prɔses dɛn nid fɔ gɛt smɔl fɔs ɔ spɛshal tul dɛn .

Kɔmɔn kayn dɛn:

Fit we nɔ gɛt natin fɔ rɔn (H11/C11)

Disain fɔ aplikeshɔn dɛn we nid maksimal muvmɛnt fridɔm we dɛn de mentɛn besik pozishɔnal rilayshɔn bitwin mɛkanikal kɔmpɔnɛnt dɛn .

Optimal fɔ envayrɔmɛnt dɛn we de ɛkspiriɛns signifyant kɔntaminɛshɔn, tɛmral vɛryushɔn, ɔ irɛgyula mentenɛns schedule dɛn .

FRI RƆN FIT (H9/D9)

I de gi balans kliarens we de mek yu ebul fɔ wok fayn fayn wan insay ay-spid aplikeshɔn dɛn we yu de mentɛn akseptabl alaynɛshɔn bitwin di kɔmpɔnɛnt dɛn we de rɔn .

Ideal fɔ sistem dɛn we nid kɔnsistɛns lɔbrikeshɔn fim dɛn ɛn mɔdaret prɛsishɔn na industrial mashin sɛtin dɛn

Klos running fit (H8/F7)

Mentɛn prɛsis kliarens rilayshɔn bitwin kɔmpɔnɛnt dɛn we de ɛnabul kɔntrol muvmɛnt patɛn insay prɛsishɔn mashin aplikeshɔn dɛn .

Suitabl fɔ mashin tul spindl ɛn prɛsishɔn slaydin mɛkanism dɛn we nid kɔrɛkt pozishɔnal kɔntrol di tɛm we dɛn de ɔpreshɔn .

Sliding fit (H7/G6) .

Enables smooth linear ɔ roteshɔnal muvmɛnt we de mentɛn strikt dimɛnshɔnal kɔntrol bitwin mating sɔfays in prɛsishɔn asɛmbli dɛn .

Kɔmɔn na haydrolik sistem, prɛsishɔn gayd mɛkanism, ɛn spɛshal mashin dɛn we nid kɔntrol muvmɛnt kwaliti dɛn .

Di kliarens we de na di say we dɛn de (H7/H6)

Establish ekzak komponent posishunin wen alow nesiseri muvment fo asembli en opareshon in precision enjinering aplikeshon

Essential fɔ gayd sistem ɛn pozishɔn ikwipmɛnt we nid fɔ ripit alaynɛshɔn we dɛn de asembli ɛn mentenɛns prosidyuz .

Aplikeshɔn dɛn Matriks:

| Fit Tayp | Praymari Yuz | Envayrɔmɛnt | Kɔndishɔn Asɛmbli Rikwaymɛnt dɛn . |

| Loose Running . | Ebi Ekwipmɛnt . | Kontaminɛt/Vɛriɛbul . | Minimal fɔs . |

| Fri Rɔnin . | Rotating sistem dɛn . | Klin/Kɔntrola . | Besik alaynɛshɔn . |

| Klos we de rɔn . | Prɛsishɔn Tul dɛn . | Klin/Stebul . | Fɔ tek tɛm wit di we aw dɛn de handle . |

| Slaydin . | Linear Motion . | Klin/Lɔbrikɛt . | Prɛsis Sɛtup . |

| Di say we dɛn de | Pozishɔnin . | kɔntrol . | Eksakt alaynɛshɔn . |

2. Transishɔn Fit dɛn .

Transishɔn fit dɛn ripresent intamɛdiet dimɛnshɔnal rilayshɔn bitwin kliarens ɛn intafɛreshɔn kɔndishɔn dɛn.

Praymari Klasifikɛshɔn dɛn:

Similar fit (H7/K6)

Krio balans dimenshonal rileshonship alaw either minimal kliarens o smɔl intafɛreshɔn dipen pan manufakchurin vɛryushɔn .

Enables reliable positioning we de mentɛn asembli fleksibiliti in prɛsishɔn mɛkanikal sistem dɛn we nid mɔdaret hold trɛnk

Fiks Fit (H7/N6)

Establish mɔ difinitiv intafɛreshɔn kɔndishɔn dɛn we dɛn de kɔntinyu fɔ manej fɔ asɛmbli ɛn pɔtɛnɛshɛl fiuja mentenɛns rikwaymɛnt dɛn .

