Tunda farkon masana'antar kera motoci a ƙarshen karni na 19, masana'antar masana'antu sun kasance da karfi a bayan girma da nasara. Daga gabatarwar layin taron da Henry Ford a cikin 1913 zuwa hauhawar atomatik a cikin shekarun da suka gabata, masana'antar kera tau ta ci gaba da biyan bukatun duniya mai canzawa.

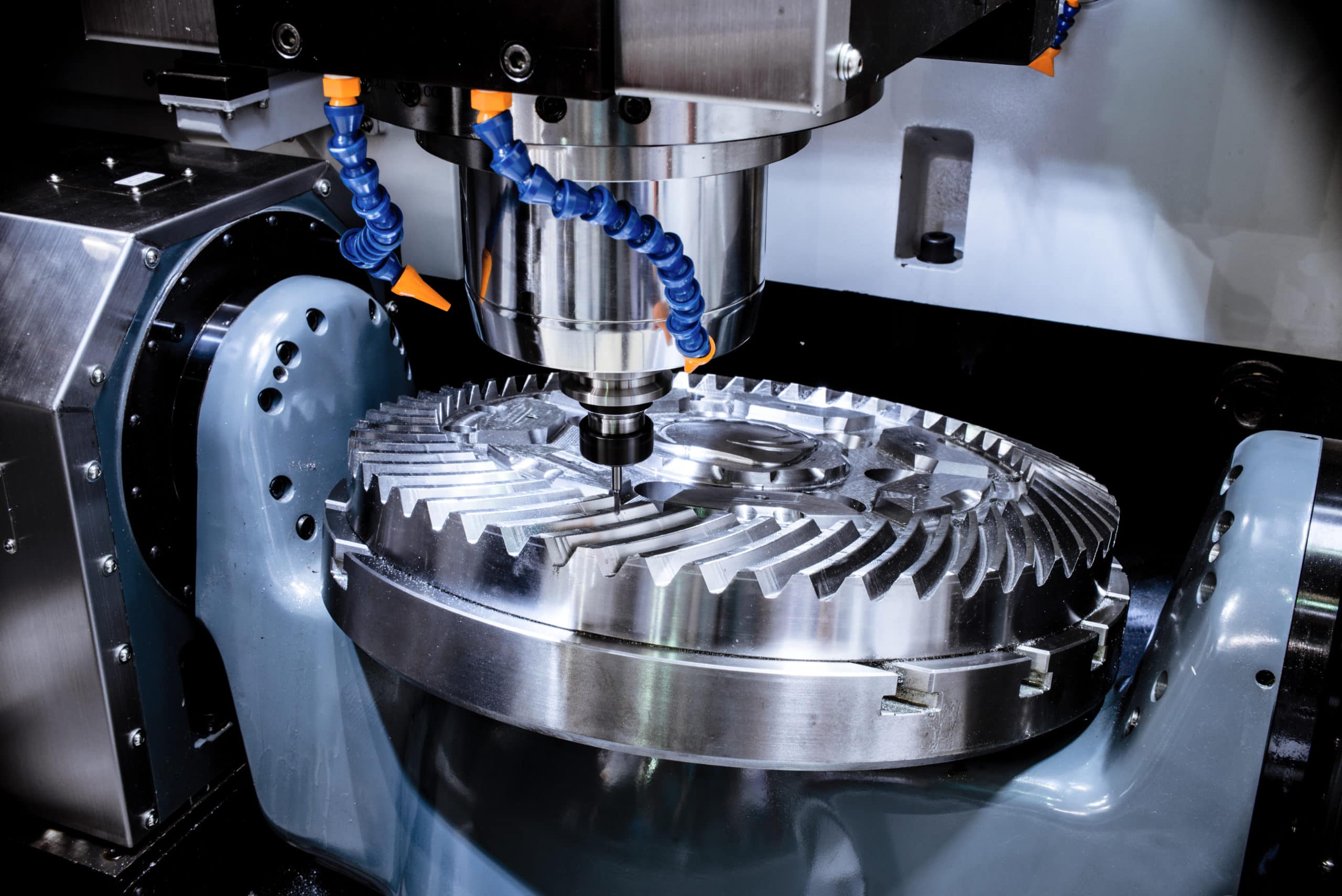

A yau, Kamfanin CNC ya fito a matsayin wani muhimmin wani muhimmin masana'antu na zamani, yana ba da samar da babban inganci, daidai, da sassa masu haɓakawa da maimaitawa.

Wannan talifin zai bincika mahimman kayan masarufi na cikin CNC na mahara a cikin masana'antar kera motoci kuma yadda ta sauya motocin da aka samar.

Menene Kaman CNC?

Kamfanin CNC, gajere don kiran kwastomomi na kwamfuta, tsari ne wanda yake amfani da kayan aiki da kayan yankewa tare da babban daidaito da maimaitawa. Wannan fasaha ta sauya masana'antar kera ta hanyar samar da samar da hadaddun, abubuwan ingantattun ingantattun abubuwa a cikin tsari mai inganci da inganci.

Yadda CnC Maca suke Aiki

Injinan CNC suna aiki ta hanyar bin umarnin da aka riga aka tsara, wanda aka sani da G-Lambar, wanda ke jagorantar kayan aikin don cire kayan daga madaidaicin hanya da sarrafawa. Tsarin ya shafi matakan masu zuwa:

1. Tsara: Injiniyoyi suna ƙirƙirar samfurin 3D na ɓangaren da ake so ta amfani da Software (ƙirar kwamfuta).

2. G-Code tsara: Daga nan sai aka canza tsarin CAD zuwa CODE ta amfani da Software (masana'antu na taimako) software.

3. Saita: Aikin yana da aminci a kan injin CNC, kuma an sanya kayan aikin yankan yankan.

4. Kashewa: na'urfin CNC yana karanta G-lambar kuma yana aiwatar da motocin da aka tsara, cire kayan daga kayan aiki kamar yadda aka ƙayyade.

5. Ganawa: Da zarar an cire tsarin mikin, an cire ɓangaren da aka gama daga injin, an bincika, da duk wani bayan aiki na gaba (kamar tsabtatawa) ana yin su.

