Pikiriw dilanni muɲuliw bɛ a to plastiki yɔrɔw ka ɲɛ. Mun na u nafa ka bon kosɛbɛ? Ni tolerances tigitigi tɛ, a yɔrɔw bɛ se ka kɛ u tɛ bɛn walima u tɛ baara kɛ ka ɲɛ. Nin sɛbɛn in kɔnɔ, aw bɛna nin muɲuli ninnu nafa dɔn, fɛn minnu bɛ nɔ bila u la, ani cogo ɲuman na walasa ka ɲɛtaa ɲuman sɔrɔ.

Pikiriw dilanni muɲuli ye mun ye?

Pikiriw dilanni muɲuni bɛ tali kɛ fɛn dɔw la minnu bɛ se ka kɛ, yɔrɔ minnu na, olu hakɛ ni u cogoyaw la. U ɲɛfɔlen don dilanbagaw ni injiniyɛriw fɛ walasa ka a lajɛ ni a yɔrɔw bɛ bɛn ani ka baara kɛ i n’a fɔ a laɲininen don cogo min na.

Muɲuli nafa ka bon pikiri kɛli la. Hali bɔnɛ dɔɔnin bɛ se ka kɛ sababu ye ka ɲɔgɔn lajɛ walima ka nɔ bila fɛn dilannenw ka baarakɛcogo la. Tolerances ɲumanw ɲɛfɔli bɛ dɛmɛ ka yɔrɔ ɲuman ni ɲɔgɔndɛmɛ mara.Walisa ka kunnafoni wɛrɛw sɔrɔ ko minnu bɛ kɛ ɲɔgɔn fɛ, minnu bɛ se ka nɔ bila muɲuli la, aw ye an ka gafe lajɛ . Pikiriw dilanni tiɲɛniw ani u ɲɛnabɔcogo ..

Pikirili Mulding Tolerances suguyaw .

Muɲuli suguya damadɔ bɛ yen minnu ka kan ka jateminɛ pikiri kɛli la:

Dimensions tolerances +/- mm

|

Commercial Tolerance |

Precision A ka ca a la |

|

|

|

|

|

| Dimension 1000 . |

1 ka se 20 ma (+/-mm) . |

21 ka se 100 ma (+/-mm) . |

101 ka se 160 ma (+/-mm) . |

ka ɲɛsin 20mm kelen-kelen bɛɛ ma 160 kan fara a kan . |

1 ka se 20 ma (+/-mm) . |

21 ka se 100 ma (+/-mm) . |

100 ni kɔ . |

| ABS . |

0.100 |

0.150 |

0.325 |

0.080 |

0.050 |

0.100 |

|

| ABS/PC ɲagaminen . |

0.100 |

0.150 |

0.325 |

0.080 |

0.050 |

0.100 |

|

| GPS . |

0.075 |

0.150 |

0.305 |

0.100 |

0.050 |

0.080 |

|

| HDPE . |

0.125 |

0.170 |

0.375 |

0.100 |

0.075 |

0.110 |

|

| LDPE . |

0.125 |

0.170 |

0.375 |

0.100 |

0.075 |

0.110 |

|

| Mod PPO/PPE . |

0.100 |

0.150 |

0.325 |

0.080 |

0.050 |

0.100 |

|

| PA . |

0.075 |

0.160 |

0.310 |

0.080 |

0.030 |

0.130 |

|

| PA 30% GF . |

0.060 |

0.120 |

0.240 |

0.080 |

0.030 |

0.100 |

|

| PBT 30% GF . |

0.060 |

0.120 |

0.240 |

0.080 |

0.030 |

0.100 |

Porozɛ ka lajɛ . |

| PC . |

0.060 |

0.120 |

0.240 |

0.080 |

0.030 |

0.100 |

A wajibiyalen don bɛɛ ma . |

| PC 20% Glass . |

0.050 |

0.100 |

0.200 |

0.080 |

0.030 |

0.080 |

Fɛn minnu bɛ kɛ . |

| PMMA . |

0.075 |

0.120 |

0.250 |

0.080 |

0.050 |

0.070 |

|

| Pom . |

0.075 |

0.160 |

0.310 |

0.080 |

0.030 |

0.130 |

|

| PP . |

0.125 |

0.170 |

0.375 |

0.100 |

0.075 |

0.110 |

|

| pp 20% Talc . |

0.125 |

0.170 |

0.375 |

0.100 |

0.075 |

0.110 |

|

| PPS 30% GF . |

0.060 |

0.120 |

0.240 |

0.080 |

0.030 |

0.100 |

|

| San . |

0.100 |

0.150 |

0.325 |

0.080 |

0.050 |

0.100 |

|

Tigɛ/flatness tolerances: Ninnu bɛ kuma surfaces flat warpage kan. Fɛn minnu bɛ kɛ i n’a fɔ da yɔrɔ, nɛnɛ kelen, ani fɛnw sugandili bɛ se ka warping dɔgɔya. Walasa ka kunnafoni wɛrɛw sɔrɔ warping kunbɛnni kan, aw bɛ se ka taa an ka barokun kan . Warping in pikiri kɛli ..

