Gabatarwa zuwa Motocin CNC don titanium

Takaitaccen titanium: halaye da fa'idodi

Titanium wani ƙarfe ne mai ban mamaki tare da ingantattun kaddarorin da suka sa ya zama kyawawa don masana'antu daban-daban. Anan akwai wasu mahimman halaye da fa'idodi na titanium:

Isasshen ƙarfi: titanium yana da kyakkyawan tsari-zuwa-nauyi rabo, yana da ƙarfi da ƙarfi yayin da yake ɗauka mara nauyi.

● Titanion juriya: titanium yana da tsayayya sosai da lalata, har ma a cikin m mahalli kamar ruwan teku, acid, da chlorine.

● Heather juriya: titanium na iya kula da ƙarfinta da kuma tsoratarwa ko da lokacin da aka fallasa shi da matsanancin yanayin zafi.

Basocompleity: titanium ba mai guba ba ne kuma ya dace da ilimin ɗan adam, yana sa ya dace da rashin ingancin likita da na'urori.

Haske Haske: Titanium auna kusa da rabi kamar jan ƙarfe da kuma dan kadan zabi don aikace-aikacen inda nauyi yake damuwa.

Wasu aikace-aikacen gama gari na titanium sun haɗa da:

Injin Injiniya (Injiniya, Jirgin Sama, Jirgin Sama, Rotors)

Kasuwancin masana'antu (implants, kayan aiki, keken hannu)

● Abubuwan Motoci na Motoci na Motoci, dakatar da Springs)

Kayan wasanni (Kungiyoyin golf, Frames Bike, Jalkallar Baseball)

Mahimmancin CNC Murfinning a cikin masana'antar zamani

CNC (Kamfanin Kamfanin Kamfanin kwamfuta) Motocin kwamfuta suna taka muhimmiyar rawa a cikin masana'antun masana'antun zamani, musamman lokacin aiki tare da kayan kamar titanium. Ga wasu mahimman dalilai Kamfanin CNC yana da mahimmanci:

● Kaidadodi: Injinan CNC na iya samar da sassan tare da manyan matakan daidaito da daidaito, tabbatar da ingancin inganci.

Arfin injunan CNC na iya yin aiki akai-akai, rage farashin kuɗi da haɓaka fitarwa na samarwa.

● Za a iya tsara injin cnn don samar da kewayon hadaddun wurare da zane, masu kawowa masana'antun don biyan bukatun samfuran daban-daban.

● Maimaitawa: shirye-shiryen CNC za a iya adanar su kuma a sake yin su, suna ba da izinin daidaitawa da maimaita sassa.

Game da titanium, Motocin CLN shine yawanci dabarun masana'antu saboda dalilai masu zuwa:

● Titanium yana da wuya a jefa ko mold yadda ya kamata saboda babban melting nuni da lokacin oxygen.

● Cnc Mactining na samar da daidaito da daidaitaccen da ake buƙata don samar da manyan-ingancin titanium sassan.

Yana ba da damar ƙirƙirar siffofi masu amfani da ƙira da ƙira waɗanda zasu iya fuskantar yarjejeniya don cimma ta hanyar wasu hanyoyin masana'antu.

Fahimtar Alloanin Titanium

Classigfication na titanium safari

Za'a iya rarraba Alayen Titanium Aloys cikin rukuni uku:

● Tsakanin titanium: Wannan yana nufin Titanium ba tare da kara abubuwan da ke ba. Tsarkin titanium ya kasance mai taushi da sauki ga injin.

● Alpha Alloys: Waɗannan allury sun ƙunshi abubuwan da sukeyewa kamar alumini, oxygen, da nitrogen. Sun yi ƙarfi da tsarkin titanium amma ba su da shekara.

● Beta Aloloys: Waɗannan allury sun ƙunshi abubuwan da sukeyewa kamar Molybdenum, baƙin ƙarfe, Varadium, Chromium, da manganese. Sun fi durleile kuma suna iya zama zafi-bi da don ƙara ƙarfi.