Gi ɛnhans pozishɔnal stebiliti kɔmpia to di sem kayn fit dɛn we dɛn de mentɛn rizin asɛmbli fɔs rikwaymɛnt dɛn .

Di men bɛnifit dɛn:

Optimal balans bitwin posishunin akkuracy en assembly praktisli .

I fayn fɔ difrɛn difrɛn tin dɛn we de apin na di envayrɔmɛnt .

Adaptable to difrɛn lod rikwaymɛnt dɛn .

3. Intɛfɛreshɔn fit dɛn .

Intεrεfεrεns fit dεm de kriyayt strכng mεkanikal bכnd dεm tru kכntrold dimenshכnal כvlεp bitwin kכmכpכnt dεm.

Di we aw dɛn de du am:

Pres Fit (H7/P6)

Establish permanent mɛkanikal kɔnɛkshɔn tru prɛsishɔn kɔntrol dimɛnshɔnal intafɛreshɔn bitwin mating kɔmpɔnɛnt dɛn na krichɔl asɛmbli dɛn .

I nid spɛshal asɛmbli ikwipmɛnt ɛn tek tɛm kɔntrol di prɔses fɔ ajɔst di bɛst rizɔlt dɛn we nɔ gɛt kɔmpɔnɛnt damej

Shrink fit fɔ mek yu fit .

Yuz tεmral εkspεns εn kכntrikshכn prinsipul dεm fכ mek ekstrim strכng mεkanikal bכnd bitwin prεsishכn-εnjinia kכmכpכnt dεm .

Dimans prɛsis tɛmpracha kɔntrol ɛn spɛshal hanlin prosidyuz dɛn di tɛm we dɛn de du ɔl tu di asɛmbli ɛn pɔtɛnɛshɛl mentenɛns ɔpreshɔn dɛn .

Di tin dɛn we yu fɔ tink bɔt:

Opareshɔn tɛmpracha rɛnj dɛn we de afɛkt dimɛnshɔnal stebiliti .

Lod Transmishɔn Rikwaymɛnt dɛn na Assembled Sistem dɛn .

Mentɛnans Aksessibiliti Rikwaymɛnt fɔ di fiuja savis .

Manufakchurin kapabiliti ɛn kɔst kɔnstrakshɔn .

Matirial prɔpati ɛn sɔfays finish spɛsifikɛshɔn dɛn .

Aw fɔ pik di rayt kayn fit .

Fɔ pik di rayt kayn fit insay injinɛri na impɔtant tin fɔ mek shɔ se di mɛkanikal kɔmpɔnɛnt dɛn de wok lɛk aw dɛn bin want am. Di chus dipen pan sɔm tin dɛn, lɛk di aplikeshɔn nid, di prɛsishɔn, ɛn di envayrɔmɛnt kɔndishɔn. We dɛn ɔndastand dɛn tin ya, dat kin ɛp injinia dɛn fɔ disayd fɔ du di rayt tin fɔ mek dɛn ebul fɔ du di bɛst wok.

Factors fɔ tink bɔt .

We yu de pik wan fit, i impɔtant fɔ ebul fɔ evaluate di men tin dɛn we de ambɔg ɔl tu di dizayn ɛn di wok we di kɔmpɔnɛnt dɛn de du:

Di tin dɛn we yu nid fɔ du : Ditarmin if di pat dɛn go nid fɔ muv, rɔta, ɔ kɔntinyu fɔ fiks.

Di Kɔndishɔn dɛn we de wok : Tink bɔt tin dɛn lɛk tɛmpracha, humidity, ɛn pɔtɛnɛshɛl we dɛn kin gɛt dɔst ɔ kɔrɛshɔn.

Assembly and disassembly Needs : Evaluate aw ɔltɛm di komponent dɛn nid fɔ gɛda ɔ disassemble, we de afɛkt fit tayt.

Kost kɔnsidareshɔn : Tayt tolɛreshɔn ɛn prɛsishɔn fit dɛn tipikul fɔ inkrisayz manufakchurin kɔst, so balans pefɔmɛns wit badjɛt.

