Ta yaya masana'antun suke samar da sassan filastik masu inganci yayin da farashin ceton? Asirin ya ta'allaka ne a cikin Master allurar sauyawa . A kasuwa na yau da kullun, kowane na biyu yana ƙidaya, da Inganta wannan sake zagayowar na iya yin canji mai mahimmanci.

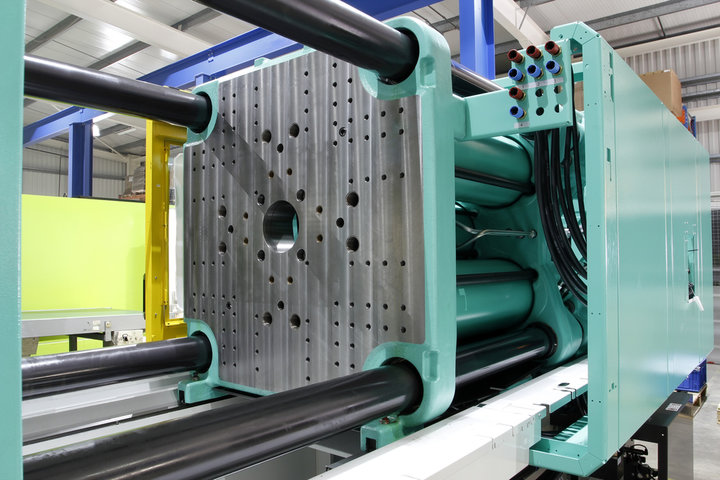

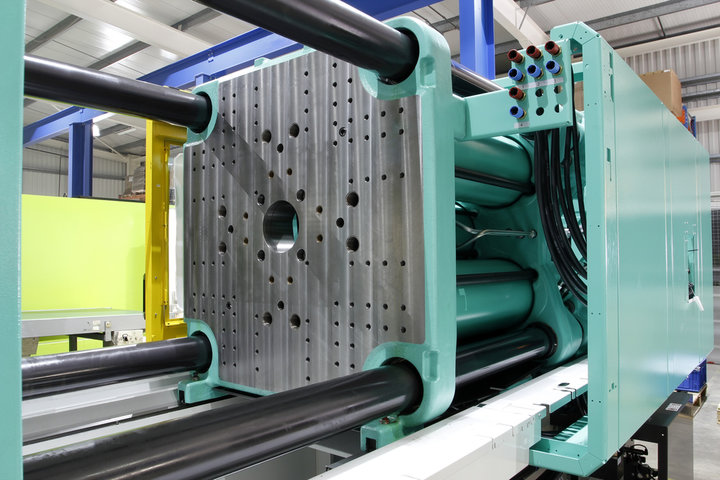

Tsarin allura wanda ya haɗa da dumama kayan filastik, yin amfani da shi cikin mold, kuma sanyaya shi don samar da wani sashi mai ƙarfi. Amma tsawon lokacin da ya ɗauka don kammala zagayowar ɗaya, kuma waɗanne abubuwa ne tasiri a wannan lokacin? Gwaji da rage lokacin sake zagayawa na iya inganta haɓaka da ƙananan farashin samarwa.

A cikin wannan post din, zaku iya koyon abin da ke tasirin lokacin zagaye a cikin allurar da aka gano da kuma gano dabarun inganta tsarin. Daga Daidaita sojojin murɗa zuwa sake fasalin tashoshin sanyaya, zamu rufe dabarun da aka tabbatar don yanke lokatai na ci gaba ba tare da sadaukar da kayan aiki ba.

Mene ne lokacin zagayowar yanayin tsari?

Lokacin juyawa na allurar rigakafi yana nufin jimlar lokacin da ake buƙata don kammala ɗayan zagayowar tsari na allurar rigakafi. Yana farawa lokacin da kayan molten ke allura cikin kogon ƙirar da ƙare lokacin da aka gama ɓangaren da aka gama daga ƙirar.