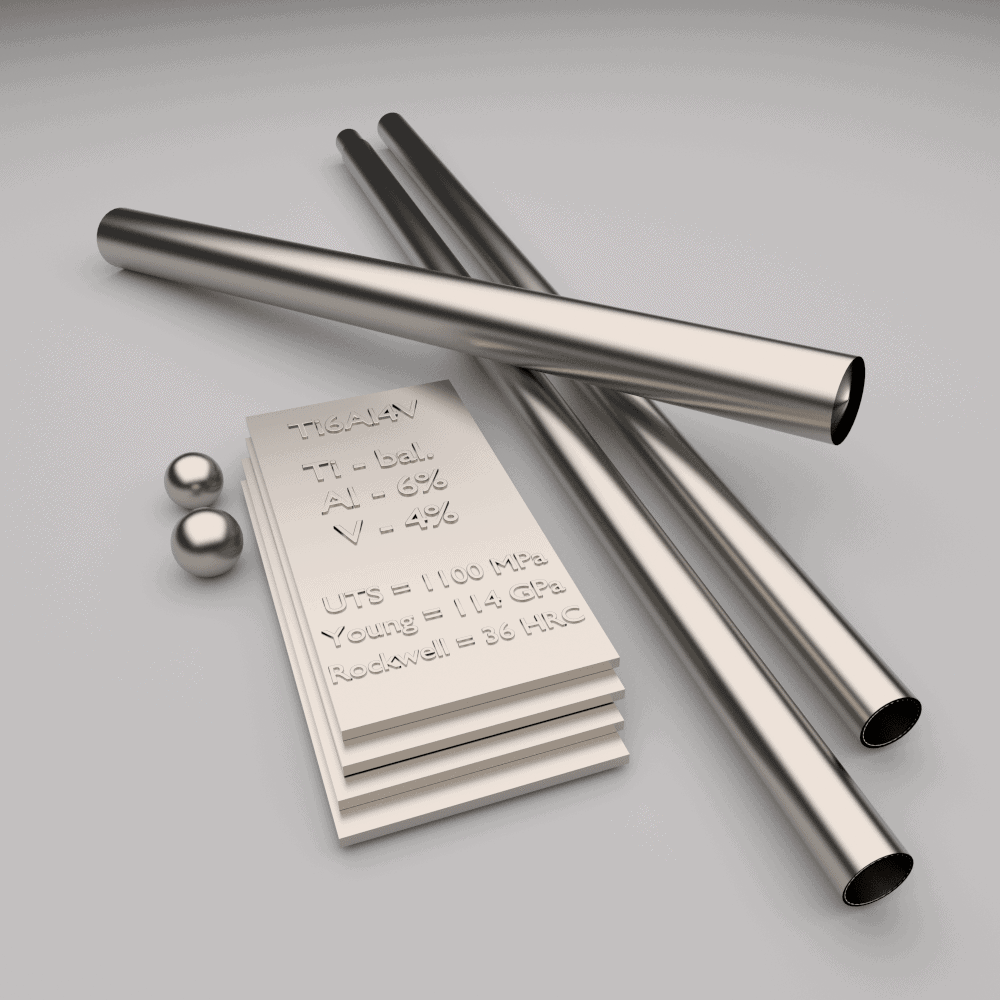

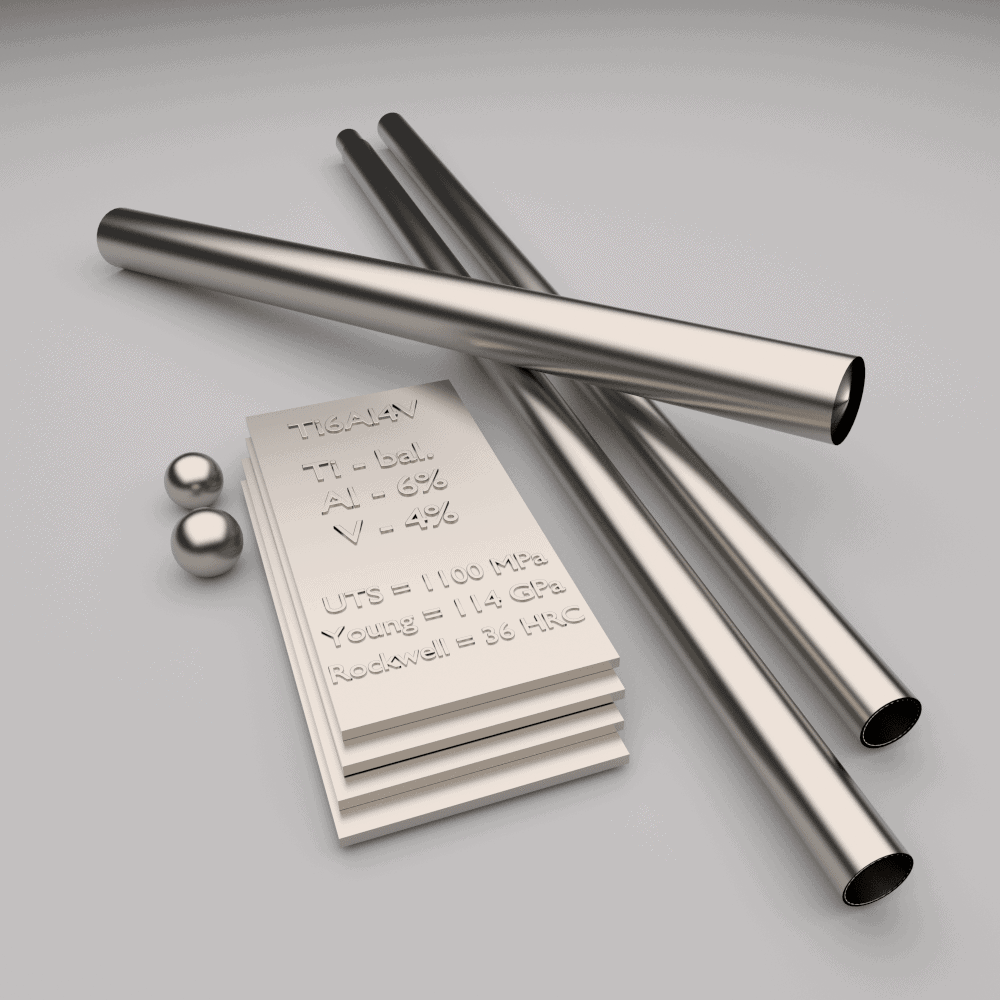

Kaddarorin tsarkakakken titanium

Tsinkayen titanium mai tsabta, wanda kuma aka sani da tsabta (CP) titanium, yana da kaddarorin masu zuwa:

Ogh ma ormroon juriya juriya: tsarkakakken titanium ne mai tsayayya da lalata, har ma a cikin matsanancin mahalli.