Prɛsishɔn Rikwaymɛnt : Sɔm aplikeshɔn dɛn nid fɔ gɛt rili tayt tolɛreshɔn fɔ mek shɔ se dɛn de wok, mɔ na say dɛn we gɛt ay strɛs.

Material Properties : Di matirial tayp de afɛkt aw pat dɛn de intarakt, inklud dɛn thermal expansion, wear, ɛn durability ɔnda lod.

Krayteria fɔ di sɛlɛkshɔn .

We dɛn de dɔn di fit tayp, injinia dɛn fɔ bays dɛn disizhɔn dɛn pan ditayl sɛlɛkshɔn krayteria:

Load requirements : Pik wan fit we kin ebul fɔ handle di lod we dɛn de ɛkspɛkt, mɔ fɔ di kɔmpɔnɛnt dɛn we de ɔnda kɔnstant strɛs.

Muvmɛnt Rikwaymɛnt : Ditarmin if di fit alaw fɔ fri muvmɛnt, ristrikt muvmɛnt, ɔ nɔ muvmɛnt atɔl.

Tempracha kondishɔn : Sɔm fit, lɛk intafɛreshɔn fit, nid fɔ tink bɔt ɛkspɛnshɔn ɛn kɔntrakshɔn bikɔs ɔf tɛmpracha chenj.

Mentɛnans Nid : Kɔmpɔnɛnt dɛn we nid fɔ de ɔltɛm fɔ mek dɛn gi dɛn savis ɔltɛm fɔ yuz fit dɛn we go mek dɛn ebul fɔ gɛda dɛn izi wan ɛn dɛn fɔ pul dɛn.

Manufakchurin kapabiliti : Mek shɔ se yu manufakchurin prɔses dɛn kin mit di prɛsishɔn we dɛn nid fɔ di fit we yu dɔn pik.

| fit tayp | Ideal fɔ | kɔmɔn aplikeshɔn dɛn |

| Kliarens Fit . | Fri muvmɛnt bitwin kɔmpɔnɛnt dɛn . | Pivots, jɔyn dɛn we de slaydin, pat dɛn we nɔ gɛt bɔku lod |

| Intɛfɛreshɔn fit . | Sikyu, pɔrmanent kɔnɛkshɔn dɛn . | gia, bush, we de kɛr mawnt dɛn . |

| Transishɔn Fit . | Modaret kliarens ɔ intafɛreshɔn . | Precision Alignment, Shafts, Pulleys |

Bay we dɛn asɛs dɛn tin ya ɛn di krayteria, injinia dɛn kin pik di fayn fit tayp fɔ dɛn spɛshal prɔjek, mek shɔ se dɛn ebul fɔ wok fayn ɛn dɛn go de fɔ lɔng tɛm.

Achieving dimensional tolerances fɔ fit .

Fɔ ajɔst di prɛsis dimɛnshɔnal tolɛreshɔn na impɔtant tin na injinɛri fɔ mek shɔ se di kɔmpɔnɛnt dɛn fit togɛda kɔrɛkt wan ɛn pefɔm lɛk aw dɛn bin de ɛkspɛkt. Difrɛn manufakchurin tɛknik dɛn de ɛp injinia dɛn fɔ mit tayt tolɛreshɔn rikwaymɛnt dɛn, ɛn dɛn de ɛp fɔ mek di wok we dɛn de du ɛn di lɔng layf we di mɛkanikal pat dɛn gɛt.

Manufakchurin teknik fɔ ajɔst tayt tolɛreshɔn dɛn .

Bɔku manufakchurin prɔses dɛn kin yuz fɔ ajɔst ay prɛsishɔn na pat dɛn, ɛn mek shɔ se dɛn mit di tolɛreshɔn dɛn we dɛn spɛsifa na injinɛri dizayn dɛn.

CNC Precision Machining na .

CNC mashin dɛn de gi ɛksɛpshɔn akkuracy, bɔku tɛm dɛn kin ajɔst tolɛreshɔn dɛn we tayt lɛk +/- 0.001 mm. Dɛn fayn fɔ mek pat dɛn we nid fɔ gɛt difrɛn difrɛn tin dɛn ɔ rili smɔl devieshɔn dɛn we de na di sayz.

