Filastik Yin allurar rigakafi shine mabuɗin hanya don ƙirƙirar abubuwan daidaitawa. Amma me ya ci nasara? Da mold core da rami. Waɗannan abubuwan haɗin suna samar da fasali na ciki da waje na samfuran samfuran da aka gyara.

A cikin wannan post, zaku iya koyon yadda cibiya da kuma rami suna aiki tare, me yasa suke da mahimmanci, da bambance-bambancen su.

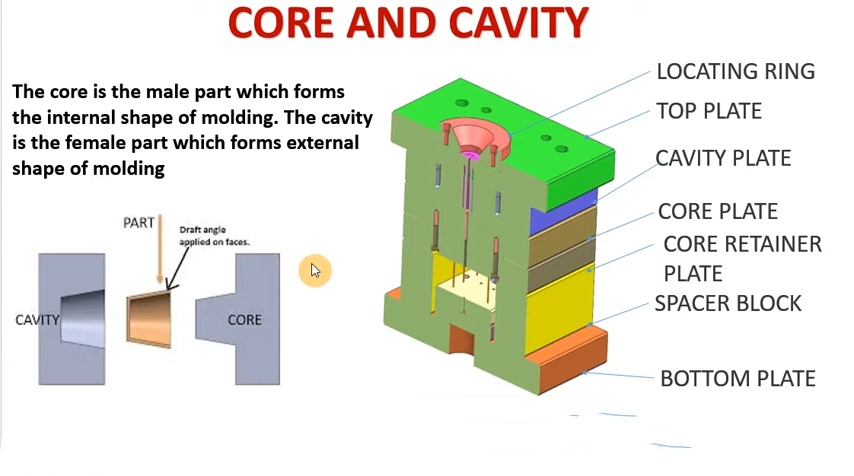

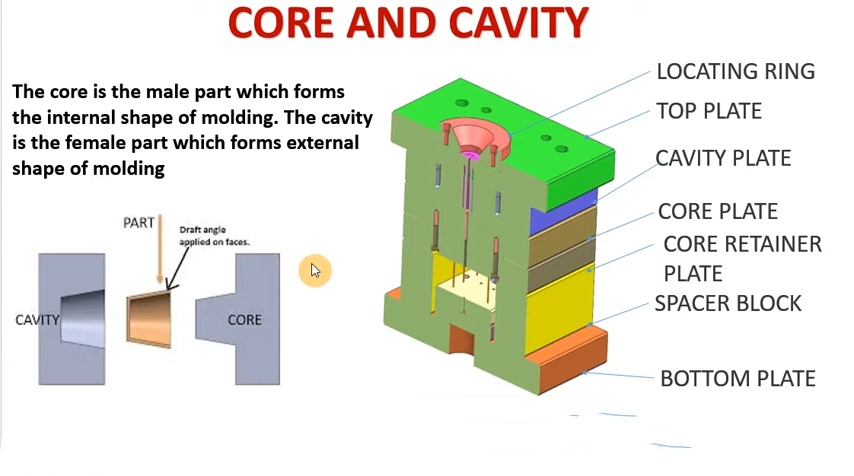

Core da rami: Ma'anar da Matsayi

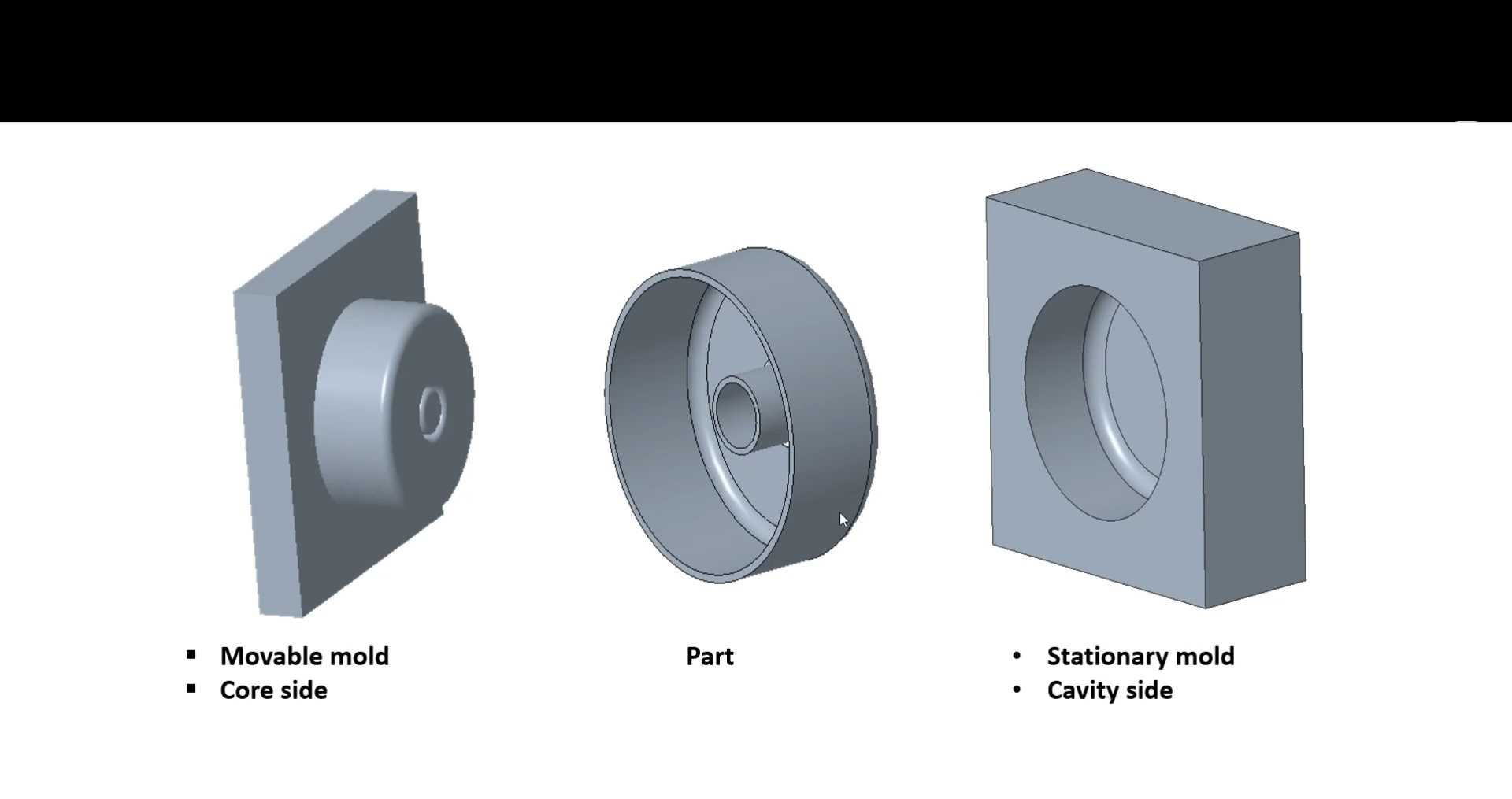

Da mold core

Da mold Core fasali na ciki fasali na allurar rigakafi. Yana da mahimmanci don ƙirƙirar sassan tsayayyen ɓangare da ƙayyadaddun tsarin ciki. A lokacin aiwatar da allura, da zuciyar tana zaune a cikin B-gefen na mold. Yana motsawa tare da tsarin ejecor, tabbatar da sassan saki da kyau bayan sanyaya.

Mabuɗin abubuwa game da molds cores:

Tsara Cutar ciki da cikakkun bayanai

Yawanci an yi shi daga ƙarfe mai ƙarfi

Na bukatar ingantaccen inji don daidaito

Sau da yawa sun haɗa da tashoshin sanyaya don samarwa da sauri

Da m kogin

Mold ciyayi sun ayyana fasali na waje na sassan da aka gyara. Suna da alhakin abubuwan da aka yi na waje da girma. Kawancen ya ci gaba da kasancewa a cikin gefen mold a lokacin samarwa. Suna ƙirƙirar abokan cinikin da ake gani suna hulɗa da su.