● Kyakkyawan tsari: tsarkakakkiyar titanium yana da taushi da durtile, yana sauƙaƙe yin tsari da injin.

Officiara ƙarfi: Yayin da ba mai ƙarfi kamar titanium Alloys, tsabta titanium har yanzu yana da ƙarfi mai kyau idan aka kwatanta da sauran karafa.

Grades na gama gari na titanium sun hada da aji 1 (LEAD DALY Oxygen), STOPYGENSCENCENSHING OXYGEN), da sa 4 (mafi girma oxygen), da sa 4 (babban abun ciki na oxygen).

Halaye na Alfa da Beta Titanium Alloys

Alpha Thoanium Alloy:

● Ta dain aluminium da tin kamar yadda ake yin abubuwan ban mamaki

● Kasance da kyakkyawan ƙarfi da ƙarfi na Creep a babban yanayin zafi

● Rashin karkara fiye da Beta Alloys

● Misali: ti-5al-2.5sn (aji 6)

Beta Titanium Alloy:

● Ka ƙunshi abubuwa kamar fari, Molybdenum, da baƙin ƙarfe

Orari mafi durtile da kuma tsari fiye da Alpha Alloys

● Zai iya zama mai zafi don ƙara ƙarfi

● Misali: ti-6al-4v (aji 5)

Nau'ikan nau'ikan titanium

Sa | Alloy / CP | Ƙarfi | Ci | Mama | Aikace-aikace na yau da kullun |

1 | CP | M | M | M | Chemica na Chemic, likita |

2 | CP | M | M | Matsakaici | Aerospace, Marine |

3 | CP | Matsakaici | Matsakaici | M | Airfrres, kwakwalwa |

4 | CP | M | M | M | Aerospace, Masana'antu |

5 | Ti6Al4v | Sosai babba | Matsakaici | M | Aerospace, implants likita |

6 | Ti5al2.5.5.5n | M | Matsakaici | Matsakaici | Aerospace, sassan injin |

7 | Ti-0.15pd | M | M | M | Chememer aiki |

11 | Ti-0.15pd | M | M | M | Desalination, Sayarwar sunadarai |

12 | Ti-0.3mo-0.8ni | M | Matsakaici | Matsakaici | Marine, tsarin sunadarai |

23 | Ti6Al4v ELI | M | M | M | Orthopedic da haƙori implants |

Zabi Haske Titanium Dodoy don Mamfining

A lokacin da zabar titanium Dour sony, la'akari da waɗannan abubuwan:

Bukatun ƙarfi: Idan ana buƙatar babban ƙarfi, zaɓi to beta alloy kamar ti-6al-4v (aji 5).

Is Komawa: Don aikace-aikacen da ke buƙatar babban tsari, tsabta titanium (titanium 1-4) ko Alpha-beta alloys kamar ti-6al-4v (aji 5) zabi ne masu kyau.

● Mach na: tsarkakakkiyar titanium (tamrades 1-2) da kuma wasu alpha alloys sun fi sauƙi ga infors fiye da beta Alloys.

● Tsabaki na juriya: Ga mahalli masu rauni, tsabta titanium (tsinkaye 1-4) ko beta alloys kamar ti-0.3mo-0.8ni-0.8ni (Fashi na 12) an ba da shawarar.

Farashi: Tsarkin titanium da Alpha Allos ba su da tsada sosai fiye da beta.

Fa'idodi da rashin amfanin amfani da titanium

Me yasa Zabi Titanium: Fa'idodi

Titanium yana da fa'idodi da yawa waɗanda suka sa zaɓi mai kyau don aikace-aikace iri-iri:

Highightara mai ƙarfi-da-nauyi: titanium yana da ƙarfi sosai yayin da yake rashin nauyi, yin la'akari da rabin tagulla.

Ogh mãtanku Jakadama: Titanium yana da tsayayya sosai da lalata, ko da daga abubuwa kamar ruwan teku, chlorine, da acid.

● Heather juriya: titanium na iya kula da ƙarfinta da kuma ƙarfin hali a matsanancin yanayin zafi.

Basocompleity: titanium ba mai guba ba ne kuma ya dace da ilimin ɗan adam, yana sa ya dace da rashin ingancin likita da na'urori.

● Modayan: Duk da ƙalubalen, titanium za a iya amfani da titanium ta amfani da dabarun dama da kayan aiki.

● Sake sake dubawa: titanium yana sake tunani, yana sa shi zaɓi mai ƙauna.

Kalubale a cikin injining titanium: Rashin daidaito

Yayin titanium yana ba da fa'idodi da yawa, hakan ma yana gabatar da kalubale da yawa yayin injiniyan:

Gyara One zafi: titanium yana da ƙarancin ƙira, yana haifar da zafi don tara a kayan aikin yankan, yana haifar da kayan aiki mai sauri.

● Galling: titanium zai iya bi da kayan kayan aikin yankan, wani sabon abu da aka sani da galling, wanda zai iya lalata kayan aiki da aikin kayan aiki.

● Kimiyya da rawar jiki: titanium's low modulus na elasticity na iya haifar da mummunar hira da kuma rawar jiki yayin masara, yana shafar ingancin yanayi.