Tigɛ / Flatness Tolerances

|

Commercial Tolerance |

Precision A ka ca . |

|

|

| Dimensions . |

0-100 (+/-mm) . |

101-160 (+/-mm) . |

0-100 (+/-mm) . |

101-160 (+/-mm) . |

| ABS . |

0.380 |

0.800 |

0.250 |

0.500 |

| ABS/PC ɲagaminen . |

0.380 |

0.800 |

0.250 |

0.500 |

| Acetal . |

0.300 |

0.500 |

0.150 |

0.250 |

| Acrylique . |

0.180 |

0.330 |

0.100 |

0.100 |

| GPS . |

0.250 |

0.380 |

0.180 |

0.250 |

| Mod PPO/PPE . |

0.380 |

0.800 |

0.250 |

0.250 |

| PA . |

0.300 |

0.500 |

0.150 |

0.250 |

| PA 30% GF . |

0.150 |

0.200 |

0.080 |

0.100 |

| PBT 30% GF . |

0.150 |

0.200 |

0.080 |

0.100 |

| PC . |

0.150 |

0.200 |

0.080 |

0.100 |

| Polikarbonati, 20% Glass . |

0.130 |

0.180 |

0.080 |

0.100 |

| Poliɛtilɛni . |

0.850 |

1.500 |

0.500 |

0.850 |

| Poliporopilini . |

0.850 |

1.500 |

0.500 |

0.850 |

| Poliporopilini, 20% TALC . |

0.850 |

1.500 |

0.500 |

0.850 |

| PPS 30% GF . |

0.150 |

0.200 |

0.080 |

0.100 |

| San . |

0.380 |

0.800 |

0.250 |

0.500 |

Hole diamètre tolerances +/- mm

|

Commercial Tolerance |

Precision A ka ca a la |

|

|

|

|

|

|

| Dimension 1000 . |

0-3 (+/-mm) . |

3,1-6 (+/-mm) . |

6,1-14 (+/-mm) . |

14-40 (+/-mm) . |

0-3 (+/-mm) . |

3,1-6 (+/-mm) . |

6,1-14 (+/-mm) . |

14-40 (+/-mm) . |

| ABS . |

0.050 |

0.050 |

0.080 |

0.100 |

0.030 |

0.030 |

0.050 |

0.050 |

| ABS/PC . |

0.050 |

0.050 |

0.080 |

0.100 |

0.030 |

0.030 |

0.050 |

0.050 |

| GPS . |

0.050 |

0.050 |

0.050 |

0.090 |

0.030 |

0.030 |

0.040 |

0.050 |

| HDPE . |

0.050 |

0.080 |

0.100 |

0.150 |

0.030 |

0.050 |

0.050 |

0.080 |

| LDPE . |

0.050 |

0.080 |

0.100 |

0.150 |

0.030 |

0.050 |

0.050 |

0.080 |

| PA . |

0.050 |

0.080 |

0.080 |

0.130 |

0.030 |

0.040 |

0.050 |

0.080 |

| PA30% GF . |

0.050 |

0.050 |

0.080 |

0.080 |

0.030 |

0.040 |

0.050 |

0.050 |

| PBT30% GF . |

0.050 |

0.050 |

0.080 |

0.080 |

0.030 |

0.040 |

0.050 |

0.050 |

| PC . |

0.050 |

0.050 |

0.080 |

0.080 |

0.030 |

0.040 |

0.050 |

0.050 |

| PC 20% GF . |

0.050 |

0.050 |

0.080 |

0.080 |

0.030 |

0.040 |

0.050 |

0.050 |

| PMMA . |

0.080 |

0.080 |

0.100 |

0.130 |

0.030 |

0.050 |

0.050 |

0.080 |

| Pom . |

0.050 |

0.080 |

0.080 |

0.130 |

0.030 |

0.040 |

0.050 |

0.080 |

| PP . |

0.050 |

0.080 |

0.100 |

0.150 |

0.030 |

0.050 |

0.050 |

0.080 |

| pp, 20% talki . |

0.050 |

0.080 |

0.100 |

0.150 |

0.030 |

0.050 |

0.050 |

0.080 |

| PPS 30% Glass . |

0.050 |

0.050 |

0.080 |

0.080 |

0.030 |

0.040 |

0.050 |

0.050 |

| San . |

0.050 |

0.050 |

0.080 |

0.100 |

0.030 |

0.030 |

0.050 |

0.050 |

Fiyentɔw ka dingɛ jugumanw Tolerances +/- mm

|

Commercial Tolerance |

Precision A ka ca . |

|

|

|

|

| Dimension 1000 . |

1-6 (+/-mm) . |

6,1-14 (+/-mm) . |

14 (+/-mm) ni kɔ . |

1-6 (+/-mm) . |

6,1-14 (+/-mm) . |

14 (+/-mm) ni kɔ . |

| ABS . |

0.080 |

0.100 |

0.130 |

0.050 |

0.050 |

0.080 |

| ABS/PC ɲagaminen . |

0.080 |

0.100 |

0.130 |

0.050 |

0.050 |

0.080 |

| GPS . |

0.090 |

0.100 |

0.130 |

0.050 |

0.050 |

0.080 |

| HDPE . |

0.100 |

0.120 |

0.150 |

0.050 |

0.080 |

0.100 |

| LDPE . |

0.100 |

0.120 |

0.150 |

0.050 |

0.080 |

0.100 |

| PA . |

0.100 |

0.100 |

0.130 |

0.050 |

0.080 |

0.100 |

| PA, 30% GF . |

0.050 |

0.080 |

0.100 |

0.050 |

0.050 |

0.080 |

| PBT, 30% GF . |

0.050 |

0.080 |

0.100 |

0.050 |

0.050 |

0.080 |

| PC, 20% GF |

0.050 |

0.080 |

0.100 |

0.050 |

0.050 |

0.080 |

| PMMA . |

0.100 |

0.100 |

0.130 |

0.050 |

0.080 |

0.100 |

| Polikarbonati . |

0.050 |

0.080 |

0.100 |

0.050 |

0.050 |

0.080 |

| Pom . |

0.100 |

0.100 |

0.130 |

0.050 |

0.080 |

0.100 |

| PP . |

0.100 |

0.120 |

0.150 |

0.050 |

0.080 |

0.100 |

| pp, 20% talki . |

0.100 |

0.120 |

0.150 |

0.050 |

0.080 |

0.100 |

| PPO/PPE . |

0.080 |

0.100 |

0.130 |

0.050 |

0.050 |

0.080 |

| PPS, 30% GF . |

0.050 |

0.080 |

0.100 |

0.050 |

0.050 |

0.080 |

| San . |

0.080 |

0.100 |

0.130 |

0.050 |

0.050 |

0.080 |

Concentricity/ovality tolerances +/- mm

|

Commercial Tolerance |

Precision A ka ca a la |

| Dimension 1000 . |

fo ka se 100 (+/-mm) ma . |

fo ka se 100 (+/-mm) ma . |

| ABS . |

0.230 |

0.130 |

| ABS/PC ɲagaminen . |

0.230 |

0.130 |

| GPS . |

0.250 |

0.150 |

| HDPE . |

0.250 |

0.150 |

| LDPE . |

0.250 |

0.150 |

| PA . |

0.250 |

0.150 |

| PA, 30% GF . |

0.150 |

0.100 |

| PBT, 30% GF . |

0.150 |

0.100 |

| PC . |

0.130 |

0.080 |

| PC, 20% GF |

0.130 |

0.080 |

| PMMA . |

0.250 |

0.150 |

| Pom . |

0.250 |

0.150 |

| PP . |

0.250 |

0.150 |

| pp, 20% talki . |

0.250 |

0.150 |

| PPO/PPE . |

0.230 |

0.130 |

| PPS, 30% GF . |

0.130 |

0.080 |

| San . |

0.230 |

0.130 |

Commercial vs. Tolerances fine .

Pikiriw dilanni muɲuni bɛ se ka tila ka caya ka kɛ suguya fila ye:

Jagokɛlaw ka muɲuli: Olu tɛ tigitigi nka u ka sɔrɔ ka bon. U bɛnnen don baarakɛminɛnw ma minnu tɛ kɔrɔfɔ ye ani u bɛ se ka fɛn caman caman ɲɔgɔnna caman caman ɲɔgɔnna.

Tolerances fine (precision): Olu bɛ kuntigiya gɛlɛn di yɔrɔ hakɛw kan. U bɛ mɔli ɲumanw ni baarakɛcogo kɔlɔsili gɛlɛnw de wajibiya, o b’a to u sɔngɔ ka gɛlɛn.

Sugandili min bɛ kɛ jago ni muɲuli ɲumanw cɛ, o bɛ bɔ a yɔrɔ in ka baarakɛcogo kɛrɛnkɛrɛnnen n’a ka baarakɛcogo wajibiyalenw na.

Walasa ka kunnafoni wɛrɛw sɔrɔ o ko la, aw ye an ka gafe ɲɛ 10nan lajɛ . Da suguya minnu bɛ kɛ ka pikiri kɛ ..

Pikiri molidali muɲuni nafa .

Pikiriw dilanni muɲuli jɔyɔrɔ ka bon kosɛbɛ plastiki yɔrɔw dilanni na minnu ka ɲi kosɛbɛ. U b’a to yɔrɔw ka se ka fɛn ɲɛfɔlenw dafa ani ka baara kɛ i n’a fɔ a laɲininen don cogo min na. An ka a sɛgɛsɛgɛ mun na muɲuliw nafa ka bon kosɛbɛ ani min bɛ kɛ ni u ma mara ka ɲɛ.

Mun na muɲuliw nafa ka bon kosɛbɛ?

ka a jira ko a yɔrɔ dɔw bɛ se ka baara kɛ ani ko a bɛ bɛn .

Tolerances bɛ a jira ko pikirijikɛlanw bɛ bɛn ani ka baara kɛ ka ɲɛ. U bɛ sira Di fɛnw ma minnu bɛ ɲɔgɔn Bɔ dɔɔnin dɔɔnin k’a sɔrɔ u bɛ yɔrɔ in dafalen mara hali bi. Ni muɲuni bɛnnen tɛ, a yɔrɔw tɛ se ka ɲɔgɔn sɔrɔ ka ɲɛ u lajɛtuma na walima u bɛ baara kɛ i n’a fɔ a dabɔra cogo min na.

Miiri k’a filɛ, i b’a ɲini ka boon tilayɔrɔ fila ta ɲɔgɔn fɛ. Ni muɲuliw bɛ lafiya kojugu, yɔrɔw bɛna sɔrɔ ani ka wuli. Ni u sirilen don kojugu, a yɔrɔw tɛna bɛn fewu. Tolerances tigitigiw bɛ a to a bɛ se ka kɛ cogo la min bɛ lakana, min tɛ fɛn tiɲɛ.

nɔ min bɛ sɔrɔ jamalajɛ ni baarakɛcogo la .

