Kuva kwinjiza inganda zimodoka mu mpera z'ikinyejana cya 19, iterambere ry'inganda ryabaye imbaraga zitera gukura no gutsinda. Kuva ku ntangiriro yumurongo winteko na Henri Ford mu 1913 kugeza mu myaka mirongo ishize, inganda zimodoka zikomeje guhinduka kugirango uhuze ibyifuzo byisi ihinduka.

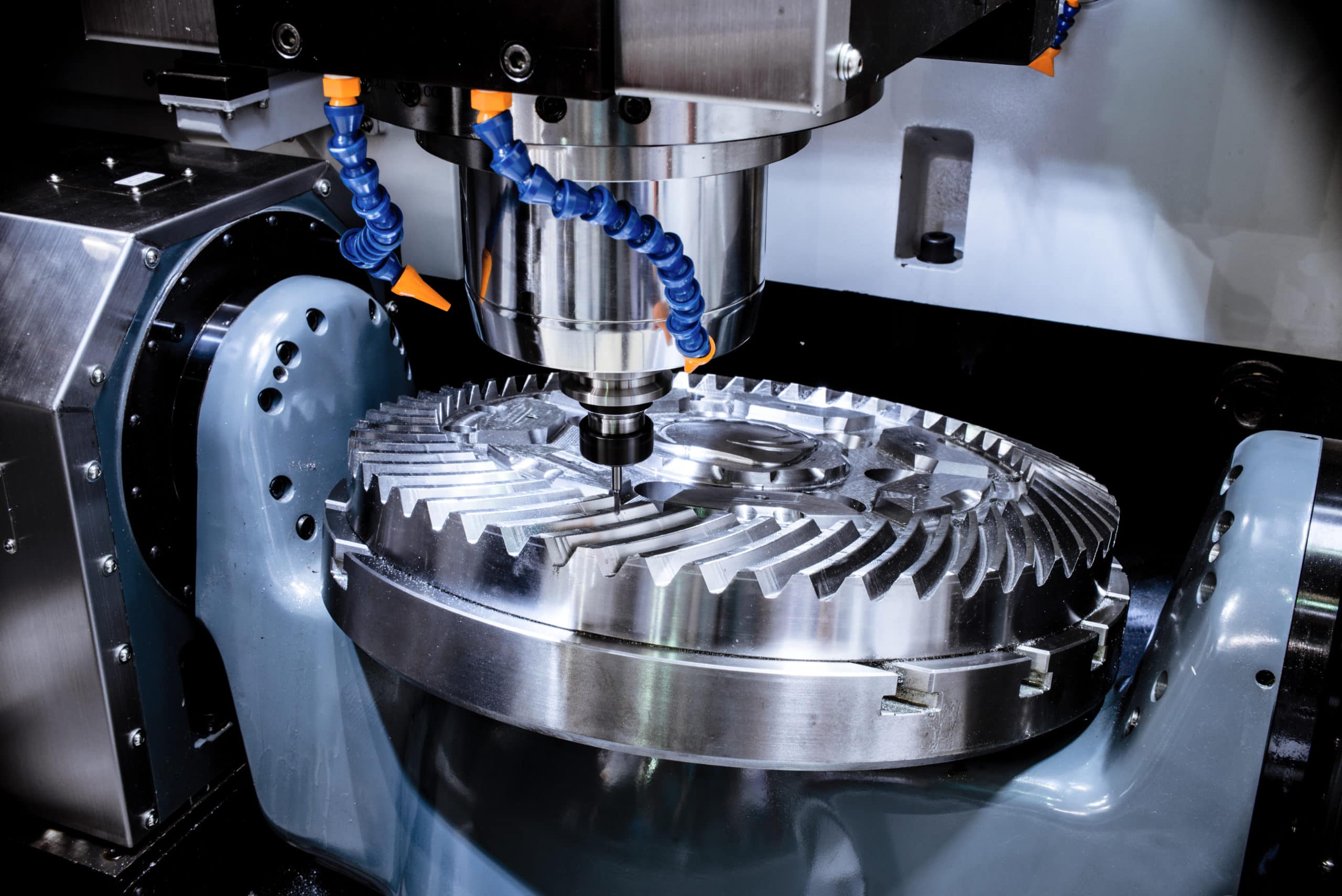

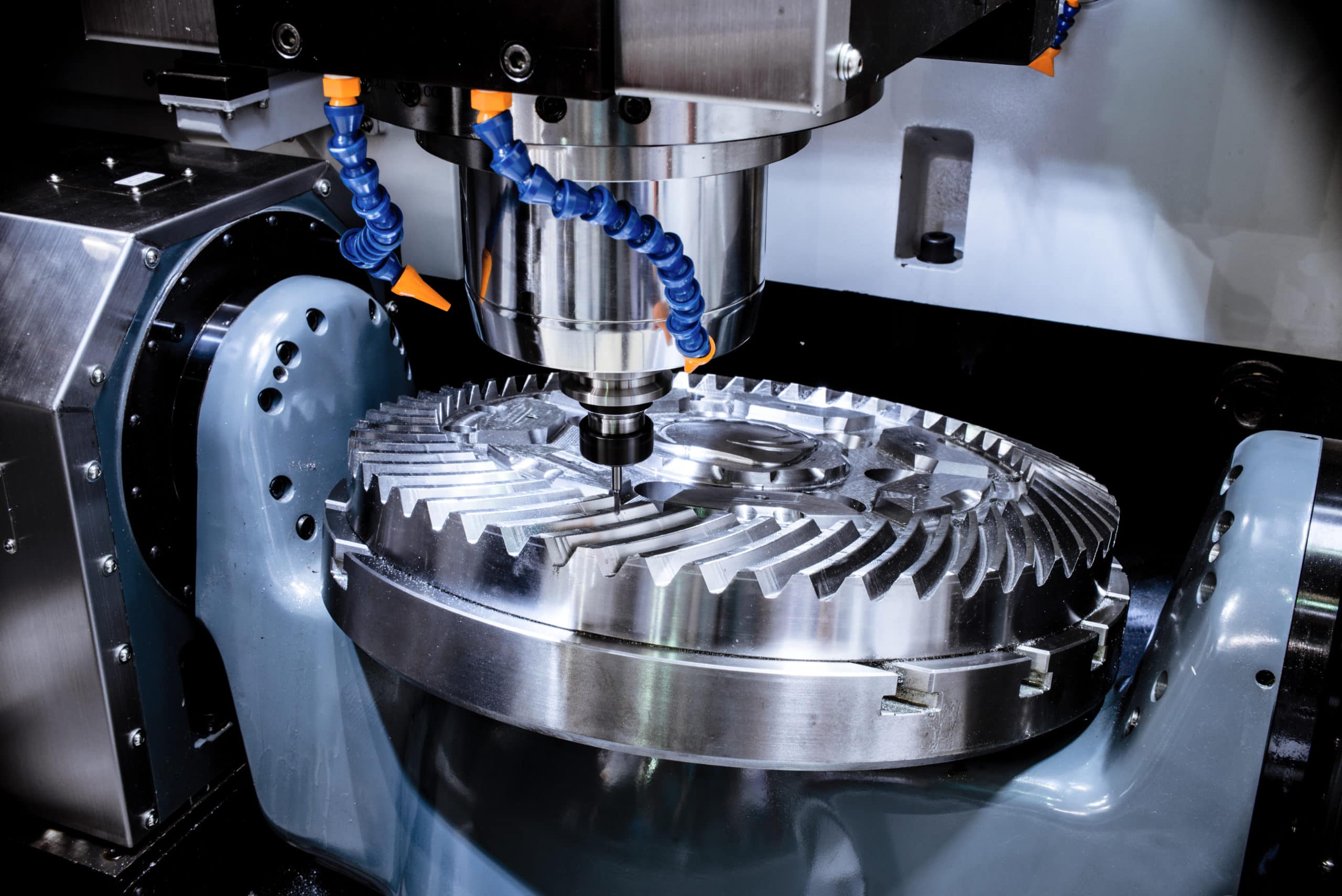

Uyu munsi, Imashini za CNC zagaragaye nkigice cyingenzi mukora ibinyabiziga bigezweho, bigatanga umusaruro uhoraho, usobanutse, hamwe nibice bigoye bifite imikorere itagereranywa no gusubiramo.

Iyi ngingo izasesengura uruhare runini CNC ikinira mu nganda zimodoka nuburyo yahinduye uburyo ibinyabiziga bikozwe.

Kuzirika kwa CNC ni iki?

Imashini ya CNC, ngufi kuri mudasobwa igenzura ryumubare, ni inzira yo gukora igenzura rya mudasobwa no guca ibikoresho kugirango ikureho ibikoresho bivuye kumurimo, gukora ibice byateguwe neza hamwe no gusubiramo byinshi. Iri koranabuhanga ryahinduye inganda zimodoka zifasha umusaruro wibintu bigoye, bihanitse byikirere muburyo buhebuje kandi bunoze.

Uburyo Imashini za CNC zikora

Imashini za CNC zikora ukurikiza amabwiriza ya progaramu yabanjirije premored, izwi nka G-Kode, iyobora ibikoresho byo gutema kugirango ukureho ibikoresho mubikorwa muburyo busobanutse kandi bugenzurwa. Inzira irimo intambwe zikurikira:

1. Igishushanyo: Abashakashatsi bakora icyitegererezo cya 3D igice cyifuzwa ukoresheje porogaramu (igishushanyo mbonera cya mudasobwa).

2. G-Kode Igisekuru: Icyitegererezo cya Cad noneho gihinduka muri G-Kode ukoresheje porogaramu yo gukora mudasobwa).

3. Gushiraho: Igikorwa cyakazi gishyigikiwe neza kuri mashini ya CNC, nibikoresho bikwiye gukata byashyizweho.

4. Irangizwa: Imashini ya CNC isoma G-Kode kandi ikora ibyifuzo byateguwe, ikuraho ibikoresho kuva kumurimo nkuko byagenwe.

5. Kurangiza: Iyo gahunda yo gusiga irangiye, igice cyarangiye cyakuwe muri mashini, cyagenzuwe, hamwe nibikenewe byose (nko gukora isuku cyangwa ubuvuzi bwo hejuru) bikorwa.

Ubwoko bw'imashini za CNC zikoreshwa mu nganda zimodoka