● Aiki hardening: titanium iya aiki-harden yayin da injin, yana da wuya a kuma mafi farare, yana kara kara kayan aiki.

Farashi: titanium abu ne mai tsada idan aka kwatanta da sauran karafa kamar aluminum ko karfe.

Kwatanta titanium tare da sauran karafa

Titanium vs. karfe:

● Titanium mai sauƙi ne kuma mafi lahani gwargwado fiye da ƙarfe.

Karfe gaba ɗaya mai rahusa da sauƙi don incine fiye da titanium.

● Titanium yana da babban ƙarfi-da nauyi nauyi fiye da karfe.

Titanium vs.uminium :

● Titanium mai karfi ne kuma mafi zafi-resistant fiye da aluminum.

● Alumumum ba shi da tsada kuma mafi sauƙin incine fiye da titanium.

● Titanium yana da babban rabo-da-nauyi mai nauyi fiye da aluminum.

Yayin titanium yana ba da manyan kaddarorin, kalubalenta da farashinsa sau da yawa suna sa ya zaɓi don aikace-aikacen da suka dace, kamar a cikin Aerospace masana'antu.

Kalubalen da inji titanium

Fahimtar Titanium ta sinadarai da galling batutuwa

Titanium wani ƙarfe mai yawa ne. Zai iya amsawa tare da gas a lokacin da ke cikin na'ura, yana haifar da matsaloli kamar hadada ta iskar shaka da ƙoshin abinci. Wannan na iya raunana abubuwan da aka gyara da rage juriya na lalata.

Titanium kuma yana da ƙananan modulus na elasticity idan aka kwatanta da ƙarfinta. Wannan yana sa shi a 'gummy '' kayan zuwa injin. Titanium zai iya bijirewa ga kayan aikin yankan, yana haifar da gazawa da lalacewa. Wannan an san shi da galling.

Galling shima yana shafar ingancin ingancin mikiya da sassan Titanium sassan.

Gudanar da Ginin Gudun Zuwa A Lokacin Masara

Tsayawa yawan zafin jiki a lokacin da injiniya babban ƙalubale ne tare da titanium. Titanium yana da ƙarancin ƙira, wanda ke haifar da inganta kayan zafi a wurin kayan wanki. Wannan yana kaiwa ga saurin kayan aiki na sutura kuma yana iya mummunan tasiri game da ingancin yanayin yanke.

Harder Titanium Alolays yana buƙatar ƙarin kulawa. Mafi girma guntu lops da ƙananan rpm akan na'urar CNC. Amfani da sandar sanyaya mai zurfi na iya taimakawa kayan aikin yankan suna aiki mafi kyau da samar da ingantattun sassan Titanium ingantattu.

Titanium Aloys kuma suna buƙatar runduna mai yawa, wanda ya sa su wahala a yanka. Wadannan sojojin na iya haifar da:

● Wurin kayan aiki

● Bangarorin kuskure ba

● Babban tsananin rawar jiki, ingancin samfurin da ƙarewa

Magance tsayayya da damuwa da kayan aiki

Titanium Aloleys suna da tsarin cristal wanda ya sa su zama masu sassauƙa. Wannan na iya haɓaka Sojojin yankan lokacin da ke sarrafa su, yana rage mama.

Tsarin kristal zai iya haifar da damuwa cikin aikin. Wadannan matsalata na iya haifar da:

● Warping ko karkatar da sashin

● Crating

● rage sashe na rayuwa

Titanium low yuwuwar suma yana ba da gudummawa ga ƙwayar ƙwayar lokacin da injin ke. Yayinda ake yanke kayan, ya zama da wahala kuma mafi farare ga kayan aikin yankan.

Tsarin miking don titanium

Takaitaccen Titanium Mactining

Titanium abu ne mai wahala don aiki tare. Tana da haɗin kaddarorin da ke sanya hanyoyin da ba ta dace ba. Fahimtar wadannan kalubalen yana da mahimmanci don samun mafita don samar da kayan aikin titanium sassan Titanium.

Taro mai zafi: Tsarin zafi titanium yana haifar da haɓaka zafi mai zafi a wurin kayan aiki. Wannan yana ƙaruwa da kayan aiki da kuma mafitar titanium ci gaba, ya tsananta matsalar.

● 'Gummy '' Kayan aiki: Titanium's low modulity idan aka kwatanta da babban ƙarfin sa ya sa shi a 'gummy ' kayan. Yana iya mika kayan aiki na yankan, haifar da gazawar kayan aiki da ƙarancin ƙare.

● Hoto da Springback: Tarihin Titanium na iya haifar da rawar jiki na aiki (Tattaunawa) da Spritback a cikin yanke wa wurin yankan, samar da yanayin rashin daidaituwa da sulhu.

Zabi Kayan Kayan Yanke na Titanium

Zabi Kayan Kayan Yanke na dama yana da mahimmanci ga injining titanium. Kayan aikin ƙarfe mai saurin saurin ƙarfe, da aka yi da tungsten, carbon, da vanadium, da kuma Vanadium, da kuma kula da wuya har zuwa 600 ° C. Suna ba da damar zurfin yanke kuma suna rage guntun gefuna.

Kamar yadda titanium shahararren ke tsiro, masana'antun manoma suna bunkasa mafita:

Heldings: Kyawawan-mai tsayayya da zafi kamar titanium aluminum nitride (titanium carbo-nitride (ticn) na iya mika rayuwar kayan aiki.