Pikiriw bɛ kɛ yɔrɔ minnu na, olu ka teli ka baara kɛ ɲɔgɔn fɛ ni fɛn wɛrɛw ye. U bɛ se ka kɛ ko u ka kan ka sirilanw ladon, ka u ni ɲɔgɔn cɛ yɔrɔw labɛn, walima ka sira di fɛn lamagannenw ka baara kɛcogo ɲuman ma. Muɲuli nafa ka bon walasa ka a jira ko nin jɛɲɔgɔnya ninnu bɛɛ bɛ kɛ cogo dafalen na.

Aw bɛ plastiki minɛnw ta i n’a fɔ misali. Ni gese hakɛw bɔra muɲuli la, a bɛ se ka kɛ a tɛ mesh ka ɲɛ n’a ɲɔgɔnna ye. O bɛ se ka kɛ sababu ye ka baarakɛcogo ɲuman dɔgɔya, ka sɛgɛn kojugu, walima hali ka se ka fɛɛrɛ tiɲɛ pewu.

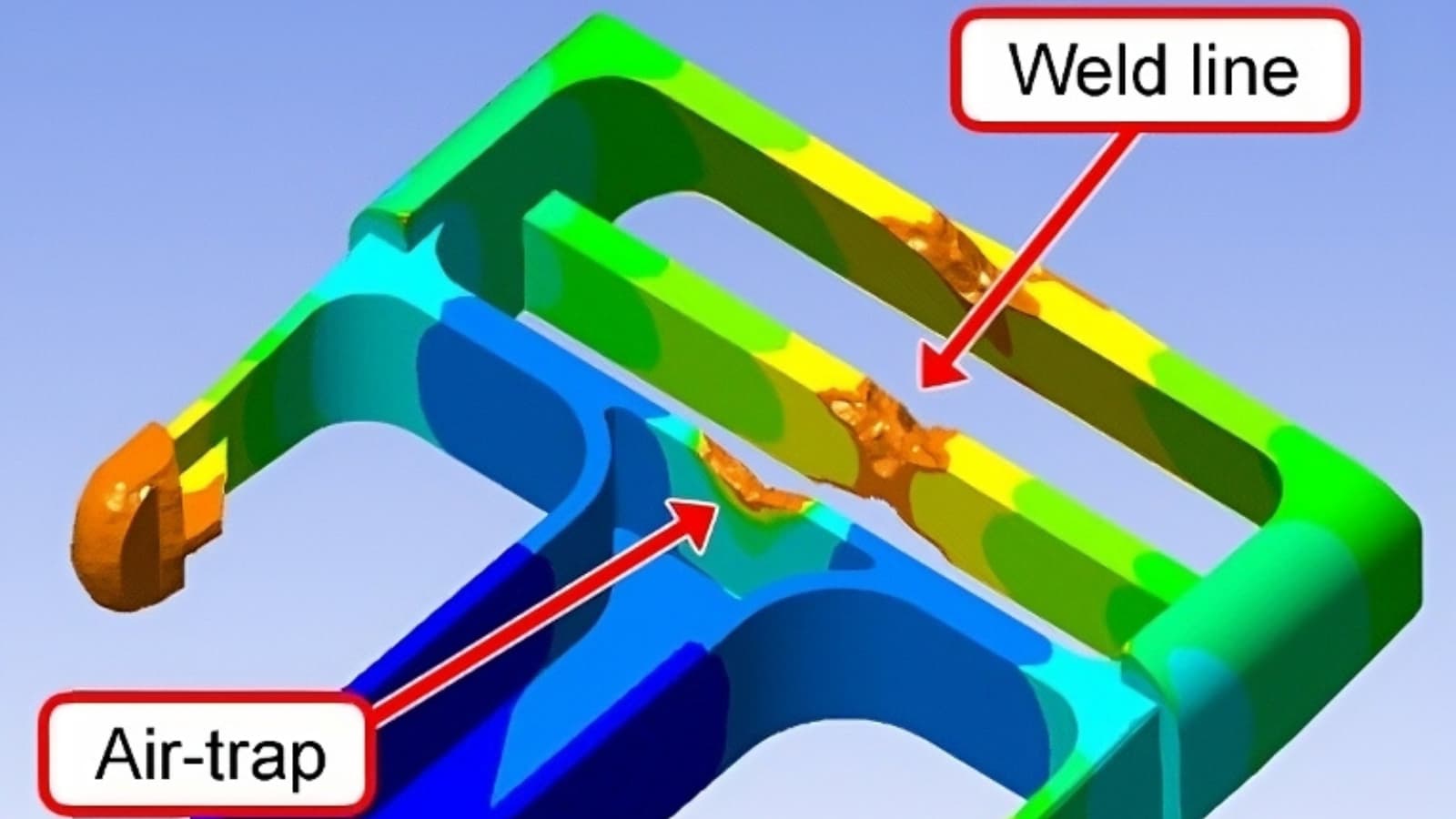

Muɲuli kunbɛncogo jugu kɔlɔlɔw .

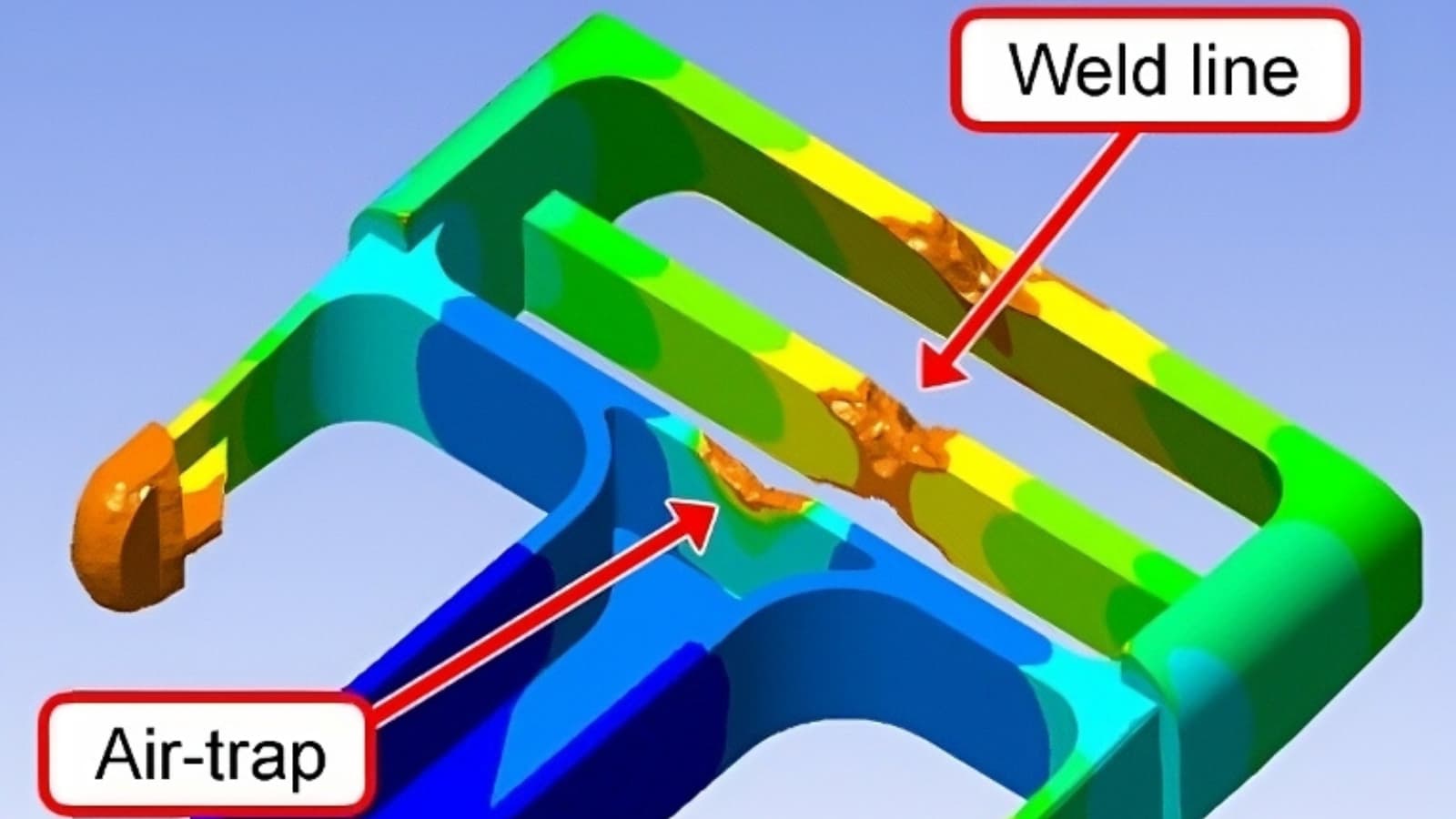

Lajɛba filiw .