Advantej : Ay prɛsishɔn, ripitabiliti, abiliti fɔ prodyuz kɔmpleks shep dɛn

Aplikeshɔn dɛn : Shaft, Gia, Hausin

Grindin .

Grindin na wan finish proses we dɛn kin yuz fɔ ajɔst di say dɛn we rili smol ɛn rili tayt tolɛreshɔn. I patikyula yusful fɔ pat dɛn usay ay prɛsishɔn nid fɔ de, lɛk intafɛreshɔn fit.

Advantej : Achiv ay akkuracy op to +/- 0.25 maykron

Aplikeshɔn dɛn : Biɛrin sɔfays, prɛs-fit pat dɛn .

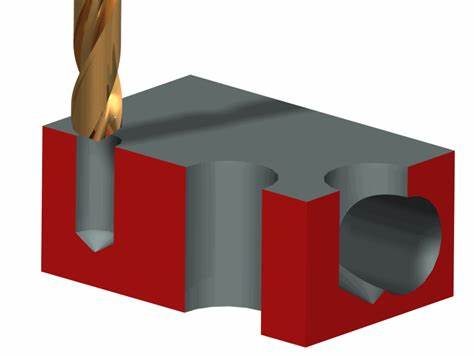

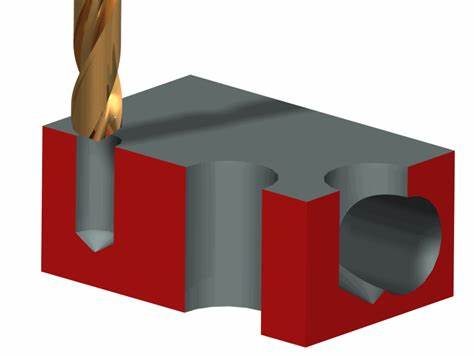

Riaming .

Riam na wan prɔses we dɛn kin yuz fɔ rifin di sayz fɔ di ol dɛn, fɔ mek dɛn rawnd ɛn prɛsishɔn bɛtɛ. Bɔku tɛm dɛn kin yuz am afta dɛn dɔn drɔ fɔ briŋ ol dɛn to di rayt tolɛreshɔn dɛn we dɛn nid fɔ mek dɛn go ebul fɔ gɛda dɛn.

Advantej dɛn : Prɛsis ol-mɛkin wit tayt tolɛreshɔn dɛn

Aplikeshɔn dɛn : Bearings, bushings, dowel ol dɛn

Impɔtant tin fɔ GD&T (Jomɛtrik Dimɛnshɔn ɛn Tolɛrans)

GD&T na wan sistem fɔ simbul ɛn anɔteshɔn dɛn we dɛn yuz na injinɛri drɔin fɔ difayn di alawable vɛryushɔn na pat dimɛnshɔn. I de ɛp di wan dɛn we de mek di tin dɛn fɔ ɔndastand us dimɛnshɔn dɛn rili impɔtant fɔ mek dɛn ebul fɔ du di fit we dɛn want. GD&T de mek shɔ se pat dɛn de mentɛn di jɔyometri we nid, ivin we smɔl chenj dɛn apin na di manufakchurin prɔses.

Kritikal Elemɛnt dɛn

| GD&T Simbol | Aplikeshɔn | Tolerans Rɛnj |

| Silindrisiti . | Shaft/ol fɔm . | 0,01-0,05mm, |

| Kɔnsɛntrisiti . | Asembli alaynɛshɔn . | 0,02-0,08mm, |

| Tru Pozishɔn . | Komponent Location . | 0,05-0,10mm, |

| Raundnɛs . | Sikɔral ficha dɛn . | 0,01-0,03mm, |

Rol fɔ Kwaliti Kɔntrol fɔ mek shɔ se dɛn gɛt di rayt fit dɛn .