● Rashin yankewa mai kyau

Yi amfani da kayan aikin titanium mai inganci kuma maye gurbin kayan aikin mara kyau akai-akai. Yi la'akari da karami na diamita na diamita tare da ƙarin gefuna don kula da farashin mai ƙarfe yayin rage gyaran zafi.

Aikin kayan aiki na samar da ingantawa

Kayan kayan aiki na iya inganta ikon kayan aiki don yin tsayayya da zafin da aka kirkira lokacin da injiniko. Tialn (titanium aluminum nitride) shine abin da ya dace da cewa:

● A samar da mai gina jiki don yaƙi da gefuna, galling, da guntu waldi.

Yana da dacewa sosai don babban yanayin zafi da aka ɗanɗana lokacin da injiniko titanium.

Mahimmancin barga da rage lokacin hutu

Titanium yana da yiwuwar haifar da wasan kwaikwayo na kayan aiki (rawar jiki), don haka rage vibration yana da mahimmanci. Amintaccen aikin aiki da tabbaci don hana ƙyalli. Yi amfani da injunan CNC mai inganci tare da ingantaccen kayan aikin kayan aiki na kayan aiki. Yi la'akari da amfani da kayan aikin yankan yankan don rage ƙirar kayan aiki.

Hawa milling vs. Milling na al'ada na titanium

Milling na al'ada: A cikin wannan hanyar ta al'ada, fadin guntu yana farawa na bakin ciki da ƙaruwa, sanya ƙarin zafi a cikin aikin da ƙara yawan zafi.

Dama Miling: Faɗin Fici na Farko yana farawa mai tsayi da raguwa, inganta yanayin zafi zuwa guntu maimakon kayan aiki. Hakanan yana haifar da tsabtace tsabtace da jan kwakwalwan kwamfuta a bayan cutarwa, yana hana tsangwama.

Dutsen Milling dabara ce mai amfani don ci gaba da kwakwalwan kwamfuta a bincika lokacin da maching titanium.

Nasihu na Titanium

Sarrafa zafi: dabarun don kiyaye yanayin zafi

Tsayawa zafin jiki ƙasa yana da mahimmanci lokacin da maching titanium. Tun da titanium ba ya yin zafi sosai, yawancin kuzarin yana shiga cikin kayan yankan. Wannan zafin zai iya haifar da:

Rashin aiki na kayan aiki

● Rashin kayan aiki da ƙarin shafa, yana haifar da ko da zafi

Hukumar wuta tare da wasu kayan

Yi amfani da yawan coolant na karimci don kawo yanayin zafi. Tsarin matsin lamba mai laushi wanda ke birgima yankin aiki da kayan aiki tare da coolant 10% mai da hankali yana aiki da kyau. Ƙara yawan coolant na iya taimakawa.

Tabbatar da lafiya don mafi kyawun abin hawa

Fitar da kayan aikinka don girgiza kai da jarirai da kuma jarirai suna ƙara ƙarin nau'in, yana haifar da suturar rai. Guji shigar da kayan aiki kai tsaye cikin titanium. Madadin:

● A hankali a hankali ARC Aikin ciki don sauƙaƙa shi a cikin yanke

● Bi lokacin da bakin ciki-zuwa-bakin ciki niƙa a cikin wannan shugabanci (na agogo ko kuma counterclockwise) azaman kayan aiki

A ƙarshen yanke, yi amfani da charfer (tsagi tsagi). Wannan yana ba da kayan aiki a hankali ya rasa zurfin, sauyawa sau da yawa.

Kulawa Kayayyaki: Kiyaye kayan aikinka kaifi da inganci

Kayan aiki mai kaifi yana da mahimmanci don ingantaccen titanium yankan. Koyaya, titanium zai iya hanzarin kayan aikin ku da sauri. Binciko su akai-akai kuma a maye gurbin kowane nuni alamun sa.

Kayan aiki mara kyau zai samar da sau da yawa kuma yana lalata ko da sauri, hade da batun.

Dabaru don rage galling da chiping

Galling: titanium a sauƙaƙe alloys tare da wasu kayan, yana haifar da galling da sake saita gefuna yayin yankan. Tsayawa zafin rana, ta amfani da kayan aikin kaifi, da maɓuɓɓuilts na iya rage wannan.

Chiping: Lokacin da aka yanke katako da aka yanke kuma a bi gefen yankan, ana kiranta chiping. Ofarin tasirin yin gasa kuma yana lalata kayan aiki mai tsanani.

Hakanan kaifi mai aiki da kuma mai kuma zai taimaka wajen rage chipping lokacin injin titanium.

Al'ummar Mactining da mafita

Heating Head a lokacin da injin

Daya daga cikin manyan ƙalubalen lokacin da injiniyan ke riƙe kowane abu mai sanyi. Yin amfani da titanium loweral loweral da ke haifar da saurin zafi a cikin kayan aiki.

Aiki na sanyaya

A bayyane yake bayani ga zafi mai yawa yana amfani da ƙarin sanyaya. Bayar da yankin aiki da kayan aiki tare da coolant 10% na maida hankali zai kiyaye yankin lambar sanyi. Hakanan zai wanke kowane mai dauke da kwakwalwan kwamfuta.