Ni muɲuli ma minɛ ka ɲɛsin fɛnsɛbɛnni ma, jamalajɛ bɛ kɛ gɛlɛya ye. Yɔrɔw man kan ka bɛn, ka u siri, walima ka u siri i n’a fɔ a laɲininen don cogo min na. O bɛ na ni waati latɛmɛni ye, ka baara kɛ kokura, ani ka dɔ fara fɛn dilanni musakaw kan.

Aw ye jateminɛ kɛ ɛntɛrinɛti minɛn dɔ kɔnɔ. Ni buruburuw kuntigiw bɔra muɲuli la, a bɛ se ka kɛ ko o minɛn tɛna ɲɔgɔn lajɛ ka ɲɛ. Vis tun bɛ se ka bɔ, walima so tun tɛ se ka datugu ka ɲɛ. O koɲɛw bɛ na ni waati tiɲɛni ye ani fɛnw.

Baarakɛcogo ni ɲɛnajɛko nafamafɛnw .

Tolerance control jugu bɛ se ka kɛ sababu ye ka baarakɛcogo gɛlɛyaw sɔrɔ a laban na. Yɔrɔ minnu ma bɛn walima minnu tɛ bɛn, olu bɛ se ka kɛ sababu ye:

Leaks .

gaps .

Yɔrɔ minnu tɛ kelen ye .

A bɛ sɛgɛn kojugu .

baarakɛbaliya .

O fiɲɛw tɛ dan fura in kɛcogo dɔrɔn ma, nka u bɛ dɔ bɔ a cogoya fana na. Yɔrɔ minnu bɛ ye, dakun minnu tɛ bɛn ɲɔgɔn ma, walima minnu bɛ se ka wuli, olu bɛ se ka fɛn dɔ kɛ fɛn ye min sɔngɔ man gɛlɛn ani min tɛ se ka da a kan.Walisa ka kunnafoni caman sɔrɔ pikiri kɛcogo juguw kan minnu bɛ kɛ tuma caman na ani u balili cogo la, aw ye an ka gafe bɛɛ lajɛlen lajɛ min bɛ kuma Pikirili molding defauts ..

Ko kelen min bɛ kɛ kɛrɛnkɛrɛnnenya la min bɛ tali kɛ muɲuni kunbɛnni jugu la, o ye ka kirin. O bɛ se ka nɔba bila yɔrɔw ka bɛn ni u ka baarakɛcogo la. Walasa ka kunnafoni wɛrɛw sɔrɔ nin barokun in kan, aw bɛ se ka taa an ka barokun kan . Warping in pikiri kɛli ..

Aesthetic issue wɛrɛ min bɛ se ka sɔrɔ tolerance control jugu fɛ, o ye sink marks yecogo ye. Olu bɛ se ka kɛ gɛlɛya ye kɛrɛnkɛrɛnnenya la yɔrɔ in yɔrɔw ye minnu bɛ ye. Walasa ka kunnafoni caman sɔrɔ sinkɔrɔkɛrɛdimi taamasiɲɛw kan ani u kunbɛncogo kan, aw ye an ka gafe ɲɛ 10nan lajɛ . Sinsin taamasiɲɛw pikiri kɛli la ..

Fɛn minnu bɛ pikiri kɛcogo muɲu .

Ka muɲuli gɛlɛnw sɔrɔ pikiri kɛli la, o bɛ ɲini ka jateminɛ kɛ kosɛbɛ fɛn caman kan. K’a ta yɔrɔ dilanni na ka taa a bila fɛnw sugandili la, baarakɛminɛnw na, ani baarakɛcogo kɔlɔsili la, fɛn kelen-kelen bɛɛ jɔyɔrɔ ka bon kosɛbɛ. An ka don fɛn kolomaw la minnu bɛ nɔ bila pikiri kɛcogo muɲuni na.

Yɔrɔ min bɛ kɛ ka fɛnw dilan .

A bonya bɛɛ lajɛlen .

A yɔrɔ bɛɛ hakɛ bɛ nɔba bila muɲuli la. Yɔrɔ belebelebaw ka teli ka dɔgɔya kosɛbɛ nɛnɛ waati la, o bɛ a to a ka gɛlɛn ka muɲuli gɛlɛnw mara. Dilanbagaw ka kan ka jatebɔ kɛ o kan ni u bɛ hakɛw ni muɲuliw ɲɛfɔ.

Kogo ka bon .

Kogo janya basigilen nafa ka bon muɲuliw kunbɛnni na. Yɛlɛma minnu bɛ kɛ kogo janya la, olu bɛ se ka kɛ sababu ye ka nɛnɛ ni dɔgɔyali kɛ cogo la min tɛ kelen ye, o bɛ na ni kɛlɛyɔrɔ ni hakɛ tiɲɛniw ye. A nafa ka bon kosɛbɛ ka kogo janya kelen mara a yɔrɔ bɛɛ la.

Angles de draft .

Angles de draft (angles de draft) ka kan walasa ka yɔrɔ in bɔ nɔgɔya la ka bɔ mɔni na. Nka, u bɛ se ka nɔ bila muɲuli fana na. A bɛ se ka kɛ ko fɛn minnu ka dun, olu bɛ se ka kɛ fɛn juguw ye, minnu bɛ se ka nɔ bila a yɔrɔ hakɛw la. Dilanbagaw ka kan ka balansi don bɔli nɔgɔya ni muɲuli marali cɛ.