Nau'in Makullin CNC da aka yi amfani da su a cikin masana'antar kera motoci

Masana'antu mai kayatarwa sun dogara da injin CRN na CNC don samar da kayan aikin da yawa da ake buƙata don masana'antar abin hawa. Wasu nau'ikan nau'ikan da aka fi haɗa su:

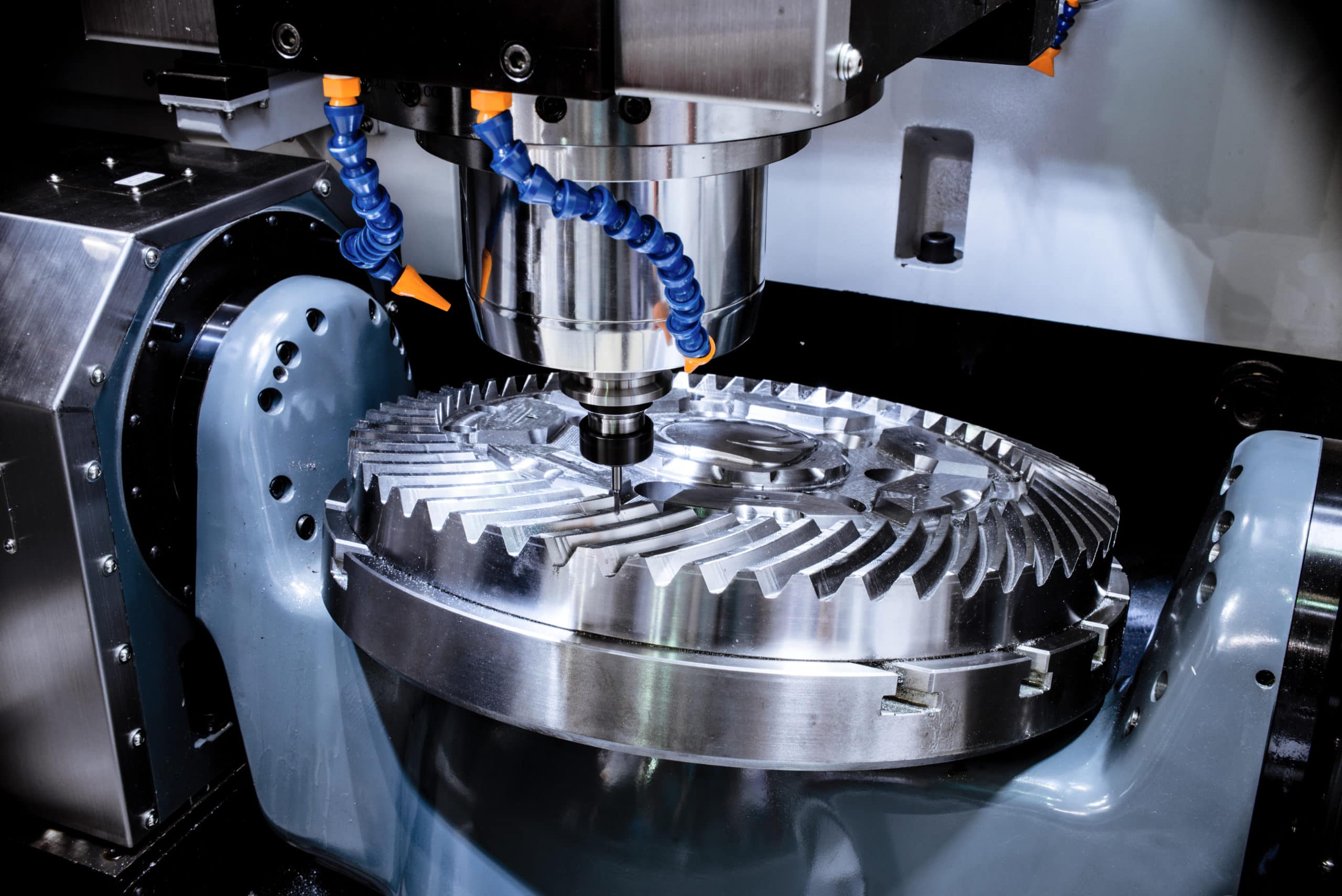

1. Injinan miliyoyin injina : Wadannan injina suna amfani da kayan aikin yankan kayan maye don cire kayan daga kayan aikin, samar da fasali kamar ramuka, ramuka, da aljihuna. Suna da kyau don samar da kayan aikin injin, sassan watsa labarai, da kuma abubuwan dakatarwa.

2. Hakanan an san sujunansu na CNC : Waɗannan wuraren wasan CNC, waɗannan injunan suna jujjuya kayan yayin cire kayan silima yayin da silinda suke cire kayan, busasshiyar, da ɗaukar kaya.

3. Cnc Grinding injunan : Wadannan injunan suna amfani da ƙafafun abarsu su cire adadi mai yawa daga kayan aikin, cimma m jure da gama gari gama gari. Ana amfani dasu musamman don samar da damar da ke da goron ruwa, kamami, da sauran kayan aikin babban daidaitawa.

4. CnN Laser yankan inji injuna : Wadannan injunan suna amfani da lauyoyin da suka fi karfi da aka yanka, rawar jiki, ko kuma alamu kayan aikin kayan ƙarfe, kamar su bangarorin jiki.

Ta hanyar leveringarfin iyawar wadannan injina na CNC daban-daban na iya haifar da daidaitattun kayan aiki tare da daidaito mai yawa tare da daidaito, ingantaccen aiki zuwa manyan motocin samarwa da kuma manyan hanyoyin samar da ingantattu.

Abvantbuwan amfãni na Cnc Mactining don masana'antar kera motoci

Motocin CNC ya zama kayan aikin da ba makawa a masana'antar kera motoci, bayar da fa'idodi da yawa waɗanda suka sauya tsarin masana'antu. Daga daidaito da daidaito ga atomatik da cigaba, mikikan Cinc ya tabbatar da zama wasan kwaikwayo don masana'antun sarrafa motoci.

Daidaici da daidaito

Daya daga cikin mafi mahimmancin fa'idodi na CNC Motocing shine iyawarta don samar da sassan da daidai daidai da daidaito. Wannan yana da mahimmanci a cikin masana'antar kera motoci, inda har ma da 'yar karamar karkacewa zata iya samun sakamako mai tsanani akan aikin abin hawa da aminci.

1. Tsanani : Injinan CNC na iya samun haƙurinsu kamar yadda ± 0.0001 inci, tabbatar da cewa sassa sun dace tare da aiki kamar yadda aka nufa.

2. Daidaitawa cikin kayan aiki : Kamfanin CNC yana ba da tabbacin sakamako mai daidaituwa da yawa, rage haɗarin da kowane bangare ya cika daidai.

Automation da Inganci

Cnc Mactining shine tsari mai sarrafa kansa, wanda ya fassara zuwa Ingantaccen Ingantaccen aiki da aiki masana'antu.

1. Rage kudin aikin aiki : ta atomatik aiwatar da aikin injin din, masana'antun na iya rage farashin aiki da ke hade da ayyukan da aka yi na'am.

2. Lokacin samar da sauri : injunan CNC na iya yin aiki da manyan abubuwan da suka fi yawa tare da karamin downtime, masu karbar kerawa don samar da sassan da sauri fiye da hanyoyin da suka shafi na al'ada.