Muhimmin bangare na cavities na mold:

Siffar filaye na waje da rubutu

Sau da yawa an goge shi don gama da ake so

Dole ne a yi la'akari da kayan shrinkage

Hada tsarin gating don kwarara na filastik

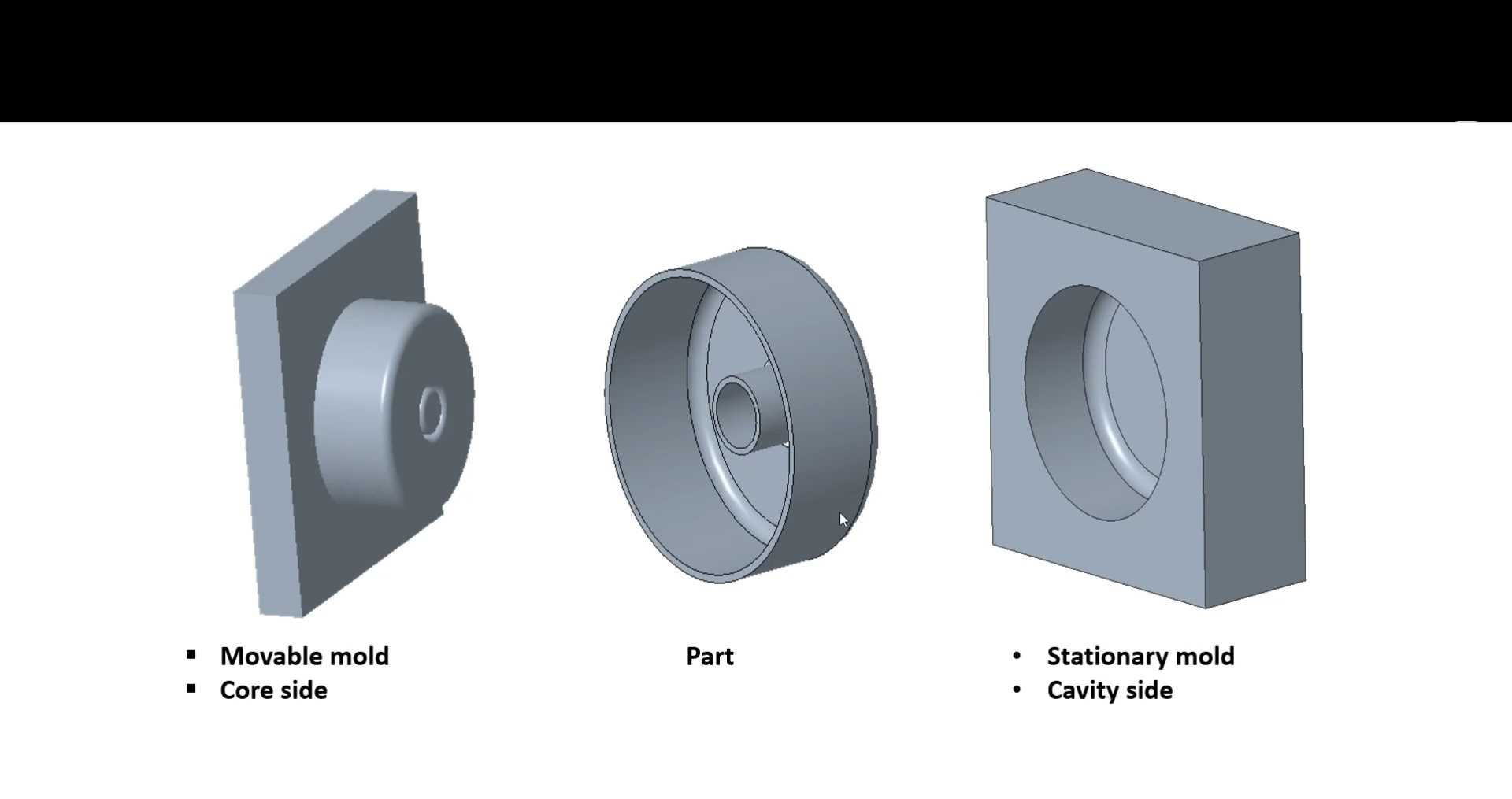

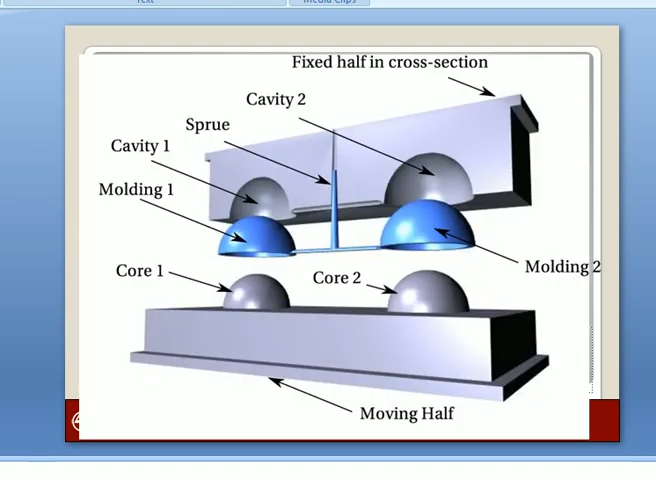

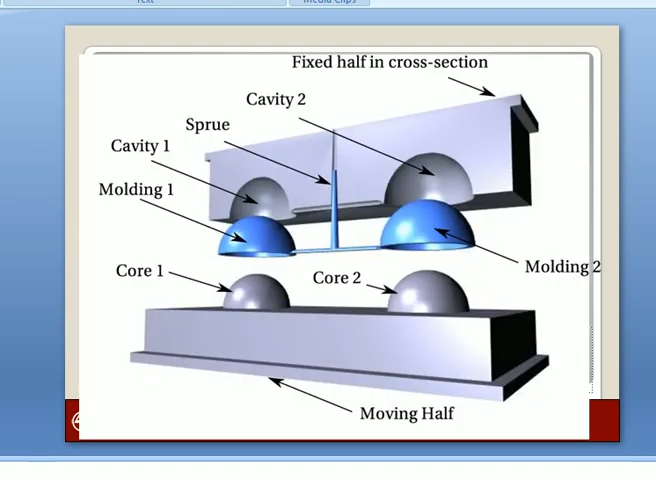

Yaya core da rami aiki tare

Cores da Caves sun hada don samar da cikakkun sassan. Lokacin da ƙwararrun rufe, suna ƙirƙirar watsar da komai a cikin samfurin samfurin ƙarshe. Molten filastik ya cika wannan sarari, yana ɗaukar fasalin ɓangarorin biyu.

Tsarin hulɗa:

Mold rufe, a daidaita cibiya da rami

Filastik injected a cikin kafa

Kayan sanyi da karfafawa

Mold yana buɗewa, Core yana motsawa tare da tsarin ejector

Kashi na saki, riƙe fasali daga biyun kuma rami

Nau'in kayan molds da cavities

Kafaffen ka'idodi da cavities

Kafaffen ka'idodi da masu wahala sune tushe na allurar rigakafi. Suna ci gaba da kasancewa a ko'ina cikin tsarin samarwa.

Daidaitattun ka'idodi da cavities

Waɗannan abubuwa na asali ne da ke cikin ƙarfe mai ƙarfi. An tsara su don dogon samarwa yana gudana da daidaituwa sashi mai inganci.

Mai sauki core / rami

Amfani da sassan tare da zane madaidaiciya. Suna da kyau ga samfuran ba tare da hadaddun kayan ciki ba.

Multi-Core / rami

Waɗannan molds suna haifar da sassa da yawa a cikin sake zagayo. Suna haɓaka haɓaka haɓaka amma suna buƙatar ƙira mai hankali don daidaita cikawa.

Canzawa cores da kuma cavities

Abubuwan da ke canzawa suna ba da sassauci a samarwa. Suna ba da izinin sauƙaƙe da bambancin samfur.