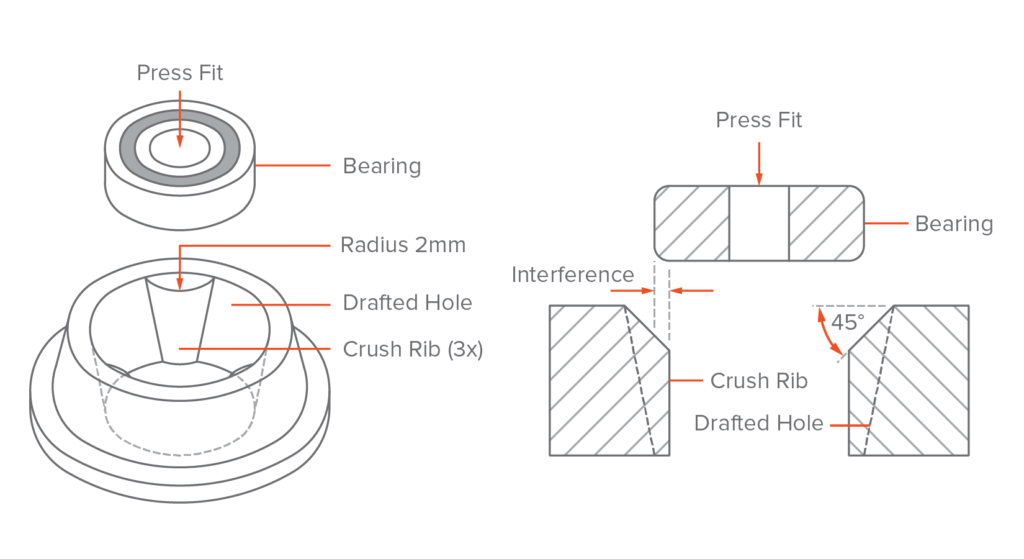

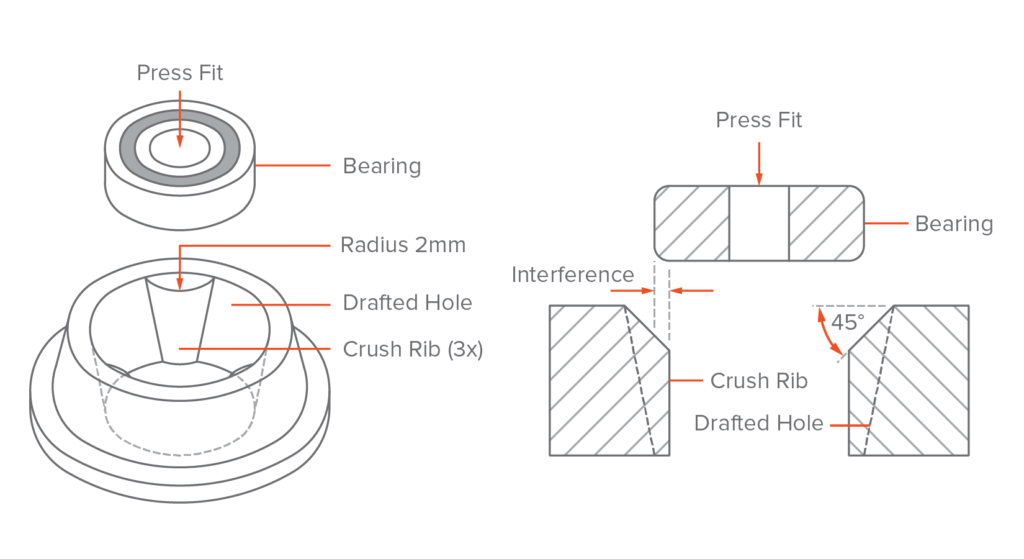

Bosses .

Bossew ye fɛn kɔrɔtalenw ye minnu bɛ kɛ ka jiginni walima ka fanga di. U bɛ se ka kɛ gɛlɛya ye ka bɔ muɲuli siratigɛ la. Bosses thicks bɛ se ka kɛ sababu ye ka sink marks ani warpage kɛ ka sababu kɛ nɛnɛ ye dɔɔnin dɔɔnin. Dilanbagaw ka kan ka tugu fɛɛrɛ ɲumanw na minnu bɛ kɛ ka kuntigiw ka dilancogo ɲɛnabɔ, i n’a fɔ ka kogo janya sabatilen mara ani ka u yɛrɛ tanga fɛn caman yeli ma minnu bɛ kɛ ka caya. Walasa ka kunnafoni caman sɔrɔ sinkɔrɔkɛrɛdimi kunbɛnni kan, aw ye an ka barokun lajɛ . Sinsin taamasiɲɛw pikiri kɛli la ..

Material Selection .

Plastiki suguya caman dɔgɔyali hakɛw .

Plastiki suguya wɛrɛw bɛ ni dɔgɔyali hakɛ caman ye. Fɛn dɔw, i n’a fɔ poliporopilini, u ka dɔgɔyali ka bon ka tɛmɛ dɔw kan, i n’a fɔ ABS. Fɛn dilannikɛlaw ka kan ka fɛn sugandilenw dɔgɔyali hakɛ jateminɛ ni u bɛ muɲuliw ɲɛfɔ. Mold designers fana ka kan ka jatebɔ kɛ ka dɔgɔya ni baarakɛminɛn in bɛ dilan.

| Minɛ |

shrinkage range . |

| ABS . |

0,7–1,6 . |

| PC/ABS . |

0,5–0,7 ye. |

| Acetal/POM (Delrin®) . |

1,8–2,5 . |

| ASA . |

0,4–0,7 ye. |

| HDPE . |

1,5–4 . |

| TƆ̀GƆ |

0,2–0,8 . |

| LDPE . |

2–4 . |

| Nilon 6/6. |

0,7–3. |

| Nilon 6/6 gilasi falen (30%) . |

0,5-0,5 ye. |

| PBT . |

0,5–2,2. |

| PBT gilasi falen (30%) . |

0,2–1. |

| Peek . |

1,2–1,5 ye. |

| peek gilasi falen (30%) . |

0,4–0,8 ye. |

| PEI (ultem®) . |

0,7–0,8 ye. |

| SOKƆBAGAN MISƐNI |

0,2–3. |

| PMMA (Acrylique) . |

0,2–0,8 . |

| PC . |

0,7-1. |

| PC gilasi falen (20–40%) . |

0,1–0,5 . |

| Poliɛtilɛni gilasi falen (30%) . |

0,2–0,6 . |

| Poliporopilini ka homopolimɛri . |

1–3 . |

| Kopolimɛri poliporopilini . |

2–3 . |

| PPA . |

1,5–2,2. |

| PPO . |

0,5–0,7 ye. |

| PPS . |

0,6–1,4. |

| ppsu . |

0,7-0,7 ye. |

| PVC rigide . |

0,1–0,6 . |

| San (as) |

0,3–0,7 ye. |

| TPE . |

0,5–2,5 . |

| TPU . |

0,4–1,4. |

Tablo : [Sɔrɔ hakɛ].

Filɛlikɛlaw ni farankanw bɛ nɔ min bila u ka dɔgɔyali la .

Filɛlikɛlaw ni farankanw fana bɛ se ka nɔ bila dɔgɔyali ni muɲuliw la. Misali la, plastiki minnu falen don gilasi la, olu ka teli ka dɔgɔya hakɛ dɔgɔya ka tɛmɛ u labɛncogo kan minnu tɛ fa. Nka, fiɲɛw ɲɛsincogo bɛ se ka kɛ sababu ye ka anisotropi dɔgɔya, yɔrɔ min na a yɔrɔ bɛ dɔgɔya cogo wɛrɛ la. A nafa ka bon ka jateminɛ kɛ fasaw ni farankanw nɔw kan ni u bɛ fɛnw sugandi ani ka muɲuliw sigi sen kan.

Baarakɛminɛnw .

Mold design ani nɛnɛ kanw .

Mɔbili dilanni ɲuman nafa ka bon kosɛbɛ walasa ka muɲuni sabati. Fɔɲɔ siraw bilali n’u dilanni bɛ se ka nɔba bila yɔrɔ hakɛw la. Nɛnɛ kɛcogo tɛ kelen ye, o bɛ se ka kɛ sababu ye ka kɛlɛcɛw ni hakɛ caman ɲɔgɔnna ye. Mɔbili dilannikɛlaw ka kan k’a lajɛ ko nɛnɛ bɛ kɛ cogo kelen na baarakɛminɛn bɛɛ kɔnɔ walasa ka o ko ninnu dɔgɔya.

Gate ani ejector pin yɔrɔw .

Gates ni ejector pinw sigiyɔrɔ fana bɛ se ka nɔ bila muɲuliw la. Dabaw ye dondaw ye plastiki wulilen na, wa u bilali bɛ se ka nɔ bila fɛn in bolicogo n’a nɛnɛ na. Ejector pins bɛ kɛ ka yɔrɔ in bɔ nɔgɔ la, wa u sigiyɔrɔ n’u dilanni bɛ se ka nɔ bila yɔrɔ laban hakɛ la. Gate ni ejector pin bilali jateminɛ koɲuman walasa ka muɲuli mara. Walasa ka kunnafoni wɛrɛw sɔrɔ da suguyaw kan ani u nɔfɛkow kan, aw ye an ka gafe ɲɛ 10nan lajɛ . Da suguya minnu bɛ kɛ ka pikiri kɛ ..

Taabolow kɔlɔsili .

Pikiri tansiyɔn .

Pikiri tansiyɔn ye taabolo paramɛtiri kɔrɔlen ye min bɛ muɲu muɲuliw la. Pikiri tansiyɔn ka bon kojugu, o bɛ se ka kɛ sababu ye ka fɛnw falen-falen, o bɛ kɛ sababu ye ka fɛnw hakɛ caman wuli ani ka degun sɔrɔ a yɔrɔ kɔnɔ. Degun ka dɔgɔn kojugu, o bɛ se ka kɛ sababu ye ka facogo dafabali ni hakɛ bɛnbaliya sɔrɔ. Pikiri tansiyɔn ɲuman sɔrɔli ye muɲuli sabatili kunba ye.