3. Aikin CNN : Motocin CNC na iya gudana ci gaba, sa'o'i 24 a rana, kwana 7 a mako, ƙara haɓakar fitarwa da rage tasirin sakamako.

Sassauƙa da daidaitawa

Cinc Mactining yana ba da sassauƙa da daidaitawa, ba da damar masana'antun sarrafawa da sauri don karɓar buƙatun kasuwa da sauri don canza abubuwan canzawa da haɓaka abubuwan haɗin.

1. Ikon samar da hadaddun geometries : injunan CNC na iya sauƙaƙe hadadden tsare-tsaren mutane, gami da kulawar da aka haɗe, yana sa su zama masu samar da kayan aikin ci gaba.

2. Canje-canje na kayan aiki na sauri : Injinan CNC suna ba da damar saurin kayan aiki na kayan aiki, waɗanda ke ba da masana'antun masana'antu don canzawa tsakanin tsari daban-daban da kayan tare da downtime downtime.

3. Ka'idoji da abubuwa daban-daban : Motocin CNC ya dace da kewayon kayan da yawa, ciki har da farji, masu kera masana'antu don zaɓar mafi kyawun kayan ga kowane aikace-aikacen.

Tasiri

Duk da farkon saka hannun jari a cikin injunan CNC, fasaha tana ba da tanadi mai kuɗi masu tsada a cikin dogon lokaci, yana sanya shi zaɓi mai kyan gani don masana'antun sarrafa kansa.

1. Rage kayan sharar gida : Motocin CNC shine ingantaccen tsari wanda ya rage yawan kayan sharar gida, rage farashin kayan ƙasa da tasirin yanayi.

2. Rayayyen kayan aiki na CNC Amfani da Kayan Kayayyakin Kayan yankunan yankunan yankan da kayan aikin kayan aikin, wanda zai iya mika rayuwar kayan aiki da rage farashin kayan aikin akan lokaci.

3. Yawan ƙananan kayayyaki don sassan girma : Motocin CLN yana da tsada musamman don haɓakar haɓaka na farko yana gudana, kamar yadda farashin saiti na farko an shimfiɗa shi akan adadin sassan.

Ta hanyar ɗaukar daidai, ingantaccen aiki, sassauci, da kuma ingancin masana'antu na iya samar da ingantattun masana'antu masu inganci.

Aikace-aikacen CNC na CNC a cikin masana'antar kera motoci

Motsin CNC yana taka muhimmiyar rawa wajen samar da abubuwan haɗin kayan aiki, daga sassan injin don dakatar da tsarin. Daidai da aiki, da kuma ma'abta suna sanya shi kayan aiki na yau da kullun don masana'antun da suke neman ƙirƙirar manyan sassan. A wannan bangare, zamu bincika wasu manyan aikace-aikacen aikace-aikacen CNC a cikin masana'antar kera motoci.

Abubuwan injiniyoyi

Injin shine zuciyar kowane abin hawa, kuma Motocin CTN yana da mahimmanci a samar da yawancin kayan aikinta masu mahimmanci. Ga wasu 'yan misalai:

1. Ana amfani da kayan silinda : Ana amfani da Motar Kayayyakin Geometries da siffofin fasali na shugabannin silinda, irin su bawul ɗin bawul, da wurare masu sanyaya, da wurare masu sanyawa. Daidai da daidaito sun cimma nasarar ta hanyar Kamfuraren CNC don tabbatar da ingantaccen aikin injiniya da inganci.

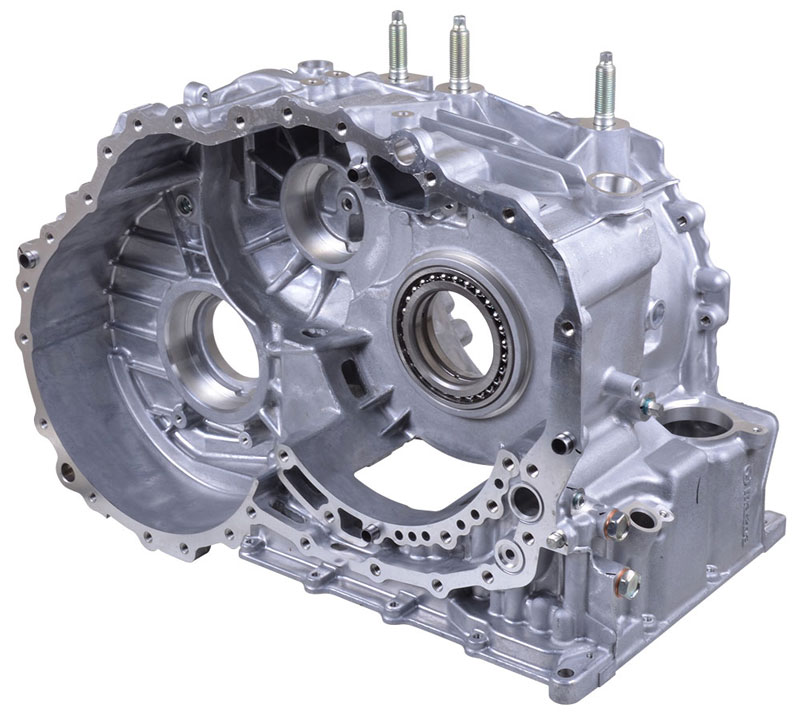

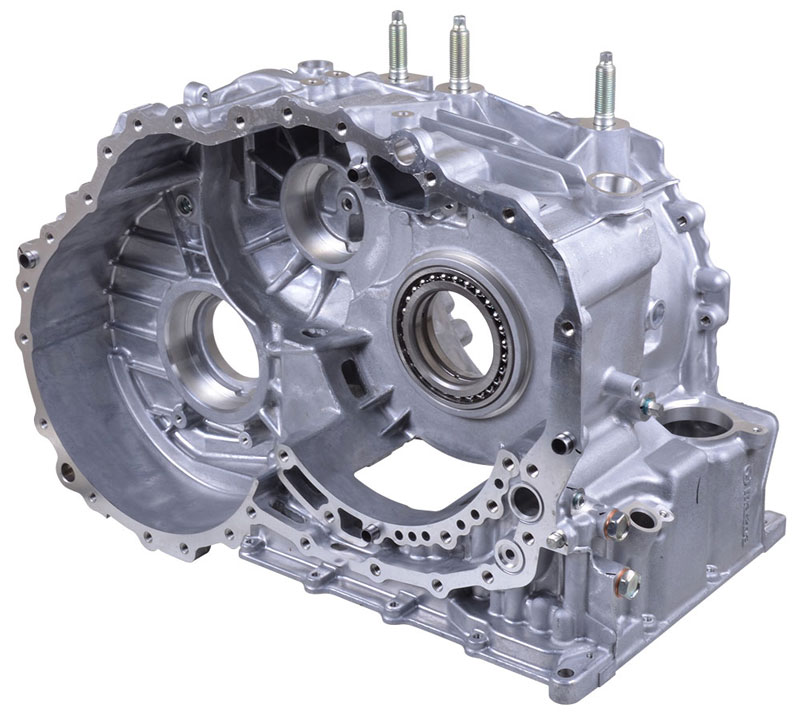

2. Tubalan injiniya : Ana aiki da Motocin CNC don ƙirƙirar geomet na ciki na tubalan injiniyoyi, gami da silinda, manyan masu ɗaukar hoto, da kuma ayoyin mai. Babban daidaitaccen da maimaita rafin CNC yana bada garantin cewa toshe injin ya sadu da haƙurin da ake buƙata don kyakkyawan aiki da tsawon rai.