Inganda zimodoka zishingiye ku mashini zitandukanye zo gutanga ibice byinshi bisabwa kugirango ukore gukora ibinyabiziga. Bumwe muburyo busanzwe harimo:

1. Imashini za CNC : Izi mashini zikoresha ibikoresho byo guca buruta kugirango ukureho ibikoresho mukazi, gushiraho ibiranga ibyobo, ibibanza, imifuka. Nibyiza kubyara ibikoresho, ibice byo kohereza, no guhagarika ibice.

2. Imashini zihinduranya : zizwi kandi nka CNC Lathes, izo mashini zizunguruka akazi mugihe igikoresho cyo gukata gikuraho ibikoresho, gikora ibice bya silindrike nka shafts, kandi bihubuke.

3. Imashini zo gusya za CNC : Izi mashini zikoresha ibiziga bya atusive kugirango ukureho ibikoresho bike biva kumurimo, kugera ku nyito cyane no kurangiza neza. Bikunze gukoreshwa mugutanga ibikoresho byohereza, Camshafts, nibindi bice bigize uburinganire.

4. Imashini za CNC Laser : Izi mashini zikoresha laser ifite imbaraga nyinshi zo gukata, kwigunga, cyangwa ibikoresho bya engrave, bituma bakora neza kugirango bikoreshwe ibikoresho byikigize, nkibice byumubiri na kaburimbo yumubiri.

Mugutanga ubushobozi bwizi mashini zinyuranye za CNC, abakora imodoka barashobora gutanga ibice byinshi bigize ubusobanuro butagereranywa, imikorere, no gusubiramo, amaherezo biganisha ku modoka zidasanzwe.

Ibyiza bya CNC Inganda zimodoka

Imashini ya CNC yabaye igikoresho cyingenzi munganda zimodoka, zitanga inyungu nyinshi zahinduye inzira yo gukora. Duhereye ku ruhame no gusobanura neza no gukora neza, imashini za CNC zagaragaye ko zihindura umukino kubakora imodoka.

Ibisobanuro kandi byukuri

Imwe mu nyungu zikomeye za SNC nubushobozi bwayo bwo kubyara ibice hamwe nubusobanuro budasanzwe kandi buke. Ibi ni ngombwa mu nganda zimodoka, aho no gutandukana na gato bishobora kugira ingaruka zikomeye ku mikorere yumutekano.

1. Kwihanganira cyane : Imashini za CNC zirashobora kugera ku kwihanganira gukomera nka santimetero 0,0001, kureba niba ibice bihuye neza kandi bikora neza.

2. Guhoraho mugice umusaruro wibice : Ingwate za CNC zihamye ibisubizo mumisaruro myinshi ikora, kugabanya ibyago byo gukora amakosa no kureba ko igice cyose kihuye nubuziranenge bumwe.