Minɛni waati .

Minɛni waati bɛ tali kɛ waati min na degun bɛ mara pikiri fɔlɔ kɔfɛ. Minɛni waati dafalen ka kan walasa a yɔrɔ ka se k’a hakɛw sabati ani k’u mara. Minɛni waati dafabaliya bɛ se ka kɛ sababu ye ka jisigiyɔrɔw ni hakɛ caman yeli kɛ. O cogo kelen na, minɛ waati tɛmɛnen bɛ se ka kɛ sababu ye ka mɔgɔ minɛ ka tɛmɛ a dan kan ani ka degun bila mɔgɔ la. Minɛni waati ɲuman nafa ka bon walasa ka muɲuli gɛlɛnw sɔrɔ.

Mold température .

Moli funteni jɔyɔrɔ ka bon muɲuliw kunbɛnni na. Nɔgɔ funteni bɛ nɔ bila plastiki nɛnɛ hakɛ la, o de kosɔn, a yɔrɔ ka dɔgɔya ani a ka kɛlɛ. Ka mɔli funteni hakɛ basigilen mara, o nafa ka bon kosɛbɛ walasa ka se ka hakɛw sɔrɔ minnu bɛ se ka segin-ka-bɔ. Nɔgɔ ka kan ka kɔlɔsi ka ɲɛ ani ka a kɔlɔsi kosɛbɛ walasa ka muɲuli sabatilenw sɔrɔ.

Designing for optimal injection molding tolerances .

Design for Manufacturability (DFM) sariyakolow .

DFM sariyakolow labatoli bɛ a to a yɔrɔw dilanni ka nɔgɔn. O bɛ filiw dɔgɔya ani ka muɲuli kunbɛncogo ɲɛ. Dilancogo ɲuman bɛ musakaw dɔgɔya ani ka fɛn dilanni teliya.

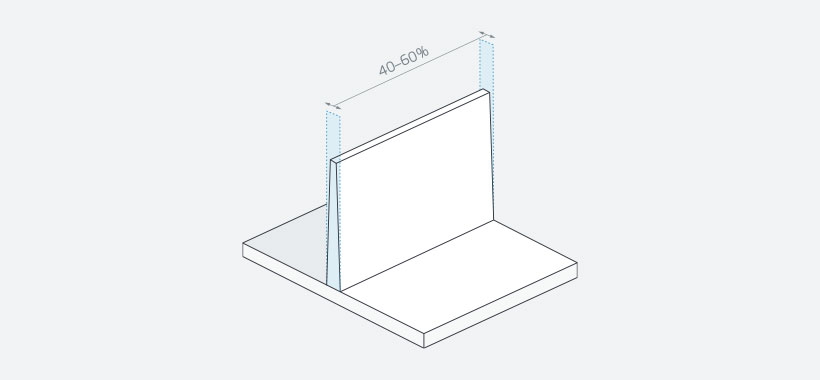

Uniform mur thickness .

Kogo janya kelen marali nafa ka bon kosɛbɛ. Kogow minnu tɛ bɛn ɲɔgɔn ma, olu bɛ kɛ sababu ye ka wuluwulu ni jigin. Aw bɛ aw jija hali ka bonya yɔrɔ bɛɛ la. O bɛ dimension stabilité (hakɛ sabatili) bonya.

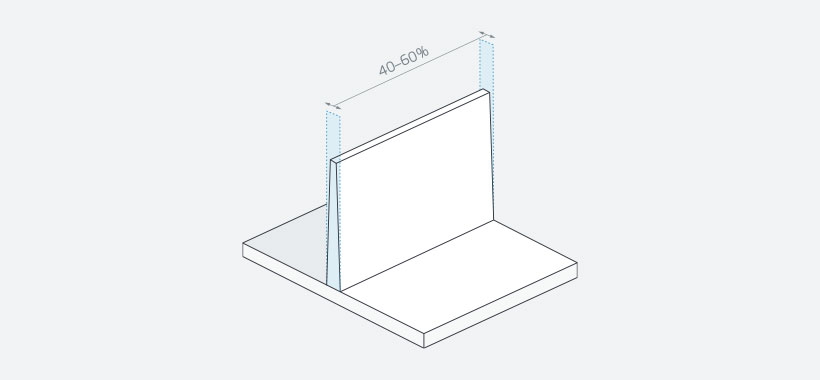

Ja: Kogo janya nɔw .

Angles de draft propre .

Draft angles bɛ dɛmɛ don yɔrɔw bɔli nɔgɔya la ka bɔ mɔni na. Ni sɛbɛnfura bɛrɛ tɛ a la, a yɔrɔw bɛ se ka nɔrɔ ani ka u tiɲɛ. A ka c’a la, 1-2 degree draft bɛ fɔ a yɔrɔ fanba la. Walasa ka ɲɛfɔli caman sɔrɔ anglɛw kan ani u nafa kan, aw bɛ taa an ka barokun kan . Angles de draft (Angles draft) bɛ kɛ pikiri kɛli la ..

Core ani cavity dilancogo jateminɛw .

Ka core ni cavity dilan ka ɲɛ, o nafa ka bon kosɛbɛ. Aw bɛ aw jija ka kurukuruw bɔ minnu bɛ gɛlɛya don u la. Dilancogo ɲuman bɛ mɔli ɲɛnamaya ni a yɔrɔ tiɲɛni bonya.

Tablo: Core and Cavity Design Tips

| Consideration |

Impact . |

| Aw bɛ aw yɛrɛ tanga fɛnw ma minnu bɛ tigɛ . |

A bɛ nɔgɔya don mɔli la . |

| Aw bɛ baara kɛ ni surfaces kelenw ye . |

Aw bɛ a lajɛ hali ka nɛnɛ . |

| Optimiser ejection points . |

A bɛ yɔrɔ dɔw tiɲɛni bali . |

Parting Line Placement .

O farali sira bɛ nɔ bila a yɔrɔ laban ka ɲɛnajɛko ni a ka baarakɛcogo la. Aw bɛ a bila yɔrɔ la min tɛ kɔrɔfɔ ye walasa ka a tanga fiɲɛ yetaw ma. Yɔrɔ ɲuman bɛ a to a ka se ka faranfasiya saniyalen ni flash fitinin sɔrɔ. Walasa ka kunnafoni wɛrɛw sɔrɔ farali layini jateminɛw kan, aw ye an ka gafe ɲɛ 10nan lajɛ . Parting lines injection molding ..

Material Selection ani Tolerances .

pikirijikɛlanw dilanni minɛnw ani u dɔgɔyali hakɛw .

Plastiki amorphes vs semi-crystalline .

Plastiki amorphes, i n'a fɔ . ABS , ka a dɔgɔya ka dɔgɔn ni plastiki semi-kirisitalini ye. Plastiki semi-kirisitalini, i n’a fɔ poliporopilini, olu ka dɔgɔya hakɛ ka ca. O danfara in nafa ka bon kosɛbɛ walasa ka muɲuli gɛlɛnw sɔrɔ.

Walasa ka kunnafoni caman sɔrɔ poliporopilini pikiri kɛcogo kan ani a jogo kɛrɛnkɛrɛnnenw kan, aw bɛ se ka taa an ka barokun kan . Poliporopilini pikiri kɛcogo ..

Filɛlikɛlaw ni farankanw nɔfɛkow dɔgɔyali ni muɲuli kan .

Filɛlikɛlaw ni farankanw bɛ se ka nɔba bila u dɔgɔyali la. Misali la, gilasi fiyɛw bɛ dɔ bɔ dɔgɔyali la ani ka sabatili sabati. O bɛ yɔrɔ mɔlenw tiɲɛni ɲɛ. Plastikiw bɛ dɔ fara fɛnw sɛgɛsɛgɛli kan nka u bɛ se ka u ka dɔgɔya hakɛ caman Changer.