Abubuwan da ke cikin yanayin daidaitawa

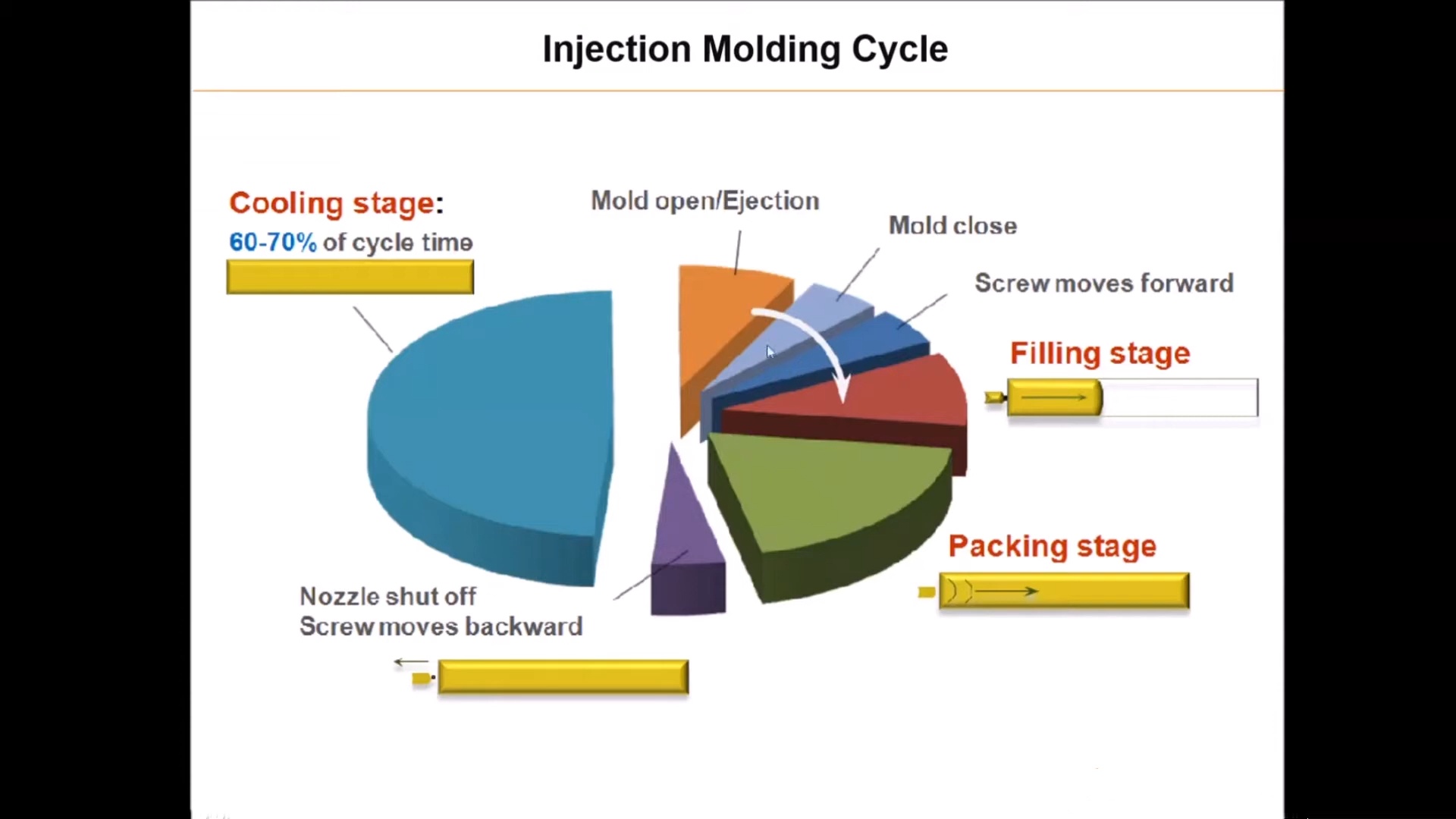

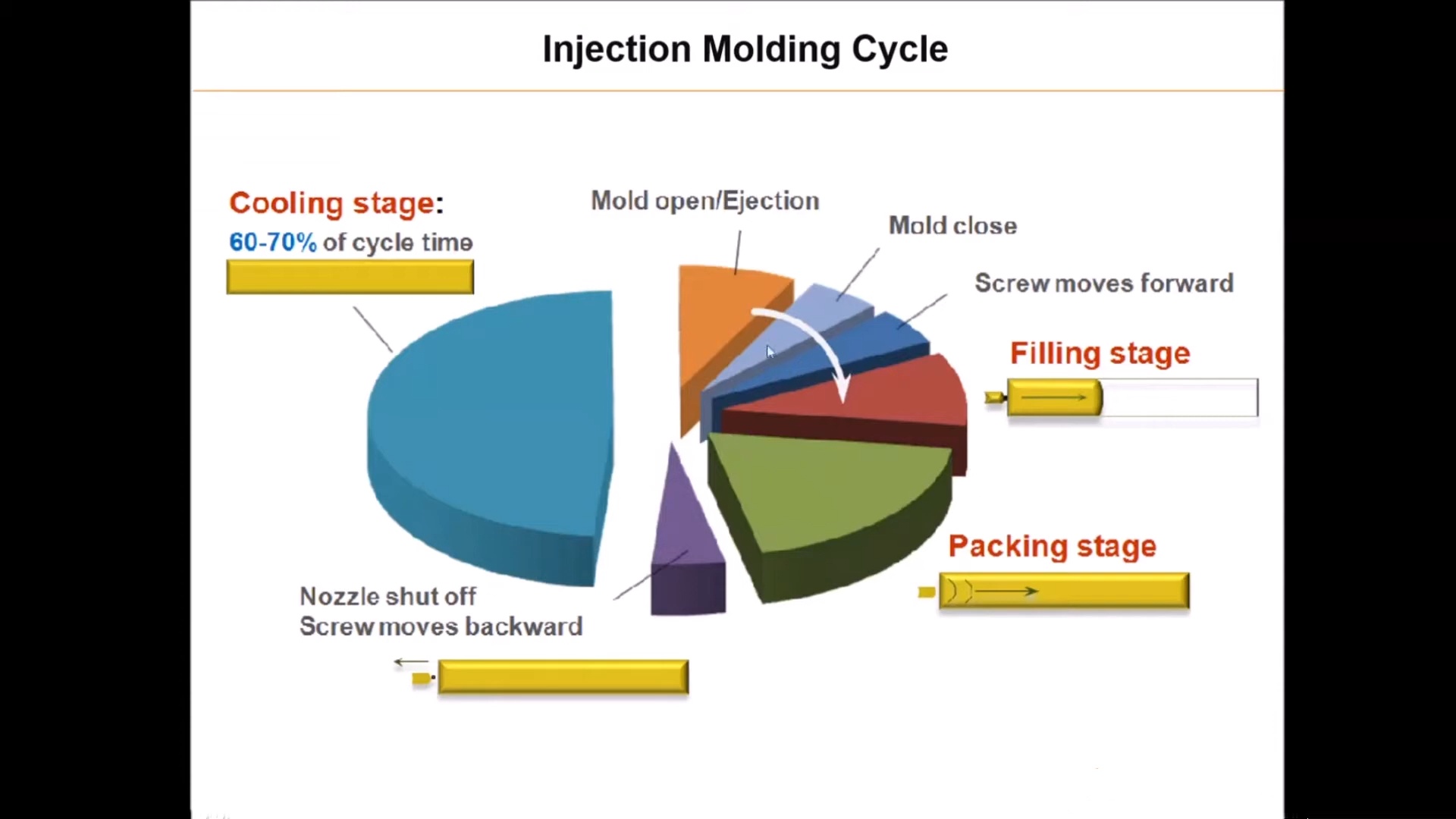

Tsarin gyara na allurar rigakafi ya ƙunshi matakai da yawa. Kowane mataki yana ba da gudummawa ga lokacin sake zagayowar gaba ɗaya. Tsarin mahalli na tsarin daidaitaccen tsari shine:

Lokacin Neman :

Tsawon lokacin da yake ɗauka don yin amfani da kayan molten a cikin ƙirar ƙwayar cuta har sai an cika shi gaba ɗaya

Tasiri da dalilai kamar su halaye na kayan abu, allura saurin, da kuma sashe na sashi

Lokacin sanyi :

Zamani domin filastik na molten don sanyaya da ƙarfi bayan an cika muryar

Sashin mahimmancin sake zagayowar yayin da yake shafar kwanciyar hankali da inganci

Rinjayi ta nau'in kayan, kayan kauri, da ingantaccen tsarin sanyaya

Lokaci :

Lokacin kiyayewa :

Mold Bude / Rufewa :

Muhimmancin fahimta da kuma inganta lokacin sake fasalin

Gwaji da Ingantar da lokacin zagayowar daidaitaccen tsari yana da mahimmanci ga dalilai da yawa:

Mabuɗin Key:

Lokacin juyawa na allurar allurar in shine jimlar lokaci daya don cikar zagaye

Ya hada da lokaci guda, lokacin sanyaya, lokaci, lokaci, lokaci, da kuma buɗe buɗe / rufewa

Inganta lokacin sake fasalin yana inganta ingancin samarwa, yana rage farashi, kuma inganta ingancin samfurin

Game da lokacin ratsa yana da mahimmanci don kasancewa gasa a cikin masana'antar ingantaccen tsari

Yadda za a lissafa lokacin zagayawa

Gayyato lissafin tsarin zagaye yana da mahimmanci ga inganta hanyoyin daidaitattun hanyoyin gyara. Wannan sashin yana samar da cikakken jagora don ingantaccen tsarin sake zagayawa.

Mataki-mataki jagora don lissafin lokacin zagayawa

Adai da Lokaci

Yi rikodin tsawon lokacin da ake buƙata don cike murfin murfin

Yi amfani saitin kayan adon allurar rigakafi ko bayanan samarwa

Yi la'akari da ragin kayan abu, saurin alluna, da kuma girma kofe

Tantance lokacin sanyi

Gane nau'in kayan da kayan zane

Kimanta ingantaccen tsarin sanyaya

Yi amfani da Software na Binciken Mold Rentis Software don daidaitaccen kimantawa

Kimanin Lokaci

Memara ƙarin lokaci don cikakkiyar doka

Tushe a kan kaddarorin kayan da kuma bukatun

Yawanci gajere fiye da lokacin sanyi

Lokaci na Kidayi

Abubuwanda suka shafi lokaci:

Sashe na Geometry

Kewaya kayan aiki

Mallaka ƙira

Lissafin kuɗi don buɗewar / rufewa

Tsarin zagaye na zagayawa

Yi amfani da wannan tsari don lissafta lokacin sake zagayawa:

Time lokaci ɗaya = lokacin yin allura + lokacin zama + wurin buɗe lokaci

Kayan aikin Otline da Simululation don kimantawa lokacin sake zagayawa

Akwai albarkatun da yawa don ingancin lokacin zagayawa:

Lissafi akan layi

Mold Farawar Software

Nemo dukkan allurar gyara

Bayar da cikakkiyar fahimta a cikin kowane matakin

Misalai: Autodesk Moldflow, Moldex3D

Kayan aikin takamaiman kayan aiki

Software na cae

Waɗannan kayan aikin suna taimakawa masana'antun masana'antu, haɓaka inganci, kuma rage farashi a cikin ayyukan gyara na gyara.

