Kabini mobili baara daminɛna san kɛmɛ 19nan laban na, fɛn dilanni ɲɛtaa kɛra sababu ye k’a ka yiriwali n’a ka ɲɛtaa sabati. K’a ta Henri Ford ka lajɛba daminɛni na san 1913 ka se ɔtomatizi jiginni ma nin san tan laban ninnu na, mobili baarakɛlaw bɛ ka wuli ka taa a fɛ walasa ka diɲɛ caman caman ɲɔgɔnna ɲininiw dafa.

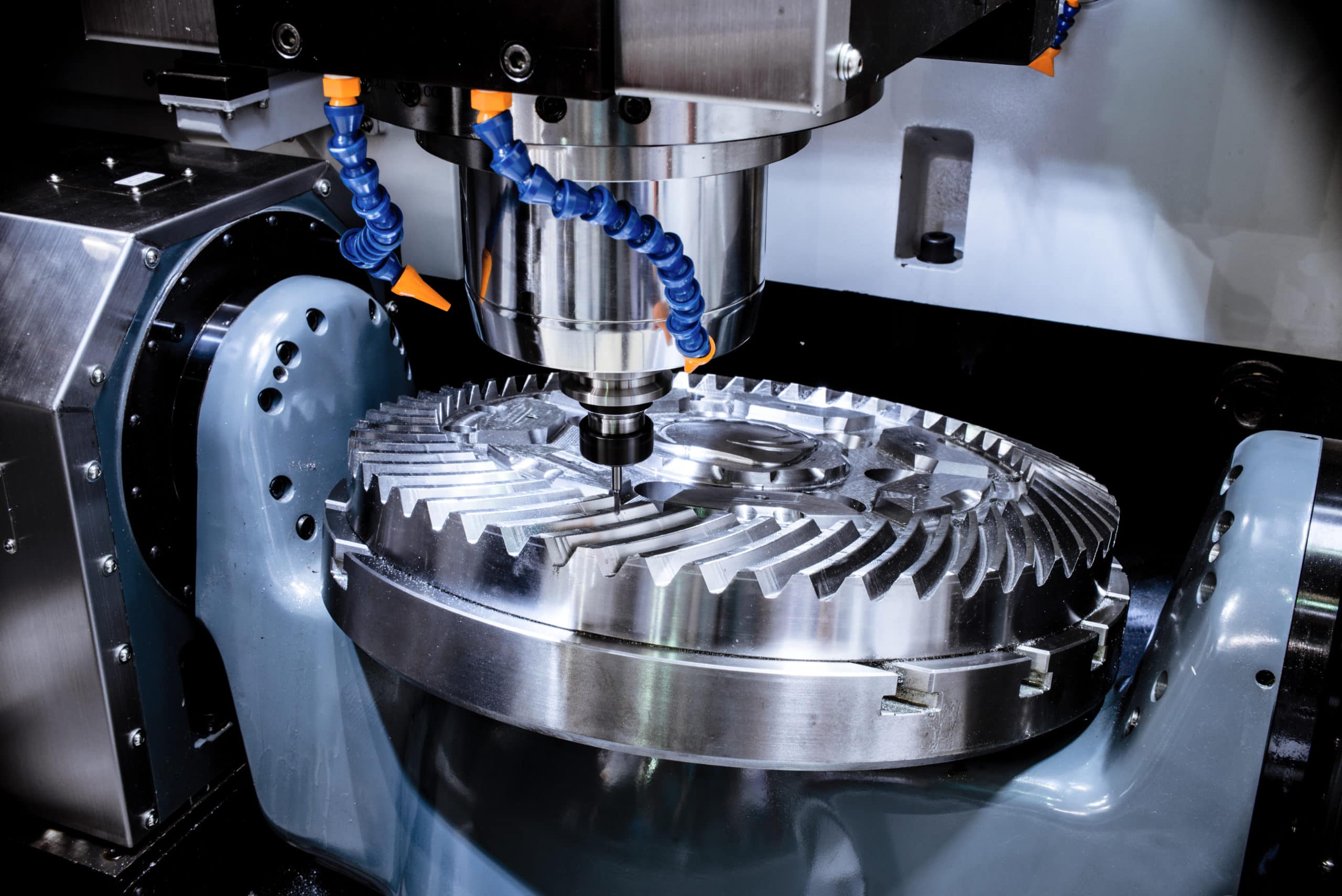

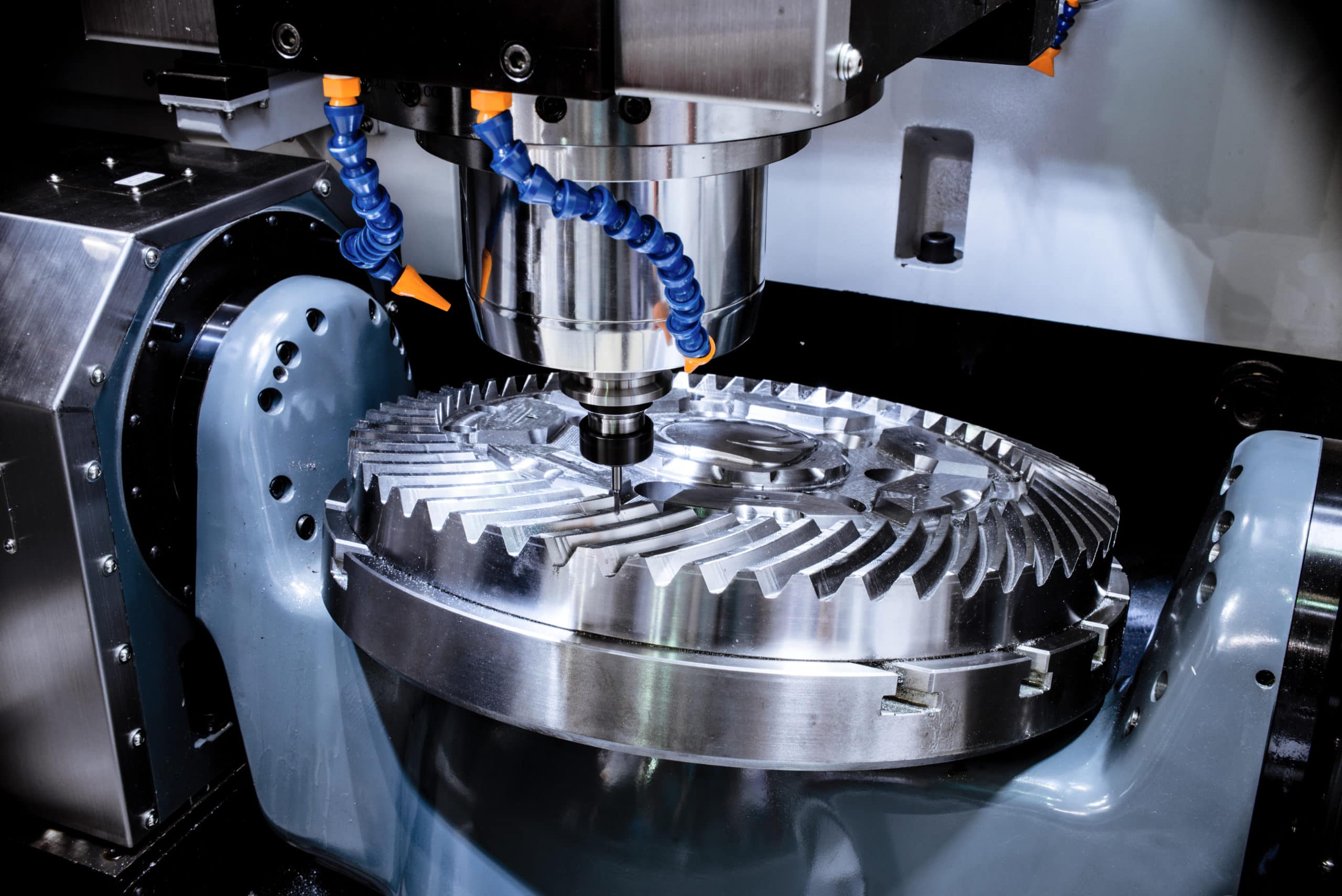

Bi, CNC masinw bɔra kɛnɛ kan ka kɛ fɛnba ye bi mobili dilanni na, min bɛ se ka kɛ sababu ye ka yɔrɔ ɲumanw, tigitigiw, ani yɔrɔ gɛlɛnw dilan ni baarakɛcogo ɲuman ye min ɲɔgɔn tɛ ani ka segin a kan.

Nin barokun in bɛna CNC masinw jɔyɔrɔba sɛgɛsɛgɛ mobili baara la ani a ye fɛn caman sɛmɛntiya mobili dilanni cogo la.

CNC machining ye mun ye?

