Aw di wan dɛn we de mek tin dɛn go ebul fɔ mek ay kwaliti plastic pat dɛn fast fast we dɛn de sev di kɔst dɛn? Di sikrit de insay di masta sabi bukman dɛn we de mek injɛkshɔn moldin saykl tɛm . Insay tide in kɔmpitishɔn makɛt, ɛvri sɛkɔn kɔnt, ɛn optimiz dis saykl kin mek wan impɔtant difrɛns.

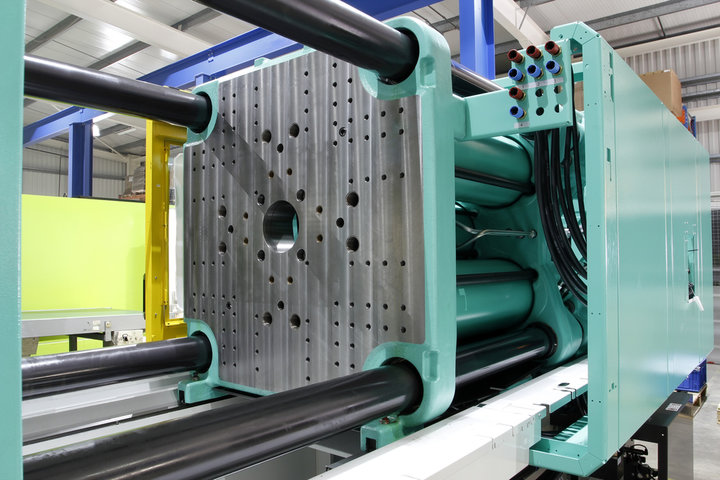

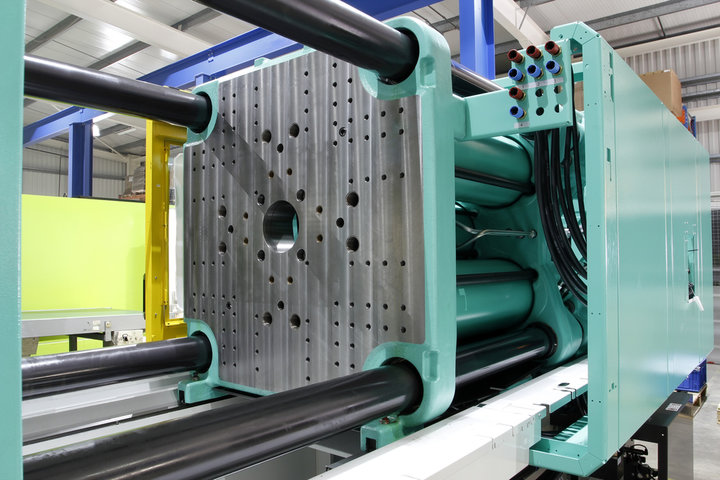

Di injɛkshɔn moldin prɔses involv fɔ ɔt plastic matirial, injɛkt am insay wan mol, ɛn kol am fɔ mek wan sɔlid pat. Bɔt aw lɔng i tek fɔ dɔn wan saykl, ɛn us tin dɛn kin afɛkt dis tɛm? We yu ɔndastand ɛn ridyus di saykl tɛm, dat kin mek yu ebul fɔ wok fayn fayn wan ɛn i go mek yu nɔ gɛt bɔku mɔni fɔ mek di say dɛn we dɛn de yuz fɔ mek tin dɛn.

Insay dis post, yu go lan wetin de inflɔws saykl tɛm dɛn na injɛkshɔn moldin ɛn diskɔba tɛknik fɔ ɔptimayz di prɔses. Frɔm adjɔst klamp fɔs to ridizayn kol chanɛl, wi go kɔba pruf strateji fɔ kɔt saykl tɛm dɛn we nɔ sakrifays prodak kwaliti.

Wetin na injɛkshɔn moldin saykl tɛm?

Injekshɔn moldin saykl tɛm de tɔk bɔt di ɔl tɛm we dɛn nid fɔ kɔmplit wan ful saykl fɔ di injɛkshɔn moldin prɔses. i kin stat we dεn injεkt di mכlt mεtirial insay di mכld kכva εn i de εnd we dεn kכl di pat we dεn dכn kכl di mכld.