Fɛn minnu bɛ fara ɲɔgɔn kan, olu misaliw .

Glass fibres : A bɛ dɔ bɔ a dɔgɔyali la, a bɛ fanga bonya.

Plastikiw : A bɛ dɔ fara fɛnw sɛgɛsɛgɛli kan, a bɛ se ka fɛn caman Changer.

Flame Retardants : A bɛ tasuma kɛlɛli sabati k’a sɔrɔ a ma nɔ bila shrinkage la kosɛbɛ.

Mold Flow Analysis ka ɲɛsin dɔgɔyali ma .

Mɔbiliw bolicogo sɛgɛsɛgɛli bɛ dɛmɛ ka fɛnw bɛna dɔgɔya cogo min na, o fɔ. Nin simulation baarakɛminɛn in bɛ kɛ sababu ye ka dilanbagaw bila ka fɛnw bolicogo ni u nɛnɛ. A bɛ dɛmɛ don ka mɔli kɛcogo ɲuman sɔrɔ walasa ka muɲuli ɲininenw sɔrɔ.

Fɛn minnu bɛ kɛ ka ɲɛsin nɔgɔw bolicogo sɛgɛsɛgɛli ma .

Model Creation : Ka 3D modɛli dɔ labɛn yɔrɔ in na.

Simulation Setup : Input material properties ani processing conditions.

Boli simulation : Analyse flow, cooling, ani shrinkage patterns.

Seginkanni jaabiw : Labɛnni ladilan ka da simulatigɛ kunnafoniw kan.

Ni baara kɛra ni mɔbili bolicogo sɛgɛsɛgɛli ye, fɛn dilannikɛlaw bɛ se ka ko minnu bɛ se ka kɛ, olu ɲɛfɔ. O bɛ a to muɲuli tigitigiw ni yɔrɔ ɲumanw. Walasa ka fɛn kɔrɔw sɔrɔ minnu ka dɔgɔyali jogo kɛrɛnkɛrɛnnenw bɛ u la, i n’a fɔ peek, aw ye an ka barokun kalan . Peek pikiri kɛcogo ..

Baarakɛminɛnw ni pikiri kɛcogo muɲuni .

Mold design ani a nɔfɛkow muɲuni na .

Moli dilanni bɛ nɔ bila pikiri kɛcogo muɲuni na k’a ɲɛsin a ma. Nɔgɔ min dilannen don koɲuman, o b’a to a yɔrɔw ka kɛ tigitigi ye ani u bɛ kɛ cogo kelen na. Dilancogo jugu bɛ na ni dimension inaccuracies ani defauts ye. Walasa ka hakilinaw sɔrɔ ka ɲɛsin mɔli yɔrɔ kolomaw dilanni ma, aw ye an ka gafe lajɛ . Bololabaarakɛlaw ka tasa funteniman dilanni pikiri kɛcogo la ..

Cooling Channel Placement ani Uniforme Cooling .

Fɔɲɔ-kan-kan-yɔrɔ-ko ɲuman ye ko ye min nafa ka bon kosɛbɛ. Nɛnɛ bɛ kɛ cogo kelen na, o bɛ kɛ sababu ye ka kirinni ni dɔgɔyali bali. Kanalw ka kan ka bila strategiki la hali funteni jɛnsɛnni kama.

Gate ani ejector pin yɔrɔw .

Gate ni ejector pin yɔrɔw bɛ nɔ bila a yɔrɔ cogoya la. Dabaw ka kan ka kɛ yɔrɔw la minnu ka bon kosɛbɛ walasa ka u labɛn ka ɲɛ. Ejector pinw ka kan ka bila walasa yɔrɔ dɔw ka wuli ka bɔ u nɔ na.

Tablo: Da ni ejector PIN tips

| jateminɛ |

kɛcogo . |

| Gate yɔrɔ minnu ka bon . |

A bɛ a lajɛ ko fɛnw bɛ woyo ka ɲɛ . |

| Pin de pin de pin , min bɛ kɛ ka baara kɛ ni a ye . |

A bɛ warping ni deformation bali . |

Walasa ka ejector pins ani u jɔyɔrɔba lajɛ, aw bɛ se ka taa an ka gafe ɲɛ 10nan na . Ejector pins in injection moulding ..

Multé matériel ani machining tolerances .

Nɔgɔfɛnw sugandili bɛ nɔ bila masinw muɲuni na. Fɛn minnu ka ɲi kosɛbɛ, olu bɛ a to muɲuli ka gɛlɛn. Machining precision b’a to mɔli bɛ a ka tiɲɛni mara waati kɔnɔ.

Lisiti: Mold Material jogo .

Gɛlɛyaba: A bɛ dɔ bɔ sɛgɛn na .

Sumayako ɲuman: A bɛ a to a ka nɛnɛ cogo kelen na .

Corrosion resistance: A bɛ mɔli ɲɛnamaya janya .

Taabolow kɔlɔsili walasa ka muɲuliw mara .

Nafa min bɛ sɔrɔ taabolo paramɛtɛrɛw la minnu bɛ bɛn ɲɔgɔn ma .

Taabolow kɛcogo basigilenw nafa ka bon pikiri kɛli la. U bɛ yɔrɔ dɔw cogoya sabati ani ka muɲuli gɛlɛnw mara. Yɛlɛma minnu bɛ kɛ paramɛtɛrɛw la, olu bɛ se ka kɛ sababu ye ka fiɲɛw ni hakɛw tiɲɛ.

Pikiri tansiyɔn n’a nɔ min bɛ tolerances kan .

Pikiri tansiyɔn bɛ nɔ bila fɛnw bolicogo la k’a ɲɛsin u ma. Tansiyɔnba bɛ a to a bɛ se ka kɛ sababu ye ka kɔnɔnatumuw fa. Degun min tɛ bɛn ɲɔgɔn ma, o bɛ se ka kɛ sababu ye ka yɔrɔ lakolonw ni a dɔgɔya, ka nɔ bila muɲuli la. Walasa ka kunnafoni wɛrɛw sɔrɔ ko dɔw kan minnu ɲɛsinnen bɛ fa dafabaliya ma, aw ye an ka gafe lajɛ . Short shots in injection molding ..

Minɛni waati ni mɔli funteni .

Minɛni waati bɛnnen bɛ fɛnw kɔtigɛ bali. A b’a To yɔrɔw b’u cogoya n’u hakɛw mara. Minɛni waati jugu bɛ na ni warping ni sink taamasiyɛnw ye. Moli funteni hakɛ kɔlɔsili nafa ka bon o cogo kelen na. Funteni min bɛ to sen na, o bɛ a to a ka nɛnɛ cogo kelen na ani ka kɔnɔna degunw dɔgɔya.

Tablo: Minɛni waati ɲuman ni funteni hakɛ

| paramɛtiri |

Optimal Range . |

| Minɛni waati . |

5-15 segin . |

| Mold température . |

75-105°C . |

dɔnniya mouli fɛɛrɛ .

Dɔnniya-mooli bɛ pikiri kɛcogo ɲɛ. A bɛ baara Kɛ ni kunnafoniw ye walasa ka fɛn caman sɛgɛsɛgɛ i n’a fɔ degun, waati ani funteni. O fɛɛrɛ in bɛ segin-ka-bɔ ni ɲɔgɔndɛmɛ sabati, ka muɲuli gɛlɛnw mara sɛnɛfɛnw bɔli boliw la.

Fɛn minnu bɛ kɛ ka ɲɛsin dɔnniya yiriwali ma .

Donanw lajɛ : Baarakɛcogo kunnafoniw lajɛ.

Sɛgɛsɛgɛli : Ka sigida ɲumanw dɔn.

Waleya : A’ ye settings (labɛnniw) kɛ production (sɛnɛ) la.

Kɔlɔsili : Aw bɛ to ka kɔlɔsili kɛ ani ka ladilan.

Sumani ni sɛgɛsɛgɛli fɛɛrɛw .

Sɛgɛsɛgɛli yelen .