CNC Machining, n’o ye ɔridinatɛri jatebɔ-minɛn ye, o ye fɛn dilanni ye min bɛ baara kɛ ni ɔridinatɛriw ka kunnafonidilanw ye ani tigɛminɛnw ye walasa ka fɛnw bɔ baarakɛminɛn dɔ la, ka yɔrɔw dilan minnu dilannen don ka kɛɲɛ ni mɔgɔw sago ye, ani minnu bɛ se ka segin-ka-bɔ. O fɛɛrɛ in ye fɛn caman sɛmɛntiya mobili baara la, a kɛlen ka se ka fɛn gɛlɛnw, minnu ka ɲi kosɛbɛ, olu dilanni na, cogo la min musaka ka dɔgɔ ani min bɛ baara kɛ ka ɲɛ.

CNC masinw bɛ baara kɛ cogo min na .

CNC masinw bɛ baara kɛ ni cikanw ye minnu bolodara ka kɔn, minnu bɛ wele ko G-Code, minnu bɛ tigɛminɛnw bilasira walasa ka fɛnw bɔ baarakɛminɛn na cogo tigitigi la ani cogo la min bɛ se ka kɔlɔsi. Taabolo in bɛ tali kɛ nin wale ninnu na:

1. Design: Enzeniyɛriw bɛ 3D modɛli dilan yɔrɔ ɲininen na ni CAD (computer-aided design) porogaramu ye.

2. G-Code Generation: O kɔfɛ, CAD modɛli bɛ wuli ka kɛ G-Code ye ni CAM (Ɔridinatɛri dɛmɛna ni fɛn dilanni) porogaramu ye.

3. Setup: Baarakɛminɛn bɛ siri ka ɲɛ CNC masin kan, ani tigɛminɛn bɛnnenw bɛ sigi sen kan.

4. waleyali: CNC masin bɛ G-code kalan ani ka lamaga-lamagali porogaramulenw kɛ, ka fɛnw bɔ baarakɛminɛn na i n’a fɔ a ɲɛfɔlen bɛ cogo min na.

5. Finishing: Ni masina baara dafara, a yɔrɔ laban bɛ bɔ masin na, ka sɛgɛsɛgɛli kɛ, ani ka baara kɔfɛta wajibiyalen o baara kɛ (i n’a fɔ saniya walima yɔrɔ furakɛli) o bɛ kɛ.

CNC masin suguya minnu bɛ kɛ mobili baara la .

Mobiliko bɛ tali kɛ CNC masin suguya caman na walasa ka fɛn caman dilan minnu ka kan ka kɛ mobili dilanni na. A suguya dɔw ye:

1. CNC Milling Machines : Nin masin ninnu bɛ baara kɛ ni tigɛminɛnw ye minnu bɛ wuli ka bɔ u nɔ na walasa ka fɛnw bɔ baarakɛminɛn kɔnɔ, ka fɛnw dilan i n’a fɔ dingɛw, yɔrɔw, ani bɔrɔw. U ka ɲi kosɛbɛ motɛri yɔrɔw, transmisi yɔrɔw ani suspension yɔrɔw dilanni na.

2. CNC jiginni masinw : A bɛ fɔ fana ko CNC lathes, o masinw bɛ baarakɛminɛn wuli ka sɔrɔ tigɛminɛn bɛ fɛnw bɔ, ka silinda yɔrɔw dilan i n’a fɔ shafts, bushings, ani bearings.

3. CNC grinding machines : Nin masin ninnu bɛ baara kɛ ni abrasive wheels ye walasa ka fɛn fitininw bɔ baarakɛminɛn na, ka tolerances sirilenw sɔrɔ kosɛbɛ ani ka finiw nɔgɔya. U bɛ kɛ ka caya ka ɲɛsin transmission gears, camshafts ani fɛn wɛrɛw dilanni ma minnu bɛ se ka kɛ fɛn wɛrɛw ye.

4. CNC laser tigɛlanw : O masinw bɛ laser fanga caman kɛ ka fɛnw tigɛ, ka u sɔgɔ, walima ka u sɔgɔ, o b’a to u ka ɲi kosɛbɛ walasa ka nɛgɛdaga gɛlɛnw dilan, i n’a fɔ farikolo panɛriw ani kɔnɔna fɛnw.

Ni nin CNC masin suguya caman bɛ se ka baara kɛ, mobili dilannikɛlaw bɛ se ka fɛn caman dilan minnu bɛ se ka kɛ ni tiɲɛni ye, min tɛ se ka suma ni fɛn wɛrɛ ye, min bɛ se ka kɛ, ani min bɛ se ka segin a kan, o laban na, o bɛ na ni bolifɛnw ye minnu ka ɲi kosɛbɛ, ani ka fɛn dilanni taabolo nɔgɔya.

Nafa minnu bɛ CNC masin na mobili baarakɛlaw la .

CNC masinw kɛra baarakɛminɛn ye min nafa ka bon mobili baara la, min bɛ nafa caman di minnu ye fɛn dilanni taabolo caman sɛmɛntiya. K’a ta tiɲɛni ni tiɲɛni na ka se otomatiki ni musaka dɔgɔyali ma, CNC masinw y’a jira ko u ye tulonkɛfɛn ye mobili dilannikɛlaw bolo.

Tiɲɛni ni tiɲɛni .

CNC masinko nafa min ka bon kosɛbɛ, o dɔ ye a seko ye ka yɔrɔw dilan minnu bɛ se ka kɛ fɛn ye min bɛ se ka kɛ fɛn ye min bɛ se ka kɛ fɛn ye min bɛ se ka kɛ. O nafa ka bon kosɛbɛ mobili baara la, yɔrɔ min na hali fɛn fitinin minnu bɛ se ka kɛ, olu bɛ se ka kɔlɔlɔ juguw lase mobili baarakɛcogo n’a lakanani ma.

1. Tolerances sirilenw : . CNC masinw bɛ se ka muɲuli sɔrɔ ka gɛlɛn i n’a fɔ ±0,0001 insi, k’a lajɛ ko yɔrɔw bɛ bɛn ɲɔgɔn ma cogo dafalen na ani u bɛ baara kɛ i n’a fɔ a laɲininen don cogo min na.

2. Bɛnkansɛbɛn yɔrɔ dɔ dilanni na : CNC masinw bɛ jateminɛ kɛ ka ɲɛsin sɔrɔw ma minnu bɛ bɛn ɲɔgɔn ma sɛnɛ caman na, ka dɔ bɔ fɛn dilanni filiw farati la ani k’a lajɛ ko yɔrɔ bɛɛ bɛ bɛn sariyaba kelenw ma.

Otomatiki ni baarakɛcogo ɲuman .

CNC masinw ye baara ye min bɛ kɛ ni otomatiki ye kosɛbɛ, min bɛ baara kɛ ni baarakɛcogo ɲuman ni baarakɛcogo ɲuman ye mobili dilanni siratigɛ la.

1. Baara musakaw dɔgɔyali : Ni u bɛ masinw dilanni kɛ otomatiki ye, u dilannikɛlaw bɛ se ka dɔ bɔ baara musakaw la kosɛbɛ minnu bɛ tali kɛ bololabaarakɛlaw ka baarakɛminɛnw na.

2. A dilanni waati teliya : CNC masinw bɛ se ka baara kɛ teliya la ani ni jɔli waati ka dɔgɔn, o bɛ kɛ sababu ye ka fɛn dilannikɛlaw dɛmɛ u ka se ka yɔrɔw dilan teliya la kosɛbɛ ka tɛmɛ masinw ka laadala fɛɛrɛw kan.

3. 24/7 Baarakɛcogo : CNC masinw bɛ se ka boli ka taa a fɛ, sanga 24 tile kɔnɔ, tile 7 dɔgɔkun kɔnɔ, ka bɔnɔgɔla bɔli caya ani ka ɲɛtaa waatiw dɔgɔya.

Flexibilité et adaptibilité .

CNC masinw bɛ fɛn caman sɛgɛsɛgɛ ani ka ladamu, o bɛ kɛ sababu ye ka mobili dilannikɛlaw bila ka teliya ka jaabi di suguya caman ɲinini ma ani ka fɛn caman dilan.

1. Se ka jateminɛ gɛlɛnw dilan : CNC masinw bɛ se ka jateminɛ kɛ nɔgɔya la yɔrɔko gɛlɛnw na, i n’a fɔ kurufe gɛlɛnw, kɛrɛw, ani kontoronw, o b’a to u ka ɲi kosɛbɛ mobili yɔrɔ kɔrɔlenw dilanni na.

2. Yɛlɛma teliyalen : CNC masinw b’a to baarakɛminɛnw caman cili teliya la, o bɛ kɛ sababu ye ka fɛn dilannikɛlaw dɛmɛ u ka se ka fɛnw ni fɛnw cɛ minnu tɛ kelen ye ni jɔli waati fitinin ye.

3. Bɛn ni fɛn suguya caman ye : CNC machining bɛ bɛn ni fɛn caman ye, i n’a fɔ nɛgɛw, plastikiw, ani fɛnɲɛnamafagalanw, ka mobili dilannikɛlaw dɛmɛ u ka se ka fɛn bɛɛ la ɲuman sugandi a kɛcogo kelen-kelen bɛɛ kama.

musaka-nafa .