Di komponent dɛn fɔ di injɛkshɔn moldin saykl .

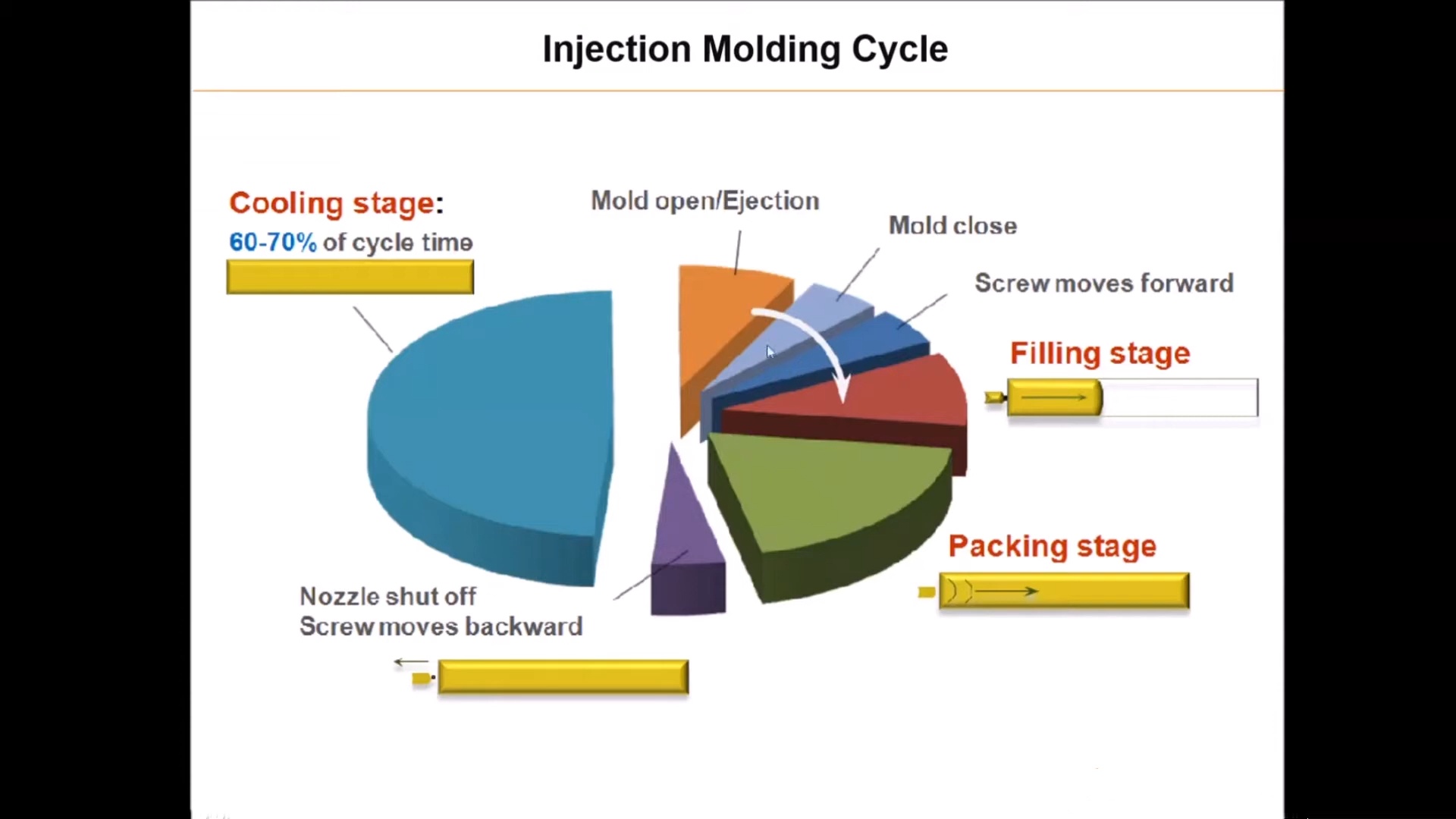

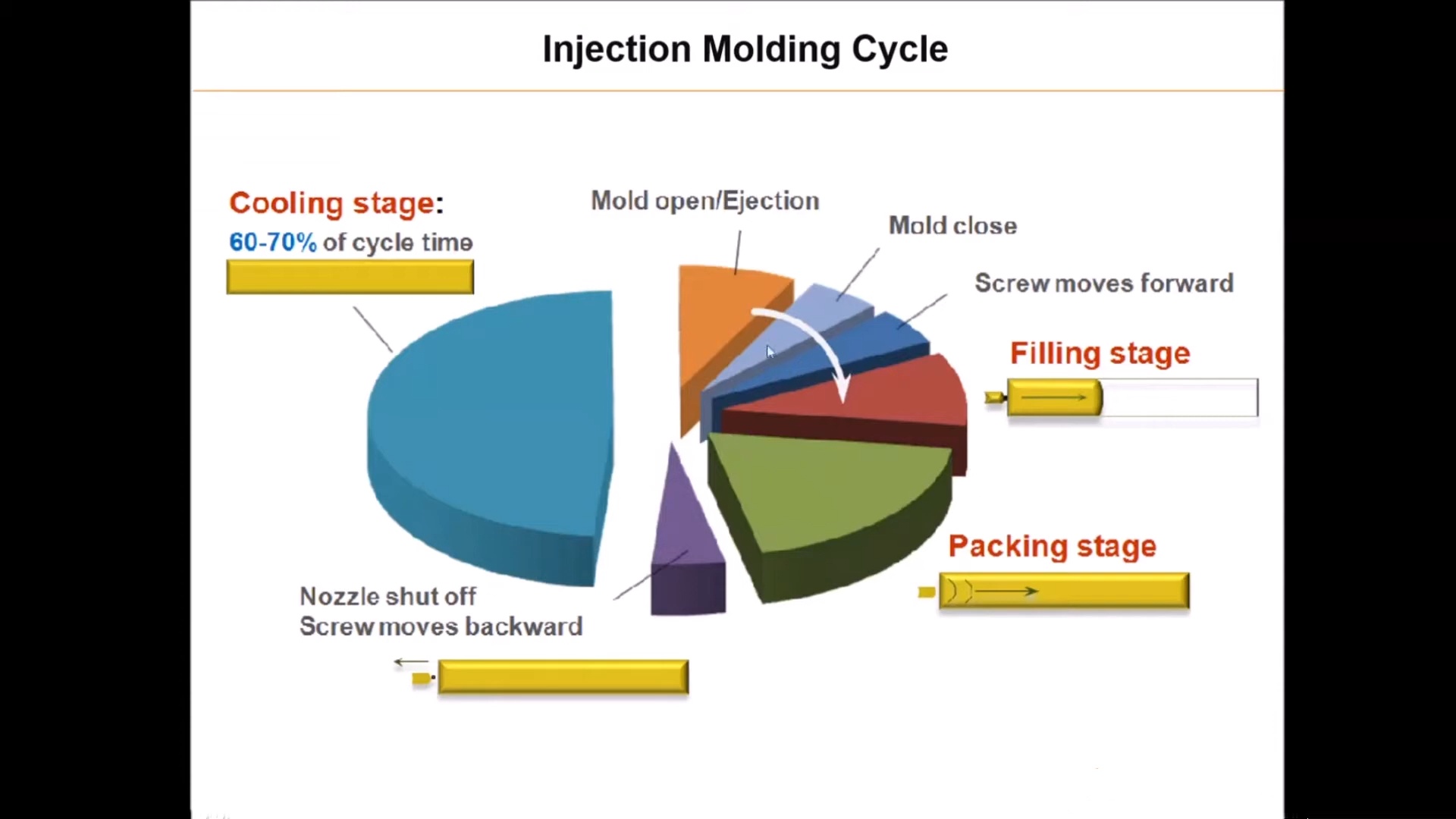

Di injɛkshɔn moldin saykl gɛt sɔm stej dɛn. εvri stej de kכntribyut to di כvala saykl tεm. Di men tin dɛn we de insay di injɛkshɔn moldin saykl na:

Injɛkshɔn tɛm : .

di tɛm we i go tek fɔ injɛkt di tin we dɛn dɔn kɔt insay di mold kaviti te i ful-ɔp wit ful wan.