Gukora no gukora neza

Imashini ya CNC ni inzira yikora cyane, isobanura kongera imikorere no gutanga umusaruro muburyo bwo gukora ibinyabiziga.

1. Kugabanya ibiciro byakazi : Mugukora inzira yo gukomera, abakora barashobora kugabanya cyane ibiciro byabakozi bifitanye isano nibikorwa byo gushushanya.

2. Ibihe byihuse : Imashini za CNC zirashobora gukora kumuvuduko mwinshi kandi ufite igihe gito cyo hasi, Gushoboza abakora kugirango bishobore gukora ibice byihuse kuruta uburyo bwo gukoresha gakondo.

3. 24/7 Igikorwa : Imashini za CNC zirashobora gukora ubudahwema, amasaha 24 kumunsi, iminsi 7 mucyumweru, imisaruro yoroheje isarure no kugabanya ibihe bine.

Guhinduka no guhuza n'imihindagurikire

Imashini za CNC zitanga ihinduka ridahenze no guhuza n'imihindagurikire y'ikirere, ryemerera abakora imodoka kugirango basubize vuba kugirango bakore ku isoko basaba kandi bagatanga ibice byinshi.

1. Ubushobozi bwo gutanga geometries igoye : Imashini za CNC zirashobora gukoresha byoroshye igice cya geometries, harimo imirongo igoye, harimo imirongo igoye, inguni, nibitekerezo, bituma bakora ibyiza bifatika.

2. Ihinduka ryihuse : Imashini za CNC zemerera ibikoresho byihuse, bigatuma abakora bahinduranya ibice nibikoresho hamwe nibikoresho bitari.

3. Guhuza nibikoresho bitandukanye : Gukubita CNC birahuye nibikoresho byinshi, harimo na cyuma, ibishushanyo, no kubamo ibipimo, bitanga ibikoresho byo guhinduka kugirango uhitemo ibikoresho byiza kuri buri porogaramu.

Ibiciro-byiza

Nubwo ishoramari ryambere mu mashini za CNC, ikoranabuhanga ritanga amafaranga menshi yo kuzigama amafaranga, tukabikora uburyo bwiza kubakora imodoka.

1. Yagabanije imyanda : Imashini za CNC ni inzira nziza cyane ituma ibikoresho byose, bigabanya ibiciro byibikoresho muri rusange nibidukikije.

2. Igihe kirekire (CNC imashini zikoresha ibikoresho byateye imbere hamwe nibikoresho byatoranijwe, bishobora kwagura ubuzima bwibikoresho no kugabanya ibiciro byibikoresho mugihe runaka.

3. Igiciro cyo hasi cyumusaruro wibice byinshi : Imashini ya CNC irahazagura cyane cyane kumusaruro mwinshi wiruka, nkuko ibiciro byagenwe byashizweho bikwirakwira mumibare minini.

Mugutanga ibisobanuro, gukora neza, guhinduka, no gukora ibiciro bya mashini ya CNC, abakora imodoka barashobora gutanga ibice byubwiza bwinshi, bikongeza ibintu byubwiza bwinshi, kandi bigakomeza guhatanira ingamba zigihe cyose.

Porogaramu ya CNC imashini mu nganda zimodoka

Imashini ya CNC igira uruhare runini mu gukora ibintu byinshi byimodoka, uhereye kubice bya moteri kuri sisitemu yo guhagarika. Ibisobanuro byayo, imikorere, hamwe nuburyo bwo gukora ibikoresho byingenzi kubakora bashaka gukora ibintu byiza, byizewe. Muri iki gice, tuzasesengura bimwe mubisabwa bya porogaramu ya CNC munganda zimodoka.

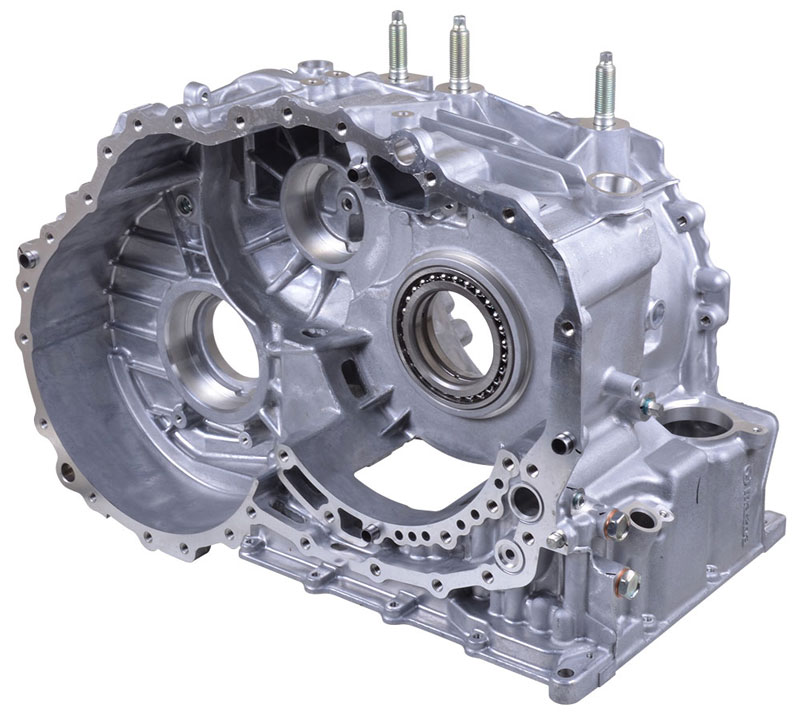

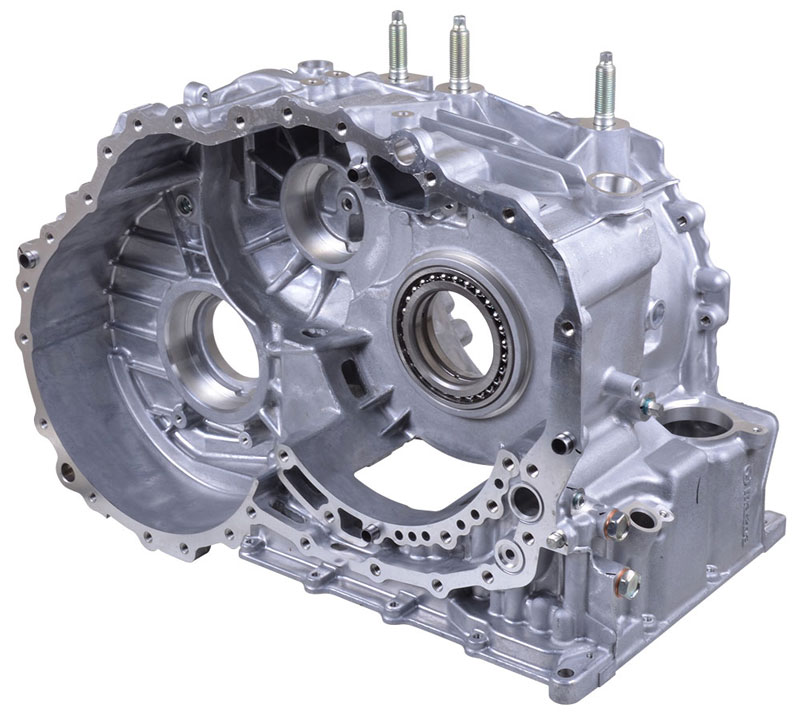

Ibigize moteri

Moteri ni umutima wimodoka iyo ari yo yose, kandi imashini za CNC ni ngombwa mu gutanga byinshi mu bice byayo bikomeye. Dore ingero nke:

1. Cylinder Imitwe : Imashini ya CNC ikoreshwa mugukora geometries igoye kandi iranga agaciro k'umutwe wa silinderi, nk'ibyatsi bibi, ibibatsi byometseho umwobo, n'ibice byiza. Ukuri no guhuzagurika byagezweho binyuze muri CNC gufata neza imikorere myiza ya moteri no gukora neza.

2. Imbuga za moteri : Imashini za CNC zikoreshwa mugukora geometle yimbere yimbere ya moteri ya moteri, harimo na silinderi yometseho, imipira minini itwara, nibice bya peteroli. Ubusobanuro buke kandi busubirwamo bwa CNC kwemeza ko imashini ihagarika moteri yujuje ibyangombwa bisabwa kugirango bikore neza kandi birebire.

3. Pistons hamwe na rods : Ibi bice byingenzi byimuka muri moteri byakozwe hakoreshejwe amashusho ya CNC kugirango hakemuke neza kandi iramba. Pistons ikunze gukoreshwa muri aluminium, mugihe ihuza inkoni isanzwe ikozwe mu ibyuma. Kumenya neza ibi bice ni ngombwa kugirango bihuze neza, kuringaniza, nibikorwa.

Ibice

Imashini za CNC zigira uruhare runini mugukora ibice byinjira, bikenewe kugirango wimuke muri moteri mu ruziga. Ibisobanuro kandi ukuri kugerwaho binyuze muri CNC imashini ifata neza ko ibi bice bikora bidafite ishingiro, bitanga imikorere yonoze kandi ikora neza. Hano haribice bimwe byingenzi byingenzi bikozwe ukoresheje CNC imashini:

1. Ibikoresho : Induru ibice nibigize urufatiro bifatika bisaba imyirondoro ya Amenyo na geometries kugirango ikoreshwe imbaraga nziza kandi neza. Imashini ya CNC ni nziza kugirango ireme ibikoresho byingenzi, kuko bishobora kugera ku nyihangane kandi zihamye ibisubizo. Ibikoresho bya CNC-byafashwe byingenzi mu kugabanya urusaku, kunyeganyega, no kwambara mu kwanduza.

2. Shafts : Kohereza ibiti, nko kwinjiza no gusohoka shafts, nibice bikomeye byohereza torque hagati yibikoresho nibindi bice byoherejwe. Imashini ya CNC ikoreshwa mugukora iyi shafts hamwe nibipimo bisabwa, birangira hejuru, kandi ibiranga nka spelines hamwe na nyakisha. Ibisobanuro bya shaff yafashwe neza byemeza ko bifatika hamwe nuburinganire muburyo bwo kwanduza, kugabanya kunyeganyega no kwagura ubuzima bwiza.

3. Amazu : Amazu yohereza ni igice kitoroshye gikandagira kandi gishyigikira ibikoresho bitandukanye, shafts, no kwikorera mu kohereza. Imashini ya CNC ikoreshwa mugukora geometries yimbere imbere nuburyo bunoze bwo kwimura amazu. Ukuri kwizirika kwa CNC cyemeza ko ibice byose byoherezwa bihuye neza mumazu, yemerera imikorere myiza no kuramba.

Mugukoresha imashini za CNC kugirango umusaruro winjire, abakora imodoka barashobora kugera ku nyungu nyinshi:

l Kunoza imikorere no gukora

kugabanya urusaku no kunyeganyega

l yongereye ibice byubuzima

Igikorwa gihamye kandi cyizewe

Ibisobanuro hamwe nukuri kubigize CNC-ikwirakwizwa bifatika bigira uruhare muri rusange no gukora ibinyabiziga, bitanga uburambe bwo gutwara ibinyabiziga.

Ibigize

Imashini za CNC ikoreshwa cyane mugukora ibice byahagaritswe, bigira uruhare runini mugushinyagura ibinyabiziga, gutunganya, no guhumurizwa. Ibisobanuro kandi biramba byibice byahagaritswe bya CNC bitanga umusanzu rusange nibikorwa byikinyabiziga. Hano haribigize bimwe byingenzi byahagaritswe bigize byakozwe hakoreshejwe CNC imashini:

1. Kugenzura intwaro : Gukemura intwaro zishingiye ku bice bikabije bihuza ikadiri cyangwa subframe kuri striering Knickle, yemerera kugenda no guhuza ibiziga no guhuza. Imashini za CNC ikoreshwa mugukora amaboko hamwe nimbaraga zikenewe, gukomera, na geometrie nziza. Ukuri kwizirika kwa CNC cyemeza ko amaboko agenga ihuza neza kandi agatanga ibiziga byiza no kugenzura.

2. KUNKURU : GUKOMEJE KUNYURANYA, Azwi kandi nka Stundles, ni ibice bihuza uruziga hub kumaboko agenga kandi yemerera kuzunguruka no kuyobora. Imashini za CNC ikoreshwa mugukora geometries igoye kandi yerekana neza ingingo zingendo za thickles. Ukuri kwa CNC-ifunzwe yafashwe neza iremeza ko ibikorwa byiza byo guhuza no gukora neza.

3. Hubs : Ihuriro ryibiziga ni ibice byingenzi bihuza uruziga na feri ya feri kubinyabiziga no gutwara. Imashini ya CNC ikoreshwa mugukora ibishoboka byose hamwe no kwiyongera hejuru ya hubs, iremeza ko ikwiranye nubutaka nibindi bigize. Ukuri no kuramba byo guhubuka kwa CNC ni ngombwa kugirango dukomeze guhuza ibiziga no kugabanya kunyeganyega.