Hali ni wari fɔlɔ donna CNC masinw na, o fɛɛrɛ in bɛ musaka caman bɔ a la waati jan kɔnɔ, o b’a to a bɛ kɛ fɛɛrɛ ye min bɛ mɔgɔ ɲɛnajɛ mobili dilannikɛlaw bolo.

1. Fɛn tiɲɛnenw dɔgɔyali : CNC masinw ye baara ye min bɛ kɛ ka ɲɛ kosɛbɛ, min bɛ fɛnɲɛnamafagalanw musaka dɔgɔya, ka fɛnw musaka bɛɛ lajɛlen dɔgɔya ani ka sigida laminiko gɛlɛya.

2. Baarakɛminɛnw ɲɛnamaya janya : CNC masinw bɛ baara kɛ ni tigɛminɛnw ye minnu bɛ taa ɲɛ ani baarakɛminɛnw sira ɲumanw, minnu bɛ se ka baarakɛminɛnw ɲɛnamaya janya ani ka baarakɛminɛnw musakaw dɔgɔya waati kɔnɔ.

3. Yɔrɔ caman na, fɛn minnu bɛ bɔ fɛn caman na, olu dilanni musakaw dɔgɔyali : CNC masinw musaka ka dɔgɔ kɛrɛnkɛrɛnnenya la sɛnɛfɛnw dilanni boliw la minnu bɛ kɛ ni hakɛ caman ye, bawo, sigicogo musaka fɔlɔw bɛ jɛnsɛn yɔrɔ caman kan.

Ni CNC masinw ka baarakɛcogo ɲuman, u ka baarakɛcogo ɲuman, u ka fɛn caman sɛgɛsɛgɛli, u ka fɛnw sɛgɛsɛgɛli, ani u ka musakabɔcogo bɛ se ka kɛ sababu ye ka fɛnw dilan minnu ka ɲi kosɛbɛ, ka u dilanni taabolo nɔgɔya, ani ka to ɲɔgɔndan na baarakɛyɔrɔ la min bɛ ka wuli tuma bɛɛ.

CNC masinw baarakɛcogo mobili baara la .

CNC masinw jɔyɔrɔ ka bon kosɛbɛ mobili yɔrɔ caman dilanni na, k’a ta motɛri yɔrɔw la ka se suspension systems ma. A ka ɲɛfɔli dafalen, a ka baarakɛcogo ɲuman ani a ka fɛn caman kɛli b’a kɛ baarakɛminɛn ye min nafa ka bon kosɛbɛ dilanbagaw bolo minnu b’a fɛ ka yɔrɔw dilan minnu ka ɲi, minnu bɛ se ka da u kan. Nin yɔrɔ in na, an bɛna CNC masinko baarakɛcogo jɔnjɔn dɔw sɛgɛsɛgɛ mobili baara la.

Motɛri yɔrɔw .

Motɛri ye mobili suguya bɛɛ dusukun ye, wa CNC masin nafa ka bon a yɔrɔ nafama caman dilanni na. Misali damadɔw filɛ nin ye:

1. Silindri kunkolow : CNC masinw bɛ kɛ ka silinda kunkolow jateminɛcogo gɛlɛnw ni u cogoya tigitigiw dilan, i n’a fɔ valve sigilanw, buji dingɛw, ani nɛnɛmadafɛyɔrɔw. Tiɲɛni ni bɛnkan min bɛ sɔrɔ CNC masinw fɛ, o bɛ motɛri baarakɛcogo ɲuman ni a kɛcogo ɲuman sabati.

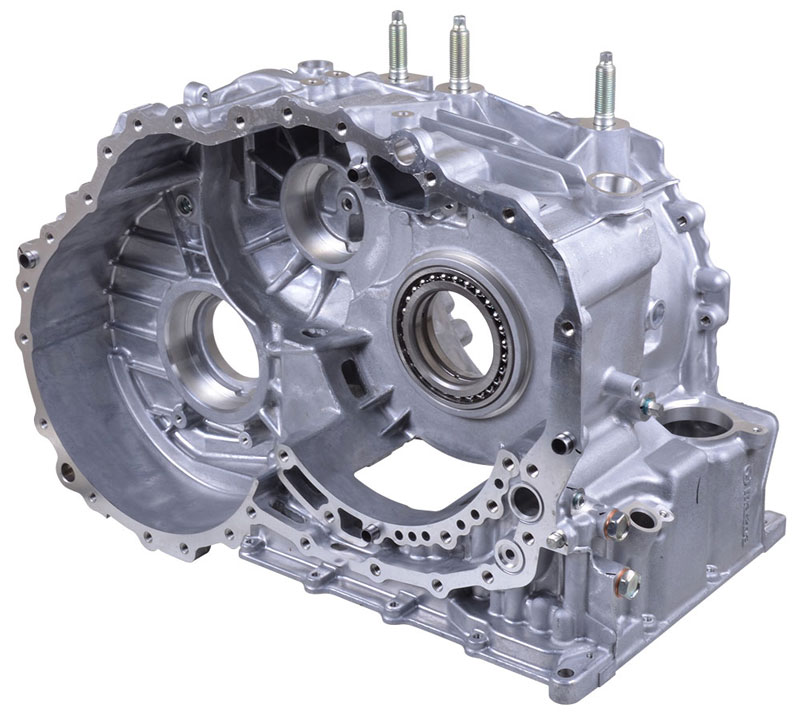

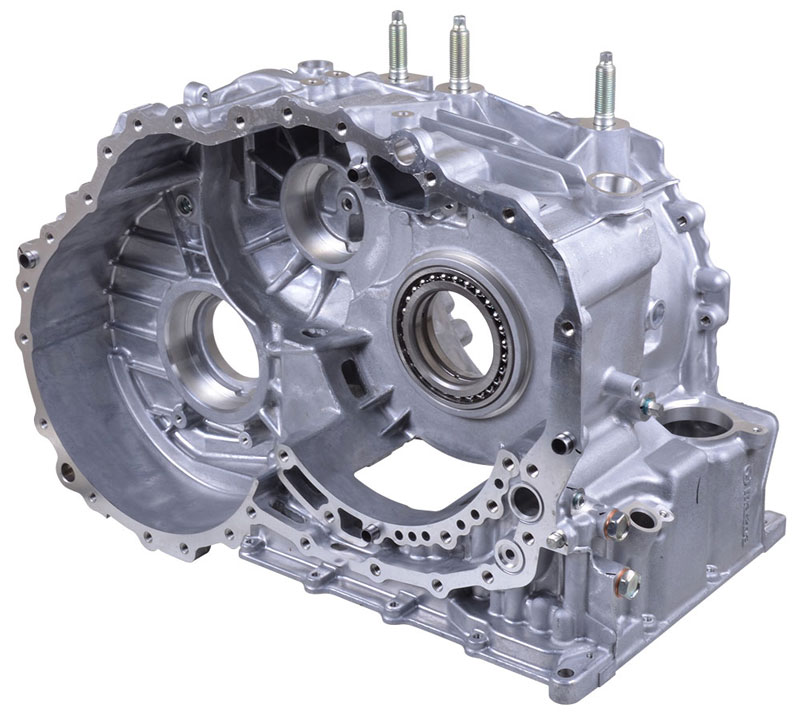

2. Motɛri blokiw : CNC masinw bɛ baara kɛ walasa ka motɛri blokiw kɔnɔna jateminɛ gɛlɛnw dilan, i n’a fɔ silindaw, birikiw kunbabaw, ani tulu tɛmɛsira. CNC masinw ka tiɲɛni ni u ka segin-ka-bɔnyeba bɛ a jira ko motɛri bloki bɛ muɲuli wajibiyalenw dafa walasa ka baara kɛ ka ɲɛ ani ka mɛn.

3. Pistons ani connecting berew : Nin yɔrɔ girinmanw bɛ motɛri kɔnɔ, olu bɛ dilan ni CNC masin ye walasa ka a jira ko a ka kan ka kɛ ni tiɲɛni ye ani ka a muɲu. A ka c’a la, pistonw bɛ kɛ ni masinw ye, ka sɔrɔ berew bɛ ɲɔgɔn sɔrɔ, a ka c’a la, olu bɛ dila ni nɛgɛ ye min bɛ kɛ ni nɛgɛ ye. O yɔrɔw dilanni tigitigi nafa ka bon kosɛbɛ walasa u ka bɛn, u ka balansi, ani u ka baara kɛcogo ɲuman.

Transmission yɔrɔw .