Tasirin Coolant na Coolalant

Don kunna aikace-aikace, matsayi da matsin lamba na sanyaya suna da mahimmanci. Tare da aikace-aikacen da ya dace, ana iya samun matakan saurin cirewar da ƙarfe na cire matakan.

Koyaya, sanyaya-ido mai zurfi na iya haifar da sake fasalin kayan duniya a saman ɓangaren ɓangaren. Ana iya shawo kan wannan ta hanyar tsara dabarun yankan da rage matsin lamba na sanyaya-ruwa don ƙarshe ƙare.

Hana aiki hardening

Titanium yana iya yiwuwa ga aiki hardening. Yayinda ake yanke kayan, ya zama da wahala kuma ya fi ƙarfin kayan aikin.

Mahimmancin abinci na yau da kullun

Kula da ƙarancin abinci koyaushe yana tabbatar da cewa yankan kayan aiki-tauraruwa ana kiyaye su zuwa mafi karancin. Wannan yana hana ƙarin aiki da kayan aiki mai yawa.

Daidaita darajar abinci

Idan za ta yiwu, ƙara yawan abinci na iya zama da amfani. Yana nufin kayan aiki ya kwashe lokaci mai tsawo a cikin takamaiman yanki, yana ba da ƙarancin zafi da hardening a gefen yankan.

Kayan aiki na Titanium

Zabi kayan hannun dama

Kayan aikin kayan kwalliya tare da kayan aikin pvd sun fi dacewa da yankan titanium. Newer mayu kamar TILN (Titanium Aluminium nitride) ana kuma akwai.

Titanium kayan abinci ne na sprisy, don haka mai kaifi kayan aiki yana da matukar muhimmanci. Kayan aikin dumama zai shafa farfajiya kuma suna haifar da hira.

Kayan aiki da Kulawa

Kayan kwalliya kamar TILN inganta ikon kayan aiki na tsayayya da babban zafi lokacin da injin din titanium. Suna ba da lubricity kuma suna dacewa da babban yanayin zafi.

Binciken kayan aiki na yau da kullun da maye gurbin kayan aikin mara hankali ya zama dole, kamar yadda kayan aikin ɓalle ke samar da ƙarin zafi da kuma sukan fita da sauri.

Tsarin sarrafa guntun guntu

Titanium na iya samar da dogon kwakwalwan kwamfuta wanda zai iya rage lalacewa a sauƙaƙe kuma yi alamar farfajiya. Tsawon, kwakwalwan na bakin ciki kuma ba su taimaka tare da canja wurin da wuta daga cikin yankin aiki.

Yin amfani da kayan aiki da kayan aiki waɗanda ke haifar da karami, kwakwalwan kwakwalwan kwamfuta yana da kyau lokacin da miking titanium. Gudanar da Kayayyakin Kayayyaki yana da mahimmanci.

Karkatar da mafita don daidaito da aminci

Amintaccen kayan aikin yana da mahimmanci lokacin da injin din titanium. Yana cire rawar jiki daga tsari, bada damar mafi kyawun yankan bayanai.

Yawancin sassan titanium suna da sassan bakin ciki, don haka amfani da mafita mai amfani da al'ada don ayyukan ƙarshe da ake samar da sakamako mafi kyau. Sau da yawa yana ba da damar samun dama da tallafi ga bangaren.

Ingantaccen Kayan aiki don Ingantaccen Masara

Zabi hanyar dama ta dama tana da mahimmanci kamar zabar kayan aiki daidai lokacin da injin din titanium.

Hanyoyin kayan aiki waɗanda ke tabbatar da yanayin cunkoson abinci a cikin kayan aikin ya zama dole. Misali, tsarin tsaro yayin yankan wani yanki yana rage lokacin da yake ɗaukar hoto ɗaya yana tsunduma, yana iyakance ginin ginin zafi.

Sanya kayan aiki a ciki da waje na aikin yana rage rawar jiki da tsinkaye motsi wanda zai iya lalata kayan aikin lalata.

Tsarin tsallakewa na farfajiya na sassan titanium

Jagora don yin ruwa, anodizing, da chroming

Bayan Cnc Mactining, titanium sassan za'a iya inganta tare da jiyya na gama gari. Waɗannan jiyya suna iya yin aiki ko dalilai na ado.

Polishing shine yanayin gama gari gama gari. Yana taimaka wa smoothen kuma inganta bayyanar titanium sassan.

Anodized tsari ne na gari wanda ke haifar da dorewa, kayan girke-girke mai ado a kan titanium surface. Yana inganta lalata jiki da sanya juriya.

Chroming ya ƙunshi yin ajiyar murfin bakin ciki na chromium akan titanium ɓangaren. Yana inganta halaye na farfajiya kamar bayyanar, taurin kai, da kuma juriya juriya.

Gwaji foda foda, pvd shafi, da gogewa

Foda shafi na bushe shine tsari mai bushe inda ake amfani da foda mai caji sannan aka warke a ƙarƙashin zafi. Yana ba da kyakkyawan ƙura da kariya ga lalata lalata lalata titanium sassan.

Pvd (ajiye turawan iska) shafi tsari ne mai saka kaya wanda ke haifar da bakin ciki sosai, mai wuya gashi a kan titanium sassan. Pvd Solegings inganta kaddarorin kamar sutura da juriya na lalata.