M cores da cavities

Za'a iya canzawa don samar da zane daban-daban. Suna rage farashin kayan aiki don iyalai masu kaya.

Zamewa cores da cavities

Suna motsawa cikin mold don ƙirƙirar fasali mai rikitarwa. Abubuwan da aka gyara na zamewa suna da mahimmanci don sassan da ke cikin ruwan tabarau ko cikakkun bayanai.

Saka cores da cavities

Ana amfani da waɗannan don ƙirƙirar takamaiman fasali ko haɗa kayan da aka riga aka kafa. Ana amfani da su sau da yawa don abubuwan haɗin da aka sanya ko kayan musamman.

CORES

Matsakaicin Cores suna da mahimmanci ga sassa tare da zaren ciki ko wuraren hadaddun sassan. Suna kwangila don ba da izinin eudtion, sannan a faɗaɗa don sake zagayowar gaba.

Key fa'idodi:

Uncreting cores da cavities

Waɗannan abubuwan haɗin suna juyawa don sakin ɓangarorin da siffofin da aka yiwa. Suna da mahimmanci don kamun murfin dunƙule, kayan ruwa, da samfuran iri ɗaya.

Abvantbuwan amfãni:

Samar da cikakkun zaren a mataki daya

Kawar da Ayyukan Sakandire

Haɓaka haɓaka samarwa don sassan zaren

Tsararren molds cores da cavities

Kyakkyawan abubuwan ƙira

Kirkirar ingantattun kayan masarufi da cavities yana buƙatar la'akari da abubuwa da yawa:

Kashi na Geometry: Coparfafa nau'ikan hadaddun fasali suna buƙatar madaidaicin core da tsari.

Zaɓin Kayan Aiki: Jagoranci daban-daban suna buƙatar takamaiman kayan molds da ƙarewa.

Shrinkage: Asusun don shrinkage don tabbatar da daidaito daidai.

Rubutun da ya dace: kusurwoyi da suka dace suna sauƙaƙe kayan sassauƙa.

Tsarin kiyayewa: Tsarin cire kayan maye ba tare da lalacewa ba.

Tsarin sanyaya: inganta tashoshin sanyaya don daidaitaccen bangare.

Jagorori

Bi waɗannan jagororin don nasarar mold mold da zane:

Kayan aiki

Kula da kauri a cikin sashin.

Yana hana warping, alamomin rami, da kuma sanyaya sanyaya.

Dragles da ya dace

RADII da fillet

Venting da gating

Kalubalen gama gari da

| ƙalubalen | gargajiyar |

| Lura | Yi amfani da abubuwan da aka sanya ko abun ciki |

| Ganyen bakin ciki | Aiwatar da cascade ko gunding |

| Weld Lines | Inganta Katunan Great da Yanayin Yanayin Yanayin |

| Alamar ruwa | Daidaita tsarin sanyaya da kauri |

Zabi na abu don Core da Shirye-shiryen

Muhimmancin zaɓin abubuwan

Zabi kayan hannun don daidaitattun kayan mold da kuma rashin ƙarfi yana da mahimmanci. Yana da kai tsaye kai tsaye rayuwa da kuma farashin samarwa. Zaɓin da ya dace yana tabbatar da karkara, daidaici, da tsada.

Abubuwan da aka saba amfani da su

Abubuwa da yawa sun shahara sosai ga daidaitattun abubuwan da suka dace

P20: M karfe tare da kyakkyawan mama

738: Inganta kaddarorin sama da P20

Nak80: Madalla da Aikace-aikacen Polish

2316: Dalibai don Rikicin Corirƙira

2344: ya fi dacewa da samar da girma

Samar da kayan samarwa

Zabin kayan ya bambanta dangane da ƙarar samarwa:

Hanya-girma-girma ya tabbatar da saka hannun jari a cikin kayan masarufi. Suna yawan rayuwa da ƙuntata da rage farashi na dogon lokaci.