CNC masinw jɔyɔrɔ ka bon kosɛbɛ transmisi yɔrɔw dilanni na, minnu nafa ka bon walasa ka fanga bɔ motɛri la ka taa wotoro la. Tiɲɛni ni tiɲɛni min bɛ sɔrɔ CNC masinw fɛ, o b’a to o yɔrɔw bɛ baara kɛ cogo la min tɛ fɛn tiɲɛ, ka mobili baara kɛ cogo nɔgɔman na ani cogo ɲuman na. Nin ye kunnafoni-falen-falen-yɔrɔ koloma dɔw ye minnu dilannen don ni CNC masin ye:

1. Gears : transmission gears ye fɛn gɛlɛnw ye minnu bɛ ɲinw cogoya tigitigiw ni u jateminɛcogo ɲini walasa ka fanga jiginni nɔgɔya ani ka a kɛ ka ɲɛ. CNC masinw ka ɲi kosɛbɛ nin cogoya gɛlɛnw dilanni na, bawo a bɛ se ka muɲuli gɛlɛnw sɔrɔ ani ka sɔrɔw sɔrɔ minnu bɛ to sen na. CNC-machine gears ka tiɲɛni nafa ka bon mankan, yɛrɛyɛrɛ ani sɛgɛn dɔgɔyali la transmission kɔnɔ.

2. Shafts : transmission shafts, i n’a fɔ donnafɛnw ni bɔli jirisunw, olu ye fɛn nafamaw ye minnu bɛ torque ci girinw ni transmission yɔrɔ wɛrɛw cɛ. CNC masinw bɛ Kɛ ka o jirisunw Dabɔ ni u hakɛ wajibiyalenw ye, u dakunw, ani u ka fɛnw i n’a fɔ splines ani keyways. CNC-machine shafts tigitigi bɛ a to a bɛ se ka ɲɔgɔn sɔrɔ ani ka balansi sɔrɔ a jiginni kɔnɔ, ka yɛrɛyɛrɛli dɔgɔya ani ka a yɔrɔw ka ɲɛnamaya janya.

3. Sow : Laseli so ye fɛn gɛlɛn ye min bɛ girinw, jirisunw ani birikiw datugu ani ka dɛmɛ don fɛnw jiginni kɔnɔ. CNC masinw bɛ kɛ ka so kɔnɔna jateminɛ gɛlɛnw ni sow jiginni yɔrɔ tigitigiw dilan. CNC masinw ka tiɲɛni bɛ a to transmission yɔrɔw bɛɛ ka bɛn ɲɔgɔn ma so kɔnɔ, ka sira di baara kɛcogo ɲuman ma ani ka muɲu.

Ni CNC masinw bɛ baara kɛ ni fɛnw ye minnu bɛ bɔ fɛnw na, mobili dilannikɛlaw bɛ se ka nafa caman sɔrɔ:

l Ka baara kɛcogo ɲuman ni baara kɛcogo ɲɛ .

l Mankan ni yɛrɛyɛrɛ dɔgɔyali .

l Extended component lifespan .

l Baarakɛcogo basigilen ani dannaya bɛ min na .

CNC-machine transmission components ka tiɲɛni ni a ka tiɲɛni bɛ kɛ sababu ye ka mobili bɛɛ lajɛlen cogoya n’a baara kɛ, ka bolifɛn bolicogo ɲuman di feerekɛlaw ma.

Suspension components .

CNC masinw bɛ baara kɛ kosɛbɛ suspension yɔrɔw dilanni na, minnu jɔyɔrɔ ka bon kosɛbɛ mobili sabatili la, a minɛcogo la, ani a bolicogo la. CNC-machine suspension yɔrɔw ka tiɲɛni ni u ka muɲuli bɛ kɛ sababu ye ka mobili bɛɛ lakana ani ka baara kɛ. Nin ye fɛn dɔw ye minnu bɛ sɔrɔ ni CNC machining ye:

1. Contrôle arms : Contrôle arms ye fɛn kɔrɔlenw ye minnu bɛ mobili ka frame walima subframe ni bolifɛn ɲɛminɛlan cɛsiri, o bɛ sira di wotoro lamagacogo ma ani a ɲɔgɔnna ma. CNC masinw bɛ kɛ ka bolokɔfɛfɛnw dilan ni fanga, gɛlɛya ani jateminɛ tigitigi ye. CNC masinw ka tiɲɛni bɛ a to u ka se ka u kunbɛn ka ɲɛ ani ka wotoro labɛncogo ɲuman ni a kunbɛncogo ɲuman di.

2. Knuckles : steering knuckles, n’a bɛ fɔ fana ko spindles, olu ye fɛnw ye minnu bɛ wotoro yɔrɔ siri ni control bolow ye ani ka sira di wotoro jiginni ni bolifɛn ma. CNC masinw bɛ Kɛ ka kùnkolo-yɔrɔw ni u jɔli yɔrɔ tigitigiw Dabɔ. CNC-machine knuckles ka tiɲɛni bɛ a to wotoro ka ɲɔgɔn sɔrɔ cogo bɛnnen na ani ka bolifɛn bolicogo nɔgɔya.

3. Hubs : Wheel hubs ye cɛmancɛ yɔrɔw ye minnu bɛ wotoro ni frein rotor siri mobili ka suspension ni drivetrain na. CNC masinw bɛ kɛ ka hubuw ka bore ni u jiginni yɔrɔw tigitigi dilan, ka a to a ka bɛn kosɛbɛ ni birikiw ni fɛn wɛrɛw ye. CNC-machine hubs ka tiɲɛni n’a ka muɲuli nafa ka bon kosɛbɛ wotoro labɛnni sabatili la ani ka yɛrɛyɛrɛli dɔgɔya.

Nafa minnu bɛ CNC masin na ka ɲɛsin suspension yɔrɔw dilanni ma, olu ye:

l a minɛcogo ɲuman ni a sabatili .

l Yɛrɛyɛrɛli ni mankan dɔgɔyali .

l Extended component lifespan .

l Baarakɛcogo basigilen ani dannaya bɛ min na .

Ni CNC masinw bɛ se ka kɛ ka fɛnw jɔ, olu bɛ se ka kɛ sababu ye ka mobili lakana, ka a dusu saalo, ani ka baara kɛ cogo min na, o bɛ dɛmɛ don. O fana bɛ bolifɛn bolicogo ɲuman di feerekɛlaw ma ani ka mobili dilannikɛlaw dɛmɛ u ka se ka ɲɔgɔndan kɛ sugu la.

frein system components .

CNC masinw jɔyɔrɔ ka bon kosɛbɛ freinw ka sigida yɔrɔw dilanni na, minnu nafa ka bon walasa ka mobili lakana ani ka baara kɛ. CNC-machine frein yɔrɔw ka tiɲɛni n’u ka dannaya bɛ kɛ sababu ye ka mobili ka freinw bɛɛ lajɛlen nafa ani ka u jaabi. Nin ye kilisi frein sitɛmu yɔrɔ dɔw ye minnu dilannen don ni CNC masin ye:

1. Freinw ka sɛgɛsɛgɛlikɛlaw : freinw ka jateminɛnanw ye fɛnw ye minnu bɛ freinw bila ani ka degun kɛ frein rotor la, o bɛ kɛ sababu ye ka mobili sumaya walima ka jɔ. CNC masinw bɛ kɛ ka jateminɛ gɛlɛnw kɛ ani ka kalifaw yɔrɔ tigitigiw dilan, ka a labɛn ka ɲɛ ani ka baara kɛ ka ɲɛ. CNC-machined calipers ka tiɲɛni nafa ka bon kosɛbɛ walasa ka frein baara kɛcogo basigilen mara ani ka freinw dɔgɔyali dɔgɔya.

2. Frein rotors : frein rotors, minnu bɛ wele fana ko frein disques, olu ye fɛnw ye minnu bɛ wuli ka wuli, freinw bɛ siri minnu kan walasa ka friction kɛ ani ka mobili sumaya. CNC masinw bɛ kɛ ka rotorw ka yɔrɔ tigitigiw ni nɛnɛbɔlanw dilan, ka funteni jɛnsɛnni ɲuman sabati ani ka frein baara kɛcogo basigilen kɛ. CNC-machine rotors ka tiɲɛni nafa ka bon walasa ka freinw yɛrɛyɛrɛ dɔgɔya ani ka hali freinw don.

3. Master Cylindres : Silindri master ye frein system dusukun ye, min ka baara ye ka fanga caman tigɛli kɛ frein pedal kan ka kɛ hydraulique pressure ye min bɛ frein calipers baara. CNC masinw bɛ kɛ ka silinda master bore ni piston tigitigiw dilan, ka baara kɛcogo ɲuman ni dannamɔgɔ sabati. CNC-machine master cylinders ka tiɲɛni nafa ka bon kosɛbɛ walasa ka frein pedal feel ani frein baarakɛcogo sabati.

Nafa minnu bɛ CNC masin na ka ɲɛsin freinw ka sigida yɔrɔw dilanni ma, olu ye:

l freinw ka baara kɛcogo ɲuman ni u ka baarakɛcogo ɲuman .

l frein fade ni vibration .

l Extended component lifespan .

L FRESING baarakɛcogo min bɛ kɛ cogo kelen na ani min bɛ se ka da a kan .