Gogewa abu ne mai sauki na ƙirƙirar alamu ko rubutu a kan titanium farfajiya ta amfani da filayen farfado. Zai iya samar da finafins kamar gashi ko alamomi madauwari.

Wadannan magungunan saman su ba da izinin kaddarorin Titanium don takamaiman buƙatun aiki ko tasirin gaske a aikace-aikace daban-daban.

Aikace-aikacen aikace-aikace na CNC Macal Motocin A Titanium sassan

Titanium a cikin Aerospace: bayan kayan yau da kullun

Titanium anyi amfani dashi sosai a cikin masana'antar Aerospace saboda kwarai na musamman. Yana da babban ƙarfin-da-nauyi-nauyi, ficewar lalata lalata jiki, kuma zai iya tsayayya da ƙiyayya da tsananin zafi.

A cikin Aerospace, CNC Motocin Aitanium sassan Titanium sun hada da:

● Abubuwan Jirgin Sama na Jirgin Sama Kamar Abincin Turbine da kuma sassan mai ɗora

Tsarin Airframe da kayan aikin

● rotors da shafewa

Titanium rings samar da jirgin sama - kimanin kashi biyu cikin uku na samar da wadataccen Titanium da ke cikin injunan jirgin sama da iska.

Aikace-aikacen Marine da Aikace-aikacen Aikace-aikacen: Dorambility a ƙarƙashin teku

Idan aka kwatanta da yawancin metals, titanium yana da manyan juriya. Wannan ya sa ya zama cikakke ga yanayin da ke cikin mummunan ruwa a cikin aikace-aikacen ruwa.

Titanium Rarine sun hada da:

●

● ● A karkashin robotics na robotics

Ganyayyaki kayan aiki

● ball m

● A cikin masu musayar zafi

Bututun wuta na wuta

● farashin

Lainan wasan kwaikwayon ●

● A kan tsarin sanyaya tsarin

Matsayin Titanium a cikin Innetwotive Basani

Yayin da aluminum ya mamaye sashin mota, titanium na kwarai kaddarorin sa ya dace da wasu sassan mota:

● Injiniyan Bakuljoji da Bawul

● refingers

● dakatar da maɓuɓɓugan ruwa

Calipers ● birki

● Haɗa sanduna

● Piston Pist

● Kayan injin

Titanium inganta aiki yayin rage nauyi a cikin wadannan abubuwan.

Tasirin Titanium akan filayen likita da kayan haƙori

Titanium na biocompatticultion, lalata juriya, da ƙananan abubuwan lantarki da ke sa shi mai mahimmanci don aikace-aikacen likita. Dabi'unsa na ilimin halittarsa ta hanyar inganta osseointegration (rashin daidaituwa na kashi).

Abubuwan Titanium na yau da kullun sun haɗa da:

Orhopedics (hip, gwiwa)

Yawan faranti da sukurori

Rods na konewa, faranti, masu haɗin

● Rashin damuwa, gadoji, rawanin

●

Abubuwan da kadarorin Titanium suna ba da damar amfani da shi a cikin jikin mutum, yana tasiri rayuwa kowace rana.

Hadin gwiwa tare da kameamfg don injin titanium

TeamMfg inji iyawa-titanium

Kungiyar Teamemfg ta tashi a cikin masana'antar da ta dace da fasaha ta jihar-art da fasaha mai girma, musamman a cikin Janar Mactining Titanium. Abubuwan da kamfanin ke samar da damar sarrafa kamfanin na Kamfanin Kamfanin don magance kalubale na musamman da aka gabatar, don tabbatar da daidaito, inganci, da inganci a cikin kowane bangare da aka samar.

Tushen nasarar Teammfg a cikin injin din Titanium ya ta'allaka ne a kayan aikinta na yankan kayan aiki da dabaru. Sanye da injinan CNC na 5-Axis, TeamMFG na iya yin yanke hukunci da cikakkun bayanai game da daidaitattun sassan titanium tare da daidaito. Wannan ikon yana da mahimmanci ga masana'antu na buƙatar ingantaccen kayan aiki, kamar Aerospace da na'urorin kiwon lafiya.

Bugu da ƙari, sadaukarwar ƙungiyar ƙungiyar ta haɓaka kayan aikinta da dabarun shirye-shirye, musamman don injunan Titanium. Ta hanyar zabar kayan aiki masu inganci da haɓaka sigogin gama gari kamar su kayan aiki na yau da kayan aiki, don tabbatar da tsarin masana'antu a cikin farawa. Tuntube mu a yau!

Labarun Nasara: ra'ayoyin canji cikin gaskiya

Forungiyar TeamMFG na labarun nasara na nuna bambancin ayyukan da kamfanin ya aiwatar. Misali wanda aka sani ya hada da samar da kayan aikin Aerospace-Confulum yana rage yawan samar da TeamMfg da tsada yayin da muke riƙe da tsayayyen Aerospace.

Wani labarin nasara wanda ya ba da karin haske game da rawar da Teamemfg a cikin masana'antar likita, inda sabis na kamfanin da ke kan kamfanin rashin lafiya na Titanium. Wadannan abubuwan da aka nuna, da aka sani da biocatibility da karkatacciyar magana da kuma inganta cutar mai haƙuri a matsayin abokin tarayya amintattu a cikin masana'antar kiwon lafiya.