3. Pistons da haɗa sanduna : Waɗannan mahimman sassa cikin injin ana samar da amfani da injin CNC don tabbatar da mahimmancin daidaito da karko. Pistons yawanci yana zuwa daga Aluman Alumanum, yayin da haɗa sanduna yawanci daga ƙarfe. Ainihin machining na waɗannan abubuwan da ke da mahimmanci don dacewa dacewa, ma'auni, da aiki.

Sassa masu watsa hankali

Cnc Mactining yana taka muhimmiyar rawa wajen samar da kayan haɗin watsa, waɗanda suke da mahimmanci don canja wurin iko daga injin zuwa ƙafafun. Daidai da daidaito da aka samu ta hanyar Motocin CNC suna tabbatar da cewa waɗannan sassan suna aiki ba su dace ba, samar da ingantaccen aiki. Anan akwai wasu mahimman kayan aikin da aka samar ta amfani da injin CNC:

1. Ganuwa : Mashuwa Gears ne masu rikitarwa waɗanda ke buƙatar ainihin bayanan haƙori da geometries don tabbatar da canja wuri mai laushi. Kamfanin CNC ya dace da ƙirƙirar waɗannan sifofin da ke cikin haɗe, saboda yana iya cimma kwanciyar hankali da sakamako mai daidaituwa. Daidaitaccen kayan haɗin CNC mai mahimmanci don rage amo, rawar jiki, da kuma sutura a cikin watsa.

2. Shafts : kamar matattakala da shigarwar da kayan fitarwa, masu mahimman abubuwa ne masu mahimmanci waɗanda ke watsa Torque tsakanin gears da sauran sassan watsa. Ana amfani da Motocin CNC don ƙirƙirar waɗannan matakan tare da girman da ake buƙata, saman ƙare, da fasali kamar sarakuna da keyfes. Tsarin ƙirar CNC na CNC yana tabbatar da daidaituwa da daidaituwa a cikin watsa, rage rawar jiki da kuma shimfida salon.

3. Gidaje : Gidan da watsa watsa kai shine hadaddun abubuwa masu ƙarfi da ke da ƙarfi da tallafawa wasu gears, shafuka, da ɗaukar ciki a cikin watsa. Ana amfani da Motocin CNC don ƙirƙirar geometri na ciki da daidai hawa saman saman gidaje. Daidaitaccen tsarin cnn na tabbatar da cewa duk abubuwan haɗin watsa shirye-shiryensu sun dace da daidai a cikin gidaje, ba da izinin aiwatarwa da karko.

Ta amfani da Motocin CNC don samar da sassan watsa abubuwa, masana'antun masana'antu na iya samun fa'idodi da yawa:

l Ingantaccen inganci da aiki

l rage amo da rawar jiki

l mika bangaren rayuwa

l daidaitaccen da abin dogara aiki

Daidai da daidaito na abubuwan da aka watsa wajan CNC-Makamai na gudummawa ga ingancin gaba da aikin abin hawa, suna ba da ingantacciyar ƙwarewa ga masu amfani.

An gyara abubuwan

Ana amfani da Motocin CNC mai yawa wajen samar da abubuwan dakatarwa, wanda ya taka muhimmiyar rawa wajen tabbatar da kwanciyar hankali ta hanyar tabbatar da lafiyar motar, da kulawa, da gudummawar ta'aziyya. Mahimmawa da ƙwararrun sassan CNC-Mulkined suna ba da gudummawa ga aminci da ayyukan abin hawa. Anan akwai wasu abubuwan dor da ket ɗin da ke samarwa ta amfani da injin CNC:

1. Gudanar da makamai : Hadarin sarrafawa suna da mahimmin abubuwan dakatarwa wanda ke haɗa tsarin abin hawa ko ƙananan subframe zuwa matattarar motocin da ke tattare da motsi da jingina. Ana amfani da Motocin CNC don ƙirƙirar makamai tare da ƙarfin da ya wajaba, tauri, da madaidaicin mutane. Daidaitaccen kayan Cnc yana tabbatar da cewa makaman sarrafawa ya dace da daidaituwa da kuma samar da ingantacciyar hanya.

2. Knuckles : Tafiya Knickles, kuma da aka sani da spindles, sune abubuwan da ke haɗa hoto zuwa makamai da kuma ba da izinin juyawa da tuƙi. Ana amfani da Motocin CNC don ƙirƙirar maharan geometries da daidai hawa na ƙwanƙwasa. Daidaitaccen kulmin CNC mai dacewa yana tabbatar da daidaitattun jeri mai kyau da kuma aikin motsa jiki mai santsi.

3. Hubs : The Hubs da ke da ƙafa sune asalin abubuwan da aka gyara na tsakiya wanda ke haɗa ƙafafun da birki mai jujjuyawa zuwa dakatarwar abin hawa da DrowTrain. Ana amfani da Motarfin CNC don ƙirƙirar madaidaicin karar da hauhawar saman na rums, tabbatar da cikakkiyar dacewa da bearings da sauran abubuwan haɗin. Daidaitawa da kuma ƙarfin hali na HUBs masu mahimmanci suna da mahimmanci don riƙe jeri na ƙafafun da rage rawar jiki.

Fa'idodi na amfani da Mactining CLN don samar da abubuwan haɗin dakatarwar sun hada da:

l inganta kulawa da kwanciyar hankali

l ya rage rawar jiki da amo

l mika bangaren rayuwa

l daidaitaccen aiki da aminci

Ta hanyar tabbatar da daidaito da kuma ƙwararraki na abubuwan haɗin CNC, abin da CNC na ba da gudummawa ga aminci gaba ɗaya, ta'aziyya, da kuma wasan kwaikwayon. Wannan, bi da bi, yana ba da ingantaccen ƙwarewa na tuƙi don masu amfani kuma yana taimaka wa masana'antun sarrafa motoci a cikin kasuwa.