Halayen kayan

Lokacin zaɓi Kayan Aiki, Yi la'akari da waɗannan kaddarorin:

| halaye | Muhimmancin |

| Sa juriya | Tsawanta rayuwa |

| Tauri | Yana hana chipping da fatattaka |

| Polishan kadari | Cimma burin gama |

| Ƙanƙanci | Ya tsinta nakasa a karkashin matsin lamba |

Sa juriya

Kayan aiki tare da babban juriya yana kula da daidaito daidai lokacin. Suna da mahimmanci don samar da kar girma.

Tauri

Abubuwan da ke da wuya kayan da ke tsayayya da yanayin maimaita hanyoyin haɗarin. Suna rage haɗarin rashin nasarar da aka saba.

Polishan kadari

Wasu kayan yafa goge fiye da wasu. Wannan yana da mahimmanci ga sassan sassan da ke buƙatar babban mai yawa.

Ƙanƙanci

Abun da wuya wuya tsayayya da nakasarwa a karkashin allura matsa lamba. Suna kula da daidaitaccen tsari amma na iya zama da wuya a injin.

Masana'antar masana'anta na mold core da rami

1. Shiri na abu

Tsarin yana farawa ne tare da zabi kayan da suka dace da kayan aikin. Wannan matakin yana da mahimmanci don tabbatar da ingancin mold da tsawon rai.

2. Milly na al'ada

Shauna na farko ya ƙunshi:

Waɗannan ayyukan suna samar da tushe na tsarin ƙirar.

3. Cnc Mactining

Yanke mai rauni yana ba da ma'anar asali na zuciyar da rami. Fasahar CNC tana tabbatar da daidaito da inganci a wannan matakin.

4. Jiyya mai zafi

Wannan matakin ya inganta:

Ƙarko

Sa juriya

Ado mai kyau

Amincewa da zafi yana da mahimmanci don tsayar da rayuwar ƙira.

5. Nika da ƙarewa

Daidaitaccen abinci:

6. CNC Karo

Ayyukan babban aiki sun haɗa da:

Wadannan matakan suna ƙara fasali mai mahimmanci ga abubuwan haɗin ƙirar.

7. Yanke waya

Wire Edm yana haifar da fasali irin su:

Ramuka na lian

Ejector PIN

Prounds inticate

8

EDM Excels a samar da:

Lafiya grooves

Kunkuntar slots

Madaidaici mai ƙarawa

Yana da kyau don fasali mai wahala a al'ada.

9. Polishing m

Formace ta gama gari ya ƙunshi:

10. Majalisar

Wannan matakin ya hada da:

Maƙƙarfan taro yana tabbatar da kyakkyawan tsari.

11. Gwaji

Gwajin da aka kammala ya ƙunshi:

Samar da sassan samfurin

Dubawa ingancin

Tabbatar da aikin da

Wannan matakin na karshe na tabbatar da mold ɗin yana shirye don samarwa.

Matakai daban-daban na m

Tsarin rashin daidaituwa ya ƙunshi yin hulɗa a hankali tsakaninta tsakaninta da kogon. Fahimtar wannan sassa yana da mahimmanci don fahimtar cikakken ikon yin gyara.

Mataki na 1: allura

Gran filastik sun shiga sararin samaniya da aka kafa ta hanyar kogin ƙura. Wannan sararin samaniya, wanda aka kirkiro da ainihin injiniyan injiniya da rami, yana bayyana siffar samfurin ƙarshe.

Mabuɗin Key:

Mataki na 2: Sanyaya da Kwarewa

Corwararrun mold ya yi daidai da kogon lokacin wannan lokaci. Kamar yadda filastik yayi sanyi, yana ɗaukar takamaiman siffar haɗin haɗin haɗin.

Muhimmin fannin:

Mataki na 3: Budewa da Etione

Bayan an tabbatar da karbuwa, karfin mold. Samfurin, yanzu m, an fitar da shi daga zuciyar ta tsarin kare.

Cikakken bayani:

Mold yana buɗewa

Core mai jan hankali

Ejector Pins Kunna

Kashi daga Core

Mold kogon

A duk faɗar waɗannan matakai, kogon ƙwanƙwasa ya kasance tsaye. Yana ba da ingantaccen tunani don fasalolin waje na ɓangare.