Ni frein sitɛmu yɔrɔw bɛ se ka kɛ fɛn ye min bɛ se ka kɛ, CNC machining bɛ dɛmɛ don mobili bɛɛ lajɛlen lakanani n’a baara la. O fana bɛ hakilisigi di feerekɛlaw ma, wa u bɛ mobili dilannikɛlaw dɛmɛ u ka tɔgɔ ɲuman mara, u ka mobili ɲumanw, minnu lakananen don.

Steering System Components .

CNC masinw bɛ baara kɛ kosɛbɛ bolifɛnko siratigɛ yɔrɔw dilanni na, minnu nafa ka bon kosɛbɛ walasa ka bolifɛnw minɛcogo ɲuman ni jaabi di. CNC-machine steering yɔrɔw tiɲɛni n’u muɲuni bɛ kɛ sababu ye ka mobili bɛɛ lakana ani ka baara kɛ. Nin ye key steering system components dɔw ye minnu bɛ dilan ni CNC machining ye:

1. Steering Rack and Pinion : Bololabaarakɛminɛn ni pinion ye bolifɛn ɲɛminɛcogo dusukun ye, min ka baara ye ka bolifɛn jiginni lamagacogo caman tigɛli kɛ ka don layini lamagacogo la min bɛ wotoroninw wuli. CNC masinw bɛ kɛ ka rack ni pinion ka gese ɲinw ni so yɔrɔw tigitigi dilan, ka ɲɛminɛni baara kɛ ka ɲɛ ani ka kɛ cogo bɛnnen na. CNC-machined rack ni pinion assemblies ka tiɲɛni nafa ka bon kosɛbɛ walasa ka bolifɛn ɲɛminɛcogo tigitigi mara ani ka bolifɛn bolicogo dɔgɔya.

2. Steering column : Bololabaarakɛminɛn ye yɔrɔ ye min bɛ bolifɛn ni bolifɛn cɛsira siri ɲɔgɔn na, ka bolifɛntigi ka donta lase wotoro ma. CNC masinw bɛ kɛ ka bolifɛnw jɔyɔrɔ tigitigiw ni u jiginni yɔrɔw dilan, ka jiginni nɔgɔya ani ka yɛrɛyɛrɛli dɔgɔya. CNC-machine steering columns ka tiɲɛni nafa ka bon walasa ka bolifɛn bolicogo tigitigi mara ani ka bolifɛn bolilan flex dɔgɔya.

3. Tie berew : Tie berew ye fɛnw ye minnu bɛ bolifɛnw siri ni bolifɛn ye, ka bolifɛn fanga lase wotoro ma. CNC masinw bɛ kɛ ka sirilanw ni bolokuruw sirilan tigitigiw dilan, ka wotoro sinsinni tigitigi ni bolifɛn bolicogo ɲuman sabati. CNC-machine tie berew ka tiɲɛni nafa ka bon kosɛbɛ walasa ka bolifɛnw jateminɛcogo tigitigi mara ani ka pankurun sɛgɛn dɔgɔya.

Nafa minnu bɛ CNC masin na ka ɲɛsin bolifɛnw ma minnu bɛ kɛ ka ɲɛsin bolifɛnw ma, olu ye :

l Bololabaarakɛlaw ka ɲɛtaa ni u ka jaabi .

l Boloci ni yɛrɛyɛrɛli dɔgɔyali .

l Extended component lifespan .

L Bololabaara kɛcogo basigilen ani dannaya bɛ min na .

Ni bolifɛnw bɛ se ka kɛ sababu ye ka bolifɛn ɲɛminɛ, o bɛ kɛ sababu ye ka mobili lakana, ka a minɛ, ani ka baara kɛ cogo min na, o bɛ dɛmɛ don. O fana bɛ bolifɛn bolicogo ɲuman ni dannaya di feerekɛlaw ma ani ka mobili dilannikɛlaw dɛmɛ u ka se ka u ka ɲɔgɔndan kɛ sugu la.

Kɔnɔna ni kɛnɛma trim yɔrɔw .

CNC masinw bɛ kɛ ka caya kɔnɔna ni kɛnɛma trim yɔrɔw dilanni na, minnu bɛ kɛ sababu ye ka mobili cɛɲi, a dusu saalo, ani a ka baarakɛcogo. CNC masinw ka tiɲɛni n’u ka fɛn caman kɛli bɛ sira di cogoya gɛlɛnw ni kunnafoni gɛlɛnw dabɔli ma minnu bɛ mobili cogoya n’a cogoya bɛɛ lajɛlen bonya. Nin ye kɔnɔna ni kɛnɛma trim yɔrɔ koloma dɔw ye minnu bɛ dilan ni CNC masin ye:

1. Dashboard components : CNC machining bɛ kɛ ka dashboard yɔrɔ suguya caman dilan, i n’a fɔ minɛnw pannew, cɛmancɛ konsolɛw, ani fiɲɛbɔyɔrɔw. CNC masinw tiɲɛni bɛ sira di cogoya gɛlɛnw, muɲuli gɛlɛnw, ani yɔrɔ nɔgɔlenw dabɔli ma minnu bɛ don ɲɔgɔn na ni mobili kɔnɔna dilanni ye cogo nɔgɔman na. CNC-machine dashboard yɔrɔw tɛ dɔrɔn ka ɲɛnayeli diyabɔli bonya nka u bɛ a lajɛ fana ko a bɛ se ka kɛ ko a bɛ se ka kɛ ko a bɛ se ka kɛ ko a bɛ se ka kɛ ko a bɛ se ka kɛ ko a bɛ se ka kɛ ko a bɛ se ka kɛ ko a bɛ se ka kɛ.

2. Da minɛw ni panɛriw : CNC masinw bɛ kɛ ka da minɛ, da pannew, ani kɔnɔna trim yɔrɔ wɛrɛw dilan. CNC masinw tiɲɛni n’u kɛcogo ɲuman b’a to o yɔrɔw bɛ bɛn kosɛbɛ ani ka baara kɛ ka ɲɛ, o bɛ kɛ sababu ye ka mobili kɔnɔna jateminɛ cogo ɲuman na. CNC-machine da bololanɛgɛw ni panɛriw bɛ se ka dabɔ ni dilancogo gɛlɛnw ye, ni fɛnw ye minnu bɛ kɛ ni fɛnw ye, ani jiginni yɔrɔ tigitigiw, ka mobili daaw cɛɲi ni u baarakɛcogo bɛɛ bonya.

3. Grilles and Emblems : CNC machining bɛ kɛ ka kɛnɛma trim yɔrɔw dilan i n’a fɔ grilles ani emblèmes, minnu ye fɛn nafamaw ye mobili ɲɛfɛ fascia la. CNC masinw ka tiɲɛni n’u ka fɛn caman kɛli bɛ sira di dilancogo gɛlɛnw ni danfaralenw dabɔli ma minnu bɛ mobili ka taamasiyɛn dɔnniya jira. CNC-machine grilles ni emblèmes bɛ se ka dilan ni muɲuli gɛlɛnw ye, ka a to a ka bɛn ani ka bɛn a lamini farikolo baara ma. O yɔrɔ ninnu tɛ dɔrɔn ka mobili ɲɛnajɛko ɲɛnajɛ bonya, nka a bɛ dɔ fara a ka aerodinamiki baarakɛcogo n’a nɛnɛko ɲuman fana kan.

Nafa minnu bɛ CNC masin na ka ɲɛsin kɔnɔna ni kɛnɛma trim yɔrɔw dilanni ma, olu ye:

l Ɲɛnamaya kɛcogo ɲuman ani a tɔgɔlafɛnw .

l Fitini ni baarakɛcogo ɲɛnabɔlen .

L yecogo basigilen ani min ka bon kosɛbɛ .

l Se ka siginiden gɛlɛnw ni kunnafoni gɛlɛnw dilan .

Ni kɔnɔna ni kɛnɛma fɛnw bɛ se ka kɛ fɛn ye min bɛ se ka kɛ, CNC masinko bɛ kɛ sababu ye ka mobili kɔnɔna bɛɛ lajɛlen wasa ani ka a faamuya. O fana bɛ mobili dilannikɛlaw dɛmɛ u k’u ka fɛn dilannenw danfara ani k’u ka ɲɔgɔndan kɛcogo mara sugu la.

CNC Machining Materials ka ɲɛsin mobili baarakɛlaw ma .

Mobiliko baarakɛlaw bɛ u jigi da fɛn caman kan walasa ka fɛnw dilan minnu ka ɲi, minnu bɛ mɛn, ani minnu bɛ baara kɛ ni baara ye. CNC masinw bɛ bɛn o fɛn caman ma, o bɛ kɛ sababu ye ka fɛn dilannikɛlaw bila ka yɔrɔw dilan ni nafolo kɛrɛnkɛrɛnnenw ye minnu bɛ bɛn u ka baarakɛcogo ma.

Nɛgɛw .