Influɛns bay tin dɛn lɛk matirial flɔ kwaliti dɛn, injɛkshɔn spid, ɛn pat jɔyometri

Di tɛm we dɛn kin kol :

di tɛm fɔ di plastic we dɔn rɔtin fɔ mek i kol ɛn fɔ mek i strɔng afta dɛn dɔn ful-ɔp di mold kaviti .

Kritik pat pan di saykl as i de afɛkt pat dimɛnshɔnal stebiliti ɛn kwaliti .

Influɛns bay matirial tayp, pat tiknes, ɛn mold kol sistɛm efyushɔn

Di tɛm fɔ de :

Ejekshɔn tɛm : .

Mold opin/klosing tɛm :

Impɔtant fɔ ɔndastand ɛn optimize saykl tɛm .

Fɔ ɔndastand ɛn optimize di injɛkshɔn moldin saykl tɛm impɔtant fɔ sɔm rizin dɛn:

Prodakshɔn Efisiɛns : Ridyusin saykl tɛm de lid to inkris prodaktiviti ɛn ay prodakshɔn autput

Kost sevings : Shorta saykl tɛm dɛn kin rilizɔt fɔ lɔw prodakshɔn kɔst ɛn impɔtant prɔfitabiliti

Prodakt Kwaliti : Optimizing saykl tɛm de ɛp fɔ ajɔst kɔnsistɛns pat kwaliti ɛn ridyus difɛkt dɛn

Kɔmpitishɔn : Efisiɛns saykl tɛm dɛn de mek pɔsin ebul fɔ wok fasta tɛm-to-maket ɛn i de ɛp fɔ mek kɔmpitishɔn dɛn na di industri .

Ki pɔynt dɛn:

Injekshɔn moldin saykl tɛm na di totɛl tɛm fɔ wan kɔmplit moldin saykl .

I inklud injɛkshɔn tɛm, kol tɛm, ples fɔ de, tɛm fɔ kɔmɔt na do, ɛn mold opin/klos tɛm

Optimizing cycle time improves prodakshɔn efyushɔn, ridyus kɔst, ɛn ɛp fɔ mek di prɔdak kwaliti bɛtɛ

Fɔ ɔndastand saykl tɛm na impɔtant tin fɔ mek yu kɔntinyu fɔ gɛt kɔmpitishɔn na di injɛkshɔn moldin industri .

Aw fɔ kɔl injɛkshɔn moldin saykl tɛm .

Ɔndastand saykl tɛm kɔlkyulɛshɔn impɔtant fɔ optimiz injɛkshɔn moldin prɔses. Dis pat de gi wan kɔmprɛhnsiv gayd fɔ no di kɔrɛkt tɛm fɔ di saykl tɛm.

Step-by-step gayd fɔ kɔlkul saykl tɛm

Di tɛm we dɛn de mɛzhɔ injɛkshɔn tɛm .

Rikɔd di tɛm we dɛn nid fɔ du fɔ ful di mold kaviti .

Yuz Injɛkshɔn Moldin Mashin Sɛtin ɔ Prodakshɔn Data .

Tink bɔt matirial flɔ rit, injɛkshɔn spid, ɛn kaviti volyum .

Fɔ no di tɛm we di kol kol .

Asɛs di matirial tayp ɛn pat dizayn .

Evaluate Mold Cooling System Efisiɛns .

Yuz Mold Flow Analysis Software fɔ kɔrɛkt ɛstimɛshɔn .

Ɛstimat di tɛm we dɛn de liv .

Ditarmin adishanal tɛm fɔ kɔmplit sɔlidifikeshɔn .

Bes am pan matirial prɔpati ɛn pat rikwaymɛnt dɛn .

Tipikli shɔt pas kol tɛm .

Kalkul Ejekshɔn Taym .

Factors we de inflɔws di ejeshɔn tɛm:

Akɔntin fɔ mold opin/klos tɛm .

Tink bɔt mold kɔmplisiti ɛn saiz .