Abubuwa suna shafar lokacin juyawa

Abubuwa da yawa suna tasiri lokacin zagayowar yanayin yanayin. Ana iya rarrabe su cikin manyan sigogi guda hudu: sigogi na zanen mold, sigogi na samfuri, zaɓi na zamani, da zaɓin yanayin allurar rigakafi.

Motar zanen zanen

Tsarin tsarin sanyaya :

Rushnon da Gate Design :

Yawan cavities :

Tsarin venting :

Sigogin zane

Kauri mai kauri :

Kashi na Geometry :

Lokaci na Zabi

Narke da sanyaya halaye :

Yawan kauri da tasirinsa game da lokacin sanyi :

Abubuwan Albarka gaba ɗaya suna buƙatar ƙarin sanyaya mai sanyi idan aka kwatanta da na bakin ciki

Teburin da ke ƙasa yana nuna alaƙar da ke tsakanin kauri da lokacin sanyaya abubuwa don kayan da yawa:

| kayan | sanyi lokaci (seconds) na kauri daban-daban |

|

|

|

|

|

| 1mm | 2mm | 3mm | 4mm | 5mm | 6mm |

| Abin da | 1.8 | 7.0 | 15.8 | 28.2 | 44.0 | 63.4 |

| PA6 | 1.5 | 5.8 | 13.1 | 23.2 | 36.3 | 52.2 |

| PA66 | 1.6 | 6.4 | 14.4 | 25.6 | 40.0 | 57.6 |

| PC | 2.1 | 8.2 | 18.5 | 32.8 | 51.5 | 74.2 |

| Hdpe | 2.9 | 11.6 | 26.1 | 46.4 | 72.5 | 104.4 |

| Ldpe | 3.2 | 12.6 | 28.4 | 50.1 | 79.0 | 113.8 |

| Hula | 2.3 | 9.0 | 20.3 | 36.2 | 56.5 | 81.4 |

| Yi shelar alkjjada | 1.9 | 7.7 | 20.3 | 30.7 | 48.0 | 69.2 |

| Pp | 2.5 | 9.9 | 22.3 | 39.5 | 61.8 | 88.9 |

| Zasa | 1.3 | 5.4 | 12.1 | 21.4 | 33.5 | 48.4 |

Table 1: Lokacin sanyaya don kayan daban-daban da kauri

Sigogi na allurar rigakafi

Saurin alluna da matsin lamba :

Narke zazzabi :

Zazzabi zazzabi :

Riƙe lokaci da matsin lamba :

Yanayin muhalli

Zafi :

Ingancin iska :

Zazzabi :

Dabaru don rage lokacin zagayawa

Rage lokacin daidaitaccen tsari na tsari yana da mahimmanci don inganta ingancin samarwa da tsada. Zamu iya cimma sauye sauye-sauye ta hanyar inganta bangarori daban-daban na tsarin sarrafa tsari. Bari mu bincika wasu dabarun manyan dabaru.

Inganta ƙirar mold

Inganta ingancin tsarin sanyaya :

Inganta Ingantaccen Runner da Design Design :

Inganta hanji :

Haɗa isasshen isasshen iska a cikin ƙirar ƙira

Ingantaccen isasshen iska yana ba da damar haɓaka iska da iskar gas, rage lokacin rufewa

Inganta Tsarin Samfura

Kulawa da kauri bangon bango :

Sauƙaƙe Sashe Geometry :

Zabi kayan hannun dama

Zabi kayan tare da yawan sanyaya ruwan sanyi :

La'akari da kauri na kayan :

Kyakkyawan allurar rigakafi

Yin amfani da allurar babban gudu :

Inganta magance matsalar magance :

Saita allura matsa lamba ga mafi karancin da ake buƙata don daidaitaccen bangare cike

Ingantaccen tsari na allura na taimakawa a guji gina matsin lamba da ba dole ba kuma yana rage lokacin sake zagayawa