Sɛgɛsɛgɛli yelen ye jogoɲini fɛɛrɛ fɔlɔ ye. A bɛ dɛmɛ don ka dugukolo yɔrɔw tiɲɛniw ni Warpage dɔn joona. Sɛgɛsɛgɛlikɛlaw bɛ sɔgɔsɔgɔninjɛ, ɲinw ani dafabaliya wɛrɛw ɲini.

Ja: Surface commun .

Manuel Sumanikɛminɛnw .

Kalifaw ni mikromɛtiriw .

Kalifaw ni mikromɛtiriw nafa ka bon bolo sumani na. U bɛ dimensions (janya) kalanni tigitigiw Di. Aw bɛ baara kɛ n’u ye walasa ka u bonya, u cɛmancɛ ani u juguya suman.

Bolo sumani kɛcogo ɲumanw .

Aw bɛ baara kɛ ni fɛɛrɛ basigilen ye walasa ka a dɔn ko a bɛ se ka kɛ. zeru kalifa ka kɔn baara kelen-kelen bɛɛ ɲɛ. Aw bɛ degun nɔgɔman kɛ walasa aw kana a yɔrɔ tiɲɛ.

Tablo: Manuel Sumanikɛcogo ɲuman Baarakɛminɛnw

| baarakɛcogo |

Tip . |

| Kalifaw . |

Zero sani a ka baara kɛ . |

| Micromɛtiriw . |

Aw bɛ degun dususuman kɛ . |

Sumanikɛlan minnu bɛ kɛ ni otomatiki ye .

Coordinate Sumanikɛlanw (CMMS) .

CMMw bɛ tiɲɛniba di yɔrɔ gɛlɛnw ma. U bɛ baara Kɛ ni sonda ye walasa ka yɔrɔ in sanfɛla coordinates suman. Nin fɛɛrɛ in ka ɲi kosɛbɛ walasa ka fɛn caman sɛgɛsɛgɛli kɛ.

yelifɛnw sigicogo .

yelifɛnw bɛ baara kɛ ni kameraw ni sensɛriw ye. U bɛ jaw minɛ ani ka hakɛw sɛgɛsɛgɛ u yɛrɛma. O sigida ninnu bɛ teliya ani ka baara kɛ ka ɲɛ sɛgɛsɛgɛliw la minnu bɛ kɛ ni mɔgɔw hakɛ ye.

Barokun fɔlɔ sɛgɛsɛgɛli (FAI) .

FAI ye sɛgɛsɛgɛli dafalen ye a tilayɔrɔ fɔlɔ la min bɔra. A b’a to a yɔrɔ fɔlɔ ka se ka dilancogo ɲɛfɔ. FAI ye fɛn bɛɛ sumani ye ani k’u suma ni dilancogo ye.

sɛgɛsɛgɛli bɛɛ lajɛlen .

FAI bɛ dimension critique bɛɛ lajɛ. O sɛgɛsɛgɛli in b’a Jira ko yɔrɔ in bɛ Bɛn ni dilancogo ye.

Ka a lajɛ ni a yɔrɔ fɔlɔ bɛ tiɲɛ .

Barokun fɔlɔw tigitigiw sigi sen kan ka ɲɛsin u dilanni ma. U bɛ dɛmɛ don ka ko minnu bɛ se ka kɛ, olu dɔn joona. O bɛ kɛ sababu ye ka jogo ɲuman sabati yɔrɔ nataw la.

Tablo: FAI ka sɛgɛsɛgɛli

| kɛcogo |

ɲɛfɔli . |

| Sumanikɛlanw hakɛw . |

Aw ye a suma ni design specs ye . |

| Aw bɛ a lajɛ . |

Aw bɛ a lajɛ ni fiɲɛw tɛ . |

| Aw bɛ fɛnw sɛgɛsɛgɛ . |

Aw ye aw jija ka fɛn bɛnnenw kɛ minnu bɛ kɛ . |

Gɛlɛyaw ni furakɛli minnu bɛ kɛ ɲɔgɔn fɛ .

Ka ɲɛsin Warpage ni shrinkage ma .

Dilancogo ladilanni ani fɛnw sugandili .

Warpage ani shrinkage ye ko ye min bɛ kɛ tuma caman na. Ni aw ye a dilanni ladilan, o bɛ se ka dɛmɛ don. Aw bɛ baara kɛ ni kogo janya ye min bɛ kɛ tuma bɛɛ walasa ka warpage dɔgɔya. Aw bɛ fɛnw sugandi minnu ka dɔgɔya hakɛ ka dɔgɔn walasa u ka se ka u bonya ka ɲɛ.

Tablo: Fɛnw ni dɔgɔyali hakɛw

| Fɛnw |

dɔgɔyali hakɛ . |

| ABS . |

Fɛ́gɛn |

| Poliporopilini . |

Jamanjan |

| Nylon . |

Ka bɛrɛbɛn |

Taabolo caman b'a la .

Ni aw ye pikiri kɛcogo caman sɛmɛntiya, o bɛ se ka dɔ bɔ Warpage la. Aw bɛ nɛnɛ kɛcogo kelen kɛ walasa ka dɔgɔyali kɛcogo bɛnbali bali. Aw bɛ pikirijikɛlan tansiyɔn ladilan walasa ka a dɔn ko a bɛ fa ka a fa.

Tolerance stack-ups ɲɛnabɔli .

Dimensional deviations (Diɲɛnabɔli) ka nɔ bɛɛ lajɛlen .

Tolerance stack-ups bɛ kɛ ni deviations misɛnninw farala ɲɔgɔn kan. O bɛ se ka nɔ bila yɔrɔw lajɛlenw ka bɛn ni u ka baara la. Faamuyali minnu bɛ sɔrɔ k’u kɛ ɲɔgɔn fɛ, olu faamuyali ye u ɲɛnabɔli kunba ye.

Fɛɛrɛ minnu bɛ kɛ walasa ka ɲɔgɔndɛmɛ koɲɛw dɔgɔya .

Fɛɛrɛ caman bɛ dɛmɛ ka stack-ups dɔgɔya. Aw bɛ muɲuli gɛlɛnw kɛ hakɛ gɛlɛnw kan. Aw bɛ Statistical Process Control (SPC) kɛ walasa ka sɛnɛfɛnw kɔlɔsi. Aw bɛ a labɛn walasa a ka lajɛ walasa a yɔrɔw ka bɛn ɲɔgɔn ma ka ɲɛ.

Tablo: Fɛɛrɛ minnu bɛ kɛ ka muɲuli stack-ups

| technique |

nafa . |

| Tolerances sirilenw . |

A bɛ dɔ bɔ deviations cumulatifs la . |

| Jateminɛ kɛcogo ɲɛnabɔli (SPC) . |

Monitors ani controls qualité . |

| Design for Assembly . |

A bɛ a lajɛ ni a yɔrɔ bɛnnen don . |

Kuncɛli

pikiri kɛcogo muɲuni faamuyali ni a kunbɛnni nafa ka bon kosɛbɛ. Tolerances tigitigiw bɛ a to yɔrɔw ka bɛn ani ka baara kɛ ka ɲɛ. Dilancogo, fɛnw sugandili, ani baarakɛcogo kunkankow bɛɛ muɲuni. Kow ɲɛnabɔli i n’a fɔ Warpage ani shrinkage, o nafa ka bon kosɛbɛ jogo ɲuman na.

Ka jɛɲɔgɔnya kɛ ni pikiri kɛcogo ɲɛnabɔbagaw ye minnu bɛ se kosɛbɛ, o bɛ nafa caman lase u ma. U bɛ na ni dɔnniya ni fɛɛrɛ kuraw ye. O bɛ kɛ sababu ye ka yɔrɔw sabati minnu ka ɲi, minnu bɛ se ka da u kan. Baara kɛli ni baarakɛlaw ye, o bɛ waati tiɲɛ ani ka musakaw dɔgɔya.

Kuma surun na, pikiri kɛcogo muɲuni ka ɲɛ, o bɛ na ni fɛn ɲumanw ye. O nafa ka bon kosɛbɛ walasa ka fɛn dilanni ɲɛnabɔ ani ka kiliyanw wasa.