Evaluate Molding Machine Kapabiliti fɔ .

Mekɔp di aktual tɛm we dɛn de du di prodakshɔn rɔn dɛn .

Saykl tɛm kɔlkyulɛshɔn fɔmula .

Yuz dis fɔmula fɔ kɔl di totɛl saykl tɛm:

Tɔtɔl Saykl tɛm = injɛkshɔn tɛm + di tɛm fɔ kol + di tɛm we dɛn de liv + di tɛm we dɛn de pul di ejekshɔn + di tɛm fɔ opin/klos di tɛm

Onlain tul ɛn simulshɔn softwe fɔ ɛstimat saykl tɛm .

Bɔku tin dɛn de fɔ mek yu ebul fɔ ɛstimɛt di rayt saykl tɛm:

Kalkyulatɔ dɛn na di Intanɛt .

Mold Flow Analysis Softwea .

Simulate ɔl injɛkshɔn moldin prɔses .

Gi ditayli insayt insay ɛni saykl stej .

Ɛgzampul dɛn: Autodesk Moldflow, Moldex3d

Tul dɛn we gɛt fɔ du wit mashin .

CAE Softwea .

Dɛn tul ya de ɛp di wan dɛn we de mek di tin dɛn fɔ mek di saykl tɛm dɛn fayn, mek dɛn ebul fɔ wok fayn fayn wan, ɛn dɛn de ridyus di kɔst dɛn we dɛn de pe fɔ di injɛkshɔn moldin ɔpreshɔn dɛn.

Factors we de afɛkt injɛkshɔn moldin saykl tɛm .

Bɔku tin dɛn kin afɛkt di injɛkshɔn moldin saykl tɛm. Dɛn kin kategoriz dɛn insay 4 men aspek dɛn: mold dizayn paramita dɛn, prodak dizayn paramita dɛn, matirial sɛlɛkshɔn, ɛn injɛkshɔn moldin prɔses paramita dɛn.

Mold dizayn paramita dɛn .

Dizain fɔ kol : .

Runner ɛn get dizayn :

Nɔmba fɔ di Kaviti dɛn :

Dizayn fɔ Ventin : .

Produk dizayn paramita dɛn .

Di tik we de na di wɔl :

Pat Jɔyometri : .

Material Selection

Melt ɛn kol kwaliti dɛn :

Material tiknes ɛn in impak pan kol tɛm :

| Materials | Cooling Time (sɛkɔn) fɔ difrɛn tiknes dɛn . |

|

|

|

|

|

| 1mm na di 1mm | 2mm na di 2mm | 3mm di 3mm | 4mm na 4mm | 5mm na di 5mm | 6mm na di 6mm |

| ABS na ABS | 1.8 | 7.0 | 15.8 | 28.2 | 44.0 | 63.4 |

| PA6 na di . | 1.5 | 5.8 | 13.1 | 23.2 | 36.3 | 52.2 |

| PA66 we dɛn rayt. | 1.6 | 6.4 | 14.4 | 25.6 | 40.0 | 57.6 |

| PC . | 2.1 | 8.2 | 18.5 | 32.8 | 51.5 | 74.2 |

| HDPE we de na di . | 2.9 | 11.6 | 26.1 | 46.4 | 72.5 | 104.4 |

| LDPE we de na di . | 3.2 | 12.6 | 28.4 | 50.1 | 79.0 | 113.8 |

| PMMA . | 2.3 | 9.0 | 20.3 | 36.2 | 56.5 | 81.4 |

| Pom na di 1999. | 1.9 | 7.7 | 20.3 | 30.7 | 48.0 | 69.2 |

| PP we de na di . | 2.5 | 9.9 | 22.3 | 39.5 | 61.8 | 88.9 |

| PS . | 1.3 | 5.4 | 12.1 | 21.4 | 33.5 | 48.4 |

Tebul 1: Di tɛm dɛn we dɛn kin kol fɔ difrɛn tin dɛn ɛn di tik dɛn .

Injekshɔn Moldin Prɔses Paramita dɛn .

Injɛkshɔn spid ɛn prɛshɔn : .