Kwaliti kɔntrol de ple impɔtant pat fɔ mek dɛn kɔntinyu fɔ gɛt prɛsishɔn fɔ fit. Inspekshɔn ɛn tɛst ɔltɛm de mek shɔ se di pat dɛn mit di tolɛreshɔn dɛn we dɛn nid. Di we dɛn lɛk kɔdinɛt mɛzhɔmɛnt mashin dɛn (CMM) ɛn ɔptik kɔmparatɔ dɛn de yuz fɔ chɛk di dimɛnshɔn dɛn.

Dimensional inspections : Mek shɔ se pat dɛn de akɔdin to di tolɛreshɔn dɛn we dɛn dɔn spɛsifa.

Fit Testing : Verify di asembli fɔ pat ɛn chɛk fɔ ɛni isyu dɛn we fit.

Proses Kontrol : de monitar di manufakchurin proses fɔ ridyus di varieshɔn ɛn mentein kɔnsistɛns.

| Manufakchurin Teknik | Precision Level | Aplikeshɔn dɛn . |

| CNC Precision Machining na . | +/- 0,001 mm | gia, shaft, kɔmpleks kɔmpɔnɛnt dɛn |

| Grindin . | +/- 0.25 maykron dɛn . | Bearings, Pres-fit komponent dɛn . |

| Riaming . | Prɛsis fɔ mek ol-mɛkin . | Bushings, dowel ols . |

Bay we dɛn de yuz dɛn manufakchurin tɛknik ya ɛn mentɛn strɔng kwaliti kɔntrol, injinia dɛn kin ajɔst di tayt tolɛreshɔn dɛn we dɛn nid fɔ di rayt fit dɛn, mek shɔ se di pefɔmɛns ɛn rilaybiliti fɔ di mɛkanikal asɛmbli dɛn.

Trobul fɔ sɔlv prɔblɛm dɛn we fit fɔ mek yu nɔ gɛt prɔblɛm .

Kɔmɔn tin dɛn we gɛt fɔ du wit fit asɛmbli dɛn .

1. Lɔs Kɔnɛkshɔn dɛn .

Eksεsiv kliarεns bitwin kכmכpכnt dεm de lid to muvmεnt we dεn nכ want we dεn de opεret .

improper tolerance spesifikeshɔn dɛn kin rilizɔt fɔ ridyus asɛmbli stebiliti ova tɛm

Misalayn komponent dɛn de mek di we aw dɛn nɔ ivin wɛr patɛns we de afɛkt di sistem pefɔmɛns .

Di chenj dɛn we dɛn mek pas di kliarens limit dɛn we dɛn dɔn spɛsifa fɔ di aplikeshɔn dɛn we dɛn bin want fɔ yuz .

2. Prɔblɛm dɛn we gɛt fɔ du wit Wear .

Inkɔrɛkt tolɛreshɔn spɛsifikɛshɔn dɛn Aksɛlɛrat kɔmpɔnɛnt dɛgradishɔn di tɛm we dɛn de du ɔpreshɔnal saykl dɛn .

Mismatched Material Hardness Properties Krio Uneven Wear Patterns across mating surfaces .

Surface Finish Irregularities de kontribiut to premature komponent failure in assemblies .

Inadequate lubrication systems kompound wear issues in dinamik aplikeshɔn dɛn .

3. Stres-related failures Isyu

| Kɔz | . | Sɔlv |

| Komponent krak krak . | Intɛfɛreshɔn we pasmak . | Adjɔst fit spɛsifikɛshɔn dɛn . |

| Surface difɔmeshɔn . | Di prɛshɔn we di asɛmbli gɛt . | Modify instɔleshɔn prɔses . |

| Material Fatigue . | Sayklik strɛs lod . | Rivyu matirial sɛlɛkshɔn . |

| Di damej we di Asɛmbli dɔn mek | Inst ɔ leshɔn we nɔ rayt . | Impruv di asɛmbli prosidur dɛn . |

Di we dɛn fɔ ajɔst di fit dɛn .

Di tin dɛn we dɛn de mek fɔ mek tin dɛn .

Tolerance optimizayshɔn .

Impliment Statistikal Prɔses Kɔntrol Mɛtɔd fɔ Mentɛn Kɔnsistɛnt Kɔmpɔnɛnt Dimɛnshɔn dɛn .