Nɛgɛw ye fɛnw ye minnu bɛ kɛ ka caya mobili baara la k’a sababu kɛ u fanga ye, u muɲuni, ani u caman. CNC masinw bɛnnen don kosɛbɛ nɛgɛdaga suguya caman labɛnni na, o bɛ kɛ sababu ye ka jateminɛ gɛlɛnw ni muɲuli tigitigiw dabɔ. Nin ye nɛgɛw ye minnu bɛ kɛ ka caya CNC masinw na mobili baara kama:

1. Aluminiyɔmu bɔgɔlanw : Aluminiyɔmu bɔgɔlanw ka nɔgɔn, u bɛ se ka sɔgɔ, wa u bɛ kɛ ni masinw ye minnu ka ɲi kosɛbɛ. U bɛ kɛ ka caya motɛri yɔrɔw la, a jɔli yɔrɔw la, ani farikolo panɛriw la. Aluminiyɔmu aluminiyɔmuw minnu bɛ fɔ kosɛbɛ mobili CNC masinw kama, olu dɔw ye:

kelen. 6061: A bɛ dɔn a ka fanga balancogo ɲuman fɛ, a ka sɔgɔli, ani a ka masina.

B. 7075: A bɛ fanga caman di ani ka sɛgɛn, o b’a to a bɛnnen don fɛnw ma minnu bɛ se ka kɛ ka fɛnw jɔ ani minnu bɛ doni ta.

2. Steel Alloys : Nɛgɛdaga tɔgɔ bɔra u ka fanga, u ka gɛlɛya ani u ka muɲuli kosɔn. U bɛ baara kɛ ni mobili baara suguya caman ye, i n’a fɔ bolifɛnw yɔrɔw, u jɔli yɔrɔw, ani u sirilanw. CNC Machining ka nɛgɛdaga minnu bɛ sɔrɔ tuma caman na, olu ye:

kelen. 4140 : chrome-molybdenum alloy min fanga ka bon ani a sɛgɛn, o bɛ kɛ ka caya ni girinw ni jirisunw ye.

B. 1045 : nɛgɛ karɔbɔli cɛmancɛ ni masina ɲuman ani sɛgɛnbaliya, a bɛnnen don brackets ni fixtures ma.

3. Titanium alloys : Titanium alloys bɛ fanga ni girinya hakɛ danfaralen di, ka fɛnw sɔgɔ, ani ka funteni caman kɛ. U bɛ kɛ baarabaw la, i n’a fɔ motɛriw, berew ni ɲɔgɔn cɛ, ani turbochargeur yɔrɔw. Titanium alloy min ka ca ni tɔw bɛɛ ye mobili CNC masin na, o ye:

kelen. TI-6AL-4V: A bɛ dɔn a fanga ka bon, a girinya ka nɔgɔn, ani a ka sɛgɛn kunbɛncogo ɲuman.

4. Magnesium Alloys : Magnesium alloys ye nɛgɛw ye minnu dilannen don ni fanga ye, minnu bɛ fanga ni girinya hakɛ ɲuman di ani ka masina ɲuman sɔrɔ. U bɛ kɛ baarakɛyɔrɔw la, girinya dɔgɔyali nafa ka bon yɔrɔ minnu na, i n’a fɔ motɛri blokiw, fɛnw cicogo kɛsu, ani bolifɛn ɲɛminɛlanw. CNC masinw ka manje caman bɛ sɔrɔ minnu na, olu dɔw ye:

kelen. AZ91D: A bɛ fɛn ɲuman di, a fanga ka bon, ani a bɛ se ka fɛnw sɔgɔ.

B. AM60B: A bɛ dɔn a ka ductility (ductility) ɲuman fɛ, a bɛ se ka a yɛrɛ minɛ, ani a ka masina.

Minɛ | densité (g/cm³) | Tensile fanga (MPa) . | Machinability . |

Aluminiyɔmu (6061-T6) . | 2.70 | 310 | Ɲuman ɲuman |

Nɛgɛ (4140) . | 7.85 | 655 | Duman |

Titanium (TI-6AL-4V) . | 4.43 | 950 | Fisa |

Manje (Az91d) . | 1.81 | 230 | Ɲuman ɲuman |

Plastikiw .

Ka fara nɛgɛw kan, plastikiw bɛ baara kɛ ka caya mobili baara la baara suguya caman kama, k’a ta sokɔnɔna trim yɔrɔw la ka se baarakɛyɔrɔw ma. CNC masinw bɛnnen don kosɛbɛ ɛntɛrinɛti plastikiw dilanni na, minnu bɛ se ka jateminɛ gɛlɛnw dilan, ka muɲuli gɛlɛnw kɛ, ani ka surface finish smooth. Nin ye plastiki dɔw ye minnu bɛ kɛ ka caya CNC masinw na mobili baara kama:

1. ABS (acrylonitrile butadiene styrene) : ABS ye sɛnɛfɛnw ye minnu bɛ fɔ kosɛbɛ, a bɛ dɔn a ka se ka a yɛrɛ tanga, a ka gɛlɛn, ani a ka dimension stabilité. A bɛ kɛ ka caya sokɔnɔna trim yɔrɔw la, i n’a fɔ dashboard panneaux, console datugulanw, ani fiɲɛbɔyɔrɔw. ABS bɛ masina ɲuman di, min bɛ sira di dilancogo gɛlɛnw ni yɔrɔ nɔgɔlenw dabɔli ma.

2. Nylon : Nylon ye ɛntɛrinɛti plastiki ye min bɛ se ka kɛ fɛn caman ye, a ka masinw ka ɲi kosɛbɛ, a fanga ka bon, a sɛgɛnbaliya, ani a sɔgɔli ka dɔgɔn. A bɛ kɛ mobili baara suguya caman na, i n’a fɔ girinw, birikiw, ani fɛnw sirilanw. Nylon ka yɛrɛlafili-cogoyaw b’a to a ka ɲi yɔrɔ lamagannenw na, ka dɔ bɔ tulumafɛn wɛrɛw la.

3. Acetal : Acetal, a bɛ fɔ fana ko poliokisimetilɛni (POM), o ye plastiki ye min bɛ se ka baara kɛ kosɛbɛ, a hakɛ sabatili ka ɲi, a gɛlɛyali, ani a sɛgɛnbaliya. A bɛ kɛ ka caya mobili yɔrɔw la minnu bɛ kɛ ka ɲɛ, i n’a fɔ fɛnɲɛnamafagalanw yɔrɔw, da tugucogo fɛɛrɛw, ani finɛtiriw labɛncogo. Acetal ka ji minɛcogo dɔgɔyali ani a dilanni ɲuman b’a to a bɛnnen don ka baara kɛ ni muɲuli ye.

4. Peek (Polyether Ether Ketone) : Peek ye funteni hakɛ ye min bɛ baara kɛ kosɛbɛ ni a ka masinw ni a ka funteni cogoya ye. A bɛ fanga caman di, ka gɛlɛya, ani ka bonya sabati, hali ni funteni kɔrɔtalen don. Peek bɛ baara kɛ ni mobili baarakɛcogo caman ye, i n’a fɔ motɛri yɔrɔw, transmisi yɔrɔw, ani freinw. A ka sɛgɛnbaliya ka ɲi ani a ka kemikaliya bɛ se ka kɛ sababu ye a ka bɛn sigida gɛlɛnw ma.

Minɛ | densité (g/cm³) | Tensile fanga (MPa) . | Max. Baara kɛli ni funteni ye min bɛ to sen na (°C) . |

ABS . | 1.04 | 44 | 85 |

Nylon 6 . | 1.14 | 79 | 100 |

Acetal . | 1.41 | 68 | 100 |

Peek . | 1.32 | 100 | 250 |

Ni u bɛ plastiki fɛn dɔ sugandi CNC masinko la mobili baara la, ɛntɛrinɛti injiniyɛriw bɛ fɛnw jateminɛ i n’a fɔ masinw ka baarakɛcogo, funteni kunbɛncogo, kemikɛli kunbɛncogo, ani musaka. Plastikiw tali mobili baarakɛcogo la, o bɛ nafa caman di, i n’a fɔ girinya dɔgɔyali, sɔgɔli, ani kuran sɔgɔli.

Ni CNC masinw seko ni nin ɛntɛrinɛti plastikiw sekow ye, mobili dilannikɛlaw bɛ se ka fɛnw dilan minnu ka nɔgɔn, minnu bɛ mɛn, ani minnu bɛ se ka kɛ fɛn ye min bɛ se ka kɛ fɛn ye min bɛ se ka kɛ sababu ye ka mobili baara, a ka baarakɛcogo ɲuman ani a ka dususalo sabati.

Composites .