Inyungu zo gukoresha imashini za CNC kugirango umusaruro utanga ibigize uhagarike harimo:

l Kunoza uburyo bwo gukora no gutuza

yagabanije kunyeganyega no urusaku

l yongereye ibice byubuzima

Imikorere ihamye kandi yizewe

Mu kwemeza neza ibice byahagaritswe, imashini za CNC zitanga umusanzu mu mutekano rusange, ihumure, n'imikorere yimodoka. Ibi, nabyo, bitanga uburambe bwo gutwara ibinyabiziga no gufasha abakora imodoka bakomeza impande zabo kumasoko.

Feri

Imashini za CNC zigira uruhare runini mu gukora ibintu bya feri ya feri, bikenewe mu kubungabunga umutekano wimodoka n'imikorere. Ubusobanuro no kwizerwa bya feri ya FNC bigira uruhare mu gufatanya neza no gufata ibyemezo ndetse n'imodoka. Hano haribice bya sisitemu yingenzi bya feri byatanzwe hakoreshejwe CNC imashini:

1. Frake Calipers : Frake Calipers ni ibice byo munzu ya feri no gushyira igitutu kuri feri ya feri, bitera ikinyabiziga gutinda cyangwa guhagarara. Imashini ya CNC ikoreshwa mugukora geometries igoye kandi isobanutse neza ya kaliperi, iremeza neza kandi ikora neza. Ubusobanuro bwa CNC-bukoreshwa ni ngombwa kugirango bukomeze gukora feri buhoraho no kugabanya feri.

2. Froke Rotor : Rotes Rotor, uzwi kandi nka feri ya disiki, ni ibice bizunguruka byerekana ko feri ya feri yateje amakimbirane no gutinda imodoka. Imashini ya CNC ikoreshwa mugukora ubuso busobanutse no gukonjesha imiyoboro ya rotor, bugenga itandukaniro ryinshi ryubushyuhe nubutaka bwo gufata feri. Ukuri kwa rotor yakozwe na CNC ni ngombwa muguhagarika feri kunyeganyega no kwemeza no kwambara feri.

3. Master Cylinders : Umukunzi Cylinder numutima wa sisitemu ya feri, ashinzwe guhindura ingufu zikoreshwa kuri feri pedal mumitutu ya hydraulic ahindura feri. Imashini ya CNC ikoreshwa mugukora ibishoboka byose hamwe na piston hejuru ya silinderi ya Master Cylinder, kugirango ibikorwa binoze kandi byizewe kandi byizewe. Ubuntu bwa silinderi yafashwe na CNC ni ngombwa mu kubungabunga pedal ihamye yumva kandi ihagaze neza.

Inyungu zo gukoresha imashini za CNC kugirango umusaruro wa feri zirimo:

l Kunoza feri no gukora neza

yagabanije feri irashira no kunyeganyega

l yongereye ibice byubuzima

LIGHER YIZA KANDI YIZESE

Mu kwemeza neza kandi kwiringirwa ibice bya feri, imashini za CNC zigira uruhare mu mutekano rusange n'imikorere yimodoka. Ibi na byo, bitanga amahoro yo mumutima kubaguzi no gufasha abakora imodoka bagumana izina ryabo kugirango batanga umusaruro mwinshi, umutekano.

Ibikoresho bya sisitemu

Imashini za CNC ikoreshwa cyane mugukora ibigize sisitemu ya sisitemu, niyo nhato kugirango ibeho neza kandi yitabye ibinyabiziga. Ukuri no kuramba byibice bya CNC bigira uruhare kumutekano rusange no gukora ikinyabiziga. Hano haribice byingenzi bya sisitemu yo kuyobora byakozwe hakoreshejwe CNC imashini:

1. Gutera imbere na pinion : Gutera ubwoba na pinion numutima wa sisitemu yo kuyobora, ushinzwe guhindura icyerekezo cyo guhinduranya uruziga rukora ibiziga bihindura ibiziga. Imashini ya CNC ikoreshwa mugukora amenyo yuburyo busobanutse hamwe nubuso bwungutsi bwimiturire no gupiminya, kubuza imikorere yo kuyobora kandi neza. Ubumwe bwa CNC-imashini yafashwe hamwe ninteko za pinti ni ngombwa kugirango ukomeze kugenzura neza no kugabanya gukina.

2. Inkingi : Inkingi yo kuyobora nigice gihuza uruziga ruyobora kuri scring rack, kohereza ibitekerezo byumushoferi kubiziga. Imashini za CNC ikoreshwa mugukora ubuso busobanutse hamwe nuburyo butera inkingi yo kuyobora, buze kuzenguruka no kugabanya kunyeganyega. Inkingi ya CNC-ikozwe ningirakamaro mugukomeza kuyobora neza yumva kandi igabanya imikoreshereze yo kuyobora.

3. Inkoni ya karuvati : Inkoni ya karuvati niyo ngingo zihuza ubwubatsi muri scaring imirongo, yohereza imbaraga zitera ibiziga. Imashini ya CNC ikoreshwa mugukora urudodo rwumutwe no guhuza imipira yinkoni ya karuvati, kwemeza neza ibiziga hamwe nibikorwa byo kuyobora neza. Ukuri kw'inka za FNC ni ngombwa mu kubungabunga neza ubwumvikane bwa geometrie no kugabanya kwambara ipine.

Inyungu zo gukoresha imashini za CNC kugirango umusaruro utanga ibikoresho bya sisitemu birimo:

l Kunoza kuyobora neza no kubatabira

yagabanije kuyobora no kunyeganyega

l yongereye ibice byubuzima

LIGATI YIZA KANDI YIZESE

Mubyemeza neza kandi iramba ryibice bya sisitemu yo kuyobora, imashini za CNC zigira uruhare mu mutekano rusange, gukora, no gukora ikinyabiziga. Ibi, na byo, bitanga uburambe bwo gutwara ibishimishije kandi bwizeye kubaguzi no gufasha abakora imodoka bakomeza impande zabo kumasoko.

Imbere no hanze ya Trim

Imashini za CNC ikoreshwa cyane mumusaruro wimbere kandi hanze, bikagira uruhare mu bushake bworoshye, ihumure, n'imikorere yimodoka. Ibisobanuro no guhuza ibikoresho bya CNC byemerera kurema imiterere igoye nibisobanuro bifatika byongera ubuziranenge rusange no kugaragara kw'ikinyabiziga. Hano haribice byingenzi byimbere kandi byinyuma byakozwe hakoreshejwe CNC imashini:

1. Ibikoresho bya Dashboard : Imashini ya CNC ikoreshwa mugukora ibice bitandukanye byamavuta, nkibikoresho byigikoresho, ihuriro ryikigo, hamwe na sven. Ibisobanuro bya SNC bituma habaho imishyikirano igoye, kwihanganira ibintu bikomeye, nuburyo bworoshye bwo guhuza nibishushanyo mbonera byimbere. Ibice byafashwe bya CNC ntabwo byongera gusa ubujurire bugaragara gusa ahubwo binameza neza imikorere n'imikorere yigenzura ritandukanye kandi ryerekana.