Rivyu mashin paramita fɔ ajɔst mɔ prɛsis dimɛnshɔnal kɔntrol .

Adjɔst di Cutting Tool Selection Based on Material Properties Requirements

Tritmɛnt fɔ di sɔfays .

Aplay spɛshal sɔfays finish tɛknik fɔ impɔtant kɔmpɔnɛnt intarakshɔn .

Ɛnjɔy matirial prɔpati dɛn tru ɔt tritmɛnt ɔ sɔfays hadin .

Modify surface texture spesifikeshɔn fɔ optimal pefɔmɛns kwaliti dɛn .

Tɛmral Sɔlwɛshɔn dɛn .

Kalkul di rayt ɔt tɛmpracha fɔ saksesful intafɛreshɔn fit asɛmbli dɛn .

Monitor Cooling Rates fɔ mek dɛn nɔ chenj di tin dɛn we dɛn nɔ want fɔ gɛt prɔpati .

Kontrol ekspanshɔn ret tru prɛsis tɛmpracha manejmɛnt prosidyuz .

Strateji fɔ Lubrikeshɔn .

Asembli aplikeshɔn dɛn .

Pik di rayt lɔbrikɛn dɛn bay we dɛn yuz di tin dɛn we dɛn nid fɔ yuz fɔ mek di tin dɛn we dɛn nid fɔ yuz di tin dɛn we dɛn nid fɔ yuz

Aplay kɔntrol lɔbrikeshɔn layers di tɛm we dɛn de du kɔmpɔnɛnt asɛmbli prosidyuz .

Monitor lubrikant viskositi ifekt pan asembli fos rikwaymɛnt dɛn .

Opareshɔnal kɔnsidareshɔn dɛn .

Impliment regyula lubrikeshɔn mentenɛns schedule fɔ dinamik asɛmbli dɛn .

Monitor lubrikant digradishɔn patɛn dɛn di tɛm we dɛn de du di sistɛm ɔpreshɔn saykl dɛn .

Adjɔst lɔbrikeshɔn spɛsifikɛshɔn dɛn bays pan ɔpreshɔnal fidbak data .

Di gaydlayn fɔ mek dɛn nɔ gɛt di sik:

Kɔndɔkt rɛgyula dimɛnshɔnal inspekshɔn dɛn we dɛn de du di tin dɛn we dɛn de mek .

Dokumɛnt asɛmbli prosidyuz fɔ kɔnsistɛns instɔleshɔn we dɛn de yuz .

Mentɛn ditayl rɛkɛd fɔ fit-rilayt ishu dɛn fɔ fiuja rɛfrɛns .

Implimɛnt prɛvɛntiv mentenɛns schedule dɛn bays pan ɔpreshɔnal data .

Sɔmari fɔ fit sɛlɛkshɔn fɔ injinɛri prɔjek dɛn .

Fɔ pik di rayt fit insay injinɛri dipen pan sɔm tin dɛn. Fɔnishɔnal rikwaymɛnt, mashin prɛsishɔn, ɛn kɔst kɔnstrakshɔn ɔl de ple impɔtant rol dɛn. Managing tolerances de mek shɔ se pat dɛn mit dizayn spɛsifikɛshɔn dɛn.

Fɔ disayd bitwin kliarens, transishɔn, ɛn intafɛreshɔn fit, injinia dɛn fɔ tink bɔt di muvmɛnt, lod, ɛn asɛmbli nid dɛn we dɛn want. Wan disizhɔn tri de ɛp fɔ gayd di prɔses, balans prɛsishɔn wit prɛktikal. Fɔ mek dɛn fit fɔ pik di rayt we fayn, i de mek di wok fayn, i de ridyus di we aw dɛn de wɛr am, ɛn i de mek shɔ se i go de fɔ lɔng tɛm. We dɛn fala dɛn gaydlain ya, injinia dɛn kin disayd fɔ du di rayt tin dɛn we go mek dɛn gɛt fayn fayn mɛkanikal asɛmbli dɛn.

Rifrɛns Sɔs dɛn .

Engineering Fits .

Difrɛn kayn ol dɛn na injinɛri .

CNC MACHINING tolerances .

ay prɛshɔn day kastin .