Tsarin birki na birki

Motsin CNC yana taka muhimmiyar rawa wajen samar da kayan birki na birki, wanda ke da mahimmanci don tabbatar da amincin abin hawa da aiki. Daidai da amincin birki na CNC-Makamai ya ba da gudummawa ga ingantaccen aikin braking da kuma inganta abin hawa. Anan akwai wasu maɓallan tsarin birki da aka samar ta amfani da injin CNC:

1. Calipers : Calipers na Broks shine abubuwanda suke da kayan birki kuma suna amfani da matsin lamba zuwa lalacewa ko tsayawa. Ana amfani da Motarfin CNC don ƙirƙirar mahaɗan geometries da ingantaccen ɗora saman calipers, tabbatar da dacewa da aiki mai santsi. Daidaitaccen misalai na CNC mai mahimmanci yana da mahimmanci don kula da aikin ƙarfe da rage birki mai.

2. Brown rotors : reces birki, wanda kuma aka sani da rusawa na birki, sune kayan haɗin juyawa wanda birki mai birki mai fashewa da kuma ya haifar da abin hawa. Ana amfani da Motocin CNC don ƙirƙirar madaidaitan saman da sanyaya kayan maye, tabbatar da ingantacciyar zafi dissipation da kuma daidaita aikin braking. Daidaitaccen rotors masu juyawa na CNC mai mahimmanci yana da mahimmanci don rage ƙarancin birki kuma tabbatar da sa a kan murfin birki.

3. Master silinda : Master silinda shine zuciyar tsarin birki, wanda ke da alhakin sauya karfin amfani da birki na birki wanda ya aiwatar da calittar birki wanda ya aiwatar da calittar birki wanda ya aiwatar da calittar birki wanda ya aiwatar da calipers na birki wanda ya aiwatar da calipers na birki wanda ya aiwatar da calittar birki wanda ya aiwatar da calittar birki wanda ya aiwatar da calittar birki wanda ya aiwatar da calittar birki wanda ya aiwatar da calittar birki wanda ya dauki calipers na birki wanda ya aiwatar da calittar birki wanda ya dauki calipers na birki wanda ya aiwatar da calittar birki wanda ya dauki calipers na birki wanda ya aiwatar da calipers na birki wanda ya aiwatar da calittar birki wanda ya aiwatar da calittar birki wanda ya dauki calipers na birgima wanda ya dauki calipers na birgima. Ana amfani da Motarin CNC don ƙirƙirar madaidaicin toon da piston filayen silinda, tabbatar da ingantaccen aiki da abin dogaro. Daidaitar Master Master Master Master yana da mahimmanci don kula da rashin daidaituwa na birki mai rauni da ƙarfin ƙarfe.

Fa'idodin amfani da inc inji na CNC don samar da kayan haɗin tsarin birki sun haɗa da:

l Inganta brakinka da inganci

l Rage birki birki da rawar jiki

l mika bangaren rayuwa

l daidaitaccen da abin dogaro da aikin yi

Ta hanyar tabbatar da daidaito da amincin tushen tsarin birki, injin CNC na bada gudummawa ga aminci da aikin abin hawa. Wannan, bi da bi, yana ba da kwanciyar hankali ga masu amfani da masu amfani da masu siye da kuma taimaka wa masana'antun sarrafa kansa suna kula da suna don samar da manyan motocin.

Mai gudanar da tsarin tsarin

Ana amfani da Motarfin CNC mai yawa wajen samar da kayan aikin shirya, waɗanda ke da mahimmanci wajen tabbatar da daidaitaccen abin hawa mai mahimmanci. Daidaitawa da kuma ƙarfin hali na wuraren motsa jiki na CNC. Anan akwai wasu abubuwan da aka gyara na tsarin da aka samar ta amfani da injin CNC:

1. Steing Rick da Péon : Matsalar Rage kuma Purion shine zuciyar mai wakiltar tsarin, da ke da alhakin canza motsi daga motsi a cikin motsi motsi wanda ya kunna ƙafafun. Ana amfani da Motarfin CNC don ƙirƙirar ainihin hakora da gidaje na rack da pusaon, tabbatar da ingantaccen aiki. Cikakken rijiyoyin CNC da kuma taron PINON yana da mahimmanci don kiyaye madaidaicin tuƙin sarrafawa da rage wasan tuƙi.

2. Shafin tuƙi : Shafin tuƙi shine bangaren da ke haɗa motunan zuwa matattarar tuƙi zuwa ƙafafun. Ana amfani da Motarfin CNC don ƙirƙirar madaidaicin abubuwan da ke ɗauke da wuraren da ke haifar da yanayin tuƙi, tabbatar da jujjuyawar mai laushi da rage rawar jiki. Daidaitawar kayan aiki na CNC-Mahimmanci yana da mahimmanci don kiyaye madaidaicin tuƙi yana ji da kuma rage girman shaskewa.

3. Ieulla sanduna : ƙulla sandunan sune abubuwan da ke da kayan haɗin da suke haɗa batutuwa zuwa matattarar tuƙi zuwa ƙafafun. Ana amfani da Motocin CNC don ƙirƙirar madaidaicin zaren da kayan haɗin gwiwa na ɗorawa sanduna, yana tabbatar da daidaitaccen daidaituwa da aikin motsa jiki. Daidaitar da kayan kwalliya na CNC mai mahimmanci yana da mahimmanci don kiyaye madaidaicin tuƙi mai ɗaukar hoto da rage satin taya.

Fa'idodi na amfani da Motocin CTN don samar da abubuwan haɗin tsarin sarrafawa sun haɗa da:

l Inganta daidaito da martani

l rage yawan tuƙi da rawar jiki

l mika bangaren rayuwa

l daidaitaccen da abubuwan da suka dace na motsa jiki

Ta hanyar tabbatar da daidaito da rafin kayan aikin na CNC, Motar CNC ta ba da gudummawa ga aminci ga gaba ɗaya, gudanarwa, da kuma aikin abin hawa. Wannan, bi da bi, yana ba da ƙarin ƙwarewar tuki mai zurfi ga masu amfani kuma yana taimaka wa masana'antun sarrafa kuɗi a kasuwa.