Fɛn minnu bɛ kɛ ɲɔgɔn fɛ, olu bɛ ka baara kɛ ka caya mobili baara la k’a sababu kɛ u ka nafaw faralen ɲɔgɔn kan cogo kɛrɛnkɛrɛnnen na, i n’a fɔ fanga ni girinya hakɛ caman, sɔgɔli kɛcogo, ani dilancogo sɛgɛsɛgɛli. CNC masinw jɔyɔrɔ ka bon kosɛbɛ fɛnw labɛnni na, o bɛ kɛ sababu ye ka cogoya gɛlɛnw ni fɛn tigitigiw dilan. Nin ye fɛn fila ye minnu bɛ kɛ ka caya CNC masinw na mobili baarakɛcogo la:

1. Plastiki barikamaw (CFRP) : CFRP ye fɛn ye min bɛ se ka kɛ fɛn ye min bɛ se ka kɛ fɛn ye min bɛ se ka kɛ fɛn ye min bɛ se ka kɛ fɛn ye min bɛ se ka kɛ fɛn ye min bɛ se ka kɛ fɛn ye min bɛ se ka kɛ fɛn ye min bɛ se ka kɛ fɛn ye. A bɛ fanga ni girinya hakɛ danfaralenw di, ka gɛlɛya, ani ka sɛgɛn kunbɛn. CFRP bɛ kɛ mobili baara suguya caman na, i n’a fɔ:

kelen. Fɛn minnu bɛ kɛ ka fɛnw jɔ: chassis, arms suspension, ani roll cages.

B. Kɛnɛma farikolo pannew: hood, so sanfɛ, ani trunk datugulanw.

C. Kɔnɔna trim: dashboard, sigilanw, ani bolifɛnw.

CNC masinw bɛ kɛ ka CFRP yɔrɔw tigɛ, ka u sɔgɔ, ani ka u dilan, ka u hakɛw ni u yɔrɔw nɔgɔya. Nka, masinw CFRP bɛ baarakɛminɛnw ni fɛɛrɛ kɛrɛnkɛrɛnnenw de wajibiya walasa ka delaminasiyɔn ni fibre pullout dɔgɔya.

2. Plastiki barikamaw (GFRP) : GFRP ye fɛn ye min bɛ kɛ ni gilasi fiyɛw ye minnu bɛ don polimɛri matiriyali kɔnɔ. A bɛ fanga ni girinya hakɛ ɲuman di, ka kuran sɔgɔ, ani ka sɔgɔli kɛ. GFRP bɛ kɛ mobili baara suguya caman na, i n’a fɔ:

kelen. Farikolo pannew: Fenders, da fariw, ani tire datugulanw.

B. Kuran yɔrɔw: Batiriw ka sanubɔlanw, fiɲɛbɔlanw, ani ɲɔgɔndan so.

C. Yɔrɔw jɔyɔrɔw: furabuluw, bumper beams ani cross membres.

CNC masinw bɛ kɛ ka GFRP yɔrɔw tigɛ, ka u sɔgɔ, ani ka u cogoya di, o bɛ kɛ sababu ye ka jateminɛ gɛlɛnw ni muɲuli gɛlɛnw dilan. GFRP machining bɛ tigɛminɛnw ni paramɛtiriw sugandili ɲuman wajibiya walasa ka fibre breakout dɔgɔya ani ka a lajɛ ni edge dafalen ye.

Minɛ | densité (g/cm³) | Tensile fanga (MPa) . | Modulu élastique (GPA) . |

CFRP . | 1.55 | 2000-2500 . | 130-150 . |

GFRP . | 1.85 | 500-1000 . | 20-40 . |

Baara kɛli ni fɛnw ye minnu bɛ kɛ ɲɔgɔn fɛ mobili baara la, olu bɛ nafa caman di, i n’a fɔ girinya dɔgɔyali, sɛnɛfɛnw sɛnɛcogo ɲuman, ani baara kɛcogo ɲuman. Nka, masinw ka fɛnɲɛnamafagalanw bɛ gɛlɛya kɛrɛnkɛrɛnnenw jira ni u bɛ tali kɛ nɛgɛw ni plastikiw la. Baarakɛminɛnw sugandili ɲuman, tigɛcogo paramɛtɛrɛw, ani masinw dilanni fɛɛrɛw nafa ka bon walasa ka masinw ka fɛnw kɛcogo ɲuman n’u dafalen sabati.

Ni CNC masinw seko ni nin fɛn dilannenw nafaw bɛ tali kɛ, mobili dilannikɛlaw bɛ se ka fɛnw dilan minnu ka nɔgɔn, minnu fanga ka bon, ani minnu bɛ se ka kɛ ni fɛn ye min bɛ se ka kɛ fɛn ye min bɛ se ka kɛ sababu ye ka mobili baara ni a kɛcogo ɲuman dancɛw gɛlɛya.

CNC masinw ka siniɲɛsigi mobili baara la .

Mobiliko bɛ ka taa ɲɛ cogo min na, CNC masinko labɛnnen don ka jɔyɔrɔba ta ka tɛmɛn fɔlɔ kan, mobili dilanni nata labɛnni na. Ni ɲɛtaa kɛra fɛɛrɛtigɛ la ani ko kura jiginni, i n’a fɔ izini 4.0, faralifɛnw dilanni, ani kuran ni yɛrɛmahɔrɔnya bolifɛnw, CNC masinko bɛ ka ladamu walasa ka izini magoɲɛfɛn caman ɲɛnabɔ.

Industri 4.0 ani Smart Manufacturing .

Industri 4.0, n’a bɛ fɔ fana ko Industrie Revolisiyɔn naaninan, o bɛ ka mobili yɔrɔw dilacogo caman sɛmɛntiya. Nin fɛn dilanni waati kura in bɛ sinsin fɛɛrɛ kuraw doncogo kan, i n’a fɔ fɛnw ka ɛntɛrinɛti (IoT), hakililata (AI), ani kunnafonidilanba sɛgɛsɛgɛli, walasa ka izini hakilitigiw dilan. CNC masinko hukumu kɔnɔ, o kɔrɔ ye ko:

1. CNC masinw doncogo ni IoT minɛnw ye : Ni CNC masinw bɛ kɛ ni IoT sensɛriw ni ɲɔgɔndanw ye, dilanbagaw bɛ se ka kunnafoniw lajɛ waati yɛrɛ la masinw ka baara kɛcogo kan, baarakɛminɛnw doncogo kan, ani fɛn dilannenw cogoya kan. Nin kunnafoniw bɛ se ka kɛ ka masinw kɛcogo ɲɛ, ka dɔ bɔ u jɔli waati la, ani ka minɛnw bɛɛ lajɛlen nafa bonya (OEE).

2. Kunnafoni minnu bɛ sɔrɔ waati yɛrɛ la, olu sɛgɛsɛgɛli ka ɲɛsin ladonniko kɔrɔfɔlen ma : Ni AI ni masin kalanni algorisimuw dɛmɛni ye, kunnafoniw minnu lajɛra CNC masinw kɔnɔ minnu bɛ se ka kɛ IoT ye, olu bɛ se ka sɛgɛsɛgɛ walasa ka masinw ka dɛsɛw fɔ minnu bɛ se ka kɛ ani ka waati boloda ka ɲɛ. Nin ladonni fɛɛrɛ min bɛ se ka kɛ, o bɛ dɔ bɔ baara jɔli la min ma labɛn, ka dɔ bɔ ladonni musakaw la, ani ka fɛn dilanni taabolo dannaya sabati.