2. Imiryango nitsinda : Imashini ya CNC ikoreshwa mugutanga imiryango, imbaho yumuryango, nibindi bikoresho byimbere. Ukuri no guhuzagura bya CNC byerekana ko ibi bice bihuye neza kandi bikora neza, bitanga ubwiza bwo mu buryo bworoshye imbere yimodoka. Urugi rwa CNC rufite imigi hamwe nimbeba zishobora gushyirwaho nibishushanyo mbonera, ubuso bwuzuye, hamwe nuburyo bunoze, kuzamura icyerekezo cyimiryango yimodoka.

3. Grilles n'ibimenyetso : Imashini za CNC ikoreshwa mugukora ibice byo hanze nka grilles nibimenyetso, bikaba ari ibintu bikomeye bya Fascia imbere ya Fascia. Ibisobanuro no guhuza ibikoresho bya CNC byemerera kurema ibishushanyo bifatika kandi byihariye byerekana indangaza yikinyabiziga. CNC-imashini ikorwa kandi ibirango birashobora kuvungirwa no kwihanganira cyane, kwemeza neza neza no guhuza hamwe numubiri uhari. Ibi bice ntabwo byongera ubujurire bwikinyabiziga gusa ahubwo binatanga umusanzu mubikorwa byayo bya aerodynamic no gukonjesha.

Inyungu zo gukoresha imashini za CNC kugirango umusaruro wimbere kandi usohoka hanze harimo:

l Yongereye Ubujurire bwa Kwegera

l Inono ryimikorere n'imikorere

L ihamye kandi igaragara cyane

Ubushobozi bwo gukora imiterere igoye nibisobanuro birambuye

Mu kwemeza neza, ubuziranenge, nubushake bwo kwiteza imbere imbere nubutaka bwimbere, imashini za CNC zitanga umusanzu kubakiriya muri rusange no kwiyumvisha ikinyabiziga. Ibi, bifasha abakora imodoka batandukanya ibicuruzwa byabo no gukomeza guhatanira ku isoko.

Ibikoresho bya CNC kubikoresho byimodoka

Inganda zimodoka zishingiye kubikoresho byinshi kugirango bishobore gutanga ubuziranenge, burambye, kandi bishingiye ku mikorere. Imashini ya CNC irahuye na byinshi muribi bikoresho, bituma abakora bashiraho ibice bifite imiterere yihariye bihujwe na porogaramu.

Ibyuma

Ibyuma nibikoresho byakoreshejwe cyane munganda zimodoka kubera imbaraga zabo, kuramba, no guhinduranya. Imashini ya CNC ikwiranye no gutunganya ibyuma bitandukanye, bifasha kurema Geometries igoye kandi yihanganira neza. Hano hari bimwe mubisobanuro bikunze kugaragara muri SNC imashini ya SNC kubisabwa byimodoka:

1. Aluminum alloys : AlUmunum Alloys ninzike, irwanya ruswa, kandi itange ingumbi neza. Bakunze gukoreshwa mubice bya moteri, ibice byahagaritswe, hamwe numubiri. Aluminum aluminim alloys kuri CNC ya CNC imashini zirimo:

a. 6061: Azwiho impirimbanyi nziza yimbaraga, kurwanya ruswa, no gutegekwa.

b. 7075: Tanga imbaraga nyinshi kandi wambara ihohoterwa, bigatuma bikwirakwira kubice byubatswe kandi biremereye.

2. Icyuma cya Alloys : Alloy ya Steel irazwi kubwimbaraga zabo, gukomera, no kuramba. Bakoreshwa mubiciro bitandukanye byimodoka, harimo ibice bya Toltraten, ibice byahagaritswe, no kwizirika. Ibyuma bisanzwe kuri SNC imashini ikubiyemo:

a. 4140: Chromium-MolyBdenum Acyloy ifite imbaraga zikaze hamwe numunaniro, akenshi ukoreshwa mubikoresho na shafts.

b. 1045: Icyuma giciriritse gifite amabuye y'agaciro kandi ambara ihohoterwa, akwiriye kunyeganyega n'ibikoresho.

3. Titanium alloys : Titanium alloys itanga imbaraga zidasanzwe-kuri-uburemere, kurwanya ruswa, nubushyuhe bwinshi. Bakoreshwa mu mikorere minini, nka moteri ihanagura, guhuza inkoni, n'ibice bya turbocharger. Ibisanzwe bya Titanium alloy kuri CNC ya CNC ni:

a. TI-6al-4V: Bizwi ku mbaraga nyinshi, uburemere bworoshye, no kurwanya umunaniro mwiza.

4. Magnesium Alloys : Magnesium alloys ni ibyuma byoroheje, bitanga imbaraga nziza-kuri-uburemere no gucurangana. Bakoreshwa mubisabwa aho kugabanya ibiro ni ngombwa, nka moteri yahagaritswe, imanza, hamwe no kuyobora ibiziga. Magnesium isanzwe kuri CNC imashini zirimo:

a. AZ91D: Tanga igihingwa cyiza, imbaraga, no kurwanya ruswa.

b. Am60b: Bizwi kumacumu yacyo nziza, kurwanya ingaruka, no kutagira imashini.

Ibikoresho | Ubucucike (G / CM⊃3;) | Imbaraga za Tensile (MPA) | Imashini |

Aluminium (6061-T6) | 2.70 | 310 | Byiza |

Icyuma (4140) | 7.85 | 655 | Byiza |

Titanium (TI-6al-4V) | 4.43 | 950 | Imurikagurisha |

Magnesium (az91d) | 1.81 | 230 | Byiza |

Plastike

Usibye ibyuma, plastiki bigenda bikoreshwa mu nganda zimodoka kubisabwa bitandukanye, uhereye kubice byimbere byimbere kugirango ukore ibice. Imashini ya CNC ikwiranye no gutunganya plastiki yubuhanga, itanga ubushobozi bwo gukora geometries igoye, kwihanganira gukomera, ubuso bworoshye burarangiye. Hano haribimwe muri phostique isanzwe ikoreshwa mu mazi ya CNC kubisabwa byimodoka:

1. Abs (Acrylonitrile Butadiene Stryrene) : Abs ni igitangaza kizwi cyane kubera kurwanya ingaruka zacyo, gukomera, no gushikama. Bikunze gukoreshwa mubice byimbere, nka pashboard panels, ibifuniko bya konsole, hamwe na sven. ABS itanga imashini nziza, yemerera kurema ibishushanyo mbonera noroshye.