Sarrafa mold zazzabi :

Rage rage lokacin rike da matsin lamba :

Zuba jari a Kayan Aiki

Tsarin Azumi :

Ingantattun hanyoyin aiwatarwa :

Stretlining na yin allurar rigakafi

Inganta daidaitaccen tsari :

Iyakar taga mai lamba :

Aiwatar da ƙa'idodin ilimin kimiyya :

Kafa tsari kafin canje-canje na kayan aiki :

Dubawa Kayan aiki da aiki da kuma venting :

Binciken kayan aiki na kayan aiki a samfuri :

Fa'idodi na rage lokacin zagayawa

Inganta lokacin daidaitaccen yanayin daidaitaccen tsari yana ba da fa'idodi da yawa don masana'antun. Wannan sashin yana bincika mahimman amfanin hanyoyin samar da ƙasa.

Yawan fitarwa

Rage lokacin zagayawa kai tsaye yana tasiri karfin samarwa:

Misali: Rashin 10% a lokacin sake zagayowar na iya haɓaka haɓaka shekara-shekara da raka'a 100,000 don layin samar da babban-girma.

Ƙananan farashin samarwa

Matsayi na guntu yana ba da gudummawa ga tanadin kuɗi:

| Fasta | yana haifar da rage lokacin sake zagayowar lokacin |

| Kuzari | 5-15% rage kowane bangare |

| Aiki | 10-20% rage a cikin mutum-awanni |

| Sama da | 8-12% rage farashin tsayayyen farashi |

Inganta ingancin samfurin

Addaddamar lokacin sake rufewa sau da yawa yana haifar da ingancin ingancin:

Ta hanyar rage girman fallasa ga zafi da matsin lamba, hanyoyin da suka dace suna taimakawa wajen tabbatar da amincin duniya, wanda ke haifar da samfuran ƙarshe.

Kasancewa lokaci-zuwa-kasuwa

Ingantattun hanyoyin samarwa na hanzarta ƙaddamar da samfurin:

Wannan rashin hankali yana ba masu kera don yin amfani da damar da suka fi dacewa da amsa da sauri ga masu amfani.

Ingantaccen gasa

Matakan da aka shimfida shi yana samar da gefen gasa:

Ikon bayar da gajere na teburin

Inganta sassaucin farashi

Karanci don magance umarni na Rush

Wadannan dalilai suna sarrafa masana'antun da aka fi so a kasuwannin cunkoso.

Ingancin ƙarfin kuzari

Rage lokutan rarar yana ba da gudummawa ga ƙoƙarin dorewa:

Sayayyar kuzari:

Manyan shekara-shekara: 1,000 kwh adon makamashi na samar da makamashi: 5 KWH samar da tanadin kuzari na zamani: 6,945 Kwh

Ƙarshe

Inganta lokacin daidaitaccen tsari na daidaito yana da mahimmanci ga ingancin masana'antu da gasa. Ta hanyar aiwatar da dabaru kamar inganta zane mai kyau, zabar kayan da suka dace, da sigogi masu dacewa, kasuwancin na iya cimma fa'idodi masu mahimmanci. Waɗannan sun haɗa da haɓaka fitarwa, ƙananan farashi, inganci mafi kyau, da kuma saurin kasuwa.

Lokaci na gajarta yana haifar da ingantacciyar ƙarfin makamashi da inganta sassauci a cikin jadawalin samarwa. Wannan tsari na ingantawa da kamfanoni na dogon lokaci a cikin masana'antar da ke tattare da kerawa.

Masu sana'ai su fi maida hankali kan ragin lokacin aiwatarwa don aiwatar da ayyukan layin dogo, haɓaka riba, da haɗuwa da bukatun ci gaba. Cigaba da Kulawa da daidaitawa sune mabuɗin don rike Peak Perfin cikin Tsarin Inging Molding.