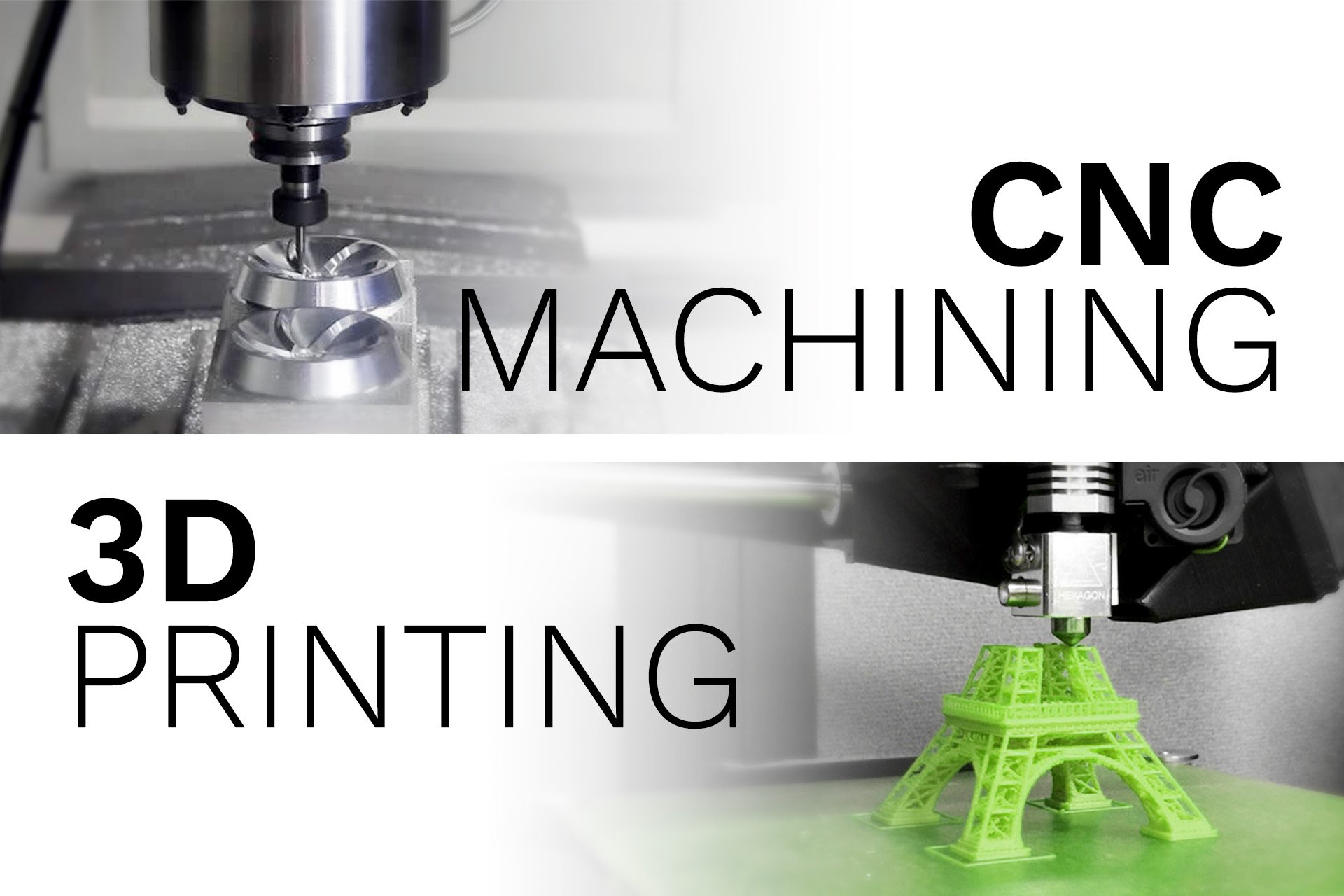

Fàrafinna ka fɛn dilanni ani 3D sɛbɛnni .

Fàrafinna fɛn dilanni, n’a bɛ fɔ fana ko 3D sɛbɛnni, o bɛ ka baara kɛ ka caya mobili baara la walasa ka prototyp, baarakɛminɛnw, ani hali a yɔrɔ labanw dilanni. While CNC machining remains the primary method for producing high-volume, precision components, additive manufacturing offers new possibilities for complex geometries and lightweight designs.

1. CNC masinw ni farankan dilanni faralen ɲɔgɔn kan : Ni u ye fɛɛrɛ fila ninnu fanga fara ɲɔgɔn kan, mobili dilannikɛlaw bɛ se ka yɔrɔ wɛrɛw dilan minnu bɛ CNC masinw ka tiɲɛni ni u ka dugukolo dafalen ni u dilanni hɔrɔnya ani u girinya dɔgɔyali ye. Misali la, 3D sɛbɛnnen yɔrɔ bɛ se ka kɛ CNC masin ye walasa ka muɲuli gɛlɛnw sɔrɔ ani ka yɔrɔ nɔgɔlenw sɔrɔ yɔrɔw la minnu nafa ka bon.

2. Prototyping teliya ni baarakɛminɛnw : farankan dilanni bɛ se ka kɛ sababu ye ka prototype yɔrɔw ni baarakɛminɛnw dilan teliya la ani musaka tɛ minnu na, i n’a fɔ mɔli ni fɛnw. O prototyping seko teliya in b’a to mobili injiniyɛriw bɛ se ka dilanw segin teliya la, ka hakilinaw tiɲɛ, ani ka na ni fɛn kuraw ye sugu la joona. O kɔfɛ, CNC masin bɛ se ka kɛ ka fɛn laban dilancogo nɔgɔya ani k’a kɛ ka ɲɛ.

Mobiliw ni yɛrɛmahɔrɔnya bolifɛnw .

Kuran ni yɛrɛmahɔrɔnya mɔbiliw wulili bɛ ka ɲinini kuraw bila sen kan fɛn nɔgɔmanw na ani yɔrɔw la minnu bɛ se ka kɛ ni masin ye. CNC masinw bɛ ka ladamu walasa ka nin gɛlɛyaw kunbɛn ani ka dɛmɛ don mobili nataw yiriwali la.

1. CNC Machining for lightweight components : Kuran mɔbiliw bɛ fɛn nɔgɔmanw de wajibiya walasa ka batiri hakɛ ni a kɛcogo ɲuman sɔrɔ. CNC masinw bɛ kɛ ka yɔrɔ nɔgɔmanw dilan ka bɔ fɛn kɔrɔw la, i n’a fɔ aluminiyɔmu sɔgɔlenw, manjew, ani fɛnɲɛnamafagalanw. Ni u ye dilanw kɛ ka ɲɛ ani ka CNC masinw tiɲɛni kɛcogo ɲuman sɔrɔ, fɛn dilannikɛlaw bɛ se ka fɛnw dilan minnu bɛ fanga, gɛlɛya ani girinya balansi ɲuman di.

2. Masini tigitigi min bɛ kɛ ka sensɛriw ni ɛntɛrinɛtiw sɔrɔ : Mobiliw bɛ u jigi da senfɛfɛnw, kameraw ani ɛntɛrinɛti yɔrɔw kan minnu ka gɛlɛn walasa k’u sigida dɔn ani k’u ɲɛminɛ. CNC masinw jɔyɔrɔ ka bon kosɛbɛ sow, brackets ani ɲɔgɔndanw dilanni na minnu bɛ se ka kɛ sababu ye ka nin sigida ninnu baara ni dannaya ye. Ni yɛrɛmahɔrɔnya bolifɛnw ka fɛɛrɛbɔ ɲinini bɛ ka caya, CNC-machine yɔrɔw mago bɛna bonya dɔrɔn.

CNC masinw ka siniɲɛsigi mobili baara la, o bɛ kɛ kɛnɛ kan, min bɛ ɲɛminɛ ni ɲɛtaa ye fɛɛrɛtigɛ la, fɛn dilanni misali kura wulilen, ani mobili minnu bɛ bɔ mɔgɔw la minnu bɛna bɔ ɲɔgɔn na, olu mago bɛ ka wuli. Ni o fɛn caman b’a la ka fɛn caman sɛgɛsɛgɛ ani ka ladamu gɛlɛya kuraw la, CNC masinw bɛna to ka kɛ baarakɛminɛn nafamaba ye mobili dilannikɛlaw bolo san nataw kɔnɔ.

Ekipu MFG: Aw ka baarakɛɲɔgɔn .

CNC Machining baarakɛlaw ka baarakɛcogo .

Team MFG la, an bɛ CNC masinw ɲɛnabɔcogo labɛn ka ɲɛsin mobili dilannikɛlaw mago kɛrɛnkɛrɛnnenw ma. An ka fɛn kuraw ni dɔnnikɛlaw ka jɛkulu bɛ yɔrɔw di minnu bɛ kɛ ka kɛɲɛ ni mɔgɔw sago ye ni u ka tiɲɛni ni u ka jogo ɲuman ye. K’a ta prototyping teliya la ka se mass production boliw ma, an bɛ nin di:

L 3, 4, ani 5-axis CNC masin seko .

l A bɛ se ka kɛ nɛgɛw, plastikiw, fɛnɲɛnamafagalanw ani fɛn wɛrɛw ye .

l Teliya la , waati .

L In-house design for Manufacturing (DFM) dɛmɛni .

l Jogoɲumanya ni sɛgɛsɛgɛli gɛlɛn .

Ka daminɛ ni Team MFG ye .

An ka jɛkulu labɛnnen don k’aw ka mobili yelifɛnw lase ɲɛnamaya ma masinko fɛɛrɛ kuraw fɛ. Nin ye a daminɛcogo ye:

1. Aw ye anw sɔrɔ : Aw bɛ se ka telefɔni, email walima site web sɛbɛn fɛ walasa ka baro kɛ aw ka poroze kan.

2. Design Review : An ka injiniyɛriw bɛ aw ka CAD misaliw sɛgɛsɛgɛ ani ka DFM hakilinaw di.

3. Prototyping : An bɛ teliya ka prototypes dilan ka ɲɛsin dilancogo sɛgɛsɛgɛli ni sɛgɛsɛgɛli ma.

4. Fɛn dilanni : Ni i sɔnna, an bɛ taa fɛn dilanni na min musaka ka dɔgɔ, min ka ɲi kosɛbɛ.

5. Delivery : Precision auto parts bɛ ci ka taa i ka yɔrɔ la.

Aw ye fɛɛrɛ fɔlɔ tigɛ ka ɲɛsin jɛɲɔgɔnya ma ni masinko dɔnbagaw ye Team MFG la bi!