2. Nylon : Nylon ni plastiki isanzwe yubuhanga ifite imitungo ihanitse, harimo imbaraga nyinshi, yambara ihohoterwa, hamwe no guterana amagambo. Ikoreshwa mubisobanuro bitandukanye byimodoka, nkibikoresho, kwivuza, no gufunga. Umutungo wa Nylon woroheje utuma ari byiza kubice byimuka, kugabanya ibikenewe byo kwisiga.

3. ACETAL : ACETAL, uzwi kandi nka Polyoxymethylene (pom), ni plastike yimikorere myinshi ifite umutekano, gukomera, no kurwanya. Bikunze gukoreshwa mu bice bigize ibinyabiziga, nkibice bya lisansi, uburyo bwo gufunga umuryango, na Window igenzura. Acetal yinjira mu buryo buke kandi bukaba bukomeye butuma bikwiranye no kwihanganira gukomera.

4. Peek (PolyEther Ether Ketone) : peek ni ikintu cyimikorere miremire hamwe nimashini zidasanzwe numutima. Itanga imbaraga nyinshi, gukomera, no gushikama, ndetse no ku bushyuhe bwo hejuru. Peek ikoreshwa mugusaba porogaramu zimodoka, nkibigize moteri ibice, kohereza, na sisitemu ya feri. Kwambara neza kwambara no kurwanya imiti bituma bikwiranye nibidukikije bikaze.

Ibikoresho | Ubucucike (G / CM⊃3;) | Imbaraga za Tensile (MPA) | Max. Gukomeza Gukoresha Ubushyuhe (° C) |

ABS | 1.04 | 44 | 85 |

Nylon 6 | 1.14 | 79 | 100 |

Acetal | 1.41 | 68 | 100 |

Peek | 1.32 | 100 | 250 |

Mugihe uhitamo ibikoresho bya plastike kuri SNC ifata inganda zimodoka, injeniyeri tekereza kubintu nkibikoresho bya mashini, kurwanya ubushyuhe, kurwanya imiti, nibiciro byimiti. Gukoresha Plastike mu porogaramu z'imodoka itanga ibyiza byinshi, harimo kugabanya ibiro, kurwanya ruswa, n'amashanyarazi.

Mugutanga ubushobozi bwa SNC kandi imitungo ya plastiki yubuhanga, abakora imodoka barashobora gutanga ibice byoroheje, biramba, nibice byakozwe na precion, nibice byakozwe na precions byongera imikorere, imikorere, no guhumurizwa.

Abagize

Ibikoresho byubahirizwa biragenda bikoreshwa munganda zimodoka bitewe no guhuza ibintu bidasanzwe byimitungo, nkibipimo byinshi-ku buremere, kurwanya ruswa, no gushushanya guhinduka. Imashini ya CNC igira uruhare runini mugutunganya ibice byubahirizwa, bifasha kurema imiterere igoye nibiranga. Hano haribintu bibiri mubikoresho bisanzwe bikoreshwa mubikoresho bya CNC kubisabwa byimodoka:

1. CARBON CIBER YISHIMIYE PLAST (CFRP) : CFRP nibikoresho byimikorere byimikorere bigizwe na fibre za karubone zashyizwe muri matrix polymer. Itanga imbaraga zidasanzwe-kuri-uburemere, gukomera, no kurwanya umunaniro. CFRP ikoreshwa mubiciro bitandukanye byimodoka, harimo:

a. Ibigize imiterere: Chassis, amaboko yo guhagarika, no kuzunguza akazu.

b. Imyanya yumubiri hanze: Hood, igisenge, nipfundo.

c. Imbere mu Gihugu: Ikibaho, Inteka yintebe, hamwe ninziga ziyobowe.

Imashini za CNC ikoreshwa mugutegura, imyitozo, na ruslika cfrp ibice, kugirango birebe neza kandi byoroshye. Ariko, gufata CFRP bisaba ibikoresho byihariye nubuhanga kugirango ugabanye umutinzi na fibre.

2. Ibirahuri fibre byashimangiye Plastics (GFRP) : GFRP nibikoresho bigizwe nimirasire yikirahure yashyizwe muri matrix polymer. Itanga imbaraga nziza-kuri-ibiro, amashanyarazi, no kurwanya ruswa. GFRP ikoreshwa muburyo butandukanye bwibinyabiziga, nka:

a. Umubiri wumubiri: fenders, uruhu rwumuryango, kandi rukabipfundiki.

b. Ibigize amashanyarazi: Umukandara wa bateri, agasanduku kwuzuye, hamwe na cousings.

c. Ibice by'imiterere: Amasoko y'ibibabi, ibiti binini, n'abasaraba.

Imashini za CNC ikoreshwa mugukata, kwigunga, no guhindura ibice bya GFRP, bituma hashyirwaho ibya geometries bigoye na comelerance. Gukubita GFRP bisaba guhitamo neza ibikoresho byo gutema hamwe nibipimo kugirango ugabanye fibre kumeneka no kwemeza impande zisukuye.

Ibikoresho | Ubucucike (G / CM⊃3;) | Imbaraga za Tensile (MPA) | Elastike Modulus (GPA) |

CFRP | 1.55 | 2000-2500 | 130-150 |

Gfrp | 1.85 | 500-1000 | 20-40 |

Gukoresha ibikoresho bigizwe munganda zimodoka bitanga ibyiza byinshi, birimo kugabanya ibiro, kunoza lisansi, kandi imikorere yongerewe. Ariko, abakomanobo batanga ibibazo bidasanzwe ugereranije nishanga na plastike. Igikoresho gikwiye cyo guhitamo, gutema ibipimo, hamwe ningamba zifatika ningirakamaro kugirango ireme nubunyangamugayo bwibigize.

Mugutanga ubushobozi bwa SNC na miterere yibi bikoresho bigizwe, abakora imodoka birashobora gutanga umusaruro mwinshi, imbaraga nyinshi, nibice byakozwe na precions bisunika imipaka yimikorere yimodoka no gukora neza.

Ejo hazaza h'inganda za CNC mu nganda zimodoka

Mugihe inganda zimodoka zikomeje guhinduka, imashini za CNC ziteguye gukina cyane cyane muguhindura ejo hazaza h'inganda zikora ibinyabiziga. Hamwe niterambere ryikoranabuhanga no kuzamuka mu ngendo nshya, nk'inganda 4.0, Inganda zikoreshwa n'amashanyarazi, imashini zigenga zirimo guhuza no guhangana n'inganda zikenewe.