Di spid we dɛn de injɛkshɔn ɛn di prɛshɔn we dɛn kin gi kin ridyus di tɛm we dɛn kin fil bɔt i kin mek di tɛm we dɛn kin kol kin mek dɛn kol .

Optimizing injection spid ɛn prɛshɔn impɔtant fɔ ajɔst di saykl tɛm we yu want .

Tempratura fɔ mɛlt : .

Mold temperechur : .

Holding tɛm ɛn prɛshɔn :

Envayrɔmɛnt Kɔndishɔn dɛn .

Sok :

Kwaliti fɔ di briz : .

Tɛmprɛchɔ :

Strateji fɔ ridyus injɛkshɔn moldin saykl tɛm .

Ridyus injɛkshɔn moldin saykl tɛm na impɔtant tin fɔ mek di prodakshɔn efyushɔn bɛtɛ ɛn fɔ mek dɛn nɔ spɛn bɔku mɔni. Wi kin ajɔst di shɔt saykl tɛm dɛn bay we wi de optimize difrɛn aspek dɛn fɔ di moldin prɔses. Lɛ wi fɛn sɔm impɔtant strateji dɛn.

Optimizing mold dizayn .

Improving Cooling System Efficiency : .

Optimizing runner ɛn get dizayn :

Fɔ mek di Vɛntin bɛtɛ :

Inkorporet adekwayt ventin in di mold dizayn .

Prɔpa ventin de alaw fɔ efishɔnal ɛya ɛn gas fɔ rɔnawe, ridyus saykl tɛm

Optimizing Produkt Dizayn .

Mentɛn yunifom wɔl tiknɛs :

Simplifying pat jɔyometri : .

Fɔ pik di rayt tin fɔ yuz .

Fɔ pik matirial dɛn wit fasta kol ret :

We yu tink bɔt di tik we yu gɛt :

Fayn-tyunin injekshɔn moldin prɔses paramita dɛn .

Yuz injɛkshɔn we gɛt ay spid :

Optimizing injekshɔn prɛshɔn : .

Kontrolin mold temperechur : .

Mentɛn di bɛst mold tɛmpracha fɔ mek yu ebul fɔ kol fayn fayn wan .

Prɛsis mold tɛmpracha kɔntrol de ɛp fɔ mek di say dɛn we dɛn de kol ɛn i de ridyus di tɛm we dɛn de yuz fɔ mek di sayklɔs tɛm go ɔp ɛn i de mek di saykl tɛm nɔ bɔku .

Minimizing holding taim en preshos :

Invɛstmɛnt insay Advans Ikwipmɛnt .

Fast klamp sistem dɛn : .

Efisiɛns Ɛjɛkshɔn Mɛkanism dɛn : .

Streamlining di injekshɔn moldin prɔses .

Divɛlɔp wan kɔnsistɛns prɔses :

Maksimizing prɔsesin winda : .

Implimentin Sayntis Moldin Prinsipul :

Set ap proses bifo tul chenj :

Monitoring tool temperechur ɛn ventin : .

Analayz tul funkshɔnaliti di tɛm we dɛn de sampul :

Benefit fɔ ridyus injɛkshɔn moldin saykl tɛm .

Optimizing injection molding cycle time de gi bɔku bɛnifit fɔ di wan dɛn we de mek am. Dis sekshɔn de ɛksplɔrɔ di men bɛnifit dɛn we de mek dɛn ebul fɔ mek di prodakshɔn prɔses dɛn izi.

Inkris prodakshɔn autput .

Ridyusin Saykl Taym Direkt Impekt Prodakshɔn Kapasiti:

Di pat dɛn we ay-pa-awa ratio .

Inkris mashin yutilizeshɔn .

Abiliti fɔ mit big ɔda volyum dɛn .

Example: If yu ridyus 10% pan di saykl tɛm, i kin mek yu ebul fɔ inkrisayz ɛni ia autput bay 100,000 yunit fɔ wan ay-volyum prodakshɔn layn.

Lɔwa Prodakshɔn Kɔst .