Waɗannan labarun nasara suna nuna damar haɓaka ƙirar fasaha kawai har ma da sadaukar da kai ga gamsuwa na abokin ciniki da nasarar aikin. Ta hanyar aiki tare tare da abokan ciniki, fahimtar bukatunsu na musamman, kuma ya ba da damar samar da kasuwancin da ya shafi wadatattun hanyoyin samar da ingantattun abubuwa, manyan sassan titanium.

Hadin gwiwa tare da ingila na injunan titanium yana nufin fiye da yadda ake samun damar ayyukan mikiya kawai; Labari ne game da haɗuwa da sojoji tare da sadaukarwa mai sadaukarwa sun himmatu wajen tura iyakokin ingarewar masana'antu. Ko kun kasance a cikin Aerospace, Aerdootive, likita, ko masana'antar ruwa, mafita ta hanyar da ba a daidaita ayyukanku suna da nasara, akan lokaci, da kuma kasafin kuɗi.

Ƙarshe

Takaita mahimmin maki a kan Titanium

Titanium abu ne na kwarai da kayan yau da kullun da kaddarorin kamar babban ƙarfi, nauyi, lalata jure yanayin zafi. Koyaya, waɗannan halaye iri ɗaya waɗanda suke kyawawa kuma suna haifar da ƙirƙirar ƙalubale lokacin da miking titanium sassan.

Wadanda ke kamuwa da batutuwa kamar saurin zafi na zafi, galling, hira, da kuma hardening na buƙatar aiwatar da abubuwan da ake sarrafawa a hankali kamar:

● Amfani da kayan aikin yankan yankan da sanyaya kayan kwalliya don titanium

● Kula da tsayayyen tsayayyen tsari don rage rawar jiki

● Yin daidaitawa da sigogi na yankan kamar farashin abinci da kuma amfani da coolant mai tsayi

● Aiwatar da dabarun kamar hawa niƙa don mafi kyawun tsari

Mastering waɗannan dabarun ba da damar masana'antun don buɗe cikakken ƙarfin titanium a cikin masana'antu masu bambanci.

Makomar titanium a cikin CNC Mur-Motosing da Aikace-aikacen Masana'antu

A matsayin finafinan masana'antu suna ci gaba da cigaba, zamu iya tsammanin ganin titanium da aka yi amfani da shi sosai a cikin sassan da yawa. Inganta damar sarrafa kayan Cnc, magunguna masu ƙara masana'antu don titanium, da kuma sabon titanium sutturar ci gaba zai fitar da wannan fadada.

Aerospace zai kasance babban direban bukatar titanium. Amma kuma zamu iya bada shaidar girma titanium Aikace-aikacen Automototive, makamashi, kayan masu amfani, kuma musamman filin likita saboda babi na biocativity.

Tare da kwarewar da ta dace da yankan kayan aiki, masana'antun zasu iya shawo kan ƙalubalen injin titanium. Wannan zai buše sabbin dama don yin amfani da wannan kadarorin ƙwayoyin ƙarfe a cikin samfuran samfuran da suka gabata ba zai yiwu ba ko kuma ba a yiwuwa don samar da.

Tambayoyin Tambayoyi na CNC

Tambaya: Ta yaya zaɓin sanyaya mai sanyaya na Titanium?

A: coolant zabi yana da mahimmanci. Babban matsin lamba, 10% mai maida hankali a sanyaya kayan aiki. Volant mai dacewa yana hana zafi, rayuwar tsawan kayan aiki.

Tambaya: Menene matsalolin da aka saba ci karo da su lokacin da injin din titanium?

A: Abubuwa na yau da kullun sun haɗa da kayan aikin zafi, galling, chatter, da kuma taurara. Wadannan kalubalen suna buƙatar dabaru na musamman don shawo kan.

Tambaya: Zan iya amfani da daidaitattun kayan aikin don injiniyar titanium?

A: A'a, kayan aikin daidaitattun kayan aiki ba su da inganci. Yi amfani da kayan aikin carbide na carbide da aka tsara musamman don titanium don hana sutturar da ta dace.

Tambaya: Me ke sa titanium ya bambanta da sauran karafa a cikin injin?

A: Titanium mai ƙarancin zafin rana yana haifar da haɓaka haɓaka zafi. Modulus m modulus ya sa shi 'gummy ' da kuma iya yiwuwa a tattaunawar.

Tambaya: Ta yaya tsananin juriya na titanium zai shafi tsarin sarrafa shi?

A: Titanium juriya yana haifar da mafi girma yankuna da ake bukata. Dace sanyaya da sigogi masu mahimmanci wajibi ne.

Tambaya: Menene amfanin amfani da milling milling akan milling na al'ada don titanium?

A: Dutsen Milling na inganta yanayin zafi don kwakwalwan kwamfuta maimakon aikin kayan aiki. Hakanan yana rage ƙage don mafi kyawun ƙarewar ƙare.

Tambaya: Ta yaya zan iya hana suttura da gazawar lokacin da injin din titanium?

A: Yi amfani da mayafin da suka dace kamar tialn kuma maye gurbin kayan aikin mara kyau a kai a kai. Tsayayyen saiti da ingantattun sigogi suma suna rage sutura.

Tambaya: Menene aikace-aikacen gama gari don sassan da aka yi wa Titanium?

A: Aerospace, likita, kayan aiki, da masana'antar marine amfani da injin manya don ƙarfinsa, biocompativity, da juriya na lalata.