Cikin ciki da na waje

Ana amfani da marinsing CNC sosai wajen samar da sassan cikin gida da na waje, waɗanda ke ba da gudummawa ga roko na yau da kullun, ta'aziyya, da ayyukan abin hawa. Daidaitawa da kuma tasirin Mactining na CNC yana ba da damar ƙirƙirar siffofin hadaddun da kuma cikakkun bayanai waɗanda ke haɓaka ƙimar da ke gaba da bayyanar da abin hawa. Anan akwai wasu maɓalli na maɓallin ciki da na waje wanda aka samar da amfani da injin CNC:

1. Ana amfani da kayan dashboard : Ana amfani da Motocin CNC don ƙirƙirar abubuwan haɗin dashboard daban-daban, kamar bangon waya, consoles na cibiyar, da iska. Tsarin Motocin CNC yana ba da damar ƙirƙirar siffofin hadaddun siffofin, m amincewa, da santsi a saman da ba a haɗa shi da ƙirar ciki ba. Abubuwan da aka gyara na CNC. Kawai don inganta rokon gani ne amma kuma tabbatar tabbatar da dacewa da aiki daban-daban sarrafawa da nunawa.

2. Kofar rataye da bangarori : Ana amfani da Motsin CNC don samar da ƙofofin ƙofa, bangarori kofa, da sauran kayan haɗin datsa. Daidaici da daidaito na Motocin CNC suna tabbatar da cewa waɗannan sassan suna dacewa da kyau da kuma yi aiki da kyau, samar da ingantacciyar hanyar abin hawa. Za'a iya ƙirƙirar masu ɗaukar hoto na CNC.

3. Grilles da embles : Ana amfani da Motocin CNC don ƙirƙirar sassan dunƙule kamar griles da alamomi, waɗanda ke da mahimmancin masifa na gaba. Daidai da ayoyin da CNC suna ba da damar ƙirƙirar ƙwararrun zane da keɓaɓɓen zane wanda ya nuna alamar alama ta abin hawa. Za'a iya samar da grilles na CNC-mach. Wadannan bangarorin ba wai kawai inganta roko na mai ban sha'awa bane amma kuma yana ba da gudummawa ga aikin yi da sanyaya sanyaya.

Fa'idodi na amfani da injin CNC don samar da sassan datsa da na waje sun haɗa da:

l Ingantaccen roko na gani da kuma asalin alama

l Ingantaccen dacewa da aiki

l m da ingancin inganci

l ikon ƙirƙirar sifofin hadaddun da kuma bayanai masu rikitarwa

Ta hanyar tabbatar da daidaito, inganci, da kuma roko na yau da kullun, mama na CNC suna ba da gudummawa ga gamsuwa na abokin ciniki da tsinkaye na abin hawa. Wannan, bi da bi, yana taimaka wa masana'antun sarrafa kayan aiki suna bambance samfuran su kuma suna kula da fannin su a kasuwa.

Kayan Cnc don masana'antar kera motoci

Masana'antu mai wucewa sun dogara da ɗimbin kayan don samar da ingantacciyar inganci, mai dorewa, da kuma daidaita-da aka kirkira. Abubuwan da CNC sun dace da yawa daga waɗannan kayan, suna ba da damar masana'antun don ƙirƙirar sassa tare da takamaiman kaddarorin da aka dace da aikace-aikacen su.

Metals

Metalal sune kayan da aka fi amfani dasu a masana'antar kera bata ciki sakamakon ƙarfinsu, karkatarwa, da kuma ma'ana. Kamfanin CNC ya dace sosai don sarrafa allon ƙarfe daban-daban, yana ba da damar ƙirƙirar mahimman hanyoyin ƙasa da ingantaccen yarda. Anan akwai wasu daga cikin mafi yawan baƙin ƙarfe na yau da kullun suna amfani da injin CNC don aikace-aikacen mota:

1. Alumomin allo na aluminium : aluminium aluminiy suna da nauyi, lalata corroson-resistant, kuma suna ba da kyakkyawan marina. Ana amfani dasu musamman don abubuwan haɗin injin, dakatar da sassan, da bangarorin jiki. Mashahuri Alumuran Alumini na Al'ada na Motocin Cinc sun hada da:

a. 6061: Aka sani don shi kyakkyawan ma'aunin ƙarfi, juriya na lalata, da mama-mama.

b. 7075: Yana bayar da ƙarfi da ƙarfi da sanya juriya, sanya shi dace da abubuwan da ke da kaya.

2. Karfe Alayen ƙarfe : Alayen ƙarfe sun shahara da ƙarfinsu, tauri, da karko. Ana amfani dasu a aikace-aikacen mota daban-daban, gami da abubuwan haɗin kai, dakatar da sassa, da masu ɗaure. Alloys na yau da kullun don Motocin CNC sun haɗa da:

a. 4140: Chromium-Molybdenum Dayoy tare da tsararru mai tsayi da juriya, sau da yawa ana amfani da shi don gears da mashigai.

b. 1045: matsakaici carbon karfe tare da kyakkyawan machin da sa juriya, dace da baka da gyarawa.

3. Titanium Aloleys : titanium Aloys suna ba da wani kwararre-da-nauyi rabo, lalata juriya, da kuma babban zazzabi. Ana amfani dasu a aikace-aikace na manyan aiki, kamar su bawuloli na injin, suna haɗa sanduna, da abubuwan haɗin turboching. Mafi yawan yau da kullun titanium alloy don injin Cinikin Kulawa na mota shine:

a. Ti-6A-4A-4V: sanannen ƙarfin ƙarfinta, nauyi mai nauyi, kuma kyakkyawar qarba.

4. Magnesium na allo : Alloum na magnesium sune ƙananan ƙarfe masu yawa, suna ba da kyakkyawan tsari mai ƙarfi da kyakkyawan macheoos da machinable mai kyau. Ana amfani dasu a aikace-aikace inda rage nauyi yake da mahimmanci, kamar su toshe injiniyoyi, da kuma tuƙi firam din. Allos na kowa da na kowa don Motocin CNC sun hada da:

a. Az91d: Yana ba da kyakkyawan similleable, ƙarfi, da juriya na lalata.

b. AM60B: Sanannu ne don aikinsa mai kyau, tasirin juriya, da mama-machinable.

Abu | Density (g / cm³) | Tenerile ƙarfi (MPa) | Mama |

Aluminium (6061-T6) | 2.70 | 310 | M |

Karfe (4140) | 7.85 | 655 | M |

Titanium (ti-6al-4v) | 4.43 | 950 | M |

Magnesium (az91d) | 1.81 | 230 | M |

Robobi

Baya ga magungunan, farawar makusanci ana amfani dasu a cikin masana'antar kera motoci don aikace-aikace daban-daban, jere daga kayan datsa cikin ciki zuwa sassa masu aiki. Abubuwan da CNC suna dacewa da wuraren shakatawa na CNC, suna ba da ikon kirkirar geometries, m amincewa, da santsi saman ƙare. Anan akwai wasu daga cikin matsalolin da suka fi amfani da su a cikin injin CNC don aikace-aikacen mota:

1. ABS (acrylonitrile Ryurey Styfene) : ABU sanannen sanannen abu: Sanarwa da thermoplalic da aka sani da magungunansa na tasirinsa, tausayi, da kwanciyar hankali. Ana amfani dashi don haɗin gwiwar damfani na ciki, kamar bangarori na Dashboard, na'ura wasan bidiyo, da iska. Abs yana ba da machinability mai kyau, yana ba da izinin ƙirƙirar ƙirar zane da santsi.