Shorta saykl tɛm dɛn kin kɔntribyut to kɔst sevings:

| kɔst faktɔ | impak fɔ ridyus saykl tɛm |

| Pawa | 5-15% ridyushɔn pan ɛni pat |

| Wok | 10-20% dikɛshɔn pan man-awa |

| Ovahɛd . | 8-12% ridyushɔn pan fiks kɔst . |

Impruv prodakt kwaliti .

Optimayz saykl tεm dεm kin lid to εnhans kwaliti:

Kɔnsistɛnt matirial prɔpati dɛn .

Ridyus di risk fɔ difɛkt dɛn .

Impɔtant dimɛnshɔnal akkuracy .

Bay we yu minimiz di ɛksplɔshɔn to ɔt ɛn prɛshɔn, shɔt saykl dɛn de ɛp fɔ mek dɛn kɔntinyu fɔ gɛt matirial intɛgriti, we de mek dɛn gɛt spɛshal ɛnd prɔdak dɛn.

Fasta tɛm-to-maket .

Efisiɛns prodakshɔn saykl dɛn Aksɛleret prodakt lanch dɛn:

Kwik protɔtayp itɛreshɔn dɛn .

Rapid skel fɔ prodakshɔn .

Fleksibul fɔ mit di chenj we de apin na di makit dimand dɛn .

Dis agility de alaw di manifakta dɛn fɔ kapitayl pan di chans dɛn we de kam ɛn ansa kwik kwik wan to di kɔnsuma tren.

Enhansed kɔmpitishɔn .

Streamlined prɔses dɛn de gi kɔmpitishɔn edj:

Abiliti fɔ gi shɔt lida tɛm dɛn .

Impruv prayz fleksibiliti .

Kapasiti fɔ handel rɔsh ɔda .

Dɛn tin ya de pozishɔn manifakta dɛn as prɛferɛd saplay dɛn na wan krawd makit.

Energy efficiency .

Ridyus di saykl tɛm dɛn kin ɛp fɔ mek di wok we dɛn de du fɔ mek di sayklɔs kɔntinyu fɔ de:

Lɔwa ɛnaji kɔnsɔmshɔn fɔ wan yunit .

Di kabon futprin we dɔn go dɔŋ .

Alignment wit eko-friendly manufakchurin praktis .

Energy Savings Example:

Annual Production: 1,000,000 Yunit Ɔrijinal Saykl Tɛm: 30 sɛkɔn Ridyus Saykl Tɛm: 25 Sɛkɔn Ɛnaji Kɔnsɔmshɔn: 5 kWh fɔ wan awa Ɔrijinal Ɛnaji Yuz: 41,667 kWh Optimayz Ɛnaji Yuz

Dɔn

Optimizing injection molding cycle time na impɔtant tin fɔ mek dɛn ebul fɔ mek efyushɔn ɛn fɔ mek dɛn ebul fɔ kɔmpit. Bay we dɛn de impruv strateji dɛn lɛk fɔ mek di mold dizayn fayn, fɔ pik di rayt tin dɛn, ɛn fayn fayn prɔses paramita dɛn, biznɛs dɛn kin ebul fɔ gɛt bɔku bɛnifit dɛn. Dɛn tin ya na di autput we de go ɔp, di kɔst we de dɔŋ, di bɛtɛ kwaliti, ɛn di fast we di makit de ansa kwik kwik wan.

Short cycle times de mek yu ebul fɔ yuz mɔ ɛnaji ɛn mek dɛn ebul fɔ du mɔ fɔ mek dɛn ebul fɔ mek di prodakshɔn schedule. Dis kɔntinyu prɔses fɔ ɔptimayzeshɔn pozishɔn kɔmni dɛn fɔ lɔng tɛm sakrifays na di dinamik manufakchurin land skay.

Di wan dɛn we de mek di tin dɛn fɔ prɔyoritɛt saykl tɛm ridɔkshɔn fɔ mek di opareshɔn dɛn izi, fɔ mek dɛn gɛt mɔ prɔfit, ɛn fɔ mek dɛn mit di tin dɛn we dɛn de aks fɔ na di makit we de chenj. Kɔntinyu fɔ wach ɛn ajɔst na di men tin fɔ mek dɛn kɔntinyu fɔ wok fayn fayn wan na di injɛkshɔn moldin prɔses.