Ayyukan kogon:

Wannan aikin da aka yi da shi yana tabbatar da daidaito, samar da sassa masu inganci. Intanit tsakanin CORE da kuma rami ne na asali ga nasarar aiwatar da ingantaccen ayyukan gyara.

Bambance-bambancen matsa lamba da aka jimre ta hanyar mold core da kuma rami

Matsakaicin ƙarfin da kogon yana fuskantar matakai na matsin lamba yayin allurar. Wadannan bambance-bambance suna da mahimmanci tasiri wani sashi da kuma tsawon rai.

Mold kogon: Yankin matsin lamba

Kogon yana tsallake mafi girman matsin lamba ga dalilai da yawa:

Mabuɗin abubuwa game da matsin lamba:

Na iya kai dubban PSI

Ya bambanta da kayan abu da kayan zane

Yana shafar gamsuwa da daidaitaccen daidaito

Mold Core: ƙaramin matsin lamba

Sabanin haka, ainihin ainihin yana jure ƙananan matsin lamba. Ayyukan farko sun hada da:

Core matsin lamba na matsin lamba:

Gabaɗaya ƙasa da matsanancin iska

Mai da hankali ga fasalolin waje

Tasirin ingancin inganci da cikakken bayani

Tablewararrun Distress Drogs

| Matsakaicin | Matsayi | na Farko |

| Kogo | M | Tabbatacciyar amincin ciki |

| Cibiya | Saukad da | Bayyanar waje na waje |

Fahimtar wadannan bambance-bambancen matsin lamba yana da mahimmanci ga:

Tsarin ƙira da ya dace

Zabin Abinci

Tsarin tabbatarwa

Bambancin Amfani da Amfani da Amfani da Ingantaccen Tsaro tsakanin Mods Core da Kogara

Mold kog: mafi girma bukatun

Mower muryar tana fuskantar babbar damuwa yayin alluna mai amfani:

Waɗannan abubuwan suna haifar da ƙarin buƙatun kiyayewa akai-akai:

Binciken yau da kullun

Lokaci na lokaci

Ƙarin sauyawa akai-akai

Masu kera suna tsara tsarin kula da kogon don tabbatar da ingancin samfurin.

Mold Core: Batun Kayayyaki

Sabanin haka, m mold yana jin daɗin rawar da ke neman:

Wannan yana haifar da:

Cikakken Gyarawa

Mabawa

Ƙananan farashi na gaba

yarjejeniya

| daidai | | Kwatanta |

| Fitar da matsin lamba | M | Saukad da |

| Saka kudi | Da sauri | M |

| Rayuwar Ma'aikata | Gaɓa | Yai tsayi |

| Mitawar Kulawa | Sama | Saukad da |

| Canji canzawa | Fiye da sau da yawa | Kadan da yawa |

Tasiri kan samarwa

Fahimtar wadannan bambance-bambance suna taimakawa masu kera:

Jadawalin shirin aiwatarwa

Kasafin kuɗi don sauyawa daidai

Inganta ingancin samar da aiki

Kulawa na yau da kullun yana tabbatar da ingancin samfurin. Karancin hadadden tsari mai sauqi yana rage raguwa da farashi.

Hanyoyi don rarrabe mold da rami

Rarrabe tsakanin madaidaicin cores da kuma cavities yana da mahimmanci don ingantaccen ƙirar ƙira da kiyayewa. Yawancin fasalulluka masu yawa suna taimakawa gano abubuwan haɗin:

Bayyanawa

Mold cavities yawanci nuna:

Smoother saman

Daban-daban

A bayyane suka dawo

Mold cores sau da yawa suna nuna:

Ruugher textures

Ramuka na bayyane

Yankan alamomi

Wadannan halaye na gani suna ba da alama mai sauri a yawancin lokuta.