2. Nailon : nailan aro injiniya ne mai mahimmanci tare da ingantattun kayan aikin injiniyoyi, gami da ƙarfi, sa juriya, da ƙananan tashin hankali. Ana amfani dashi a aikace-aikacen mota daban daban, kamar su gears daban-daban, kamar yadda mutane masu kwalliya. Abubuwan da ke cikin Headon na Nylon suna yin shi da kyau don sassan motsi, rage buƙatar ƙarin lubrication.

3. ATTAL : Acetal, kuma ana kiranta Polyoxymethylene (pom), filastik mai kyau ne tare da kyakkyawan kwanciyar hankali tare da kyakkyawan kwanciyar hankali mai kyau sosai tare da kyakkyawan kwanciyar hankali mai kyau sosai tare da kyakkyawan kwanciyar hankali mai kyau sosai tare da kyakkyawan kwanciyar hankali mai kyau tare da kyakkyawan yanayin kwanciyar hankali mai kyau, mai tauri, da kuma sa juriya. Ana amfani dashi don abubuwan da aka gyara na kayan aiki, kamar sassan tsarin mai, kayan kulle kulle, da kuma masu gudanar da taga. Acetal cuta ce mai danshi mai danshi da kyakkyawan machinm da ya dace da m aikace-aikace.

4. Peek (polyether Ethone) : Peek shine babban aikin thermoplastic tare da kaddarorin inji da therminal kaddarorin. Yana ba da ƙarfi sosai, taurin kai, da kwanciyar hankali, ko da a tsawan yanayin zafi. Ana amfani da peek a cikin buƙatar aikace-aikacen mota, kamar kayan haɗin injin, sassa da kuma ja layi. Kyakkyawan sa juriya da juriya na sinadarai sanya shi dace da matsanancin mahalli.

Abu | Density (g / cm³) | Tenerile ƙarfi (MPa) | Max. Ci gaba da amfani da zazzabi (° C) |

Abin da | 1.04 | 44 | 85 |

Naylon 6 | 1.14 | 79 | 100 |

Acetal | 1.41 | 68 | 100 |

Ƙafa | 1.32 | 100 | 250 |

Lokacin zabar kayan filastik don mikarfin CNC a cikin masana'antar kera, injiniyan suna ɗaukar dalilai kamar kayan aikin injin, juriya, juriya na sunadarai, da farashi. Amfani da makomar makoki a aikace-aikacen mota suna ba da fa'idodi da yawa, gami da ragin nauyi, juriya na lalata, da rufin lantarki.

Ta hanyar leverarget ɗin da CNC Murtining da kadarorin waɗannan hanyoyin injiniya, masana'antun masana'antu zasu iya samar da kayan kwalliya, inganci, da kuma ta'aziyya.

Tsarin aiki

Abubuwan da aka haɗa suna ƙara amfani da kayan aikin sarrafa motoci saboda haɓakar kayan aikinsu, kamar ingancin ƙarfinsu, da sassaucin ra'ayi, da sassauci. Motsin CNC yana taka muhimmiyar rawa a cikin aiki na kayan haɗin kai, yana ba da ƙirƙirar ƙirƙirar siffofi da siffofin fasali. Anan ne biyu daga cikin kayan da aka fi amfani da kayan aikin CNC don aikace-aikacen CNC don aikace-aikacen mota:

1. Carbon fiber karfafa filastik (CFRP) : Cfrp shine babban aikin kayan aiki wanda ya ƙunshi carbon zarbens saka a cikin wani matrix. Yana ba da tsawan-tarko mai nauyi-da-nauyi, taurin kai, da gajiya juriya. Ana amfani da CFRP a aikace-aikacen mota daban-daban, gami da:

a. Abubuwan da aka gyara na tsari: Chassis, Dakatarwar makamai, da kuma Cages.

b. Bangarorin jiki na waje: Hood, rufin, da murfin kwalba.

c. Cikin gida mai datsa: dashboard, firam ɗin wurin zama, da kuma tuƙi ƙafafun.

Ana amfani da Motocin CNC don datsa, rawar soja, da niƙa cfrp na CFRP, tabbatar da madaidaicin girma da kuma santsi. Koyaya, inji Cfrp yana buƙatar kayan aikin ƙwararru da dabaru don rage dala da fiber.

2. Jirgin ruwan tabarau na gilashi (GFRP) : GFRP abu ne mai ban sha'awa wanda ya kunshi 'yan bindiga da aka saka a matrix. Yana ba da kyakkyawan ƙarfi-da-nauyi, rufi na lantarki, da juriya na lalata. Ana amfani da GFRP a aikace-aikacen mota daban-daban, kamar:

a. Manufar jiki: fened-penders, kofa fãtun, kuma ya rufe Magana Taya.

b. Abubuwan haɗin lantarki: trays baturi, akwatunan fis, da kuma haɗin haye.

c. Abubuwan da ke cikin tsari: Bangaren marmari, katako na fure, da kuma membobin giciye.

Ana amfani da Motarin CNC don yanke, harkokin gfrp na GFRP, yana ba da izinin ƙirƙirar hadaddun geometries da kuma haƙurin yarda. Machtining gfrp yana buƙatar zaɓi mai sakewa da kayan aikin yankewa da sigogi don rage girman fiber da kuma tabbatar da tsabta.

Abu | Density (g / cm³) | Tenerile ƙarfi (MPa) | Modulus na zamani (GPA) |

CFRP | 1.55 | 2000-250000 | 130-150 |

GFRP | 1.85 | 500-1000 | 20-40 |

Amfani da kayan kwalliya a masana'antar kera motoci yana ba da fa'idodi da yawa, gami da rage nauyi, inganta haɓakar mai, kuma inganta aiki. Koyaya, Kwakwalwar Masara ta gabatar da ƙalubale na musamman idan aka kwatanta da karafata da robobi. Zabin kayan aiki na yau da kyau, yankan sigogi, da dabarun da ke da mahimmanci don tabbatar da ingancin da amincin kayan aikin da aka haɗa su.

Ta hanyar leverauki iyawar CNC da kadarorin waɗannan kayan aikin da zasu iya samar da haske, babban ƙarfi, da daidaitattun kayan aikin injiniya waɗanda ke tura iyakokin aikin aiki da inganci.