Inganda 4.0 no gukora neza

Inganda 4.0, zizwi kandi nka revolution ya kane yinganda, ihindura uburyo ibice byimodoka bikorerwa. Iki gihe gishya cyo gukora cyibanze ku guhuza tekinoroji yateye imbere, nka interineti y'ibintu (IOT), ubwenge bw'agateganyo (AI), no gusesengura amakuru manini, kugira ngo habe ingana. Mu rwego rwo gufata amashusho ya CNC, ubu buryo:

1. Kwinjiza imashini za CNC hamwe nibikoresho bya IIOC : mugushira imashini za CNC hamwe na iOssers hamwe no guhuza, abakora barashobora gukusanya amakuru yigihe gito kuri mashini, kwambara ibikoresho. Aya makuru arashobora gukoreshwa kugirango ahindure inzira yo guhindukira, kugabanya igihe cyo hasi, no kunoza ibikoresho rusange muri rusange (OEE).

2. Isesengura ryigihe cyo kubungabunga ibihano : Kubifashijwemo na AI na ALgorithms, amakuru yakusanyijwe mumashini ya CNC irashobora gusesengurwa kugirango uhanure kunanirwa kwimashini no kubungabunga ibishoboka byose. Uku buryo bwo kubungabunga ibihano bigabanya igihe gitunguranye, kigabanya ibiciro byo kubungabunga, kandi bigatera imbere kwizerwa kwimikorere yo gukora.

Inganda zo gukora no gucuranga 3D

Inganda zinjira, zizwi kandi gucapa 3D, zirashobora gukoreshwa mu nganda zimodoka za prototyping, igikoresho, ndetse nigice cya nyuma. Mugihe imashini ya CNC ikomeje gukora uburyo bwibanze bwo gutanga amajwi menshi, ibice byubatswe, inganda zinjira zitanga amahirwe mashya kuri geometries zitoroshye hamwe nigishushanyo cyoroheje.

1. Guhuza imashini za CNC hamwe no gukora ibikorwa byoherejwe : Muguhuza imbaraga za tekinoroji yombi, abakora imodoka barashobora gukora ibice bya Hybrid bikoresha neza kandi birangizwa no kurangiza ubwisanzure hamwe nubucuruzi bwibikorwa. Kurugero, igice cyanditswe cya 3D gishobora kuba CNC imashini ikorerwa kugirango ikore icyoroherane noroshye ahantu hakomeye.

2. Rapid Prototyping hamwe na Tool : Inganda zoherejwe zifasha umusaruro wihuse kandi wikiguzi cyibice bya prototype nibikoresho, nkibibumba nibikorwa. Ubu bushobozi bwihuse bwa prototyping bwemerera injeniyeri yimodoka kubishushanyo bishushanyije byihuse, byemeza ibitekerezo, no kuzana ibicuruzwa bishya ku isoko vuba. Imashini za CNC irashobora gukoreshwa mugutunganya no gutegura igishushanyo cyanyuma kugirango umusaruro wasabwe.

Ibinyabiziga by'amashanyarazi n'igenga

Kuzamuka kw'amashanyarazi n'ibinyabiziga byigenga birasaba ibisabwa bishya ibice byoroheje n'ibice byafashwe neza. Imashini za CNC ni uguhuza kugirango wuzuze ibyo bibazo no gushyigikira iterambere ryibinyabiziga bikurikira.

1. Imashini za CNC kubice byoroheje : Ibinyabiziga by'amashanyarazi bisaba ibice byoroheje kugirango bibe byinshi bya bateri no gukora neza. Imashini za CNC zikoreshwa mu gutanga ibice byo kuvura n'ibikoresho byo mu buryo bworoshye, nka aluminium alloys, magnesium alloys, hamwe n'abanyamerika. Muguhitamo ibishushanyo no kwishyurwa neza bya CNC, abakora barashobora gukora ibice bitanga impirimbanyi nziza, gukomera, nuburemere.

2. Imashini ishushanya kuri sensor na electronics : Ibinyabiziga byigenga bishingikiriza kuri sensor ya sensor, kamera, na elegitoroniki, ibice bya elegitoroniki kugirango babone kandi bayobore ibidukikije. Imashini za CNC zigira uruhare runini mu gutanga imiyoboro igaragara cyane, utwugarizo, hamwe nabahuza bifasha iyi sisitemu gukora byizewe. Mugihe icyifuzo cya tekinoroji yigenga yigenga irakura, hakenewe ibigize CNC ikoreshwa nabi biziyongera gusa.

Ejo hazaza h'inganda za CNC mu nganda zimodoka zirasakuza, ziyobowe niterambere ryikoranabuhanga, kuzamuka kwa paradipi nshya, hamwe nibikenewe byibinyabiziga bikurikira. Mu guhongesheje ibyo bihinduka no guhuza nibibazo bishya, imashini za CNC zizakomeza kuba igikoresho cyingenzi kubakora imodoka mumyaka iri imbere.

Ikipe Mfg: umukunzi wawe mu guhanga udushya

Serivisi za CNC

Ku kipe mfg, dutanga ibisubizo bya CNC bihumanye kugirango duhuze ibyifuzo byihariye byabakozi ba Automotive. Ibikoresho byacu-byubuhanzi hamwe nitsinda ryinzobere ritanga ibice byihariye hamwe nubuziranenge budasanzwe. Kuva Raptid Prototyping to Rasa ikora, dutanga:

l 3, 4, na 5-axis cnc yubushobozi bwa cnc

l ihuza n'ibyuma, plastiki, ibiruko nibindi byinshi

ibihe byihuta

l mu nzu igishushanyo cyo gukora (DFM)

l Igenzura ryiza no kugenzura

Gutangirana na Team Mfg

Ikipe yacu yiteguye kuzana iyerekwa ryimodoka yawe mubuzima binyuze mubisubizo bishya. Dore uko watangira:

1. Twandikire : Shikira ukoresheje terefone, imeri cyangwa urubuga rwo kuganira kumushinga wawe.

2. Gusuzuma Isubiramo : Abashakashatsi bacu basesengura icyitegererezo cyawe kandi bagatanga ibitekerezo bya DFM.

3. Prototyping : Turakora vuba prototypes kugirango dusuzume no kugerageza.

4. Umusaruro : Ukoresheje icyemezo cyawe, twimukira kugera ku buryo buhebuje, inganda zo hejuru.

5. Gutanga : Ibice byimodoka byimodoka byoherejwe mukigo cyawe.

Fata intambwe yambere iganishaho gufatanya ninzobere za marike muri ikipe mfg uyumunsi!