Abubuwa masu tsari

Tsarin rami sun hada da:

Abun Kayayyakin Core:

Rabuwa saman

Motsa hannayen riga

Ejector Pin Ramuka

Nauyi da kuma kayan duniya bambance-bambancen

| yanayi | rauni | mai |

| Nauyi | Gabaɗaya wuta | Yawanci nauyi |

| Abu | Wuya, mai tsauri (misali, mold karfe) | Ciza baƙin ƙarfe, karfe, allon |

Abubuwan da za a iya aiwatar da tsarin mulki da aikin kowane bangare.

Marking da kuma ganowa

Masu kera suna amfani da takamaiman alamomi:

Cire:

'F ' (gyara gefen)

'1 ' (rabin farko)

Core:

'R ' (gefe mai cirewa)

'2 ' (rabi na biyu)

Waɗannan alamun suna sauƙaƙe Majalisar da kiyayewa.

Hanyoyin bincike na inganci don daidaiton mold

Tabbatar da ingancin ƙarfin abu mai mahimmanci yana da mahimmanci don samar da madaidaicin alluna. Bi waɗannan matakan don ingantaccen bincike:

Ana shirya micrometer mai zurfi

Kafin amfani:

Duba sassauci na silinda

Tabbatar da motsi mai santsi na dunƙule

Tabbatar da amincin Na'urar Kulle

Zabi Kayan Aiki

Tsarin daidaitawa

Yi amfani da Tsarin Tsabtace na Tsabtace

Tsabtace rarar mai tsabta da kuma aunawa surface

Tabbatar da daidaitaccen daidaitaccen matsayin

Dabarun fahimta

Ga ramuka na makafi da tsagi mai zurfi:

Babban ma'aunin diamita

A lokacin da rami diamita ya wuce bitar micrometer:

Yi amfani da farantin suttura

Tabbatar da farantin yana da tsabta da lebur

Dauki ma'auni da yawa don daidaito

Binciken Binciken

| mataki | Mataki | mataki |

| 1 | Duba ayyukan micrometer | Yana tabbatar da daidaitattun karatu |

| 2 | Zaɓi sanda mai dacewa | Wasikar bincike na buƙata |

| 3 | Mai tsabta da daidaitawa | Yana samar da ingantaccen sifili |

| 4 | Yi amfani da dabarar kulawa | Yana hana lalacewar kayan aiki da sashi |

| 5 | Daidaita da manyan diamita | Yana kunna daidaitaccen ma'auni na kowane fasali |

Kiyayewa da matsala

Ayyukan gyara na yau da kullun

Kula da kyau na molds cores da kuma rashin ƙarfi yana tabbatar da tsawon rai da samar da inganci.

Tsaftacewa da lubrication

Cire saura bayan kowane samarwa

Aiwatar da abubuwanda suka dace don motsawa

Yi amfani da masu tsabta marasa hankali ga masu hankali

Dubawa da gyara

Batutuwa na yau da kullun da mafita

| ba | sa haifar da | bayani |

| Sa | Gogewa yayin gyaran | Yaren mutanen Poland ko Sake shiga |

| Lahani | Kayan aikin sunadarai | Aiwatar da kayan kariya |

| Lalacewa | Babban abin da ke gudana | Sake fasalin tsarin Gating |

| Ɓarna | Mishandling ko haɗari | Sauya abubuwan da suka lalace |

Matakan kariya

Mika rayuwa ta gamsuwa da waɗannan ayyukan:

Yi amfani da kayan molds da suka dace

Inganta tsarin sanyaya

Aiwatar da ingantaccen iska

Horar da masu aiki a daidai hanyoyin

Nasihu na Life Feed

Kulawa da lokacin hayaki don hana sama

Juya molds don koda sa rarraba

Adana molds yadda yakamata lokacin da ba ayi amfani ba

Ƙarshe

Mold cores da kuma zalunta suna da muhimmanci ga allurar. Suna siffar sassa, tabbatar da daidaito, kuma suna shafar haɓaka samarwa. Masu zane-zane, injiniyoyi, da masana'antu su mai da hankali kan zaɓi na abu, ingantacce, da tabbatarwa.

Masu sana'ai suna amfana daga bincike na yau da kullun da kuma matsala ta ci gaba. Waɗannan ayyukan suna tsawaita rayuwa da haɓaka haɓakar samarwa.