Makomar CLN Mactining a cikin masana'antar kera motoci

Kamar yadda masana'antar kera motoci ta ci gaba da samo asali, an shirya Motocin CNC don taka muhimmiyar rawa wajen gyara makomar masana'antar abin hawa. Tare da ci gaba a cikin fasaha da hauhawar sabbin al'amura, kamar masana'antu 4.0, masana'antu masu haɓakawa, da injin lantarki da motocin CTNC na iya biyan bukatun masana'antu.

Masana'antu 4.0 da Smart

Masana'antu 4.0, wanda aka sani da Juyin masana'antu na huɗu, yana canzawa hanyar sarrafa kayan aiki. Wannan sabon zamani na masana'antu mai da hankali ne akan hadewar fasahar zamani, kamar intanet na abubuwa (AI), da kuma babban masana'antu na yau da kullun. A cikin mahallin Cnc Mactining, wannan yana nufin:

1. Haɗin injunan CNC tare da na'urorin iot : Ta hanyar wadatar na'urorin CNC tare da na'urori na iot, da masana'antun na iya tattara bayanan na ainihi akan aikin injiniya, Searshe, da ingancin samfurin. Za'a iya amfani da wannan bayanan don inganta hanyoyin sarrafa na'ura, rage kashe-lokaci, kuma inganta kayan aikin haɓakawa gaba ɗaya (OEE).

2. Binciken Data na Real-Lokaci don tabbatarwa na Gaskiya : tare da taimakon Ai da injiniyan CNC na ba da damar yin hasashen wurin da aka samu na IOT da jadawalin kulawa a baya. Wannan tsarin tabbatar da tsinkaye yana rage yawan downtime, yana rage farashin kiyayewa, kuma yana inganta amincin masana'antar.

Masana'antu mai ƙara da 3D bugu

Masana'antarwa mai ƙara, wanda kuma aka sani da bugu na 3D, ana ƙara amfani da amfani da masana'antar kera motoci, kayan aiki, har ma da haɓaka sashi na ƙarshe. Yayin da CLN Mactining ya kasance babban tsari don samar da babban girma, kayan aikin babban abu, masana'antu yana ba da sabon damar Geometries da zane mai sauƙi.

1. Hada Kayayyakin CNC tare da masana'antu mai ƙari : ta hanyar haɗa ƙarfi na fasahar biyu da ke haifar da daidaito da kuma rage girman masana'antu da kuma rage ƙirar masana'antu. Misali, wani yanki mai buga-da aka buga na 3D na iya zama CNC da aka jijjiga don samun wadatar farin ciki da kuma shimfidar wurare masu mahimmanci.

2. Mahimmanci mai sauri : masana'antu mai kikawa yana ba da amfani da sauri da ingantaccen ingantaccen sassan sassan da kayan aiki, kamar gyarawa da gyarawa. Wannan ikon sauya injiniyan mai saurin ba da damar Injiniya na Kulawa da keɓancewa da sauri, ingantattun tsare-tsaren, kuma ku kawo sababbin kayayyaki zuwa kasuwa da sauri. Daga nan za a iya amfani da Motocin CNC don tsaftacewa da inganta zane ta ƙarshe don samar da taro.

Wutar lantarki da motocin motsa jiki

Tashi na motoci masu lantarki da masu kaifin kai suna tuki sabbin buƙatun don abubuwan da aka gyara mara nauyi da sassan da aka tsara. Motocin CNC suna dacewa da waɗannan kalubale da tallafawa ci gaban motocin motocin na gaba.

1. Cnc Mactining na kayan aiki : motocin lantarki na buƙatar kayan haɗawa mara nauyi don ƙara yawan kewayon baturi da inganci. Ana amfani da Motocin CNC don samar da sassan Lildweight daga ci gaba, kamar aluminium, da allonum, da kuma kwafin. Ta hanyar inganta zane-zane da leverging da daidaitaccen CLN Mactining, masana'antun na iya kirkirar kayan haɗin da ke ba da mafi kyawun ƙarfin ƙarfi, taurin kai, da nauyi.

2. Tsarin daidai da na'urori da na'urori da lantarki : Motocin kansu masu rikitarwa suna dogara ne akan mahimman tsarin na'urori, kyamarori, da kuma abubuwan lantarki don gane da kewayawa yanayin su. Motsin CNC yana taka muhimmiyar rawa wajen samar da babban hidusing, brackets, da masu haɗin kai suna ba da damar waɗannan tsarin don aiki dogaro. A matsayin buƙatun fasahar abin hawa na m abin hawa na motsa jiki yana girma, buƙatar daidaiton abubuwan haɗin CNC na CNC da ke canzawa zasu ƙaru ne kawai.

Nan gaba na Motocin CNC a cikin masana'antar kera motoci yana da haske, wanda ya kori ta hanyar ci gaba, hauhawar sabon masana'anta, da buƙatar motocin motocin. Ta hanyar runguma wadannan canje-canje da kuma daidaita su ga sabon kalubale, injin CNC zai ci gaba da zama kayan aiki mai mahimmanci ga masana'antun sarrafa kansa a cikin shekaru masu zuwa.

Teamungiyar Mfg: Abokokin ku a cikin bidi'a

Ayyukan CLN CLN

A kungiya MFG, muna ba da mafita na CNC na CNC don saduwa da keɓaɓɓen buƙatun na musamman na masana'antun sarrafa kayan aiki. Gidajenmu na-da-art da kuma ƙungiyar ƙwayoyin cuta suna isar da sassan al'ada tare da daidaitaccen daidai da inganci. Daga sauri prototy zuwa yawan ci gaba, muna samarwa:

L 3, 4, da 5-Axis CNC Kayayyakin Kayayyakin Kayayyaki

L dace tare da karafa, robobi, da composites da ƙari

l saurin takan

Led -gidan zane don masana'antu (DFM) Tallafi

Lorgorous ingancin kulawa da dubawa

Farawa tare da ƙungiyar MFG

Kungiyoyinmu a shirye suke don kawo wahayi mai kayatarwa zuwa rayuwa ta hanyar mafi yawan hanyoyin inganta. Ga yadda ake farawa:

1. Tuntube mu : Ku isa ta waya, imel ko yanar gizo don tattauna aikinku.

2. Binciken zane : Injiniyanmu suna nazarin ƙirar yankinku da samar da bayanan DFM.

3. PrototyPing : Muna saurin haifar da prototypes don ingantaccen tsarin tabbatarwa da gwaji.

4. Owlis : Tare da yardar ku, muna ƙaura zuwa ingantaccen tsari, masana'antu mai inganci.

5. Isarwa : An tura ɓangarorin mota kai tsaye zuwa wurin aikinku.

Takeauki mataki na farko don yin hadin gwiwa tare da masana Multining a kungiyar MFG a yau!